3D printed robot kit

Top 12 3D-Printed Robots — From Amphibians to Humanoids

Published on August 26, 2021 by Mikahila L.

Robotics brings together all the technologies that make it possible to design autonomous machines; combining knowledge in electronics, mechanics, and even biology. This is a field that has evolved quite a bit since C-3PO first hit the movie screens in Star Wars in1973. Roboticists have been in constant search of innovations that result in greater speed and productivity. Today, we have smarter robots because of advancements in artificial intelligence, machine learning, and of course, additive manufacturing. Indeed, 3D printing is widely used to manufacture robots, whether in the prototyping or final production stage, to imagine structure, materials, and new functionality. This is why we wanted to present to you some of the fascinating 3D printed robots we’ve come across, everything from humanoids, research tools, or even DIY machines—a section that should be of interest to all makers!

DIY Projects

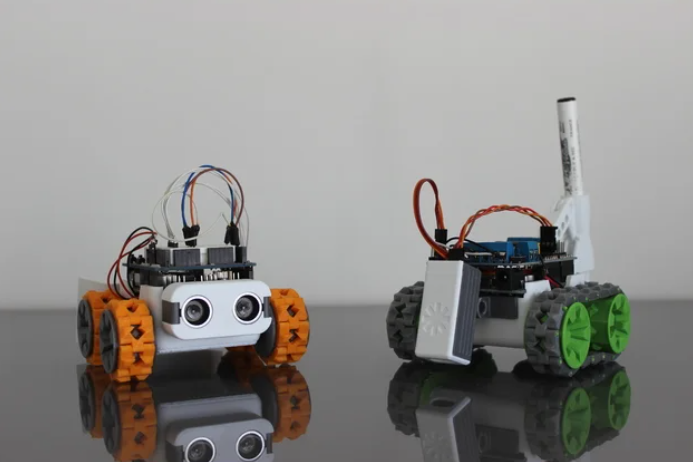

Intel Openbot

Research organization Intel Labs used 3D printing to develop the Openbot, one of the robots that caught our team’s attention the most. The objective of the project was to create a small electric vehicle intended for smartphones, with the motto ‘Transforming smartphones into robots‘. The device is equipped with vast networks of sensors and has powerful computing capabilities allowing it to take advantage of the advanced functionalities of smartphones. Intel experts say they have opted for 3D printing because of its great accessibility, and also thanks to free software that facilitates the development of this type of project.

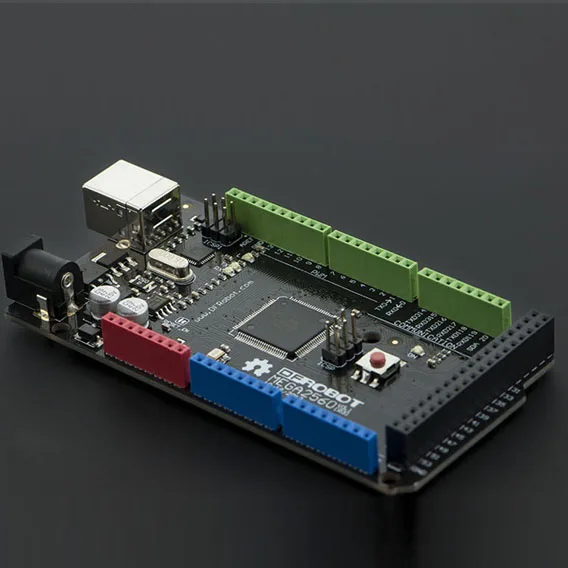

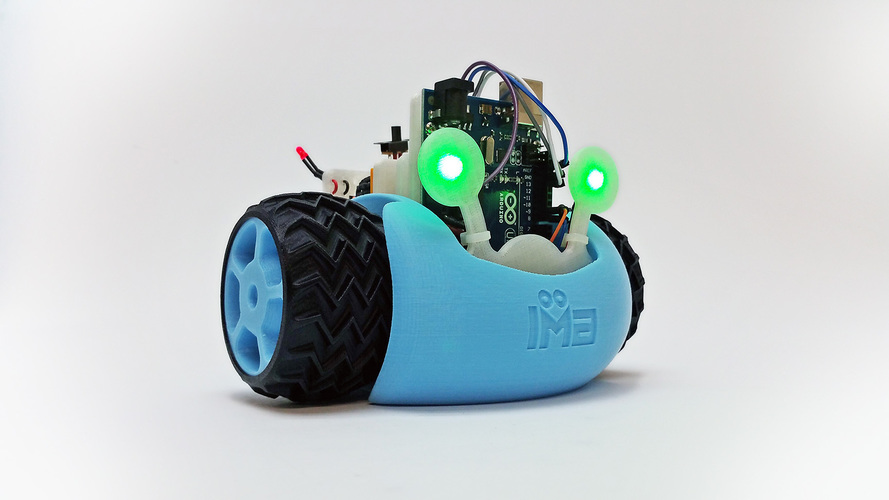

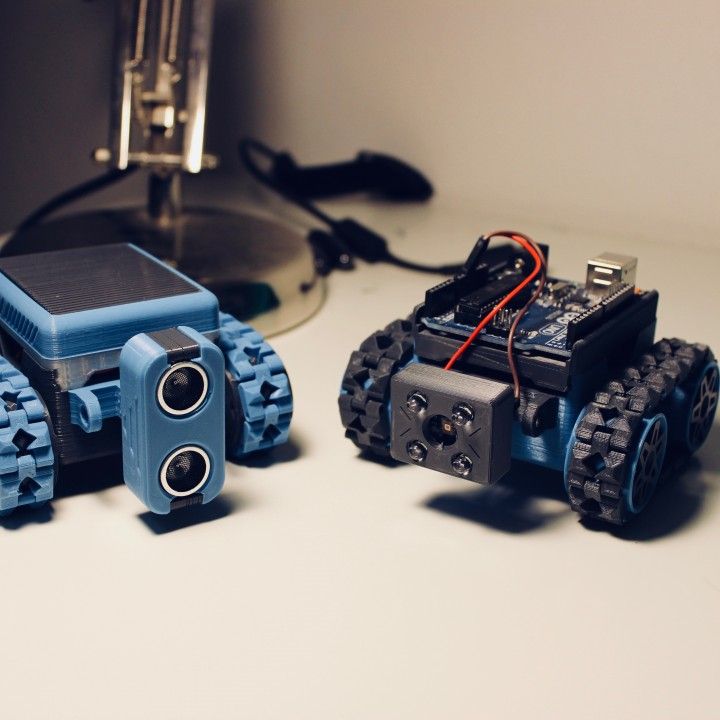

LittleBots is another project that you can do at home with your 3D printer. This robotics kit was created to serve as an introduction to robotics. It features all the necessary components of robotics: sensors, decision-making, and articulation, all in one simple, easy-to-assemble kit. What’s interesting is that LittleBot is fully 3D printed, so it can be made with just 3 screws. The device is open-source and controlled by an Arduino Nano, to take advantage of the global community around it. You can find the 3D print files of these robots through Thingiverse; The Arduino code can be found on the LittleBots download page.

You can find the 3D print files of these robots through Thingiverse; The Arduino code can be found on the LittleBots download page.

Humanoids

Atlas by Boston Dynamics

Boston Dynamics’ Atlas humanoid robots have recently caused quite a stir online with their performance during an obstacle course. Although they have already had some success, Boston Dynamics aims to test the limits of what is possible and continue developing Atlas to make robots withstand extreme conditions. The company relied on 3D printed components for the development of Atlas robots. For example, the legs are 3D printed, which made it possible to integrate hydraulic lines into the structure. Additive manufacturing has also been used to produce custom servo valves.

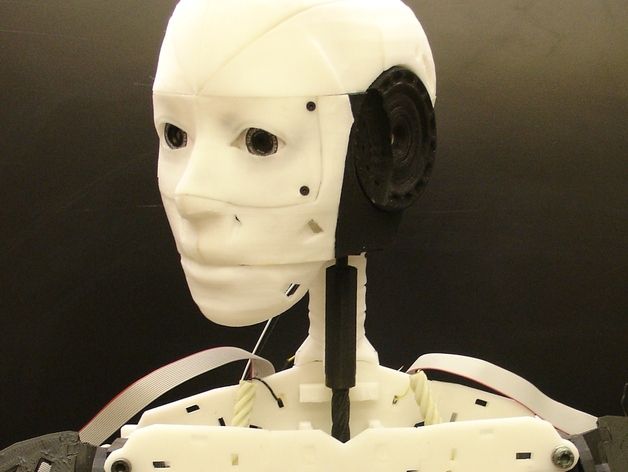

We could have classified the InMoov robot in the DIY category, as it is an open-source project. Indeed, it is the first human-sized open-source 3D printed robot in the world, created in 2012 by the French Gaël Langevin. Anyone with a 3D printer can therefore design their humanoid robot at home, all you need is a printing area of 120 x 120 x 120 mm. The different parts of the body are printed separately—arms, head, neck, back, shoulder, etc. Everything is meticulously detailed on the dedicated site, whether it is the printing, assembly, and commissioning of this 3D printed robot.

PoppyThe humanoid robot ‘Poppy’ was developed by INRIA Flowers Laboratory in Bordeaux, France. Poppy is open-source and is used by a community of educators, scientists, and artists by sharing hardware, software, and web tools used for a wide variety of visual programming, simulation, and experiments. The robot relies on 3D-printed components made using polyamide material, giving the robot thermal and high-abrasion resistance. Standing at 83 cm tall (32.6 inches) and weighing 3.5 kg (7.7 lbs), Poppy includes a series of electronic components including a 4.2-inch screen and HD camera and costs about €9,039 ($10,610), with less expensive versions available including the Poppy Torso and Ergo Jr.

The robot relies on 3D-printed components made using polyamide material, giving the robot thermal and high-abrasion resistance. Standing at 83 cm tall (32.6 inches) and weighing 3.5 kg (7.7 lbs), Poppy includes a series of electronic components including a 4.2-inch screen and HD camera and costs about €9,039 ($10,610), with less expensive versions available including the Poppy Torso and Ergo Jr.

Jimmy is a 3D printed robot that was developed by the 21st Century Robot company with the goal of getting as many people as possible to build and customize their own robot through 3D printing. Jimmy is made up of custom 3D printed shells that cover his humanoid endoskeleton. Completely open-source, it is powered by an Intel Edison microcomputer, and controlled via WiFi on a smartphone, tablet, or PC using a dedicated application.

Pollen Robotics Reachy

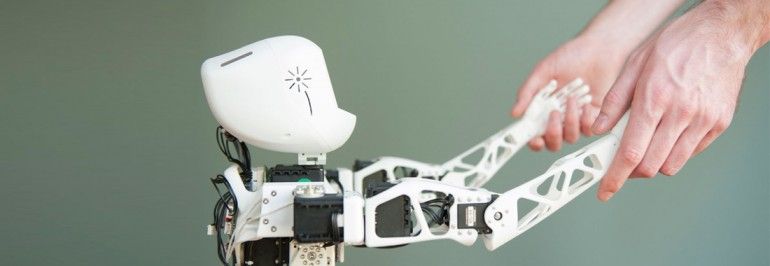

Another offering from the French company Pollen Robotics (also the creators of Pollen), Reachy is described by the company as an expressive open-source humanoid platform that is programmable with Python and made using 3D printing. Though really just a torso, head, and arms, the main drawing point of this particular robot is not just how expressive it is but also how good it is at interacting with people and manipulating objects. The robot’s maneuverability is to thank for these features. For example, its head is free-moving and it can use antennas to convey emotions. Its two arms have similar dimensions, proportions, and movement as an adult human arm, capable of lifting up to 500 grams. Best of all, the robot is completely customizable and learns thanks to machine learning and AI capabilities.

Research Projects

JSK Laboratory’s Kengoro

Researchers at the JSK laboratory in Tokyo have succeeded in developing a humanoid robot capable of doing push-ups. But playing sports is not Kengoro’s only special feature—its 3D printed metal coating also makes it unique. A well-known problem with humanoid robots is the overheating of motors. In order to better dissipate the heat generated by the 108 engines, the research team opted for an efficient cooling system that can be implemented using SLS 3D printing. The process made it possible to integrate a cooling system into the Kengoro housing and to modify the energy density of the material at various points. This allows water to escape easily and increases Kengoro’s performance. You might even think that the robot sweats during its athletic efforts!

But playing sports is not Kengoro’s only special feature—its 3D printed metal coating also makes it unique. A well-known problem with humanoid robots is the overheating of motors. In order to better dissipate the heat generated by the 108 engines, the research team opted for an efficient cooling system that can be implemented using SLS 3D printing. The process made it possible to integrate a cooling system into the Kengoro housing and to modify the energy density of the material at various points. This allows water to escape easily and increases Kengoro’s performance. You might even think that the robot sweats during its athletic efforts!

Pleurobot the Amphibious Robot

Pleurobot is a 3D-printed robot that mimics a salamander and was designed by the Ecole Polytechnique de Lausanne in Switzerland. This amphibious robot has practical application for neuroscientists, biomechanists, functional morphologists, and paleontologists as well as roboticists. For instance, Pleurobot will enable research that benefits quadriplegic patients as researchers gain better insights into anatomy and motor skills. Research may also focus on the evolution of the passage from a swimming animal to one that walks. Swiss engineers also replicated a nervous system using electronic components with a careful scan of a real salamander. Equipped with motors, Pleurobot can swim, crawl and walk like its amphibian counterparts.

Research may also focus on the evolution of the passage from a swimming animal to one that walks. Swiss engineers also replicated a nervous system using electronic components with a careful scan of a real salamander. Equipped with motors, Pleurobot can swim, crawl and walk like its amphibian counterparts.

‘Astro’, the Intelligent Robodog that Sees and Hears

Scientists at Florida Atlantic University’s Cognitive Robotics and Machine Perception Laboratory (MPCR) have developed Astro, one of the few quadrupedal robots in the world. Unlike many robots, Astro is specified to have a computerized brain inside his head. This one, which looks like that of a Doberman, has been 3D printed. But the commonalities with dogs don’t end with the physical. Astro also has artificial intelligence and machine learning that allows it to learn like a canine. Equipped with sensors, radars, and a microphone, the robotic dog responds to classic commands such as “sit”, “stand” and “lie down”. In some time, Astro will be able to help the police as a scout dog or as a service dog for the visually impaired.

Equipped with sensors, radars, and a microphone, the robotic dog responds to classic commands such as “sit”, “stand” and “lie down”. In some time, Astro will be able to help the police as a scout dog or as a service dog for the visually impaired.

“Micro-Bristle-Bots”

While most of the time human-designed robots are large, this is not always the case. At the Georgia Institute of Technology, researchers have developed microscopic 3D printed robots. Dubbed ‘micro-bristle-bots’, they are barely visible to the naked eye and can be controlled by tiny vibrations. Like ants, microscopic robots work in teams and are able to transport materials. To manufacture the ‘micro-bristle-bots’, the Georgia Tech team used Nanoscribe’s Photonic Professional GT 3D printer, based on the two-photon polymerization (TPP) process. According to the manufacturer, this technology achieves a high level of precision and detail and is ideally suited for micro-printing.

Soft Robots from UC San Diego Jacobs School of Engineering

At the University of California San Diego’s Jacobs School of Engineering, engineers have been working on soft robotics, or the construction of robots from compliant materials, often taking significant inspiration from the movements of living organisms. One such recent project was when researchers designed and tested 3D-printed insect-like robotics. Using FDM and filaments like ABS or PLA, the insects were made using a flexoskeleton process that added rigid features to key components, allowing them to keep their flexibility. This is not the only 3D-printed soft robotics project coming from the school with more expected in the future.

What do you think of our selection of 3D-printed robots? Let us know in a comment below or on our Facebook and Twitter pages. Don’t forget to sign up for our free weekly newsletter, with all the latest news in 3D printing delivered straight to your inbox!

Don’t forget to sign up for our free weekly newsletter, with all the latest news in 3D printing delivered straight to your inbox!

Arduino-Compatible 3D Printed Robot Ki – RadioShack

RadioShack.com Online Return Policy | Damaged or Defective Items | In-Store Purchases Return Policy | Product Warranties

RadioShack.com Online Return Policy

Due to COVID-19, processing times for returns may take longer than normal. Please allow 14 to 21 days before contacting Customer Care regarding the status of your return. Thank you for your patience.

At RadioShack.com, we want you to be fully satisfied with every item that you purchase. If you are not satisfied with your RadioShack.com purchase, you may return most items within 30 days for a full refund of the purchase price, minus shipping, handling or other additional charges. See the “Exceptions” section for products not covered by our return policy.

IMPORTANT: With limited exceptions, returns are refunded in the form of online store credit redeemable at RadioShack. com. RadioShack does not refund any shipping charges. With limited exceptions, we do not provide pre-paid return labels; you are responsible for covering any shipping costs to return your item(s).

com. RadioShack does not refund any shipping charges. With limited exceptions, we do not provide pre-paid return labels; you are responsible for covering any shipping costs to return your item(s).

Please be sure to send your item(s) back in full accordance with our Online Return Policy:

- Item(s) must be sent back within 30 days of the delivery date.

- Item(s) must be unused and in like-new condition.

- All merchandise must be returned in its original packaging and with all included accessories and paperwork.

- Returns sent back to our warehouse without a return authorization generated through our Returns Center or by contacting our Customer Care team will be charged a $10 manual processing fee.

Exceptions: RadioShack.com cannot accept returns for certain items. Items that are ineligible for return are noted online. Non-refundable items include:

- Products that were resold or altered (or tagged) for resale will not be accepted.

- Opened software or kits.

- Electronic media products that are not defective (such as USB thumb drives and memory cards).

- Personal care products (such as face masks, face shields).

- Products listed as final sale or non-returnable.

- Products not purchased from RadioShack.com.

To return or exchange your item(s):

- Start by visiting our Returns Center at radioshack.com/returns and enter the email address used when you placed your order.

- Your request to return your item(s) must be within 30 days of your delivery date or otherwise within our within our Return Policy.

- With limited exceptions, we do not provide pre-paid return labels; you are responsible for covering return shipping costs. The return shipping label cost will be deducted from your refund amount.

- You will receive an email with return instructions. Select "Start a Return" and choose the item(s) you wish to return.

Follow the instructions to print a return shipping label.

Follow the instructions to print a return shipping label. - Please use the issued shipping label to ensure proper processing of your return. Keep the return tracking number from the package you are returning to ensure the package is returned to our warehouse.

- You may return your package to any U.S. Post Office location. An email confirmation will be sent to you once your return is received and processed by our warehouse.

International Returns

Should you choose to return your item(s), RadioShack does not provide pre-paid return labels and you will be responsible for covering the shipping costs. In addition, customers outside of the United States will be unable to use our online Returns Center. Instead, please follow the instructions below to return in accordance with our Online Return Policy.

To return your item(s) by mail, please contact our Customer Care team at [email protected]. We will provide you with a return label that you may take to any of your local carriers. Send your return items to our Returns Department at the address below:

Send your return items to our Returns Department at the address below:

RadioShack Returns

900 Terminal Road #244

Fort Worth, TX 76106

Damaged or Defective Item(s)

If you receive a damaged or defective item from RadioShack.com, contact a Customer Care representative immediately.

● Please supply the representative with your order number, item number and tracking number from your original confirmation email. The representative will also need your email address and phone number.

● RadioShack.com will make every reasonable effort to assist you with your return.

● A defective item may be replaced within 30 days from date of purchase under our Warranty Policy, or within the manufacturer's warranty period, whichever is longer. Contact a Customer Care representative for assistance.

● When possible, please have picture(s) available of the damage or defect to expedite assistance.

● Damaged or defective item(s) will be replaced if available or RadioShack. com store credit will be issued.

com store credit will be issued.

Lost in Transit Item(s)

If your tracking number shows the order was delivered, but you never received it from RadioShack.com, contact a Customer Care representative immediately.

● Contact the carrier and submit a claim for the lost in transit item(s). Please supply the representative with your order number, item number, tracking number from your original confirmation email, and claim number. The representative will also need your email address and phone number. ● RadioShack.com will make every reasonable effort to assist you with a replacement if available or store credit will be issued.

Order Cancellations

We strive to have all orders picked, packed, and shipped as quickly as possible because we know you can't wait to receive it! With that in mind, once your order is placed, we are not able to cancel your order. Please see the return policy for additional information if a return is still needed.

In-Store Purchases Return Policy

RadioShack stores are independently owned and operated and may vary by location. Please contact your local store for a copy of their Return Policy. RadioShack.com cannot process returns for products purchased from RadioShack stores.

Please contact your local store for a copy of their Return Policy. RadioShack.com cannot process returns for products purchased from RadioShack stores.

Product Warranties

Click here for Terms and Conditions for all states.

Many of the items that are sold on RadioShack.com come with a manufacturer's warranty. Applicable warranty information can usually be found inside the box or packaging. For additional information on the manufacturer's warranty for a specific product, contact the manufacturer directly.

Our RadioShack-branded private label products include either a 90-day or 1-year warranty, depending on the product. You may read the terms of these limited warranties below.

Warranty Terms and Conditions

Except in California, RadioShack makes no additional warranties of any kind, express or implied, for any product manufactured by a party other than RadioShack.

EXCEPT WHERE PROHIBITED BY LAW, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE SPECIFICALLY DISCLAIMED: (1) FOR ALL 'AS IS' SALES; AND (2) UPON THE LATER TO OCCUR OF: [A] THE EXPIRATION OF ANY APPLICABLE EXPRESS WARRANTIES, OR [B] 90 DAYS FROM DATE OF PURCHASE.

RadioShack is not liable for any loss or damage (including indirect, special, incidental or consequential damages), caused directly or indirectly by the products listed on this receipt. Some states do not allow limitations on implied warranties (such as warranties of merchantability or fitness for a particular purpose), or the exclusion of incidental or consequential damages, so the above limitations or exclusions may not apply to you. In addition, you may have other rights which vary from state to state.

Products which have been subject to misuse (including static discharge), neglect, accident or modification, or which have been soldered or altered during assembly and are not capable of being tested are excluded from any warranty by RadioShack.com.

The products we sell are not authorized for use as critical components in human implantable devices, or life support devices or systems. A critical component is any component of a human implantable device, a life support device or system, whose failure to perform can be reasonably expected to cause the failure of the implant, life support device or system, or to affect its safety or effectiveness.

Many other products offered on this web site are covered by a manufacturer's warranty. A copy of a specific warranty, where one is offered by a warrantor, will be made available for inspection before sale, upon specific request by our Catalog Number.

We supply many products that meet military specifications as represented by the manufacturer. We do not maintain traceability on these products; therefore we only supply them as commercial parts.

Information for international customers or customers traveling internationally: products purchased on RadioShack.com or through our retail locations in the United States cannot be returned for warranty servicing at any of our international locations.

90-Day Limited Warranty

RadioShack Online OpCo LLC (hereafter “RadioShack”) warrants this product against defects in materials and workmanship under normal use by the original purchaser for ninety (90) days after the date of purchase from a RadioShack-owned store, RadioShack. com, or an authorized RadioShack franchisee or dealer. RADIOSHACK MAKES NO OTHER EXPRESS WARRANTIES.

com, or an authorized RadioShack franchisee or dealer. RADIOSHACK MAKES NO OTHER EXPRESS WARRANTIES.

This warranty does not cover: (a) damage or failure caused by or attributable to abuse, misuse, failure to follow instructions, improper installation or maintenance, alteration, accident, Acts of God (such as floods or lightning), or excess voltage or current; (b) improper or incorrectly performed repairs by persons who are not a RadioShack-authorized service facility; (c) consumables such as fuses or batteries; (d) ordinary wear and tear or cosmetic damage; (e) transportation, shipping or insurance costs; (f) costs of product removal, installation, set-up service, adjustment or reinstallation; and (g) claims by persons other than the original purchaser.

Should a problem occur that is covered by this warranty, take the product and the RadioShack sales receipt as proof of purchase date to the original purchase location or visit www.radioshack.com/warranty. RadioShack will, at its option, unless otherwise provided by law (a) replace the product with the same or comparable product, or (b) refund the purchase price. All replaced products, and products on which a refund is made, become the property of RadioShack.

All replaced products, and products on which a refund is made, become the property of RadioShack.

RADIOSHACK EXPRESSLY DISCLAIMS ALL WARRANTIES AND CONDITIONS NOT STATED IN THIS LIMITED WARRANTY. ANY IMPLIED WARRANTIES THAT MAY BE IMPOSED BY LAW, INCLUDING THE IMPLIED WARRANTY OF MERCHANTABILITY AND, IF APPLICABLE, THE IMPLIED WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE, SHALL EXPIRE ON THE EXPIRATION OF THE STATED WARRANTY PERIOD.

EXCEPT AS DESCRIBED ABOVE, RADIOSHACK SHALL HAVE NO LIABILITY OR RESPONSIBILITY TO THE PURCHASER OF THE PRODUCT OR ANY OTHER PERSON OR ENTITY WITH RESPECT TO ANY LIABILITY, LOSS OR DAMAGE CAUSED DIRECTLY OR INDIRECTLY BY USE OR PERFORMANCE OF THE PRODUCT OR ARISING OUT OF ANY BREACH OF THIS WARRANTY, INCLUDING, BUT NOT LIMITED TO, ANY DAMAGES RESULTING FROM INCONVENIENCE AND ANY LOSS OF TIME, DATA, PROPERTY, REVENUE, OR PROFIT AND ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES, EVEN IF RADIOSHACK HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

Some states do not allow limitations on how long an implied warranty lasts or the exclusion or limitation of incidental or consequential damages, so the above limitations or exclusions may not apply to you. This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

You may contact RadioShack at:

RadioShack Customer Care

www.radioshack.com

[email protected]

Updated 10/06

1-Year Limited Warranty

RadioShack Online OpCo LLC (hereafter “RadioShack”) warrants this product against defects in materials and workmanship under normal use by the original purchaser for one (1) year after the date of purchase from a RadioShack-owned store, RadioShack.com, or an authorized RadioShack franchisee or dealer. RADIOSHACK MAKES NO OTHER EXPRESS WARRANTIES.

This warranty does not cover: (a) damage or failure caused by or attributable to abuse, misuse, failure to follow instructions, improper installation or maintenance, alteration, accident, Acts of God (such as floods or lightning), or excess voltage or current; (b) improper or incorrectly performed repairs by persons who are not a RadioShack-authorized service facility; (c) consumables such as fuses or batteries; (d) ordinary wear and tear or cosmetic damage; (e) transportation, shipping or insurance costs; (f) costs of product removal, installation, set-up service, adjustment or reinstallation; and (g) claims by persons other than the original purchaser.

Should a problem occur that is covered by this warranty, take the product and the RadioShack sales receipt as proof of purchase date to the original purchase location or visit www.radioshack.com/warranty. RadioShack will, at its option, unless otherwise provided by law (a) replace the product with the same or comparable product, or (b) refund the purchase price. All replaced products, and products on which a refund is made, become the property of RadioShack.

RADIOSHACK EXPRESSLY DISCLAIMS ALL WARRANTIES AND CONDITIONS NOT STATED IN THIS LIMITED WARRANTY. ANY IMPLIED WARRANTIES THAT MAY BE IMPOSED BY LAW, INCLUDING THE IMPLIED WARRANTY OF MERCHANTABILITY AND, IF APPLICABLE, THE IMPLIED WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE, SHALL EXPIRE ON THE EXPIRATION OF THE STATED WARRANTY PERIOD.

EXCEPT AS DESCRIBED ABOVE, RADIOSHACK SHALL HAVE NO LIABILITY OR RESPONSIBILITY TO THE PURCHASER OF THE PRODUCT OR ANY OTHER PERSON OR ENTITY WITH RESPECT TO ANY LIABILITY, LOSS OR DAMAGE CAUSED DIRECTLY OR INDIRECTLY BY USE OR PERFORMANCE OF THE PRODUCT OR ARISING OUT OF ANY BREACH OF THIS WARRANTY, INCLUDING, BUT NOT LIMITED TO, ANY DAMAGES RESULTING FROM INCONVENIENCE AND ANY LOSS OF TIME, DATA, PROPERTY, REVENUE, OR PROFIT AND ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES, EVEN IF RADIOSHACK HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

Some states do not allow limitations on how long an implied warranty lasts or the exclusion or limitation of incidental or consequential damages, so the above limitations or exclusions may not apply to you. This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

You may contact RadioShack at:

RadioShack Customer Care

www.radioshack.com

[email protected]

Updated 10/06

most advanced projects of 2022

Robots and 3D printing - a powerful combination! Let's take a look at some of the most impressive and cutting-edge 3D printed robot designs, many of which you can make yourself at home.

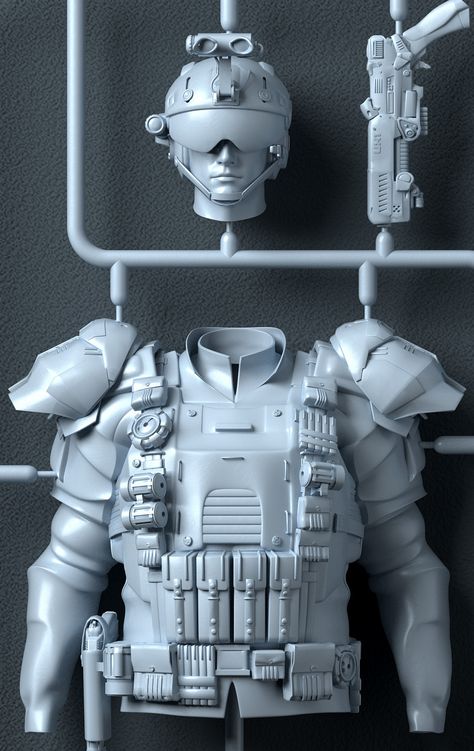

Humanoids

Combining robotics and 3D printing, humans push their limits every day, and humanoid robots are a perfect example.

Humanoid robots are designed to somehow represent or mimic the appearance and actions of a human. Every day, experts are working on the creation of new robotic systems, trying to make them as close to reality as possible. Humanoid robots can walk, talk, gesticulate, and more. They are suitable for many applications including medicine and nursing.

Humanoid robots can walk, talk, gesticulate, and more. They are suitable for many applications including medicine and nursing.

Let's look at some interesting models of humanoid robots, popular among amateurs and professionals in the field of robotics.

1. Kengoro (Kengoro).

This humanoid robot, created by researchers at the University of Tokyo, can do more push-ups than anyone else. When developing it, scientists focused on muscle abilities.

Force is a big problem for articulated robots. As the number of degrees of freedom and accuracy of movements increase, their muscle strength decreases.

But Kengoro does not have this problem. He can do push-ups, play sports, run and even play badminton. To perform all of the above, the robot does not require any remote control, since all its movements are independent. For example, when playing badminton, this humanoid performs all the necessary movements, determines the direction of the shuttle and moves in the right direction at will.

One of the secrets of Kengoro's abilities is built-in cooling, which mimics a person's ability to regulate their body temperature. During certain physical activities, the robot artificially sweats to cool the mechanism, which allows it to work more efficiently and for a longer time.

What role did 3D printing play in the creation of this humanoid robot? The mechanical parts and frame of the Kengoro were manufactured using selective laser sintering (SLS).

2. InMoov

InMoov is one of the oldest projects in the field of 3D printed robotics. Created by French sculptor and designer Gaël Langevin in 2012, this robot originally served as a prosthetic arm. Its design has been gradually modified and improved, and now it is a life-size 3D printed robot. This model is a truly impressive achievement, not only due to its size, but also due to the smooth, graceful gestures right down to the fingertips. In addition, it is an open source project intended as a development platform for students, developers, and scientists. In fact, InMoov was the first open source 3D printed prosthetic arm.

In fact, InMoov was the first open source 3D printed prosthetic arm.

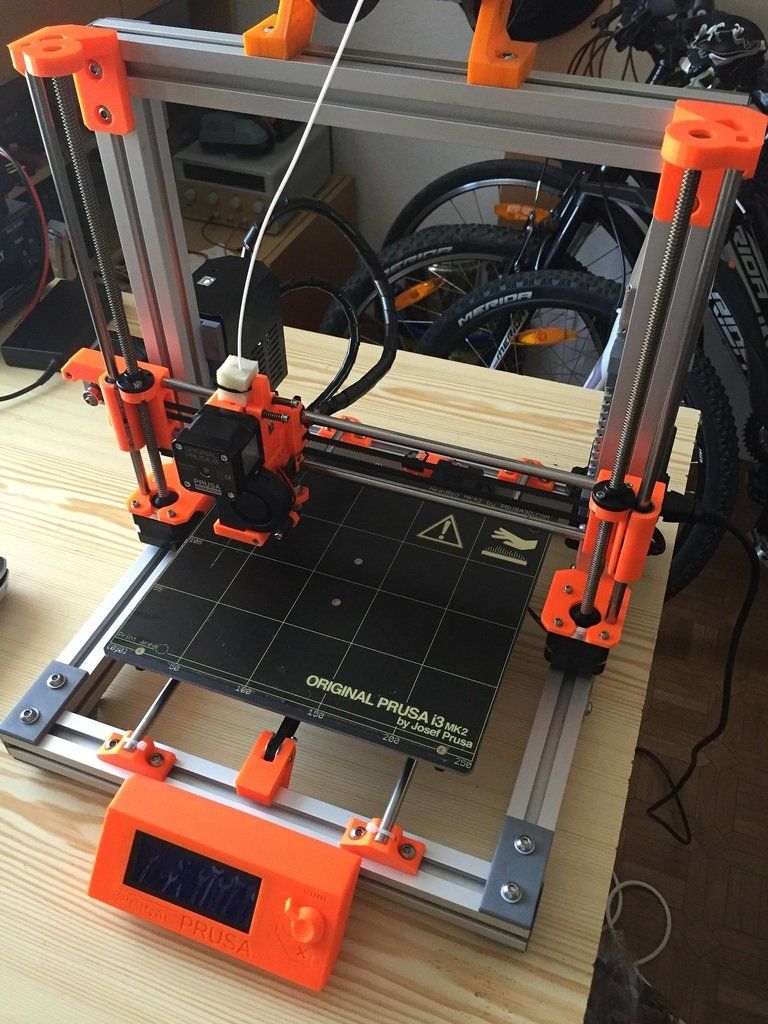

You can make your own InMoov robot. To do this, you will need:

- desktop 3D printer, the print volume of which is at least 12x12x12 cm, for example, the Picaso Designer Classic model;

- Arduino Uno and Mega microcontroller boards;

- three servomotors - HK15298B, HiTec HS805BB, MG996;

- software - MyRobot Lab, Python.

InMoov continues to be a favorite among developers around the world. Every year it gets more and more opportunities. For example, its design has recently been improved by adding a vision system, improved mechanics and legs.

Fun fact: there is a world map that can be used to connect with the creators of InMoov around the globe.

3. Reachy.

In 2019, the French company Pollen Robotics introduced its Reachy, a highly interactive robot equipped with artificial intelligence. Richie is a 3D printed robotic torso capable of playing tic-tac-toe or, for example, serving coffee. The main purpose of its development is use in the field of customer service.

The main purpose of its development is use in the field of customer service.

The robot looks pretty cute with animated antennae and a head with two "eyes" that can move to convey emotions. Richie's arms have a wide range of motion, are similar in size to those of an adult, and are capable of lifting objects weighing up to 500 grams. You can use VR to control the robot.

Every part of Reachy is 3D printed. In addition, Pollen Robotics has made its design open so that anyone can contribute to the development of this robot.

Ritchie is available in several different configurations, from the basic one-handed headless model to the advanced headed two-handed version. You can even choose a robot shirt design!

4.ED-A.

This robot looks like it's straight out of a science fiction movie, but it's actually real. The name of this impressive humanoid is ED-A, or simply Eddie. It was designed by an engineer named Greg at Gwas Tech and is a fully 3D printed robot using artificial intelligence and machine learning. In development mode, Eddie's robot can be controlled both by voice and by remote control.

In development mode, Eddie's robot can be controlled both by voice and by remote control.

ED-A can talk, walk and turn as instructed, and can recognize and address the presence of a person. He knows how to form opinions about what he likes or dislikes. In addition, Eddie is friendly to animals: he can talk to dogs, give them treats and even train them!

Developer Eddie shares his achievements on YouTube and Instagram social networks, so everyone can watch how the robot evolves as new features are added. You can see some very advanced features in the developer videos. For example, how the robot uses its own voice to communicate with users. And in one of the videos, the author shows the robot various objects, in particular, a keyboard and an electric screwdriver, and ED-A recognizes them, pronounces their names and expresses their own opinion about these objects.

5. Jimmy

Jimmy has a friendly design. This is a 21st century humanoid robot with the technical name Interbotix HR-OS1, powered by an Edison chip from Intel. The model was created in 2014 and has an open source code that can be controlled remotely via Wi-Fi. Development of the robot Jimmy continues to this day.

The model was created in 2014 and has an open source code that can be controlled remotely via Wi-Fi. Development of the robot Jimmy continues to this day.

This robot is based on an endoskeleton, and the outer shell, which gives Jimmy a friendly look, can be printed and customized to the taste of the user. You can customize not only the shell, but also the functionality of the machine. By the way, this is even desirable and highly encouraged, as developers are actively promoting such an aspect as personalization.

Jimmy has many skins available. Since its development, this robot has been regularly used in many educational campaigns, as well as in the field of social work with children with special needs. One of his shells, called Callim, was designed by an 11-year-old boy, and the 21st Century Robot team turned it into a real 3D printed exoskeleton.

6. Aspir V2

The Aspir V2 is an open source 3D printed humanoid robot with a lot to talk about. In 2018, the first Aspir was released - an "autonomous robot for support and positive inspiration", created by John Choi based on the "Robot Ambassador Halley" (2015). A year after Aspir, a second version was released called Aspir V2. With its "childish" size - height 4 feet (a little over 1.2 m) and weight of only 30 pounds (about 13.5 kg) - this robot operates with the help of 22 motors. It is equipped with humanoid automation and is highly maneuverable. There are six extra-large servos per leg, and four high-torque standard servos per arm. In addition, each arm is equipped with five metal gear micro-servos. To top it off, the robot has two additional standard servos for head tilt and turn mechanisms.

In 2018, the first Aspir was released - an "autonomous robot for support and positive inspiration", created by John Choi based on the "Robot Ambassador Halley" (2015). A year after Aspir, a second version was released called Aspir V2. With its "childish" size - height 4 feet (a little over 1.2 m) and weight of only 30 pounds (about 13.5 kg) - this robot operates with the help of 22 motors. It is equipped with humanoid automation and is highly maneuverable. There are six extra-large servos per leg, and four high-torque standard servos per arm. In addition, each arm is equipped with five metal gear micro-servos. To top it off, the robot has two additional standard servos for head tilt and turn mechanisms.

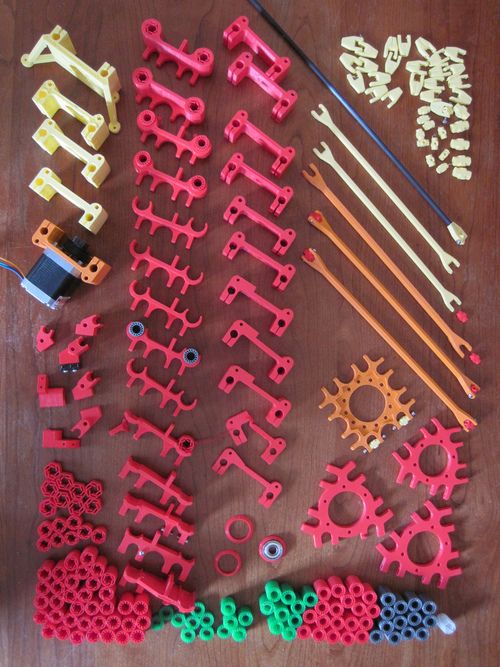

Each of the 90 parts that make up the Aspir V2 is 3D printed. The total printing time for all elements is approximately 300 hours. To make a robot yourself, you will need: a 3D printer with an assembly volume of at least 250x250x250 mm, for example, the Hercules G6 model, 5 kg of PLA plastic filament, files from GitHub. A complete guide and a list of available materials can be found on the Instructables website.

A complete guide and a list of available materials can be found on the Instructables website.

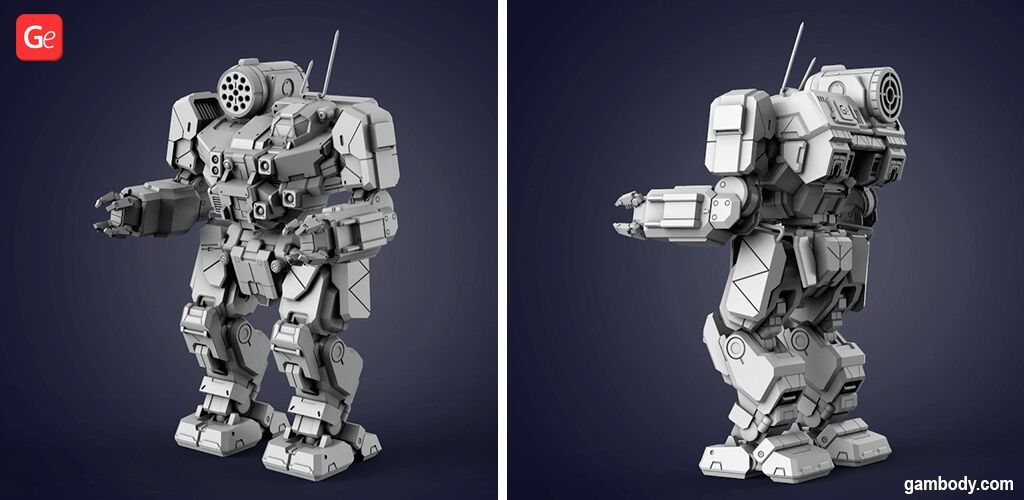

7. Atlas

The Atlas robot, developed by Boston Dynamics, is one of the most popular robots among Internet users. However, only a few people know that it is partially 3D printed. The model was based on the earlier Peatman humanoid robot from Boston Dynamics and was originally designed to perform search and rescue missions.

According to the manufacturer, Atlas has been designed to push the boundaries of "whole body mobility". His arms and legs are 3D printed in metal. Because of this, they are endowed with sufficient lightness and strength to perform the gymnastic movements for which this robot is intended.

The original versions of the Atlas, developed in 2013, were purely mechanical. But in recent years, the possibilities of 3D printing with metals have reached such a high level that it has become possible to produce functional parts for such maneuverable robots.

8. Biomimetic Mechatronic Hand (biomimetic mechatronic hand)

This robotic hand is incredibly similar to the real thing! It was designed by Will Cogley and is currently a work in progress. The biomimetic mechatronic hand is a university project that aims to create a mechanism that mimics the motion, grip and strength of the human hand as closely as possible. At the moment, the first criterion of the three has already been achieved.

The human hand is made up of many muscles and tendons, which is why it is a big problem in the field of prosthetics. The creation of the mechatronic hand was a very successful attempt to replicate real hand movement systems. To date, this mechanism has an impressive 23 degrees of freedom and is able to exactly repeat the movements of a real hand. The developer plans to improve the grip so that it can be as effective as gripping a real hand. This is what the author focused his attention on: now he is studying the possibilities in terms of increasing the strength of the structure.

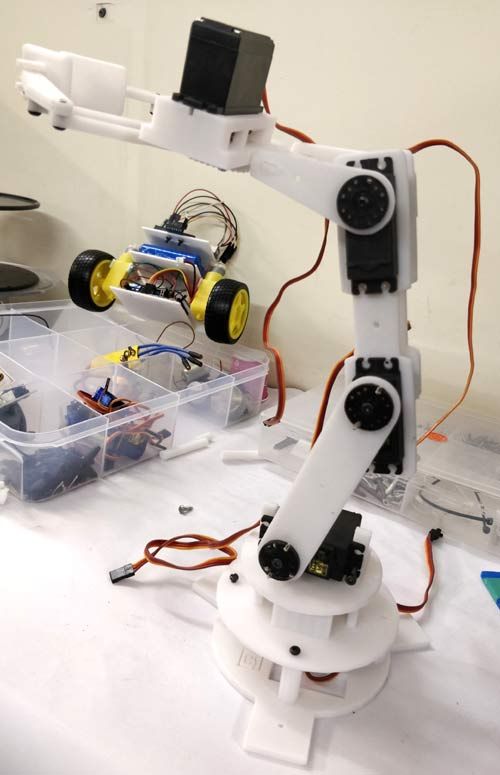

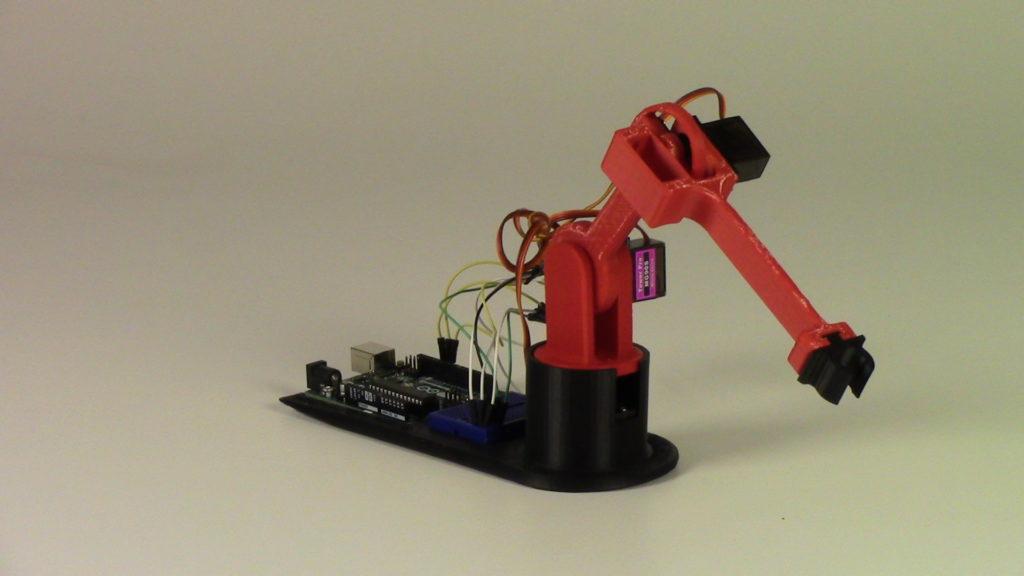

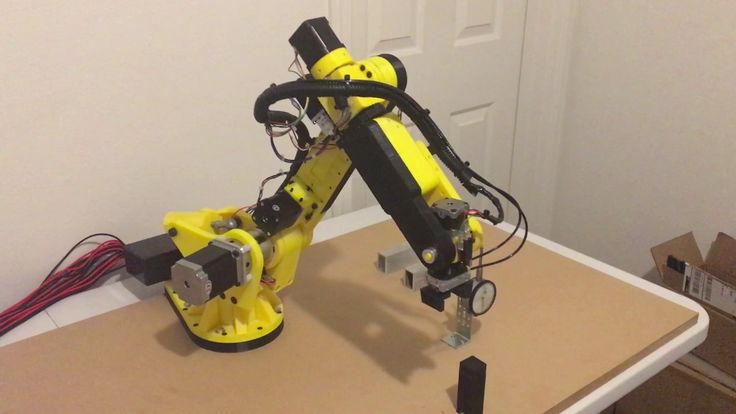

Robotic arms

Robotic arms are mechanical systems consisting of axes that are connected to each other to give the arm different degrees of freedom and provide different types of movement. The limbs of such a mechanism are able to turn and rotate to reproduce a certain movement.

Robotic arms operate on the basis of software, the type and functionality of which depend on the function that the mechanical arm is to perform. At the same time, most robotic arms are very similar to each other and differ only in the data transmission method used and the programmed movement.

Not so long ago, robotic arms were used primarily in industry, but thanks to 3D printing, they can now be used at home as well.

Below are the best robotic arms available today.

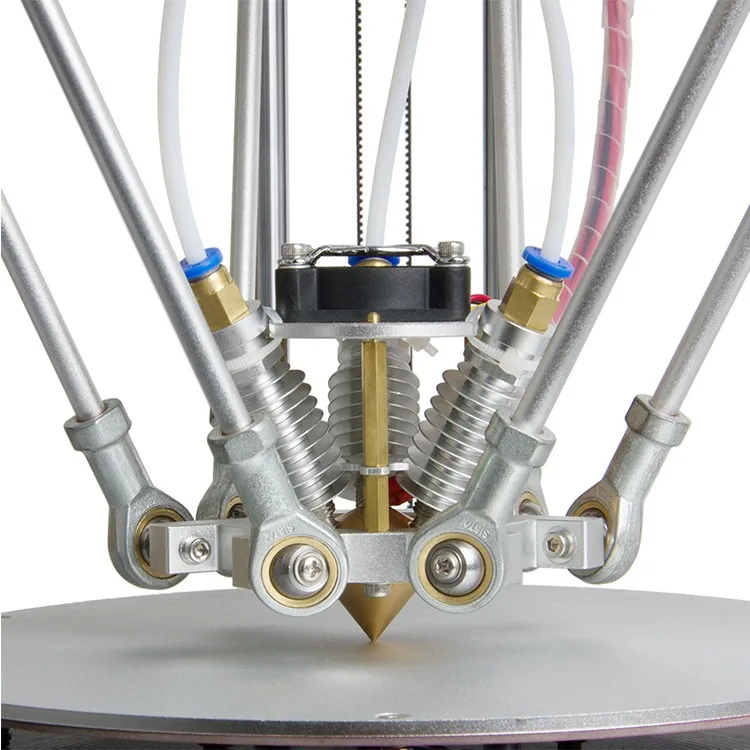

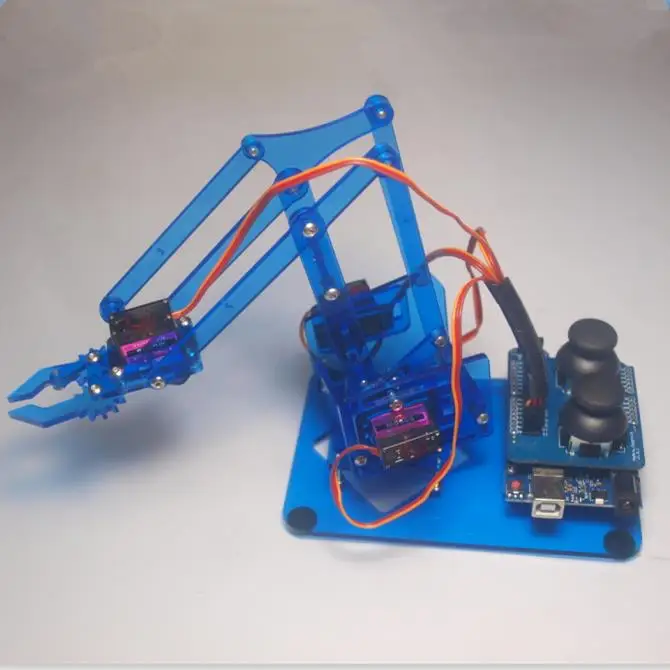

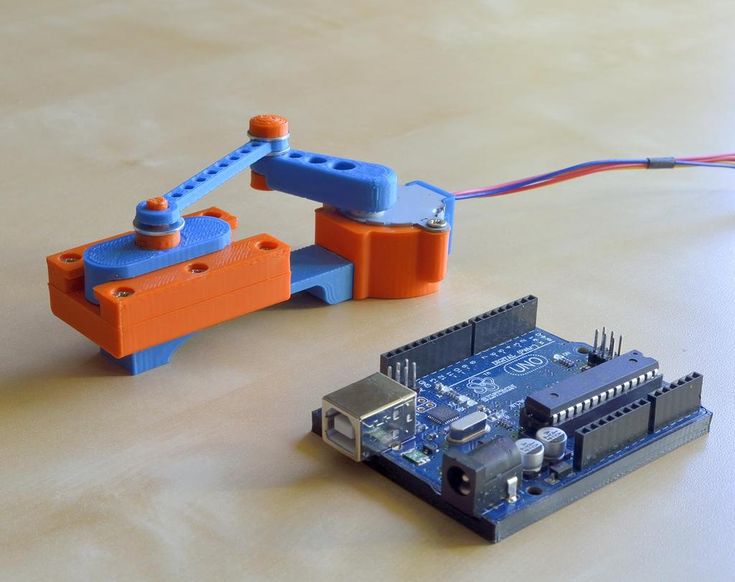

1. LittleArm V3

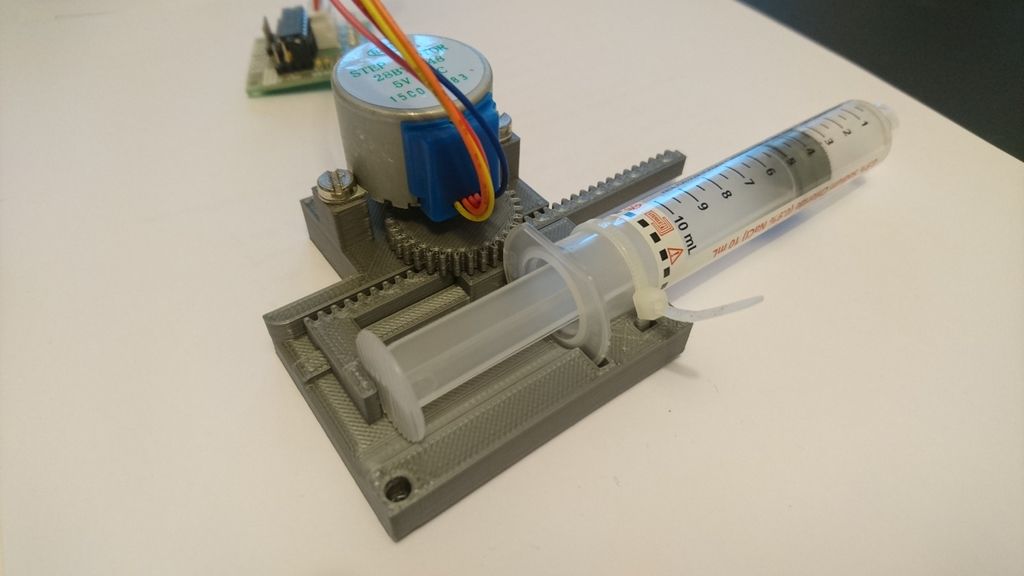

LittleArm V3 is a fully 3D printed Arduino-based robotics kit based on the first LittleArm project that was developed in 2016. With a 3D printed grip, this robot arm is easier to assemble than previous versions.

LittleArm Robots is a project by designer Gabe Bentz to introduce STEM (Science, Technology, Engineering, Mathematics) into the learning process. When he succeeded, he realized that he would have to make more robotic arms than expected. This led to the creation of a huge printer farm, which later became Slant 3D. Based on this company, a line of LittleBots robot kits with Arduino, designed for learning STEM, was created.

The LittleArm V3 consists of only four 3D printed parts and does not require any screws to articulate the grip. Instead of screws, an integrated 3D printed hinge is used. The overall design of the device looks quite elegant. The hand is easy to assemble, has an improved grip and, unlike previous versions, is equipped with an updated version of the software. The V3 is perfect for use as a learning tool for kids, but can be used by adult robotics enthusiasts as well.

2. Niryo One

Niryo One is a 3D printed 6-axis robotic arm designed for collaboration in education. The model was developed in 2016 and is available for purchase both as a set and fully assembled. Originally launched on Kickstarter, Niryo developed through software and design improvements.

The model was developed in 2016 and is available for purchase both as a set and fully assembled. Originally launched on Kickstarter, Niryo developed through software and design improvements.

The Niryo One robotic arm is used to introduce industrial robots. It is very precise and controlled by stepper motors, which are in turn controlled by the Arduino and Raspberry Pi systems. The device is easy to program - the process is done using a free desktop application and takes less than five minutes.

3. Gesture-Controlled (Gesture-Controlled Robotic Arm)

"One step closer to being Iron Man" is the motto of this unique device.

Hand gesture controlled robotic arm designed by Eben Couao. The structural elements of the movement are 3D printed. The author provides the complete code and detailed open source instructions, as well as a list of parts needed to reproduce the paddle.

The model consists of two systems: a robotic arm and a 3D printed glove that is used to control the movements of the hand. Movements, such as finger movements, can open and close the hand clamp, and wrist movements can move the entire arm.

Movements, such as finger movements, can open and close the hand clamp, and wrist movements can move the entire arm.

The developer encourages users to come up with their own features for the robotic arm and share them on the GitHub platform so that they can further improve the device.

4. LittleArm Big

The LittleArm Big project can be described as "several arms coming together".

This is another educational model originally designed to be used as a teaching tool for high school and college students in STEM classes.

LittleArm Big is a complex 3D printed servo-assisted robotic arm developed by Slant Robotics in 2017. The device can measure up to 11.5 inches (approx. 29cm) and carry objects weighing up to 0.25 pounds (approximately 113 grams). The hand is designed for programming and can be controlled via Bluetooth as well as via Windows apps. To control this robot from iOS devices, you will need to migrate from Python code.

From less than 50 components of the LittleArm Big arm, 12 parts are 3D printed. These parts are not servos or electronics and are controlled by the Arduino Nano. The developers claim that the model can be assembled in less than two hours, but the assembly and adjustment of a manipulator with six DOF (degrees of freedom) may require the appropriate experience.

These parts are not servos or electronics and are controlled by the Arduino Nano. The developers claim that the model can be assembled in less than two hours, but the assembly and adjustment of a manipulator with six DOF (degrees of freedom) may require the appropriate experience.

5. Scara and Scara printers

Scara robotic arms are highly accurate and easy to copy.

The term Scara stands for "selective assembly robotic arm". This is a type of robotic arm that can be 3D printed and used for 3D printing.

The type of movement of these manipulators allows for high accuracy, although they are more limited in degrees of freedom than other designs. Scara robots can be used to assemble more traditional robotic arms or specifically for 3D printing. Due to the simple geometry of the design, they are very easy to print on your own. With such a simple but smart system, you can print a new 3D printer or robotic arm.

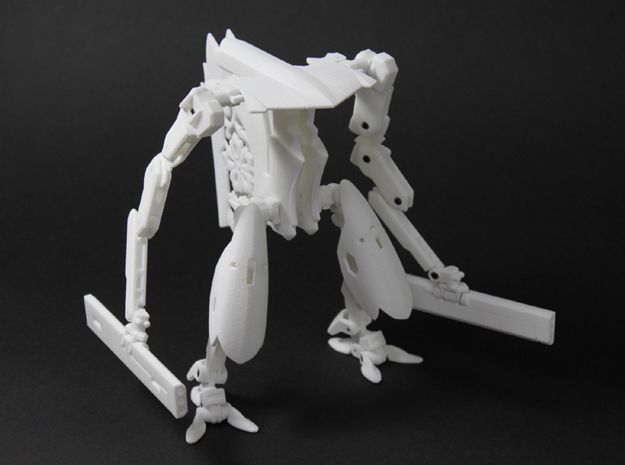

Zoomorphic robots

Zoomorphic robots are robotic mechanisms that use the anatomical features and features of animals to work. Currently, one of the most popular are robots that move with movements that resemble crab. They are interesting in that they use a complex system of movements to move each of the "legs" in turn. Thanks to this, such mechanisms are able to move on different surfaces without any problems, unlike robots that use wheels to move. Wheeled robots are limited in movement, as they cannot move on some types of soil.

Currently, one of the most popular are robots that move with movements that resemble crab. They are interesting in that they use a complex system of movements to move each of the "legs" in turn. Thanks to this, such mechanisms are able to move on different surfaces without any problems, unlike robots that use wheels to move. Wheeled robots are limited in movement, as they cannot move on some types of soil.

Consider the most modern models of zoomorphic robots with four or more legs.

1. Strandbeest

This original robot walks in style like no other. The creation of this model was inspired by a mechanical design made by the Dutch artist Toe Janses, a developer of the Thingiverse service under the nickname nraynaud. Strandbeest is equipped with a walking mechanism consisting of a crankshaft that is connected to all legs. Each leg has several connecting rods, the dimensions of which were determined empirically. The whole structure moves with the help of motors, is controlled remotely and has a gait resembling that of a four-legged animal.

Driven by the force of the wind, Strandbeest can move forward or backward without turning as it has no forward direction. It needs at least four legs to move, but the number of limbs can be increased to any even number.

Like its prototype, Strandbeest can rotate. Watching the robot gait is truly impressive, as the complex articular mechanism underlying the design allows for truly fluid movement.

The robot has simple electronics and is easy to program, so it is considered small. But where the device really stands out is that it has a complex system of joints.

The 3D printing files for this robot can be found on the Thingiverse website.

2. Flexoskeleton

Flexoskeleton walks like a beetle and moves like an obedient machine.

What happens when you combine flexible mechanisms and beetles? Flexoskeleton! This zoomorphic robot was designed by James Jiang, a graduate student at the University of California, San Diego. The mechanism of the device uses the flexibility of the material to mimic the flexibility of muscles. The body of the robot is completely 3D printed.

The body of the robot is completely 3D printed.

Instead of using screws and rods, the flexoskeleton uses the principle of a flexible mechanism to move the legs and return them to their natural position. This eliminates the need for joints, springs and pistons. The flexibility of the material acts as the robot's own spring. As a result, not only is less material wasted, but a more natural gait, reminiscent of that of a living being, is created. In addition, this design simplifies programming, since it is not necessary to take into account the movements of independent joints.

The flexoskeleton vividly demonstrates the principle that sometimes a solution doesn't have to be complicated, just think about it differently.

3. OpenCat

OpenCat is Dr. Lee's robotic cat model.

Rongzhong Li is an assistant professor at Wake Forest University in North Carolina and the creator of an open source 3D printed robotic cat. After OpenCat got into the weekly selection of videos about robots on the IEEE Spectrum website, a flurry of proposals fell upon the developer to further develop his personal project.

On his Hackster page, Dr. Li explains that he started working on the project in the summer of 2016. Since then, his robotic cat has gone through seven iterations, each more difficult than the last.

On the GitHub platform you can find a complete list of materials and files needed to create this cat. Dr. Lee recommends using ABS filament, rubber (TPU), conductive and nylon filaments.

The Doctor currently has two working models: a smaller one powered by an Arduino module for the STEM education and developer community, and a larger model with a built-in Raspberry Pi module for AI-enhanced perception.

Dr. Lee is currently looking for funding to develop OpenCat from private to collaborative and eventually to a mainstream product.

4. Kame

The Kame robot is the very embodiment of movement. It's a 3D printed robot based on FreeCAD and shaped like a small quadruped. The mechanism was created in order to study the features of various gaits and the corresponding algorithms.

Built around the Esp8266 Wi-Fi module, Kame has eight servos (two for each leg), a small LiPo battery, and can be programmed with an Arduino. Watching him walk forward with unwavering confidence is both impressive and intimidating.

More information, including the complete FreeCAD sources and source code, can be found in the GitHub service repository. Detailed building instructions for this robot are also available on the Hackaday page.

5. Vorpal

The Vorpal hexapod robot is another great educational tool.

Vorpal is a design by Steve Pendergast. Since a successful crowdfunding campaign in 2018, this robot has continued to be a unique artisan project in classroom 3D printing.

The Vorpal robot is completely open source, can be programmed from scratch and controlled via Bluetooth. This is a great project for kids and adults to get familiar with robotics and coding. You can get more information about the project on the Vorpal Robotics website.

The Vorpal robot can be assembled by yourself (approximately $60), or purchased fully assembled or in kits for various levels of assembly.

6. Xpider

If you're afraid of insects and arachnids, you might not like the Xpider 3D printed spider-like robot. But, fortunately, he does not look very scary and even quite harmless.

Xpider was designed by the Chinese design team Roboeve in 2017. This tiny movement is 3.4 inches (8.6 cm) in diameter and weighs only 5.3 ounces (about 200 grams).

Xpider's key feature is the miniature camera mounted on its head. The robot makes its way and crawls through difficult obstacles to reach a given goal, and then transmits the footage to its operator. The shell of the device is printed on a 3D printer. Before reaching the final design, it was developed over several iterations.

On the Hackaday website, you can find files for self-printing of the Xpider robot skin.

Small robots

Not all robots have to be complex or large to be considered cutting edge. Sometimes advanced features can be programmed or used for educational purposes, or as part of the study of one particular movement method.

Sometimes advanced features can be programmed or used for educational purposes, or as part of the study of one particular movement method.

Robotics has many interesting challenges and many aspects to experiment with. Reducing the size of mechanisms is one such challenge.

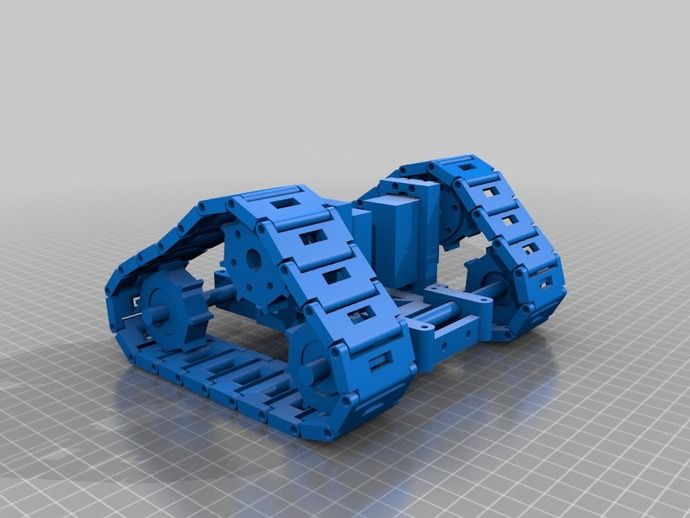

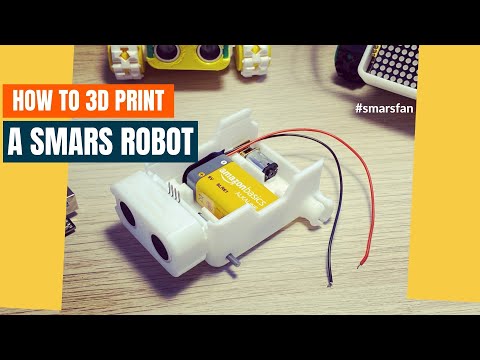

1. SMARS

The SMARS robot has a modular design, so the possibilities of its customization are truly endless.

SMARS is an acronym for Screwless/Screw Modular Robotic System. This simple and inexpensive 3D printed modular robot was created for use in education. It has a minimal number of components and can be assembled without screws, soldering or glue.

Thanks to the modular design of the robot, designers can easily install various sensors and tools into the mechanism, and even create their own parts. Inventor Kevin Thomas set the example by releasing a huge number of working mods. If you look for DLCs (additional modules) for SMARS, you can find ways to turn the robot into a quadruped or add a shovel to it, etc.

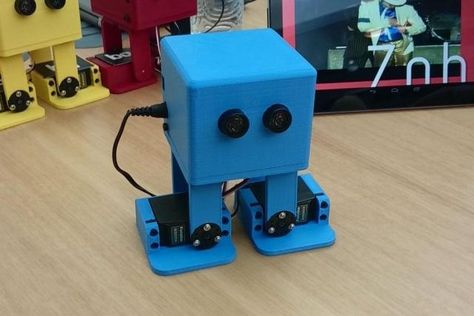

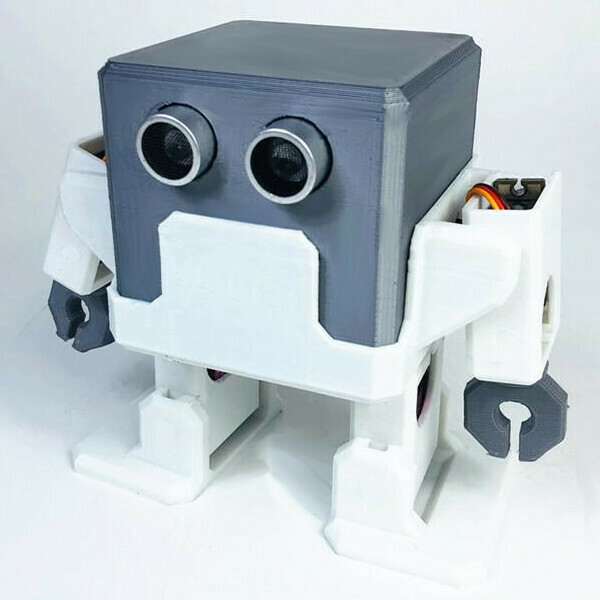

2. LittleBot

This manipulator arm can be modified to add new features.

LittleBot was created by Slant Concepts, formerly known as Slant Robotics, in 2017. The mechanism has a very simple chassis and operates on the basis of ultrasonic sensors that prevent the robot from colliding with objects. However, the beauty of this robot is that it can be programmed to perform many different functions, including line following, object detection, and noise recognition. LittleBot can even be used as a small accessory basket to connect additional Arduino components to enhance the robot's decision-making capabilities.

The LittleBot is a great starter robot for exploring sounding and decision making. Originally developed as part of a Kickstarter campaign, it attracted 58 supporters, far exceeding the campaign's goal. Learn more about the project and its successors on YouTube, the Arduino Project Hub, and Hackster.io.

3. IMA Juno

The IMA Juno is a simple robot designed for beginning robotics.

In 2016, Canadian company Explore Making released the IMA Juno as an educational tool for learning the basics of robotics, Arduino coding, and 3D printing. Based on SolidWorks, this educational robot can move forward, backward and turn sideways.

By following the step by step instructions, the user will learn about basic wiring, LED elements, servos and Arduino code. All Ima Juno 3D printed parts are optimized for printing on any desktop 3D printer (just keep in mind that you will have to use overhangs).

If you're looking for a deep 3D printing project, the IMA Juno is the perfect entry-level choice and an impressive little robot for its size.

4. Simple (no name robot)

This four-legged robot uses pencils as legs.

When it comes to making things, Randy Sarafan, a maker legend of sorts, comes into play. Randy founded the Instructables design studio, has written over 300 instructions, and has written several books on robotics and electronics. His unnamed 3D printed robot is fairly easy to print and build, and is easy to program and walk. All you need to make this mechanism is a 3D printer, servos, an Arduino module, 9-Volt battery, some nuts and bolts and four leg pencils. On his Instructables page, Randy gives detailed instructions for each step of the robot building process.

His unnamed 3D printed robot is fairly easy to print and build, and is easy to program and walk. All you need to make this mechanism is a 3D printer, servos, an Arduino module, 9-Volt battery, some nuts and bolts and four leg pencils. On his Instructables page, Randy gives detailed instructions for each step of the robot building process.

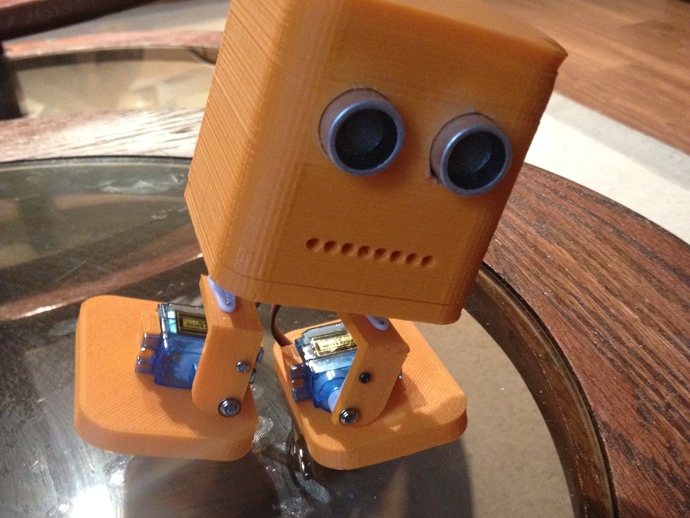

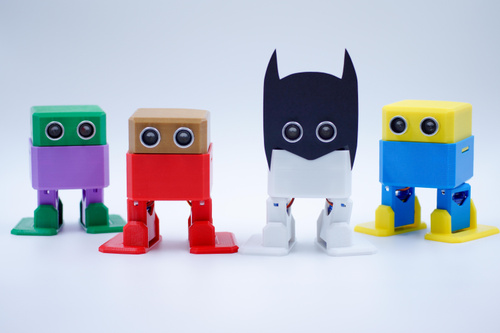

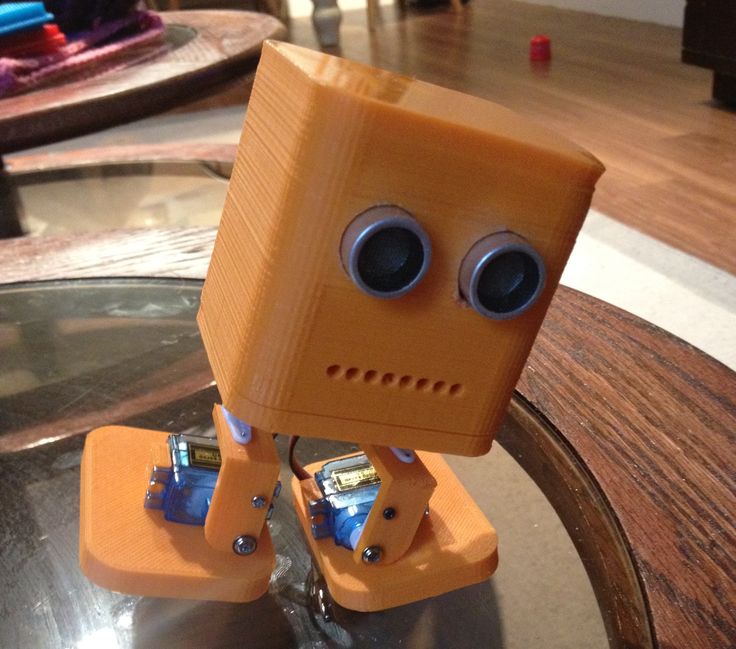

5. Buddy

Buddy is a cute, adorable “social” robot from LittleBots that is different from their robotic arms. The robot has a simple mechanism that is easy to do with your own hands. It is completely printed on a 3D printer, controlled using a programmable Arduino module and is designed to introduce social robotics. Buddy uses an ultrasonic sensor to "see" and interact with the world around him. Despite the fact that the robot has only three points of articulation, it is very expressive.

Check out the Instructables website for a tutorial and parts list for building Buddy.

6. Fighting

This fighting robot is capable of defeating other robots! He just can't hit.

The 3D printed combat robot, designed by Matt Cho, is a flexible robotic mech capable of performing combat moves such as an uppercut or a hook with both hands.

Currently, there are many modifications of combat robots, the main characteristics of which are high strength and resistance to falls. The Fighting model was created as an experiment to study the properties of a different type of fighting robot - lighter, more dynamic, able to walk and strike quickly. Due to the peculiarities of its design, this robot can stand up after a push, bend them, walk sideways and forward. But due to the increased stability of the lower torso, which does not allow it to fall, the robot cannot raise its legs to perform strikes.

This model is recommended to be printed from a durable material so that the combat robot can withstand impacts without damaging the structure.

The use of additive technologies contributes to the active development of the robotics industry and makes it possible to create almost any mechanism - from four-legged or humanoid robots to insectoid machines.

3D printing goes hand in hand with robotics, as it opens up a lot of possibilities for designers to add new features to their creations and allows end users to customize robots to their specific needs.

Source: 3DVision blog: https://3dvision.su/blog/roboty-napechatannye-na-3d-printere-samye-peredovye-proekty-2022-goda/

What kind of robots urgently need to be printed on a 3D printer

We want to turn to 3D printing again, as this industry is developing very quickly and offers us a lot of new interesting opportunities.

Despite all this, many people have questions: "What is all this for?", "What can be printed on a 3D printer?", "Where can I download ready-made models for 3D printing?" And we hope that after reading this article, most of your questions will disappear. So let's get started.

In this review, we will focus on 3D printed kits for building and programming simple robots from BQ, Poppy and ROFI.

Entertaining 3D robots from BQ

The Spanish company BQ provides excellent kits for beginner robotics. Consider Evolution, RHINO and Zowi. All kits are open source and available for around 100 euros.

Consider Evolution, RHINO and Zowi. All kits are open source and available for around 100 euros.

Evolution Robot

This is a simple educational kit that allows you to assemble a small robot on wheels and add any shell from 3D printed parts.

The Evolution kit helps young explorers develop creativity, teamwork, critical thinking, motor skills and 3D design.

The robot is controlled via the Robopad app for smartphones and tablets. The assembled kit itself measures 269 x 195 x 73 mm and weighs 703 g. The central part is made using 3D printing. Electronics components include battery pack, continuous rotation servos, ZUMbloq light sensor, USB cable, ZUM BT-328 circuit board, ZUMbloq buzzer, infrared and ultrasonic sensors.

By putting everything together and programming the resulting robot, you will be able to control it when it moves, avoids obstacles, makes turns and other maneuvers.

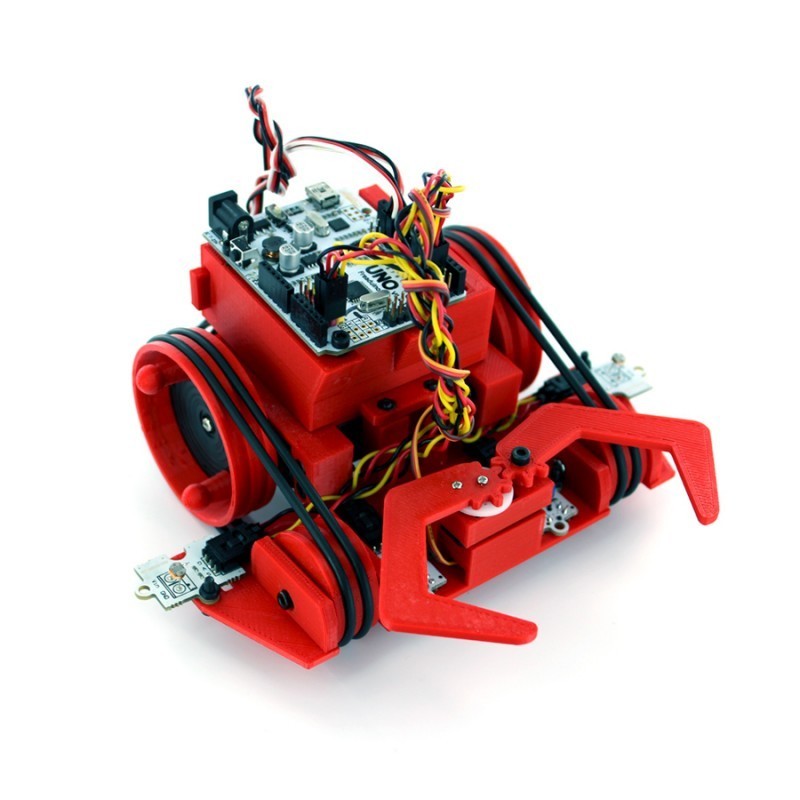

RHINO Robot

This is an educational rhino robot kit that is easy to build and program just like Evolution. He is able to act as a mini-bulldozer, pushing objects, and also take part in sumo robo-fights.

He is able to act as a mini-bulldozer, pushing objects, and also take part in sumo robo-fights.

To assemble the robot, just connect all the components together: servos, wheels, LEDs, electronics, Freduino UNO board, buzzer and other components that come in the box.

The RHINO can be controlled via Bluetooth via an Android app, or it can work standalone.

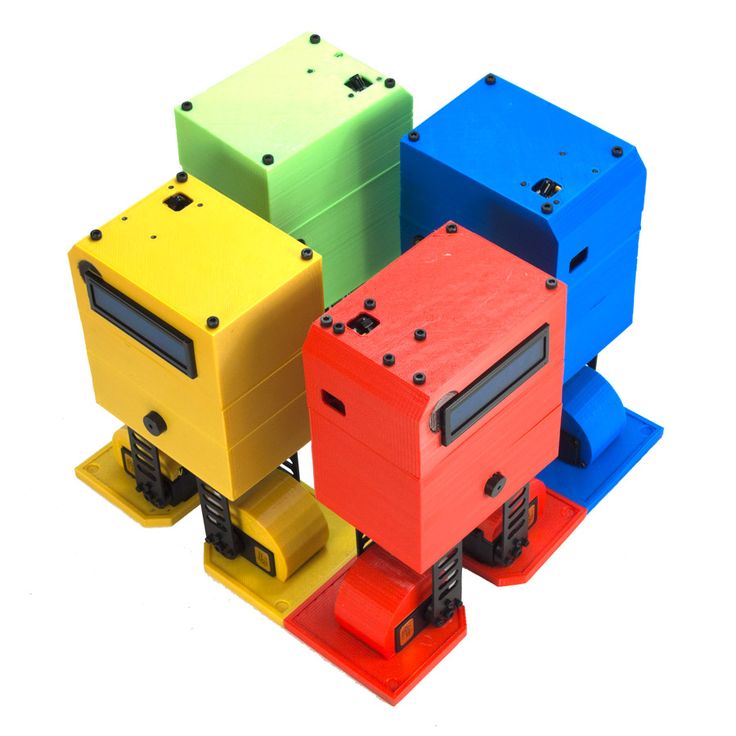

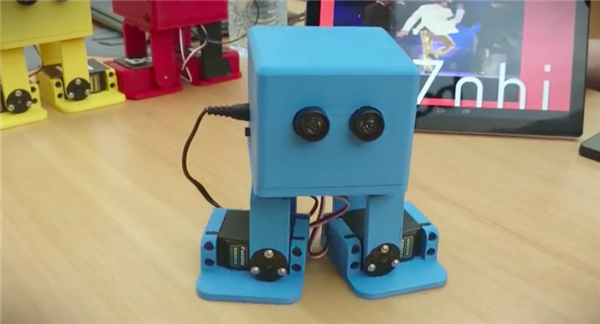

Zowi Robot

Miniature two-legged robot designed to teach children programming and robotics. It can be controlled from a smartphone via Bluetooth, set commands, connect to a computer via USB. The robot can walk and even dance.

The device consists of 3D printed parts for the body and legs, a BQ ZUM BT328 control board (Arduino will do), Futaba 3003 servos for adjusting the feet and legs, a microphone, a speaker, and an LED light for expressing emotions.

This video shows how Zowi dances to Michael Jackson, repeating almost all of his signature moves:

Poppy 3D kits

The French Poppy kit is an open source platform for building, using and interacting with 3D printed robots. The kit is suitable for beginners and experts in robotics, scientists, educators, developers and designers. Let's take a closer look at the main creations from Poppy - Humanoid and Torso.

The first is a bipedal robot made from 3D printed parts.

The device is 85 cm tall and weighs 3.5 kg. The apparatus also has 25 degrees of freedom with a multi-articulated torso (with 5 degrees of freedom). The robot is powered by Robotis servo motors, which allows it to respond to the reactions of external forces. So, the device is able to move its head, arms and walk on two legs.

The head of the robot contains the ODROID U3 board, which allows you to run programs and communicate via WiFi and Ethernet. Alternatively, you can replace this board with a RaspberryPi 2.

Other components include the USB wide-angle camera (120° FOV) located in the head for artificial vision, as well as all the sensors built into the Robotis motors.

Of course, such a complex set has a rather high cost, although the main costs are servo drives that can be ordered from us.

This video shows the main design features and capabilities of Humanoid:

Torso robot

This is a variation of the Humanoid, but without the legs. The robot is more accessible than the Humanoid, making it especially suitable for robotics engineers as well as STEM students. The device has a height of 38 cm, weight 1.8 kg and 13 servos for the movement of the arms and head.

The robot is also made from 3D printed parts and powered by Dynamixel servo motors, renowned for their reliability. Instead of legs, Torso has a suction cup base, which guarantees it high stability and stability.

The robot is programmed using IPython and Jupyter, although it can also be programmed using web-based visual programming tools such as Snap! The system will allow beginners to learn the program, or a group of scientists to perform a scenario of interactive behavior.

Video from Torso:

Official website of the project: https://www.poppy-project.org The device was designed to encourage more people to learn about robotics. Therefore, the kit is quite cheap ($350) and comes with open source. The robot can walk using a feedback accelerometer, 12 degrees of freedom and an ultrasonic sensor that allows it to bypass obstacles. A small Android tablet in the head provides ROFI with the brains, and an Arduino Mega circuit board provides the hardware interface. The device can be programmed to perform the simplest actions, such as walking, moving hands, dancing.

The robot measures 17.75 cm x 11.45 cm x 30.5 cm and weighs 227 grams.

Video from ROFI:

Official site of the project: http://www.projectbiped.com/

These were the next sets for training and development of robotic projects.