3D printer affirm financing

Buy Now Pay Later, Monthly Payment Plans, Rent to Own

252 products found for "

3D Printer Financing"Sort by Most PopularMonthly Price: Low to HighMonthly Price: High to LowAlphabetical: A to ZAlphabetical: Z to ARecently Added

Official Creality Ender 3 V2 Upgraded 3D Printer with Silent Motherboard...

$319.99 $279.00

- 6,244

As low as $47/mo*

Official Creality Ender 3 3D Printer Fully Open Source with Resume Print.

$269.00 $199.00

- 8,539

As low as $33/mo*

Official Creality Ender 5 Pro 3D Printer Upgrade Silent Mother Board Met...

$420.99 $399.00

- 1,060

As low as $33/mo*

Official Creality Ender 3 Pro 3D Printer with Removable Build Surface Pl.

..

.. $339.99 $246.00

- 8,704

As low as $41/mo*

Official Creality Ender 5 Plus 3D Printer with Auto Bed Leveling Sensor ...

$617.99 $599.00

- 621

As low as $50/mo*

R QIDI TECHNOLOGY i Fast 3D Printer, Industrial Grade Structure, with Du.

..

.. $2,499.00

- 150

As low as $104/mo*

Flashforge 3D Printer Adventurer 3 Pro, Auto Leveling Glass Hot Bed, Bui...

$399.00

- 135

As low as $33/mo*

ANYCUBIC Photon M3 Max Resin 3D Printer, 13.

6“ 7K UV LCD 3D Printer, Aut...

6“ 7K UV LCD 3D Printer, Aut... $1,549.98 $1,299.99

- 2,606

As low as $72/mo*

ELEGOO Saturn MSLA 3D Printer UV Photocuring LCD Resin 3D Printer with 4...

$415.99 $379. 99

99

- 1,348

As low as $32/mo*

ANYCUBIC MEGA X 3D Printer, Large Metal FDM 3D Printer with Patented Hea...

Out of Stock

- 2,930

As low as $27/mo*

Anycubic Kobra Max 3D Printer, Smart Auto Leveling with Self-Developed A.

..

.. $772.98 $749.99

- 2,825

As low as $62/mo*

R QIDI TECHNOLOGY Large Size Intelligent Industrial Grade 3D Printer New...

$999.00

- 913

As low as $83/mo*

Creality HALOT ONE Resin 3D Printer with 5.

96 inches 2K Mono LCD, Interg...

96 inches 2K Mono LCD, Interg... $181.99 $169.00

- 646

As low as $28/mo*

FLASHFORGE Adventurer 4 3D Printer with 2 Removable Nozzle Extruders and...

$799.00

- 74

As low as $67/mo*

Official 3D Printer Creality Ender 3 v2 Neo New Upgrade Version with CR-.

..

.. $319.00

- 357

As low as $27/mo*

ANYCUBIC Mega Pro 3D Printer, 4th Gen 3D Printing & Laser Engraving 2 in...

Out of Stock

- 2,893

As low as $32/mo*

COMGROW Creality Ender 5 Plus 3D Printer with BL Touch, Tempered Glass P.

..

.. $639.00

- 475

As low as $53/mo*

ELEGOO Resin 3D Printer, Mars 3 MSLA 3D Printer with 6.66 inches Ultra 4...

$508.98 $258.99

- 2,483

As low as $43/mo*

Affirm Financing is now available at YoraHome!

by Alban Bredou

Contents

Print now, pay later: that's the whole idea behind our partnership with Affirm.

What is Affirm?

Affirm is a financing alternative to credit cards and other credit payment products.

Affirm offers instant financing for online purchases to be paid in fixed monthly installments over 3, 6, 12, 18, 24 or 36 months:

- If your order value is between $50 - $250, you may qualify for 3 month terms at an APR starting at 10%.

- If your order value is $250 or greater, you may qualify for 3, 6, 12, 18, 24 and 36-month terms at an APR starting at 10%.

Here are 3 reasons why should should consider buying YoraHome products with Affirm:

- Buy and receive your purchase, and pay for it over several months. This payment option allows you to split the price of your purchase into fixed payment amounts that fit your budget.

- The application process is secure and real-time. Affirm asks you for a few pieces of information. After you provide this information, Affirm notifies you of the loan amount that you’re approved for, the interest rate, and the number of months that you have to pay off your loan -- all within seconds.

- You don’t need a credit card to make a purchase. Affirm lends to the merchant directly on your behalf. Affirm bases its loan decision not only on your credit score, but also on several other data points about you. Affirm does a “soft” credit check, which verifies the customer's identity but does not affect a customer’s credit score.

To sign up for Affirm, you must:

- Be 18 years or older (19 years or older in Alabama or if you’re a ward of the state in Nebraska).

- Provide a valid U.S. or APO/FPO/DPO home address.

- Provide a valid U.S. mobile or VoIP number and agree to receive SMS text messages. The phone account must be registered in your name.

- Provide your full name, email address, date of birth, and the last 4 digits of your social security number to help us verify your identity.

- At checkout, choose Pay with Affirm.

- Affirm prompts you to enter a few pieces of information: Name, email, mobile phone number, date of birth, and the last four digits of your social security number. This information must be consistent and your own.

- To ensure that you’re the person making the purchase, Affirm sends a text message to your cell phone with a unique authorization code.

- Enter the authorization code into the application form. Within a few seconds, Affirm notifies you of the loan amount you’re approved for, the interest rate, and the number of months you have to pay off your loan.

- To accept Affirm’s financing offer, click "Confirm Loan" and you’re done.

After your purchase, you’ll receive monthly email and SMS reminders about your upcoming payments. You can also set up autopay to avoid missing a payment.

Can customers outside the U.S. use Affirm?Affirm is available only to shoppers residing in the United States. Affirm hopes to expand its services to customers outside the U. S. very soon.

S. very soon.

you might also like...

The Yora Draw Pen Plotter Meets Generative Art

by Janice Sherriffs Nov 27, 2022

Bonjour! La Bizounerie Reviews The YoraHome Mandrill 3036 CNC Router

by Jim Rarey Nov 06, 2022

How To Laser Engrave Glass With A Diode Laser

by Janice Sherriffs Oct 30, 2022

Afterpay Financing is now available at YoraHome!

by Alban Bredou Oct 19, 2022

How To Use YoraHome Offline Controller With LCD Touchscreen

by Alban Bredou Oct 15, 2022

Why Do I Want A 32-Bit Controller For My Laser?

by Jim Rarey Sep 26, 2022

Get The Freshest ContentStraight To Your Inbox

Join over 3,000 creators who receive premium content, exclusive discounts, and all the must-know info on a weekly basis.

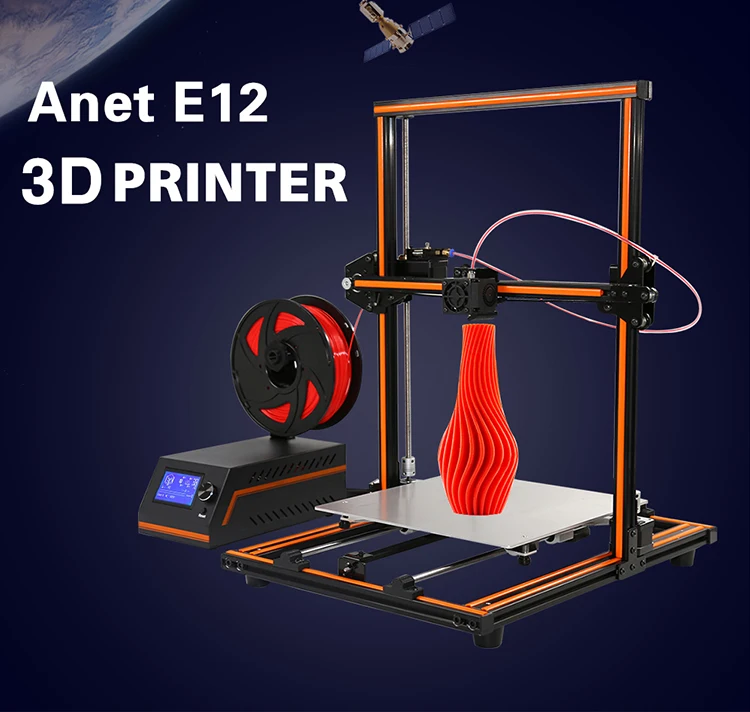

How a 3D printer can save you money How a 3D printer can save you money

The justification for investing in a new, state of the art 3D printer is that it actually saves money.

New research confirms that buying a 3D printer to make plastic iPhone cases (or paper towel holders) at home saves money in the long run. This does not mean that 3D printers will soon crowd out stores or lead to the closure of factories in China or Vietnam. But it's fair to assume that this technology creates a world where you could end up printing a lot of things at home or at your local shop. nine0003

“Printing money” (or rather, saving money)

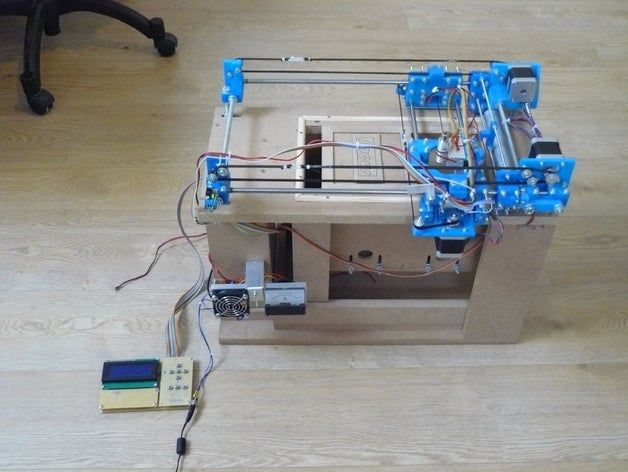

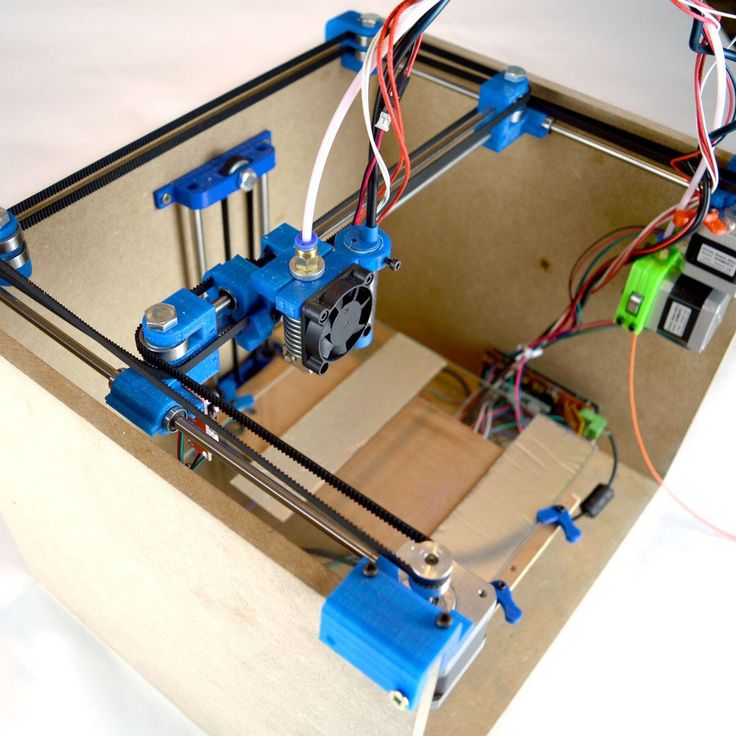

For example, purchasing an open source RepRap 3D printer can not only pay off, but actually lead to money savings if you print on it (by at least) 20 household items per year (for example: shower curtain rings and safety razors). A recent study (known to the general public as the “life-cycle economic analysis of distributed manufacturing using open source 3D printers”) challenges not only the skepticism of the world’s major manufacturers, but also the wariness of 3D printing experts who believe that this technology is still in its infancy. nine0003

nine0003

Today we already have the ability to print with plastic, and this opens up a huge potential for making thousands of products that are already in our homes and that we use every day. The range of printed material is expanding rapidly, and it is likely that consumers are likely to print many products themselves instead of buying them.

Owners of RepRap 3D printers can save between $300 and $2,000 per year, depending on which 20 household items they print. RepRap 3D printer owners can also continuously improve their open source 3D printer and even print new parts (as technology advances) rather than having to purchase a new 3D printer every few years. nine0003

3D printed cups

Other costs associated with the 3D printing process

Despite its merits, assembling an open source 3D printer is a labor-intensive DIY process. RepRap spare parts cost $500-600 and in order to assemble them, you need to spend about 24 hours of working time. And a beginner may need to first learn the assembly process at an appropriate workshop or use an online assembly guide. However, beginners can pay double the price of a collected RepRap. (It's still a good deal compared to so-called polished models like the $2,000 Makerbot Replicator 2.)

And a beginner may need to first learn the assembly process at an appropriate workshop or use an online assembly guide. However, beginners can pay double the price of a collected RepRap. (It's still a good deal compared to so-called polished models like the $2,000 Makerbot Replicator 2.)

Also, don't expect, for example, that the iPhone's plastic case (made from 3D printing) will have the same quality or gloss as a store-bought version. Today, 3D printers still render objects with very small steps or ridges on the sides (no smooth finish). Of course, the object can be smoothed with a nail polish remover and painted, but this is additional labor.

Is the quality of products resulting from the 3D printing process on par with the quality of products that are made in a traditional production and then sold? Unfortunately not: it doesn't even come close to factory quality. nine0003

Disadvantages of 3D printing

Today, 3D printers are able to print products with unusual shapes and unique customer requirements: they are well suited for printing a limited number of expensive parts for jet fighters or a custom implant to restore a destroyed part of the skull (both of which are already happened). However, this technology is not yet capable of making items from a variety of materials, and is too slow and too expensive to produce a large number of items. nine0003

However, this technology is not yet capable of making items from a variety of materials, and is too slow and too expensive to produce a large number of items. nine0003

Very inexpensive and relatively uncomplicated mass-produced items (such as plastic trash cans) will be made in large industrial centers for a long time. Such products, which are produced in the hundreds of thousands or millions, are not good candidates for 3D printing due to the speed and cost of the process.

No one has done a definitive study comparing the cost of 3D printing plastic products locally to the cost of making plastic products in a Chinese factory and shipping them around the world. But some experts believe that industrial production is still able to easily compete with 3D printing. One reason for this is that industrial grade 3D printing requires more energy per unit than traditional industry. nine0003

How 3D printing could be used in mass production

3D printing technology could improve over the next 10 to 15 years to the point where it can compete with industrial production. This can be compared to how personal computers took over large electronic computers in less than 10 years.

This can be compared to how personal computers took over large electronic computers in less than 10 years.

3D printers still have a long way to go in order to take their place among the must-have household gadgets. nine0003

You will be able to make toys (like McDonalds Happy Meal), but hardly anyone will like having to buy a device for $300 or $400 (the price range of cheap modern 3D printers) in order to make such toys themselves. For this to happen, print quality needs to go up and the price of the device goes down.

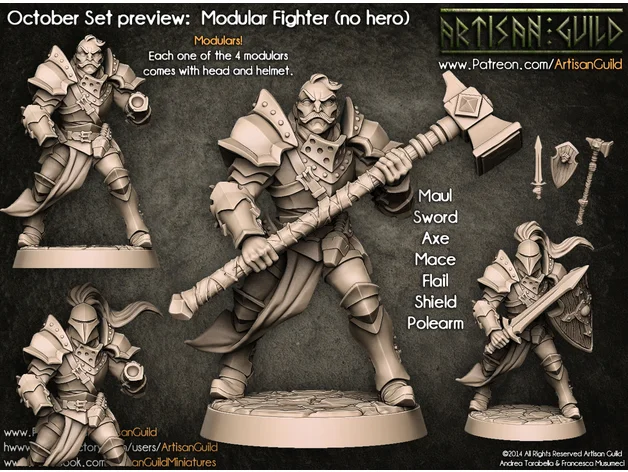

However, 3D printing is still able to compete with factory-made products. 3D printing allows the customer to customize the final product design and have it produced on site immediately. For example, toy stores may someday be able to offer a custom doll with unique characteristics based on a 3D scan of a customer's face or body. (One company (3D Systems) is already offering custom 3D printed Star Trek figurines.) nine0003

Even a savvy engineer can construct many simple 3D printable pieces that will snap together as easily as Lego bricks to create larger or more complex objects such as chairs and cabinets. It could be called a 3D printed version of IKEA furniture that needs to be assembled by yourself.

It could be called a 3D printed version of IKEA furniture that needs to be assembled by yourself.

Order and print anywhere

The ability to print anything, almost anywhere, gives 3D printing a huge advantage over factories. The military in the US has recognized this advantage by placing 3D printers on ships and in remote battlefields in order to recreate equipment prototypes and possibly someday make vehicle replacement parts. nine0003

Global shipping company DHL is already thinking about how 3D printing will impact the way and where you shop for products in the future. According to a 2012 DHL report, the full opportunity for a "customizable lifestyle" scenario is given to 2050. It will be a world in which 3D printing devices in homes or local shops will replace the mass production industry in most cases. In such a world, only raw materials and digital developments will cross national borders. nine0003

A small glimpse of this future can already be seen at Kraftwurx. It is a Houston-based company that operates in the digital marketplace with orders for simple 3D printed products (such as metal jewelry and plastic figurines) around the world. The Kraftwurx network consists of more than a hundred 3D printing companies scattered around the planet: this allows buyers and sellers to save on international shipping and paying duties on imported goods.

It is a Houston-based company that operates in the digital marketplace with orders for simple 3D printed products (such as metal jewelry and plastic figurines) around the world. The Kraftwurx network consists of more than a hundred 3D printing companies scattered around the planet: this allows buyers and sellers to save on international shipping and paying duties on imported goods.

Breakthroughs in 3D printing technology

This future may become even closer as 3D printing technology begins to overcome its current limitations. Companies involved in 3D printing continue to work on making 3D printers cheaper and better. Better software is allowing more people to create and share designs for 3D printing online, both for free and for sale.

So what does all this mean right now? A printed watch strap or shower head that you can make at home is not yet comparable in quality or aesthetics to the same products you can buy at your local store. But if you have the time, money, and patience to invest in a 3D printer, then you can start saving money today (if you're happy with the quality of the 3D print). nine0003

nine0003

Will consumers be willing to continue paying $50 for an iPad stand when they can print it themselves for $1 or buy it (pre-printed) for $2 on eBay?

How the 3D printing market grew in 2018 and what it means for business The purpose of the study is to provide a complete overview of the additive technology market, analyze trends and help companies build their business strategies. The report is based on a year-long survey of over 1,000 manufacturing executives and technicians around the world. nine0067

3D printing is a clear competitive advantage

No matter what industry you're in, 3D printing is a real competitive advantage. Thus, 93% of respondents consider 3D printing as a competitive advantage, and this figure continues to grow from year to year.

Do you see 3D printing as a competitive advantage?

It can also be noted that as 3D printing is now being used in a wide variety of industries, it is becoming increasingly important to stay competitive. Thus, the majority of respondents noted that their competitors also use 3D printing - in 2018 the number of such answers was 74% against 59% in 2017.

Thus, the majority of respondents noted that their competitors also use 3D printing - in 2018 the number of such answers was 74% against 59% in 2017.

This once again confirms that more and more companies include additive manufacturing in their strategy; in many industries, this is already a reliable and common manufacturing or prototyping process.

Do your competitors use 3D printing?

When it comes to companies' ROI in 3D printing, 46% of respondents said that ROI increased in 2018, while 49% of respondents said it was almost the same as the previous year. This is a stable result, professional additive manufacturing users are satisfied with their investment in 3D printing. nine0003

What is the return on investment in 3D printing in your company?

Harnessing the full potential of 3D printing for a variety of applications

In 2018, companies were more inclined to invest in 3D printing. Professionals, in fact, are beginning to use this technology to solve a wider range of problems, expanding the number of areas in which additive manufacturing is being introduced.

Professionals, in fact, are beginning to use this technology to solve a wider range of problems, expanding the number of areas in which additive manufacturing is being introduced.

3D printing applications

As in 2017, 3D printing is mainly used for prototyping, manufacturing and prototyping. There are no big changes here, but at the same time, companies around the world are more inclined to use 3D printing for several purposes at once. It can be noted a higher degree of integration of 3D printing in various fields of activity of companies. Thus, the share of enterprises operating on the principle of "first - 3D printing" has grown from 15% to 22%!

Integration

Businesses are taking full advantage of this cutting-edge technology and using it without hesitation in a variety of applications.

Which departments benefit the most from additive manufacturing?

As in 2017, 3D printing is mainly used for R&D, design and manufacturing purposes. The share of use of 3D printing by R&D departments is 46%, by design departments - 43%, and the share of additive technologies used directly in production is 41%. nine0003

The share of use of 3D printing by R&D departments is 46%, by design departments - 43%, and the share of additive technologies used directly in production is 41%. nine0003

As for the benefits of 3D printing, (although respondents cite cost reduction and reduction of production time as one of the main reasons for using additive manufacturing), a significant role for 48% of them also plays the ability to create products with complex geometries.

Benefits of 3D printing

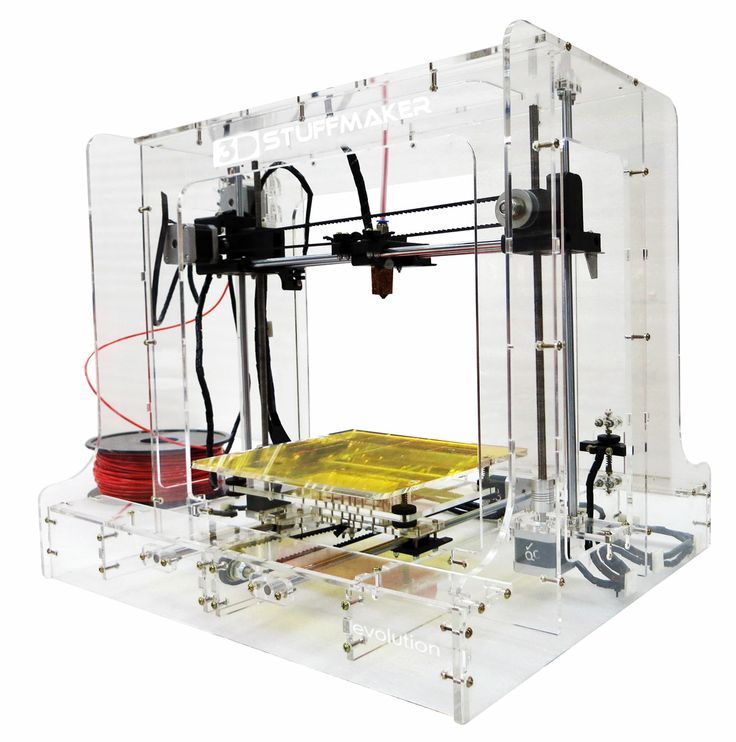

Businesses buy more 3D printers but still use 3D printing services

We clearly see that more and more companies are making the decision to purchase 3D printers. Thus, the majority of respondents have their own 3D printer (66%), and 44% have more than one. In 2017, 53% did not own a single printer, and only 28% owned two or more printers. nine0003

Does your company have its own 3D printer?

Most of the respondents own FDM printers (75% of those who own a 3D printer), which is quite justified since this is the cheapest type of 3D printer. Additive plants of this type are also easier to use. SLA printers are in second place (29%), and only 15% of respondents have printers using SLS technology.

Additive plants of this type are also easier to use. SLA printers are in second place (29%), and only 15% of respondents have printers using SLS technology.

Thus, consumers are obviously less inclined to purchase professional 3D printers such as SLS printers due to their higher price and complexity. However, this type of printer has a much larger number of enterprises than in 2017 (8%), while the share of FDM printers has decreased (85% in 2017), which indicates an increase in the professional level of this market, even in terms of view of acquired technologies. nine0003

When it comes to metal 3D printing, DMLS printers are the most common (16%). Only 4% of respondents have additive installations based on SLM technology. At the same time, the share of enterprises with metal 3D printers has increased significantly (2017 figures: 1% for DMLS printers and 2% for SLM printers).

What type of 3D printer do you use?

Do you use other digital production technologies?

What about 3D printing services?

For example, 38% of respondents use SLS technology, but only 15% of them have their own SLS printer. This suggests that companies are making extensive use of professional 3D printing services, giving themselves access to additive manufacturing technologies that they do not have.

This suggests that companies are making extensive use of professional 3D printing services, giving themselves access to additive manufacturing technologies that they do not have.

Top 8 changes companies need to make to get the most out of 3D printing

- Improving the level of qualifications and training of employees.

- Marketing and communications.

- Investments in 3D printers.

- Reduce the cost of 3D printing.

- Increased sales.

- Increasing the integration of 3D printing in the company's areas of activity.

- Attraction of financing.

- Improving corporate culture and organization.

According to survey participants, in order to get the maximum benefit from 3D printing, they, first of all, need to improve the skills and training of their employees. Indeed, it is often the lack of training in additive manufacturing technologies that is the factor that prevents enterprises from fully using 3D printing. Many point to the need to change the corporate culture and organization. nine0003

Many point to the need to change the corporate culture and organization. nine0003

There are also many changes to be made in the area of marketing, sales and profits. Respondents said that in order to get the most out of the use of additive technologies, it is important to invest more in marketing activities related to 3D printing, as well as look for new ways to generate income, either by increasing sales or by attracting financing.

Top 7 trends that will have a significant impact on 3D printing

- Cost reduction.

- Innovations in the field of materials.

- Metal 3D printing.

- Speed.

- 3D printing in medicine and bioprinting.

- Quality and precision.

- 3D printed for mass production.

The trend, which is mentioned much more often than others, from year to year remains the reduction in costs. This is understandable, as reducing the cost of 3D printing means making the technology easier to use. Also, metal 3D printing is still among the most influential trends. nine0003

Also, metal 3D printing is still among the most influential trends. nine0003

Compared to 2017, respondents were much more likely to emphasize the need for material innovation, due to the growing importance of material supply and cost.

Another trend that has been cited more frequently is 3D printing for mass production, as it is increasingly becoming a full-fledged manufacturing process used to make final products. This also leads to the fact that speed and quality of workmanship begin to play an increasingly important role. nine0003

The significant decline in the role of personal 3D printing is understandable, as it confirms the upward trend in the professional level of this market.

Industry statistics: aviation industry

Among the aviation industry, there are practically no newcomers to the field of 3D printing (unlike other industries). For example, 59% of respondents working in the aviation industry have qualifications at the specialist level and 38% have an average level of knowledge in 3D printing. Obviously, these companies have mastered additive technologies quite well and are more capable of implementing technical projects in their industry. nine0003

Obviously, these companies have mastered additive technologies quite well and are more capable of implementing technical projects in their industry. nine0003

How would you rate your skill level in 3D printing?

While other industries use AM more for prototypes and prototypes, the aviation industry uses 3D printing mainly for manufacturing, with 64% of respondents using 3D printing for this purpose, which is much more than than in other industries.

For what purpose do you use 3D printing?

This shows that the technology is advancing and already allows the creation of technical details for similar industries.

54% of respondents working in the aviation industry increased their revenues by 1-50%, while the overall share of companies that increased their revenues was 71%. This looks quite promising and suggests that 3D printing provides real financial benefits to such companies using additive technologies for manufacturing.