What is resin 3d printing

Resin vs. Filament 3D Printer: Which is Best for You?

Research Hub > Resin vs. Filament 3D Printer

June 27, 2022

Article

4 min

Resin and filament are the two most common materials used in 3D printing. But which is better for your project, and what equipment do you need?

What's Inside

- What is Stereolithography (SLA) 3D Printing?

- What is Digital Light Processing (DLP) 3D Printing?

- What is Fused Deposition Modeling (FDM) 3D Printing?

-

Filament vs.

Resin Printers

- Which 3D Printer Should You Buy?

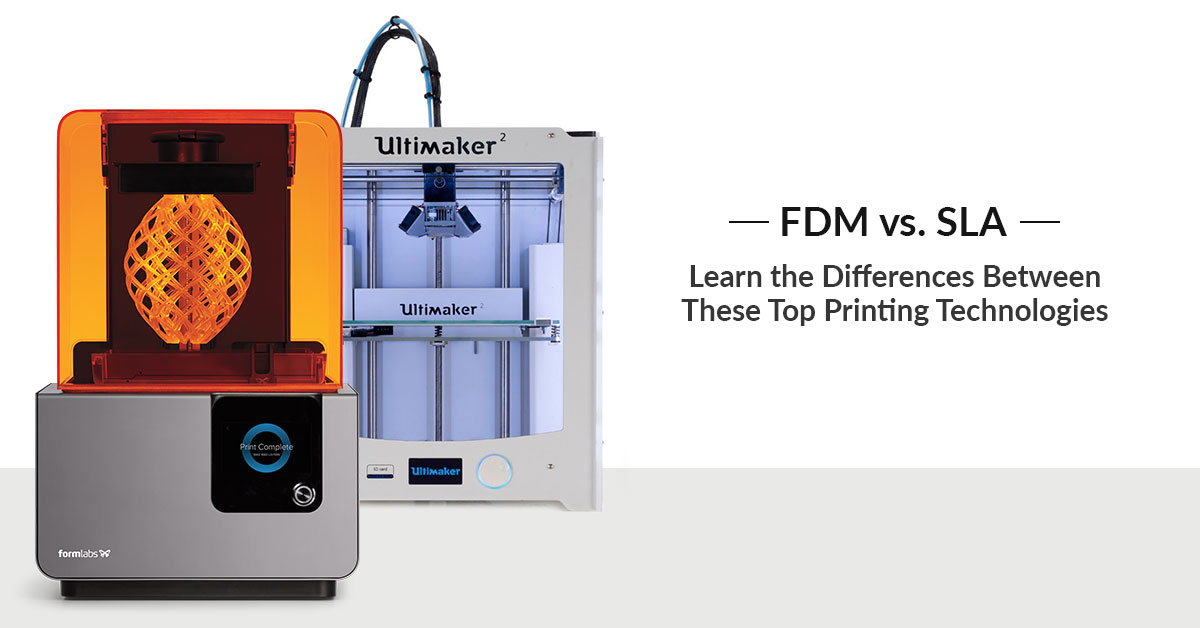

SLA and DLP are two different types of resin 3D printers, while FDM are filament 3D printers. Read our breakdown below to compare.

What is Stereolithography (SLA) 3D Printing?

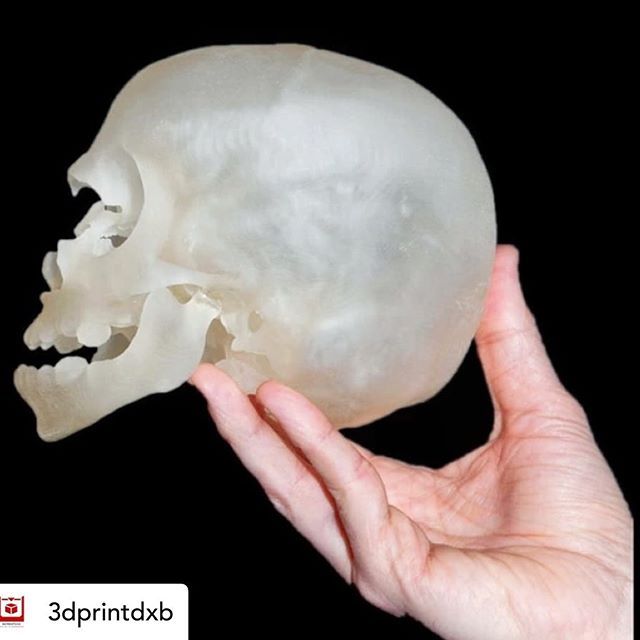

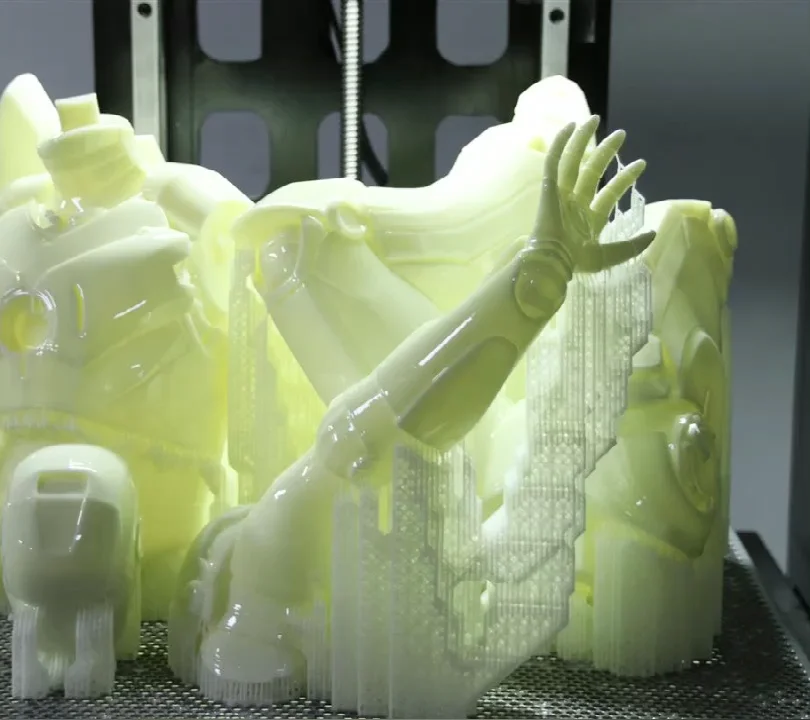

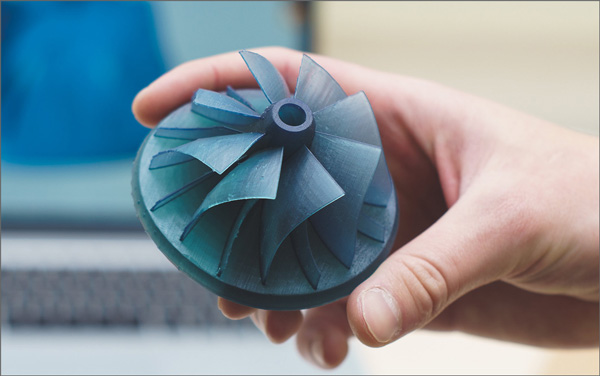

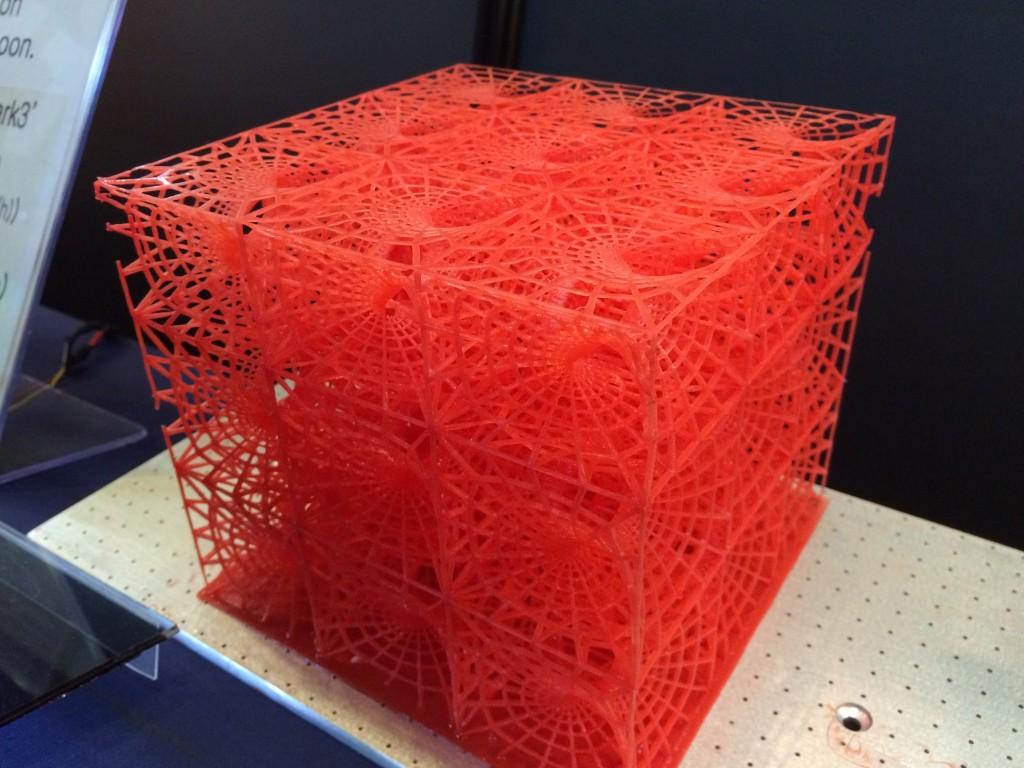

Stereolithography (SLA) is the oldest form of 3D printing. It works by exposing a layer of photosensitive liquid resin to a UV-laser beam; the resin then hardens in the desired pattern, and the object is built layer by layer until it is complete. This allows you to print a model with extremely fine detail.

Objects printed by SLA 3D printers have smooth surfaces, but often the quality depends upon the printer type. SLA resin printers tend to have smaller build plates, so you can't make larger pieces on them. Printing via SLA involves a longer process as printed objects need to be rinsed using a solvent and then put into an ultraviolet oven to complete processing.

SLA resin printers tend to have smaller build plates, so you can't make larger pieces on them. Printing via SLA involves a longer process as printed objects need to be rinsed using a solvent and then put into an ultraviolet oven to complete processing.

What is Digital Light Processing (DLP) 3D Printing?

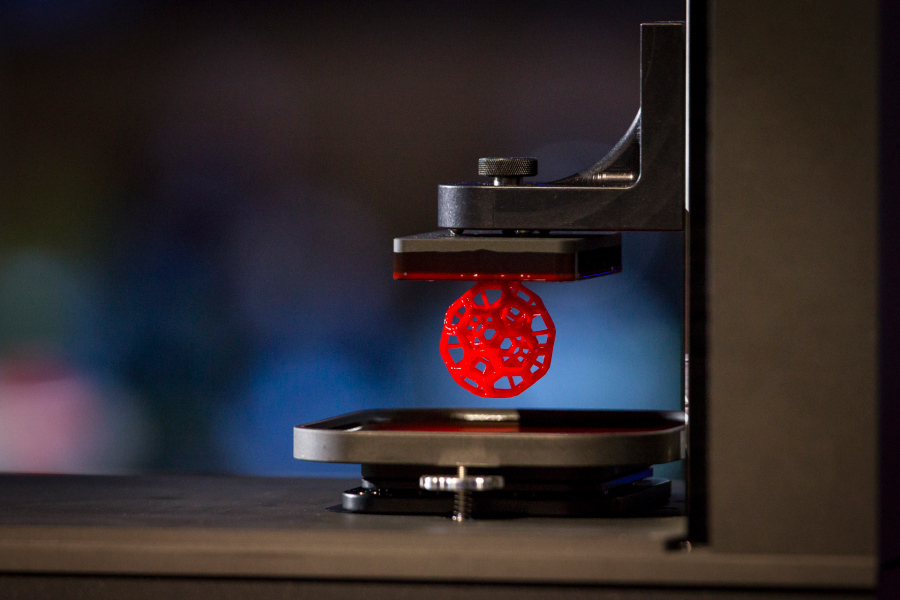

Digital Light Processing (DLP) is the fastest of all 3D printing methods. A layer of hardened material can be printed in a few seconds and quickly transferred to allow for printing of the next layer. Like SLA, DLP 3D printers use liquid plastic resin, but instead of a UV-laser beam, the resin is melted with arc lamps. This light source causes the impressive printing speeds because the amount of light allows the resin to quickly harden. DLP is a robust technology that produces high-resolution models every time, even allowing you to use cheaper materials for complex and detailed objects.

What is Fused Deposition Modeling (FDM) 3D Printing?

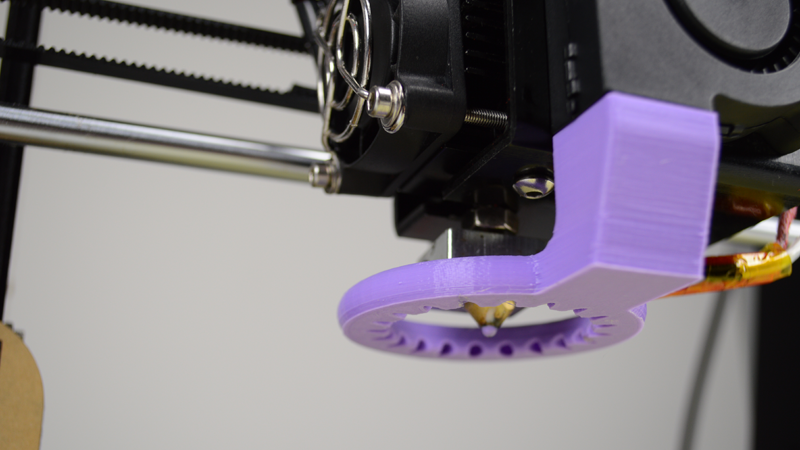

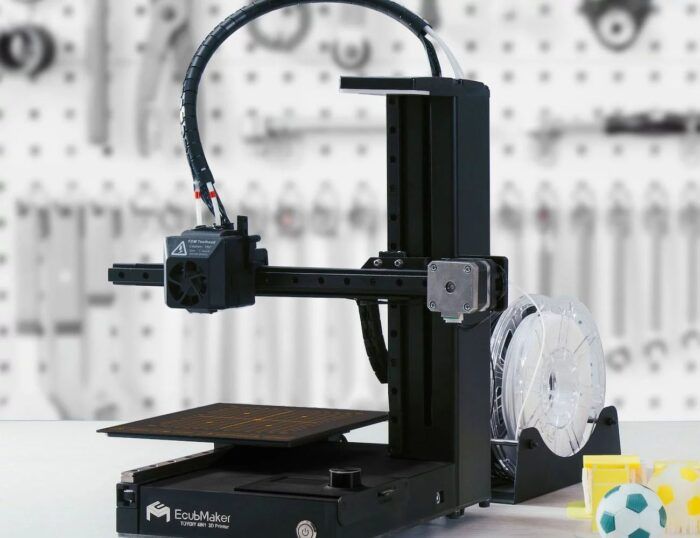

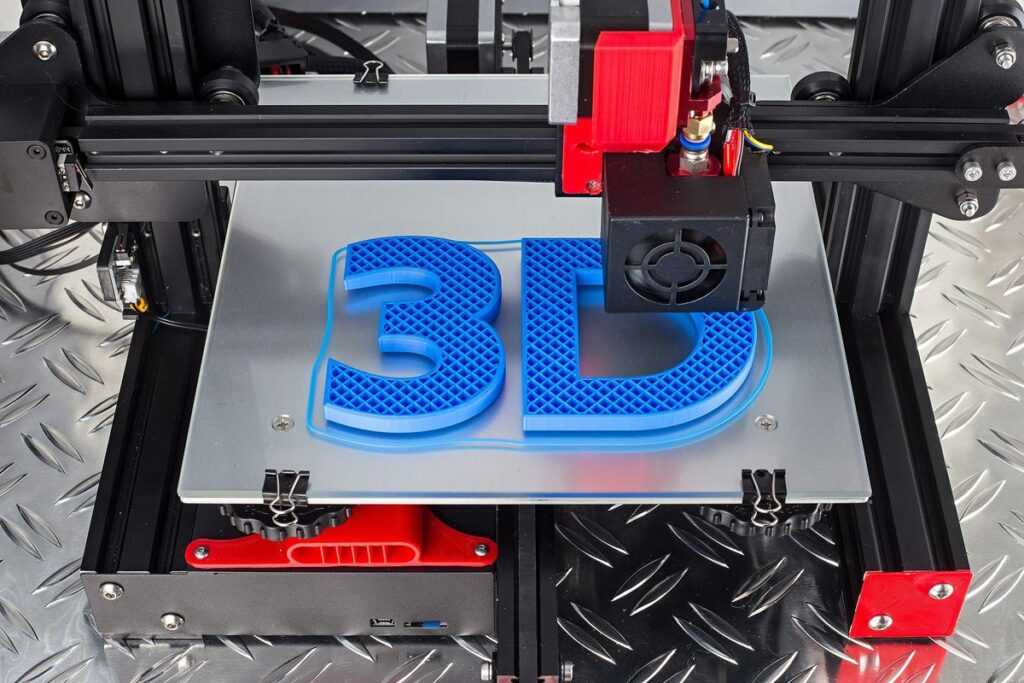

Fused Deposition Modeling (FDM) is filament 3D printing, the most popular and readily available form of 3D printing available on the market. Developed and originally implemented in the 1980s, FDM allows you to print operational prototypes as well as ready-to-use products as such LEGO, plastic gears and much more

All components printed with FDM can go in high performance and engineering-grade thermoplastic, which makes this technology useful for mechanical engineers and manufacturers. Printed pieces have excellent mechanical strength and heat resistance. FDM printers construct 3D objects layer by layer, starting at the bottom and moving upwards by heating and extruding thermoplastic filament. This form of 3D printing is useful in all fields, from new product development to prototyping to end-product manufacturing.

Filament vs. Resin Printers

There are several key factors to consider when deciding whether an FDM or SLA/DLP printer is the right choice for you.

- Cost - When purchasing a 3D printer, it is not only the printer cost that you must take into account; it is the filament or resin cost, as well as other accessory and time demands. On printer cost, FDM printers easily win over SLA/DLP printers at every level. Especially for novices, budgetand entry-level SLA/DLP printers are few and far between.

In addition, you must consider the upkeep of the printer. A spool of filament will cost you $25 or less, with infrequent nozzle replacement given regular cleaning and maintenance. With resin printers, you will need to replace both resin and resin tanks frequently. A tank costs $40 or so, and a liter of resin is around $80.

When comparing costs, an FDM printer is far more affordable.

When comparing costs, an FDM printer is far more affordable.

- Quality - A major consideration in 3D printing is the quality of objects that you will be printing. FDM printers rely on several factors, such as extruder precision, nozzle size and adhesion between layers. Warping, shrinkage and shifting are not uncommon as the layers are slowly squeezed together. However, these issues can be cleaned up in post-processing.

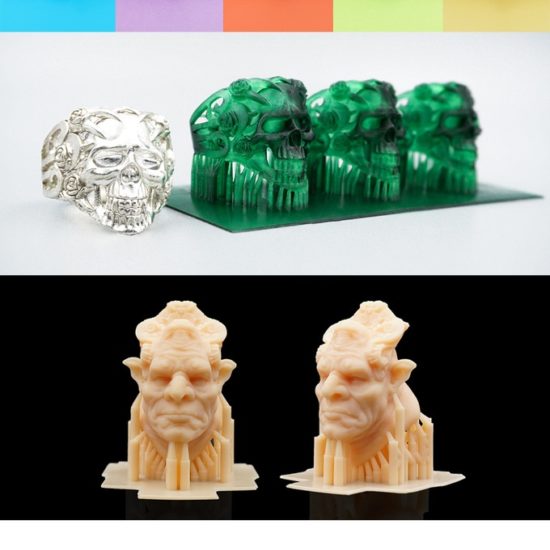

On the other side, SLA/DLP printers provide superb quality because the laser determines fine details, leading to extremely precise, high-quality print jobs. When comparing finished products, resin 3D printing yields better final results.

- Ease of Use - There is a definite learning curve no matter if you choose a filament or resin 3D printer. For filament printers, you will need to remove the final print from the print bed using a palette knife and then perform some post-processing snipping off of excess plastic, as well as a bit of sanding.

For resin printers, removing the final print is a bit more cumbersome as there is a lot of excess resin leftover. In addition, objects will need to be wiped with isopropyl alcohol and sometimes put into an ultraviolet oven for final processing. Both printer types require postprocessing, though filament printers might be a little easier to use.

- Durability - Both types of printers have been shown to form pieces offering high durability. Alternatively, materials such as PETG and ABS can be exposed to heat and UV rays, adding more durability to filament printing. This means that anything from a children’s toy to an outdoor coaster can be printed and they will stay intact if left outside for an extended period.

- Build Volume - Resin printers can vary from smaller build volume to much bigger based on the printer. Many of the entry level printers are standardized at 130 x 80 x 160 mm, printing anything an individual or business could need. 192 x 120 x 150 mm is a smaller size in which more advanced resin printers can produce products at, much smaller than that of your everyday resin printer.

- Print Speed - For most resin printers, a print speed of around 100mm/hour is a good speed if an individual or business has the time on their hands and does not worry too much about efficiency. DLP and SLA printers can achieve a top speed of 720 mm/hour if the details do not matter as much. Those printers tend to be the most effective amongst the rest, so normally the job will be done at a high rate of print speed and look great.

Conclusion: Which 3D Printer Should You Buy?

Choosing the 3D printer that is right for you depends on your needs and the objects that you are creating. Filament and an FDM printer is the right choice for hobbyists and makers, those building low-cost materials, when strength and durability are important or when precision and surface finish aren’t crucial. Resin and an SLA/DLP printer is the right choice when high precision and smooth finish is of utmost importance and cost isn't a factor.

Looking for a 3D printer? Find what you need on CDW.com.

What is a Resin 3D Printer & How Does it Work? – 3D Printerly

Resin 3D printers have been growing in popularity for a while now, mainly due to how easy they are to use, as well as the significant price decrease. That has led to many people wondering what exactly a resin 3D printer is, and how it works.

That’s why I decided to write an article about this, giving people simply to understand information about what the process is like, what to expect, and some great resin 3D printers you can look towards getting for yourself or as a gift.

Keep on reading through this article for more in-depth information about those awesome resin 3D printers.

What is a Resin 3D Printer?

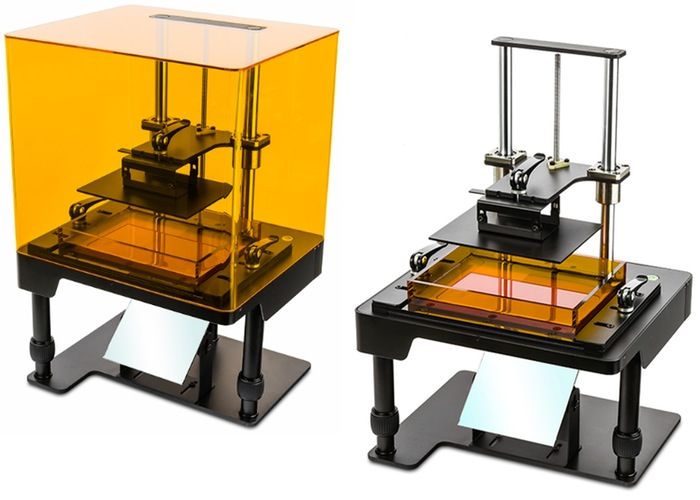

A resin 3D printer is a machine that holds a vat of photosensitive liquid resin and exposes it to UV LED light beams layer-by-layer to harden the resin into a plastic 3D model. The technology is called SLA or Stereolithography and can provide 3D prints with extremely fine detail at a 0.01mm layer height.

The technology is called SLA or Stereolithography and can provide 3D prints with extremely fine detail at a 0.01mm layer height.

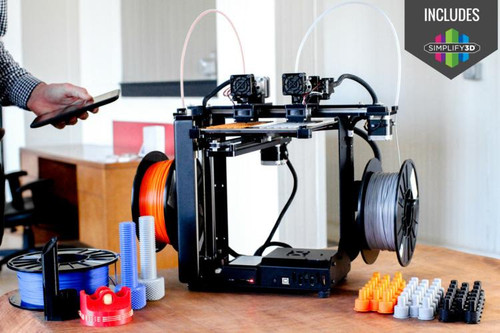

You mainly have two major options while picking up a 3D printer, first is the filament 3D printer which is widely known as FDM or FFF 3D printer and the second is resin 3D printer also known as SLA or MSLA 3D printer.

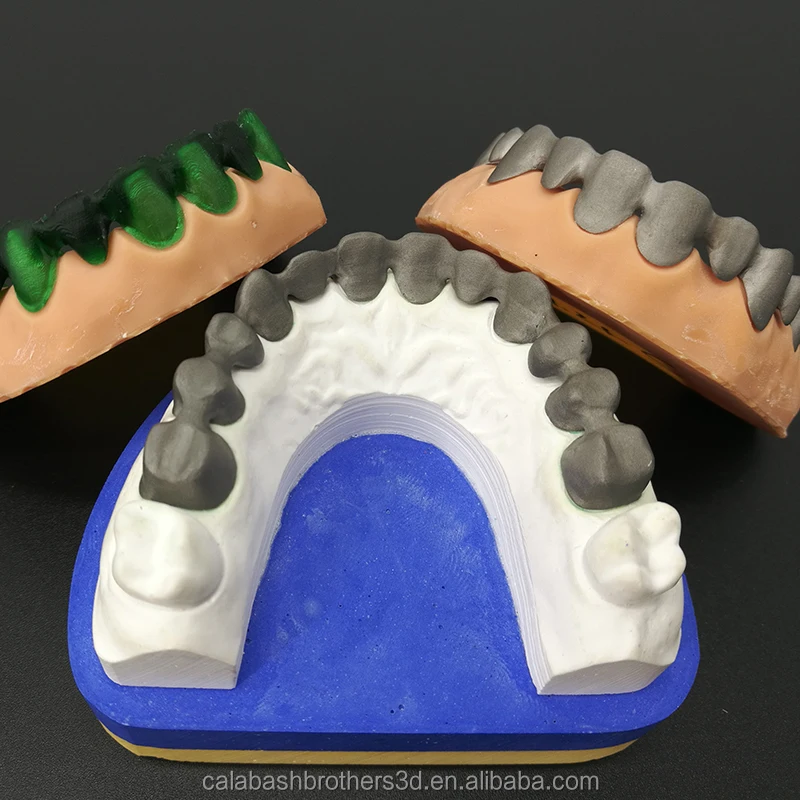

If you look at the resultant models printed with these two different technologies, you are likely to notice a great difference in quality. Resin 3D printers have the ability to print 3D models that will have super smooth surfaces with fine details.

FDM 3D printers may not be able to print models of such high quality because of the positioning accuracy, nozzle size and large layer height capabilities.

Here are the main components of a resin 3D printer:

- Resin vat

- FEP film

- Build plate

- UV LCD screen

- UV acrylic lid to retain and block light

- Linear rails for Z movement

- Display – Touchscreen

- USB & USB Drive

- Thumb screws to secure build plate and resin vat

You can get a clear idea that an FDM 3D printer of excellent quality can usually print at a minimum of a 0. 05-0.1mm (50-100 microns) layer height while a resin printer can print at as low as 0.01-0.25mm (10-25 microns) which ensures much better details and smoothness.

05-0.1mm (50-100 microns) layer height while a resin printer can print at as low as 0.01-0.25mm (10-25 microns) which ensures much better details and smoothness.

It does also translate into taking longer to print overall, but another key difference is how resin 3D printers can cure a whole layer at a time, rather than needing to outline the model like filament printers do.

A model printed with a resin 3D printer is going to have layers better fused with each other in a way that brings those high quality models that people love.

They are known to be more brittle than filament 3D prints, but there are now some great high-strength and flexible resins that you can make use of.

A resin 3D printer has fewer moving components than a filament printer which means that you don’t have to worry about dealing with too much maintenance.

In terms of replacements, the FEP film is the main part that is consumable, though you can get several 3D prints without changing it, as long as you take the right precautions.

In the early days, you are likely to damage your FEP film since it is prone to punctures – mainly due to residue not being cleaned out before the next 3D print. They aren’t too expensive to replace, with a pack of 5 going for around $15.

Another consumable is the LCD screen within the 3D printer. With the more modern monochrome screens, these can last 2,000+ hours of 3D printing. The RGB types of screens run out of steam quicker and could last you maybe 700-1,000 hours of printing.

The LCD screens can be fairly pricey depending on what 3D printer you have, the larger being the more expensive ones. A large one for say the Anycubic Photon Mono X could set you back around $150.

Manufacturers have gotten better at prolonging the lifespan of these screens and have started to design their resin 3D printers to have improved cooling systems that help the LED lights go on for longer.

Over time, they will get dimmer but you can also extend the life even further by having a longer “Light Delay” time between each layer cure.

The video below is a great illustration on how resin 3D printing works, as well as an overall guide on how beginners can get started.

What Types of Resin 3D Printing Are There – How Does it Work?

Resin 3D printing is the technology in which liquid resin is stored in a container instead of being injected through a nozzle. The major terms or types of resin 3D printing include Stereolithography (SLA), Digital Light Processing, and Liquid Crystal Display (LCD) or Masked Stereolithography (MSLA).

SLA

SLA stands for Stereolithography and the SLA resin 3D printer works with the help of a UV laser light that is applied on the surface of a photopolymer container which is mainly known as resin VAT.

The light is applied in a specific pattern so that desired shape can be formed.

SLA 3D printers includes various components such as a building platform, a resin VAT, a light source, an elevator, and a pair of galvanometers.

The main purpose of an elevator is to increase or decrease the height of the building platform so that layers can be formed during the printing process. The galvanometers are the pair of movable mirrors which are used to align the laser beam.

As the resin vat contains uncured resin, it hardens in layers due to the effect of UV light and begins to form a 3D model. Resin 3D printers keep on printing one layer after the other and this process is repeated until a fully 3D printed model of an object is completed.

DLP

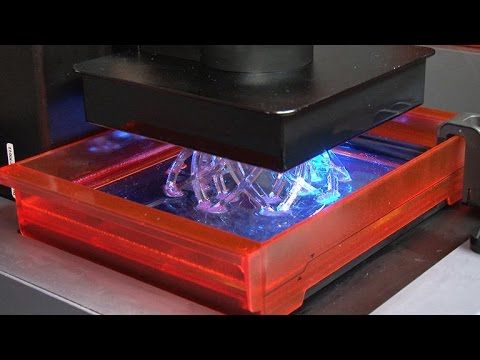

Digital Light Processing is a technology that is almost like the SLA but instead of using lasers, it uses a digital projection surface as a light source.

Where you can only print one point at a time using SLA technology, DLP resin 3D printing works by printing a complete layer at a time. This is the reason that DLP resin 3D printing is much faster as compared to SLA.

This is the reason that DLP resin 3D printing is much faster as compared to SLA.

They are also known to be very reliable since it isn’t a complex system and doesn’t have moving parts.

DMD (Digital Micromirror Device) is a device that is used to control where exactly the projection will be applied in resin 3D printers.

A DMD consists of micromirrors ranging from hundreds to millions which allow it to project light at various spots and print layered patterns in a much better way while consolidating an entire layer at once.

The image of a layer consists primarily of pixels, as a digital display is the initiation point of any layer that is formed by the DLP 3D printer. In 3D printing, the points are in the form of prisms that you can see on all three angles.

Once a layer is printed completely, the platform is lifted at a specific height so that the next layer of the model can be printed.

The major advantage of using DLP resin 3D printing is that it brings much smoother and fast prints. One thing to note here is that the increase in the print area significantly decreases the quality of processing.

One thing to note here is that the increase in the print area significantly decreases the quality of processing.

MSLA/LCD

DLP and SLA can be distinguished from each other but you may get confused while finding the difference between DLP and MSLA or LCD (Liquid Crystal Display).

As we know that DLP 3D printing requires an additional micromirror device to transmit light from the projector but there is no need for such a device while printing with LCD 3D printers.

The UV beams or light come directly from the LEDs that glow through the LCD screen. As this LCD screen works as a mask, LCD technology is also widely known as MSLA (masked SLA).

Since the invention of this MSLA/LCD technology, resin 3D printing has become more popular and accessible to the average person.

This is because the individual or additional components for LCD 3D printing are relatively inexpensive. Do keep this fact in mind that the lifespan of an LCD 3D printer is a bit shorter than the DLP chipset and it often requires more maintenance as well.

Even with this drawback, LCD/MSLA 3D printing is quite popular because it offers the advantages of smoother surfaces and prints relatively fast. Pixel distortion is an important factor in resin 3D printing which is far less than with DLP resin 3D printing.

The actual light that is emitted from LCD screens is known to be harmful to the organic compounds within, meaning you have to change them according to how many hours you have used them and its performance.

How Much Are Resin 3D Printers?

The lowest price resin 3D printer goes for around $250 like the Elegoo Mars Pro. You can get a good medium range resin 3D printer for $350-$800 like the Anycubic Photon Mono X, while a top quality professional resin 3D printer can set you back $3,000+ like the Formlabs 3. They are getting a lot cheaper.

They are getting a lot cheaper.

Resin 3D printers can be considered simple machines as they don’t include a lot of moving parts. This is the reason that resin 3D printers can be purchased at relatively low prices. Most of its components are used by us in our daily life such as LCD screens.

Elegoo Mars Pro

If you are looking for a low-budget resin 3D printer that offers good quality prints, the Elegoo Mars Pro can be a great option. This 3D printer is one of the top 5 resin 3D printers that have Amazon’s bestseller rankings at time of writing.

It includes amazing features and powerful specifications that allow the users to print high-quality prints with much ease and convenience.

This 3D printer is the best option in low price range as it can be availed at a price around $250 and has some great features such as:

- Higher Precision

- Excellent Protection

- 115 x 65 x 150mm Build Volume

- Safer and Refreshing 3D Printing Experience

- 5 Inches New user Interface

- Light Weight

- Comfortable and Convenient

- Silicon Rubber Seal that Prevents Resin Leaking

- Consistent Quality Prints

- 12 Months Warranty on Printer

- 6-Month Warranty on the 2K LCD

You can get your Elegoo Mars Pro Resin 3D Printer with a low budget on Amazon today.

Anycubic Photon Mono X

The Anycubic Photon Mono X is a medium price range resin 3D printer that includes some advanced features to have a better resin printing experience.

This 3D printer has some of the best benefits to offer in terms of good print quality, comfort, consistency, and convenience.

The most loved feature with this 3D printer is how large its build volume is, allowing you to 3D print big models or several miniatures in one print.

The Anycubic Photon Mono X was actually my first 3D printer, so I can personally say, it’s a brilliant 3D printer for beginners to get started with. Setup is very straightforward, the print quality is excellent, and it looks very professional wherever you place it.

Some of the key features of the Anycubic Photon Mono X are:

- 9 Inches 4K Monochrome LCD Display

- Upgraded LED Array

- UV Cooling Mechanism

- Sanded Aluminum Build Plate

- High-Quality 3D Prints

- App Remote Control

- Fast Printing Speed

- Sturdy Resin Vat

- Wi-Fi Connectivity

- Dual Linear Z-Axis for Extra Stability

- 8x Anti-Aliasing

- High-Quality Power Supply

You can get the Anycubic Photon Mono X 3D printer for around $700 from the Anycubic’s Official Store or Amazon.

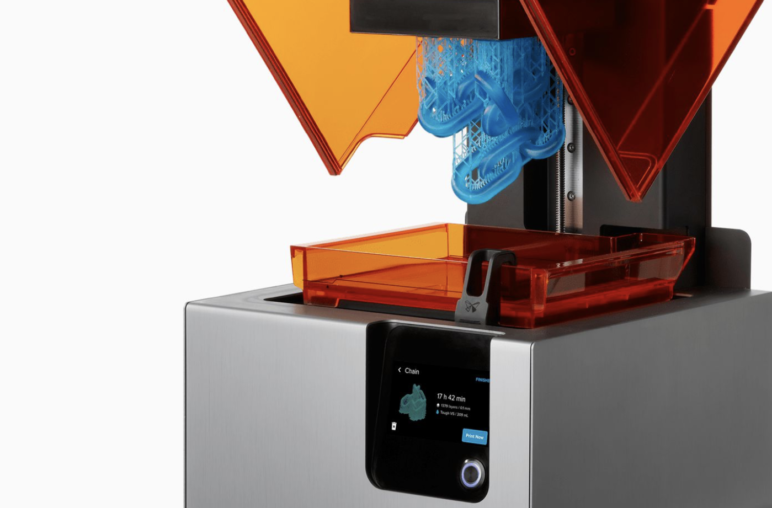

Formlabs Form 3

The Formlabs Form 3 printer has the ability to print high-quality models with a wide range of 3D printing materials but it is quite expensive.

For the people who do resin 3D printing professionally or need highly advanced 3D printing features, this 3D printer can be a great choice.

The consistency and quality of this machine is said to be higher than other resin 3D printers, but they still do pretty well!

This one is more recommended for small businesses, professionals or serious hobbyists that have experience in the resin 3D printing game.

I wouldn’t recommend it for a beginner since it is expensive and has a little more of a learning curve.

This 3D printer contains many advanced resin 3D printing features.

Some of the best things offered by the Formlabs Form 3 include:

- Incredible Print Quality

- Supports a Wide Range of Printing Materials

- Support Multiple Users and 3D Printers

- Closed-Loop Calibration

- Hassle-Free Materials Management

- Consistent Printing

- Improved Part Clarity

- Pinpoint Precision

- Easy to Replace Components

- Industrial Grade Quality Prints

- Wi-Fi Functionality

- Reprint Previous 3D Prints

You can buy the Formlabs Form 3 Printer from their official website right now.

There are a few other accessories that you should purchase when it comes to resin 3D printing such as:

- Nitrile Gloves

- Isopropyl Alcohol

- Paper Towels

- Filters with a Holder

- Silicone Mat

- Safety Glasses/Goggles

- Respirator or Facemask

Most of these items are one time purchases, or will last you a long time so it doesn’t get too expensive. The most expensive thing about resin 3D printing has to be the resin itself which we’ll discuss in the next section.

How Much is 3D Printing Resin Materials?

The lowest price for 3D printing resin that I have seen is around $30 for 1KG like the Elegoo Rapid Resin. A popular mid-range resin is the Anycubic Plant-Based Resin or the Siraya Tech Tenacious Resin for around $50-$65 per KG. Premium resins can easily go for $200+ per KG for dental or mechanical resin.

Elegoo Rapid Resin

Elegoo resin is very popular in the 3D printing industry, with their most used resin having over 3,000 Amazon reviews at a rating of 4. 7/5.0 at time of writing.

7/5.0 at time of writing.

Users love how it doesn’t have a strong odor like other resins, and how prints come out detailed.

It’s a go-to resin for many 3D printer users even after trying many other cheaper resins out there, so if you want a reliable resin, you can’t go wrong with the Elegoo Rapid Resin.

Some of the features include:

- Light Odor

- Consistent Success

- Low Shrinkage

- High Precision

- Safe and Secure Compact Package

Thousands of high quality miniatures and 3D prints have been created with this awesome resin, so try a bottle of Elegoo Rapid Resin from Amazon for your resin 3D printing today.

Anycubic Eco Plant-Based Resin

This is a medium price range resin that is loved by thousands of 3D printer users and has Amazon’s Choice tag. Many users say that they love this 3D printing resin because of its flexibility and durability.

The Anycubic Eco Plant-Based Resin contains no VOCs (Volatile Organic Compounds) or any other harmful chemicals. This is the reason that most people choose this resin even if it is more expensive than some other 3D printing resins available in the market.

This is the reason that most people choose this resin even if it is more expensive than some other 3D printing resins available in the market.

Some features of this resin:

- Ultra-Low Odor

- Safe 3D Printing Resin

- Stunning Colors

- Easy to Use

- Fast Curing and Exposure Time

- Wide Compatibility

You can find a bottle of the Anycubic Eco Plant-Based Resin from Amazon.

Siraya Tech Tenacious Resin

If you are looking for a 3D printing resin that offers high flexibility, strong prints, and high impact resistance, the Siraya Tech Tenacious Resin is a great option for you.

Although it is a little on the premium side, users mention how it is worth every penny when it comes to providing high quality.

- High Impact Resistance

- Easy to Print

- Flexibility

- Best for Strong Prints

- Best for LCD and DLP Resin 3D Printers

You can find the Siraya Tech Tenacious Resin from Amazon for your resin 3D printer.

Introduction to Resin 3D Printing and Overview Anycubic Photon S

Table of Contents

1. Introduction

2. Printer Description

2.1. Specifications Anycubic Photon S

2.2. Delivery set

2.3. Design description and comparison with the first generation

3. Operation

3.1. Starting the printer

3.2. Slicing programs

3.3. Photopolymer printing in general

3.4. Features of operation of photopolymer printer

3.5. Features of operation of Photon S

4. Conclusion and examples of printing

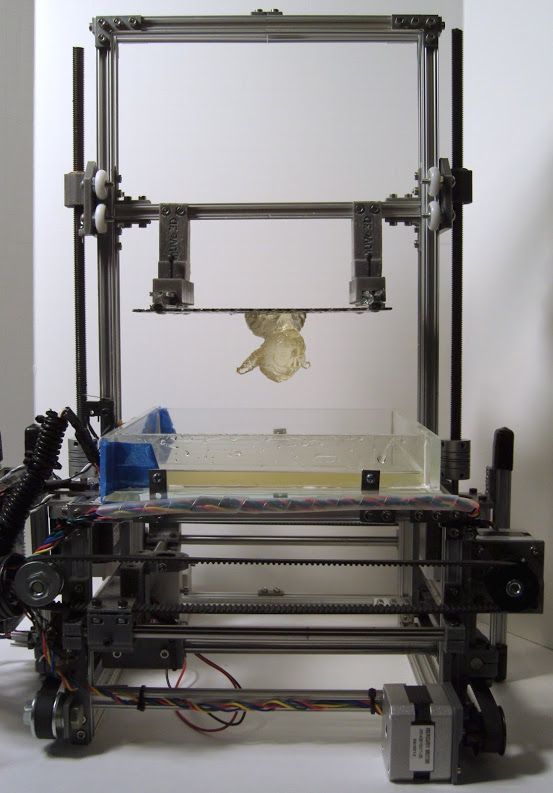

1. Introduction Your obedient entered / got into 3D printing (underline as necessary) back in 2014. After looking and reading well on almost the only forum at that time, Roboforum.ru, the topic of choosing and buying a printer and seeing that almost every first one there buys a kit of self-assembled Pryusha of a Chinese spill, after assembling which he begins to print parts on it for a new 3D printer, I made the only possible decision: in order not to fall into this inevitable vicious circle, I bought an already assembled clone of the second Makerbot - FlashForge Creator, which I have already mentioned more than once in my articles on 3D printing technologies (blowing dust).

But the topic of photopolymer printing, which gives a completely different potential for the quality of the print, albeit at the price of a smaller size of the latter, inevitably “tickled the nostrils”, enticing the opportunity to get the result already without reservations “well, what do you want, this is 3D printing, not casting”. But the projector photopolymers that were available for purchase at that time did not attract at all with an exorbitant price.

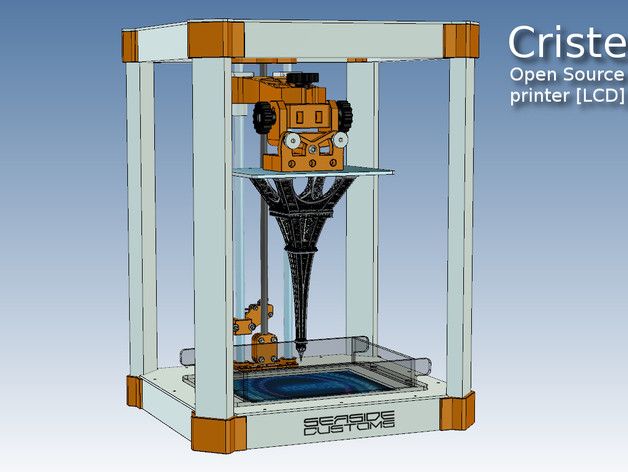

Therefore, the first acquaintance with this technology took place on a self-made printer built on 15 mm rails and ball screws with a FullHD projector. It would seem that this is it - the brightness (light speed), the size of the tray for printing 192x120, the presence of a “nod” in the design, serious mechanics. But alas, all castles in the air stumbled over the harsh reality, as often happens: large size, fragile acrylic bath, dust on the projector optics, a milled platform and its bracket that do not provide for normal cleaning of the photopolymer, let's say politely, the unpleasant smell of Chinese photopolymer, which also turned out to be practically non-working (did not freeze even in the sun), and, as a control, poor sharpness at the corners of the used Acer P1500 projector at the required short focusing distances. As a result, one (ONE in capital letters) successful printout with FunToDo Castable photopolymer was made on this printer, which was later put into experiments. And the main reason why I completely closed the topic of a home-made projector printer for myself is the actual change during this time of technology from a cumbersome and expensive projector to LCD technology that has almost completely captured the market today, when it became clear that a photopolymer, especially a home one, simply must be much more compact, simpler and uniquely to have a closed print chamber. Moreover, the cost of a projector printer and an LCD are completely incomparable, not to mention the intricacies of calibrating the coaxiality of the optics of the projector of the Z axis of the printer.0004

As a result, one (ONE in capital letters) successful printout with FunToDo Castable photopolymer was made on this printer, which was later put into experiments. And the main reason why I completely closed the topic of a home-made projector printer for myself is the actual change during this time of technology from a cumbersome and expensive projector to LCD technology that has almost completely captured the market today, when it became clear that a photopolymer, especially a home one, simply must be much more compact, simpler and uniquely to have a closed print chamber. Moreover, the cost of a projector printer and an LCD are completely incomparable, not to mention the intricacies of calibrating the coaxiality of the optics of the projector of the Z axis of the printer.0004

Thus, the real entry into the photopolymer occurred already on the first generation Anycubic Photon bought a little later. This printer had an excellent film tension system, a durable aluminum tray and a platform well adapted for cleaning, but at the same time, due to the cheaper design, it had problems with the stability of the Z axis, so a year later I was already unpacking the Anycubic Photon S bought on occasion and at a discount, which will be discussed further (hereinafter I will call it Photon, indicating the first or second, which is S, generation if necessary).

What is the point of doing a review in any form of an already morally obsolete printer, except, I confess, it’s a sin, participating in a printer review contest, when there are already more promising technologies for using monochrome matrices, and indeed, something, and even video reviews on YouTube on Is this printer enough? Firstly, it is still a very good and quite budgetary photopolymer, sold and relevant in terms of aggregate, secondly, “what we have from the goose” after a year and a half of operation are pitfalls that are difficult to stumble upon during the initial review, features of work, wear, etc. Thirdly, this is an opportunity, based on a review of this printer, to create, along with this, an article on an introduction to photopolymer 3D printing for beginners [the author wipes his hands first with isopropyl alcohol, then with a damp cloth, swearing quietly under his breath]. But I must say that this article reflects my own experience with photopolymer and therefore may be somewhat subjective.

2. Description of the printer

money change?

2.1. Characteristics of Anycubic Photon S For those who are not familiar with this printer, first I will give the main characteristics:

- a 5.5 "RGB matrix typical for photopolymers of this class with a resolution of 2560x1440, giving a dot pitch of 47 microns

- LED UV matrix, which gives better illumination uniformity and thus removes the problem of geometric distortion in the corners

- aluminum tray with groove for pouring out the photopolymer

- platform calibration system with one fixing screw - exhaust air filtering system with two charcoal filters

- Z-axis on two roller guides - ABS housing white versions, I chose black. I will give a photo from the official site, because. after a year and a half of operation, the printer no longer looks like it did when the box was first opened.

2.2. Scope of delivery

The printer itself is delivered in a cardboard box, padded around the perimeter with a sufficient amount of sealant, the print platform and tray are placed inside the case itself and individually packed in a sealant. The printer also comes with a set of disposable paper filters for filtering the polymer (you can buy them at auto enamel stores), a plastic spatula, which I personally use to clean the walls of the bath from the photopolymer when draining it back into the container, a pair of gloves, a flash drive with test files and screwdriver. Also, the kit should include half a liter or a liter of branded Ekubikov photopolymer, but this already depends on the configuration of the printer.

The printer also comes with a set of disposable paper filters for filtering the polymer (you can buy them at auto enamel stores), a plastic spatula, which I personally use to clean the walls of the bath from the photopolymer when draining it back into the container, a pair of gloves, a flash drive with test files and screwdriver. Also, the kit should include half a liter or a liter of branded Ekubikov photopolymer, but this already depends on the configuration of the printer.

2.3. Description of the design and comparison with the first generation

Now let's dwell on the design in more detail and conduct a comparative analysis of it with respect to the first generation, whether the printer has become a predecessor in everything. The first striking difference between the Photons of two generations is the case material. Those who were interested in these models, of course, know about it, but this article is primarily intended not for gurus who know all this, and have already eaten more than one dog on their own construction of 3D printers, but for people relatively distant . .. So, the case of the first generation Anycubic Photon is made of steel, the second one is made of ABS plastic. In a sense, this is even funny, because. this plastic is easily degraded, more precisely, it gradually dissolves upon contact with the photopolymer. If, in the case of a steel case with acrylic windows, it was clear that nothing would happen to him, then there are even doubts whether the walls will lead over time and whether, for example, the door will close with difficulty and stick it to body with this same photopolymer. And it's not that the metal case is a clear advantage, but for Photon, given the peculiarities of its design, unfortunately, yes. More on that below.

.. So, the case of the first generation Anycubic Photon is made of steel, the second one is made of ABS plastic. In a sense, this is even funny, because. this plastic is easily degraded, more precisely, it gradually dissolves upon contact with the photopolymer. If, in the case of a steel case with acrylic windows, it was clear that nothing would happen to him, then there are even doubts whether the walls will lead over time and whether, for example, the door will close with difficulty and stick it to body with this same photopolymer. And it's not that the metal case is a clear advantage, but for Photon, given the peculiarities of its design, unfortunately, yes. More on that below.

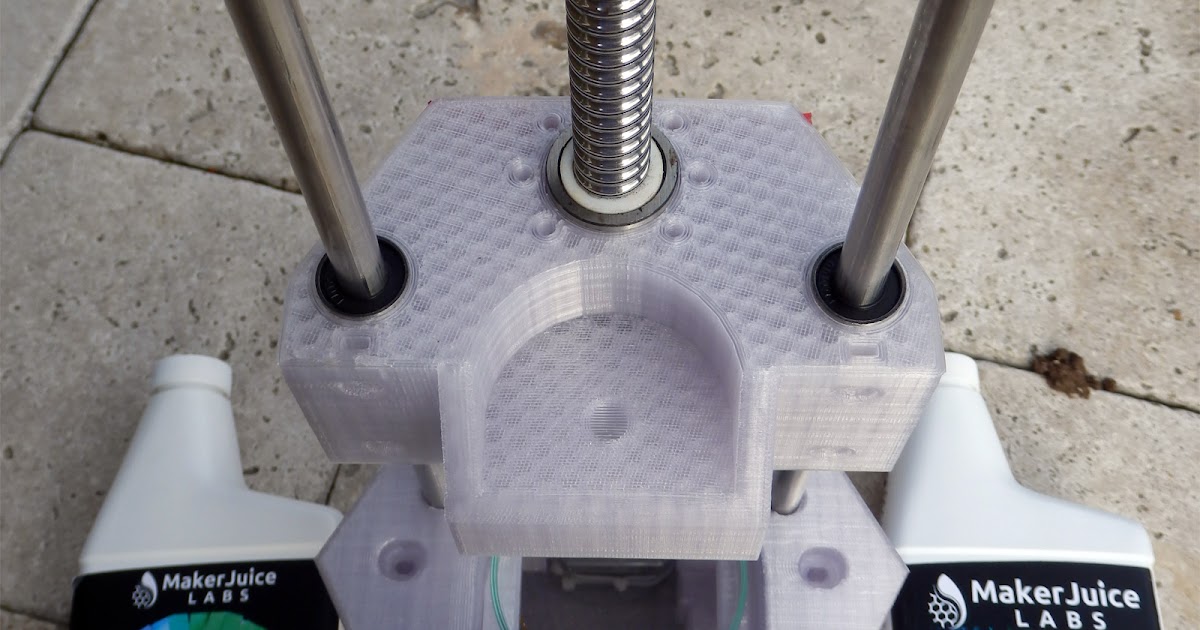

The second feature that, looking ahead a little, was decisive for me when buying, is the replacement of a single Z-axis roller guide with a double one. In the world of harsh homemade products, recognizing only the option with rail guides, when in every second homemade product you can see red-green ones similar to HIWIN (yes, in most cases they are similar, because they are ordered mainly from China, and the percentage of fakes of this fashionable home-made manufacturers, very high) rail carriages, the use of roller guides is not even bad manners, this is an excuse to lead a naked printer designer through a crowd of home-made workers, throwing rotten vegetables at him. Yes, yes, and someone's voice, periodically repeating "Shame!".

Yes, yes, and someone's voice, periodically repeating "Shame!".

Indeed, the first generation with a Z-axis roller guide was very prone to wobble depending on how lucky the owner was with a particular instance. For those unfamiliar with the terminology, this means that the carriage, when lifting and lowering, “walked” horizontally by several tens of microns and deviated by small fractions of a degree. “And how many are these several tens of microns, these are pennies!”. Believe me, no. On all more or less even vertical surfaces or close to them, unpleasant and easily noticeable “waves” appeared, with which nothing could be done. Yes, these carriages have an adjustable tightness, but an attempt to adjust the print quality on the first generation of the Photon did not lead to significant changes. On the other hand, wobbles really catch your eye only on flat surfaces with a large angle of inclination. Why, even without trying this second generation in print, I immediately decided for myself that this was almost the main reason for replacing it? It's very simple: even two such "imperfect" rollers on individual guides, separated by a long distance, despite the seemingly simple solution, wobble removes almost completely. This solution is in the “simple, blocky and works” category, and elementary geometry from high school guarantees “workability” here. These double guides are clearly visible here, as well as the Z-axis close to them (ideally, the location of this axis should be close to plane formed by vertical guides):

This solution is in the “simple, blocky and works” category, and elementary geometry from high school guarantees “workability” here. These double guides are clearly visible here, as well as the Z-axis close to them (ideally, the location of this axis should be close to plane formed by vertical guides):

The third difference from the first generation of Anycubic Photon S is the use of a backlight LED array. I repeat that, unlike the "bell"-diffuser and a single powerful LED of the previous generation of LCD photopolymers, this design makes the illumination of the entire screen somewhat more uniform, and also eliminates the geometry problems of the printout in the corners of the platform. As a nice bonus, this reduces the exposure time of the layer by approximately 15-20% due to the greater total backlight power. In this not very representative photo, I tried to show how such a block of individual LEDs, usually called “paraled”, shines through the matrix

Another feature that frankly surprised me, which is common to both generations of Foton, is the presence of a carbon filter with an exhaust fan (two fans and two filters in the second generation) of air from the printing chamber. As conceived by the developers, this was to remove the inevitable smell of photopolymer during printing by absorbing it with a carbon filter. Namely, the air extraction from the chamber is necessary so that through the leaks of the body, mainly the doors, the air does not leak out, bypassing the filters, taking with it the smell of the photopolymer. At this point, I want to pause, look thoughtfully at the ceiling and say “Mdaa”. On paper, it might have looked good. But in practice, in my experience, it turned out something like ... Imagine the situation: you work in an office building, and on your floor, sorry, the sewer broke through in the toilet. And so that this toilet does not smell so much, for a while, until everything is repaired, at the exit of it, the “kind” administration put a large fan to blow air from the toilet into the common corridor along which people walk. I agree, the analogy is a little "smelly" in every sense, and not too "literary" for such an article, but it describes the printer's ventilation system well.

As conceived by the developers, this was to remove the inevitable smell of photopolymer during printing by absorbing it with a carbon filter. Namely, the air extraction from the chamber is necessary so that through the leaks of the body, mainly the doors, the air does not leak out, bypassing the filters, taking with it the smell of the photopolymer. At this point, I want to pause, look thoughtfully at the ceiling and say “Mdaa”. On paper, it might have looked good. But in practice, in my experience, it turned out something like ... Imagine the situation: you work in an office building, and on your floor, sorry, the sewer broke through in the toilet. And so that this toilet does not smell so much, for a while, until everything is repaired, at the exit of it, the “kind” administration put a large fan to blow air from the toilet into the common corridor along which people walk. I agree, the analogy is a little "smelly" in every sense, and not too "literary" for such an article, but it describes the printer's ventilation system well. The fact is that the carbon filter does not retain the smell of the photopolymer, and when the fan in the structure actively blows air out of the working chamber, the effect is much more pronounced than if this fan is simply turned off. On the first version, I, hesitantly, turned it off after a while, having previously asked technical support if something would “fall off” there, on the second version, I turned off the blowing fans even before the first turn on.

The fact is that the carbon filter does not retain the smell of the photopolymer, and when the fan in the structure actively blows air out of the working chamber, the effect is much more pronounced than if this fan is simply turned off. On the first version, I, hesitantly, turned it off after a while, having previously asked technical support if something would “fall off” there, on the second version, I turned off the blowing fans even before the first turn on.

Here you can see the filter blocks located at the corners

The screen for controlling the printer itself has a small diagonal and is made a little smaller than on the first generation. It is sufficient to manage all the functions, when entering the print menu, each file carries an icon from the slicer, how the printouts will look, but the print icons are very small, smaller than on the first generation, and as a result, it is difficult to see them, what exactly will be printed there, basically you still have to focus on the file name.

As you can see, in the file selection menu, the legibility of icons leaves much to be desired. When you select the desired file, the preview will open in full screen, but believe me, it will not get much better.

The lifting mechanism is powered by a NEMA 17 stepper motor, as in a large percentage of 3D printers, on a trapezoidal screw and the two roller guides already mentioned above. Engine noise during operation is very low. In general, the printer can be described as quiet.

The printer has only one optical limit switch at the bottom, so keep this in mind when working: in the first generation there was not even a software upper limit, so it was easy to mechanically rest against the upper limit by pressing the platform lift. On the second generation, I personally did not check for this limitation. But in any case, when you turn on the printer, it may not know how high the platform is, so be careful.

3. Operation

3.1. Starting the Printer Starting up the printer is quite simple: 1. We check the tension of the fluoroplastic (hereinafter referred to as Teflon, since this is already an established term) film2. We remove dust from the screen and from the film on the back of the bath and put the bath in place, fixing it with the screws3 intended for this. We install the printing platform in the right place with a loosened screw that fixes the platform in the hinge4. We connect the printer to the network, turn it on and perform a zero and horizontal calibration of the platform, followed by fixing the hinge fixing screw - the calibration video is easy to find on YouTube5. Shake to mix and pour in the photopolymer. That's it, you can print the test "enicubic" that comes on the flash drive.

We check the tension of the fluoroplastic (hereinafter referred to as Teflon, since this is already an established term) film2. We remove dust from the screen and from the film on the back of the bath and put the bath in place, fixing it with the screws3 intended for this. We install the printing platform in the right place with a loosened screw that fixes the platform in the hinge4. We connect the printer to the network, turn it on and perform a zero and horizontal calibration of the platform, followed by fixing the hinge fixing screw - the calibration video is easy to find on YouTube5. Shake to mix and pour in the photopolymer. That's it, you can print the test "enicubic" that comes on the flash drive.

This turns on the cooling system of the LED (the LED block in the case of Photon S), the platform lowers until the optical zero limit switch is triggered, after which it drops to logical zero (when calibrating the printer, this same logical zero can easily be a millimeter below the limit switch), after which already turns on the illumination of the first layer.

The general rule for printing photopolymer printers is reduced to a long (30-120 seconds) first few layers to compensate for the unevenness of the platform and to ensure that these very first layers “hook” well on it, the subsequent layers are printed with a regular exposure time (about 3 -12 seconds on average depending on printer, resin and selected layer thickness). After the layer is illuminated, the platform is raised to a certain selected height (usually around 4 mm) to tear off the Teflon film from the illuminated layer, after which the platform is lowered back by the same value minus the layer thickness, then a pause is made in the region of one second to “calm down” the photopolymer , after which the illumination of the next layer is turned on. After printing is completed, the platform rises to a height close to the maximum, after which the printer remains in standby mode with an inscription on the screen about the end of printing, and the backlight cooling fan turns off.

3.2. Programs for slicing

“So how to slice on a computer?”. Download the branded Photon Slicer, which already generates printable files in the proprietary Enikubika format. But from my point of view, it is better to use ChiTuBox, which, in fact, Photon Slicer is based on. ChiToo is updated more often than the Enikubik branded slicer, so the possibilities in it will be higher. In general, I can universally recommend this slicer to a novice owner of any photopolymer.

This is how the ChiTuBox interface looks like

And this is a preview of the already cut model, on which it is good to monitor the adequacy of the spaced calipers

3.3. Photopolymer printing in general

1. This has been said by everyone and everywhere, but I cannot but repeat it. The most accurate description is the English word "messy", i.e. dirty and tedious. This is the transfusion of the photopolymer that easily blurs the surroundings, the washing of hands, which are almost impossible to protect even with gloves due to some work features, the transfusion of the photopolymer again, draining the bath, cleaning it, isopropyl alcohol, acetone, conservatory, court, Siberia . .. um ... sorry, carried away . But the general meaning, I think, is clear. Unfortunately, this is not FDM printing, in which everything is much simpler in terms of work.

.. um ... sorry, carried away . But the general meaning, I think, is clear. Unfortunately, this is not FDM printing, in which everything is much simpler in terms of work.

2. Low predictability of printing results, if you have everything in openwork or even not very calipers. Black box effect: you sent it to print, after which it’s hard to say what happens or not until you take the platform out of the printer and look at it point-blank. Yes, you can look into the windows, yes, you can see if nothing at all has appeared above the surface except for the platform itself, when you can unambiguously cancel printing, yes, you can pause with the simultaneous lifting of the platform, but the essence still remains: you are looking on the platform in the printer, and everything seems fine, but when you remove it and look at point-blank range, critical flaws are often visible there that could not be seen during printing.

3. In the same way, the required shamanism with the calibration of the exposure time and the thickness of supports for various cases, as well as the selection of scales, gaps and supports in FDM printing. This requires experience when you understand that here and here the calipers automatically set by the same ChiTu are superfluous, which will require subsequent excessive cleaning of the surface, but here and here they must be put, otherwise the output will be a marriage.

This requires experience when you understand that here and here the calipers automatically set by the same ChiTu are superfluous, which will require subsequent excessive cleaning of the surface, but here and here they must be put, otherwise the output will be a marriage.

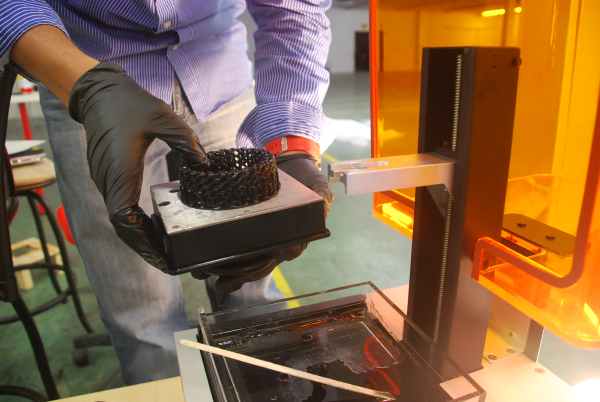

4. Corresponding to point 1. The processing cycle of the finished printout includes removal of the printout, washing in dirty isopropyl, washing in pure isopropyl, backlight-drying, preferably in an ultraviolet chamber, and washing in acetone. The latter removes that part of the photopolymer that remains even after washes with isopropyl and backlight. Some people use acetone directly instead of isopropyl, but personally I look at this approach with doubt: acetone destroys underexposed fragments more, which can lead to cracks in the model. But this is a debatable issue. In other words, post-processing of the model after printing is a separate procedure that requires time and effort.

5. Cheap photopolymers often smell. .. to be honest, especially during operation, when heating occurs as a result of the exothermic reaction during polymerization. For example, some Chinese, though not all. Our manufacturers (such as HarzLabs, but not only) initially tried to make the photopolymer not have a pronounced unpleasant odor, but now the Chinese have begun to pay attention to this, so it’s already possible to buy a photopolymer that will not carry some mixture of chemistry and fish, even Ali.

.. to be honest, especially during operation, when heating occurs as a result of the exothermic reaction during polymerization. For example, some Chinese, though not all. Our manufacturers (such as HarzLabs, but not only) initially tried to make the photopolymer not have a pronounced unpleasant odor, but now the Chinese have begun to pay attention to this, so it’s already possible to buy a photopolymer that will not carry some mixture of chemistry and fish, even Ali.

6. Most photopolymers are brittle. There are those that have some elasticity and do not prick when trying, for example, drilling, but they usually cost significantly more, at least at the moment. That is, despite the fact that these are essentially cast parts, they can often be inferior in strength to printed parts made using FDM technology.

7. Most prints require rubbing alcohol except for water washable photopolymers. Isopropyl alcohol is usually used because it evaporates faster. First, washing is done with already dirty isopropyl, after which a second washing is done in pure alcohol. Further, the printouts should be illuminated, for this you can use a special illumination camera, the sun, or even the printer's camera itself in the case of printers that have this function. After that, I would recommend doing another wash in acetone to remove the remnants of the photopolymer left after backlighting. Acetone is more aggressive to the photopolymer, but it is not dangerous for an already fully polymerized printout.

Further, the printouts should be illuminated, for this you can use a special illumination camera, the sun, or even the printer's camera itself in the case of printers that have this function. After that, I would recommend doing another wash in acetone to remove the remnants of the photopolymer left after backlighting. Acetone is more aggressive to the photopolymer, but it is not dangerous for an already fully polymerized printout.

8. Can photopolymer printing already provide unconditional quality when the printout is almost indistinguishable from the cast part? Unfortunately, not always. Just like with FDM printing, there are problems with the bottom surface of the printouts, the photopolymer has the same problems. Yes, it allows you to print with large overhang angles, does not create frank porridge in the area of \u200b\u200bcalipers, but still, the printout needs to be finalized in these areas. And even after that, it is not always possible to get a level surface “like a real one”. Also, photopolymers, like ABS plastic, have shrinkage, which must be taken into account both during printing and during subsequent exposure - in the absence of calipers, a thin part can simply be bent. But if there are no extreme angles and a large number of calipers, then it is realistic to achieve the quality “almost like casting”.

Also, photopolymers, like ABS plastic, have shrinkage, which must be taken into account both during printing and during subsequent exposure - in the absence of calipers, a thin part can simply be bent. But if there are no extreme angles and a large number of calipers, then it is realistic to achieve the quality “almost like casting”.

3.4. Features of operation of photopolymer printer

Here I will give the features of operation of photopolymer printers themselves, i. what applies to printers in general and which are relevant not only for Photon C, but also for any photopolymer built on a similar technology:

without additional manipulations. The duration of problem-free storage of the photopolymer without refilling depends on the specific brand of photopolymer.

2. Once every 10-30 hours of printing, although it is difficult to give an exact figure here, this is individual, and it also depends on the photopolymer used, it must be drained through the filter back into its original storage container. This is not related to the photopolymer itself, but is required to clean the Teflon film, which is the bottom of the bath. It could be said that during operation the Teflon film becomes contaminated, etc., but what exactly happens there, whether the film is contaminated, the photopolymer residue, or some other factors are to blame, but, simply put, the printer stops printing. Yes, something that a couple of seals ago was perfectly printed with this photopolymer and this very file is already coming out with a marriage. And yes, you just need to wipe the bottom of the bath with isopropyl alcohol, pour the photopolymer back in, and everything works fine further. I will illustrate this phenomenon with a specific example, where on the left (on the left photo), the first printout, one or two calipers were missing, as a result which part of the frame came off during printing, and on the second one there was enough of everything, but the tray that was not cleaned in time ruined the print in the bud, when not only the frame, but even the radiator was not printed.

This is not related to the photopolymer itself, but is required to clean the Teflon film, which is the bottom of the bath. It could be said that during operation the Teflon film becomes contaminated, etc., but what exactly happens there, whether the film is contaminated, the photopolymer residue, or some other factors are to blame, but, simply put, the printer stops printing. Yes, something that a couple of seals ago was perfectly printed with this photopolymer and this very file is already coming out with a marriage. And yes, you just need to wipe the bottom of the bath with isopropyl alcohol, pour the photopolymer back in, and everything works fine further. I will illustrate this phenomenon with a specific example, where on the left (on the left photo), the first printout, one or two calipers were missing, as a result which part of the frame came off during printing, and on the second one there was enough of everything, but the tray that was not cleaned in time ruined the print in the bud, when not only the frame, but even the radiator was not printed. At the same time, after cleaning the bath, the printing was already without problems.

At the same time, after cleaning the bath, the printing was already without problems.

3. If it is suspected that part of the light remains at the bottom of the bath, during a failed print, it is also necessary to drain the photopolymer and clean the bottom. Best of all, the “blots” of the polymer smeared along the bottom are removed by simply pressing a finger on the film from the back. This "blot" is easily peeled off from the film, and the film itself is not damaged. It is necessary to do this cleaning so that when you start the next print you do not damage the film, or even the printer screen by pressing this “jellyfish” with the platform from above, especially since most likely printing in the presence of such an illuminated piece of photopolymer on the film you most likely still won't work.

4. Film needs to be changed periodically. This procedure is simple, but rather painstaking, plus you must have a supply of film. The film does not have a direct "timer" of life, its wear depends on the duration of exposure of the layers, the shape of the printouts and mechanical damage during cleaning. It can work for a very long time, and require replacement if mishandled and after 2-3 prints.

It can work for a very long time, and require replacement if mishandled and after 2-3 prints.

This is the process of replacing the film, shown by the manufacturer himself - an excellent and understandable video, in which, in particular, you can appreciate the genius of the bath design. Yes, it is difficult to establish who invented it first, but the fact itself does not negate it

5. Teflon film is strong, but even a careless swipe of an angle with a plastic spatula during cleaning can easily leave an indelible mark on it in every sense. Moral: clean the film carefully, it is better to let the photopolymer drain from it without external influences and then clean it with isopropyl alcohol in the bath already put in place.

6. The film on the side of the screen and the screen itself must be clean. Free of dust and grease. You can clean it with the same isopropyl and blow it with a "pear". Do not allow photopolymer to get on the screen. And, moreover, do not turn on the backlight if there are at least small traces of photopolymer on the screen, otherwise you will change the screen.

Do not allow photopolymer to get on the screen. And, moreover, do not turn on the backlight if there are at least small traces of photopolymer on the screen, otherwise you will change the screen.

7. Do not print hard and thick parts directly on the platform itself without supports. Then you will remove such a "bar" from the platform with a hammer and a chisel, and not with a metal blade.

8. My experience is that it is easier to remove parts from the platform, for example with a knife, rather than a plastic spatula - the latter is more likely to break itself than to actually remove any part.

9. An important question that a person who has had a glimpse of photopolymer printing might ask is: "Is it possible to get a print that feels tactile like a molded part, without any signs of stickiness, slipperiness and other residual effects" I once was goo"? Yes, you can: obligatory illumination and washing in acetone after. There are still a couple of minor reservations here, but in general the answer is positive.

this greatly increases the wear of the Teflon film. The rate of its wear can be indirectly heard by the sound of a layer tearing away from it when the platform is raised. Ideally, this should be almost inaudible.

11. To select the exposure time specifically on Photon C, it is possible to use the r_e_r_f.pws file located on the flash drive, in which the printed surface is divided into fragments horizontally, each fragment is illuminated for one second more than the previous one. Thus, a sufficient exposure time can be selected. Also, on the sites of photopolymer manufacturers often publish tables of exposure time settings for different layer thicknesses, as well as rise speeds and delay times before printing.

This is how the standard Enikubik calibration model looks like. There are four elements printed at the same time with different exposure times.

3.5. Features of operation of Photon S

The main feature and, frankly, the disadvantage is the use of a one-piece body with a door, in contrast to the use of a "hood" in most printers (also in newer Enikubik printers). Thus, you do not have an insulated sealed hood with work area seals. Those. your printable area is leaking. And this means that all the same, when printing, you will get the smell of photopolymer around. Not too strong, but anyone will notice it. The fact is that the design of the door is made unsuccessfully and does not provide for seals that would hold back the evaporation of the photopolymer through leaks. Structurally, this seems to me the biggest miscalculation of the Foton developers. The lack of a normal handle is added to the disadvantages of the door already described, as a result of which the door sometimes becomes difficult to open without fear of simply breaking it. In addition, the entire top of the printer would benefit from a resin-resistant material. In this regard, even the same unsuccessful design of the upper part of the first-generation Photon printer was better, because. there was steel, plus a handle to open the door.

Thus, you do not have an insulated sealed hood with work area seals. Those. your printable area is leaking. And this means that all the same, when printing, you will get the smell of photopolymer around. Not too strong, but anyone will notice it. The fact is that the design of the door is made unsuccessfully and does not provide for seals that would hold back the evaporation of the photopolymer through leaks. Structurally, this seems to me the biggest miscalculation of the Foton developers. The lack of a normal handle is added to the disadvantages of the door already described, as a result of which the door sometimes becomes difficult to open without fear of simply breaking it. In addition, the entire top of the printer would benefit from a resin-resistant material. In this regard, even the same unsuccessful design of the upper part of the first-generation Photon printer was better, because. there was steel, plus a handle to open the door.

When printing, a small amount of photopolymer drops falls on the bottom of the door, so I would recommend immediately tape it with black tape from the inside - the standard width of the tape just fits the width of the grooves needed for pasting - if you look at the door from the inside, you will immediately understand , "about where" I'm talking about. This will reduce the chance that your door will just start to stick when you miss the photopolymer drops on it.

This will reduce the chance that your door will just start to stick when you miss the photopolymer drops on it.

In addition, I did not notice any other noticeable flaws that would complicate the operation of the printer. Oddly enough, it is difficult for me to describe any specific shortcomings of this printer that affect its operation, which would not be on others. Aside from the questionable case design and the rather odd chamber purge solution, this printer is a perfectly normal workhorse, printing fairly consistently within the limitations of technology and design. Such limitations, for example, include the missing easy layer separation mechanism that FormLabs Form 3 has, but such technologies rarely wander into budget and extra-budget solutions, to which Photon S belongs.

Double roller guide mechanism avoids wobble - please note that wobble is a very likely evil for all printers with a single guide, which is often found in budget solutions.

RGB screen, unlike monochrome ones specially released for photopolymer printers, has slightly less detail for equal screen resolution and longer exposure time of the layer, but do not forget that the total time per layer is the sum of the exposure time, rise time, fall and pause before turning on the illumination of the next, i. e. even a 100x increase in flash speed will not give you even a 10x increase in print time.

e. even a 100x increase in flash speed will not give you even a 10x increase in print time.

The LED matrix cooling fan is quite quiet, it is noticeably quieter than on the first version, it will not even interfere with sleep if it turns out that the printer is in your room, because the sound of the lifting and lowering of the platform is even a little louder than the cooling system. The only caveat: because. I immediately turned off the chamber purge fans, I can’t say about the noise of their work. But, remembering the design of the case, I would not recommend sleeping in a room with a working photopolymer without good ventilation.

i.e. the only limitation, but quite important for a certain number of potential buyers of the printer, is the leakage of the case during operation. So, to reiterate, when working, you cannot completely avoid the smell of photopolymer in a room, unless the room is large enough and well ventilated.

4. Conclusion and printing examples

Can you recommend buying Anycubic Photon S as a budget solution? Yes. It gives quite good print quality, and at the same time it is very inexpensive by today's standards. When choosing, you should pay attention to how critical the absence of a conditionally sealed print chamber will be for you, which other printers can boast of, in particular in the budget segment, but which the Photon lacks. On the other hand, I recommend paying attention to the double roller guide and the close-mounted lifting axle, which eliminates wobble, which is often not found in many other budget photopolymers. Also, the use of a matrix of LEDs can be attributed to the pluses, which is also not available for all budget solutions. This makes, with the reservations already indicated, this printer quite successful, and I can recommend it for purchase and operation.

It gives quite good print quality, and at the same time it is very inexpensive by today's standards. When choosing, you should pay attention to how critical the absence of a conditionally sealed print chamber will be for you, which other printers can boast of, in particular in the budget segment, but which the Photon lacks. On the other hand, I recommend paying attention to the double roller guide and the close-mounted lifting axle, which eliminates wobble, which is often not found in many other budget photopolymers. Also, the use of a matrix of LEDs can be attributed to the pluses, which is also not available for all budget solutions. This makes, with the reservations already indicated, this printer quite successful, and I can recommend it for purchase and operation.

And as for the question posed at the beginning of the article, was the game worth the candle, was it worth changing one printer for another that is so different from it? Yes ... The fact is that the quality of printing on the first Photon, unfortunately, did not suit me. Yes, it was possible to replace the standard Z-axis with a double rail guide, but the replacement kit at that time cost the same as the cost of an “upgrade” by replacing the entire printer with a second generation, taking into account the sale of the old one. Therefore, for me personally, the choice was obvious.

Yes, it was possible to replace the standard Z-axis with a double rail guide, but the replacement kit at that time cost the same as the cost of an “upgrade” by replacing the entire printer with a second generation, taking into account the sale of the old one. Therefore, for me personally, the choice was obvious.

At the end of the article, I will give examples of what can be obtained on this printer, so to speak, from personal stocks.

Feed augers made for testing in slightly different configurations

Models of pumps made from a photograph

Made for a co-worker a plinth for the head of a character from Warhammer.

Pay attention to the print direction. Printing on calipers allows you to easily separate the printouts from the platform later, and the slope of the surface reduces the wear of the bath film by changing the position of the boundary in layers. You can see that the calipers on the first layers still moved away, this required subsequent grinding of the base.

Cartridge cover and platform. The second one was also made for the already mentioned comrade.

One of the teeth had to be removed and placed separately for subsequent gluing, because. it just didn't fit in the printable area.

A gift for the 8th of March - a simple but quite nice one

A couple of playful medals

And finally, a couple of frames from one rather long project to create a truck model.

Thank you for reading

What is a resin 3D printer and should I buy one?

Home 3D printers have been on the market for many years and are available to anyone who wants them. They have evolved from hobbyist curiosity to useful tools that can help you solve small problems in your home, create works of art, or help you prototype parts for projects. The use of a 3D printer is only limited by your imagination!

However, a completely different type of 3D printer is now entering the domestic market. These "resin" 3D printers use completely different principles to create 3D objects compared to what you may have seen so far. What is a resin 3D printer and is it worth buying one instead of the traditional models that already exist?

These "resin" 3D printers use completely different principles to create 3D objects compared to what you may have seen so far. What is a resin 3D printer and is it worth buying one instead of the traditional models that already exist?

General 3D Printer Review

If you want a detailed explanation of how 3D printers work, check out HDG Explains: How Does 3D Printing Work? If you don't have time for that, here's the short version.

Windows programs, mobile applications, games - EVERYTHING is FREE, in our closed telegram channel - Subscribe :)

What most people call a "3D printer" is actually called an FDM printer (fusible deposition modeling). It passes a filament of material (usually plastic) through a hot extruder die and then applies precise layers of material to slowly build a model.

The most common FDM machine is the Cartesian type 3D printer. It has a print head mounted on movable rails that can position the tip of the head exactly at any XYZ coordinate within the printer's print volume.

Whichever type of FDM printer you choose, this is a multi-layer filament material extrusion that is common to all. In this regard, resin printers are fundamentally different.

Polymer 3D printers explained

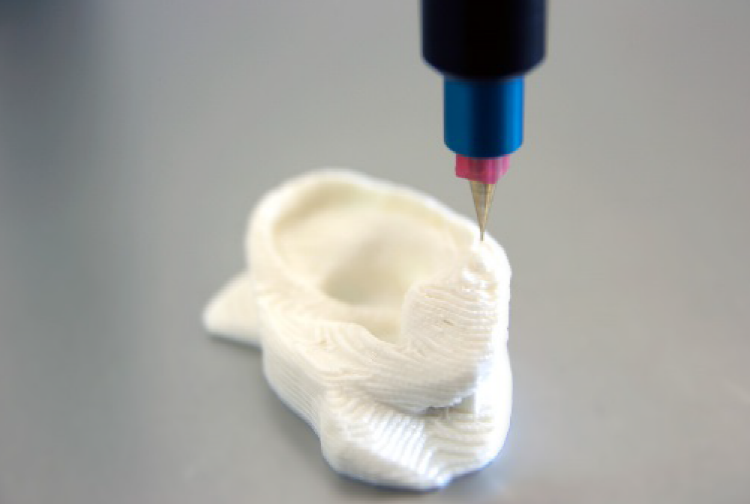

Resin 3D printers are somewhat fundamentally different from FDM printers. First, the material is liquid resin, not a spool of filament. This fluid is stored in a tank.

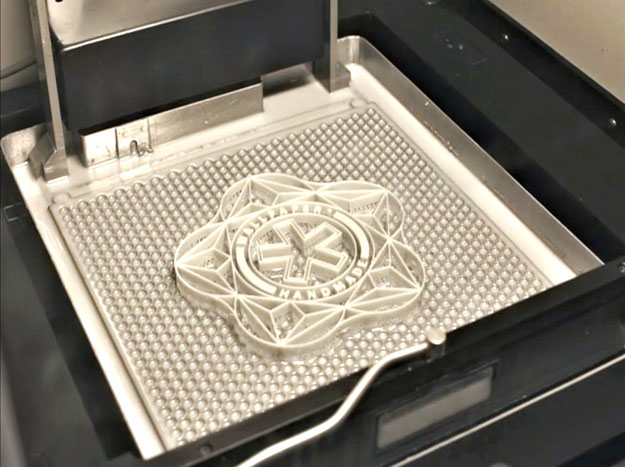

The resin printer still uses the build platform for the model being printed, but it is usually upside down. The platform rises from the resin tank as each layer is formed. The resin itself is photosensitive and hardens when exposed to the right type of light.

A precision light source is used to form each layer on top of the previous one until the entire finished model has been removed from the vat. It definitely looks much more futuristic than FDM printing!

Resin printer types: SLA, DLP and LCD technologies

Although all resin printers use the basic principle of curing photosensitive resin with a light source, not all of them do it in the same way. There are actually three main sub-types of resin 3D printers.

There are actually three main sub-types of resin 3D printers.

SLA: Stereolithography

Solidmaker

Laser 3D PrinterSLA is actually the original 3D printing technology and has a long history of development, especially in the aerospace industry.

This type of printer uses a laser and moving mirrors to direct a small point of light. Wherever the UV laser is focused, the resin will harden so each layer can be painted quickly.

SLA printers can be of upside-down design, where the model looks like it has been pulled out of the tank, but they can also be of vertical design, where the platform is lowered into the resin tank as each layer is completed.

SLA printers typically produce very smooth surfaces and produce highly accurate, detailed prints.

DLP: Digital Light Processing

Spintray Moonray DLP Printer

You may have heard the term "DLP" in relation to projector technology before, and there really is a connection. DLP printers use the same digital micromirror technology as DLP projectors to project images.

DLP printers use the same digital micromirror technology as DLP projectors to project images.

In this case, DLP projection is used to cure the entire resin layer at a time, making DLP printers slightly faster than SLA models that only cure one dot at a time.

DLP resin printers are also known for their beautifully smooth surfaces, but large print areas may not display the same crisp and precise detail as SLA laser machines.

LCD: Resin Liquid Crystal Printers

PHROZEN Sonic Mini UV Photocuring LCD Resin 3D Printer

These printers use a monochrome LCD panel with UV illumination to cure each layer. The LCD panel essentially acts like a mask, selectively blocking light or letting it through. It's a smart use of mature and well-researched LCD technology that has dramatically reduced the cost of resin printers. Most of the affordable resin printers you can buy today use LCD technology.

Resin LCD printers are faster than SLA machines and more accurate than DLP printers, which can exhibit distortion. The downside of LCD printers is that they have a shorter lifespan than the aforementioned technologies and require more maintenance.

The downside of LCD printers is that they have a shorter lifespan than the aforementioned technologies and require more maintenance.

Pros and Cons of Resin Printers

So why should (or shouldn't you) buy a resin printer over more conventional FDM machines?

On the positive side of the equation:

- Resin printers offer much more detailed and smooth models.

- Resin prints do not require extensive post-printing to look good.

- They are faster than FDM machines.

- Resin models tend to be stronger and more flexible.

On the negative side of the equation:

- Resin printing is generally more expensive.

- This is dirtier and needs more maintenance.

- You need to prepare a safe environment for printing and storing resin.

- Resin printers have lower print volumes on average.

- Uncured resin is toxic and should be handled with care.

It is important that any potential resin printer owner be fully prepared for the reality of resin printing, the hazards, environmental issues, and maintenance burdens. Take the time to watch some YouTube videos to see the printing process from start to finish.

Take the time to watch some YouTube videos to see the printing process from start to finish.

Who should buy a resin printer?

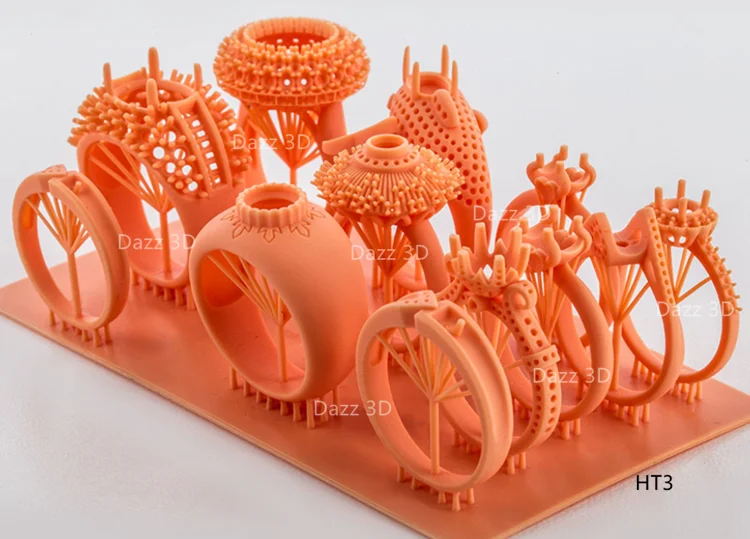

The main market for resin-based desktop printers is people who need to make small models with fine details. For example, if you want to create detailed board game items or intricate 3D decorations, a resin printer might be a good option. If you're a 3D sculptor using software like Zbrush, only a resin printer can do justice to your detailed models.

It is quite possible to paint resin models, although you will need a long process of preparing the resin surface to hold the paint. If you don't care about the detail and quality of resin prints, then you are much better off choosing an FDM 3D printer. You can also improve the quality of an FDM print using techniques such as sanding to achieve a smoother surface on the model.

Resin 3D Printer Recommendations

As time goes on, more and more resin printer options appear on the market, but one or two stand out.