3D printer aerospace

3D printing for aerospace and aviation

How does 3D printing accelerate innovation in the aerospace and aviation industry? In this article, we explain how 3D printing and additive manufacturing are commonly used in aerospace and how they improve prototyping and end-use part production for these industries.

3D printing is a clear fit for many prototyping and end-use applications within the aerospace and aviation industry. Parts produced via additive manufacturing can be stronger and lighter than those made using traditional manufacturing.

Aerospace was a very early adopter of 3D printing and still continues to contribute heavily to its development. Companies in this industry began using 3D printing in 1989, and in 2015, aerospace accounted for 16% of additive’s $4.9B global revenue.

In this article, we explore how 3D printing has made an impact on the aerospace industry. We go over design requirements for parts used in airplanes and give design recommendations for common and more niche aerospace and aviation applications. As well, we cover the best materials for 3D printing parts for this industry and examine one of our favorite case studies.

Designers and engineers creating new products in aerospace and aviation can implement 3D printing at all stages of the design workflow. Let’s break down all the major stages.

Design communication

Designs in the aerospace industry often begin as concept models showcasing a component of an aircraft. These are often also regularly used for aerodynamic testing, which is of critical importance for aerospace. SLA and Material Jetting are used to produce high detail and smooth scale models of aerospace designs. Accurate models allow design intention to be clearly communicated and showcase the overall form of a concept.

Validation

Prototyping using 3D printing is now commonplace in the aerospace industry. From a full-size landing gear enclosure printed rapidly with low-cost FDM, to a high-detail, full-color control board concept model, there is a 3D printing process suited to every prototyping need. Engineering materials for 3D printing also allow for full testing and validation of prototype performance.

Engineering materials for 3D printing also allow for full testing and validation of prototype performance.

Pre-production

One of the areas where 3D printing has been most disruptive and valuable is the production of low-cost rapid tooling for injection molding, thermoforming and jigs and fixtures. Within aerospace, this allows for tooling to be quickly manufactured at a low cost and then used to produce low to medium runs of parts. This validation mitigates the risk when investing in high-cost tooling at the production stage and can also provide production components for quantities up to 5,000 to 10,000 parts.

Production

Production volumes in the aerospace industry can reach more than 70,000 parts per year, so 3D printing has predominantly been used in the past as a prototyping solution rather than the manufacturing of end-use parts.

Today, improvements in the size of industrial printers, the speed they are able to print at and the materials that are available all make 3D printing a viable option for more medium-sized production runs, particularly for high-end interior build-outs.

Customization

3D printing technologies significantly impact the aerospace industry when a substantial improvement in aircraft performance can justify the cost of highly complex one-off components.

The average corporate aircraft travel 75,000 miles per month and a single component that was designed and manufactured with 3D printing can reduce air drag by 2.1%, reducing fuel costs by 5.41%. And that’s just the impact of one 3D-printed part.

Parts can be tailored to a specific aircraft (custom, lightweight bracketry) or type of aircraft (cargo, passenger or even helicopter). 3D printing also provides part consolidation and topology optimization of many custom aerospace components.

How is 3D printing used in aerospace engineering?

Jigs & Fixtures

Big benefits exist for several more mundane 3D printing applications, including the production of jigs and fixtures. For each individual aircraft, companies have hundreds of fixtures, guides, templates and gauges 3D printed, generally with 60 to 90 percent reductions in cost and lead time compared to other manufacturing processes.

Surrogates

Surrogates are placeholder parts used throughout production that represent components that are later installed in final assemblies. Surrogates are mainly used for training. NASA and several Air Force bases commonly use surrogate parts on the production floor.

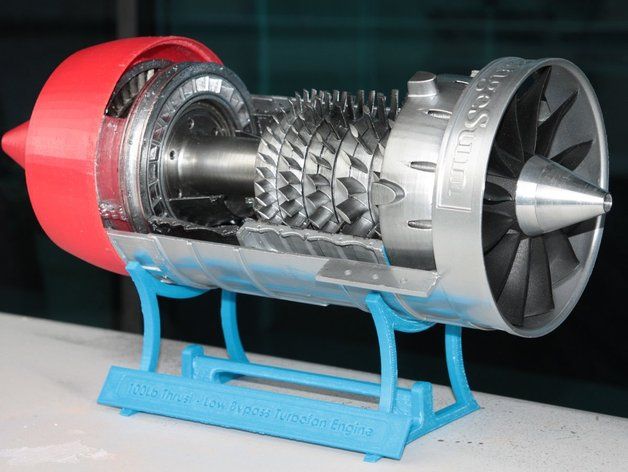

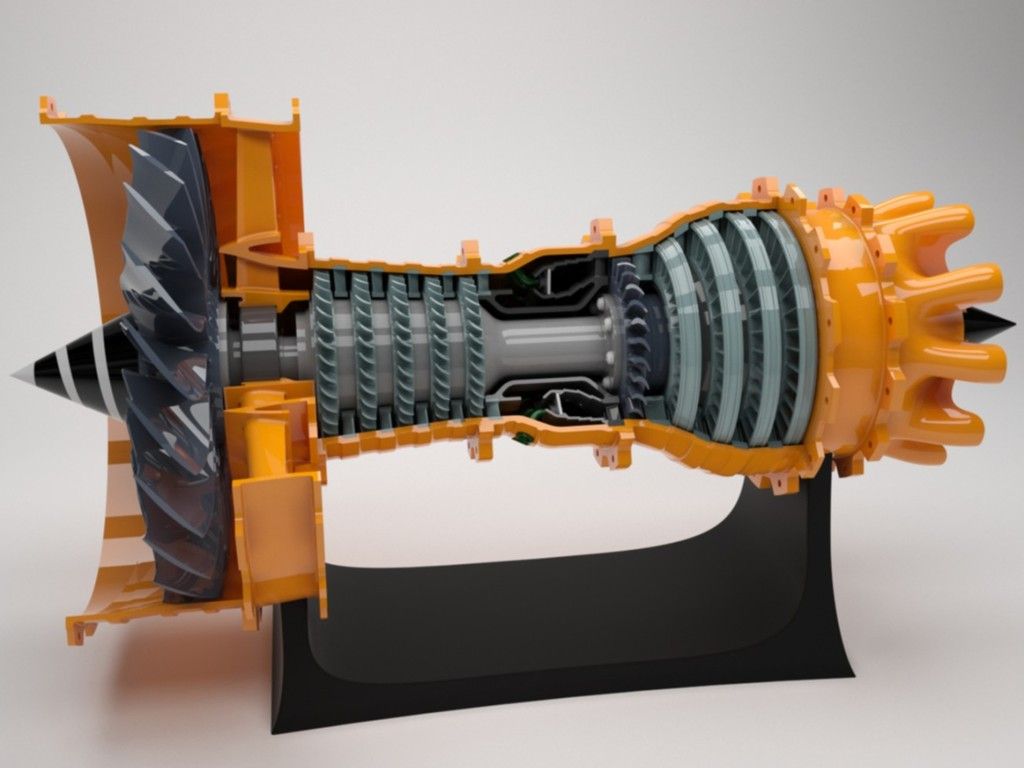

This model of a jet engine was 3D printed for educational purposes. Image courtesy of JetX.Mounting brackets

3D printing is commonly used to manufacture structural, low-volume metal brackets (with DMSL/SLM) that mount complex life-saving systems to the interior wall of a plane.

High detail visual prototypes

3D printing with Material Jetting is able to produce multicolor designs with a surface finish comparable to injection molding. These visually appealing models allow designers to get a greater understanding of the form and fit of a part before making important production decisions.

This highly accurate method of prototyping is also ideal for aerodynamic testing and analysis, as the surface finish you get with 3D printing is often representative of a final part.

3D printing is used routinely to manufacture aerospace components that rely on aesthetics over function, such as door handles and light housings to control wheels and full interior dashboard designs.

How does 3D printing improve aerospace manufacturing?

Geometric design freedom

Aerospace applications make use of advanced engineering materials and complex geometries in an attempt to reduce weight while improving performance. Aerospace parts frequently include internal channels for conformal cooling, internal features, thin walls and complex curved surfaces.

3D printing is capable of manufacturing such features and allows for the fabrication of highly complex and lightweight structures with high stability. This high degree of design freedom enables the topological optimization of the parts and the integration of functional features in a single component.

Also, certain 3D printing technologies, such as SLS, DMSL/SLM and Binder Jetting, are capable of small batch production at reasonable unit costs.

Consolidating assemblies into a single part

The design freedom you get with the 3D printing process also helps to consolidate multiple parts into a single component. This leads to weight savings (and thus cost reduction) and also reduces the amount of inventory kept at any time.

Surface finish

Having the right surface finishes is critical for the aerospace industry, and 3D-printed parts can be post-processed to a very high surface finish. Some technologies, such as Material Jetting , can produce parts with a smooth, injection-molding-like finish off the printer with little post-processing needed. High-performance metal parts produced with DMSL/SLM or low-cost metal parts produced with Binder Jetting can also be smoothed and polished (or even CNC machined) after printing to improve their accuracy and surface finish.

Part orientation

For functional parts that will bare load, part orientation in the build platform is very important. Due to the layer-by-layer nature of 3D printing, most parts will have anisotropic mechanical properties and will be weaker in the Z direction. This should be taken into consideration during the design process.

Due to the layer-by-layer nature of 3D printing, most parts will have anisotropic mechanical properties and will be weaker in the Z direction. This should be taken into consideration during the design process.

Support structures

Support structures are used in 3D printing to provide a solid base for depositing material above overhangs or at walls with steep angles (above 45 degrees). Support is also crucial in metal 3D printing, as it anchors the parts in the build plate and protects against warping.

The areas printed on supports will have a lower surface finish and some marks from the support removal. If this is suboptimal for your parts, there are processes that do not require support structures, such as SLS and Binder Jetting.

What are the best materials for 3D printing aerospace and aviation parts?

Check out this table for a more in-depth comparison of materials used to 3D print custom aerospace and aviation components.

| Application | Example part | Requirements | Recommended Process | Recommended Material |

|---|---|---|---|---|

| Engine compartment | Tarmac nozzle bezel | Heat resistant functional parts | SLS | Glass-filled Nylon |

| Cabin accessories | Console control part | Customized functional knobs | SLA | Standard Resin |

| Air ducts | Air flow ducting | Flexible ducts and bellow directors | SLS | Nylon 12 |

| Full size panels | Seat backs & entry doors | Large parts with smooth surface finish | SLA | Standard Resin |

| Casted metal parts | Brackets and door handles | Metal parts casted using 3D printed patterns | SLA & Material Jetting | Castable Resin or Wax |

| Metal components | Suspension wishbone & GE Jet Engine | Consolidated, lightweight, functional metal parts | DMLS/SLM | Titanium or Aluminum |

| Bezels | Dashboard interface | End use custom screen bezels | Material Jetting | Digital ABS |

| Lights | Headlight prototypes | Fully transparent, high-detail models | Material Jetting & SLA | Transparent Resin |

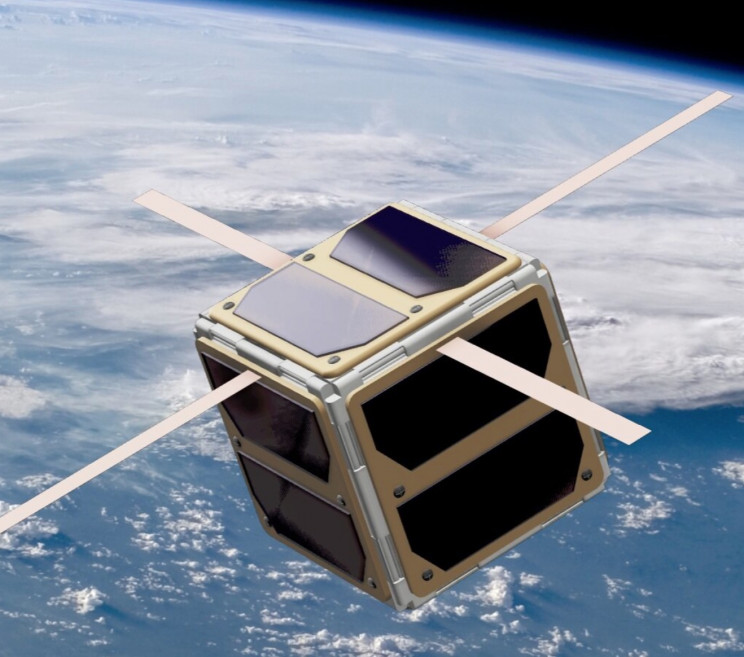

3D printing in practice: Printing parts for satellites

Satellite designs include geometrically specific brackets that link the body of the satellite with reflectors and feeder facilities mounted at each end. Manufacturing these critical brackets comes with two distinct challenges.

Manufacturing these critical brackets comes with two distinct challenges.

These brackets must affix reflector and feeder facility components securely to the body of the satellite. As well, these brackets must be able to withstand the stress of insinuating against temperatures ranging from -170 to 100 degrees celsius. Very few materials can meet the requirements for the amount of stress these brackets endure.

This satellite frame was printed using titanium. Image courtesy of Airbus.Engineers at Airbus overcame these challenges by 3D printing these brackets using titanium. By opting to manufacture the brackets the additive way, the engineers at Airbus cut down on material waste, consolidated parts (making assembly easier and less labor-intensive), optimized part geometries and ended up with lighter-weight components. 3D printing helped reduce costs to produce parts and will save fuel over the life cycle of the satellites thanks to the lighter weight of the components.

Ready to make custom parts faster & lighter?

Explore our 3D printing capabilities Get a free, instant quote today

Ready to transform your CAD file into a custom part? Upload your designs for a free, instant quote.

Get an instant quoteAerospace 3D Printing | Markforged

Aerospace 3D printing: the simplest way to fabricate advanced composite and metal parts

From on-demand MRO and spare parts in commercial aviation to innovation in Urban Air Mobility, aerospace industry leaders are improving responsiveness to rapidly shifting supply chains and labor availability with Additive Manufacturing.

The Digital Forge gives modern manufacturers the simplest way to build with materials they already know. Fabricate end-use carbon fiber composites unattended, overnight. Skip multi-week lead times and expedite fees for metal and composite prototypes, tools, and fixtures.

For the first time, Markforged supports ULTEM™ 9085 Filament on the Digital Forge. The FX20 3D printer can reinforce ULTEM™ Filament with continuous Carbon Fiber, bringing composite strength to an aerospace ready material. Traceable, flight-ready Onyx FR-A and Carbon Fiber FR-A provide another flame retardant printing solution.

*The ULTEM™ and 9085 trademarks are used under license from SABIC, its affiliates or subsidiaries.

Traceable, Purpose-Built Materials

ULTEM™ 9085 Filament, Onyx FR-A and Carbon Fiber FR-A are all lot-qualified, flame-retardant materials. Each is purpose-built for the requirements of the aerospace, transportation and automotive industries. FR-A materials establish lot-level material traceability and pass the test suite necessary for qualification under 14 CFR 25.853 for most 3D-printable parts. Onyx FR-A and Carbon Fiber FR-A as printed on the Markforged X7 are undergoing qualification through the NCAMP process.

Each is purpose-built for the requirements of the aerospace, transportation and automotive industries. FR-A materials establish lot-level material traceability and pass the test suite necessary for qualification under 14 CFR 25.853 for most 3D-printable parts. Onyx FR-A and Carbon Fiber FR-A as printed on the Markforged X7 are undergoing qualification through the NCAMP process.

Prepared for Regulated Applications

Markforged recognizes the advanced regulatory and functional requirements of the aerospace industry. Traceable materials, software version-locking for parts, Blacksmith in-process laser inspection, and ongoing NCAMP qualification for Onyx FR-A and Carbon Fiber FR-A on the X7 provide the foundations for accelerating the path from digital art to flying part.

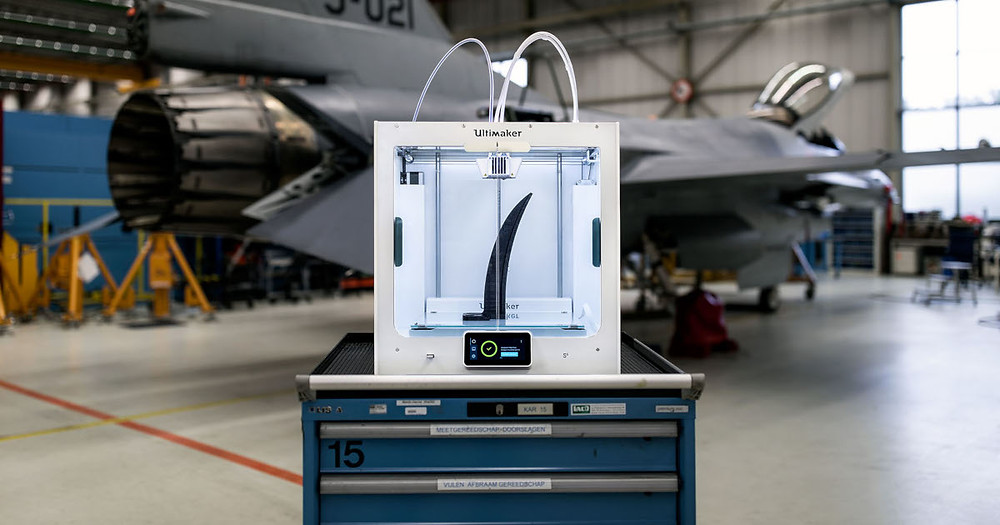

On-Demand, Distributed Manufacturing

Turn the supply chain into a competitive advantage with distributed manufacturing at bases, airports, and maintenance depots. With a digital library and on-demand fabrication, get MRO and spare parts where and when you need them with the only additive manufacturing platform built to go anywhere.

With a digital library and on-demand fabrication, get MRO and spare parts where and when you need them with the only additive manufacturing platform built to go anywhere.

Join industry leaders by investing in additive

“In aerospace, it's important to have quality parts we can adapt on the fly to make any changes the customer requests.”

Jeff Pike, VP of Engineering, Cabin Management Solutions (CMS)

ULTEM™ 9085 Filament: Aerospace Ready Polymer

Long used as a high value aerospace polymer, ULTEM™ 9085 Filament is now printable on the FX20. Its superior performance in flame, toxicity, and smoke (FST) tests and its high strength make it a choses material for aircraft and spacecraft alike.

The FX20 is Markforged’s new flagship 3D printer — capable of reinforcing ULTEM™ 9085 Filament with continuous Carbon Fiber.

Onyx FR-A and Carbon Fiber FR-A:

Traceable, Flame-Retardant Composites

Purpose-built for the requirements of the aerospace, transportation and automotive industries, FR-A materials establish lot-level material traceability and pass the test suite necessary for qualification under 14 CFR 25. 853 for most 3D-printable parts.

853 for most 3D-printable parts.

Onyx FR-A and Carbon Fiber FR-A as printed on the Markforged X7 are undergoing qualification through the NCAMP process.

Learn More about FR-A Materials

Digital Forge for 3D printed aerospace tooling

JJ Churchill trusts the precision and unmatched strength of Markforged’s fiber-reinforced Onyx material. Find out how JJC and over 100+ of the world’s top manufacturers use the Markforged platform to dream bigger and accomplish more.

“

Once we realized the directional strength properties available with the Markforged products, we haven’t used anything else.”

– Karan Singh, Manufacturing Engineer, JJ Churchill

Read the Case Study

Drill templates are a common tool used across many industries in manufacturing and are heavily relied on in aerospace tooling. When a drilling operation has to be performed by hand, custom tooling needs to be developed to simplify the process and make it repeatable. A drill template tool makes a cumbersome drilling operation as simple as locating the tool and then drill the hole.Talk to an Expert

Why invest in Markforged 3D printers?

- Secure cloud infrastructure enables on-demand manufacturing at the point of need

- Low overhead, facilities requirements, and cost of ownership for continuous carbon fiber composite solutions

- Cabin-quality surface finish without additional post-processing

- Ready for decorative finishes (plating, veneer, paint)

- NCAMP qualification is underway for traceable, flame-retardant composite printing materials Onyx FR-A and Carbon Fiber FR-A

High-value aerospace applications

- Lightweight cabin components

- Brackets, harnesses, and sensor mounts

- Precision inspection tooling

- Workholding

- Functional prototypes

Featured content

3D technologies in the development of the aerospace industry

Aerospace industry

Author: Semyon Popadyuk

Author: Semyon Popadyuk

The main advantages of additive technologies for aerospace industries | Software potential | How business models will change

Additive technologies, which seemed like science fiction a few decades ago, are now successfully used in various fields. One of the most promising markets for their application is the aerospace industry, for which the problem of reducing production and time costs is especially acute. In addition, it is this industry that is developing due to revolutionary scientific and technological achievements. The possibilities of 3D technologies are changing on such a large scale that manufacturers will have to rethink their usual business model. New strategies are just emerging, but industry giants — NASA, SpaceX, Airbus, Boeing — are already investing billions in 3D printing of prototypes, tooling and engine parts for aircraft and spacecraft.

One of the most promising markets for their application is the aerospace industry, for which the problem of reducing production and time costs is especially acute. In addition, it is this industry that is developing due to revolutionary scientific and technological achievements. The possibilities of 3D technologies are changing on such a large scale that manufacturers will have to rethink their usual business model. New strategies are just emerging, but industry giants — NASA, SpaceX, Airbus, Boeing — are already investing billions in 3D printing of prototypes, tooling and engine parts for aircraft and spacecraft.

Examples of improved production efficiency in two promising projects by Airbus and SpaceX

Key benefits of additive technologies for aerospace manufacturing

- Flexibility : 3D printers are used to create components with complex geometries that cannot be made using traditional manufacturing processes. We can confidently talk about the creation of more and more perfect designs in the future.

The materials used in 3D printing (alloys, composites, polyamides, etc.) make it possible to produce unique products.

The materials used in 3D printing (alloys, composites, polyamides, etc.) make it possible to produce unique products. - Additive technologies successfully solve the key task for the industry - weight reduction of aircraft . A 3D printer is an ideal tool for manufacturing topologically optimized components that increase payload and reduce fuel costs.

- Development of new and modernization of existing products requires less time and significantly reduces the production cycle .

- Economy : When applied to highly specialized tasks, a 3D printer allows you to use fewer parts, materials and additional equipment, while drastically reducing the cost of low-volume components. With the development of technology, the cost of the finished product is falling, and the prices of printers have decreased by an order of magnitude over the past few years. According to forecasts, the cost of consumables will also decrease.

- Finally, additive technologies in some cases make it possible minimize waste (compared to traditional processes) and improve the environmental and energy efficiency of aircraft.

GE aircraft engines use 3D printed turbines

Software potential

3D printing capabilities will expand with software development. With the help of modern software, it will be possible not only to quickly create a complex model, but also to automate the production process. Interactive models will make it possible to monitor and correct the slightest flaws in real time, calculate the safety and efficiency of all operations, and help you understand how equipment will behave in emergency situations. Thanks to advanced software technologies, suppliers, manufacturers and designers will work in a single information space and, in fact, communicate in a universal 3D language. To date, most of the tests are carried out in real conditions, but in the coming decades, software will be able to solve more and more problems.

How business models will change

So, additive technologies are an inevitable choice for a competitive enterprise. Today, most companies that implement them achieve reductions in production costs and product development time without changing the supply chain and assortment. In the medium term, a strategy that involves the development of more complex as well as new, highly functional products will come to the fore, which will lead to changes in the supply chain. And finally, in the long term, companies will be able to significantly increase the manufacturability of production and at the same time eliminate intermediaries from the supply chain. All of this will allow radically new, more efficient business models to be applied.

iQB Technologies experts have unique knowledge and experience to implement projects related to the introduction of additive technologies in a variety of industries, including the aerospace industry. We are ready to answer your questions, please contact us by phone. +7 (495) 272-81-50 or email [email protected].

+7 (495) 272-81-50 or email [email protected].

Article published on 05/25/2017, updated on 04/07/2021

Aerospace 3D Printing - Eplus3D

Brief introduction

Additive manufacturing or 3D printing is the process of creating 3D objects or products layer by layer using 3D digital models. 3D printing is the opposite of traditional manufacturing processes (such as machining) that start with blocks of material and scrape off unwanted materials. 3D printing can also start from an empty platform. If necessary, materials can be added to the empty platform in a controlled manner until the final part is produced. You can use 3D CAD software to create a 3D model from scratch, or you can use reverse engineering laser scanning to create a 3D model.

Advantages of 3D printing in the aerospace industry

Aerospace is one of the few industries where the weight of components really matters. The industry is always looking for stronger, lighter and more durable components. Today's 3D printing technology opens up new possibilities for solving these problems. By removing the limitations associated with traditional manufacturing processes, which are inherently time consuming and limited by raw material selection, lamination provides the opportunity for many aircraft design related improvements. For commercial airliners, even a small reduction in weight can significantly reduce costs. For defense aircraft and spacecraft, stronger, lighter components provide better payloads. And, of course, for all types of aircraft, the lighter the components, the higher the speed and the higher the fuel efficiency.

Today's 3D printing technology opens up new possibilities for solving these problems. By removing the limitations associated with traditional manufacturing processes, which are inherently time consuming and limited by raw material selection, lamination provides the opportunity for many aircraft design related improvements. For commercial airliners, even a small reduction in weight can significantly reduce costs. For defense aircraft and spacecraft, stronger, lighter components provide better payloads. And, of course, for all types of aircraft, the lighter the components, the higher the speed and the higher the fuel efficiency.

i . Weight loss

Let's talk about numbers. Airliners of the A330 class typically consume about 0.035 l/seat/km, 261 seats and 233 tons of takeoff weight. It is assumed that the average total weight is about 200 tons, and the aircraft flies in the range of 200-800 km / day at a speed of 25-250 days / year. Thus, the total flight time of the aircraft is estimated at 100 million kilometers. If the aforementioned fuel consumption and passenger usage are added, the total fuel consumption is 1 billion liters of jet fuel, or about 5,000 liters per kilogram of flying mass.

If the aforementioned fuel consumption and passenger usage are added, the total fuel consumption is 1 billion liters of jet fuel, or about 5,000 liters per kilogram of flying mass.

i . Aircraft design improvements

Another benefit that 3D printing brings to the aerospace industry is improved aircraft design. As 3D printing software advances, engineers can optimize designs that especially benefit from the additive manufacturing process. These improvements improve engine efficiency, reduce drag, reduce aircraft quality, and reduce aircraft life cycle costs.

i . Improving the supply chain

Designing and manufacturing an aircraft is a complex task. Aircraft demand is characterized by long delivery times, long production schedules and production delays that can last for years. With the help of 3D printing, different components can be produced from different raw materials, increasing production efficiency and reducing delivery times in the supply chain.