How much is a 3d printer in australia

3D Printers for Sale | 3D Printer Australia

3D Printers for Sale | 3D Printer Australia | 3D Printing Solutions3D Printing Solutions is Australia's premier online 3D Printer Superstore.

At 3D printing solutions, we are focused on stocking and supplying an extensive range of 3D printer gear, filaments and supplies to suit the unique requirements of business, education, home and government users in Australia.

One of our key philosophies has been to maintain a hands on approach with the brands we offer. Through consistent printing and testing, our team understand the nuances and advantages that each machine can offer to recommend the right solution for you. The printer brands we support are also used in-house every day as part of our 3D printing service.

- We only stock 3D printers and 3D Printer filament that give repeatable quality results.

- We've tested the products in our store and can advise on the best solutions.

- Service and support is handled right here in Australia.

- Australia wide delivery

- FREE Delivery for orders over $150*

*Some remote regions or products may be ineligible for free shipping.

Shop Now

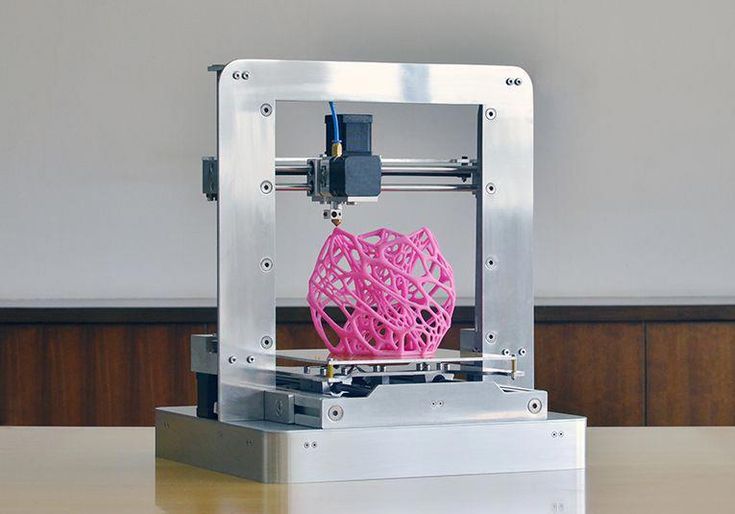

3D Printers that print with the quality and ease that you expect

3D Printer Store

What's New

More What's New...

Staff Picks

-

Ultimaker S3

Price:

AUD ($8,595.00 Incl Gst) $7,813.64 Ex Gst

See details Add to cart

-

Vaquform DT2

Price:

AUD ($1,837.

00 Incl Gst) $1,670.00 Ex Gst

00 Incl Gst) $1,670.00 Ex Gst

See details Add to cart

More Current Specials...

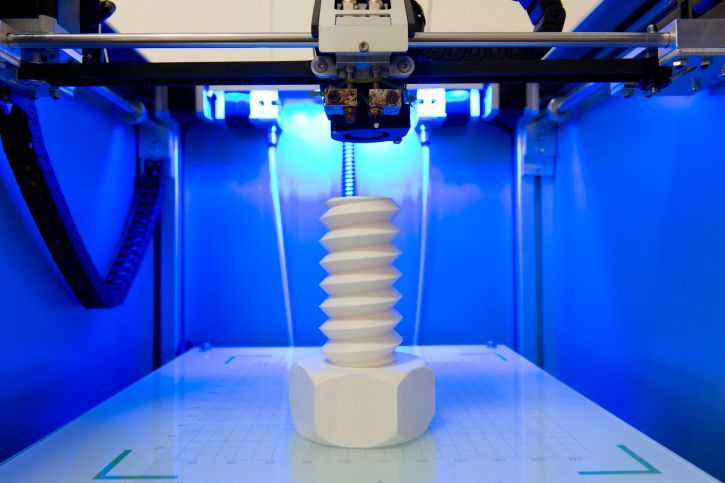

What can you do with a 3D Printer?

Need a replacement plastic part or want to prototype a new business idea?

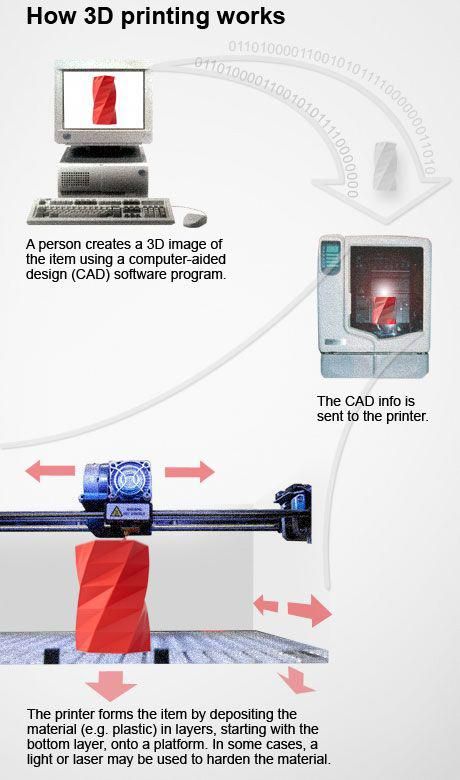

The advancement of 3D Printing has changed the way individuals and organizations are solving challenges and approaching creative expression. With such a wide range of standard, engineering and industrial materials 3D Printing; can be a powerful tool for professionals, hobbyists, teachers and businesses to rapidly manufacture custom solutions.

- Automotive Repair

- Creative Expression

- Defence

- Education Models / Cutaways

- Low Production Manufacturing

- Moulding & Casting (Plastic, Silicone, Metal)

- Rapid Prototyping

- Replacement Parts

- Research & Development

- + more!

About 3D Printing

Need Help?

Dont know where to start? Or which filament will suit your application?

We have a broad range of support options including Telephone Support

Contact Us

Personal 3D Printers for Sale Australia - Melbourne Store and Online

Home / Shop All

FeaturedBest SellingAlphabetically: A-ZAlphabetically: Z-APrice: Low to HighPrice: High to LowDate: New to OldDate: Old to New

3D Printers 3D Printers

Filaments & Resins Filaments & Resins

Spare Parts & Upgrades Spare Parts & Upgrades

Hot Ends & Nozzles Hot Ends & Nozzles

Print Surfaces Print Surfaces

3D Printing Tools 3D Printing Tools

3D Scanners 3D Scanners

Laser Cutters & Engravers Laser Cutters & Engravers

Robotics Robotics

3D Software 3D Software

Bundled Packages Bundled Packages

Educational Bundles Educational Bundles

STEM / STEAM Kits STEM / STEAM Kits

Clearance Specials Clearance Specials

Achived Products Achived Products

UP! Mini 3D printer

UP! Mini 3D printer TierTime Sold Out

Nozzle Height Detector Device

Nozzle Height Detector Device Tiertime $49. 95 ex gst

95 ex gst

Method X Nylon 12 Carbon Fibre Filament

Method X Nylon 12 Carbon Fibre Filament Makerbot Industries $189.00 ex gst

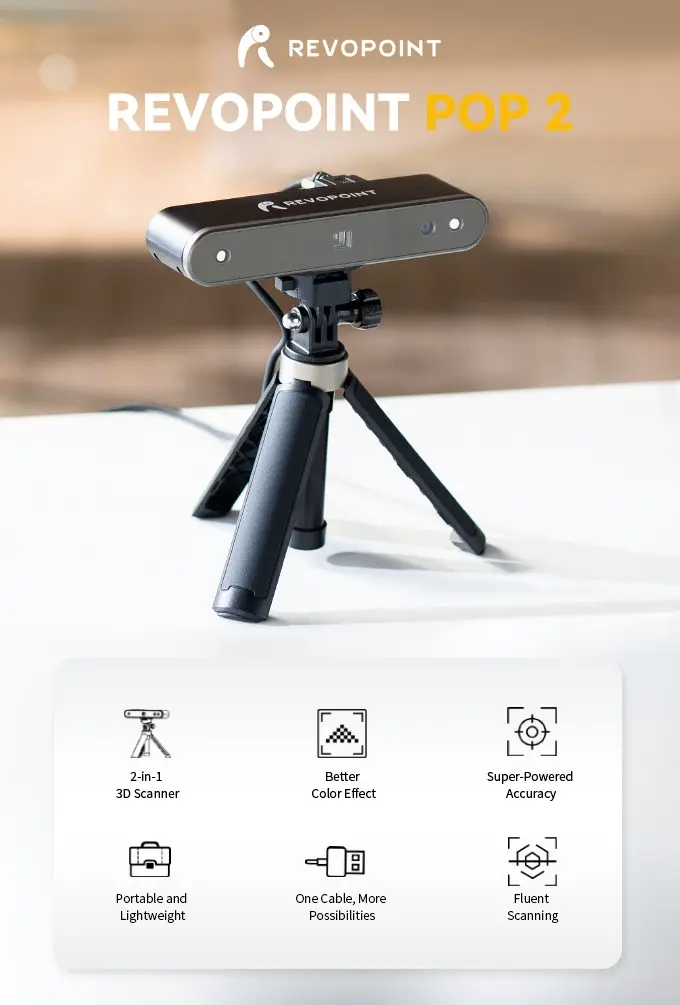

EinStar Portable Handheld 3D Scanner NEW!

EinStar Portable Handheld 3D Scanner NEW! Shining 3D from $1,454.00 ex gst $1,571.64

Method X SR-30 Soluble Support Filament (450g)

Method X SR-30 Soluble Support Filament (450g) Makerbot Industries $207.90 ex gst

Emblaser 2 / Emblaser Core - Emblaser Cutting Tray

Emblaser 2 / Emblaser Core - Emblaser Cutting Tray Darkly Labs $140.00 ex gst

Emblaser 2 / Emblaser Core - Upgrade Laser Unit 10W – E2/Core (pre order)

Emblaser 2 / Emblaser Core - Upgrade Laser Unit 10W – E2/Core (pre order) Darkly Labs $529.00 ex gst

DOBOT Magician - Basic AI Kit

DOBOT Magician - Basic AI Kit Dobot $496. 50 ex gst

50 ex gst

DOBOT Magician - Hikvision Vision Kit (NEW)

DOBOT Magician - Hikvision Vision Kit (NEW) Dobot $2,291.00 ex gst

Build Plate for MakerBot Replicator Z18

Build Plate for MakerBot Replicator Z18 Makerbot Industries $235.40 ex gst

FLASHFORGE Guider II/IIs High Temperature Extruder upgrade Kit

FLASHFORGE Guider II/IIs High Temperature Extruder upgrade Kit Flashforge Sold Out

Method X Educators Edition

Method X Educators Edition Makerbot Industries $9,999.00 ex gst $11,899.00

FFC Extruder cable for UP300

FFC Extruder cable for UP300 Tiertime $51.79 ex gst

Emblaser 2 F2000 Replacement Filter Set

Emblaser 2 F2000 Replacement Filter Set Darkly Labs $269.00 ex gst

Guider 3 (pre order)

Guider 3 (pre order) Flashforge $3,635. 45 ex gst

45 ex gst

Guider 3 Plus (pre order)

Guider 3 Plus (pre order) Flashforge $9,749.00 ex gst

Creator 4 Nozzle Kit 0.4/0.6.0/0.8mm

Creator 4 Nozzle Kit 0.4/0.6.0/0.8mm Flashforge from $210.00 ex gst

Creator 4 Flexible Filament Conversion Kit

Creator 4 Flexible Filament Conversion Kit Flashforge $2,089.00 ex gst

MakerBot Method & Method X Swap Out Warranty

MakerBot Method & Method X Swap Out Warranty Makerbot Industries from $1,999.00 ex gst

Makerbot Sketch PLA Filament 5 Pack

Makerbot Sketch PLA Filament 5 Pack Makerbot Industries $499.00 ex gst

Makerbot Sketch Tough PLA 4 Pack

Makerbot Sketch Tough PLA 4 Pack Makerbot Industries $469. 00 ex gst

00 ex gst

MakerBot Sketch Classroom Bundle

MakerBot Sketch Classroom Bundle Makerbot Industries $2,799.00 ex gst $2,999.00

Formbot T-Rex 2+ High Temperature Extruder (Pair)

Formbot T-Rex 2+ High Temperature Extruder (Pair) Formbot Sold Out

Spring Steel Build Plate for MakerBot Method

Spring Steel Build Plate for MakerBot Method Makerbot Industries $249.00 ex gst

Build Plate Tape for MakerBot Method

Build Plate Tape for MakerBot Method Makerbot Industries $189.00 ex gst $199.00

Method X ABS-R RapidRinse Support Stucture

Method X ABS-R RapidRinse Support Stucture Makerbot Industries $299.00 ex gst

Method X ABS-R Natural

Method X ABS-R Natural Makerbot Industries $175. 00 ex gst

00 ex gst

Method X ABS-R Red

Method X ABS-R Red Makerbot Industries $175.00 ex gst

Method X ABS-R Black

Method X ABS-R Black Makerbot Industries $175.00 ex gst

Vaquform DT2 - Digital Desktop Vacuum Forming Machine

Vaquform DT2 - Digital Desktop Vacuum Forming Machine Vaquform $1,690.00 ex gst

EinScan Pro HD

EinScan Pro HD Shining 3D from $10,350.00 ex gst

EinScan H

EinScan H Shining 3D $6,860.00 ex gst $7,900.00

AutoScan Inspec 3D Scanner by Shining 3D

AutoScan Inspec 3D Scanner by Shining 3D Shining 3D $15,300.00 ex gst

ABS Purple 500g

ABS Purple 500g Flashforge $27.50 ex gst

ABS Yellow 500g

ABS Yellow 500g Flashforge $27. 50 ex gst

50 ex gst

ABS Pink 500g

ABS Pink 500g Flashforge $27.50 ex gst

PLA/PBAT Pro White 3kg

PLA/PBAT Pro White 3kg Jelly Bean $89.95 ex gst

PLA/PBAT Pro Black 3kg

PLA/PBAT Pro Black 3kg Jelly Bean $89.95 ex gst

Creator 4-S (NEW) with IDEX

Creator 4-S (NEW) with IDEX Flashforge $12,269.00 ex gst $13,360.00

Adventurer 3

Adventurer 3 Flashforge Sold Out

Rhino 7 for Windows & MAC Educational Lab Kit (R70-LAB)

Rhino 7 for Windows & MAC Educational Lab Kit (R70-LAB) Robert McNeel & Associates $1,425.00 ex gst $1,449.00

Creator 3 PRO (NEW) with IDEX (pre order)

Creator 3 PRO (NEW) with IDEX (pre order) Flashforge $3,995. 00 ex gst $4,859.00

00 ex gst $4,859.00

UP300 Activated Carbon Filter - replace every 6 months

UP300 Activated Carbon Filter - replace every 6 months Tiertime $43.17 ex gst

UP300 HEPA Filter - replace every 6 months

UP300 HEPA Filter - replace every 6 months Tiertime $43.17 ex gst

Adventurer 4

Adventurer 4 Flashforge $1,190.00 ex gst

EinScan HX

EinScan HX Shining 3D from $15,250.00 ex gst

Method X ABS Grey

${{amount}}" data-single-variant="true" data-url="/collections/frontpage/products/method-x-abs-grey" data-title="Method X ABS Grey" data-details-text="View full details" data-full-description="<div data-node="5d531847efd65"> <div> <h4><span>MAKERBOT ABS</span></h4> <p><span>ABS Grey 375-0026A<span data-mce-fragment="1"> </span>(acrylonitrile butadiene styrene) is one of the most common plastics used in injection-molding, found in many common products such as LEGOS, computer keys, power-tool housings, and automotive parts. </span></p> </div> </div> <div data-node="5dc9a4648a4d9"> <div> <h5><span>REAL, PRODUCTION- GRADE ABS FOR MANUFACTURING APPLICATIONS</span></h5> </div> </div> <p>ABS is one of the most popular materials for injection molded consumer products due to its clean surface finish, durability, and heat resistance. METHOD X can print manufacturing-grade ABS without warping and without weakening additives thanks to its 100°C heated chamber.</p> <p>MakerBot real ABS is a real, production-grade ABS material formulation for creating strong and durable functional prototypes, manufacturing tools, and end-use parts. Unlike desktop ABS material formulations containing damaging modifiers and stabilizers that lead to warping and cracking, this real ABS formulation empowers engineers to achieve part properties close to injection molded parts with high dimensional accuracy, durability, and repeatability. Outpace your competition with better materials and better parts.

</span></p> </div> </div> <div data-node="5dc9a4648a4d9"> <div> <h5><span>REAL, PRODUCTION- GRADE ABS FOR MANUFACTURING APPLICATIONS</span></h5> </div> </div> <p>ABS is one of the most popular materials for injection molded consumer products due to its clean surface finish, durability, and heat resistance. METHOD X can print manufacturing-grade ABS without warping and without weakening additives thanks to its 100°C heated chamber.</p> <p>MakerBot real ABS is a real, production-grade ABS material formulation for creating strong and durable functional prototypes, manufacturing tools, and end-use parts. Unlike desktop ABS material formulations containing damaging modifiers and stabilizers that lead to warping and cracking, this real ABS formulation empowers engineers to achieve part properties close to injection molded parts with high dimensional accuracy, durability, and repeatability. Outpace your competition with better materials and better parts. Only with METHOD and MakerBot real ABS.</p> <p><img src="//cdn.shopify.com/s/files/1/0180/7671/files/Method_WithFilaments.png?v=1554170509" alt="makerbot method with filament available" data-mce-style="display: block; margin-left: auto; margin-right: auto;"><br><br>The Smart Spool contains all the information that the printer needs, including material type, color, and amount remaining via an RFID chip. This is communicated directly to MakerBot Print, while a built-in desiccant absorbs any moisture exposure during the material loading process, ensuring your material stays fresher longer. </p> <p><img alt="Makerbot Method ABS sample printed parts" src="https://cdn.shopify.com/s/files/1/0180/7671/files/method_abs_1024x1024.jpg?v=1633060488"></p> <p><strong>END-USE PARTS</strong></p> <div data-mce-style="text-align: start;"><img alt="makerbot method x ABS end user parts" src="https://cdn.shopify.com/s/files/1/0180/7671/files/Makerbot_method_abs_end_user_parts_240x240.

Only with METHOD and MakerBot real ABS.</p> <p><img src="//cdn.shopify.com/s/files/1/0180/7671/files/Method_WithFilaments.png?v=1554170509" alt="makerbot method with filament available" data-mce-style="display: block; margin-left: auto; margin-right: auto;"><br><br>The Smart Spool contains all the information that the printer needs, including material type, color, and amount remaining via an RFID chip. This is communicated directly to MakerBot Print, while a built-in desiccant absorbs any moisture exposure during the material loading process, ensuring your material stays fresher longer. </p> <p><img alt="Makerbot Method ABS sample printed parts" src="https://cdn.shopify.com/s/files/1/0180/7671/files/method_abs_1024x1024.jpg?v=1633060488"></p> <p><strong>END-USE PARTS</strong></p> <div data-mce-style="text-align: start;"><img alt="makerbot method x ABS end user parts" src="https://cdn.shopify.com/s/files/1/0180/7671/files/Makerbot_method_abs_end_user_parts_240x240. jpg?v=1633060655" data-mce-style="float: none;"></div> <p>Custom parts, low volume production, and components that require high geometric complexity</p> <p>Applications include:</p> <ul> <li>• Liquid containers</li> <li>• Signage and graphic displays</li> <li>• Enclosures for electrical equipment</li> </ul> <p> </p> <p><strong>MANUFACTURING TOOLS</strong></p> <p><strong><img alt="makerbot method x ABS manufacturing tool" src="https://cdn.shopify.com/s/files/1/0180/7671/files/Makerbot_method_abs_manutacturing_tools_240x240.jpg?v=1633060748"></strong></p> <p>Create tools, jigs, and fixtures at lower cost, with faster turnaround, and without the need for expensive skilled labor</p> <p>Applications include:</p> <ul> <li>• Manufacturing tools and aids</li> <li>• Robotic end effectors</li> <li>• Product testing tools</li> </ul> <p> </p> <p><strong>FUNCTIONAL PROTOTYPES</strong></p> <p><strong><img alt="makerbot method x ABS functional tool" src="https://cdn.

jpg?v=1633060655" data-mce-style="float: none;"></div> <p>Custom parts, low volume production, and components that require high geometric complexity</p> <p>Applications include:</p> <ul> <li>• Liquid containers</li> <li>• Signage and graphic displays</li> <li>• Enclosures for electrical equipment</li> </ul> <p> </p> <p><strong>MANUFACTURING TOOLS</strong></p> <p><strong><img alt="makerbot method x ABS manufacturing tool" src="https://cdn.shopify.com/s/files/1/0180/7671/files/Makerbot_method_abs_manutacturing_tools_240x240.jpg?v=1633060748"></strong></p> <p>Create tools, jigs, and fixtures at lower cost, with faster turnaround, and without the need for expensive skilled labor</p> <p>Applications include:</p> <ul> <li>• Manufacturing tools and aids</li> <li>• Robotic end effectors</li> <li>• Product testing tools</li> </ul> <p> </p> <p><strong>FUNCTIONAL PROTOTYPES</strong></p> <p><strong><img alt="makerbot method x ABS functional tool" src="https://cdn. shopify.com/s/files/1/0180/7671/files/Makerbot_method_abs_functional_prototypes_480x480.jpg?v=1633060712"></strong></p> <p>Get true fit and feel, test in realworld and beyond real-world scenarios, and expedite time to market in the same material as the final injection-molded part</p> <p><strong>Applications include:</strong></p> <ul> <li>• Consumer product prototypes</li> <li>• Appliance assemblies</li> <li>• Automotive parts</li> </ul> <div data-mce-style="text-align: start;"><img alt="makerbot method material smart spool filament" src="//cdn.shopify.com/s/files/1/0180/7671/files/MakerBot-Smart-Spools_480x480.png?v=1553576402" data-mce-style="margin-right: -1094.93px; float: none;"></div> <p> <br data-mce-fragment="1"><strong data-mce-fragment="1">SPOOL TYPE</strong><br data-mce-fragment="1">Smart Spool™ provides valuable information including material type, color, and amount remaining via an RFID chip directly to MakerBot Print, while a desiccant in the spool maintains a low moisture level inside the drawer bay.

shopify.com/s/files/1/0180/7671/files/Makerbot_method_abs_functional_prototypes_480x480.jpg?v=1633060712"></strong></p> <p>Get true fit and feel, test in realworld and beyond real-world scenarios, and expedite time to market in the same material as the final injection-molded part</p> <p><strong>Applications include:</strong></p> <ul> <li>• Consumer product prototypes</li> <li>• Appliance assemblies</li> <li>• Automotive parts</li> </ul> <div data-mce-style="text-align: start;"><img alt="makerbot method material smart spool filament" src="//cdn.shopify.com/s/files/1/0180/7671/files/MakerBot-Smart-Spools_480x480.png?v=1553576402" data-mce-style="margin-right: -1094.93px; float: none;"></div> <p> <br data-mce-fragment="1"><strong data-mce-fragment="1">SPOOL TYPE</strong><br data-mce-fragment="1">Smart Spool™ provides valuable information including material type, color, and amount remaining via an RFID chip directly to MakerBot Print, while a desiccant in the spool maintains a low moisture level inside the drawer bay. </p> <table> <tbody> <tr> <td data-mce-style="text-align: left;"> <p data-mce-fragment="1"><strong data-mce-fragment="1">PRINTER COMPATIBILITY</strong><br data-mce-fragment="1"><br></p> <p data-mce-fragment="1"><img data-mce-fragment="1" src="https://cdn.shopify.com/s/files/1/0180/7671/files/Compatibility-Printers-MX_240x240.png?v=1633059785" alt="Method X" data-mce-src="https://cdn.shopify.com/s/files/1/0180/7671/files/Compatibility-Printers-MX_240x240.png?v=1633059785"></p> <p data-mce-fragment="1"><br></p> <p data-mce-fragment="1">MakerBot Method X</p> <p data-mce-fragment="1"><br></p> </td> <td data-mce-style="text-align: left;"> <p><strong>EXTRUDER COMPATIBILITY</strong></p> <div data-mce-style="text-align: start;"><img src="https://cdn.shopify.com/s/files/1/0180/7671/files/Compatibility-Support-MX_240x240.png?v=1633059722" alt="Makerbot Extruder Compatibility" data-mce-src="https://cdn.

</p> <table> <tbody> <tr> <td data-mce-style="text-align: left;"> <p data-mce-fragment="1"><strong data-mce-fragment="1">PRINTER COMPATIBILITY</strong><br data-mce-fragment="1"><br></p> <p data-mce-fragment="1"><img data-mce-fragment="1" src="https://cdn.shopify.com/s/files/1/0180/7671/files/Compatibility-Printers-MX_240x240.png?v=1633059785" alt="Method X" data-mce-src="https://cdn.shopify.com/s/files/1/0180/7671/files/Compatibility-Printers-MX_240x240.png?v=1633059785"></p> <p data-mce-fragment="1"><br></p> <p data-mce-fragment="1">MakerBot Method X</p> <p data-mce-fragment="1"><br></p> </td> <td data-mce-style="text-align: left;"> <p><strong>EXTRUDER COMPATIBILITY</strong></p> <div data-mce-style="text-align: start;"><img src="https://cdn.shopify.com/s/files/1/0180/7671/files/Compatibility-Support-MX_240x240.png?v=1633059722" alt="Makerbot Extruder Compatibility" data-mce-src="https://cdn. shopify.com/s/files/1/0180/7671/files/Compatibility-Support-MX_240x240.png?v=1633059722" data-mce-style="float: none;"></div> <p><br><br></p> <p>Material Extruder 1XA </p> <p>Support Extruder 2XA</p> </td> </tr> </tbody> </table> <p><strong></strong><br><br></p> <table> <tbody> <tr> <th>TECH SPECS</th> <th>Imperial</th> <th>Metric</th> </tr> <tr> <td>Heat Deflection (ASTM 648, 66 psi)</td> <td>183°F</td> <td>84°C</td> </tr> <tr> <td>Flexural Modulus (ASTM D790, 15 mm/min)</td> <td>11,200 psi</td> <td>77 MPa</td> </tr> <tr> <td>Tensile Strength at yield (Type 1, 0.125", 0.2"/min)</td> <td>6,236 psi</td> <td>43 MPa</td> </tr> <tr> <td>Tensile Modulus (ASTM D638, 50 mm/min)</td> <td>348,000 psi</td> <td>2,400 MPa</td> </tr> <tr> <td>Strain at Yield - Elongation (%)</td> <td>>2.

shopify.com/s/files/1/0180/7671/files/Compatibility-Support-MX_240x240.png?v=1633059722" data-mce-style="float: none;"></div> <p><br><br></p> <p>Material Extruder 1XA </p> <p>Support Extruder 2XA</p> </td> </tr> </tbody> </table> <p><strong></strong><br><br></p> <table> <tbody> <tr> <th>TECH SPECS</th> <th>Imperial</th> <th>Metric</th> </tr> <tr> <td>Heat Deflection (ASTM 648, 66 psi)</td> <td>183°F</td> <td>84°C</td> </tr> <tr> <td>Flexural Modulus (ASTM D790, 15 mm/min)</td> <td>11,200 psi</td> <td>77 MPa</td> </tr> <tr> <td>Tensile Strength at yield (Type 1, 0.125", 0.2"/min)</td> <td>6,236 psi</td> <td>43 MPa</td> </tr> <tr> <td>Tensile Modulus (ASTM D638, 50 mm/min)</td> <td>348,000 psi</td> <td>2,400 MPa</td> </tr> <tr> <td>Strain at Yield - Elongation (%)</td> <td>>2. 6%</td> <td>>2.6%</td> </tr> <tr> <td>Notched Impact Strength (ASTM D256)</td> <td>0.48 ft-lb/in</td> <td>26 J/m</td> </tr> </tbody> </table> <p><br><br data-mce-fragment="1"><strong data-mce-fragment="1">SOFTWARE COMPATIBILITY</strong><br data-mce-fragment="1">MakerBot Print</p> <p><br><strong>DIMENSIONS AND WEIGHT</strong><br>Spool Diameter: 21.8 cm<br>Spool Width: 4.2 cm<br>Material Diameter: 1.75 mm<br>Shipping Weight: 1.1 kg<br>Net Weight: 0.65 kg<br><br><strong>OPERATING ENVIRONMENT</strong><br>Store MakerBot Method ABS Precision Material in the included a vacuum-sealed metalized polyester bag to avoid moisture absorption from air and long-term exposure to humidity can compromise material quality and performance. Make sure the built-in desiccant is ion the spool to absorb any moisture exposure during the material loading process.

6%</td> <td>>2.6%</td> </tr> <tr> <td>Notched Impact Strength (ASTM D256)</td> <td>0.48 ft-lb/in</td> <td>26 J/m</td> </tr> </tbody> </table> <p><br><br data-mce-fragment="1"><strong data-mce-fragment="1">SOFTWARE COMPATIBILITY</strong><br data-mce-fragment="1">MakerBot Print</p> <p><br><strong>DIMENSIONS AND WEIGHT</strong><br>Spool Diameter: 21.8 cm<br>Spool Width: 4.2 cm<br>Material Diameter: 1.75 mm<br>Shipping Weight: 1.1 kg<br>Net Weight: 0.65 kg<br><br><strong>OPERATING ENVIRONMENT</strong><br>Store MakerBot Method ABS Precision Material in the included a vacuum-sealed metalized polyester bag to avoid moisture absorption from air and long-term exposure to humidity can compromise material quality and performance. Make sure the built-in desiccant is ion the spool to absorb any moisture exposure during the material loading process. </p> <p><strong>DATA SHEET</strong></p> <p><strong>Download date sheet <a href="https://cdn.shopify.com/s/files/1/0180/7671/files/MakerBot-Precision-ABS-data-sheet.pdf?v=1633059940" title="Makerbot Method ABS data sheet" data-mce-href="https://cdn.shopify.com/s/files/1/0180/7671/files/MakerBot-Precision-ABS-data-sheet.pdf?v=1633059940">-here-</a></strong></p>" data-regular-description="MAKERBOT ABS ABS Grey 375-0026A (acrylonitrile butadiene styrene) is one of the most common plastics used in injection-molding, found in many common products such as LEGOS, computer..." data-images="28437299396683 || MAKERBOT ABS Grey 375-0026A ||" data-collection-handles="all,consumables,filaments-resins,makerbot,makerbot-compatible-filaments,makerbot-method-materials,frontpage" > Quick View

</p> <p><strong>DATA SHEET</strong></p> <p><strong>Download date sheet <a href="https://cdn.shopify.com/s/files/1/0180/7671/files/MakerBot-Precision-ABS-data-sheet.pdf?v=1633059940" title="Makerbot Method ABS data sheet" data-mce-href="https://cdn.shopify.com/s/files/1/0180/7671/files/MakerBot-Precision-ABS-data-sheet.pdf?v=1633059940">-here-</a></strong></p>" data-regular-description="MAKERBOT ABS ABS Grey 375-0026A (acrylonitrile butadiene styrene) is one of the most common plastics used in injection-molding, found in many common products such as LEGOS, computer..." data-images="28437299396683 || MAKERBOT ABS Grey 375-0026A ||" data-collection-handles="all,consumables,filaments-resins,makerbot,makerbot-compatible-filaments,makerbot-method-materials,frontpage" > Quick View

Method X ABS Grey Makerbot Industries $169.00 ex gst

Method X ABS Black

${{amount}}" data-single-variant="true" data-url="/collections/frontpage/products/method-x-abs-black" data-title="Method X ABS Black" data-details-text="View full details" data-full-description="<div data-node="5d531847efd65"> <div> <h4><span>MAKERBOT ABS</span></h4> <p><span>ABS Black 375-0025A<span data-mce-fragment="1"> </span>(acrylonitrile butadiene styrene) is one of the most common plastics used in injection-molding, found in many common products such as LEGOS, computer keys, power-tool housings, and automotive parts. </span></p> </div> </div> <div data-node="5dc9a4648a4d9"> <div> <h5><span>REAL, PRODUCTION- GRADE ABS FOR MANUFACTURING APPLICATIONS</span></h5> </div> </div> <p>ABS is one of the most popular materials for injection molded consumer products due to its clean surface finish, durability, and heat resistance. METHOD X can print manufacturing-grade ABS without warping and without weakening additives thanks to its 100°C heated chamber.</p> <p>MakerBot real ABS is a real, production-grade ABS material formulation for creating strong and durable functional prototypes, manufacturing tools, and end-use parts. Unlike desktop ABS material formulations containing damaging modifiers and stabilizers that lead to warping and cracking, this real ABS formulation empowers engineers to achieve part properties close to injection molded parts with high dimensional accuracy, durability, and repeatability. Outpace your competition with better materials and better parts.

</span></p> </div> </div> <div data-node="5dc9a4648a4d9"> <div> <h5><span>REAL, PRODUCTION- GRADE ABS FOR MANUFACTURING APPLICATIONS</span></h5> </div> </div> <p>ABS is one of the most popular materials for injection molded consumer products due to its clean surface finish, durability, and heat resistance. METHOD X can print manufacturing-grade ABS without warping and without weakening additives thanks to its 100°C heated chamber.</p> <p>MakerBot real ABS is a real, production-grade ABS material formulation for creating strong and durable functional prototypes, manufacturing tools, and end-use parts. Unlike desktop ABS material formulations containing damaging modifiers and stabilizers that lead to warping and cracking, this real ABS formulation empowers engineers to achieve part properties close to injection molded parts with high dimensional accuracy, durability, and repeatability. Outpace your competition with better materials and better parts. Only with METHOD and MakerBot real ABS.</p> <p><img alt="makerbot method with filament available" src="//cdn.shopify.com/s/files/1/0180/7671/files/Method_WithFilaments.png?v=1554170509" data-mce-style="display: block; margin-left: auto; margin-right: auto;"><br><br>The Smart Spool contains all the information that the printer needs, including material type, color, and amount remaining via an RFID chip. This is communicated directly to MakerBot Print, while a built-in desiccant absorbs any moisture exposure during the material loading process, ensuring your material stays fresher longer. </p> <p><img src="https://cdn.shopify.com/s/files/1/0180/7671/files/method_abs_1024x1024.jpg?v=1633060488" alt="Makerbot Method ABS sample printed parts"></p> <p><strong>END-USE PARTS</strong></p> <div data-mce-style="text-align: start;"><img src="https://cdn.shopify.com/s/files/1/0180/7671/files/Makerbot_method_abs_end_user_parts_240x240.

Only with METHOD and MakerBot real ABS.</p> <p><img alt="makerbot method with filament available" src="//cdn.shopify.com/s/files/1/0180/7671/files/Method_WithFilaments.png?v=1554170509" data-mce-style="display: block; margin-left: auto; margin-right: auto;"><br><br>The Smart Spool contains all the information that the printer needs, including material type, color, and amount remaining via an RFID chip. This is communicated directly to MakerBot Print, while a built-in desiccant absorbs any moisture exposure during the material loading process, ensuring your material stays fresher longer. </p> <p><img src="https://cdn.shopify.com/s/files/1/0180/7671/files/method_abs_1024x1024.jpg?v=1633060488" alt="Makerbot Method ABS sample printed parts"></p> <p><strong>END-USE PARTS</strong></p> <div data-mce-style="text-align: start;"><img src="https://cdn.shopify.com/s/files/1/0180/7671/files/Makerbot_method_abs_end_user_parts_240x240. jpg?v=1633060655" alt="makerbot method x ABS end user parts" data-mce-style="float: none;"></div> <p>Custom parts, low volume production, and components that require high geometric complexity</p> <p>Applications include:</p> <ul> <li>• Liquid containers</li> <li>• Signage and graphic displays</li> <li>• Enclosures for electrical equipment</li> </ul> <p> </p> <p><strong>MANUFACTURING TOOLS</strong></p> <p><strong><img src="https://cdn.shopify.com/s/files/1/0180/7671/files/Makerbot_method_abs_manutacturing_tools_240x240.jpg?v=1633060748" alt="makerbot method x ABS manufacturing tool"></strong></p> <p>Create tools, jigs, and fixtures at lower cost, with faster turnaround, and without the need for expensive skilled labor</p> <p>Applications include:</p> <ul> <li>• Manufacturing tools and aids</li> <li>• Robotic end effectors</li> <li>• Product testing tools</li> </ul> <p> </p> <p><strong>FUNCTIONAL PROTOTYPES</strong></p> <p><strong><img src="https://cdn.

jpg?v=1633060655" alt="makerbot method x ABS end user parts" data-mce-style="float: none;"></div> <p>Custom parts, low volume production, and components that require high geometric complexity</p> <p>Applications include:</p> <ul> <li>• Liquid containers</li> <li>• Signage and graphic displays</li> <li>• Enclosures for electrical equipment</li> </ul> <p> </p> <p><strong>MANUFACTURING TOOLS</strong></p> <p><strong><img src="https://cdn.shopify.com/s/files/1/0180/7671/files/Makerbot_method_abs_manutacturing_tools_240x240.jpg?v=1633060748" alt="makerbot method x ABS manufacturing tool"></strong></p> <p>Create tools, jigs, and fixtures at lower cost, with faster turnaround, and without the need for expensive skilled labor</p> <p>Applications include:</p> <ul> <li>• Manufacturing tools and aids</li> <li>• Robotic end effectors</li> <li>• Product testing tools</li> </ul> <p> </p> <p><strong>FUNCTIONAL PROTOTYPES</strong></p> <p><strong><img src="https://cdn. shopify.com/s/files/1/0180/7671/files/Makerbot_method_abs_functional_prototypes_480x480.jpg?v=1633060712" alt="makerbot method x ABS functional tool"></strong></p> <p>Get true fit and feel, test in realworld and beyond real-world scenarios, and expedite time to market in the same material as the final injection-molded part</p> <p><strong>Applications include:</strong></p> <ul> <li>• Consumer product prototypes</li> <li>• Appliance assemblies</li> <li>• Automotive parts</li> </ul> <div data-mce-style="text-align: start;"><img src="//cdn.shopify.com/s/files/1/0180/7671/files/MakerBot-Smart-Spools_480x480.png?v=1553576402" alt="makerbot method material smart spool filament" data-mce-style="margin-right: -1094.93px; float: none;"></div> <p> <br data-mce-fragment="1"><strong data-mce-fragment="1">SPOOL TYPE</strong><br data-mce-fragment="1">Smart Spool™ provides valuable information including material type, color, and amount remaining via an RFID chip directly to MakerBot Print, while a desiccant in the spool maintains a low moisture level inside the drawer bay.

shopify.com/s/files/1/0180/7671/files/Makerbot_method_abs_functional_prototypes_480x480.jpg?v=1633060712" alt="makerbot method x ABS functional tool"></strong></p> <p>Get true fit and feel, test in realworld and beyond real-world scenarios, and expedite time to market in the same material as the final injection-molded part</p> <p><strong>Applications include:</strong></p> <ul> <li>• Consumer product prototypes</li> <li>• Appliance assemblies</li> <li>• Automotive parts</li> </ul> <div data-mce-style="text-align: start;"><img src="//cdn.shopify.com/s/files/1/0180/7671/files/MakerBot-Smart-Spools_480x480.png?v=1553576402" alt="makerbot method material smart spool filament" data-mce-style="margin-right: -1094.93px; float: none;"></div> <p> <br data-mce-fragment="1"><strong data-mce-fragment="1">SPOOL TYPE</strong><br data-mce-fragment="1">Smart Spool™ provides valuable information including material type, color, and amount remaining via an RFID chip directly to MakerBot Print, while a desiccant in the spool maintains a low moisture level inside the drawer bay. </p> <table> <tbody> <tr> <td data-mce-style="text-align: left;"> <p data-mce-fragment="1"><strong data-mce-fragment="1">PRINTER COMPATIBILITY</strong><br data-mce-fragment="1"><br></p> <p data-mce-fragment="1"><img alt="Method X" src="https://cdn.shopify.com/s/files/1/0180/7671/files/Compatibility-Printers-MX_240x240.png?v=1633059785" data-mce-fragment="1" data-mce-src="https://cdn.shopify.com/s/files/1/0180/7671/files/Compatibility-Printers-MX_240x240.png?v=1633059785"></p> <p data-mce-fragment="1"><br></p> <p data-mce-fragment="1">MakerBot Method X</p> <p data-mce-fragment="1"><br></p> </td> <td data-mce-style="text-align: left;"> <p><strong>EXTRUDER COMPATIBILITY</strong></p> <div data-mce-style="text-align: start;"><img alt="Makerbot Extruder Compatibility" src="https://cdn.shopify.com/s/files/1/0180/7671/files/Compatibility-Support-MX_240x240.

</p> <table> <tbody> <tr> <td data-mce-style="text-align: left;"> <p data-mce-fragment="1"><strong data-mce-fragment="1">PRINTER COMPATIBILITY</strong><br data-mce-fragment="1"><br></p> <p data-mce-fragment="1"><img alt="Method X" src="https://cdn.shopify.com/s/files/1/0180/7671/files/Compatibility-Printers-MX_240x240.png?v=1633059785" data-mce-fragment="1" data-mce-src="https://cdn.shopify.com/s/files/1/0180/7671/files/Compatibility-Printers-MX_240x240.png?v=1633059785"></p> <p data-mce-fragment="1"><br></p> <p data-mce-fragment="1">MakerBot Method X</p> <p data-mce-fragment="1"><br></p> </td> <td data-mce-style="text-align: left;"> <p><strong>EXTRUDER COMPATIBILITY</strong></p> <div data-mce-style="text-align: start;"><img alt="Makerbot Extruder Compatibility" src="https://cdn.shopify.com/s/files/1/0180/7671/files/Compatibility-Support-MX_240x240. png?v=1633059722" data-mce-style="float: none;" data-mce-src="https://cdn.shopify.com/s/files/1/0180/7671/files/Compatibility-Support-MX_240x240.png?v=1633059722"></div> <p><br><br></p> <p>Material Extruder 1XA </p> <p>Support Extruder 2XA</p> </td> </tr> </tbody> </table> <p><strong></strong><br><br></p> <table> <tbody> <tr> <th>TECH SPECS</th> <th>Imperial</th> <th>Metric</th> </tr> <tr> <td>Heat Deflection (ASTM 648, 66 psi)</td> <td>183°F</td> <td>84°C</td> </tr> <tr> <td>Flexural Modulus (ASTM D790, 15 mm/min)</td> <td>11,200 psi</td> <td>77 MPa</td> </tr> <tr> <td>Tensile Strength at yield (Type 1, 0.125", 0.2"/min)</td> <td>6,236 psi</td> <td>43 MPa</td> </tr> <tr> <td>Tensile Modulus (ASTM D638, 50 mm/min)</td> <td>348,000 psi</td> <td>2,400 MPa</td> </tr> <tr> <td>Strain at Yield - Elongation (%)</td> <td>>2.

png?v=1633059722" data-mce-style="float: none;" data-mce-src="https://cdn.shopify.com/s/files/1/0180/7671/files/Compatibility-Support-MX_240x240.png?v=1633059722"></div> <p><br><br></p> <p>Material Extruder 1XA </p> <p>Support Extruder 2XA</p> </td> </tr> </tbody> </table> <p><strong></strong><br><br></p> <table> <tbody> <tr> <th>TECH SPECS</th> <th>Imperial</th> <th>Metric</th> </tr> <tr> <td>Heat Deflection (ASTM 648, 66 psi)</td> <td>183°F</td> <td>84°C</td> </tr> <tr> <td>Flexural Modulus (ASTM D790, 15 mm/min)</td> <td>11,200 psi</td> <td>77 MPa</td> </tr> <tr> <td>Tensile Strength at yield (Type 1, 0.125", 0.2"/min)</td> <td>6,236 psi</td> <td>43 MPa</td> </tr> <tr> <td>Tensile Modulus (ASTM D638, 50 mm/min)</td> <td>348,000 psi</td> <td>2,400 MPa</td> </tr> <tr> <td>Strain at Yield - Elongation (%)</td> <td>>2. 6%</td> <td>>2.6%</td> </tr> <tr> <td>Notched Impact Strength (ASTM D256)</td> <td>0.48 ft-lb/in</td> <td>26 J/m</td> </tr> </tbody> </table> <p><br><br data-mce-fragment="1"><strong data-mce-fragment="1">SOFTWARE COMPATIBILITY</strong><br data-mce-fragment="1">MakerBot Print</p> <p><br><strong>DIMENSIONS AND WEIGHT</strong><br>Spool Diameter: 21.8 cm<br>Spool Width: 4.2 cm<br>Material Diameter: 1.75 mm<br>Shipping Weight: 1.1 kg<br>Net Weight: 0.65 kg<br><br><strong>OPERATING ENVIRONMENT</strong><br>Store MakerBot Method ABS Precision Material in the included a vacuum-sealed metalized polyester bag to avoid moisture absorption from air and long-term exposure to humidity can compromise material quality and performance. Make sure the built-in desiccant is ion the spool to absorb any moisture exposure during the material loading process.

6%</td> <td>>2.6%</td> </tr> <tr> <td>Notched Impact Strength (ASTM D256)</td> <td>0.48 ft-lb/in</td> <td>26 J/m</td> </tr> </tbody> </table> <p><br><br data-mce-fragment="1"><strong data-mce-fragment="1">SOFTWARE COMPATIBILITY</strong><br data-mce-fragment="1">MakerBot Print</p> <p><br><strong>DIMENSIONS AND WEIGHT</strong><br>Spool Diameter: 21.8 cm<br>Spool Width: 4.2 cm<br>Material Diameter: 1.75 mm<br>Shipping Weight: 1.1 kg<br>Net Weight: 0.65 kg<br><br><strong>OPERATING ENVIRONMENT</strong><br>Store MakerBot Method ABS Precision Material in the included a vacuum-sealed metalized polyester bag to avoid moisture absorption from air and long-term exposure to humidity can compromise material quality and performance. Make sure the built-in desiccant is ion the spool to absorb any moisture exposure during the material loading process. </p> <p><strong>DATA SHEET</strong></p> <p><strong>Download date sheet <a title="Makerbot Method ABS data sheet" href="https://cdn.shopify.com/s/files/1/0180/7671/files/MakerBot-Precision-ABS-data-sheet.pdf?v=1633059940" data-mce-href="https://cdn.shopify.com/s/files/1/0180/7671/files/MakerBot-Precision-ABS-data-sheet.pdf?v=1633059940">-here-</a></strong></p>" data-regular-description="MAKERBOT ABS ABS Black 375-0025A (acrylonitrile butadiene styrene) is one of the most common plastics used in injection-molding, found in many common products such as LEGOS, computer..." data-images="28437289369675 || MAKERBOT ABS Black 375-0025A ||" data-collection-handles="all,consumables,filaments-resins,makerbot,makerbot-compatible-filaments,makerbot-method-materials,frontpage" > Quick View

</p> <p><strong>DATA SHEET</strong></p> <p><strong>Download date sheet <a title="Makerbot Method ABS data sheet" href="https://cdn.shopify.com/s/files/1/0180/7671/files/MakerBot-Precision-ABS-data-sheet.pdf?v=1633059940" data-mce-href="https://cdn.shopify.com/s/files/1/0180/7671/files/MakerBot-Precision-ABS-data-sheet.pdf?v=1633059940">-here-</a></strong></p>" data-regular-description="MAKERBOT ABS ABS Black 375-0025A (acrylonitrile butadiene styrene) is one of the most common plastics used in injection-molding, found in many common products such as LEGOS, computer..." data-images="28437289369675 || MAKERBOT ABS Black 375-0025A ||" data-collection-handles="all,consumables,filaments-resins,makerbot,makerbot-compatible-filaments,makerbot-method-materials,frontpage" > Quick View

Method X ABS Black Makerbot Industries $169.00 ex gst

Load More Products

An engine was printed on a 3D printer in Australia

Margarita Melnichuk

21:02, 30 March 2017

2234

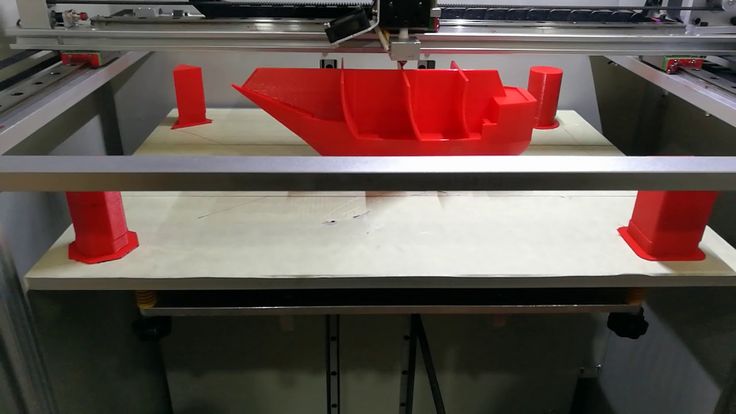

An engine was printed using a 3D printer in Australia. It was developed for the only 1914 Delage Type-S car in the world.

It was developed for the only 1914 Delage Type-S car in the world.

This is reported by "Popular Mechanics".

"> The French company Delage was founded in 1905 and produced cars before the First World War.

parts, he digitized the cylinder block inside and out using a handheld 3D scanner.

See also: Engine failed: Ukrainian tourists could not fly out of Turkey

Thanks to 3D printing, the cylinder block was made in a local foundry and carefully polished by hand, after which the engine was assembled and worked like new.

Earlier, Inform-UA reported that the well-known automotive company Ford will use 3D printing technology for parts. The technology for 3D printing of automotive parts is called Stratasys Infinite Build.

The company has pioneered the use of a 3D printer in the production of automakers. 3D printing is planned to be used for models in the Ford Performance line and personalized parts.

See also: In the Russian Federation, after an unsuccessful landing, the plane caught fire: there are victims (Photo)

Topics

engine Australia delage french company 3d printer the science science news technology news science and technology science and technology news high technology news

Text error? Select it with the mouse and press Ctrl + Enter

Science print directly on top of the damage and over time it will become exactly the same bone tissue as the rest. Whether this technology will become a breakthrough in medicine and how soon the cultivation of bones will become a planned operation - our scientific observer Nikolai Grinko understood.

Whether this technology will become a breakthrough in medicine and how soon the cultivation of bones will become a planned operation - our scientific observer Nikolai Grinko understood.

Photo: unsw.edu.au

In 1997, Luc Besson's film The Fifth Element was released. It contained a scene of the re-creation of the main character Lilu, from which, after the explosion of the spaceship, only a hand remained. In the story, scientists have deciphered DNA and printed a new body using a device that today we would call a biological 3D printer. Then, 24 years ago, such technologies seemed unrealizable fantasy. But to date, the human genome has already been deciphered, and bioprinters have learned to print living organs, albeit as an experiment so far. Medical high-tech is developing very quickly, and just the other day, researchers have learned how to print new bones directly in the body.

For complex fractures or certain diseases, the patient needs to replace a section of a bone. To do this, transplantation is used today: a bone fragment is taken from another part of the body and implanted into the damaged area.

To do this, transplantation is used today: a bone fragment is taken from another part of the body and implanted into the damaged area.

Advanced clinics today already use 3D printers for bone reconstruction: a three-dimensional scaffold is printed from experimental materials in the required place, and healthy cells from the adjacent bone tissue eventually migrate to a new place. The framework itself then dissolves and is excreted from the body. The whole process is quite slow and takes a lot of time. Australian researchers have created a new printing material: a calcium phosphate biogel, into which the patient's living bone cells are pre-integrated.

The gel is delivered to the place of "repair" by a medical printer and immediately begins to harden, turning into a bone-like structure in just a few minutes.

Photo: unsw.edu.au

Already at this stage, its strength is quite high, although less than that of real bones. The cells integrated into it begin reproduction, and they use the biogel as a building material, and over time, the entire artificial structure is replaced by living cells.

Another advantage of the method is that earlier the scaffold for cells had to be printed in advance, having previously scanned the damaged bone, and only then implanted into the body. Moreover, high-temperature furnaces and highly toxic chemicals were used for this. Now you can print a "patch" directly in the patient's body, literally building a new bone in layers.

The technology has not yet been tested on humans, it is currently undergoing the stage of experiments on laboratory animals. But bioengineers say that the experiments are taking place with absolutely predictable and encouraging results, and the reasons why the biogel could not be used in the human body have not yet been identified.

Mankind has always dreamed of learning how to repair their bodies. Medicine has come a long way – shamanism, medicinal herbs, pharmacology, surgery, bioengineering… What the next stage will be, we don’t know yet, but if the 1997 film was able to predict today’s technologies (albeit in a very approximate form), then probably today’s cinema can also be used as a forecast.