Youngstown ohio 3d printing

3D Printing Service Youngstown, OH | Instant Quotes Online

Our 3D printing capabilities

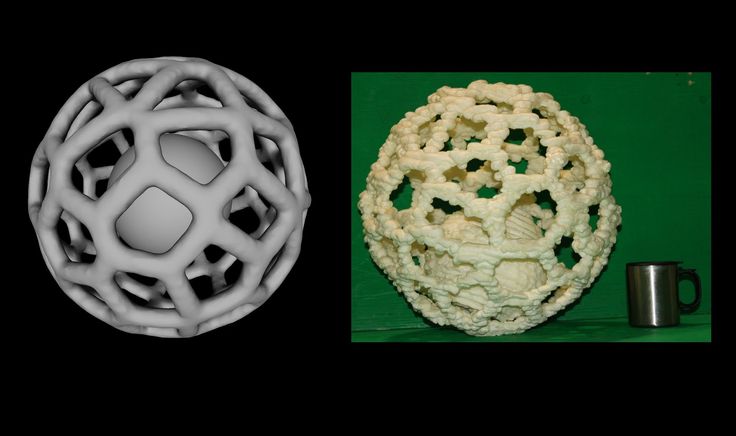

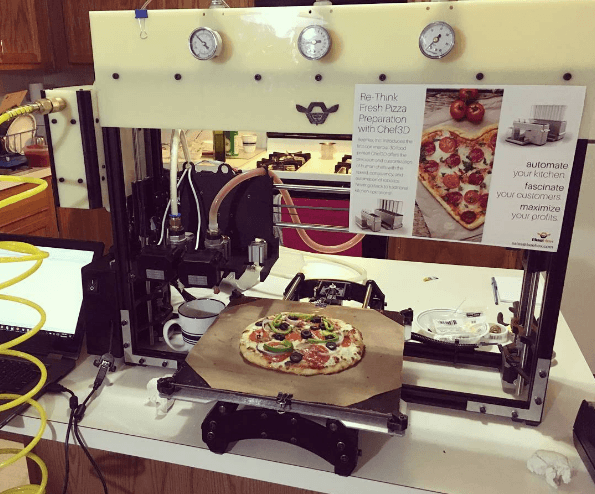

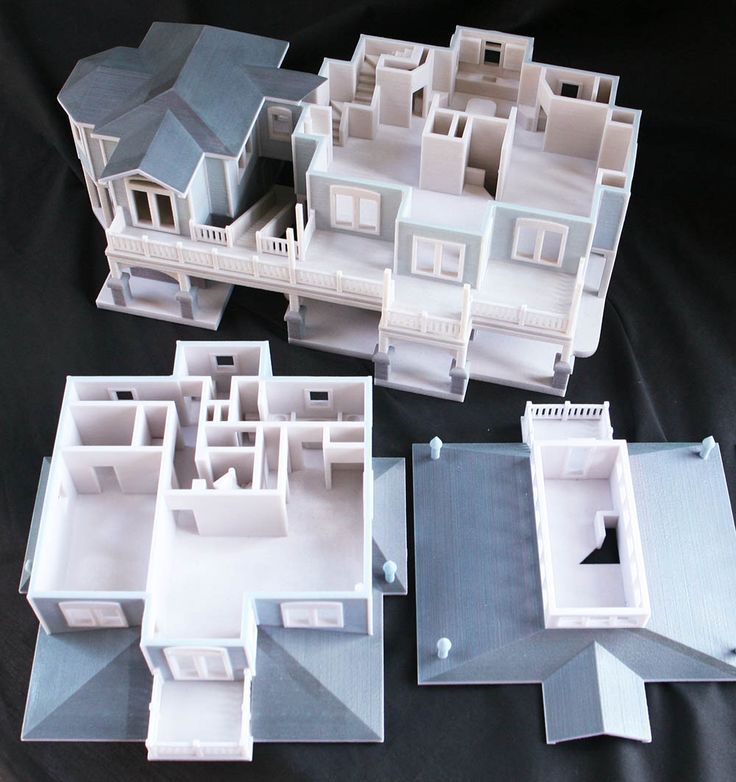

We have over 90 3D printing shops in our network and are well known for manufacturing high-quality parts at competitive prices, from rapid prototyping with Fused Deposition Modeling (FDM) to functional end parts made with Selective Laser Sintering (SLS) or Multi Jet Fusion (MJF).

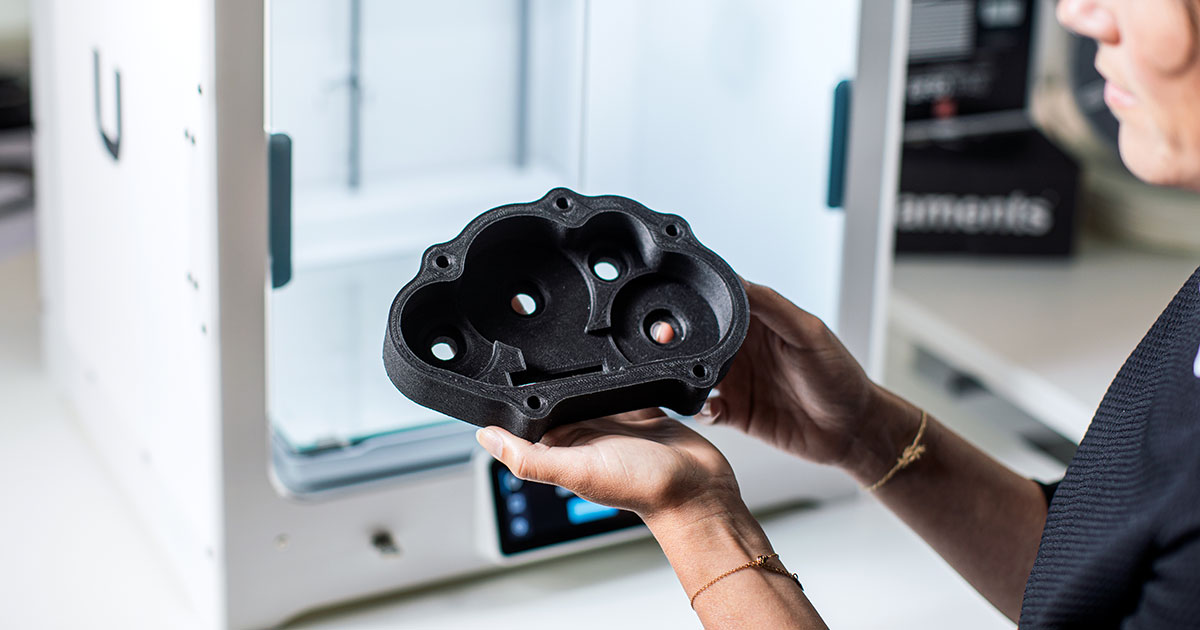

Gallery of 3D printed parts manufactured by Hubs

With over 65,000 customers from every industry, including aerospace, defense, robotics, medical, machinery, automotive and electronics, we have extensive experience meeting a diverse range of 3D printing requirements, from prototyping to production: Visual aids, concept models, injection-molding prototypes, form-fit & function prototypes, tooling and casting patterns, jigs, grips and fixtures, and durable end parts.

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

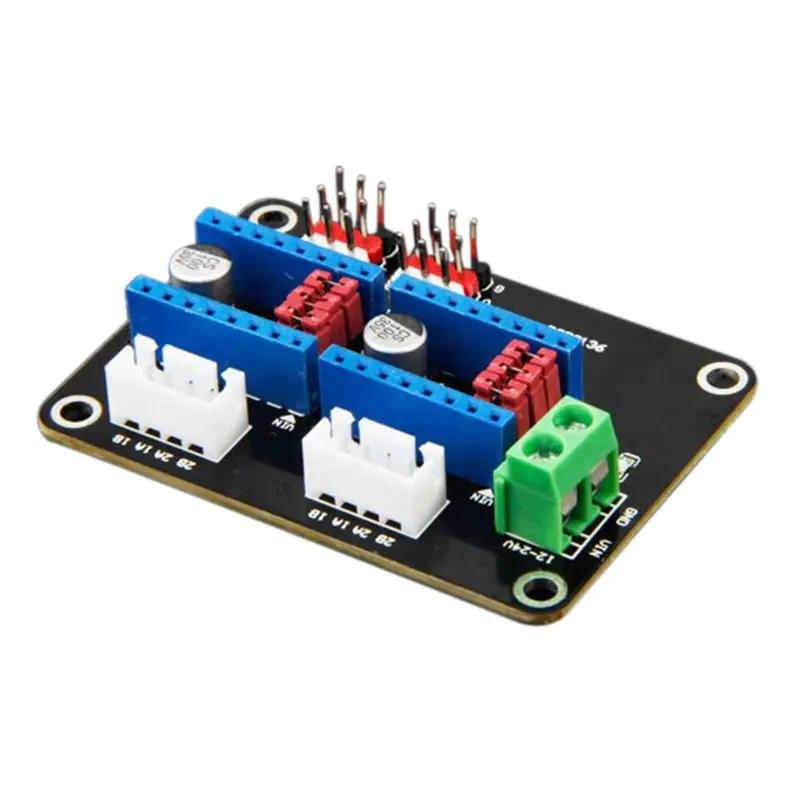

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

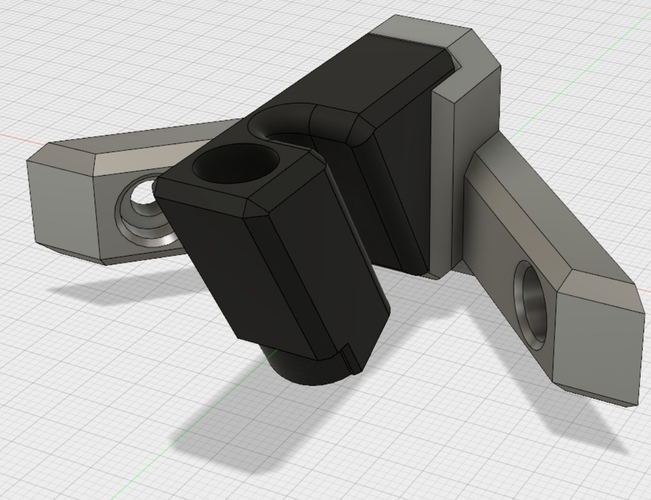

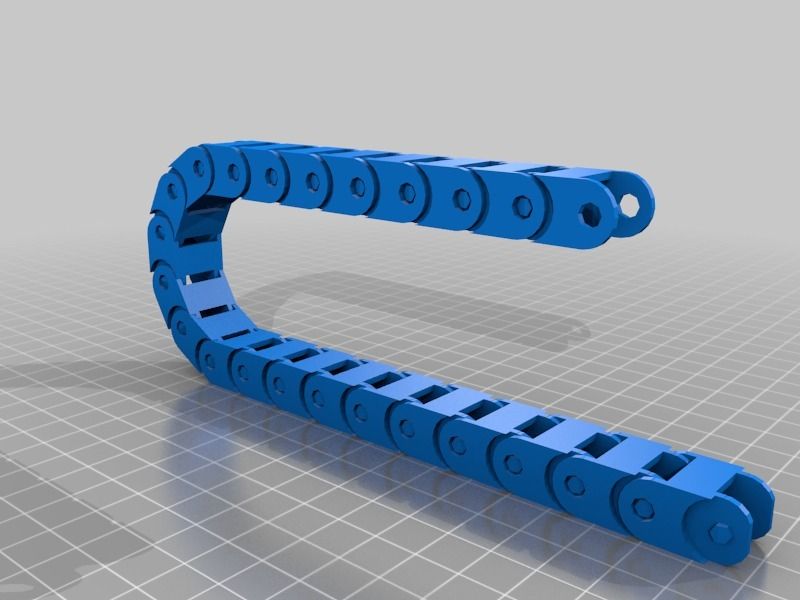

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69. 23 / $34.33 23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48. 86 86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

Instant, online 3D printing quotes

-

Upload a CAD to start (STEP, STP, IGES, IGS, SLDPRT, 3DM, SAT, STL, OBJ or X_T)

-

Price updates in real-time as you change materials, lead time, etc.

.

. -

No hidden costs. Our instant quotes are not just indications, but the actual price, and include shipping and customs up front.

Learn about how our quoting algorithm works

Our ordering process

Receive instant quote

Upload your CAD to our online quoting platform

Confirm specs

Configure your part specifications and select a lead time that suits your schedule

Production

We select the best manufacturer for your order, and production begins immediately

Quality control

We take full responsibility for making sure your parts are manufactured according to our standards

Delivery

Our 3D printing service has been rated 4.9/5

Over 219 customers are satisfied with our 3D printing service.

_1400x0_16a.jpg)

“Incredibly fast service, very high quality parts”

“Professional, great communication, and top quality parts!”

“This was my first experience in anything 3D printed, and I feel it turned out pretty great, so thank you!”

“Very quick and effortless experience, thanks!”

“Fantastic work! Was able to turn around the parts faster than was originally estimated!”

“Great print quality and expertise. Thanks for the speedy service!”

“Quality of the parts is spectacular, and I was thoroughly impressed with the professional level and quality of packaging.”

“I’m very happy with the service. My order arrived earlier than the estimated delivery date.”

“Fantastic prints, really helped me a lot directly as well.”

“Great help, item was printed quickly and good quality. ”

“The printed part is great. The dimensions are accurate. The surface finish is better than I expected. Overall very good service.”

“Prints came out great, packaged well. Very happy. ”

Very happy. ”

“Was willing to do whatever it took to make the parts right. Nice quality print.”

“Very prompt and communicated about the parts well. Gave me feedback to adjust the model so it would print better. Print quality was high and shipped quickly.”

“The parts were exactly what I ordered, and work great! The was a delay with printing due to a machine breakdown, but there was good communication throughout the delay.”

“Part turned out perfect. Could not be happier!”

“Hubs worked with me to get the highest quality delivered very fast. Thanks”

“Once again, beyond happy with the prints and the service.”

“Received the parts a day early and they look good!”

“Great service and quality. Very satisfied with the handling of our order! reliable, great communication and met our tough delivery requirement. ”

“Fantastic quality and exactly what I expected. Communication was quick and easy. My mini-figures came exactly as I would have hoped, I'm very pleased. Would definitely fill orders with this shop again in the future. ”

Would definitely fill orders with this shop again in the future. ”

“Gr8 hub. Super fast service. Prints are awesome. Loved my first experience.”

“Perfect Prints, Fast Delivery, Competitive Pricing”

“My order was ready the next day and the service was great. I will use them again for sure. Picked up my order and saw their machine's, really high end equipment and very friendly staff.”

“Great service, quick turn around time and knowledgeable hub.”

Show more reviews

Show less reviews

Teams build better parts

Create your Hubs team and start collaborating

Read more

The Hubs Standard - consistent quality, every time

Hubs takes the stress out of manufacturing by guaranteeing the quality and consistency of every part. Each order is dimensionally and visually inspected to make sure it meets the Hubs Standard.

3D printing materials

We can generate instant 3D printing quotes for 25+ plastics. For metal 3D-printed parts, you can request a quote from our parent company, Protolabs.

Available materials

SLS

PA 12 Glass filled PA 12

Desktop FDM

Prototyping PETG Prototyping ASA Prototyping TPU Prototyping ABS Prototyping PLA

Desktop SLA

Formlabs Standard Resin Formlabs Clear Resin Formlabs Tough Resin 2000 Formlabs Rigid Resin 4000 Formlabs Grey Pro Resin Formlabs Flexible Resin 80A Formlabs High Temp Resin Formlabs Durable Resin

MJF

HP PA 12 Glass filled HP PA 12

Industrial FDM

Markforged Onyx ABSplus Stratasys ULTEM 9085 Stratasys Stratasys ASA ABS M30 Stratasys ULTEM 1010 Stratasys

Industrial SLA

Accura 25 (PP-like) Accura ClearVue Accura Xtreme White 200 (ABS-like)

3D printing locations near Youngstown, OH

Youngstown, OH Canton, OH Akron, OH

Weirton, WV Parma, OH Cleveland, OH

Lakewood, OH Wheeling, WV Pittsburgh, PA

Elyria, OH

The 3D Printing Handbook

No one understands 3D printing like us - our founders literally wrote the book. Click here to download the sample chapters.

Click here to download the sample chapters.

Buy the book from Amazon

FAQ's

How much does your 3D printing service cost?

The cost of your 3D printed parts depends on factors such as part volume, part complexity, choice of material, which 3D printing technology is used, and if any post processing is required. For more details on these cost factors, see our article on the cost of 3d printing. To check the cost of your 3D printed part, simply upload a CAD (.STL) file and select your material and 3D printing technology to receive a quote within seconds.

How do you guarantee the quality of my prints?

Your parts are made by experienced 3D printing shops within our network. All facilities are regularly audited to ensure they consistently meet the Hubs quality standard. We include a standardized inspection report with every order and offer a First Article Inspection service on orders of 100+ units.

We have partners in our network with the following certifications, available on request: ISO9001, ISO13485 and AS9100.

Follow this link to read more about our quality assurance measures.

How do I select the right 3D printing process for my prints?

You can select the right 3D printing process by examining which materials suit your need and what your use case is.

By material: if you already know which material you would like to use, selecting a 3D printing process is relatively easy, as many materials are technology specific.

By use case: once you know whether you need a functional or visual part, choosing a process is easy.

For more help, read our guide to selecting the right 3D printing process. Find out more about Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), Multi Jet Fusion (MJF) and Stereolithography (SLA).

How can I reduce the cost of my 3D prints?

In order to reduce the cost of your 3D prints you need to understand the impact certain factors have on cost. The main cost influencing factors are the material type, individual part volume, printing technology and post-processing requirements.

The main cost influencing factors are the material type, individual part volume, printing technology and post-processing requirements.

Once these have been decided, an easy way to further cut costs is to reduce the amount of material used. This can be done by decreasing the size of your model, hollowing it out, and eliminating the need for support structures.

To learn more, read our full guide on how to reduce the cost of 3D printing.

Where can I learn more about 3D printing?

Our knowledge base is full of in-depth design guidelines, explanations on process and surface finishes, and information on how to create and use CAD files. Our 3D printing content has been written by an expert team of engineers and technicians over the years.

See our complete engineering guide to 3D printing for a full breakdown of the different 3D printing technologies and materials. If you want even more 3D printing, then check out our acclaimed 3D printing handbook here.

We have an extensive range of online resources developed to help engineers improve their capabilities.

Introductory guides

Design guides

Material guides

Applications

CAD & file preparation

Post processing & finishing

Our other manufacturing capabilities

CNC machining

CNC machining

Milling (3-, 4- & full 5-axis), turning and post-processing

-

50+ metals and plastics & 10 surface finishes

-

Tolerances down to ±.0008” (0.020 mm)

-

Lead times from 5 business days

See our CNC machining services

Put your 3D printed parts into production today

Get an instant 3D printing quote

Ursa Major Lab Delivers 1st 3D-Printed Rocket Engine Parts

|

Ursa Major’s Advanced Manufacturing Lab in Youngstown, Ohio Delivers its First 3D-Printed Rocket Engine Components

Reduces Production Time from 6 Months to 1 Month

Today Ursa Major announced the delivery of its first copper-based 3D-printed rocket engine combustion chambers out of its additive manufacturing (3D-printing) lab in Youngstown, Ohio.

The processes developed at this facility compress the production and delivery cycle to one month, compared to a minimum of six months using traditional manufacturing.

We will test these advanced copper alloy-based engine components for space launch and hypersonic applications.

“Speed is of the essence when it comes to producing rocket engines right now because lack of propulsion is causing a significant bottleneck in U.S. access to space and hypersonics testing,” said Joe Laurienti, founder and CEO of Ursa Major. “The Ursa Major facility in Youngstown is playing a pivotal role in accelerating our customers’ time to market in both commercial and government sectors.”

Ursa Major team members Thomas Pomorski (left) and Ty Barzak at the company’s Youngstown, Ohio, advanced manufacturing facility.It’s All About the Partnerships

The Ursa Major Advanced Manufacturing Lab began in October of 2021, with $3 million in federal financial support from U.S. Rep. Tim Ryan and Department of Defense-backed manufacturing innovation institute America Makes.

“Ursa Major’s goal to help establish the U.S. as a global supplier of rocket propulsion is in line with our efforts to foster domestic innovation and manufacturing across industries,” said Rep. Tim Ryan. “I’m pleased that Ohio is home to this state-of-the-art facility that will ultimately help the U.S. regain its leadership in space and hypersonic technologies.”

The Youngstown-based facility is equipped with an EOS large-format laser powder bed fusion 3D printer designed to make on-demand components for our rocket engines. It’s located in the Youngstown Business Incubator, an internationally recognized program focused on the development of software and additive manufacturing companies in the region.

“This type of advanced 3D printing is a great example of the kind of American innovation that America Makes seeks to support,” said John Wilczynski, Executive Director of America Makes of American Makes. “Successful projects like this are part of a resurgence in American manufacturing that helps strengthen our domestic supply chain. ”

”

Filling a Crucial Need

The existing supply chain for high temperature metal alloy components is limited, and it can take months to turn around a needed revision. The Advanced Manufacturing Lab accelerates the engine development process, allowing us to rapidly iterate on design adjustments in-house to improve engine performance and reliability.

The Advanced Manufacturing Lab was critical to rapidly redesigning our “Ripley” from a 35,000 to 50,000-pound thrust engine in order to meet market demand. The technical lessons learned from Ripley and the methods and materials produced in this facility are now contributing to the development and testing of our two other rocket engine programs – the “Hadley,” a 5,000-pound thrust, oxygen-rich staged combustion engine used in small launch and hypersonics, and the recently announced 200,000-pound thrust “Arroway” designed for medium and heavy launch.

3D printing allows us to speed up engine production and apply improvements gleaned from testing in real time, lowering costs. Our rocket engines are more than 80% 3D-printed by mass and primarily built and tested in our Berthoud, Colorado headquarters.

Our rocket engines are more than 80% 3D-printed by mass and primarily built and tested in our Berthoud, Colorado headquarters.

Ursa Major Engines

Our rocket engines are designed for flexibility and reusability, suitable for a range of missions, from air launch to hypersonic flight to on-orbit missions with many restarts. Our customers get to launch many years faster and without the development cost of building engines in-house.

We have built and tested more than 50 staged-combustion rocket engines so far and will deliver 30 of them by year’s end. To date, our engines have accumulated more than 36,000 seconds of run-time, far more than a typical engine is tested prior to first flight.

Connect with Ursa Major on LinkedIn, Twitter, Instagram, and Facebook.

More from Ursa Major

|Aerospace

Strategies to Help the U.S. Regain Leadership in Hypersonics

Read More

|Q&A

How I Got into Aerospace: An Ursa Major Series on Career Pivots

Read More

|From the CEO

We Need to Talk About Propulsion

Read More

World's first car now 3D printed

localmotors. com

com

At the International Manufacturing Technology Show now in Chicago, US-based Local Motors is 3D printing the first functioning electric car. It is reported by The Wall Street Journal.

The process of printing and assembling the two-person battery-powered car called the Strati began on Sunday and should be completed on Thursday. The huge printer builds layer upon layer of a body and chassis made of black plastic reinforced with carbon fiber. The electric motor, seats, wheels, tires and windshield are made by Local Motors in traditional ways, but it will still have only 47 parts in this car, while in ordinary cars there are thousands, says John Rogers, CEO of Local Motors: critical changes, drastically reducing the number of spare parts. nine0003

Once the bodywork is complete, a computerized machine will machine it to the desired specifications and drill 32 holes to attach the rest of the parts.

On the company's website, you can see how the process of "printing" the car is going.

The project, which was founded in 2007 by Local Motors in partnership with Oak Ridge National Laboratory, aims to confound critics who say the 3D printing process is too slow and expensive, to apply it in mass production. nine0003

“It's not about the car, it's about the process,” says Rogers. The purpose of the project is to demonstrate the possibilities of a new production technology. “It took us less than 40 hours to print one car and less than four days to assemble the prototype; it's an incredibly short amount of time. In a few months, we will be able to reduce the printing period to less than 20 hours and are confident that two people can then assemble a finished car in less than an hour, Rogers said in a statement on the Local Motors website. - Our goal is to approach the creation of a car in a completely different way: there are usually more than 20,000 parts in a modern car; we want fewer than 20 in the cars of the future.” nine0003

The first version of the Strati will be capable of traveling at speeds up to 65 km/h, with a battery charge that Rogers says will last 190-240 km. Local Motors hopes to begin sales in the coming months. The price will range from $18,000 to $30,000 depending on the set of options that buyers prefer. The company also plans to give them the opportunity to choose the design of the car to their liking. Once the Strati receives a safety certificate, the car will be able to move on highways, Rogers hopes. nine0003

Local Motors hopes to begin sales in the coming months. The price will range from $18,000 to $30,000 depending on the set of options that buyers prefer. The company also plans to give them the opportunity to choose the design of the car to their liking. Once the Strati receives a safety certificate, the car will be able to move on highways, Rogers hopes. nine0003

The Strati was based on a design submitted in a public competition held by Local Motors and open to professionals and amateurs alike. The running layout used a transmission from Renault Twizy, the company reports on its website.

The Strati 3D printer was produced by Cincinnati, an engineering company in Harrison, Ohio. It is capable of processing parts up to 1 x 1.5 x 3 m and is significantly larger than traditional 3D printers, which are usually not much larger than a washing machine. nine0003

3D printing, also known as additive printing, builds material on an object layer by layer. Unlike traditional technologies, where parts are machined from blanks, as a result of which part of the material ends up in waste, 3D printing allows you to model an object on a computer and “print” it from plastic, metal or composite materials.

Media news2

Is advertising distracting? With a subscription you won't see it on the siteBest 3D Printer Files 2d Art・Cults

DrewnJosh

Free

Daisy Litho 1

Free

Daisy

Free

Adrian

Free

Daisy 2

Free

DaisyLith

Free

Arches

Free

infernal boss Popsicles?

€0.80

date kiss2

Free

BATMAN AND ROBIN3

Free

BATMAN AND ROBIN2

Free

nine0028 BATMAN AND ROBINFree

date kiss

Free

Dolphin

Free

LEA 2

Free

LITO STANDARD

Free

LITHOGRAPHIC STANDARD 2

Free

LITO LEA

Free

MEDALLION LEA

Free

Three wise men like stained glass

Free

Brian

Free

Velma

Free

nine0028 Julie SprongFree

Rick and Morty

Free

Zia symbol

Free

Anti-Mage

Free

Prophet of nature

Free

Eggbot simple design

Free

Litopan VEGS

Free of charge

Flower Litopan

Free

snowflake ornament

Free

Helice

Free

Monstera leaves

Free

nine0028 Papa Noel (aka Santa Claus)Free

Lenny Leonard

Free

Custom globe decoration

Free

Jasmine1

Free

NFL logos

8 €

Akrapovic

0.