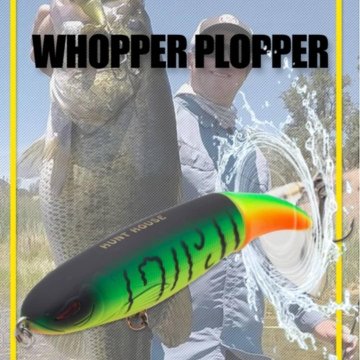

3D printed whopper plopper

Free STL file Whopper plopper v2・3D printer model to download・Cults

Crankbait Fishing Lure

€3

Fat Crankbait, easy to print and build, one piece print

€1

4-Piece-Swimbait fishing lure 14cm (easy print and build!)

€2.50

Zander/walleye multi jointed swimbait fishing lure

€3.98

Heavy duty saltwater fishing lures collection (popper, stickbait, chisel lure))

€1

2 Jig spinner, spinnerbait lead / tin / pewter master mold fishing lure

€2

Bass multi jointed swimbait or glidebait fishing lure

€3

Spinnerbait Chatterbait Lead / Tin / pewter master mold FISHING LURE

€2

Best 3D printer files of the Home category

LEGO BIKE RAMP

€1

Among Us Plant Pot

Free

Snowman Decoration

Free

Drawer Pull

€1. 49

Dental floss tooth case / Dental floss tooth case

€1.42

Mini planter

€0.70

Santa Claus crochet style

€1.25

Best sellers of the category Home

Wall Mounted Trash Can for Kitchen

€3.50 -15% €2.98

Notebook

€2.60

Samurai Incense Holder

€2.39

Dinosaur gluttonous pencil holder

€1.50

Wall shelf “Oyster fungus”

€2.40

Wolf Coat Rack

€2. 17

17

tealight holder ver.b

€1

Bordeaux, The Octopus

€2.35

Peeing Baby Succulent (Plant Vase)

€0.92

Venus and Aphrodite

€3.60

Melted girl

€3.29

Fast-print modular storage drawer system

€5.66

Epic Articulated Dragon

€2.35

chicken keychain

€1

1/14 LOADER - Vulpa L102

€61.13

Kawaii Dim Sums in a Cute Basket

€1.52

💖 Would you like to support Cults?

You like Cults and you want to help us continue the adventure independently? Please note that we are a small team of 3 people, therefore it is very simple to support us to maintain the activity and create future developments. Here are 4 solutions accessible to all:

Here are 4 solutions accessible to all:

ADVERTISING: Disable your banner blocker (AdBlock, …) and click on our banner ads.

AFFILIATION: Make your purchases online by clicking on our affiliate links here Amazon.

DONATE: If you want, you can make a donation via Ko-Fi 💜.

WORD OF MOUTH: Invite your friends to come, discover the platform and the magnificent 3D files shared by the community!

▷ whopper plopper 3d models 【 STLFinder 】

Whopper Plopper lure

thingiverse

Whopper Plopper fishing lure

Whopper Plopper type Lure

thingiverse

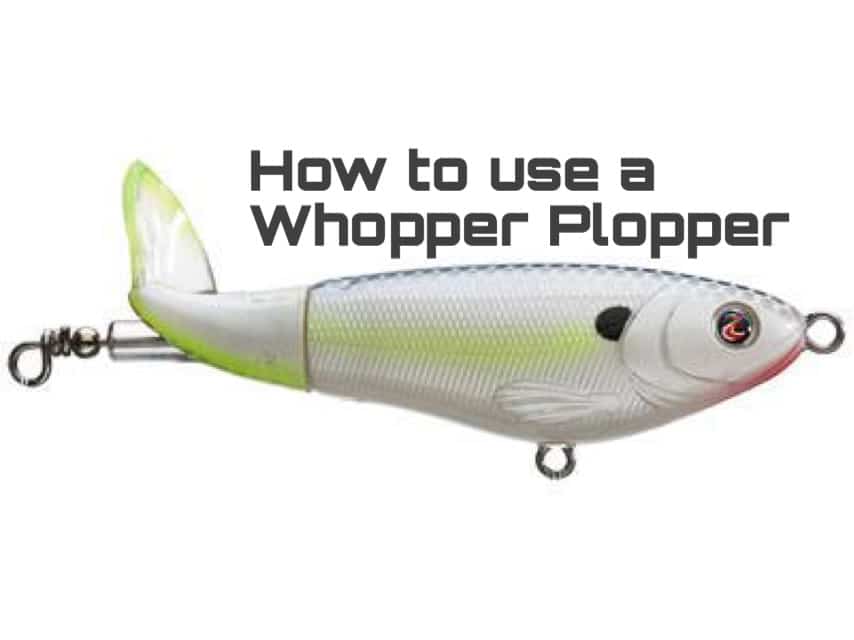

This is a similar design to the whopper plopper lure. ...This design is completely untested!

...This design is completely untested!

Frog Whopper Plopper

thingiverse

This is a whopper plopper fishing lure that I designed and 3d printed. I had some requests from the comments on my youtube channel to share the design. So here it is. Note that I stopped the print and added the steel ball to the inside of the...

Mini Whopper Plopper fishing lure (one piece)

cults3d

2 inch Whopper Plopper printed in one piece. Material used: 0.5 - 0.6mm wire M1 Screws (https://tinyurl.com/y7khpsse) 4mm eyes 1 pearl Print settings: 100% infill big Brim! 2 outer walls 0. 2mm layer height no support! ... Print orientation like on...

2mm layer height no support! ... Print orientation like on...

Whopper Plopper 2 fishing lure (one piece)

myminifactory

Easy to print and build Whopper Plopper. 70mm long, but easy to upscale. Use 0.6-0.8mm wire for 100% scale, 0.8-1mm wire for 120% scale and 1-1.2mm wire for 140% scale. Only use spring steal wire! ... Print settings: 80-90% infill (70% if you coat it...

Whopper Plopper 2 fishing lure - SapoLAB remix

thingiverse

Remix of the Whopper Plopper 2 fishing lure, from Domi1988, with longer body and bigger passthru holes, and rounder tail junction. 1.6mm and 2mm hole versions

The 2mm version can be printed ~50% smaller

Check the original Thing for the building...

1.6mm and 2mm hole versions

The 2mm version can be printed ~50% smaller

Check the original Thing for the building...

Whopper Plopper 2 fishing lure (one piece)

thingiverse

Easy to print and build Whopper Plopper. 70mm long, but easy to upscale. Use 0.6-0.8mm wire for 100% scale, 0.8-1mm wire for 120% scale and 1-1.2mm wire for 140% scale. Only use spring steal wire! For instruction scroll down. ... **Print...

Whopper Plopper 1 fishing lure (one piece)

myminifactory

2 inch Whopper Plopper printed in one piece.https://www. youtube.com/watch?v=BN4lebKy4Ho https://www.youtube.com/watch?v=SYYGoLM_nEQ Material used:0.5 - 0.6mm wire (please use strong spring wire, don´t use soft wire!)M1 Screws...

youtube.com/watch?v=BN4lebKy4Ho https://www.youtube.com/watch?v=SYYGoLM_nEQ Material used:0.5 - 0.6mm wire (please use strong spring wire, don´t use soft wire!)M1 Screws...

Mini Whopper Plopper fishing lure (one piece)

thingiverse

2 inch Whopper Plopper printed in one piece. https://www.youtube.com/watch?v=BN4lebKy4Ho https://www.youtube.com/watch?v=SYYGoLM_nEQ **Update 21.03.19** I uploaded a bigger 10cm long version, because when you just upscale the small version it...

Churn -- A printable whopper plopper lure

thingiverse

Simple design for a floating whopper plopper. Two tail options and two body options:

- The hollow body is designed for resin printers, and will print hollow with a 1.5mm shell, it will not float but will just barely sink. If you reel at medium...

Two tail options and two body options:

- The hollow body is designed for resin printers, and will print hollow with a 1.5mm shell, it will not float but will just barely sink. If you reel at medium...

Whopper Plopper Tail

thingiverse

Remixed tails, one with dual and the other with quad props, haven't tried them out but hopefully more 'plop'! 100% scale works with 18 gauge galvanized wire (may have to drill out the holes a little first though) and 150% scale also works with 18...

whopper

sketchfab

No description provided.

Double Whopper Hamburger Value Meal

sketchfab

Double Whopper value meal. ...Out of humor I post this :) Hope some people enjoy it as much as I did eating it.

...Out of humor I post this :) Hope some people enjoy it as much as I did eating it.

125mm whopper

thingiverse

Main and rings for open source whoop frame

HevORT ZR V3 (Remix) - External Motor Version

thingiverse

Remixed the HevORT ZR_V2.5 https://forums.hevort.com/viewtopic.php?f=5&t=316&sid=ff76275fbf3fa8e84ef28e81eb52c7ee Ball Screw Mount BOM: Qty 3 | 7200-2RS Angular Contact Bearing Qty 3 | 10mm Shaft Collar, 24mm OD, 9mm Height Qty 3 | 2GT Timing Pulley,...

Scissor Paint Rack

cults3d

. .. (Also works for Army Painter drop bottles) Update: Now includes v2 ! - 32 bottle capacity, still fits on an Ender3 build plate - higher resolution meshes for more accurate slicing resultsUpdate: v3 - the super whopper - 40 bottle capacity !

.. (Also works for Army Painter drop bottles) Update: Now includes v2 ! - 32 bottle capacity, still fits on an Ender3 build plate - higher resolution meshes for more accurate slicing resultsUpdate: v3 - the super whopper - 40 bottle capacity !

Spooky Tree Branch Silhouette Lamp Shade

thingiverse

It's a whopper in terms of complexity and I can't seem to think of a good approach without having a dual-extruder machine and using water-soluble filament for supports. From my research on the idea, when lighting, this needs to have the smallest, but...

On The Go Food Tray (universal mounting)

thingiverse

Tray has room for a BigMac or Whopper sized sandwich and a basket for fries!

Included 2 variations, pick whichever works best for you. The taller version with holes takes several hours longer to print...

The included mount is for the standard...

The taller version with holes takes several hours longer to print...

The included mount is for the standard...

The DanMcDumbass Configuration

thingiverse

Alright Hell Fans - Settle down because this next one is a whopper! (and not the chocolate malt kind) This week the DanMcNeil Configuration was thrown to the wolves of the intellectual Property Policy, and forced out of its spotlight within this...

Pinball Leg Bolt Washer

thingiverse

We had our product team go on a retreat into the serenity of the Rocky Mountains to come up with a real whopper of a name for this baby, and after almost two weeks of vigorous debate, it is our pleasure to introduce to you, the "Outpost Kodelia. ..

..

125mm HEAT round

thingiverse

It's a whopper... not for the faint of heart, it's a multi-day print designed for large printers (such as the CR-10). The fins are designed with some clearance (about .3mm at 100% scale, which I've found works well in other projects), and...

Impossible printed drape

thingiverse

But a whopper compared to the standard equipment.. After finding it was over cooling prints by not letting layers adhere to each other at 100% max fan speed but on the other hand it could bridge huge gaps with no support led me to hone in on the...

Mini Rack Mounted JumpDrive SD card Holder

thingiverse

Stay tuned I'm about to unveil a whopper. .. and not the kind from BK either. But speaking of BK (Burger King) if you find my designs useful tips come in handy to feed my cheesburger addiction...lol

A NOTE ON SCALE:

different slicers...

.. and not the kind from BK either. But speaking of BK (Burger King) if you find my designs useful tips come in handy to feed my cheesburger addiction...lol

A NOTE ON SCALE:

different slicers...

What Europe's first fully 3D printed house looks like

Trends

TV channel

Pro

Investments

Events

RBC+

New economy

Trends

Real estate

Sport

Style

National projects

City

Crypto

Debating Club

Research

Credit ratings

Franchises

Newspaper

Special projects St. Petersburg

Petersburg

Conferences St. Petersburg

Special projects

Checking counterparties

RBC Library

Podcasts

ESG index

Policy

Economy

Business

Technology and media

Finance

RBC CompanyRBC Life

RBC Trends

Photo: Project Milestone

Europe's first fully 3D printed home welcomes its new occupants, a couple from Amsterdam

What's happening

What it means

The creation of the first fully 3D printed house in the Netherlands is just the beginning of a new phase in the industry. Residential buildings built using 3D printing technology have a number of significant advantages over "classic" buildings. Firstly, the speed of the project, the first house was printed in five days, but going forward, the company plans to produce concrete elements on site, as well as use a 3D printer to create auxiliary installations, which will reduce construction time and costs.

Residential buildings built using 3D printing technology have a number of significant advantages over "classic" buildings. Firstly, the speed of the project, the first house was printed in five days, but going forward, the company plans to produce concrete elements on site, as well as use a 3D printer to create auxiliary installations, which will reduce construction time and costs.

In addition, in an era of global concern about the state of the environment, such "green" technologies help to reduce environmental damage to the environment - with 3D printing, the consumption of cement and waste of building materials is much less than with "traditional" construction.

Finally, with the help of a 3D printer, almost any design idea can be realized, which will allow you to move away from the concept of residential buildings in the form of "concrete boxes". The development of this technology makes it possible to erect buildings of such forms that are difficult and expensive to build using traditional methods.

The technology of printing houses on a 3D printer is actively developing in Russia, France, the USA and other countries. It is assumed that this will help solve the problem of providing citizens with affordable and decent housing.

Updated on 07/30/2021

Text

Ksenia Yanushkevich

Top of the trend

Related materials

17 real buildings printed on a 3D printer - The future on vc.ru

3D printing technologies are developing extremely rapidly and are used in various areas of human life.

45 328 views

Recently, much attention has been paid to the printing of buildings, and printed houses are increasingly appearing in recent years in different countries of the world - in the USA, Saudi Arabia, Mexico, France, Russia, the United Arab Emirates and others. I have prepared a list of existing 3D printed buildings for 2020.

I have prepared a list of existing 3D printed buildings for 2020.

What is a 3D printer for construction.

Today's 3D construction printers differ in designs and wall construction methods. The most common printers are portal construction, two- and four-support construction, based on a manipulator arm or a circular design. The equipment allows you to create small architectural forms and elements of structures for their subsequent assembly on site, or allow you to print the entire building on the construction site. The height and dimensions of the printed building depend on the specifications of the printer being used.

How the printing process works.

The extruder extrudes a fast-hardening concrete mixture with various additives. Each subsequent layer is applied on top of the previous one, due to which a vertical structure is formed. The concrete layers below are thus compacted, thereby increasing their ability to withstand the next layers, and hence the entire weight of the structure. To strengthen the structure, it is reinforced, which can be both vertical and horizontal. The laying of the horizontal armored belt is carried out between the layers, the vertical reinforcement is installed after the composition has hardened, and then it is poured with concrete.

To strengthen the structure, it is reinforced, which can be both vertical and horizontal. The laying of the horizontal armored belt is carried out between the layers, the vertical reinforcement is installed after the composition has hardened, and then it is poured with concrete.

Advantages of 3D printing over other construction methods.

3D printer fabrication opens up great opportunities for construction and related industries. Practical application has revealed the following advantages of additive manufacturing:

- It removes the limits from the imagination of designers and architects who design buildings, as it provides opportunities that are not available with the construction methods we are used to.

- High speed of construction of buildings and structures.

- Complete process automation.

- Low power equipment.

- Significant savings compared to conventional construction methods by reducing labor and energy costs and accelerating construction time.

- The formation of waste building materials is completely eliminated.

- Minimization of human intervention in the construction process not only allows building in places inaccessible to people, but also in ordinary areas eliminates the human factor and reduces the likelihood of error.

1. June 2014. China. Chinese company Shanghai WinSun Decoration Design Engineering Co presented houses built using 3D printing techniques in an industrial park in China's Jiangsu province. A total of ten houses were created, each of which cost a little more than three thousand pounds sterling. Over the next ten months, the technology improved and the company produced several different types of buildings for the exhibition, the tallest of which has five floors.

2. August 2014. USA. Company Totalkustom Andrey Rudenko printed the lock. The printing took a total of 2 months. The machine's printing speed was 50 cm in 8 hours. The main part of the castle, measuring 3m x 5m and 3.5m high, was printed as a single unit, and the towers were then printed separately.

The machine's printing speed was 50 cm in 8 hours. The main part of the castle, measuring 3m x 5m and 3.5m high, was printed as a single unit, and the towers were then printed separately.

3. July 2015. China. Chinese company Zhuoda assembled a two-story house in record time. The modular home, made up of six 3D printed modules, was assembled on site in less than 3 hours. Of course actually about 90% of the work was carried out in the company's workshops, and on the site they were only assembled into a single building.

4. September 2015. Philippines. Totalkustom Andrey Rudenko's company built apartments on the territory of a hotel in the Philippines, 10.5 mx 12.5 m in size and 3 meters high. The building was built using local materials - sand and volcanic ash.

5. May 2016. UAE. Chinese company Shanghai WinSun Decoration Design Engineering Co printed prefabricated structures for the subsequent assembly of an office building in Dubai. The area of a one-story building is about 250 square meters. m.

The area of a one-story building is about 250 square meters. m.

6. March 2017. Russia. Apis Cor introduced the first 37 sq. m.. The printed house has an interesting shape, but as the participants themselves say: this is just to show the flexibility of printing technology, the shape of the buildings can also be the usual square. Compared to other construction 3D printers, this printer is very compact (4×1.6×1.5 m), weighs 2 tons, and can be easily transported to the construction site.

7. October 2017. Russia. In Yaroslavl, Spetsavia presented the first residential building in Europe and the CIS, built using construction 3D printing technology. Construction of the house began in 2015. The box of the building was printed by a portal printer piece by piece and then assembled on the foundation in one month in December 2015. In the summer of 2017, the roof was completed and the bulk of the interior finishing work was carried out.

8. March 2018. France. Yhnova presented a five-room one-storey house with an area of 95 square meters. For its construction, the engineers used a large manipulator, at the end of which an extruder for polyurethane foam is fixed. While working, he applied the foam in accordance with the 3D model of the building loaded into it. After applying the foam, the builders periodically filled the erected part with concrete, and also inserted the frames of doors and windows.

March 2018. France. Yhnova presented a five-room one-storey house with an area of 95 square meters. For its construction, the engineers used a large manipulator, at the end of which an extruder for polyurethane foam is fixed. While working, he applied the foam in accordance with the 3D model of the building loaded into it. After applying the foam, the builders periodically filled the erected part with concrete, and also inserted the frames of doors and windows.

9. March 2018. USA. American Company Icon built a prototype house in Texas to prove the technology's performance. The area of the building was 32 sq.m., printing was performed by a portal type 3D printer moving along rails installed on the site.

10. July 2018. Spain. Be More 3D printed a 24 m2 concrete building. For the construction, a two-support 3D printer was used, the width of which is 7 meters and the height is 5 meters.

11. September 2018. Denmark. 3D Printhuset printed a 50 square meter office in Nordhavn. The 3D printer used for printing is of the portal type and has a size of 8 x 8 x 6 meters. Print speed 2.5 meters / min. Each layer is 50-70 mm. The print material is concrete made largely from recycled tiles and sand.

Denmark. 3D Printhuset printed a 50 square meter office in Nordhavn. The 3D printer used for printing is of the portal type and has a size of 8 x 8 x 6 meters. Print speed 2.5 meters / min. Each layer is 50-70 mm. The print material is concrete made largely from recycled tiles and sand.

12. October 2018. Italy. Crane Wasp built a building in ten days using a tricycle 3D construction printer. The house uses passive solar heating technology and natural ventilation. The composition for printing was created on the basis of waste from rice cultivation (it was 25% local soil (clay and sand), 40% straw, another 25% - from rice husks and 10% - from hydraulic lime).

13. November 2018. Italy. Company Arup in collaboration with the architectural bureau CLS Architetti erected a building in 1 week with an area of 100 sq.m. The building was printed in segments with subsequent assembly at the construction site.

November 14, 2018. Saudi Arabia. The Dutch company CyBe Construction has completed the construction of a building with an area of 80 sq.m. It took about a week to 3D print the necessary elements, and a little more than a day to assemble. The walls are made up of 27 printed blocks, and the parapets needed another 21 blocks to make.

Saudi Arabia. The Dutch company CyBe Construction has completed the construction of a building with an area of 80 sq.m. It took about a week to 3D print the necessary elements, and a little more than a day to assemble. The walls are made up of 27 printed blocks, and the parapets needed another 21 blocks to make.

15. August 2019. USA. S-Squared 3D Printers (SQ3D) showed a prototype residential building that can be built from floor to roof in just twelve hours. The house has an area of 46 m2. During the printing process, a 3D printer of a two-support design was used.

16. October 2019. UAE. Apis Cor has announced the completion of the world's largest 3D printed building. Located in Dubai, the 650 sq. meters has a building height of 95 meters and entered the Guinness Book of Records as the largest building printed directly on the construction site.

17. December 2019. Mexico. American company Icon erected two residential buildings for the non-profit organization New Story, in southeastern Mexico. The imprinted buildings have a flat roof, curved walls and an area of 46.5 square meters

The imprinted buildings have a flat roof, curved walls and an area of 46.5 square meters

As can be seen from the impressive list of completed projects, progress in the field of construction 3D printing clearly does not stand still, new techniques are constantly being introduced, various materials are being created, including from recycled raw materials, and high-tech equipment is being developed. In a short period of time, the technology has attracted the interest of a large number of enterprises that are engaged in the development of equipment, special building mixtures, libraries of structural solutions for designing buildings for 3D printing, as well as the preparation of a legislative, regulatory and regulatory framework.

I am sure that in the future the entire construction process will be able to become fully automated, without human intervention, not only when printing foundations and walls, but also when printing ceilings and roofs, automatically install utilities, doors and windows.