3D printer new jersey

New Jersey 3D Printing Services

Fast turnaround and high quality 3D printing in NJ. Get 3D printed parts without the hassle.

No signup required.

What makes PrintAWorld different from the other New Jersey 3D printing companies

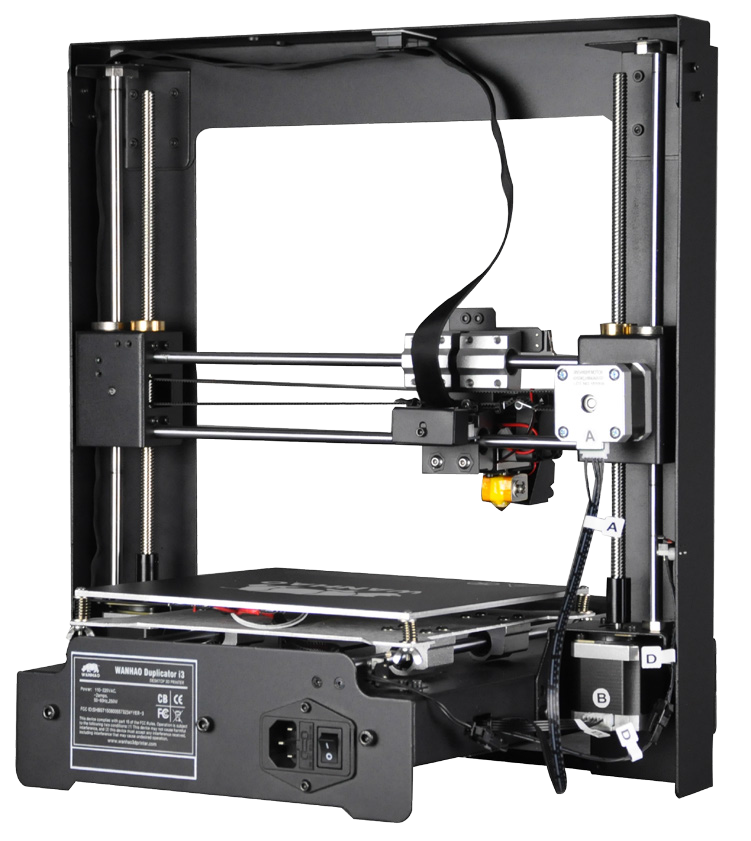

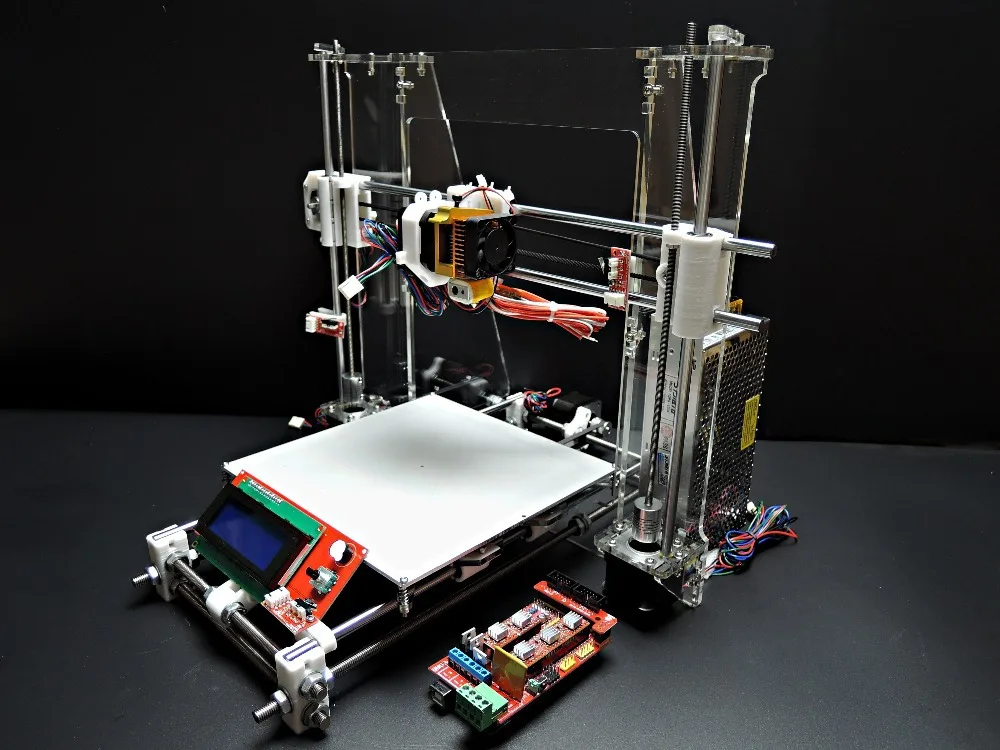

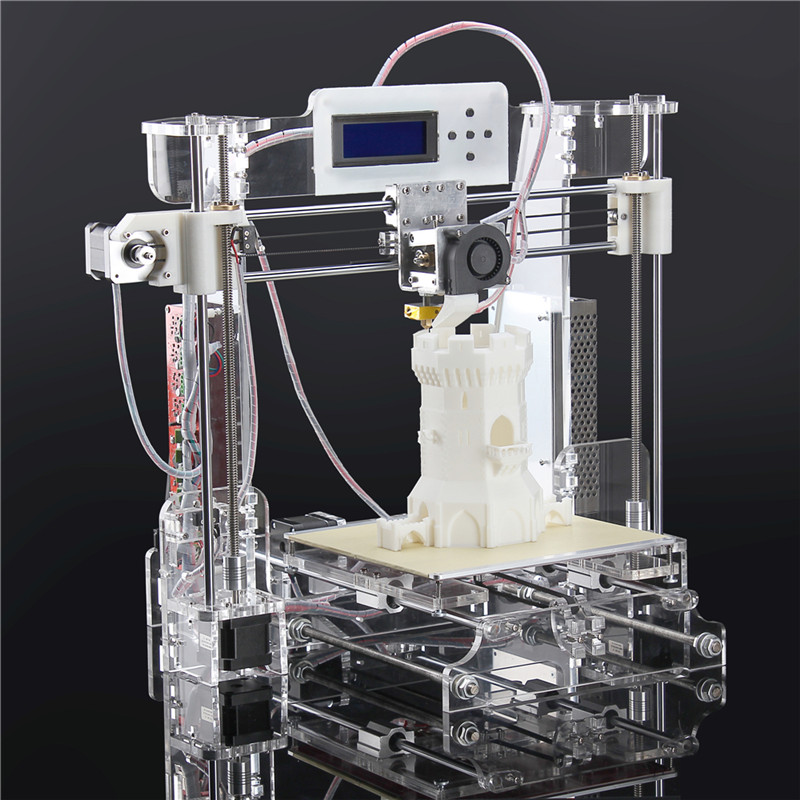

Get access to industrial 3D printers

High resolution and large scale 3d printers are expensive. At PrintAWorld, you'll get the benefits of industrial 3d printing without the cost that comes with it.

Get expert help

We’ll help you every step of the way from the design to figuring out the best way to get your project done within budget and time.

Fast turnaround

On a tight a deadline? No problem! With our 3D printing and fabrication capabilities, we can make your trophies faster than traditional trophy makers. We can even make them in 2 days!*

Select projects that we did for our clients in New Jersey

How our 3D printing service in New Jersey works

0

1

.

Send us a few information

The material you need, quantities and a short description of your project. If you're unsure, don't sweat it. We will guide you to the perfect solution!

0

2

.

Upload a 3D File

Send us your.stl or .obj files. Don't have a file ready? We also provide a professional 3D modeling service.

0

3

.

Receive a quote

You'll get an email and a call from us immediately so we can talk about the best and most cost effective way to approach your project. No minimum order quantities!

0

4

.

Pay and print

Once the quote is approved we will start 3D printing your idea.

We'll keep you updated and we'll make sure the result is exactly what you want or even more. No minimum orders.

We'll keep you updated and we'll make sure the result is exactly what you want or even more. No minimum orders.0

5

.

Shipping or pickup

We offer nationwide delivery or you can pick it up from one of our local studios near you.

3D printing materials that we offer

Looking for a material that isn't listed here? Shoot us an email at [email protected]

ABS

ABS plastic is a strong and durable material. They're ideal for prototyping mechanical parts. For prototypes that require high-precision, consider CNC machining ABS or printing in other materials. For production parts, we suggest using injection molding instead.

Nylon PA12

Nylons is a strong and durable material that is also flexible. Ideal for live hinges and functional parts.

Standard Resin

Perfect for complex 3d models that require high details and smooth finishing.

SOMOS Resin

SOMOS resin is the industrial version of standard resin. It's perfect for almost any 3d that require smooth finishing and high details. We recommend this material for any projects such as high-detailed models, architecture, art sculptures and engineering prototypes.

SOMOS Waterclear 10122 Resin

Somos® WaterClear Ultra 10122 is a clear resin that produces colorless, functional and accurate parts that simulate an acrylic appearance. Parts produced from Somos® WaterClear Ultra 10122 exhibit excellent water and temperature resistance.

F.A.Q

How much does 3D printing in New Jersey costs?

The cost of 3D printing depends on the 3D model, the material you choose and type of finishing required. Rushed orders adds additional cost as well.

How long does your 3D printing service take?

Depending on the complexity of the project, our standard turnaround time is 3-5 days. Rushed projects can take as fast as 1 day.

Do you offer delivery?

We can ship anywhere in the U.S. and the world. If you have your own Fedex or delivery account, we can use that.

3D Printing Service New Jersey | Instant Quotes Online

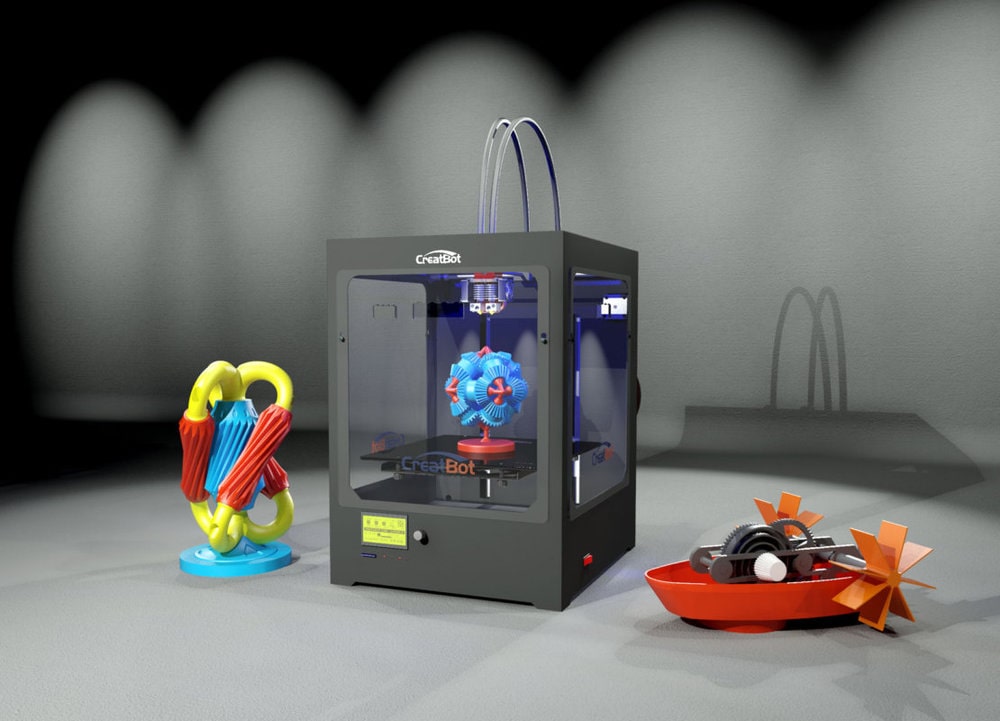

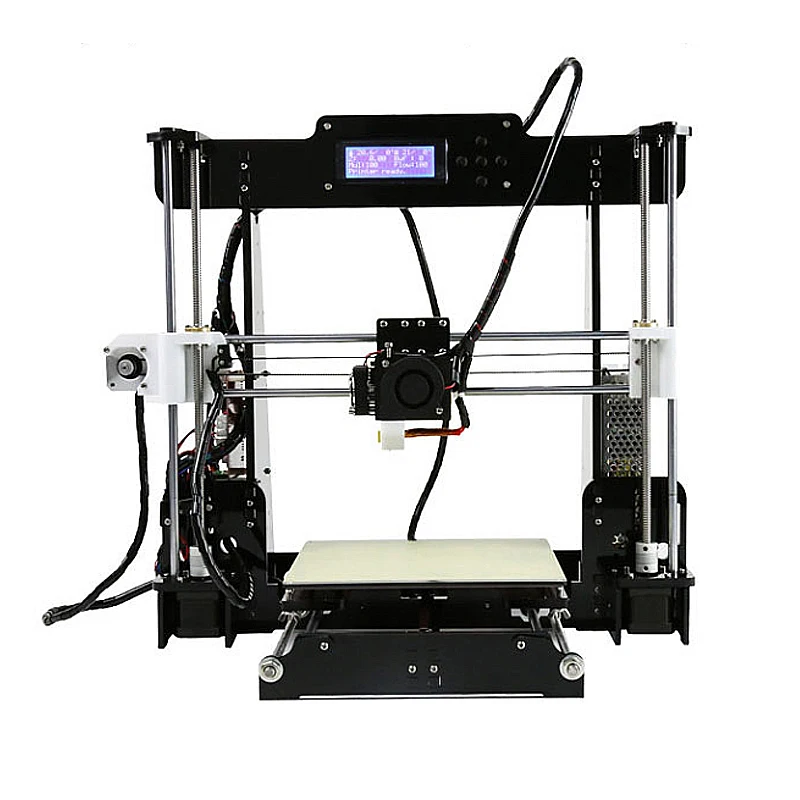

Our 3D printing capabilities

We have over 90 3D printing shops in our network and are well known for manufacturing high-quality parts at competitive prices, from rapid prototyping with Fused Deposition Modeling (FDM) to functional end parts made with Selective Laser Sintering (SLS) or Multi Jet Fusion (MJF).

Gallery of 3D printed parts manufactured by Hubs

With over 65,000 customers from every industry, including aerospace, defense, robotics, medical, machinery, automotive and electronics, we have extensive experience meeting a diverse range of 3D printing requirements, from prototyping to production: Visual aids, concept models, injection-molding prototypes, form-fit & function prototypes, tooling and casting patterns, jigs, grips and fixtures, and durable end parts.

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7.92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22. 18 18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55.38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29. 83 83 |

| Industry | Aerospace |

Instant, online 3D printing quotes

-

Upload a CAD to start (STEP, STP, IGES, IGS, SLDPRT, 3DM, SAT, STL, OBJ or X_T)

-

Price updates in real-time as you change materials, lead time, etc..

-

No hidden costs. Our instant quotes are not just indications, but the actual price, and include shipping and customs up front.

Learn about how our quoting algorithm works

Our ordering process

Receive instant quote

Upload your CAD to our online quoting platform

Confirm specs

Configure your part specifications and select a lead time that suits your schedule

Production

We select the best manufacturer for your order, and production begins immediately

Quality control

We take full responsibility for making sure your parts are manufactured according to our standards

Delivery

Our 3D printing service has been rated 4.

9/5

9/5 Over 150 customers are satisfied with our 3D printing service.

“As always, he was very flexible and helpful throughout the process working with odd pickup and delivery issues while I was out of town.”

“Lee was very professional and basically bent over backwards to ensure we got our order on time. Much appreciated!”

“Excellent work and will go right into our design. Thanks”

“Awesome prints! They were rather large prints and yet the dimensions were spot on. ”

“Print as expected. Communication and flexibility was excellent.”

“Excellent service. Great person. Very helpful. Quality work!!!”

“Completed complex parts and communicates timelines/suggestions well. A happy repeat customer. ”

“great print, quality, immediate responses. Thanks”

Thanks”

“Great service. Communications and speed were exceptional.”

“First time getting something 3D printed and it was a very easy and effortless experience. Answered all my questions and the print quality was exceptional. My expectations were exceeded and more.”

“Perfect. Prints were started the day of upload and delivered before the deadline. Quality is near perfect! ”

“Great job and shipped quickly. Item was received before quoted delivery date. ”

“Had headphone parts printed for two pairs of broken headphones. The parts work flawlessly. Fast service and communication.”

“Parts arrived in good time. Quality is great! Thanks!”

“Quick communication, quick turnaround, great print. Highly recommend using him.”

“The parts were well-printed and the service was easy to work with.”

“incredible as always. i would give 10 stars if i could!”

“Easy to work with and helped quickly process and ship the order.”

“Quick response with the process and provided additional information such as images for the end result for customer to see. ”

”

“Responded promptly and received print faster than expected, thanks again! A+++”

“Get hub, part came back just as designed.”

“Fast turnaround and the parts fit perfectly ”

“Helped me out with some geometry glitches and took the time to show me debugging tools for future projects. Print was fast and looked great.”

“Great parts, communication and overall service!”

“These brackets look great and they all fit perfect!”

Show more reviews

Show less reviews

Teams build better parts

Create your Hubs team and start collaborating

Read more

The Hubs Standard - consistent quality, every time

Hubs takes the stress out of manufacturing by guaranteeing the quality and consistency of every part. Each order is dimensionally and visually inspected to make sure it meets the Hubs Standard.

3D printing materials

We can generate instant 3D printing quotes for 25+ plastics. For metal 3D-printed parts, you can request a quote from our parent company, Protolabs.

Available materials

SLS

PA 12 Glass filled PA 12

Desktop FDM

Prototyping PETG Prototyping ASA Prototyping TPU Prototyping ABS Prototyping PLA

Desktop SLA

Formlabs Standard Resin Formlabs Clear Resin Formlabs Tough Resin 2000 Formlabs Rigid Resin 4000 Formlabs Grey Pro Resin Formlabs Flexible Resin 80A Formlabs High Temp Resin Formlabs Durable Resin

MJF

HP PA 12 Glass filled HP PA 12

Industrial FDM

Markforged Onyx ABSplus Stratasys ULTEM 9085 Stratasys Stratasys ASA ABS M30 Stratasys ULTEM 1010 Stratasys

Industrial SLA

Accura 25 (PP-like) Accura ClearVue Accura Xtreme White 200 (ABS-like)

3D printing locations near New Jersey

Brick, NJ Toms River, NJ Lakewood, NJ

Howell, NJ Jackson, NJ Middletown, NJ

Old Bridge, NJ Perth Amboy, NJ Staten Island, NY

Woodbridge, NJ

The 3D Printing Handbook

No one understands 3D printing like us - our founders literally wrote the book. Click here to download the sample chapters.

Click here to download the sample chapters.

Buy the book from Amazon

FAQ's

How much does your 3D printing service cost?

The cost of your 3D printed parts depends on factors such as part volume, part complexity, choice of material, which 3D printing technology is used, and if any post processing is required. For more details on these cost factors, see our article on the cost of 3d printing. To check the cost of your 3D printed part, simply upload a CAD (.STL) file and select your material and 3D printing technology to receive a quote within seconds.

How do you guarantee the quality of my prints?

Your parts are made by experienced 3D printing shops within our network. All facilities are regularly audited to ensure they consistently meet the Hubs quality standard. We include a standardized inspection report with every order and offer a First Article Inspection service on orders of 100+ units.

We have partners in our network with the following certifications, available on request: ISO9001, ISO13485 and AS9100.

Follow this link to read more about our quality assurance measures.

How do I select the right 3D printing process for my prints?

You can select the right 3D printing process by examining which materials suit your need and what your use case is.

By material: if you already know which material you would like to use, selecting a 3D printing process is relatively easy, as many materials are technology specific.

By use case: once you know whether you need a functional or visual part, choosing a process is easy.

For more help, read our guide to selecting the right 3D printing process. Find out more about Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), Multi Jet Fusion (MJF) and Stereolithography (SLA).

How can I reduce the cost of my 3D prints?

In order to reduce the cost of your 3D prints you need to understand the impact certain factors have on cost. The main cost influencing factors are the material type, individual part volume, printing technology and post-processing requirements.

The main cost influencing factors are the material type, individual part volume, printing technology and post-processing requirements.

Once these have been decided, an easy way to further cut costs is to reduce the amount of material used. This can be done by decreasing the size of your model, hollowing it out, and eliminating the need for support structures.

To learn more, read our full guide on how to reduce the cost of 3D printing.

Where can I learn more about 3D printing?

Our knowledge base is full of in-depth design guidelines, explanations on process and surface finishes, and information on how to create and use CAD files. Our 3D printing content has been written by an expert team of engineers and technicians over the years.

See our complete engineering guide to 3D printing for a full breakdown of the different 3D printing technologies and materials. If you want even more 3D printing, then check out our acclaimed 3D printing handbook here.

We have an extensive range of online resources developed to help engineers improve their capabilities.

Introductory guides

Design guides

Material guides

Applications

CAD & file preparation

Post processing & finishing

Our other manufacturing capabilities

CNC machining

CNC machining

Milling (3-, 4- & full 5-axis), turning and post-processing

-

50+ metals and plastics & 10 surface finishes

-

Tolerances down to ±.0008” (0.020 mm)

-

Lead times from 5 business days

See our CNC machining services

Put your 3D printed parts into production today

Get an instant 3D printing quote

Production of 3D printers in Europe.

What blond birch trees are silent about ... / Sudo Null IT News market, with whom it is only possible (whom I did not meet - my beloved partner met), after which decided “That's it, let's go! We are going to 3D”

What blond birch trees are silent about ... / Sudo Null IT News market, with whom it is only possible (whom I did not meet - my beloved partner met), after which decided “That's it, let's go! We are going to 3D” Being, on the one hand, a dreamy and enthusiastic person, but on the other hand, a cynical and prudent businessman, before diving headlong into the industry, it was decided to shake the pool of 3D printer manufacturers vigorously before choosing an accent for future distribution.

I won’t dwell on this stage too much, I’ll just say one thing: they were “shaking” with uncomfortable questions, meetings, real tests, weighted price comparisons - companies from the top 10 brands that occupied the media space, the low-level segment was not considered in principle due to strictly defined competence distribution groups.

And so, in April of this year, we were thrown by a wave in the Spanish town of Navarre, where I personally saw the European level of assembly of 3D printers at factory bq , which I wanted to share with you, not forgetting the “cherry” at the end of the story.

The town where the factory of the company bq is located, producing Witbox printers, as usual for Europe (and I have been to many factories in Europe and China), is very small and expectedly romantic:

In the morning after arrival to the city - we went to the factory ourselves, the meeting was somewhat chaotic, because on the same day, more distributors from Italy and Colombia arrived at bq.

It was all the more interesting for me to see the production through the eyes of a person for whose arrival there was no time to prepare (by building the Potemkin villages according to a custom known in Russia).

What can I say, after the Chinese cold, poorly lit workshops with girls wrapping themselves in warm clothes with belongings on the desktops, the European assembly is always like oil for the soul.

Immediately striking: Space and Cleanliness

We were taken step by step through the entire production, allowing us to take general photographs without zooming in.

Below are the most interesting of them, in my humble opinion, with a few comments:

At the first stage in production, tables with guides are assembled, fixed inside the platform, and then the control electronics are fixed.

Under each printer, there is CHECK list , in which the assemblers mark the operations performed, and the intermediate testers check the operability or lack of it at a certain stage (these are white sheets inside each Witbox printer in the photo):

External electronics - installed by blue collar guys on this line. they also test this electronics:

In the next room we found FANUC Robodrill - in fact a large 3D printer, but in a non-additive manufacturing format.

Seeing it, the engineer of our company, who came to study, trembled and began to excitedly whisper in my ear that “this thing is worth more than anything that is here,” which made me worry for no apparent reason.

Our question: "What is it used for?" was shown to us on a stack of these spare parts stacked side by side.

This is a snap-box for the electronic filling of the printer, the Spaniards in bq grind it on their own:

Then followed the phrase that made me think:

“We used to print these boards on our own Witbox 3D printers, but with an increase in production it became absolutely unjustified in terms of time costs”

Guys from Russia, manufacturers of 3D printers, often boasted to me that many of the spare parts for their "gadgets" are produced on their own printers.

It can be concluded that the number of units produced is hardly large in these specific cases and can indirectly indicate a small amount of accumulated production experience.

Next to FANUC is the Laser Cutting Plotter , which makes the outer bright panels for the future printer.

Maybe I called it wrong, but for me, an office rat, such large machines, before my eyes turning huge sheets into beautifully shaped, ready-to-install external panels with a logo on board, always make a fascinating impression.

Even before the panels are installed, each printer is started to print a calibration pattern (below you will see a number of these printing Witboxes).

If the test is successful, the printer goes to packaging. At the same time, the model printed on this particular printer MUST be put into the box.

Doesn't pass the test - they make an additional adjustment to the victorious one.

Here I trembled again and for a long time fascinated looked at the bluish backlight of the print area, appreciating with peripheral vision an elegant solution for laying PLA plastic without the flip over the top, which is standard for most devices of this kind:

Printers that have passed the print test are equipped with external panels (yellow, black or white):

to play around” to our engineer, who became very close to like-minded Spanish engineers during the short time of our visit):

I liked EVERYTHING on the final packaging.

1. Double box - beautiful inner and outer shipping:

The guys from bq said that the printer in this package can withstand a fall from a height of 1 meter:

- Reel PLA - plastic (two for Witbox printer with two extruders)

— 4GB SD - card

— Additional HOT END — extruder nozzle (I almost burst into tears when I saw it, and girlishly framed the photo as a token of sincere gratitude for such attention to customers):

- Instructions and warranty card for 2 years operation

shipments to Madrid, main warehouse bq

after the mandatory palletization procedure:

In the morning - this (printed on a Witbox 3D printer, as evidenced by the inscription on the board) forklift

… will load them onto a truck bound for sunny Madrid, so that the “swallows” will then fly around the world…

Koda. Curtain.

Cherry

(which was promised above):

Why is the actual post placed in the hub Open Source ?

At the end of our trip we asked the Europeans:

Why are you, an absolutely successful IT company, second in the market in Spain in sales of smartphones and tablets, investing in the production of 3D printers?

Why are you so actively sharing information with us, investing your time, effort and money, including in the Russian market?

Are you not afraid that the #Chinese will come and eat you? Aren't you afraid that manufacturers in Russia will be able to knock out all Europeans and Americans from the 3D printer market?

Are you confident in the long term of your strategy?

The answer of Mario and Antonio from bq threw me into complete confusion:

We are NOT afraid of the Chinese.

The exact scheme of the WitBox 3D printer with all the spare parts is posted on our website:

Download, do it yourself.

We are deeply convinced that this data should be available so that the entire engineering community can hot-start the printer to the ideal, and the culture of production, its level, believe us, is extremely difficult to repeat.

There is nothing to fear here.

In this connection - to the inquisitive inhabitants of Habr SURVEY :

3D printing in the fashion industry: a new dimension

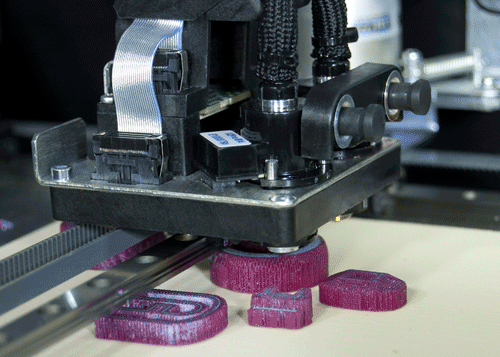

We are witnessing what many call the third industrial revolution: 3D printing, or additive technologies, can push back us from the era of mass production and lead to a new reality of customizable individual production. A good example is fashion. In the recent past, "fashion houses" were more like multidisciplinary research institutes. To create a collection of clothes, in addition to an expert sense of style, you need knowledge in anatomy, advanced sewing machines, appropriate fabrics and accessories, accessories, shoes, people (cutters, seamstresses, models and many others). Through trial and error, an art object is created, rarely successful, but always laborious. 3D printing is a toolless manufacturing method that allows physical objects to be produced from a 3D model, usually in layers. The term is also used generically as a synonym for rapid prototyping. The scope of the technology is endless: from tools and toys to robots and mechanical parts. There is no limit to what a 3D printer can create.

Through trial and error, an art object is created, rarely successful, but always laborious. 3D printing is a toolless manufacturing method that allows physical objects to be produced from a 3D model, usually in layers. The term is also used generically as a synonym for rapid prototyping. The scope of the technology is endless: from tools and toys to robots and mechanical parts. There is no limit to what a 3D printer can create.

Alexander Kornveits, expert in the field of additive technologies, founder and CEO of Tsvetnoy Mir

Fashionable futuristic design requires innovative production technologies, here 3D printing comes to the rescue. A wide variety of fashion accessories including bracelets, rings, brooches, necklaces and pendants can now be easily 3D printed. Let's take a closer look at how this technology can be used in the fashion world...

Custom Design

One of the unique aspects of 3D printing is the ability for designers to create custom shapes and sizes that would be impossible to produce with traditional methods.

Photopolymer 3D printing allows designers to produce products in small batches. Fashion designers can now create bold, one-of-a-kind pieces. In addition to time, technology can significantly reduce costs.

Accessories

The range of fashion accessories depends more on the imagination of the creator than on the possibilities of your wallet. All this can be easily printed using a conventional photopolymer 3D printer. Need a flower ring? No problem! 3D printing can do this and more. What else can be produced in this way?

Brooches

Brooches are intricate pieces of jewelry that highlight your personality. Business women especially like to use them to decorate and complement their business suits. For example, Madeleine Albright, the first female US Secretary of State, over the years of her career has created a new diplomatic language, full of metaphors and secret meanings. Through jewelry, she expressed her mood, intentions or the situation at the negotiations, and political scientists and journalists vied with each other to interpret the images on the left lapel of her jacket. 3D printing can be used to produce a custom brooch that can complement the look, and perhaps say something to the “initiates”.

3D printing can be used to produce a custom brooch that can complement the look, and perhaps say something to the “initiates”.

Rings

3D printing can be used to make a prototype ring before making it into the final version of precious metals and stones. This will allow the designer to easily and quickly make adjustments, ensuring the ring fits perfectly and matches the client's expectations and end result. Important factors are saving time, money and, of course, a significant reduction in the likelihood of errors in the final product.

If earlier only professional 3D printers costing from $50,000 were suitable for the jewelry industry, now with the introduction of inexpensive mono LCD displays with 4K resolution, such printing is available to any jewelers and designers. The purchase budget fell below $500.

Bracelets

Similarly, intricately designed bracelets can be created using photopolymer or wax 3D printers. It can be an exclusive version, one of a kind, which, if necessary, can be mass-produced. Technology allows you to think more broadly and not be afraid to experiment with expensive precious metals and stones. After all, modern consumables allow you to create prototypes with a high level of reliability.

Technology allows you to think more broadly and not be afraid to experiment with expensive precious metals and stones. After all, modern consumables allow you to create prototypes with a high level of reliability.

Clothes and shoes

Shoes, dresses and other fashion items can also be 3D printed. This allows you to create ready-made items for wear, as well as improve the design of the model before launching into mass production. Shoes with geometrically complex 3D designs often find their way into the fashion mainstream.

And for more mundane purposes, there are sneaker soles. For example, Adidas makes them from a mixture of polymer resin with polyurethane added and prints in a lattice structure that promotes proper load distribution.

Adidas claims the Futurecraft 4D shoes are incredibly comfortable, with unparalleled ergonomics and wear resistance.

Simultaneously with shoes, there are numerous experiments on the use of 3D printing to create designer outfits and especially dresses.

One of the first 3D printed dresses was presented by American model and singer Dita Von Teese in March 2013 in New York. Couturiers Michael Schmidt and Francis Bitonti teamed up with 3D printing service Shapeways to print it using additive manufacturing technology. It consisted of 17 nylon parts, which were painted black and encrusted with 13,000 Swarovski stones.

In 2019, a whole series of such models was presented at the famous MetGala charity ball in New York. In the photo - American celebrities in outfits with 3D printed elements. Everyone was especially struck by the dress in the form of a rose petal (in the center), in which the British model Jordan Dunn appeared at the ceremony.

It, like the entire collection, was created by fashion designer Zac Posen in collaboration with GE engineers and 3D printers and made a splash on the red carpet of the event.

It is too early to talk about the widespread introduction of 3D printing in the fashion industry, but it is already clear that this process will continue.