Demand for 3d printing

3D Printing Drives Growth In On-Demand Manufacturing

Fast Radius' manufacturing facility in Chicago houses a fleet of Carbon 3D printers.

Fast RadiusDespite the pandemic, inflation, the labor and chip shortages – and everything else hampering global supply chains – optimism about one manufacturing solution is so strong it propelled three companies public in 2021: Fathom, Shapeways, and Xometry. A fourth, Fast Radius, is set to debut on Wall Street in February.

This new breed of on-demand digital manufacturing company is highly invested in software and digitally driven manufacturing technologies, such as industrial 3D printing. They not only promise faster and more efficient part manufacturing locally, but digital solutions that enable cost-saving product innovations and accelerated time to market for nearly any type of product.

“There is a growing awareness about how the infrastructure to design, make, and move things today does not meet the needs of this time – it’s rigid, wasteful, outdated, and it’s also not sustainable,” says Lou Rassey, co-founder and CEO of Fast Radius headquartered in Chicago.

The company’s newest microfactory on Chicago’s Goose Island features industrial 3D printers from Carbon and HP along side digitally integrated CNC machines, as part of Fast Radius’ Cloud Manufacturing Platform. The microfactory will produce component parts for companies across industries including electric vehicles, medical and healthcare devices, and consumer goods. The World Economic Forum named Fast Radius one of nine best factories in the world implementing “technologies of the Fourth Industrial Revolution” or Industry 4.0.

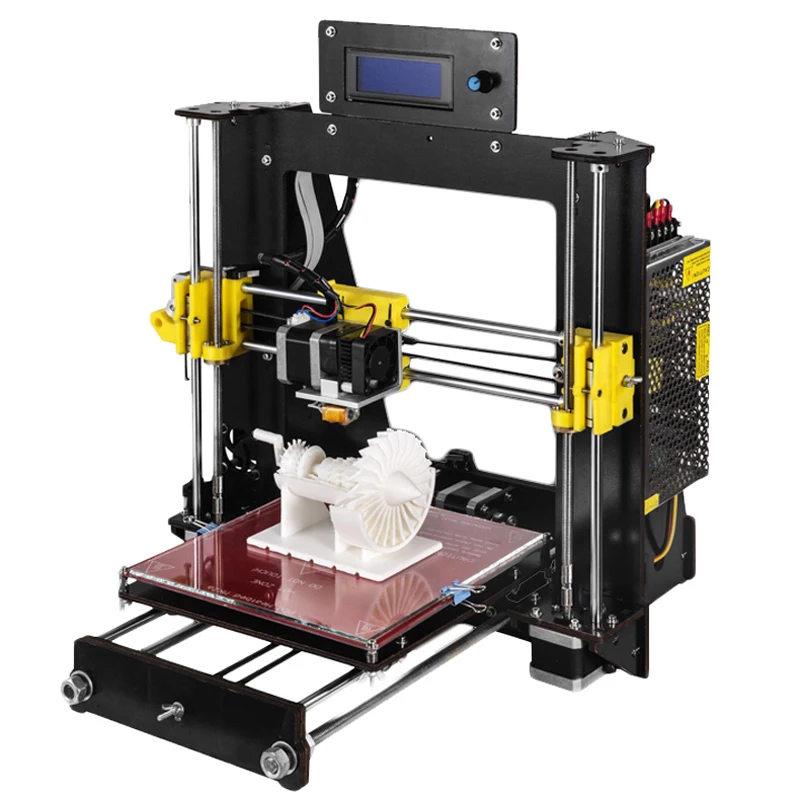

3D printers at the Fathom Digital Manufacturing headquarters in Heartland, Wis.

Fathom Digital ManufacturingMORE FROMFORBES ADVISOR

Digitally Integrated Manufacturing

Companies in this sector are often lumped together under the on-demand digital manufacturing umbrella, when in fact, they offer a range of approaches to 3D printing, Industry 4.0, and modernizing the manufacturing supply chain.

On one end of the spectrum, companies such as Shapeways and Sculpteo (owned by chemical giant BASF) offer an easy upload-and-print online platform. This on-demand 3D printing model focuses on ease of use; anyone can upload digital part files, click to choose materials, and receive parts and prototypes in hours or days. This modern, consumer-like experience aims to bring manufacturing to the masses by facilitating 3D prints of everything from product prototypes to architectural models.

This on-demand 3D printing model focuses on ease of use; anyone can upload digital part files, click to choose materials, and receive parts and prototypes in hours or days. This modern, consumer-like experience aims to bring manufacturing to the masses by facilitating 3D prints of everything from product prototypes to architectural models.

Other companies, such as Materialise, which went public in 2014, have a wide customer base for their software solutions that help companies 3D print their own digital files in-house and run their own fleet of 3D printers. The software is also used by other on-demand 3D printing services to track and print customer orders. Materialise’s on-demand manufacturing at one of Europe’s largest 3D printing facilities features six 3D printing technologies.

Fathom began as a small- to mid-volume contract manufacturer that embraced new methods, including 3D printing, early on. They still offer traditional manufacturing, but it is integrated into an end-to-end digital production process.

“The big differentiations for us and our platform is that we have decades of experience and deep entrenched customer relationships,” says Ryan Martin, CEO of Fathom. “We focus on providing large enterprise customers with a unique solution to their manufacturing challenges.”

Fast Radius is a marriage of software-driven services, engineering expertise, and factory floors of state-of-the-art hardware. They are one of the only on-demand manufacturers to own and operate all their own production facilities, which enables them to integrate their software solutions and automate production.

The company’s software can suggest improvements to a digital file, guide customers through their material and technology options, and provide transparency into the production process. But on-demand manufacturing is just one Fast Radius solution, says Rassey. “We offer custom microfactories built specifically for unique customer needs, near where the customer needs parts so that they can build flexible supply chains. ” Customers such as Satair (a subsidiary of Airbus) use the Fast Radius Virtual Warehouse to store their parts digitally, ready to manufacture at a moment’s notice, freeing up physical warehouse space and eliminating overstock.

” Customers such as Satair (a subsidiary of Airbus) use the Fast Radius Virtual Warehouse to store their parts digitally, ready to manufacture at a moment’s notice, freeing up physical warehouse space and eliminating overstock.

EOS 3D printers at the Materialise factory in Belgium.

MaterialiseThe growing number of on-demand digital manufacturers has made selecting one a challenge for many companies. Xometry and another start-up, Craftcloud, offer online portals that are marketplaces of these manufacturers. Customers upload their digital file and manufacturing partners around the world bid on the project.

“Often, customers are looking for the fastest solution or the most economical solution for their 3D printing project,” says Mathias Plica, CEO of Craftcloud. “We match them with partners locally that have the expertise to deliver in the materials and quality they need.”

Regardless of business model, what all these companies have in common is the application of smart manufacturing technology to enable a highly automated manufacturing process from concept to fulfillment. This involves cloud computing, AI, IoT, machine learning, big data, digital simulation, and, of course, 3D printing (also called additive manufacturing).

This involves cloud computing, AI, IoT, machine learning, big data, digital simulation, and, of course, 3D printing (also called additive manufacturing).

Design and engineering staff at Fast Radius help companies understand applications of 3D printing.

Fast RadiusEvangelists of Additive Manufacturing

Although Fathom, based in Heartland, Wis., has 90 industrial-grade 3D printers for plastic and metal parts, and nearly 450,000 square feet of manufacturing capacity across 12 U.S. facilities, its most powerful offering may be its staff.

“Companies come to us to understand how to use additive manufacturing,” says Martin. “In some cases we introduced companies to additive manufacturing, which is a huge growth area for us. One of our automotive customers reached out to us last week for our engineering expertise to figure out how they can develop more applications for it beyond prototyping.”

The message from on-demand digital manufacturers is that customers don't need to know much about 3D printing to benefit from the flexibility, speed, and cost savings it can offer. Nor do they need to invest in 3D printers with six-figure price tags or hire experienced engineers to get parts, prototypes, and tools that are lighter, stronger, and cheaper than those made by traditional manufacturing methods.

Nor do they need to invest in 3D printers with six-figure price tags or hire experienced engineers to get parts, prototypes, and tools that are lighter, stronger, and cheaper than those made by traditional manufacturing methods.

Large enterprises may opt for on-demand 3D printing because it offers a wider range of materials and technologies than would be practical to have at an onsite facility. Fathom counts among its clients, Tesla, 3M, Google, and Amazon. Shapeways says it works with Target and prosthetic manufacturer Fillauer, and Xometry boasts engineers at Bosch, NASA, and BMW among its customers.

Fast Radius offers a service it calls Additive Launch to help customers tap into the latest 3D printing technologies and design tools to accelerate product development.

“We've worked with companies like Rawlings, Steelcase, and Aptiv to bring new products to market that are only possible with additive manufacturing,” says Rassey. The new REV1X Rawlings baseball glove features internal 3D printed padding in the thumb and pinky that significantly reduces the glove’s weight without sacrificing protection or durability, according to Rawlings.

Volvo recently turned to Materialise to streamline production of lighter-weight manufacturing tools and fixtures for its factories. At Bell Helicopter Textron, engineers turned to the on-demand manufacturing wing of 3D printer maker Stratasys, called Stratasys Direct, to 3D print flight-certified components that cut weight by 13% and manufacturing lead time by 75%, the company says.

Beyond expertise in 3D printing, another tailwind driving growth for these on-demand manufacturers is advancements in additive manufacturing software and the 3D printers themselves. These, and other smart manufacturing technologies today, are more mature, reliable, and affordable, says Rassey. This makes it possible for companies like Fast Radius and others to establish profitable business models around these tools.

“With Industry 4.0 taking off, we're on the cusp of a significant growth opportunity," says Martin. "Product lifecycles are so much shorter than they were even five years ago, and companies need an on-demand advanced manufacturing partner who can move quickly and serve all their requirements without sacrificing quality. ”

”

If the growing number of service providers is any proof, more companies appear to be waking up to idea of agile digital manufacturing platforms and the benefits of transitioning their production from traditional to digital manufacturing through a trusted on-demand service provider.

Three Areas Holding Back The $10.6B 3D Printing Industry

Market research firm SmarTech Analysis recently released its data for the additive manufacturing (AM) industry. It determined that, in 2021, the 3D printing sector reached $10.6 billion in revenue, excluding the revenues associated with hardware maintenance contracts and post-processing equipment. The firm further projects that AM is expected to grow to over $50 billion by 2030.

The 3D printing industry is projected to reach over $50 billion by 2030, according to one market ... [+] research firm.

Image courtesy of SmarTech Analysis.This growth is closely pinned to the trend that large manufacturers will increasingly use the technology for mass production. However, in order for AM to reach wide-scale adoption, it will need to advance significantly in three crucial and interrelated areas: throughput, factory integration, and quality control. Fortunately for the industry, these are all also issues that are being actively addressed.

However, in order for AM to reach wide-scale adoption, it will need to advance significantly in three crucial and interrelated areas: throughput, factory integration, and quality control. Fortunately for the industry, these are all also issues that are being actively addressed.

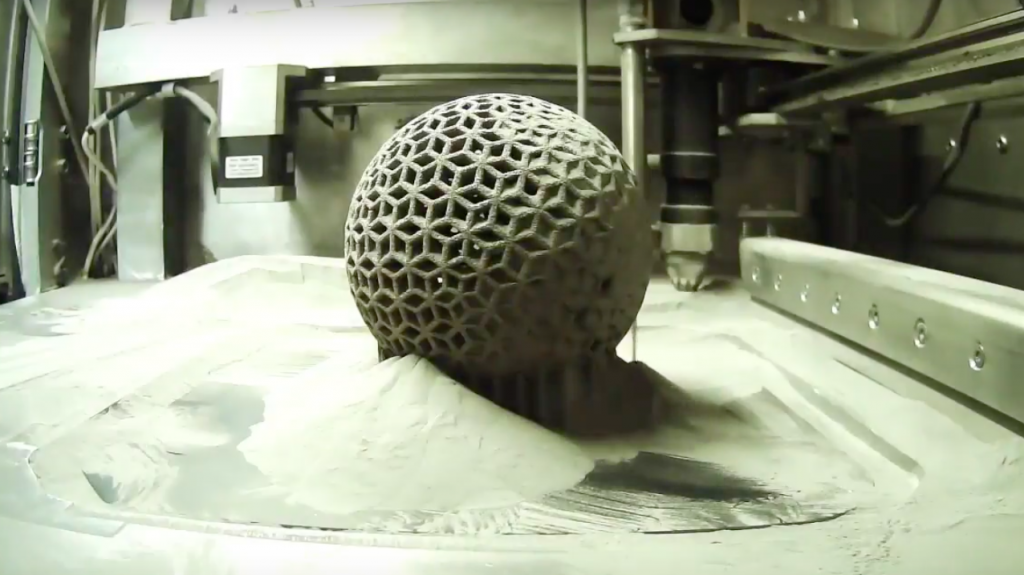

3D Printing Throughput

Due to its roots as a prototyping technology, 3D printing was never designed with mass production in mind. Instead, its ability to create complex shapes has been limited to one-off parts or small batch manufacturing. For that reason, firms across the 3D printing industry have been working to develop systems that can make many parts as rapidly as possible, a concept known as throughput.

Among the leaders in this regard is HP, which spent years researching the technology before finally unveiling technologies capable of rapid production both in plastics and metals. The 2D printing giant has ported its expertise in inkjet printheads over to 3D printing with a technology called Multi Jet Fusion (MJF). MJF is already being used to produce large batches of polymer parts for everything from eyewear to grocery bots.

MJF is already being used to produce large batches of polymer parts for everything from eyewear to grocery bots.

Legor Group in Italy is using HP Metal Jet to 3D print functional stainless steel accessories for ... [+] the jewelry and fashion markets.

Image courtesy of Legor Group SPA.MORE FROMFORBES ADVISOR

This is just the beginning for the company, which is now rolling out its Metal Jet technology. A form of what is called “metal binder jetting,” Metal Jet deposits a liquid binder onto metal powder, creating a component that must then be sintered in a furnace. Customers as large as Volkswagen are investing in the technology with a plan to mass produce up to 100,000 metal components annually for consumer vehicles.

However, HP isn’t the only company in this quickly evolving space. A widely publicized startup called Desktop Metal is working to speed up metal binder jetting. GE, too, is working on its own version of the technology. Altogether, these companies are ushering in an era in which low-cost metal powders can be used to 3D print large numbers of parts in a single job, potentially changing the cost structure for metal 3D printing altogether.

This means that they will be taking on the established leaders in metal 3D printing, which typically rely on zapping high powered laser beams at expensive metal powders. These companies are working on increasing throughput, as well, by adding up to 12 lasers to their machines.

3D Printing Factories

While a fleet of 3D printers may be capable of manufacturing at volume, that doesn’t mean that they’ll necessarily fit into an existing factory operation. In large part, this is due to the fact that they lack mass production-level software.

Now, a handful of startups have emerged to take on the challenge of developing AM-specific software for manufacturing execution systems (MES). These tools make it possible to both manage a fleet of 3D printers and connect them to a company’s existing production software. They typically aid in the entire order-to-fabrication workflow. This means order quoting and tracking, print file preparation, print job monitoring and data collection, printer fleet queuing, quality control, and shipping.

MES software necessarily connects to a business’s existing software tools. This includes product lifecycle management (PLM), enterprise resource planning (ERP), and general IT software. While PLM might include a company’s preferred 3D modeling software, ERP will be made up of everything from payroll programs to tools for tracking overall finances.

MES platforms are now working to take all of the software that a manufacturer might already be working with and inserting 3D printing into the mix. However, they’re not just limiting themselves to AM. Many MES developers are looking to connect with other production equipment, such as CNC machines. Then, with the help of machine learning, the entire workflow can be improved automatically as data from each order and each machine job feeds back into the work cycle. Artificial intelligence is significantly adding to the capabilities of MES software.

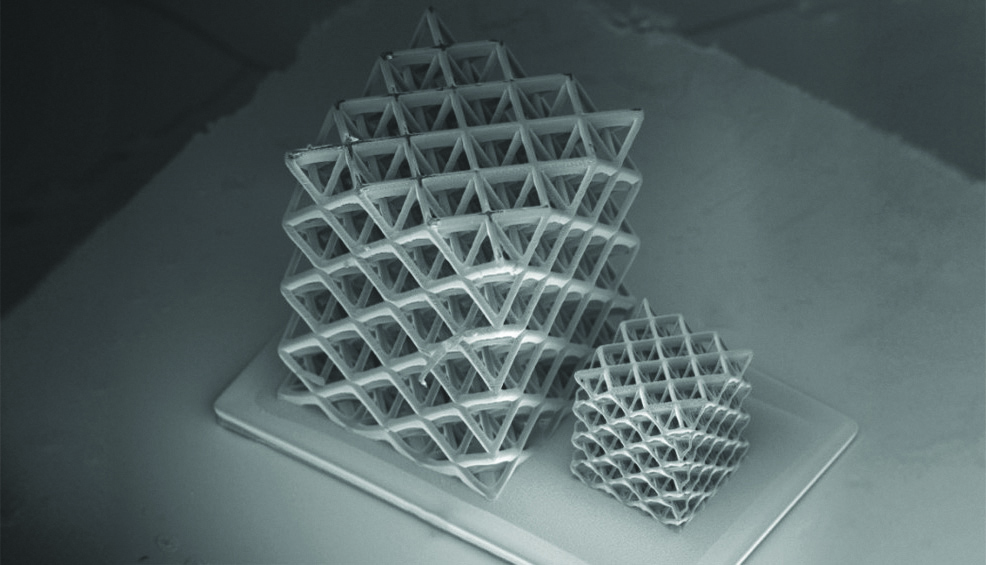

3D Printing Quality Control

Perhaps the biggest obstacle to widespread AM adoption is quality control. This is because, with additive, each part is distinct. Every point on the build platform may be slightly different and even the slightest variation in a printing parameter may change the microstructure of the printed object.

This is because, with additive, each part is distinct. Every point on the build platform may be slightly different and even the slightest variation in a printing parameter may change the microstructure of the printed object.

In turn, an object printed at one angle will not be the same as one printed at another. And, because parts are built up layer by layer, it is difficult to validate the internal geometries of an item once printing is complete. As a result, the only true way to assure the quality of a printed object is with a CT scan, typically a cost-prohibitive method for inspecting multitudes of parts.

Fortunately, not only are newer CT scanning systems with lower price tags coming onto the market, but there are other tools that are being used to ensure the quality of printed parts. Among them is computer simulation. Companies like ANSYS have developed software that can anticipate any defects that occur during the printing process and compensate for them. Hexagon is taking this one step further by predicting issues at the microscopic level.

Meanwhile, firms like Sigma Labs and Additive Assurance have created hardware to monitor the build chambers of metal 3D printers to detect errors. Increasingly, these tools will enable active feedback so that the machines can quickly correct issues during the print process. When connected with MES software and 3D printing simulation, the equipment can learn from past errors and address them before they even happen in the future.

Altogether, these areas are advancing at incredible rates, in large part because manufacturers see the value in being able to produce objects from digital files on demand. As companies as large as Ford, GE, and Siemens look to 3D printing to produce quality end parts, they are driving the entire additive market to bend to their needs. To reach a whopping $50 billion by the end of the decade, the 3D printing industry has to be capable of making millions of parts for those customers.

Which 3D printing business will be successful? / Habr

What kind of successful business can be opened using 3D printers? I will make a reservation right away that so far there are few such examples. I'll tell you about some of them.

I'll tell you about some of them.

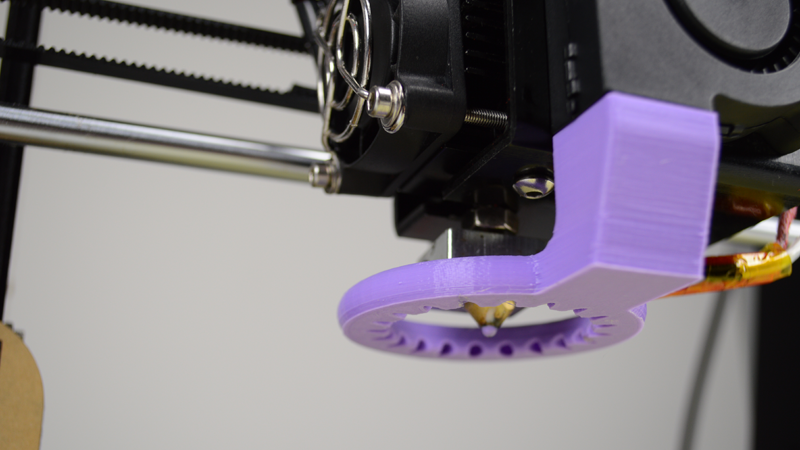

3D Printing Studio

The first thing that comes to mind is setting up a 3D printing studio. Its business model is based on modeling and printing models for the client. The main success factor is to ensure a consistently high level of equipment utilization. For such a project, it is more important to focus on mass replication than on printing single copies, even in large volumes. The cost of printing a small model should be low, and the labor costs should be high. The main production processes are the high-quality development of printing technology for each specific detail or project, the selection of the right material. The client model is checked for errors, and both the material and the printer are selected. It remains to agree on the price and, in fact, print the model. It is necessary to approve it with the customer, and, if necessary, modify it.

You can build such a studio with almost any level of investment: start with one or two printers, gradually increase the equipment fleet or immediately invest in a 3D printer fleet. You can also purchase industrial equipment for functional prototyping and small-scale production. But in any case, the most important thing is to correctly build the business model of the enterprise.

You can also purchase industrial equipment for functional prototyping and small-scale production. But in any case, the most important thing is to correctly build the business model of the enterprise.

Small-scale production

The second most popular business idea is a small-scale production studio. In this case, the main task is not to find a client, but to understand what product will be in demand. There are many examples of such studios, and their success primarily depends on the quality and originality of the products offered. For clarity, consider the production of molds for the manufacture of confectionery. They are easy to model, customize, print and sell. The target audience of this product is clear and stable, the product is easily promoted in social networks, the cost is low, and the most budget 3D printers are suitable for production. The main thing here is the optimal ratio of the number of devices with production volumes. Another popular example: accessories for gamers. Game weapons, masks, costume elements from computer games for cosplayers. The product is not so massive, but consistently in demand, and its price niche is significantly higher. More time will be spent on modeling and printing, but in return you get markets around the world, since the studio is not limited to the location of your region.

Game weapons, masks, costume elements from computer games for cosplayers. The product is not so massive, but consistently in demand, and its price niche is significantly higher. More time will be spent on modeling and printing, but in return you get markets around the world, since the studio is not limited to the location of your region.

3D printing of medical products

The third version of the 3D printing studio is medical. Today it is very much in demand. Prostheses, orthoses, orthopedic insoles, hearing aids, temporary crowns, aligners, spectacle frames are complex in conventional production, but our technologies greatly simplify this process. The equipment here is selected based on the specific task. Usually one company is focused on printing a particular line of models. The accumulated experience allows you to create a product with unique properties as efficiently as possible. In this direction, business goes in tandem with science. The success of the enterprise directly depends on innovative approaches in orthopedics and medicine in general.

3D printing of art objects

Fourth place will be given to art. 3D printing of sculptures is another way to capitalize on this technology. Creating a large art object is not an easy task, and certainly not a cheap one. However, many interiors or public spaces are in need of an aesthetic upgrade. Modern sculptors began to use the new technology in their work precisely to create final products, and not prototypes or layouts, as one might think. To achieve this goal, large-format printers using FDM technology (the model is formed from molten plastic) are needed. Typically, a computer model is divided into parts and printed on several 3D printers, after which it is glued, sanded, primed and painted in the desired colors, sometimes with the addition of texture. This makes the sculpture almost indistinguishable from those made from natural materials.

Another option is to show the model in full size, without post-processing, which allows viewers to see the 3D printed model at different stages of its creation.

It is difficult to fit into a short article all the variety of opportunities that 3D printing offers to enthusiasts of this technology, but we see that every day there are more and more new interesting stories of its application. It gives impetus to the development of new technologies and brings innovation to seemingly established areas such as the creation of sculptures or gingerbread. As the American inventor Chuck Hull, who patented the first 3D printer, said: “I don’t have a crystal ball that will tell me what should happen in the future, but one thing I know for sure: when smart people work on a specific task, they gradually move forward. forward".

Alexander Kornveits

Founder and CEO of Tsvetnoy Mir

3D printing business - How to make money with a 3D printer

3D printing

03/15/2021

Content

-

- 3D printing studio

- Small-scale production

- Medical 3D printing

- art-90 3D printing0055

What successful business can be opened using 3D printers? I will make a reservation right away that so far there are few such examples.

I'll tell you about some of them.

I'll tell you about some of them. 3D printing studio

The first thing that comes to mind is the creation of a 3D printing studio. Its business model is based on modeling and printing models for the client. The main success factor is to ensure a consistently high level of equipment utilization. For such a project, it is more important to focus on mass replication than on printing single copies, even in large volumes. The cost of printing a small model should be low, and the labor costs should be high. The main production processes are the high-quality development of printing technology for each specific detail or project, the selection of the right material. The client model is checked for errors, and both the material and the printer are selected. It remains to agree on the price and, in fact, print the model. It is necessary to approve it with the customer, and, if necessary, modify it.

You can build such a studio with almost any level of investment: start with one or two printers, gradually increase the fleet of equipment, or immediately invest in a fleet of 3D printers.

You can also purchase industrial equipment for functional prototyping and small-scale production. But in any case, the most important thing is to correctly build the business model of the enterprise.

You can also purchase industrial equipment for functional prototyping and small-scale production. But in any case, the most important thing is to correctly build the business model of the enterprise.

Small batch production

The second most popular business idea is a studio focused on small-scale production. In this case, the main task is not to find a client, but to understand what product will be in demand. There are many examples of such studios, and their success primarily depends on the quality and originality of the products offered. For clarity, consider the production of molds for the manufacture of confectionery. They are easy to model, customize, print and sell. The target audience of this product is clear and stable, the product is easily promoted in social networks, the cost is low, and the most budget 3D printers are suitable for production. The main thing here is the optimal ratio of the number of devices with production volumes. Another popular example: accessories for gamers.

Game weapons, masks, costume elements from computer games for cosplayers. The product is not so massive, but consistently in demand, and its price niche is significantly higher. More time will be spent on modeling and printing, but in return you get markets around the world, since the studio is not limited to the location of your region.

Game weapons, masks, costume elements from computer games for cosplayers. The product is not so massive, but consistently in demand, and its price niche is significantly higher. More time will be spent on modeling and printing, but in return you get markets around the world, since the studio is not limited to the location of your region.

Add to compare

Product added to compare Go

Manufacturer Creality Free Shipping

Add to compare

Product added to compare Go

Manufacturer FlashForge Free shipping

Add to compare

Product added to compare Go

Manufacturer PICASO 3D Free Shipping

Add to compare

Product added to compare Go

Manufacturer Phrozen Medical 3D printing

The third option for a 3D printing studio is medical.

Today it is very much in demand. Prostheses, orthoses, orthopedic insoles, hearing aids, temporary crowns, aligners, spectacle frames are complex in conventional production, but our technologies greatly simplify this process. The equipment here is selected based on the specific task. Usually one company is focused on printing a particular line of models. The accumulated experience allows you to create a product with unique properties as efficiently as possible. In this direction, business goes in tandem with science. The success of the enterprise directly depends on innovative approaches in orthopedics and medicine in general.

Today it is very much in demand. Prostheses, orthoses, orthopedic insoles, hearing aids, temporary crowns, aligners, spectacle frames are complex in conventional production, but our technologies greatly simplify this process. The equipment here is selected based on the specific task. Usually one company is focused on printing a particular line of models. The accumulated experience allows you to create a product with unique properties as efficiently as possible. In this direction, business goes in tandem with science. The success of the enterprise directly depends on innovative approaches in orthopedics and medicine in general.

3D printed art objects

Fourth place will be given to art. 3D printing of sculptures is another way to capitalize on this technology. Creating a large art object is not an easy task, and certainly not a cheap one. However, many interiors or public spaces are in need of an aesthetic upgrade. Modern sculptors began to use the new technology in their work precisely to create final products, and not prototypes or layouts, as one might think.

To achieve this goal, large-format printers using FDM technology (the model is formed from molten plastic) are needed. Typically, a computer model is divided into parts and printed on several 3D printers, after which it is glued, sanded, primed and painted in the desired colors, sometimes with the addition of texture. This makes the sculpture almost indistinguishable from those made from natural materials.

To achieve this goal, large-format printers using FDM technology (the model is formed from molten plastic) are needed. Typically, a computer model is divided into parts and printed on several 3D printers, after which it is glued, sanded, primed and painted in the desired colors, sometimes with the addition of texture. This makes the sculpture almost indistinguishable from those made from natural materials. Another option is to show the model in full size, without post-processing, which allows viewers to see the 3D printed model at different stages of its creation.

It is difficult to fit into a short article all the variety of opportunities that 3D printing offers to enthusiasts of this technology, but we see that every day there are more and more new interesting stories of its application. It gives impetus to the development of new technologies and brings innovation to seemingly established areas such as the creation of sculptures or gingerbread.

As the American inventor Chuck Hull, who patented the first 3D printer, said: “I don’t have a crystal ball that will tell me what should happen in the future, but one thing I know for sure: when smart people work on a specific task, they gradually move forward. forward".

As the American inventor Chuck Hull, who patented the first 3D printer, said: “I don’t have a crystal ball that will tell me what should happen in the future, but one thing I know for sure: when smart people work on a specific task, they gradually move forward. forward". Alexander Kornweitz,

Founder and CEO of Tsvetnoy Mir

Free Shipping

Add to compare

Product added to compare Go

Manufacturer Raise3D Free Shipping

Add to Compare

Product added to compare Go

Manufacturer CreatBot Free Shipping

Add to compare

Product added to compare Go

Manufacturer Raise3D Free Shipping

Add to Compare

Product added to compare Go

Manufacturer PICASO 3D #Application

Russian entrepreneur, expert in the field of additive technologies and 3D equipment.