Small batch 3d printing

Quick Tips: How To Get Started With Batch 3D Printing

Utilizing 3D printer time most efficiently is much easier once you start batch printing parts to maintain 3D printer uptime and minimize downtime.

Posted on April 9, 2020

by

Alec Richter

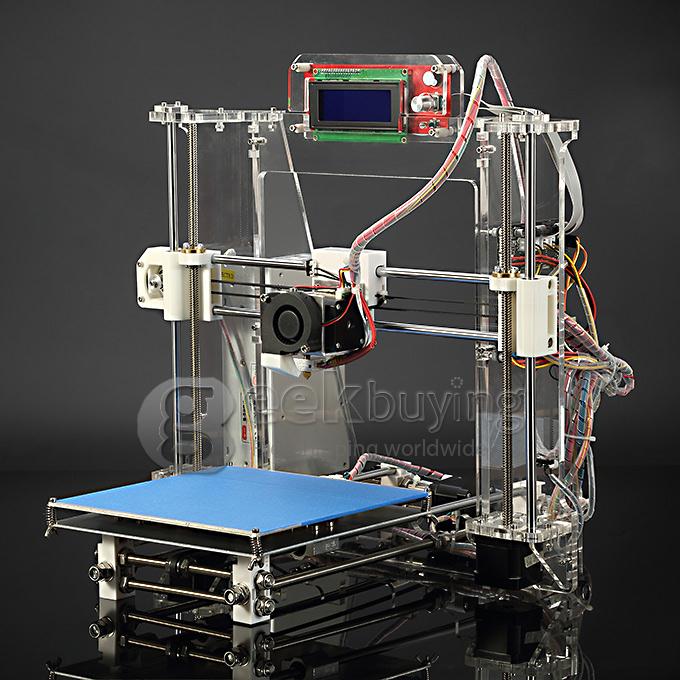

3D printers have widened the scope of what is able to be manufactured; from high-detail one-off 3D designs to small-production products, they have made it much easier to streamline the prototyping and manufacturing process for hobbyists and industrial designers alike. While 3D printers excel with the highly customized 3D models, they still fill the ever-present niche of a small-scale manufacturing device capable of producing consistent parts, that can even be iterated on the production line, for a fraction of the cost of injection molding; batch printing. With some careful tuning and considerations, every printer can be capable of batch printing and producing the same parts over and over with consistent results. Let’s get started!

Making the Right Choice

Before you even get started, it’s important to consider if batch printing is the right choice for you and your 3D models.

Pros:

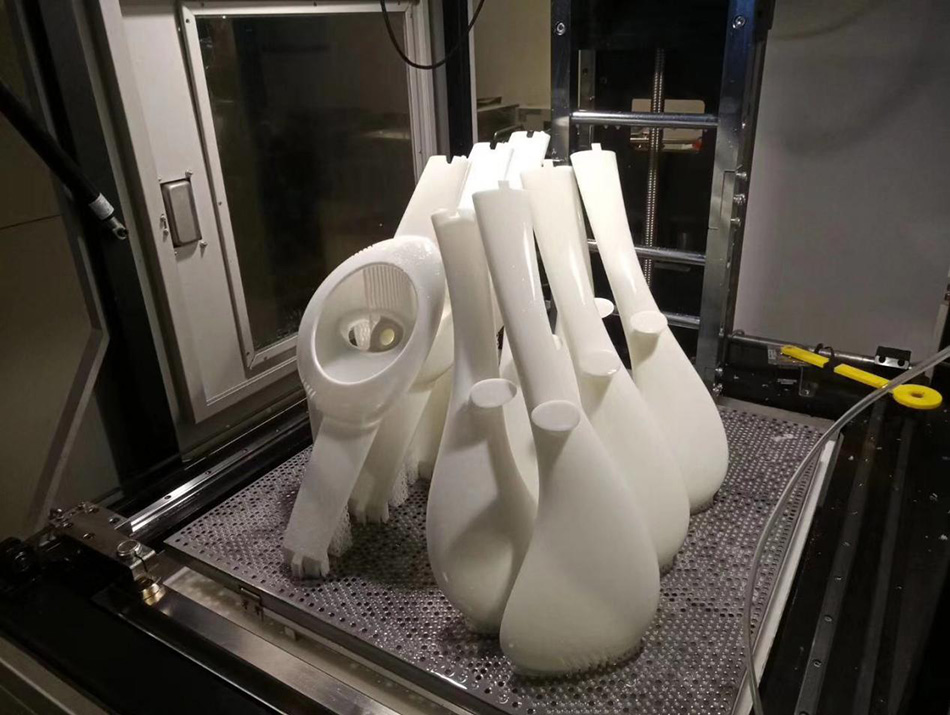

- By batch printing, you minimize downtime for your 3D printers. By starting a batch of prints at 4:30 before you head out the door for home, you can have a 16 hour print of 12 different parts continue and finish without your presence, and when you return in the morning, the print job is just finishing up and ready for you to pop off the parts and start another batch that will finish around 4:30 again.

- Some models have layers with a small cross-sectional area, which will be detected by the slicer and automatically slow down those layers to give the filament adequate time to cool down. By increasing the number of models on a print bed, you increase that layers cross-sectional area and speed up the print. Sometimes you can find that printing just two of the same part takes as much time as printing one!

- If you print by SD card or USB drive, you can have all your batches saved and organized by length of time to optimize your printing order.

And by printing untethered, you can copy and paste the same gcode to all your printer’s (as long as they are the same make and model).

And by printing untethered, you can copy and paste the same gcode to all your printer’s (as long as they are the same make and model). - Not only is downtime minimized but attention as well. Instead of getting up and swapping build plates, adding adhesive, or even just checking if your prints are finished you can focus on your other work, set a timer, and come check on the prints every so often, knowing that the print jobs are going to last 6 hours each.

Printing multiple copies of the same part can shave hours off of a project's printing time.

Cons:

- Failure rate is a bigger concern than with one part being printed at a time. If you have one part fail, no problem that’s only a couple hours and a little bit of filament. If one print starts warping or completely detaches from the build plate, you now how to gamble with canceling the print or leaving it and hoping the rest finish okay. Sometimes they do and that one only knocked a couple more off, and other times that one slip up cascaded into catching on another piece and layer shifting everything.

- Filament usage needs to be better monitored. Sure the spool looks and feels like it’s really full, but if you check the gcode you might find out your batch print is going to take 850g of filament. Running out of filament will cost a lot more in time and material than one part running out.

- A level bed is supremely important to your success. With one print and a slight skewed bed, you may not notice the skew, but with parts from edge to edge, it will quickly become apparent if the bed is not leveled correctly. With a tilted bed, parts will easily pop off and become a much bigger problem, as mentioned previously.

Part failure or print setting issues will present a bigger problem than in single-part 3D prints.

All that said, most of the big 3D printer manufacturers rely on batch printing in some form if they have 3D printed parts on their machines; Lulzbot calls their printer farm “The Cluster” and utilizes a form of Octopi to keep everything in line.

Preparations

Before you start batch printing, here’s a good checklist of things you can do to help your chances of success.

- Make sure your slicing profile is well-tuned. Any sort of retraction issues, zits, blobs, or under extrusion is going to compound as each part progresses, potentially creating one big build plate of wasted time. Take the time to check through our Top 10 Calibration Prints to see what we do to make sure our machines are ready for anything we throw at them.

- Over time the adhesive you use on your bed surface will need to be reapplied to keep parts sticking. If you use an adhesive like glue stick, Magigoo, or Stick Stick, completely clean any residue from the build plate (usually a quick splash in the sink and a credit card to squeegee off the glue works well), then without overdoing it reapply the adhesive in a crosshatch pattern on the entire bed.

- Check that your bed is level by running any bed leveling calibration wizard that your printer has or by printing out a large rectangle to cover the entire bed and adjust the bed’s level on the fly.

Or if your 3D printer has an automatic bed sensor it should be able to reliably print on a bed of any angle and maintain the same distance between the nozzle and the bed across the entire surface.

Or if your 3D printer has an automatic bed sensor it should be able to reliably print on a bed of any angle and maintain the same distance between the nozzle and the bed across the entire surface. - Keep track of your filament weight. If you followed along in our previous video, you should have started keeping track of your empty spool weight so you can know how much material you have on a spool at any time.

- Consider adding a filament sensor to your printer if it doesn’t already have one, as it can help mitigate but not remove the risk of running out of filament. Not all filament sensors are created equal and some can fail to trigger if the filament gets caught, jams in the hotend, or the trigger itself jams. Some manufacturers tape the end of the filament to their spools, which you won’t see until it’s too late and jammed itself in your printer.

- Does your 3D model have any thin parts you’re worried about tipping over? This may be a good time to add a brim to keep everything locked down.

Even if this adds more time to your post-processing than you’d like, it’s a trade-off to ensure a print sticks down and minimizing the failure rate the print job.

Even if this adds more time to your post-processing than you’d like, it’s a trade-off to ensure a print sticks down and minimizing the failure rate the print job.

Leveling the bed and wiping it clean with isopropyl alcohol (as shown here) are key steps in preparing a printer for batch printing.

Once you feel ready and prepared, start slicing and run a batch print that you can be nearby to keep an eye on in case anything isn’t working as expected. I would encourage you to wait until you have had a couple of successful batch prints with your 3D printer before batch printing unattended.

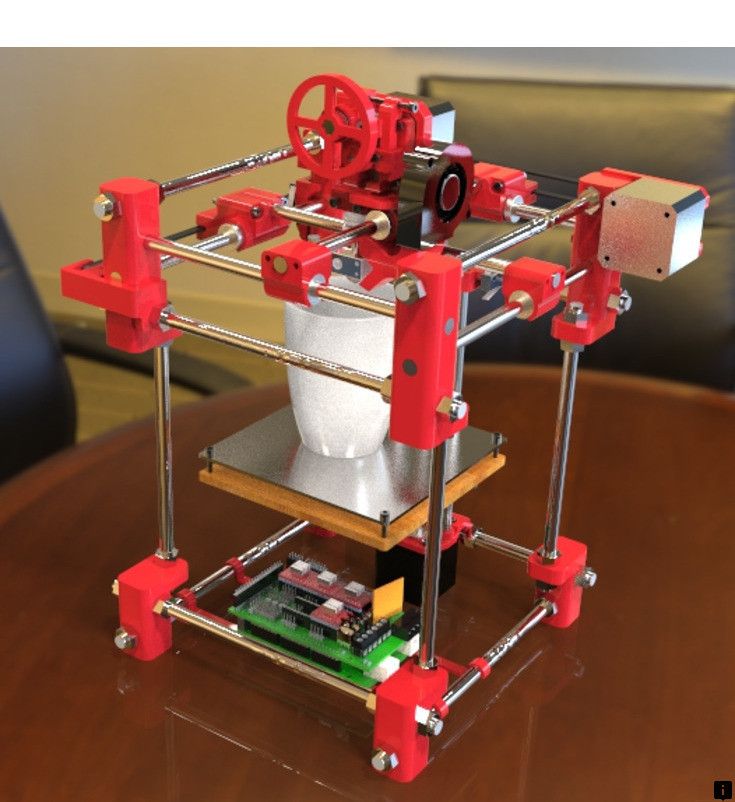

If you don’t have a printer that you can trust to batch print or are looking to find a new printer altogether, take note of any printers that have a large bed.

Single Extrusion and Traditional Dual Extrusion

The Craftbot XL is a great single-extrusion solution for batch printing with its huge build plate and print height, giving you a lot of freedom to batch print or print larger objects down the road. Dual extruder 3D printers that have both nozzles mounted to the same head like the Raise Pro2, Ultimaker S3 or S5, and the Lulzbot TAZ PRO can’t use both nozzles at the same time, so they are effectively single-extrusion 3D printers for batch printing, however, due to their large build plates and robust construction, printing a lot of parts at once is a common use case for these machines.

Dual extruder 3D printers that have both nozzles mounted to the same head like the Raise Pro2, Ultimaker S3 or S5, and the Lulzbot TAZ PRO can’t use both nozzles at the same time, so they are effectively single-extrusion 3D printers for batch printing, however, due to their large build plates and robust construction, printing a lot of parts at once is a common use case for these machines.

Dual Extrusion printers like the Lulzbot TAZ PRO are capable machines, but the dual nozzles do not offer any more utility than one nozzle while batch printing.

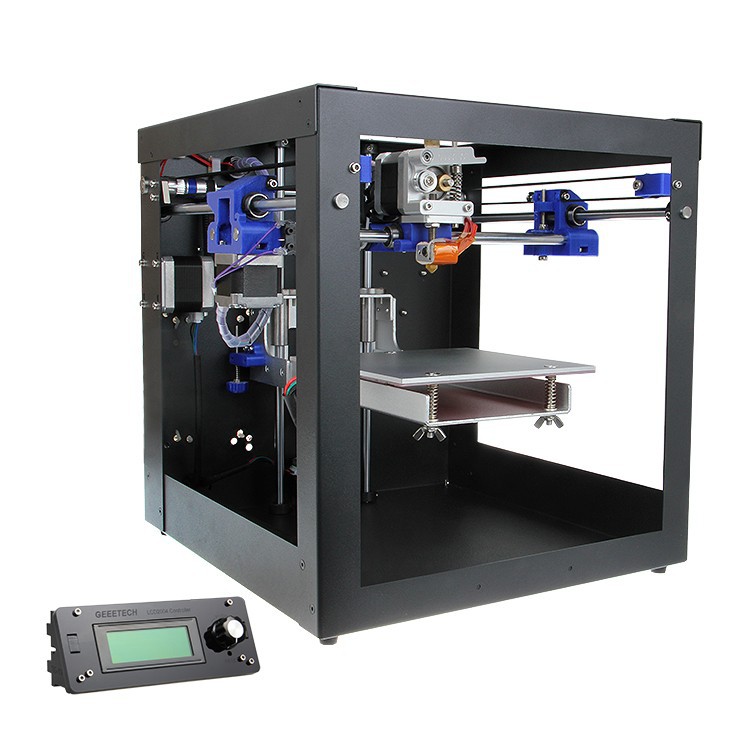

IDEX Batch Printers

The Craftbot Flow IDEX and IDEX XL, Raise E2, BCN3D Sigmax and Epsilon all feature IDEX toolheads, which means “Independent Dual EXtrustion.” Each of these printers has two nozzles, but they ride on different carriages, effectively putting two printers in the same chassis. Since each of these is on the same X-axis crossbeam, you are limited to printing in exact duplicates or mirror mode, however you are still able to use these two nozzles for separate dual extrusion printing with two colors, two materials, or one material and a support material.

IDEX 3D printers like the Craftbot FLOW IDEX XL (shown here) are able to print out twice the quantity of 3D prints as a single-nozzle 3D printer can in the same timespan.

If you’re in an industry or business that relies on 3D printing to create some part of a finished product, being able to maximize efficiency and uptime becomes a pressing issue, and hopefully with this quick tip you are one point closer to achieving the best your farm can be. Are you batch printing already and feel like I didn’t mention something that you find important to your production? I’d love to hear about it in the comments down below and educate both myself and other users. For those of you about to start your first batch print, best of luck!

Happy batch printing!

Article Tags

- 3D Printing

- Firmware

- 3D Design

- MatterControl

- Press Releases

- Small Business

- Automotive

- E3D

- Jewelry Making

- Engineering

- Entertainment Industry

- MatterControl Touch

- ESD Materials

- NylonX

- BCN3D

- Open Source

- Crafty Pen

- Digital Fabrication Anatomy

- How To

- Hardware and Upgrades

- Tips and Tricks

- Weekend Builds

- Top Ten

- Education

- Tech Breakdown

- Women in 3D Printing

- Project Ideas

- Advanced Materials

- Reference

- Pulse Dual Extrusion

- Product Spotlight

- Aerospace

- Jobs

- Military & Government

- Multi-Tool Machines

- Getting Started

- Healthcare

- How To Succeed With Any 3D Printing Material

- Creality3D

- Architecture

- 3D Printer Reviews

- Hacker of the Month

Related Products

View all related productsLow Volume Batch Production of 3D Printed Parts — 3D People UK

+ Do you offer volume discounts for 3D printing?Yes, we have a system for quantity price breaks. These discounts are automatically applied to our online quotation system when ordering 2 or more of the same file. The price breaks are as follows:

These discounts are automatically applied to our online quotation system when ordering 2 or more of the same file. The price breaks are as follows:

5% - 2+ Quantity

10% - 10+ Quantity

15% - 50+ Quantity

20% - 100+ Quantity

30% - 250+ Quantity

35% - 1000+ Quantity

Yes. Samples are produced on the same machines used for production and we will refund the sampling cost for batch production orders. To order a sample, please use our instant quote tool and purchase your design through our online system. So long as the file has not been altered, we can refund the sampling cost for batch orders above £2000 +VAT.

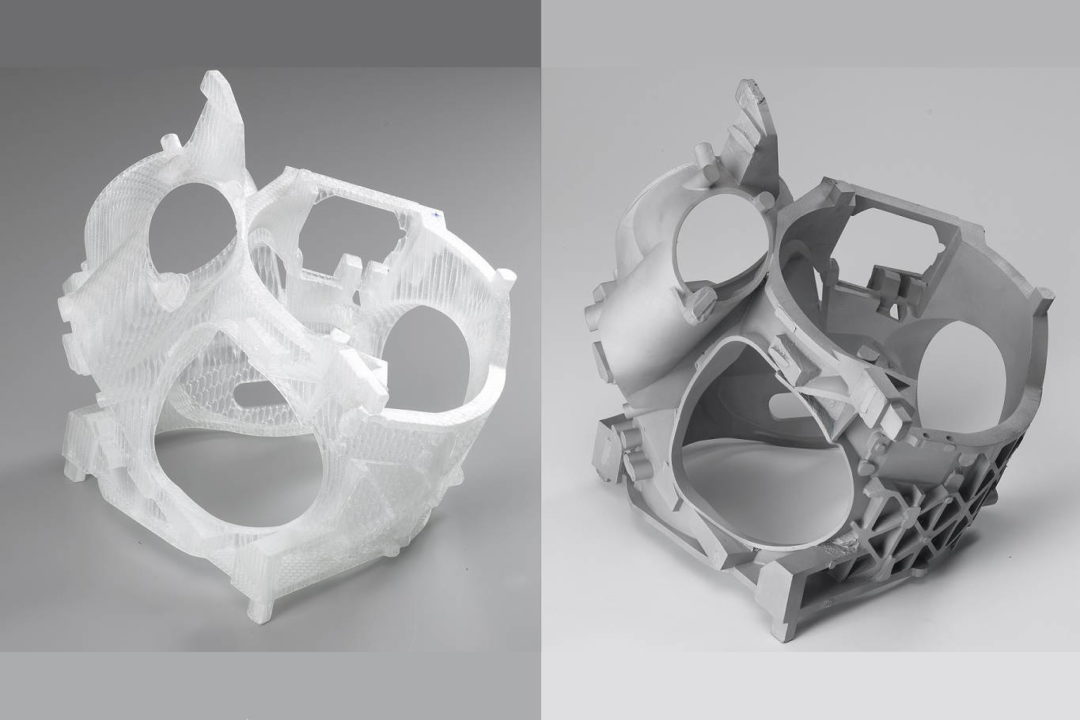

Sometimes, it is largely dependent on how many parts you are making. 3D printing is more affordable for low volumes of parts and injection moulding is cheaper for high volumes. Injection moulding requires a considerable initial investment to make the mould tools whereas 3D printing does not have any start-up costs. Once production has begun, the unit cost for injection moulding is generally cheaper than 3D printing.

We recommend using Nylon PA12 (SLS) for low volume production runs of small plastic components. PLA (FDM) is suitable for affordable manufacturing of medium sized parts.

+ Can I change the design after 3D printed production has already started?As no tooling is required for 3D printing, the design can be changed for no extra cost. We can not exchange parts that have already been manufactured but the updated design can be used for the remainder of the parts.

3D printing is only used for mass production when the product demands the technology's unique manufacturing capabilities. That is for complex geometries that cannot be made any other way such as Adidas Futurecraft. Or for bespoke products that are custom made to order such as Invisalign.

+ How can 3D printing be used in manufacturing?3D printing is used within the manufacturing sector for applications that require the technology's positive attributes.

Low volume batch production is economically viable for small plastic components as the large upfront tooling costs associated with injection moulding can be avoided.

Rapid production to fulfil urgent demand is possible with 3D printing as production can begin right away without complex design for manufacture requirements and tool set-up time.

Complex parts that cannot be made in any other way are manufactured using 3D printing.

Custom parts that are usually made to order are 3D printed as they require a short lead time and a good price for low volume.

Within the production line 3D printing is used to make tools, jigs and fixtures utilised by manufacturers to improve workflow within the factory.

Services of small-scale 3D Printing prices from 6 rubles / year | 3D Modeling

If you are a design company, a design office, an individual entrepreneur, a custom products manufacturing company, a designer, an engineer, an inventor, a small manufacturing company of any branch, an architectural company or a creative mind with your own idea, then PMK is definitely for you. Our company is able to provide exactly what you have been looking for - low prices for 3D printing, the shortest order execution times and excellent quality.

In the design workshop of Kupolov, you will not only get an excellent result, but also save a lot of money. Especially when it comes to complex parts, parts of mechanisms and functional elements of structures. Why is it so? It's very simple, let's look at two options for manufacturing spare parts.

Especially when it comes to complex parts, parts of mechanisms and functional elements of structures. Why is it so? It's very simple, let's look at two options for manufacturing spare parts.

Transfer the layout, if available, to the performer, or simply provide a live sample

Create a 3D layout using a specialized program

Send to print (offline process, which is fully controlled by the program)

Simple manual post-processing using chemicals and specialized tools

In the second method, despite the fact that we go through the same number of stages of work, there are obvious advantages:

You don't have to buy extra material, or rather, you don't think about finding and buying raw materials at all. This is already included in the cost of the work. And the type of material is selected by an experienced specialist, focusing on the needs and tasks of the client

The whole process, except for post-processing, is automated

The cost of filaments for printing is much lower than plastics for casting and iron Freedom of product shape, you don’t have to think about the capabilities of the machine, printing is strictly according to the layout and has no restrictions

Short lead times

Due to all these advantages and benefits, the cost of printing on a 3d printer is really affordable. It allows you to reduce the cost of purchasing certain parts by almost 50, and sometimes 70 percent.

It allows you to reduce the cost of purchasing certain parts by almost 50, and sometimes 70 percent.

Of course, the price of 3D printing depends on the product itself, plastic consumption, printing time and the selected material.

Kupolov's design workshop has set itself the task of making such a service as accessible and of high quality as possible. We spent a lot of time developing the database by the supplier of materials in order to make our offer the best on the market. Therefore, if you need to order 3D printing, we suggest contacting our specialists to calculate the cost. They will quickly calculate the cost, as well as conduct a detailed consultation.

Technologies do not stand still, every year new opportunities, materials, equipment appear. And what just recently seemed fantastic is now in service with manufacturing companies. One of the recent gains in the market, of course, is 3D printing. A wide range of materials, limitless options for sizes and shapes, make it more than in demand. But the maximum popularity is ensured by the possibility of piece and small-scale production. To get the right part, you do not have to run a whole workshop.

But the maximum popularity is ensured by the possibility of piece and small-scale production. To get the right part, you do not have to run a whole workshop.

You don't have to understand technology, get bogged down in complex drawings, and try to get the size millimeter by millimeter. In order to successfully complete the order of 3D plastic parts, it is enough to have a sample of the desired product, its drawing or sketch.

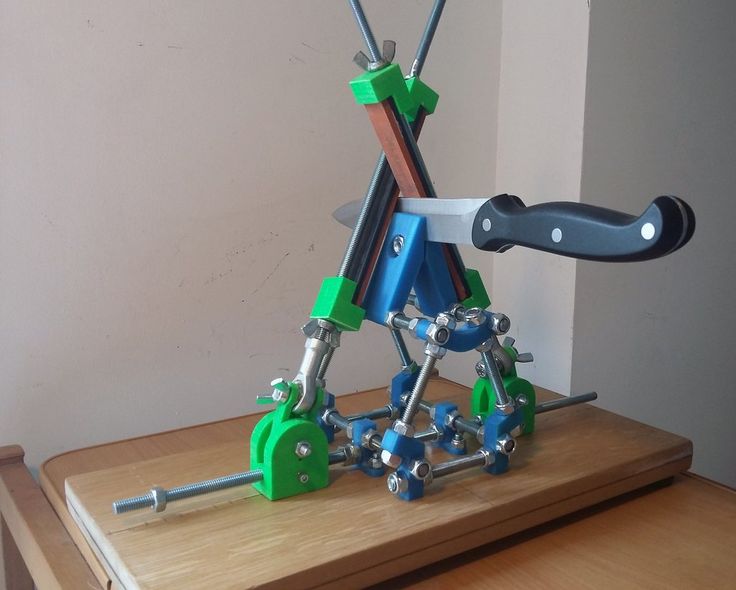

The possibilities of 3D printing are almost limitless, and these are not only technical details and elements of mechanisms, the most popular are: The prototype makes it possible to evaluate the future project in miniature, to look at it from the outside, to understand what shortcomings there are. And effectively present it at exhibitions and conferences. Prototypes, if required by the task, have moving parts, removable and rotary elements.

Serial decorative items, souvenirs - such simple but spectacular things will be a great corporate gift, especially if they have a company logo on them.

Home accessories and decor items - 3d printing material - not just plastic. Thread manufacturers offer many options, not only colors, but also textures. The most interesting are: porcelain, ceramics, rubber, carbon, wood and neon. Printed, for example, vases, from these types of plastic will become a real decoration of the interior, and meeting something similar will definitely not be realistic. The production of 3d products is a demanded service for all industrial complexes, regardless of the type of activity. Machine tools tend to wear out, break down - parts fail and there is a need to replace them. Ordering an original spare part can sometimes be very expensive and time consuming. And printing on a printer will allow you to complete the task in the shortest possible time and at no extra cost.

3D printing technologies are multifaceted, they vary depending on the material, the shape of the product and their purpose. Some things can be printed with just plastic and just post-processed, but for some things you need props and manual assembly.

3d printing services in Moscow are not difficult to find, there are a huge number of offers on the market. But how not to make a mistake with the choice of the artist? Of course, it is worth focusing on experience and technical equipment. We have a sufficient number of high-speed printers in our workshop, which allows us to produce serial orders in the shortest possible time.

Printing a 3d plastic product is a laborious job, and the result depends on the correct choice of materials, printing method and subsequent processing. Therefore, you should trust the professionals.

Working hours: Mon - Fri from 10:00 to 19:00

Phone: +7(495)-369-13-96

WhatsApp +7(977)-331-31-35

Email: zakaz@ pmk3d.ru

Moscow region, Podolsk, Okruzhnaya, 2V.

Pmk3d on the map of Podolsk — Yandex.Maps

Small-scale 3D printing of products to order, order the service of small-scale printing on a 3D printer of products from 100 pieces in St.

Petersburg

Petersburg Go&Make provides services for small-scale production of plastic products using 3d printing. The minimum number of products in a small-scale batch is from 10 pieces.

3D printing is a modern method for the production of plastic products, which uses the technology of layering material.

3D printing does not require prefabricated silicone or metal molds, reducing cost for smaller batches.

You do not need to "freeze" funds for large batches, you can order small-scale production at any time.

Cost

The cost is calculated individually and depends on the amount of material spent on manufacturing, ordered products, their quantity, material used in the work.

Send us a 3D model or drawing and our specialists will calculate the cost.

In serial production, the unit price is reduced by reducing the preparation time for printing each sample. In the production of a batch of products, the price may differ up to 2 times (depending on the quantity), in contrast to a single production..jpg) We can order 3D printing using FDM technology (layer-by-layer deposition) from various plastics: PLA, ABS, FLEX (TPU), PET-G, HIPS, etc., as well as SLA printing from liquid resins.

We can order 3D printing using FDM technology (layer-by-layer deposition) from various plastics: PLA, ABS, FLEX (TPU), PET-G, HIPS, etc., as well as SLA printing from liquid resins.

Lead time

Order lead time depends on part size and lot size. The minimum production time is 2-3 business days. The order is given to work immediately after the terms are agreed and the contract is signed.

Examples of work

Where small-batch 3D printing is in demand

Small-batch 3D printing is ordered by commercial structures, government organizations, and individuals. Most of all, the service is in demand among representatives of small and medium-sized businesses who are interested in the continuous production of plastic parts in small batches. Small-scale 3D printing is ordered by companies specializing in different industries:

- Medicine. For accurate prosthetics in dentistry, visualization of the patient's jaw is needed, so clinics order plastic 3D models of prostheses, crowns, casts.

Learn more

:quality(80)/images.vogel.de/vogelonline/bdb/1696600/1696673/original.jpg)