3D printer calgary

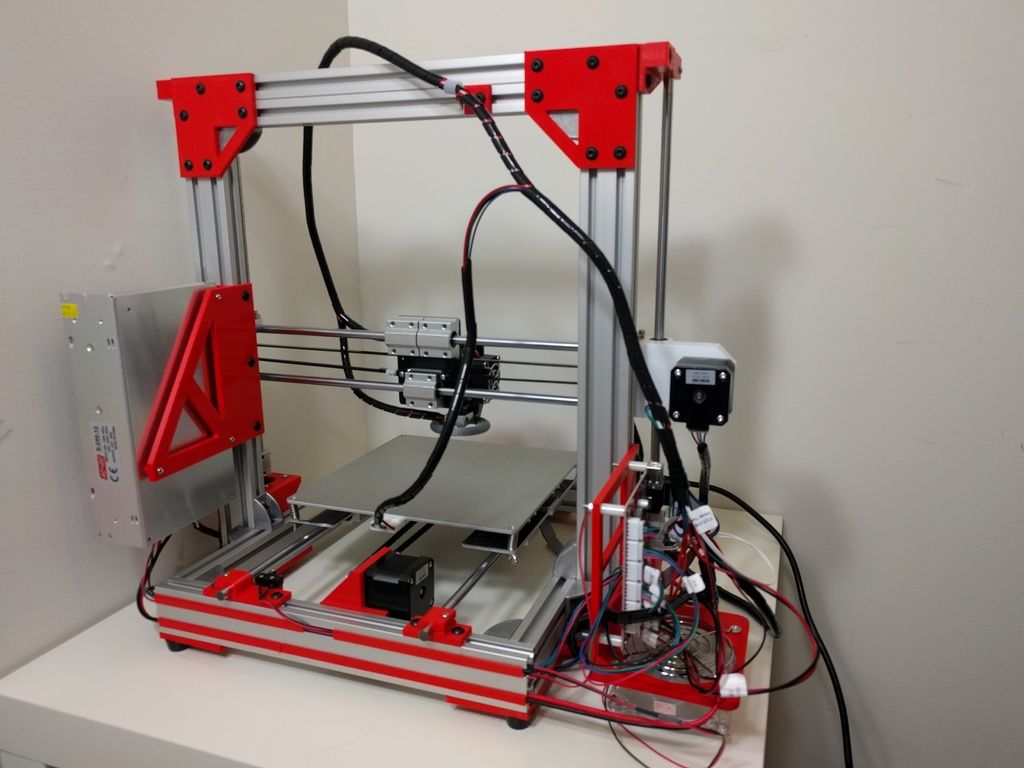

3D Printers Pre-Sale — Calgary 3D Printing

Raise3D Pro3

$7,299.00 CAD

Raise3D Pro3 Plus

$9,875.00 CAD

Raise3D Pro2

$5,599.00 CAD

Raise3D Pro2 Plus

$7,899.00 CAD on sale

Raise3D E2

$4,599.00 CAD

FULL-COLOR POWDER-BASED 3D PRINTER

$40,000. 00 CAD

Creality Ender 3 V2

$400.00 CAD

Creality CR-30

$1,500.00 CAD

Ender 5 Pro

$490.00 CAD

Ender 5 Plus

$830.00 CAD

Creality Ender 6

$800.00 CAD

Modix Big-60 V3 Base Kit

$5,300.00 CAD

Modix Big-120X V3 Base Kit

$9,500. 00 CAD

00 CAD

Modix Big-120Z

$13,800.00 CAD

DA VINCI JUNIOR 1.0 3D PRINTER

$600.00 CAD

DA VINCI 1.0 3D PRINTER

$749.00 CAD

UNIZ SLASH PLUS - Reconditioned

$4459.00 CAD

UNIZ SLASH PLUS UDP - Reconditioned

$5319.00 CAD

UNIZ SLASH PRO

$6649. 00 CAD

00 CAD

UNIZ SLASH PRO UDP

$7979.00 CAD

FOOD 3D PRINTER FOODINI

$7,500.00 CAD

Delta WASP 2040 PRO

Delta WASP 4070

Delta WASP 60100

Delta WASP 2040 Clay

Delta WASP 40100 Clay

Delta WASP 2040 Industrial X

Delta WASP 4070 INDUSTRIAL X

Delta WASP 3MT INDUSTRIAL 4. 0

0

Please click here to contact us if you have any questions.

High Quality 3D Printer Filament And Printer Parts

We don’t cut any corners here at 3D Lab Tech. We are located in Calgary, Alberta, Canada and offer the highest quality 3d printer filament and 3d printer parts that have passed the most stringent testing so you can have the best 3D printing experience which equates to less tinkering with broken or jammed printers, wasted time troubleshooting problems, inconsistent quality, and more printing. Printing should be a fun experience and not a frustrating one.

We have lots of other great products coming very soon so check back often!

Featured

Thermal Fuse

Rated 0 out of 5

$3.95+ Tax (CAD) Add to cart

Sale!

ERCF Easy BRD

Rated 0 out of 5

$44. 95

95+ Tax (CAD) Add to cart

Sale!

Sale!

Sale!

Sale!

Sale!

Sale!

Sale!

Subscribe to our newsletter for great deals!

Free Canada shipping with purchases over $100Free local shipping with purchases over $30We provide free local delivery in the Calgary, Alberta area for purchases over $30 before tax and free shipping on orders above $100 before tax across Canada. All orders placed before noon are normally shipped same day. Act fast because this is for a limited time only.

Free Canada shipping with purchases over $100Free local shipping with purchases over $30We provide free local delivery in the Calgary, Alberta area for purchases over $30 before tax and free shipping on orders above $100 before tax across Canada. All orders placed before noon are normally shipped same day. Act fast because this is for a limited time only.

All orders placed before noon are normally shipped same day. Act fast because this is for a limited time only.

Genuine reseller for these great vendors

LDO Motors

LDO Motors is very well know for the high quality electric motors they produce which range in a variety of different applications such as 3D Printers and CNC machinery. Now LDO Motors is known for much more then just motors. They also carry many other high performance 3D Printer components from aluminum extrusions to full Voron 3D Printer kits.

3D Fuel Filament

We are very proud to carry 3D Fuel branded filament. This premium 3D filament is produced end to end in the USA with NatureWorks Ingeo resin to produce a 3D filament like no other. The main focus has been to produce the best possible filament with extreme tolerances not seen normally in this industry. Their 3D printer filament have a tight tolerance of +/-0.02mm with specific spool information printed on the side of every box with the manufactured date so you know how fresh it is. If you want high quality 3D filament then look no further than 3D Fuel.

If you want high quality 3D filament then look no further than 3D Fuel.

Bondtech

Bondtech develops, designs and manufactures unique dual drive extruders that eliminate the risk of grinding, slipping, filament deformation and under extrusion. Using two counter-rotating drive gears, the Bondtech extruders grip and push the filament from both sides for a secure and stable filament feed. The result is a reliable, more precise and faster printing process.

Slice Engineering

Slice Engineering make the world’s best hot end period. With its patented design, it can eliminate heat creep, jams, and allow you to print 30% faster. Come learn more about their Mosquito and Copperhead hot ends. Their vanadium nozzles also carry a lifetime abrasion warranty as well and are virtually indestructible!

igus

igus is headquartered in he USA and is a leading manufacturer of plastic components used in motions systems using complex technical plastic polymers.

E3D-Online

They are the standard in the 3d printing industry and provide a large assortment of printer components such as nozzles, heatbreaks, hot blocks, thermistor cartridges, heater cartridges, and much more.

BLTouch

The BLTouch is a very precisely tuned auto bed leveling sensor that can quickly level your bed providing a consistent and repeatable result every time you print. It will also help provide mesh leveling for beds that are not perfectly flat (99% of all beds are not “flat”) and is accurate to 0.005mm.

Gates

Gates has been making belts for over 100 years. There is no one that does it better then Gates. Don’t compromise the stability of your printer. Choose genuine Gates belts for your next build.

BIGTREETECH

BIGTREETECH has many electronic components such as Mainboards, Screens, Stepper Drivers and much more. This is the brains of the printer so don’t trust this to just anyone. Trust someone who has experience like BIGTREETECH!

Capricorn PTFE Tubes

They have the best tolerances and are made with a special blend of materials to provide the slickest surface to allow smooth movement of any 3d printer filament. A must for any 3d printer that has a Bowden setup!

RobotDigg

These are the RobotDigg 440C Stainless Steel rails. Grade C stainless steel is the highest grade meaning they are extremely hard and very resistant to rust. They come well packaged and do not require to be coated in machine oil to prevent rusting. No mess no fuss. Just a light lubrication before installation is all that is needed. Please see the wide selection of rail sizes we have to chose from.

Grade C stainless steel is the highest grade meaning they are extremely hard and very resistant to rust. They come well packaged and do not require to be coated in machine oil to prevent rusting. No mess no fuss. Just a light lubrication before installation is all that is needed. Please see the wide selection of rail sizes we have to chose from.

Free 3D File Calgary Flames Logo・3D Printing Design to Download・Cults

D20 Dice

Free

Treasure chest with functional hinge

Free

Another D20 Dice - Easier FDM Printing

Free

Hexagon and Square Connected with NASA Inspired + Chain Details

Free

It's about 4:20 now... 510 cartridge/battery/drip holder

Free

Autobots + deceptions Transformers logo

Free

Screw Tray; one more

free

Stargate Mirror; Event Horizon Replacement

Free

Best Files for 3D Printers in the Art Category

Wall puma

1. 60 €

60 €

Rhinoceros Head

3.16 €

Fight Super Frieza from Dragon Ball Z 3D printed model

35 €

Deactivated

Pink

Free

Thousand-hand Bodhisattva

Free

Owl Sculpture

Free

Small pot

Free

Art category bestsellers

Triceratops on flexi printer

3 €

Flexi-print "Fish"

1,99 €

Flexi-print Imperial Dragon

4.02 €

Cute flexi print sloth

3 €

Cute T-Rex dinosaur with flexi print

3 €

Flexi PRINT-IN-PLACE Hand

1,99 €

SKULL OF A BEARDED PUMPKIN

3,59 €

Bearded Dragon Articulated Toy, imprinted body, snap head, cute flexi

3,03 €

Articulated bat toy, imprinted body, snap head, cute flexi

3. 54 €

54 €

Cute squirrel with flexi print

2,56 €

Folding Mystery Car - Scooby Doo

6.10 €

Pink Dragon, Valentine's Day, Articulating Animal Flexi Wiggle, Print on the Spot, Fantasy

4.13 €

Catacombs Skull of Bones, Creepy Skeleton Skull, Pile of Bones Skull

€6.04 -fifty% 3.02 €

Astronaut on flexi printer

3 €

Cute skeleton with flexi print

3 €

Baby Crystalwing, Cinderwing3D, articulating Flexi Wiggle Pet, print on site, fantasy

4.07 €

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people, so it is very easy to support us in maintaining activities and creating future developments. Here are 4 solutions available to everyone:

Here are 4 solutions available to everyone:

-

ADVERTISING: Disable the AdBlock banner blocker and click on our banner ads.

-

affiliation: Shop online by following our affiliate links here Amazon.

-

DONATIONS: If you want, you can donate via PayPal here.

-

* INVITE FRIENDS: * Invite your friends, discover the platform and great 3D files shared by the community!

How Elon Musk will print colonies on Mars / HB

- News

- Opinions

- BUSINESS

- LIFE

- Radio

- magazine

Support Subscribing

April 15, 2019, 20:00

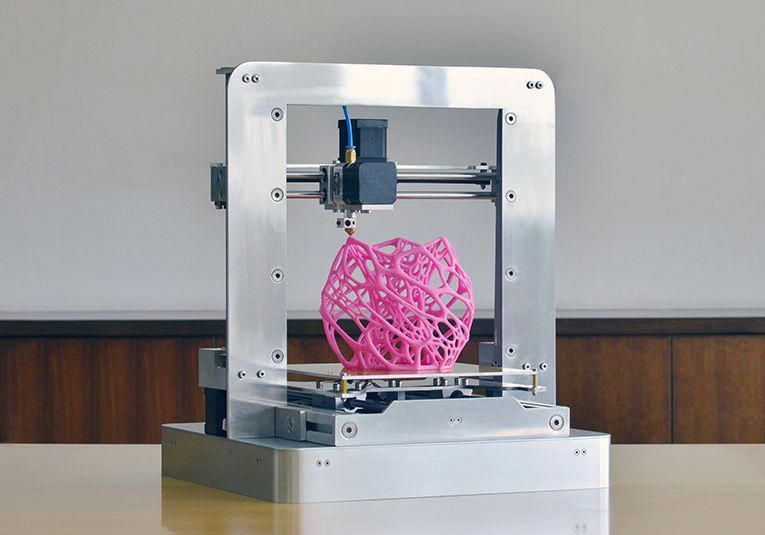

What is a space 3D-first and why you can’t do without it in the settlement of other planes.

– Houston, we have a problem. My screwdriver flies into a vacuum. Can you send me a new one?

-Yes, have you seen the prices for delivering cargo into space? And if you fly away to colonize Mars, also ask for a “transfer”? Take with you 3D - printer and print what you want there!

Video of the day

The successful launch of the Falcon Heavy makes the prospect of flying far beyond Earth much more real. However, in order to settle in the orbit of the Moon or on Mars, only one superrocket will not be enough. Oddly enough, a must have for future astronauts is a 3D printer!

However, in order to settle in the orbit of the Moon or on Mars, only one superrocket will not be enough. Oddly enough, a must have for future astronauts is a 3D printer!

Printing in space is not a toy for you!

The print head travels back and forth, layer by layer turning a simulated 3D object into its material embodiment - this is how 3D printers work. It would seem that everything is simple with them. But not in zero or microgravity. Instead of laying down in the desired shape, your "ink" - plastic, clay, glass, living cells - whatever! - will gather in one lump and hang on an extruder (a machine for forming plastic materials by punching (extrusion) through a profiling tool - an extrusion head).

In order to print in space, the parts are balanced by a powerful jet of air (instead of gravity) and printed from strong and stable materials - not all types of plastic used on Earth will work. And it’s not easy with metal: here you don’t just “heat and print”. We need a powder whose particles will be approximately the same size, have a spherical shape (or will be close to it) and will still be free-flowing. But this has never stopped those who have serious plans for space.

We need a powder whose particles will be approximately the same size, have a spherical shape (or will be close to it) and will still be free-flowing. But this has never stopped those who have serious plans for space.

First there was an extruder

In September 2014, the SpaceX Dragon spacecraft delivered the Portal 3D printer, which is about the size of a small microwave oven, to the ISS. It was created for NASA by Made in Space. "This is not a Star Trek replicator, but looks like a step in that direction," NASA wrote on its website.

https://www.youtube.com/embed/ZQ3y8U6Fbd4

The printer installation was completed on November 17, and in a week it finally produced something useful - a printhead extruder faceplate for its design. The astronauts breathed a sigh of relief: the printer will be able not only to fit everything needed for the station, but also to prepare spare parts for its repair just in case.

Cooler than 3D printer ISS!

The 3D printer is able to recycle its own waste and print the right things from it again. This is exactly what the Refabricator (from English - recycler - ed.): NASA installed it to process plastic waste into material for 3D printing. The device can also recycle plastic packaging, because basically in such packaging materials needed for research and life get to the ISS. If it was not possible to print the tool the first time, and it needs to be redone, you can “re-stick” the old one. Therefore, in practice, to have production without waste.

This is exactly what the Refabricator (from English - recycler - ed.): NASA installed it to process plastic waste into material for 3D printing. The device can also recycle plastic packaging, because basically in such packaging materials needed for research and life get to the ISS. If it was not possible to print the tool the first time, and it needs to be redone, you can “re-stick” the old one. Therefore, in practice, to have production without waste.

A 3D printer that recycles its own waste can only be cooler than a 3D printer that recycles astronaut waste. Yes, we are talking about faeces. Scientists from the Canadian University of Calgary are developing a technology that, with the help of GM bacteria (genetically modified - ed.), will allow the team's waste to be utilized, turning it into a biopolymer for 3D printing. In addition, Made in Space has developed The ZeroGravity, a printer that can print in a vacuum in low gravity. A small step for a printing needle is a big step for mankind.

After EVA, The ZeroGravity will be able to print an antenna the size of a football field

Another project that will expand our capabilities in space will be a robotic arm printer, whose name is Archinaut. One can imagine the Archinaut as a daredevil who goes about his important business in the complete emptiness of a cold, dark and quiet vacuum. Such technology is still only in the plans, but a giant robotic arm can really make telescopes, satellites and large objects - even larger than the size of the robotic arm itself. Made in Space CEO Andrew Rush said it would be possible to make an object that would not support its own weight on Earth. Under weightless conditions, there will be no such problems.

Archinaut will go into space by itself, because there will be not just a printer, but also a rocket. A prototype is being tested at NASA's Ames Research Center, and there is even a vacuum chamber in the laboratory for such tests.

Since we're already talking about rockets. ..

..

In March 2018, the Marshall Center fire tested an engine whose nozzle was 3D printed in 10 days and 18 hours, applying 8255 layers of copper powder. The resulting nozzle was able to withstand temperatures of about 300 ° C, because cooling gas is pumped through the channels of its walls with a temperature of only 100 ° C above absolute zero.

See also: Complete success. Musk is ready to reuse parts Falcon Heavy

There is another example of the use of 3D printers in space development. RocketLab is using 3D printing to make elements of the Rutherford rocket engine for the Electron launch vehicle. All the main details - the chamber, pipelines, injector heads for this rocket are printed on a printer. In addition, the European Space Agency successfully tested a fully 3D printed Berta engine this year.

And the British Orbex is currently the most manufactured engine. And the ambitious goals for the use of 3D printers in the rocket and space industry are set by the American startup Relativity Space. These guys are planning to print an entire rocket, reducing the number of parts from a hundred thousand to one. Now they have already printed and tested the Aeon rocket engine with NASA, and they plan to print rockets directly on Mars.

These guys are planning to print an entire rocket, reducing the number of parts from a hundred thousand to one. Now they have already printed and tested the Aeon rocket engine with NASA, and they plan to print rockets directly on Mars.

What about Mars?

We already know a lot about the surface of the Moon, and we have only three days to fly to it. Why not build a base there and populate it with people? Let's set up observatories with telescopes that, due to the lack of an atmosphere, give clear images of distant pieces of the universe. It would be nice to print all this on a 3D printer, and it is also desirable so that the work arrives first and everything is done for us, and if necessary, we will print the necessary equipment, tools, clothes and even food.

However, will we have something to print from there? Scientists at Northwestern University in Chicago have demonstrated this possibility. They purchased moon and Martian dust simulators from NASA, which they used to test their vehicles and probes. In shape, size and composition, these particles resemble those on the Moon or Mars - powder from regolith, the local soil. They managed to be used as a material for 3D printing. Scientists even got elements that fit together like Lego pieces.

In shape, size and composition, these particles resemble those on the Moon or Mars - powder from regolith, the local soil. They managed to be used as a material for 3D printing. Scientists even got elements that fit together like Lego pieces.

See also: Astronauts of the future. Architects and astronomers have created a project for a lunar settlement

Researchers from the European Space Agency have also been experimenting with regolith as a material for 3D printing for several years. Their newly printed parts have the highest resolution of any 3D printed lunar soil-like material. And this is very important, because the technology of sequential overlay of layers when printing in space missions requires the greatest possible accuracy.

If all goes well, the monthly colonizers will print parts, tools, and even houses out of lunar soil.

Chinese scientists also plan to create a base on the moon using 3D printers.

Already four Chang'e missions are over: during the last of them, they managed to land on the far side of the Moon. Chang'e-5 will be launched this year - the probe should bring a moon rock to Earth. The seventh mission will study the composition of the soil and the characteristics of lunar rocks, and already in the Chang'e-8 mission, Chinese scientists are testing key technologies for building a research base on the moon and assessing the prospects for 3D printing methods there. And there it’s not far to Mars - at least this knowledge will definitely come in handy.

Chang'e-5 will be launched this year - the probe should bring a moon rock to Earth. The seventh mission will study the composition of the soil and the characteristics of lunar rocks, and already in the Chang'e-8 mission, Chinese scientists are testing key technologies for building a research base on the moon and assessing the prospects for 3D printing methods there. And there it’s not far to Mars - at least this knowledge will definitely come in handy.

On Mars, millions of miles from home, where Relativity Space plans to print their rockets, 3D printers will build settlements without waiting for help from Earth. But how can the colonialists give themselves advice in emergency situations?

And here you can't do without them...

The colonizers of both the Moon and Mars will most likely live in their settlements for years, risking various injuries. An ESA-led project is already exploring the possibility of using 3D printers for biodrugs. With their help, it would be possible to make a skin fragment from the patient's cells.