3D printer business ideas in india

The Different 3D Printing Business Opportunities In India

The burgeoning 3D printing industry of India offers multiple business opportunities. Because of the tremendous growth, India’s young entrepreneurs are being attracted towards setting up a 3D printing business in the country. It is also mainly because of these reasons that the Indian 3D printing industry is largely dominated by startups. On 24th February, 2022, India launched its 3D Printing Policy and one of its focus on developing 100 new Startups. This in itself indicates that the time is ripe for you to start a 3D printing business.

However, to establish a profitable business, it is first important to know the different 3D printing business opportunities in India and how you can leverage your skills to succeed. Let us look at some of the 3D printing business opportunities in India.

Contents

- 1 3D Printing Business Opportunities in India

- 1.1 3D Printer Manufacturer

- 1.

2 3D Printing Material Manufacturer

- 1.3 3D Printing Service Provider

- 1.4 3D Printer & Material Reseller/Distributor

- 1.5 3D Printing Accessories & Supplies

- 1.6 3D Printing Courses

- 1.7 Niche Product Manufacturing (Dentistry, Jewellery, etc.)

- 1.8 3D Selfie

- 1.9 3D Printer Add-Ons

- 1.10 3D Modelling & Designing Services

- 1.11 Start a Makerspace

- 2 Make Money with 3D Printing

- 3 Conclusion

3D Printing Business Opportunities in India

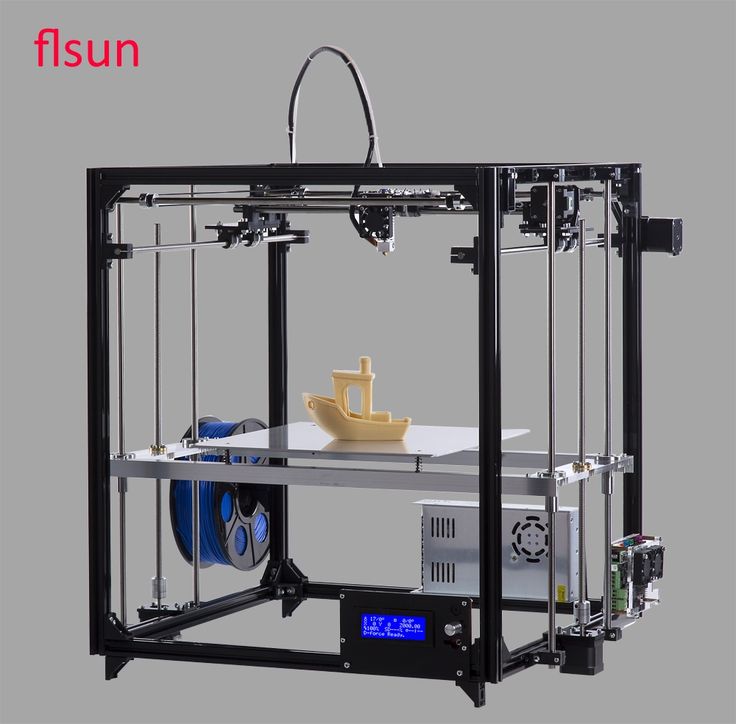

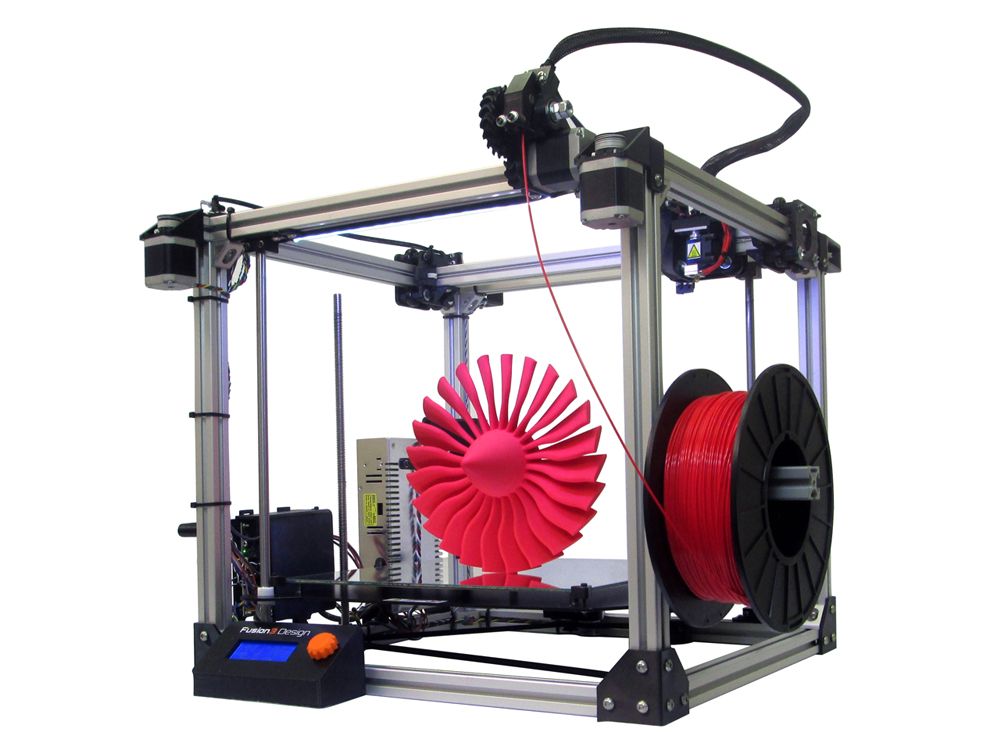

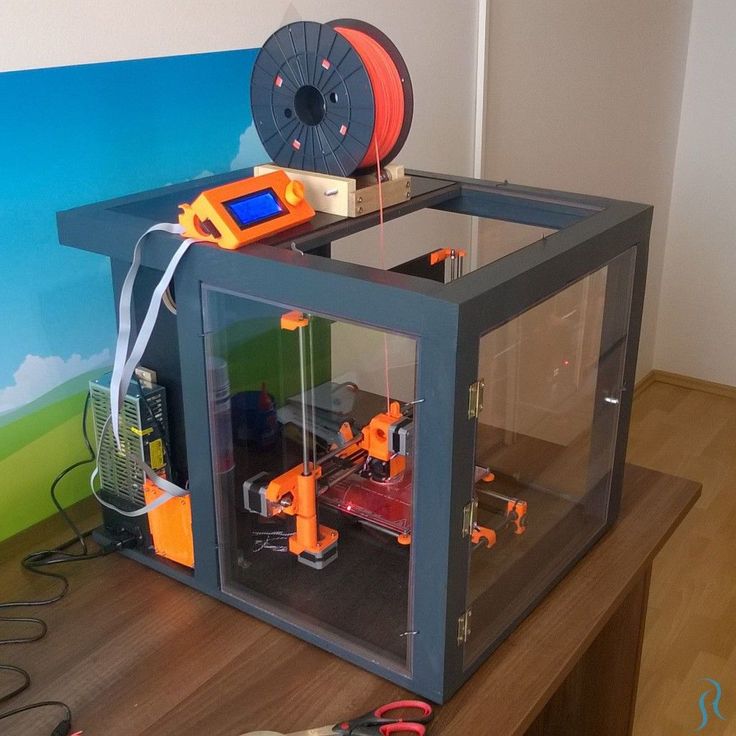

3D Printer Manufacturer

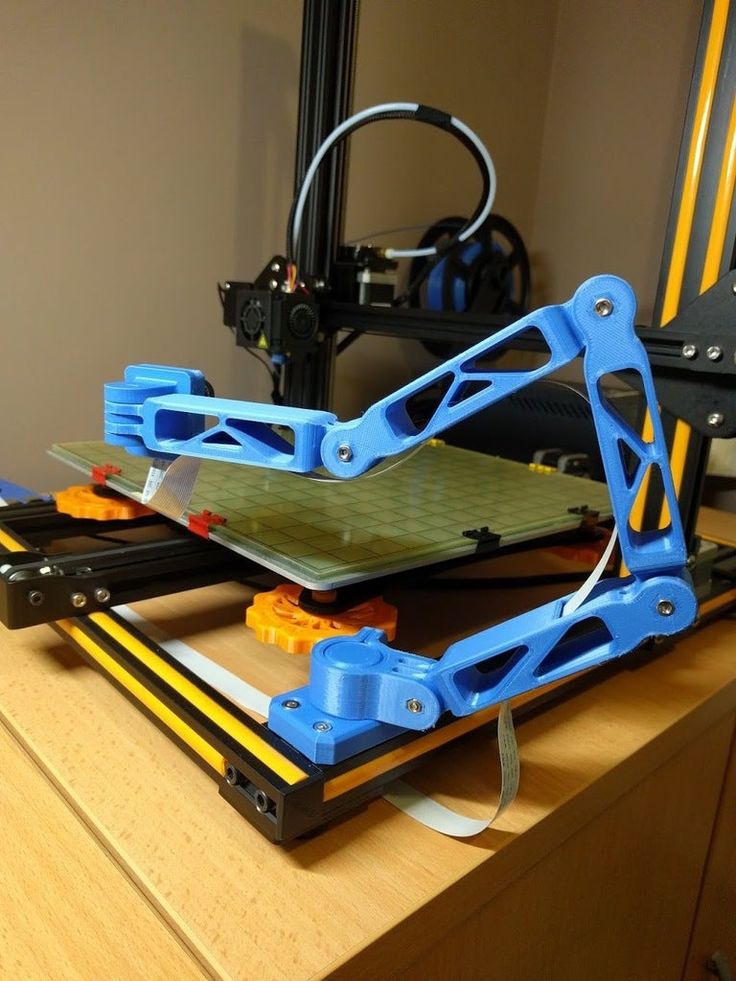

Above: Building a 3D Printer / Image Source: YouTube Popular MechanicsThis is one of the top 3D printing business opportunities in India at the moment. Manufacturing a 3D printer requires technical know-how, an experience in building machines or at least the passion to build one and a sound understanding of electronics and coding. Global manufacturers have survived long years of competition due to the stability and reliability their printers provide and with constant innovation. The industry and technology is still developing and without constantly adding new features and enhancing the printing experience, the business may not earn customers.

The industry and technology is still developing and without constantly adding new features and enhancing the printing experience, the business may not earn customers.

The current market is small for a 3D printing business in India but this also means that the opportunity to grow is huge. Now that India has its own 3D printing policy, the market is expected to grow exponentially. it is growing rapidly year on year. Now that the Government of India has launched its 3D printing policy, the scope and awareness of the technology will grow and we will see exponential growth in the coming decade.

- Initial Investment: Medium to High (Depending on which technology you want to build)

- Investment Considerations: Investment in raw materials to build multiple products, R&D costs

3D Printing Material Manufacturer

Above: Formlabs Resins/Image Source: FormlabsThis business too, like 3D printer manufacturing business, is highly technical and even more capital intensive than 3D printer manufacturing. Manufacturing of FDM filaments or SLA/DLP resins will require a considerable amount of research if you are starting from scratch. Concocting unique or new resins increase the difficulty level.

Manufacturing of FDM filaments or SLA/DLP resins will require a considerable amount of research if you are starting from scratch. Concocting unique or new resins increase the difficulty level.

Even for manufacturing filaments, you will need to invest in extruding machine/s, equipment, spend time in research and development of materials, testing and validating the products, and producing in bulk quantities. The setup will need a lot of monetary resources as well considering the fact that the returns on investment will take time to realise.

The success of the business will depend on the growth of the 3D printing industry regionally, nationally or internationally, but the main advantage here is that materials are consumables and thus have a quick turnaround time.

These are still early days for the technology and though the 3D printing materials market has a lot of competition, it is still quite easy to make a mark in the industry with a high-quality product.

- Initial Investment: High

- Investment Considerations: Upfront investment in extrusion machines to manufacture filaments and raw materials for both filament and resins

3D Printing Service Provider

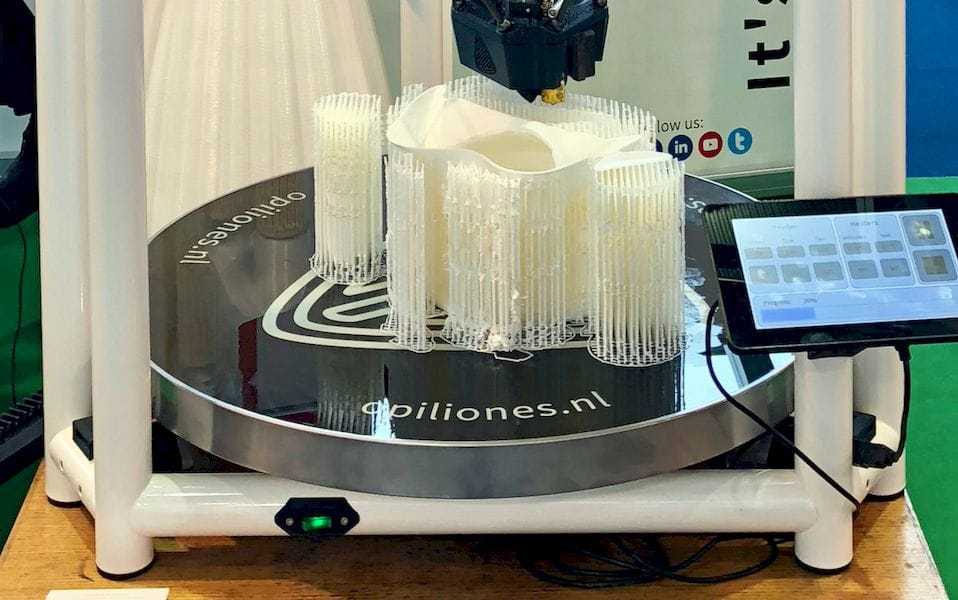

One of the most common 3D printing business opportunities in India is through providing 3D printing services to those in need. The obvious step is to buy a good reliable 3D printer and offer 3D printing services. A lot of business around the world have started in this same fashion. Once the service starts to pick up and revenue starts to flow, new printers and materials can be incorporated in the business.

The obvious step is to buy a good reliable 3D printer and offer 3D printing services. A lot of business around the world have started in this same fashion. Once the service starts to pick up and revenue starts to flow, new printers and materials can be incorporated in the business.

- Initial Investment: Low to Medium

- Investment Considerations: Upfront capital investment in buying 3D printers and materials, marketing your business as there is high competition

3D Printer & Material Reseller/Distributor

This can be called as one of the popular as global companies are looking for partners in India who can sell their products. Established brands across the world want to enter the Indian market and the simplest way is to appoint distributors and spread the brand in India. Indian buyers want easy access to the 3D printers, after-sales support and on-demand availability of the feed materials.

An easy way for young entrepreneurs to start a business but the market is competitive. It can be said that starting a distributorship or reselling the printers and materials is a great way to start a 3D printing business in India due to the huge untapped Indian market. This business will need medium to high initial investment.

It can be said that starting a distributorship or reselling the printers and materials is a great way to start a 3D printing business in India due to the huge untapped Indian market. This business will need medium to high initial investment.

- Initial Investment: Medium to High

- Investment Considerations: Upfront investment in stocking the 3D printers and materials

3D Printing Accessories & Supplies

Above: E3D v6 Metal Hot End/Image Source: E3D Online3D printing in India is fairly new and the market is still developing. Local manufacturers are still learning and trying to build a competitive product. They are constantly in need of 3D printing accessories and supplies like hot-ends, nozzles, lead screws, motors, lasers, projectors, end-stoppers, electronics, hat beds, silicone mats, etc.

Most of these items are imported from UK, US, China as they provide the best quality and many of the times low cost. The importing takes time and a small number of items end up being costly. It is better to buy from a local supplier instead of importing it individually. So, supplying 3D printing accessories is also a good business opportunity.

It is better to buy from a local supplier instead of importing it individually. So, supplying 3D printing accessories is also a good business opportunity.

This 3D printing business in India will certainly help a lot of manufacturers by reducing the delays & saving costs. This business will require a fair bit of contacts and knowledge of importing goods along with medium investment for the first shipment of goods.

- Initial Investment: Medium to High (It will also require you to on-board partners on your platform)

- Investment Considerations: Initial investment in stocking the supplies

3D Printing Courses

The world is gripped by 3D printing and India is catching up. One of the main reasons is the absence of knowledge about 3D printing business in India. Even Indian companies are facing this problem when they approach a potential client and educating them becomes a big task. The simple solution is to teach 3D printing to a wide class of people. This basically includes students and SME’s who are most likely use and make a career in 3D printing.

This basically includes students and SME’s who are most likely use and make a career in 3D printing.

Currently, very few courses are available for learning this technology. Skilled teachers with of knowledge in 3D printing can look to start a 3D printing teaching business in India. It is one of the much-needed skills for Indian students and can prove to be highly rewarding. This 3D printing business in India will require small to medium investment, mainly for the infrastructure.

- Initial Investment: Low to Medium

- Investment Considerations: Mostly on infrastructure and marketing

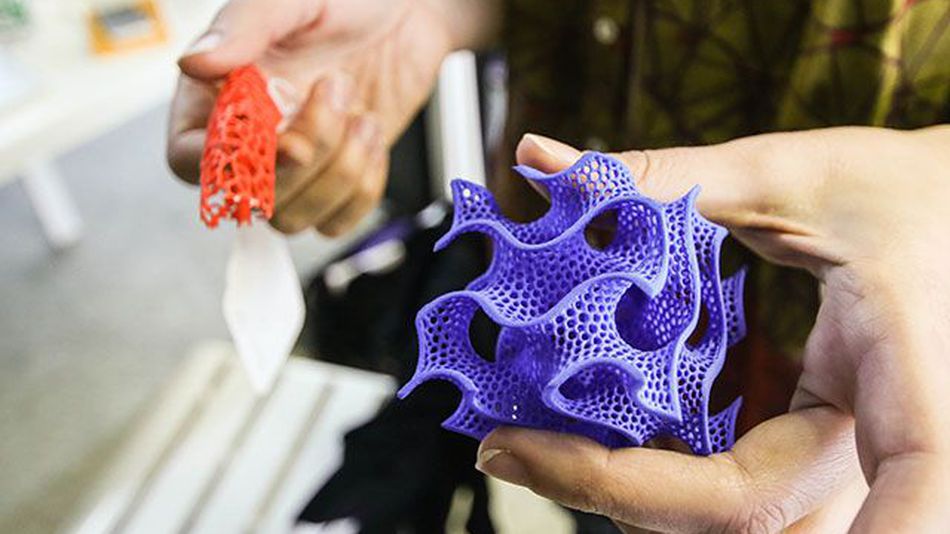

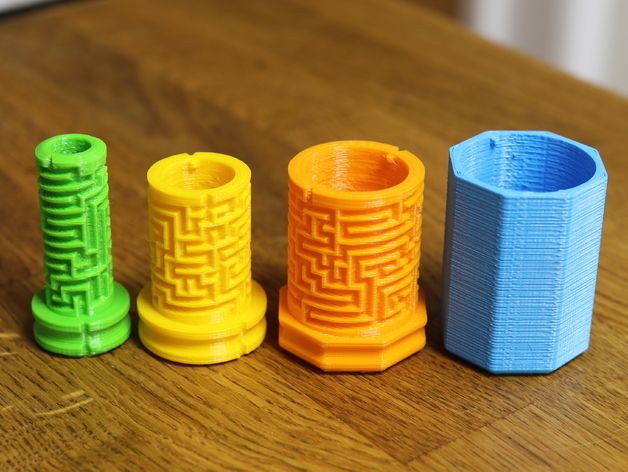

Niche Product Manufacturing (Dentistry, Jewellery, etc.)

3D printing has the potential to impact almost all business sectors but instead of catering to the complete audience, focussing on a niche can be a great start for the business. Attain expertise in your specific niche and build other products around your niche.

For example, there is a great opportunity for 3D printing in dentistry or in the jewellery industry. This will help in gaining expertise and technical problems and their subsequent solutions.

This will help in gaining expertise and technical problems and their subsequent solutions.

This idea will require focused approach and will need a medium to high investment for buying the relevant 3D printers and materials.

- Initial Investment: Medium to High

- Investment Considerations: Upfront capital investment in machines and materials

3D Selfie

Above: Charles Hull, also known as a the father of 3D printing with a 3D selfie/Image Source: 3D SystemsSelfies are a craze but they have an inherent limitation. There’s no physical form to it. A 3D Selfie is also gaining popularity around the world and kiosks are set up at malls to print 3D selfies and enabling people to take home their physical model. That is why, this is one of the most sought-after 3D printing business opportunities in India at the moment. This may be a passing trend and may not be a long-term business but cashing on this trend can prove to be highly beneficial.

A considerable amount of risk is involved and it will require high investment in the kiosk, designing artists for cleaning the 3D CAD file and then printing out the model (it can be a personal printer or getting it done through a service).

- Initial Investment: Medium to High

- Investment Considerations: You will require software solutions, 3D printers, Materials and Post-Processing equipment to offer these services which will increase costs. Also high marketing costs are involved.

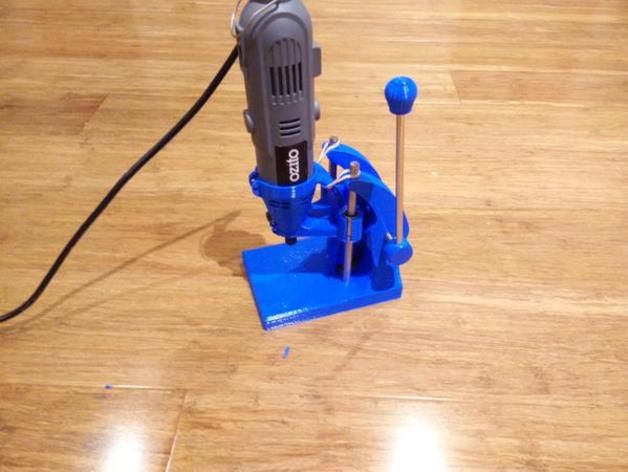

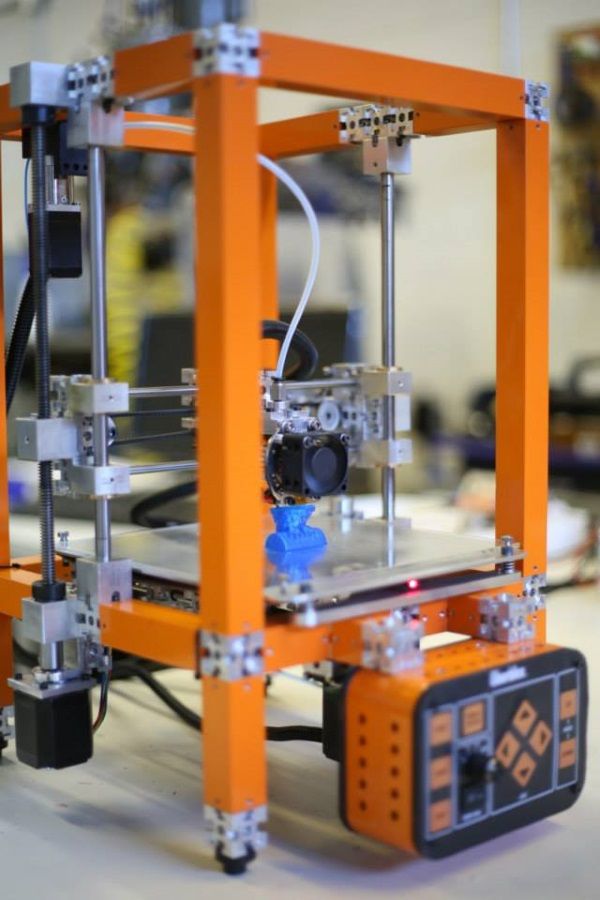

3D Printer Add-Ons

Raspberry Pi and Arduino devices have revolutionised the complete DIY industry. People are using these mini processors to build cool projects and products which are capable of winning hackathon prizes. Some such projects have even attracted established companies. 3D printing has also benefitted a lot with such devices. You can create new & intelligent solutions for a 3D printer using these devices and sell those Add-Ons to manufacturers or directly to consumers. You can check for numerous such Raspberry Pi projects online.

You can check for numerous such Raspberry Pi projects online.

Raspberry Pi modules are also useful for running OctoPrint which can be perfect if you wish to monitor and control your 3D printer from anywhere. Know more about OctoPrint and the best OctoPrint plugins to get the most out of your 3D printer.

This 3D printing business in India is completely new and people have not concentrated on building this idea into a business but it has the potential. This business will require minimal investment at the initial stage with possibly high returns. Even students can start such a business.

- Initial Investment: Medium

- Investment Considerations: Mostly marketing and initial investment in stocking the add-ons like Raspberry Pi

3D Modelling & Designing Services

3D modelling and designing services is not an actual business as such but it can be used to generate revenue. You can model and design innovative products and sell those designs online on sites 3D printing community sites like GamBody, Pinshape, etc. You can also participate in their regular competitions and possibly win prizes like an actual 3D printer.

You can also participate in their regular competitions and possibly win prizes like an actual 3D printer.

The business can be started with zero investment as it only requires a modelling software. Modelling software is freely available for students. You can know more about them in a separate article on the Best Free CAD software.

- Initial Investment: High

- Investment Considerations: Designing software license fees and designer salaries

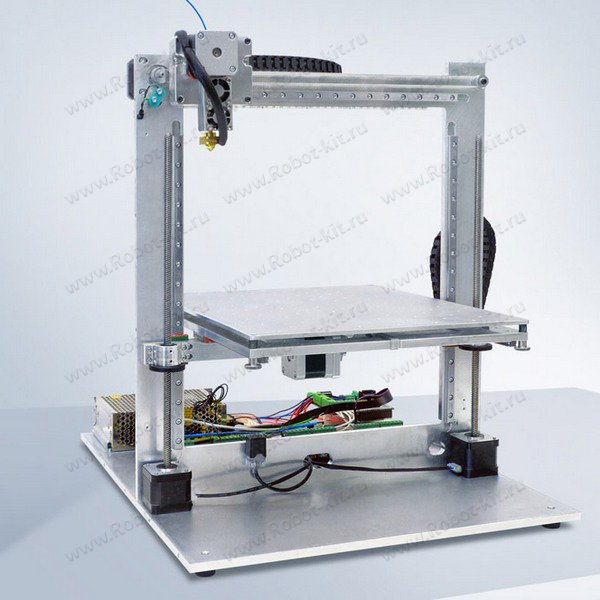

Start a Makerspace

Above: Fablab and 3D Printing/Source: Manufactur3DA makerspace is a collaborative work space that can be located inside a school, a workshop, or any public/private location where people of all ages can come to make, learn, share, and explore the joy of making things. CNC machines, laser cutters/engravers, woodworking equipment, simpler drill machines, and a variety of other tools, including 3D printers, are some of the common machines you’ll find at a makerspace. All of these tools are made available to the public for a fee in order for them to build the products they desire.

All of these tools are made available to the public for a fee in order for them to build the products they desire.

A makerspace does not need all machines and can begin with a few tools. If necessary, the founders of these makerspaces can crowdsource some tools. Makerspaces around the world also receive a lot of funding or donations from local schools and institutes where their students can go on a regular basis to gain practical experience in making things. 3D printing companies can also donate a 3D printer.

As a makerspace owner, you can charge people by the hour or by the number of machines they have access to.

Initial Investment: Medium to High

Investment Considerations: Finding a place with reasonable rent, marketing of the makerspace and buying a few machines and tools.

Make Money with 3D Printing

You will undoubtedly make money with these various business ideas; however, if you are only looking at 3D printing as a side hustle and still want to make money with 3D printing, then please see our dedicated article on How to Make Money with 3D Printing in 2022.

Conclusion

You read about some of the popular 3D printing business opportunities in India. Some of these can be started from lowest possible investment to substantially high amount of initial investment. A large number of entrepreneurs are attracted to this emerging technology and the best part is that this technology is still evolving. This is the right time to set up a 3D printing business in India considering its huge manufacturing industry. According to the recently launched 3D printing policy, India aspires to achieve goals such as contributing 5% to the global AM market with a target to add nearly US$1 Bn to the national GDP by 2025.

About Manufactur3D Magazine: Manufactur3D is an online magazine on 3D printing. which publishes the latest 3D printing news, insights and analysis from all around the world. Visit our 3D Printing Education page to read more such informative articles. To stay up-to-date about the latest happenings in the 3D printing world, like us on Facebook or follow us on LinkedIn and Twitter.

Starting a 3D Printing Business in India

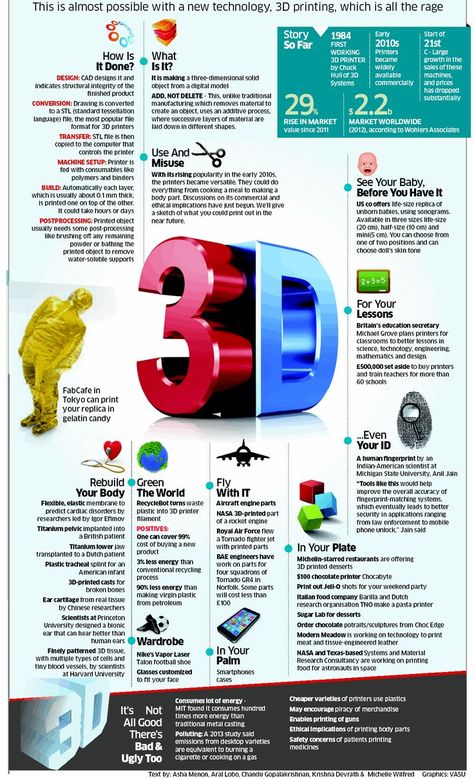

In the early days, two-dimensional printing was in existence. There was no concept of 3D prints. But those days are gone. The time to embrace the new and advanced technology has arrived. Because of the advancement of technology, the 3D Printing business has come into existence. In the traditional form of printing, only ink and paper were used. But 3D printers create amazing structures with a special or additive gum. In addition, the 3D printers also use glass, metal, plastic, and ceramic. The final result which comes as a final print is known as the three-dimensional printed object. The 3D printer produces the shapes and the objects by applying the layers on one another. There is no need to monitor the entire printing process, since the 3D printer is connected to the computer. The task of alteration in the designs is also easy, since you just need to change the data and feed it into the software.

The 3D printing business can offer many beneficial opportunities due to its tremendous growth in the market. The young entrepreneurs of India see the business of 3D prints as a brilliant start-up idea. But, to make your 3D printing business in India more profitable, you need to understand the requirements of setting up this business, the cost involved in it, its rules and regulations, and so on. Read this complete article to gain a clear understanding of the 3D printing business in India.

The young entrepreneurs of India see the business of 3D prints as a brilliant start-up idea. But, to make your 3D printing business in India more profitable, you need to understand the requirements of setting up this business, the cost involved in it, its rules and regulations, and so on. Read this complete article to gain a clear understanding of the 3D printing business in India.

Did You Know?

All the 3D printed objects that you see have multiple printed layers just like an onion.

Steps to start the 3D Printing Business in India

Research and Gain a Basic Understanding of the BusinessUp to this point, 3D printing in India is in its early stages. Many traders and manufacturers of India don’t have all the necessary information that is required for the 3D printing business. The 3D printing business in India has still not taken the predominant part in the country. So, one must understand it in detail and its business model before getting started.

When you need to step into the 3D printing business, you must invest your time to learn the details like 3D printing business scope in India, the startup cost involved, the benefits of the 3D printing business, and so on. This research will help you to get clear about the perks of the business and the risks involved with it. This will also give you a deep knowledge of the 3D business and its operation.

Also Read: Start Your Digital Printing Business

Communicate with the Experts of this IndustryJust gaining knowledge about the 3D printing business is not enough. The real-world scenario is different from what you read and see. Applying the things practically is more important to gain more profits in the business. To analyse the real-world scenario, you must know about the challenges of this business. To make this task easier, you have to consult experts who are already working in the 3D printing business for a long time.

Today, there are multiple kinds of business 3D printers available in the market. The imported 3D printers are on the higher end of the market, hence too expensive. Whereas, local 3D printers are available at a cheaper rate. The quality of the final product entirely depends on the printer that you pick for your 3D printing business. You can either purchase these machines online or directly from the distributors of a particular brand.

Acquire the Best Quality Raw MaterialsThe additives and plastic that is used for manufacturing 3D printers are mostly imported. You must discuss such raw materials from the 3D printer distributors. After acquiring a suitable 3D printer, you can easily start your 3D printing business.

Prepare the Sample Before Making the Actual Deliverable Product Before manufacturing the product, you must make the samples. When your samples are ready, you must analyse whether they are ready to come into the market. It is useless to manufacture something that doesn’t suit the market needs.

It is useless to manufacture something that doesn’t suit the market needs.

Since you are doing the business for your customers, you must always take the feedback from them at regular intervals. You must listen to their problems and their requirements. When clients are satisfied with your products and services, you feel motivated to work harder. But when they are not satisfied with your products, you need to rectify them before moving on with your business.

Promote Your BusinessThe success of the business depends on the two most important factors, and they are the price of the product and its advertisement cost. If you keep the price of your product too high, you will fail to get customers. Without promoting your business, you will fail to develop your reach in the market. So you need to ensure the balance between pricing and promotion in your 3D printing business.

3D Printing Business Startup Cost in IndiaThe 3D printing business is a capital-intensive business. It is advised that you must take credit from the bank to start this business. There are multiple 3D printers available in the market. The higher-end printers that are imported in the country can cost a minimum amount of ₹120000. Whereas, the 3D printers that are manufactured in our own country cost as low as ₹20000. You must also be aware of the cost of acquiring raw materials, rent, power, and space. So, on an average basis, a person needs an amount of ₹4 to ₹5 lakhs to start a 3D printing business in India. The Central Government has come up with various schemes to assist such startups. The banks provide loans with a low rate of interest to help beginning business owners.

It is advised that you must take credit from the bank to start this business. There are multiple 3D printers available in the market. The higher-end printers that are imported in the country can cost a minimum amount of ₹120000. Whereas, the 3D printers that are manufactured in our own country cost as low as ₹20000. You must also be aware of the cost of acquiring raw materials, rent, power, and space. So, on an average basis, a person needs an amount of ₹4 to ₹5 lakhs to start a 3D printing business in India. The Central Government has come up with various schemes to assist such startups. The banks provide loans with a low rate of interest to help beginning business owners.

Also Read: How to Start Mobile Cover Printing Business

Required Licences for Starting a 3D Printing Business in IndiaFollowing is the list of some important licences that you must have before starting a 3D Printing business in India:-

- Trade Licence: This licence is a must that you should have for attaining the government approval of your business.

- Primary Company Registration: This licence will help you to register the name of the company.

- VAT Documentation: It is mandatory to pay the value-added tax for every company. For this purpose, you must have VAT documentation to make the payments.

- Sales Tax Documents: The owner of the company has to submit all the relevant documents to the Sales Tax Office. This will help you to create representation in the books of the Government.

Apart from all the benefits and profits that the 3D printing business will offer you, there are certain problems that you may face in your journey. The problems are,

- Lack of understanding of software – You must be well aware of the usage of software to produce satisfactory 3D prints.

- Lack of awareness: You must research well about the technologies of the 3D Printing business since it becomes difficult to produce the desired results without having much knowledge about the technology used.

- Expensive 3D printers: To produce satisfactory 3D prints, you will have to invest a large amount of money in imported machines.

Conclusion

With the current economy of India, more and more startups are coming up that need the collaboration of the 3D printing industry. Business experts predict that the scope of the 3D printing business will double in the coming years. Many independent startups can come into existence by starting a 3D printing business in India. Whether you want to start the business of selling 3D printers or you want to tie up with other 3D printing industries, it will prove to be beneficial for your business growth. We hope that after going through this article, you must have got a detailed understanding of how to start your 3D printing business in India.

Follow Khatabook for the latest updates, news blogs, and articles related to micro, small and medium businesses (MSMEs), business tips, income tax, GST, salary, and accounting.

Disclaimer :

The information, product and services provided on this website are provided on an “as is” and “as available” basis without any warranty or representation, express or implied. Khatabook Blogs are meant purely for educational discussion of financial products and services. Khatabook does not make a guarantee that the service will meet your requirements, or that it will be uninterrupted, timely and secure, and that errors, if any, will be corrected. The material and information contained herein is for general information purposes only. Consult a professional before relying on the information to make any legal, financial or business decisions. Use this information strictly at your own risk. Khatabook will not be liable for any false, inaccurate or incomplete information present on the website. Although every effort is made to ensure that the information contained in this website is updated, relevant and accurate, Khatabook makes no guarantees about the completeness, reliability, accuracy, suitability or availability with respect to the website or the information, product, services or related graphics contained on the website for any purpose. Khatabook will not be liable for the website being temporarily unavailable, due to any technical issues or otherwise, beyond its control and for any loss or damage suffered as a result of the use of or access to, or inability to use or access to this website whatsoever.

Khatabook will not be liable for the website being temporarily unavailable, due to any technical issues or otherwise, beyond its control and for any loss or damage suffered as a result of the use of or access to, or inability to use or access to this website whatsoever.

Tvasta from India claims it can build a house in just three weeks and for half the cost of

Popular

Many people dream of their own housing. However, in the current realities, not everyone can afford the construction or purchase of real estate. Friends from India founded a business based on the use of 3D printing technology. They promise to quickly and inexpensively build a house.

New Technologies

Three mechanical engineering graduates in Madras, Tamil Nadu founded the modern construction firm Tvasta. They came up with a solution that allows you to build a house in just two to three weeks. The founders of the startup claim that they build houses almost twice as cheap as using traditional technology.

To construct a building, the plan is first made in 2D. Once the house plan is completed, it will be 3D printed and then the house will be built. When building houses, the use of any traditional building materials such as bricks is avoided. The founders claim that the material used for construction is stronger, lighter and more sustainable.

Faster and better

Proprietary concrete mix used for construction. Unlike traditional construction methods that take 21 to 48 days, a complete structure can be completed within 7-10 days using 3D printing technology.

Avoid Mondays and Fridays: tricks that give you a chance to get a job

Squabbles between employees and the boss: why wages should be kept secret

Fooling around at work with colleagues turned out to be useful not only for health , was developed in India. The founders of the startup said they could transform the entire housing industry if their project is accepted by the construction sector.

They target the affordable housing segment and offer to deploy the technology on an industrial scale for mass use. Concrete 3D printing technology combines machines, materials and software. It pushes the boundaries of the modern construction industry.

However, now this direction is at the stage of development. 3D printers that require the use of various sub-technologies for the formation and processing of raw materials are in the process of obtaining a patent.

Found a violation? Complain about content

- December 10, 2020

- Valeria Lazareva

- 0

- Business ideas

Share:

See also

- Builders and artists: 4 types of leaders who will be most in demand in 2023

- Persistence is the main enemy of a career: five strategies for keeping a job in turbulent times

- Comparing Yourself to Others Often Leads to Depression: How to Use This Habit to Succeed

- With minimal investment and a simple organization process: how to make money on snow removal

- Short burst of positive: how watching short viral videos at work increases productivity

How are 3D printers changing the real estate market right now?

LonGrad

Your next home can be printed

Several new homes across California are selling unusually fast. In the last two months, 82 houses have been sold out, and another 1,000 are on the waiting list. However, the wait doesn't have to be long: while a typical brick home can take weeks to build, Palari Homes and Mighty Buildings can build one in less than 24 hours. This is due to the fact that their objects are assembled from pre-assembled components at the factory. The idea itself is not new, but in this case the components are obtained in an unusual way: they are printed.

In the last two months, 82 houses have been sold out, and another 1,000 are on the waiting list. However, the wait doesn't have to be long: while a typical brick home can take weeks to build, Palari Homes and Mighty Buildings can build one in less than 24 hours. This is due to the fact that their objects are assembled from pre-assembled components at the factory. The idea itself is not new, but in this case the components are obtained in an unusual way: they are printed.

Plan of a five-acre 3D printed development in Rancho Mirage, California.

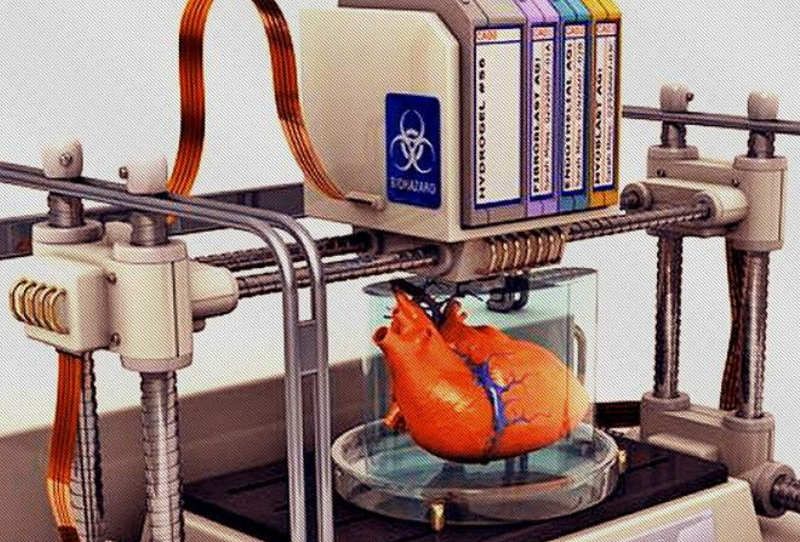

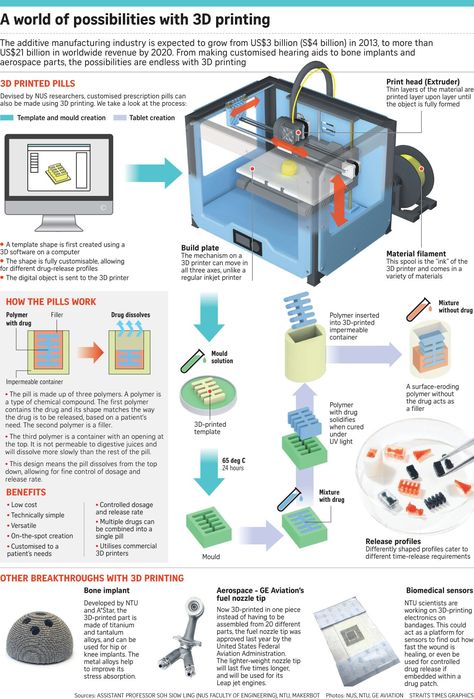

3D printing has been around since the early 1980s but is now gaining momentum. It is already being used to make everything from orthopedic implants to aircraft components.

Details vary between products and processes, but the basic principle remains the same: a layer of material is laid and fixed, another one is placed on top of it, and then another and another. By changing the shape and sometimes the composition of each layer, it is possible to create objects that would be difficult or impossible to make with more traditional methods. In addition, unlike traditional manufacturing processes, there is no waste of materials.

In addition, unlike traditional manufacturing processes, there is no waste of materials.

3D printing houses is the greenest way to build

In the case of Palari Homes and Mighty Buildings, the printers are much larger than those required for artificial knees and airplane wings, and the materials are somewhat rougher. But the principle remains the same. The nozzles extrude a paste (in this case, composite), which then hardens under the influence of ultraviolet light. This allows Mighty Buildings to print details such as cornices and ceilings without the use of reference forms - as well as simpler things like walls. They are then assembled on site and attached to a permanent foundation by the builders of Palari Homes.

Not only does 3D printing provide versatility and faster construction, it also promises lower cost and a more sustainable approach than traditional construction methods currently offer. This could be the answer to two of the problems the world is currently facing: housing shortages and climate change. About 1.6 billion people - more than 20% of the world's population - do not have adequate housing. And the construction industry accounts for 11% of global anthropogenic carbon dioxide emissions. At the same time, the industry does not show success in reducing its carbon footprint.

About 1.6 billion people - more than 20% of the world's population - do not have adequate housing. And the construction industry accounts for 11% of global anthropogenic carbon dioxide emissions. At the same time, the industry does not show success in reducing its carbon footprint.

Automation brings huge cost savings. Mighty Buildings says computerizing 80% of the printing process means the firm only needs 5% of the workforce it would otherwise have. It also doubles the rate of production. This is good news for the construction industry, which has struggled for years to increase its productivity. According to the McKinsey consulting firm, over the past two decades, the industry has grown by only a third of the overall level of productivity in the global economy as a whole. Digitization is slower than almost any other industry. In many places, the industry also suffers from a shortage of skilled labor. And it is expected that the situation will not improve further. In America, for example, about 40% of construction workers are expected to retire within the next decade.

3D printer at Mighty Buildings headquarters.

The environmental benefits come in many ways, but the important thing is that you don't have to move a lot of heavy objects. For example, Palari Homes estimates that assembling its products reduces the number of truck rides needed to build a home by as much as two tons of carbon dioxide emissions per home are reduced.

Palari Homes and Mighty Buildings are not alone in their endeavors: similar projects are being launched everywhere. The vast majority of structures are printed using concrete. 14Trees, a joint venture between Holcim (the world's largest cement producer) and CDC Group, the UK government's development finance organization, operates in Malawi. Its representatives claim that it is possible to print a house in just 12 hours for less than $10,000. 14Trees notes that this process is not only cheap and fast, but also environmentally friendly. Holcim says that by applying the exact amount of cement needed and thus reducing waste, 3D printing generates only 30% of the carbon dioxide produced by fired clay bricks.

Meanwhile, in Mexico, the homeless charity New Story partnered with 3D printing firm ICON to build ten 46-square-meter houses. Each of these houses was printed in about 24 hours (although those hours were spread over several days), with the final elements collected by Échale, another local charity. In Europe, the first 3D-printed house on the continent was built in Eindhoven, the Netherlands - the keys to it were handed over to tenants on July 30.

First 3D printed house in Europe. Based in Eindhoven, The Netherlands.

Layer cake

The house in question, the first of five detached two-bedroom houses in a project coordinated by the Eindhoven municipal government and the City University of Technology, is the result of a collaboration between several firms. The Dutch division of the French building materials company Saint-Gobain developed the required concrete mortar. Construction firm Van Wijnen erected the structure, while consultant Witteveen + Bos was in charge of the design. The building is leased by its owner Vesteda, a Dutch residential property investor.

The building is leased by its owner Vesteda, a Dutch residential property investor.

3D printed house project in Eindhoven, The Netherlands

However, using cement in these projects is not an environmentally friendly process. It converts calcium carbonate in the form of limestone to calcium oxide and carbon dioxide, and this process is believed to account for about 8% of anthropogenic emissions of this gas. So a group at Texas A&M University, led by Sarbajit Banerjee, developed a way to do without cement.

Dr. Banerjee's new building material was inspired by a project he initiated years ago. It was a program to build access roads to remote areas of the Canadian province of Alberta using materials at hand. The crushed stone he invented combined local soil with wood fiber mulch and was held together with liquid or water-soluble silicates, which then hardened and acted like cement. To build houses, he uses clay and stone debris that lie under the top layer of soil near the construction site, grinds them into powder and mixes with silicates. The resulting mixture can be squeezed out through a nozzle, after which it will quickly harden and gain strength to maintain its shape and withstand the weight of the next layer. This makes the process doubly "green": it eliminates both the cement and the need to transport to the construction site, often over long distances, the sand and aggregates used in conventional concrete.

The resulting mixture can be squeezed out through a nozzle, after which it will quickly harden and gain strength to maintain its shape and withstand the weight of the next layer. This makes the process doubly "green": it eliminates both the cement and the need to transport to the construction site, often over long distances, the sand and aggregates used in conventional concrete.

Benefits of cement

There are limits to building 3D printed houses. To begin with, it is necessary to create a legislative framework for the construction of such houses. To this end, UL, one of America's largest certification agencies, collaborated with Mighty Buildings to develop the first 3D printing standard. Its principles will be incorporated into the new International Housing Code, which is in use or has been adopted by every US state except Wisconsin. While this is a welcome move for a young industry, most governments have yet to develop country-specific standards. There are also questions about the quality and finish of houses built on 3D printers.

There are also questions about the quality and finish of houses built on 3D printers.

Nevertheless, the prospects look promising. Last year, Germany approved plans to 3D print an apartment building. The three-story structure of the German construction company Peri is assembled from parts made using printers developed by the Danish company Cobod. This building will have five apartments. The use of the technology is also expanding in the Middle East and Asia. The Dubai government wants a quarter of the country's new buildings to be 3D printed by 2030 and is dedicating an entire area on the outskirts of the capital to house 3D printing companies and their warehouses. Saudi Arabia plans to use 3D printing to build 1.5 million homes over the next decade. India's Ministry of Housing and Urban Development wants to use 3D printing to solve the country's housing shortage.

If successful, 3D printed construction could expand beyond the residential sector: warehouses, offices and other commercial buildings have good prospects. The US space agency NASA is exploring the use of 3D printing to build landing sites, living quarters and roads on Mars and the Moon. There is no soil on these two celestial bodies, only crushed rock called regolith. Dr. Banerjee's group, which works with NASA, says their 3D printing approach also works well with this material. “Ultimately we would like to have real estate on Mars and the Moon, but we won't be able to carry concrete with us there,” says Dr. Banerjee. "We'll have to work with the regolith."

The US space agency NASA is exploring the use of 3D printing to build landing sites, living quarters and roads on Mars and the Moon. There is no soil on these two celestial bodies, only crushed rock called regolith. Dr. Banerjee's group, which works with NASA, says their 3D printing approach also works well with this material. “Ultimately we would like to have real estate on Mars and the Moon, but we won't be able to carry concrete with us there,” says Dr. Banerjee. "We'll have to work with the regolith."

If you are interested in options for alternative construction methods in order to increase the return on investment, then contact us! Longrad has been actively working with developers who build prefabricated houses for several years. These technologies are several times faster than traditional methods, which helps to achieve significantly higher returns. You can get a free consultation by phone +447792174059 (WA, Telegram), via email info@longrad.

Learn more