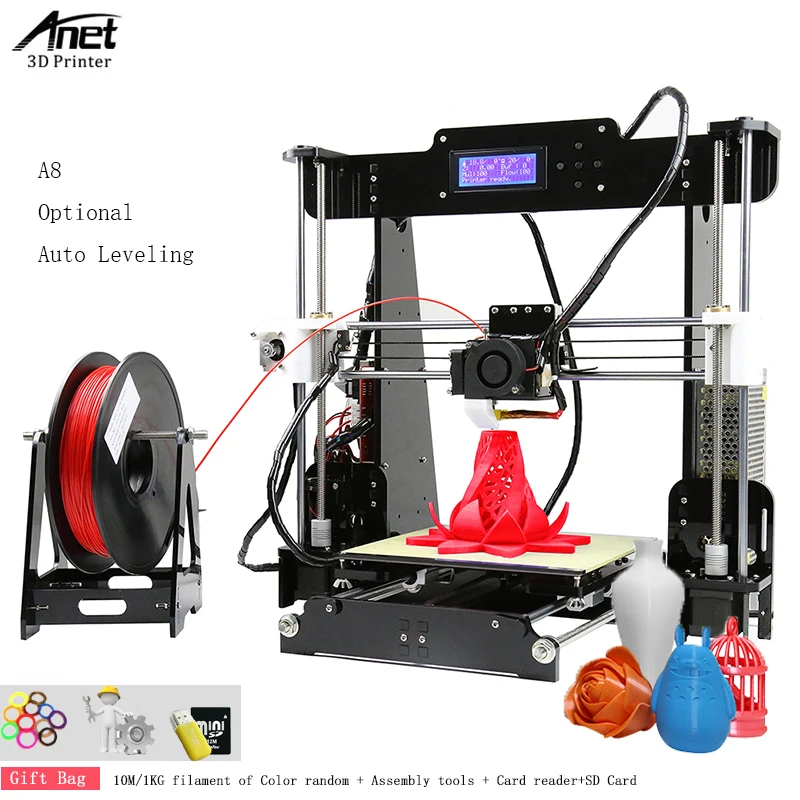

Anet a8 high precision 3d printer

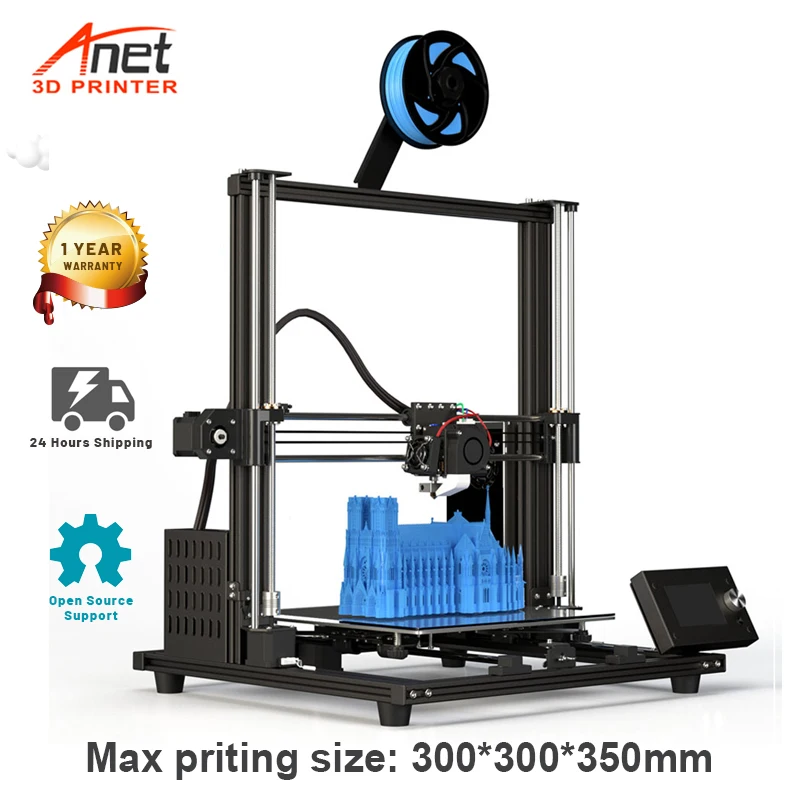

Anet A8 Plus DIY 3D Printer with 300*300*350mm Large Print Volume — Anet 3D Printer

Save $50.00

Original Price $279.00

Current Price $229.00

United States / A8 Plus (US Plug) - $229.00 United States / A8 Plus (US Plug) + Tempered Glass Hotbed Platform - $239.00 EU (VAT included) / A8 Plus (EU Plug) - $229.00 EU (VAT included) / A8 Plus (EU Plug) + Tempered Glass Hotbed Platform - $239.00 Brazil / A8 Plus (EU Plug) - $339.00 Canada / A8 Plus (US Plug) - $269.00 Russia / A8 Plus (EU Plug) - $229.00 UK (VAT included) / A8 Plus (EU Plug) - $229.00 UK (VAT included) / A8 Plus (EU Plug) + Tempered Glass Hotbed Platform - $239.00 Vietnam / A8 Plus (EU Plug) - $276.00

United States

EU (VAT included)

Brazil

Canada

Russia

UK (VAT included)

Vietnam

A8 Plus (US Plug)

A8 Plus (US Plug) + Tempered Glass Hotbed Platform

A8 Plus (EU Plug)

A8 Plus (EU Plug) + Tempered Glass Hotbed Platform

1 2 3 4 5 6 7 8 9 10+ Quantity

Quantity

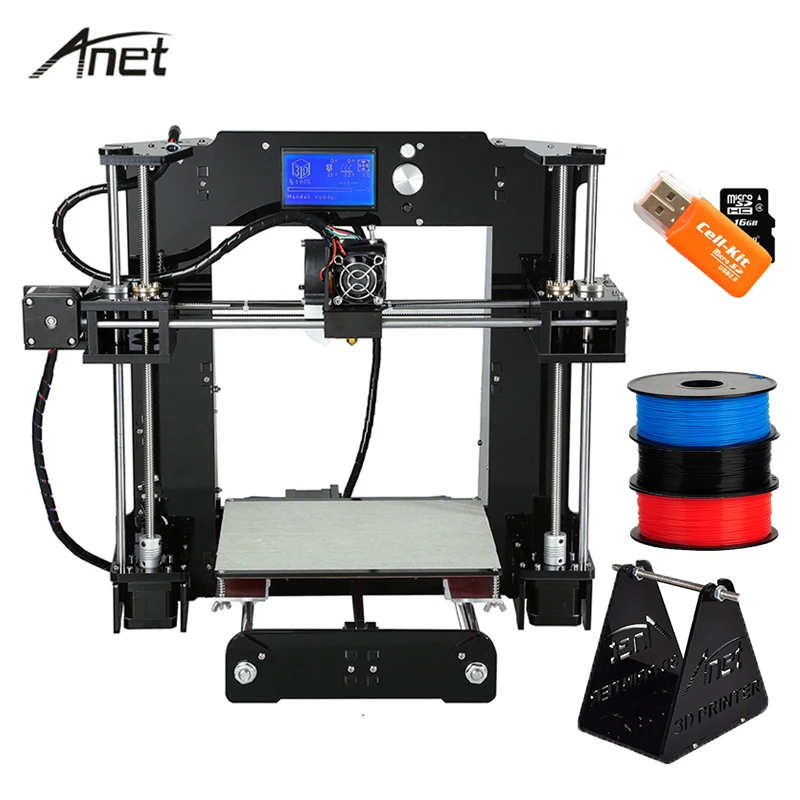

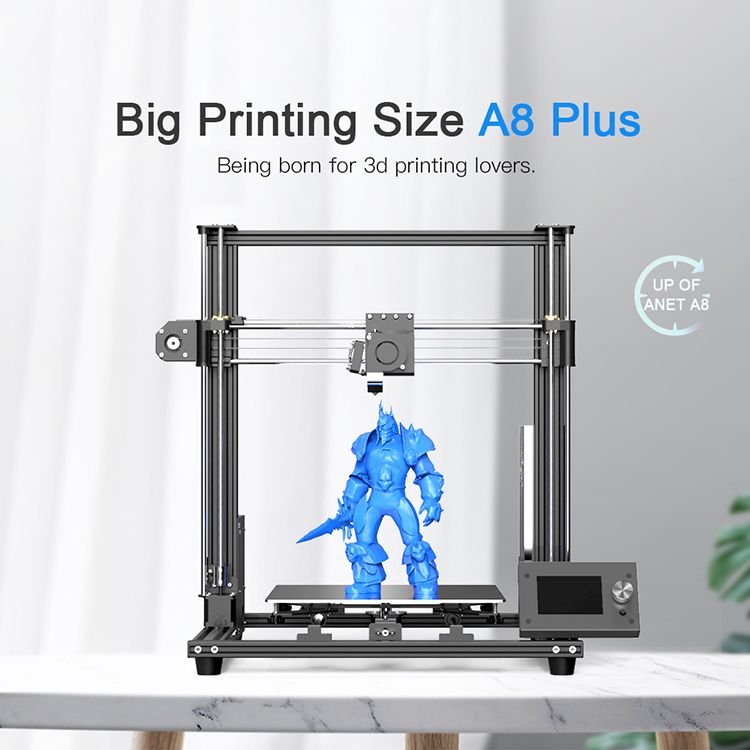

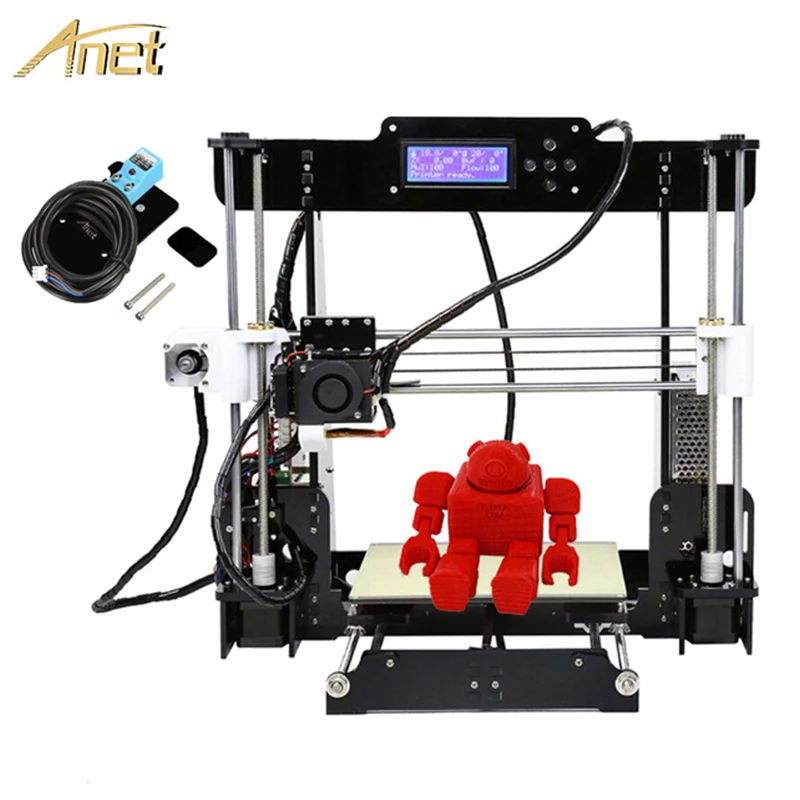

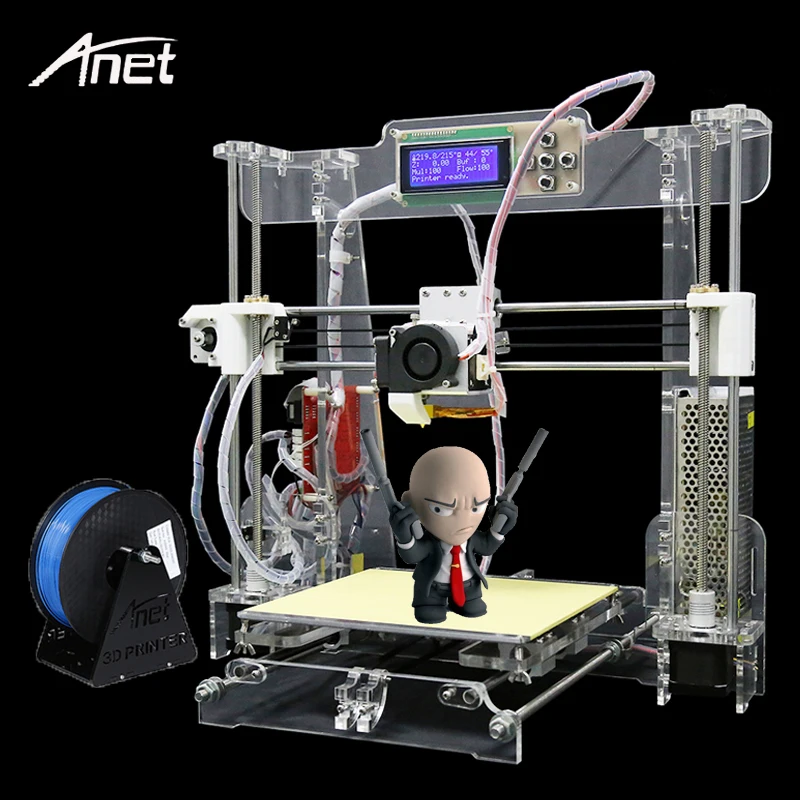

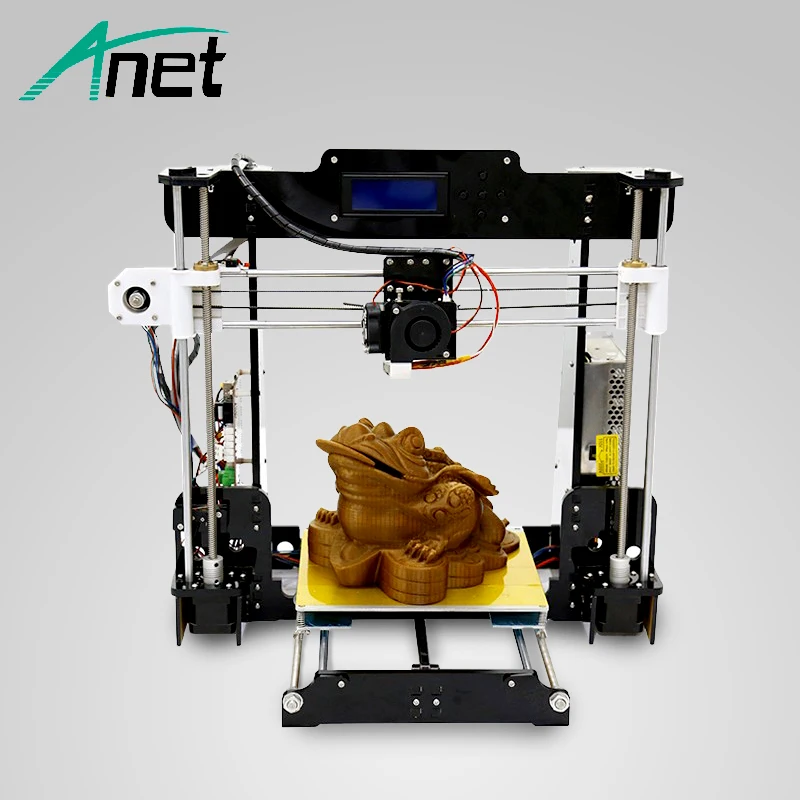

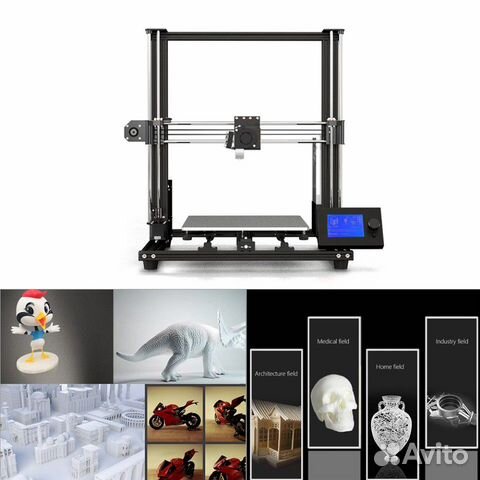

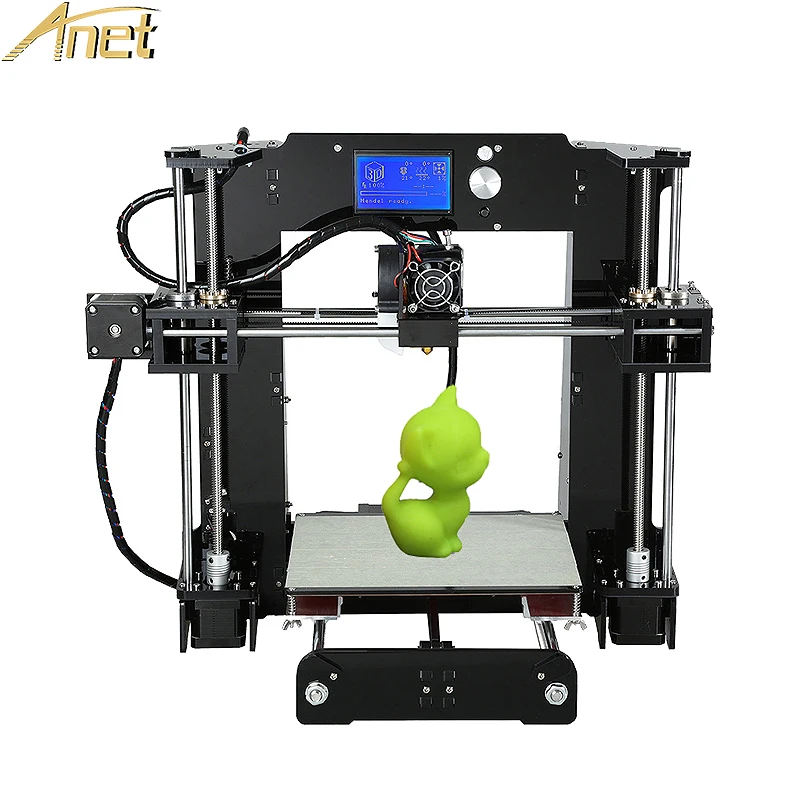

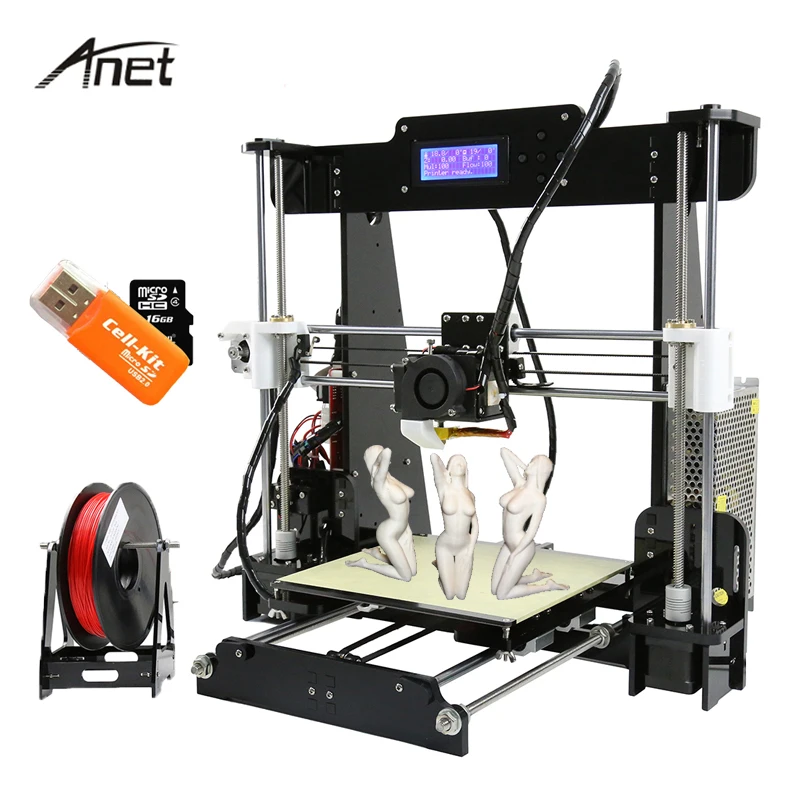

Share this:Anet A8 Plus is an upgraded version of Anet A8, comes with 300*300*350mm build area, aluminum frame, and redesigned motherboard, extruder feed, belt tensioning and much more.

【Unleash your Creality】Ideal DIY kit with open-source firmware for creative people like to do upgrades and modifications on their printers.

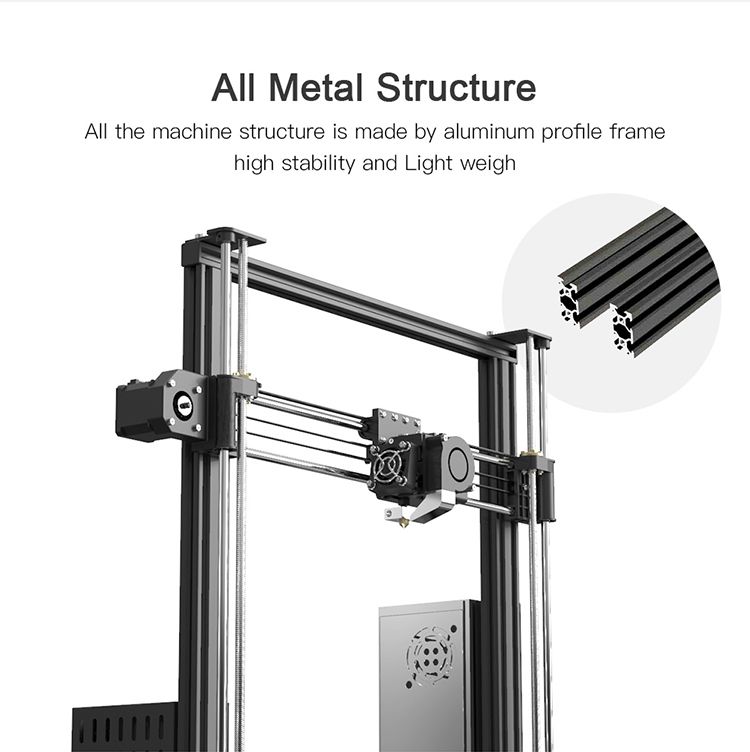

【All-metal body】Stable structure and high printing precision.

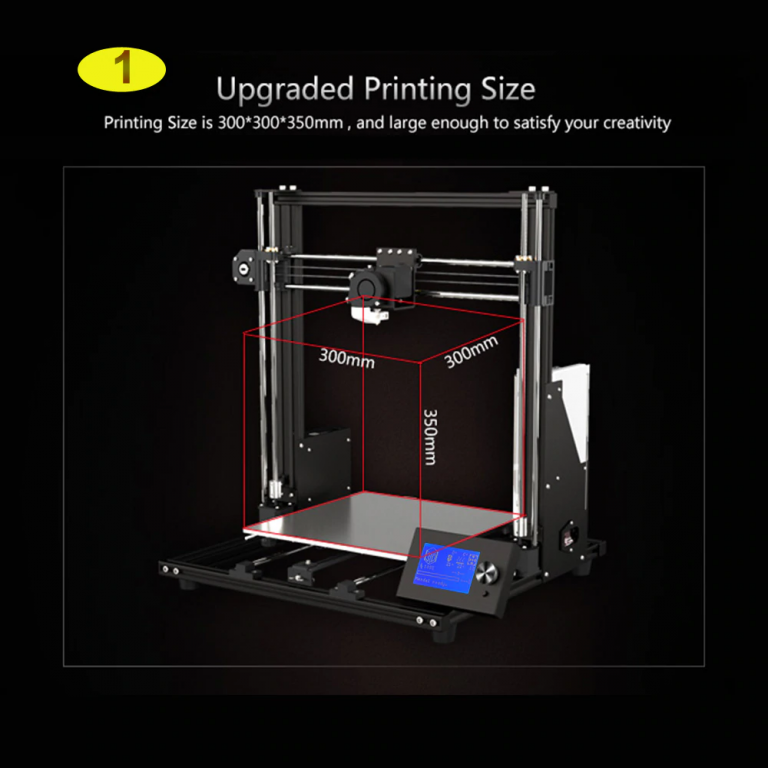

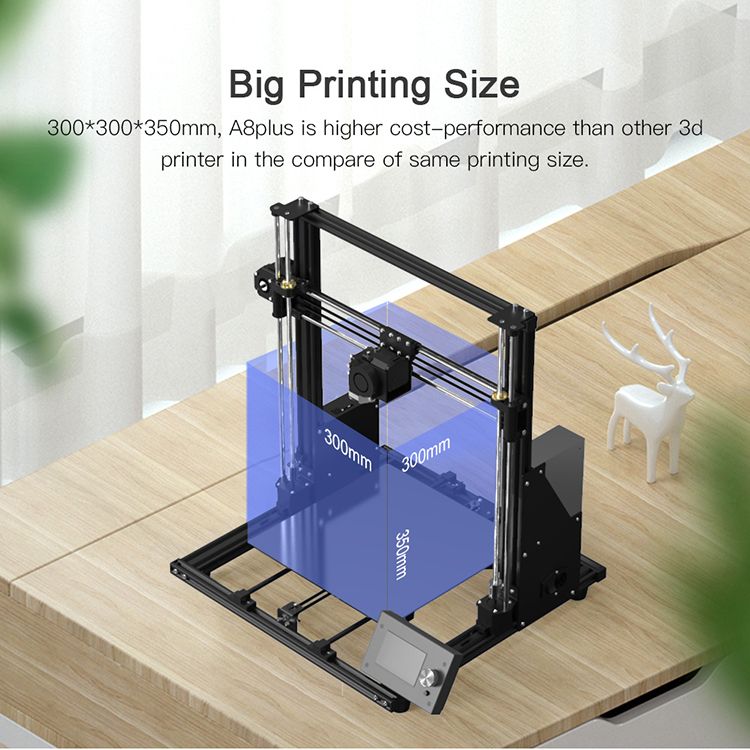

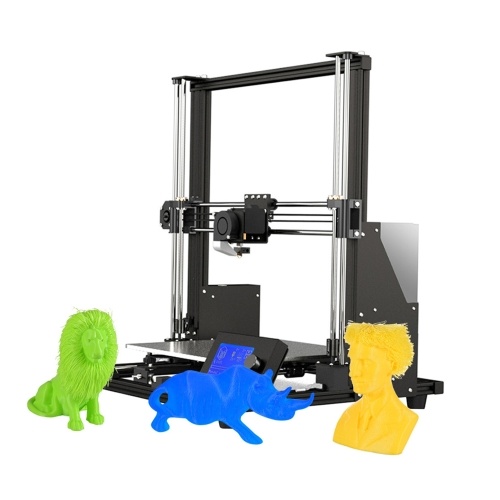

【Large Printing Volume】 Printing size is enlarged to 300*300*350mm, and large enough to satisfy your creativity. The magnetic movable LCD control panel makes your operation more efficient and more flexible.

【Automatic Filament Feeding】Automatic loading and unloading filament function.

【Upgraded Heatbed & Mainboard】Aluminum substrate heatbed comes with a glass panel so that the printing is smooth without a sharp edge and the model is easy to remove. The mainboard is safe designed with over-current protection, short-circuit protection, and a smaller current configuration.

【Anet Official Store Warranty】We provide a 6-month warranty on the printer (nozzle and build plate sheet excluded) and lifetime technical support with fast response in customer service.

Note: Please be noted that Anet A8 Plus has Full DIY version and Semi-DIY version, we'll arrange the shipment in random depending on the local warehouse stocks.

Anet A8 Plus 3D Printer - Full DIY

Save 28% Save 28%

Original price $319.00

Original price $319.00 - Original price $319.00

Original price $319.00

Current price $229.00

$229.00 - $229.00

Current price $229. 00

00

| /

SKU Anet A8 Plus

Availability In Stock

- Description

- Technical Specifications

- Details

- Printed Models

- Parameters

- Videos

- Shipping & Returns

- Price Match

Description

Available Now in the USA!!!

Ships from the USA!!!

Anet A8 Plus is an upgraded version of Anet A8, comes with 300 x 300 x 350mm build area, aluminum frame, and redesigned motherboard, extruder feed, belt tensioning and much more.

All-metal body: Stable structure and high printing precision.

Large Printing Volume: Printing size is enlarged to 300*300*350mm, and large enough to satisfy your creativity. The magnetic movable LCD control panel makes your operation more efficient and more flexible.

Automatic Filament Feeding: Automatic loading and unloading filament function.

Upgraded Heatbed & Mainboard: Aluminum substrate heatbed comes with a glass panel, so that the printing is smooth without sharp edge and the model is easy to remove. The mainboard is safe designed with over-current protection, short-circuit protection, and smaller current configuration.

Note: If you are a starter in 3D printing, we strongly recommend you choose pre-assembled version.

Technical Specifications

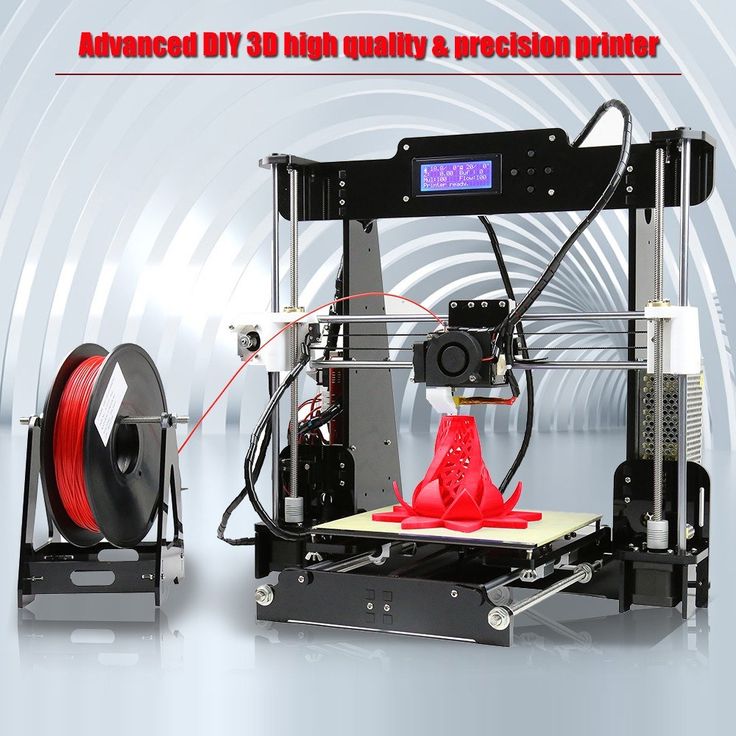

Print Size:300*300*350mm

Print Speed: 10-120mm/s

Filament Diameter:1. 75mm

75mm

Filament Support: ABS/PLA/TPU/Wood/Nylon/

PVA/PP/Luminescent etc.

Precision:Z axis: 0.004mm; XY axis: 0.012mm

Printing Precision:±0.1mm

Layer Thickness:0.1-0.3mm

LCD Display: 12864

Nozzle diameter:0.4mm(0.2/0.3mm optional)

Power: 115V/230V AC/360W

Control Temp: Extruder: Max:260 °C

Hot Bed:50-100 °C

Recommend Temp:

ABS: Nozzle:230 °C Hot Bed: 80 °C

PLA: Nozzle:210 °C Hot Bed: 50 °C

Printing Format: G-code

System Compatibility:Windows/Mac

Operation Interface:English/ Chinese

Connectors:TF card/USB/Online

Auto Leveler: Optional

Color:Black(Transparent OEM)

Frame: Aluminum

Details

Printed Models

Parameters

Videos

Shipping & Returns

Order Confirmation:

As soon as you place your order, you will receive an order confirmation e-mail. This means that we have received your order in our system and pre-authorized your credit card for the purchase. As soon as we receive your order, we automatically reach out to our suppliers to confirm that it is in stock and available for immediate shipment. If your item is on backorder or unavailable, we will void the pre-authorization and reach out to you via e-mail. If your item(s) are available for immediate shipment (within 5 business days), we will process the charges and submit the order for shipment.

Order Shipment:

If your order is in stock and we process the charges to your credit card, it will ship within five business days from the date of your order. We will send you tracking information within 24 hours of your order leaving the warehouse to the e-mail address you provided when checking out. If you do not receive tracking information from us within six business days of your order, feel free to follow up with us at [email protected].

If you do not receive tracking information from us within six business days of your order, feel free to follow up with us at [email protected].

Cancellations & Refunds/Returns:

Before accepting a return on a product that isn't functioning as it should, Project 3D Printers reserves the right to exhaust any and all means to resolve and/or repair the malfunction through technical support and replacement parts provided by both the manufacturer and Project 3D Printers. No return will be accepted without reasonable attempts to resolve the issue(s) first. All returned products must be returned within 10 days of date of purchase.

Project 3D Printers enforces a strict "No Returns Accepted" policy for opened and/or partially used products, including filament, resin, or any consumable of any size and weight that has been used or opened from its factory and vacuum seal. Only products and consumables that are unused, and in brand new factory condition are eligible for return to the manufacturer of origin within 10 days of the purchase date.

If a product is found to be non-functional or defective, the product must be returned with its full original contents within 10 days of the delivery date for inspection of the non-functionality. If the product is found to be defective or non-functional a full-refund will be given, not including return shipping at the customer's expense.

All orders cancelled after 48 hours are subject to a $20 administration fee, whether or not your order has shipped. If you order has shipped, you (the buyer) will also be responsible for actual return shipping charges. Refunds will only be issued to the original credit card that you use when placing your order. Buyer is responsible for and pays a 20% restocking of the value of the returned item(s). Buyer pays all shipping fees for the returned item(s).

Customs Fees, Tariffs, Duty Fees and Import Taxes:

Only customers are responsible for their local import taxes, tariffs, duty fees and import taxes incurred during shipping. To know about your customs import duties please contact your local customs office with this details (HS Code :8477 Product description: 3d printer or 3d printer kit). If the tax amount is high, we can provide assistance to reduce it.

To know about your customs import duties please contact your local customs office with this details (HS Code :8477 Product description: 3d printer or 3d printer kit). If the tax amount is high, we can provide assistance to reduce it.

Price Match

We work very hard to ensure that we offer the absolute best prices online. If you find another online store that offers a lower price than us within six months of your purchase date please let us know and we will refund your original payment for the difference. We want you to feel confident that you are getting the absolute best price for the product you are ordering. If you find that our own website has a lower price for the same item you have ordered within six months of your purchase date will refund the difference as well.

To request your partial refund simply e-mail us a link to the same product on our website, or on our competitors website within six months from the date of your order and we will process the credit accordingly.

Our 100% Price Guarantee has some limitations:

- You must purchase the item from our website before requesting your Price Match Guarantee

- Promotions such as rebates and buy one, get one free offers are not eligible

- The item must be in stock on the competitors website

- The competitor must be an online store, they may not have a retail location

- The website can not be a discounter or auction website (ie; eBay, overstock, etc..)

- The competitor must be an Authorized Retailer of the product in question

- The Price Match Guarantee includes the item price and the shipping charges, it excludes sales tax

Longbai Jewelry Watch Gem Small Diamond 2021 Quartz Womens Watch Fashion 6 7mm Ultra Thin Dial High Quality Leather Strap Lady W3217

DESCRIPTION

Does your product come with a box?

No, the box must be purchased separately.

I need to select multiple options, how do I choose? ?

You can add them to your cart separately and pay together.

Welcome to our store. We specialize in a huge variety of watches and related products. From timeless classics to more modern and cutting-edge, our watches cover all tastes and styles. Our team of workaholics has a life's experience and we strive to give you the best quality watches at the most competitive prices. In addition, we pride ourselves on the best customer service. Whether you're looking for the perfect finishing touch for a formal look or a gift for someone special, you can find the perfect 9 watch0003

-

Buyers may return item(s) for a refund within 7 days from the day the items were received and the buyer should afford the return shipping cost. Item(s) must be returned in the same condition as after it was delivered.

-

Buyers may return item(s) for a refund if they are not as described or with quality issues within 7 days of receipt of the item(s). from the goods received.

-

Please don't hesitate to contact us if you have any questions or concerns before or after your purchase.

We are committed to your 100% satisfaction.

We are committed to your 100% satisfaction.

Payment

There are many payment methods available on dhgate.com such as credit cards, real-time bank transfers, offline payments (bank transfers). You can choose the method which is the most convenient for you. To protect your interests, your payment will be temporarily held by DHGATE and will not be released to us until you receive your order and are satisfied with it.

Transportation

1. Conviction cost:

Select the quantity first, then click the country through the logistic methods on the page.

2. Swipe the following page, you can see the detailed shipping cost for each logistics method when you select.

3. Item Processing Time: The processing time for a specific order varies with the product type and stock status. Mostly processing time can be 3 to 15 working days.

Return Policy

If you would like to exchange the items you have received, you must contact us within 3 days of receiving your order. And you should pay the additional shipping fees incurred and the items returned should be kept in their original status.

And you should pay the additional shipping fees incurred and the items returned should be kept in their original status.

Feedback

Since your feedback is very important to our business`s development, we sincerely invite you to leave positive feedback for us if you are satisfied with our product and service. It will just take 1 minute. Thank you!

the best 3D printer in the cheap segment?

3DPrintStory Reviews Anet A8 review: the best 3D printer in the cheap segment?

Since childhood, I liked to create, design. Lego was my passion. When I first heard about 3D printing and printers, I realized that this could be my hobby as an adult.

However, a few years ago 3D printing technology was quite new and buying a 3D printer was clearly out of my budget. That is why, when I heard that now you can buy a 3D printer for $190, which is close to $1000 models in terms of print quality, I was surprised and delighted.

That is why, when I heard that now you can buy a 3D printer for $190, which is close to $1000 models in terms of print quality, I was surprised and delighted.

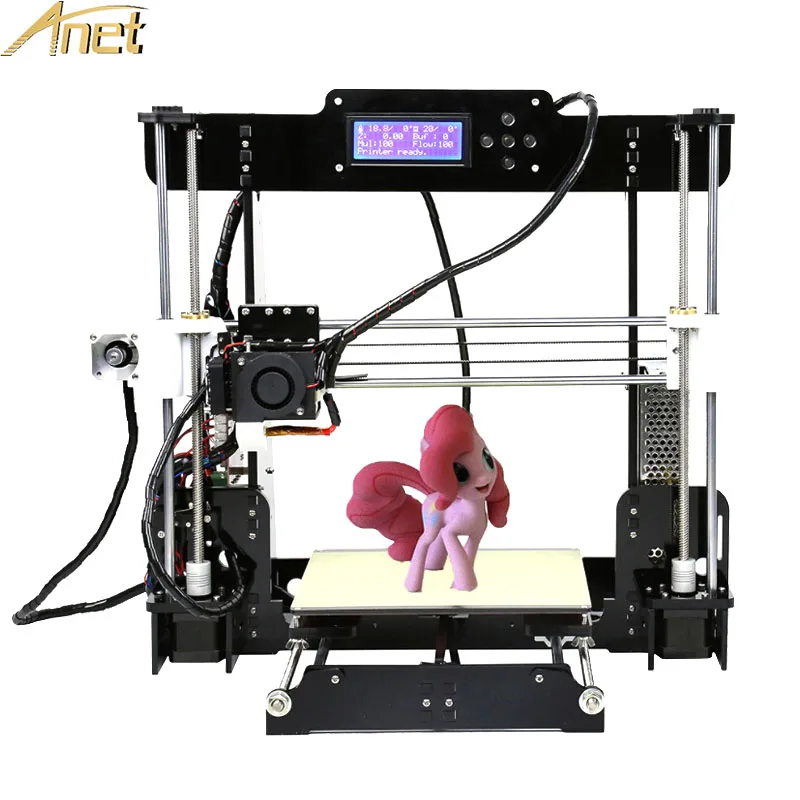

This 3D printer is called Anet A8 and is manufactured by Anet in China. The A8 garnered very positive reviews on the internet, so I bought it and present my own review below.

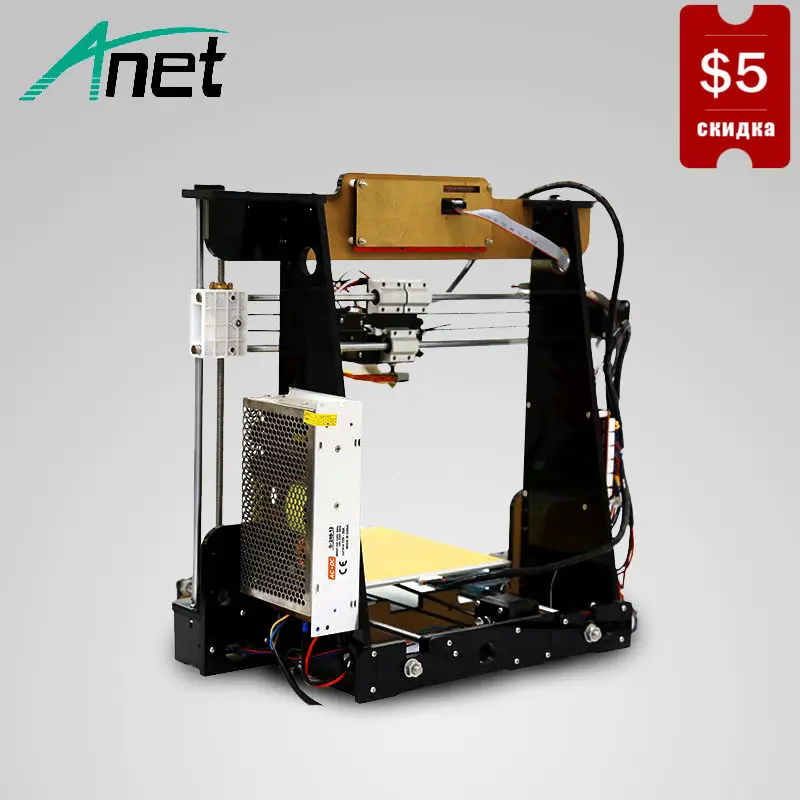

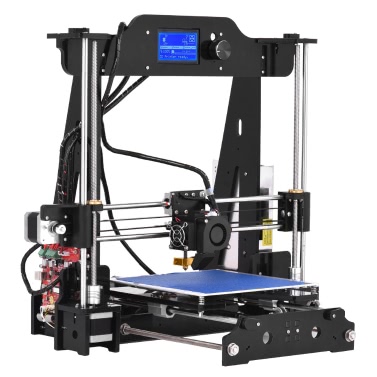

Anet A8 is a DIY 3D printer that you build yourself. Judging by the reviews in many reviews on the Internet, if it is properly calibrated and upgraded, it approaches expensive top models in terms of print quality. In addition, even a person who has absolutely no design experience can assemble it.

In the review below, the Anet A8 is being tested from a beginner's point of view. Can this cheap $170 3D printer produce good results?

Probably, if you are also a beginner, you have questions like how safe it is to use, will I burn the apartment, etc. I will also address these questions.

Specifications Anet A8

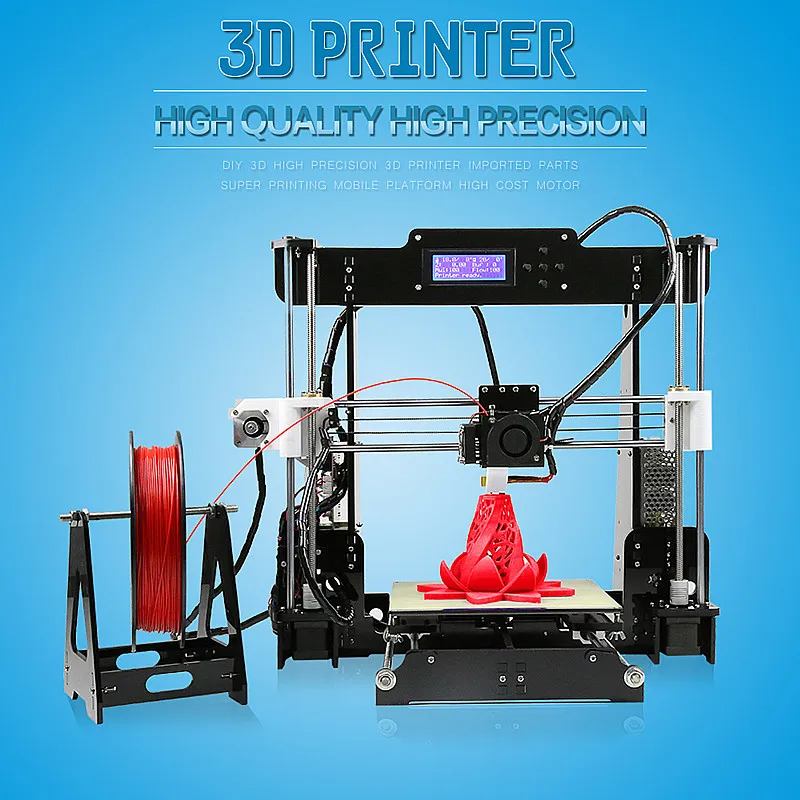

Anet A8 is a DIY 3D printer that costs in the range of $170-200. This model makes it possible to print 3D objects from various materials, completely different shapes. It can print with any materials, but is best adapted to the use of the most common PLA and ABS plastics.

This model makes it possible to print 3D objects from various materials, completely different shapes. It can print with any materials, but is best adapted to the use of the most common PLA and ABS plastics.

Anet A8 specifications are shown below.

| 3D printer | 510 x 400 x 415 mm |

| Packaging size | 510 x 400 x 415 mm |

| PCD | 9008.59.12 kg |

| Print size | 220 x 220 x 240 mm |

| Maximum 3D print speed | |

| Printing table material | Aluminum |

Where can I buy Anet A8?

This review uses an Anet A8 3D printer ordered from China from Gearbest. Delivery took about two weeks.

If you find this model in online stores in Kyiv, Moscow, St. Petersburg or Minsk, then it will certainly be with a decent markup compared to Gearbest.

Therefore, if you are ready to wait 2-3 weeks and save a quarter of the cost, then I recommend:

Buy Anet A8 with delivery from China

How does it work?

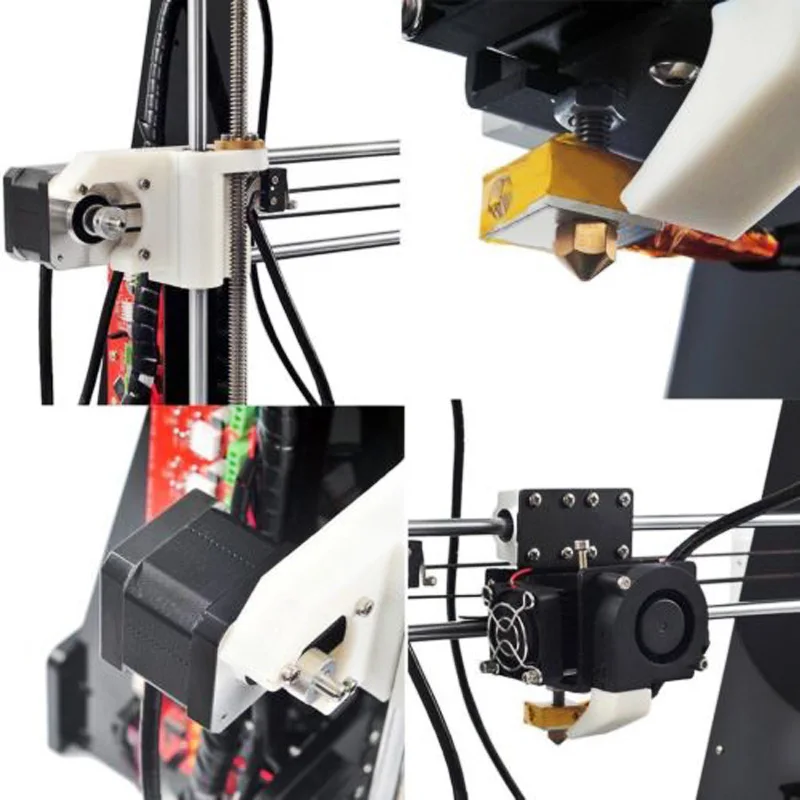

Uses FDM 3D printing technology. The main nodes of Anet A8 are shown in the figure below.

The main nodes of Anet A8 are shown in the figure below.

Assuming you've pre-calibrated it, the basic steps for 3D printing are:

- You turn on the power.

- Preheat depending on the material used for 3D printing (Quick Setting> Pre-heat PLA/ABS).

- Insert the material into the hole in the extruder. This may cause some difficulties.

- Selecting a 3D model from the SD card in the SD Card > Print a file menu

- The 3D printer warms up again and starts printing.

- The extruder pushes through the material, which begins to melt.

- The 3D printer moves along the X, Y and Z coordinate axes and feeds the melted material layer by layer onto the heated table.

- After printing is completed, you will see 100% on the LCD screen, the operation will stop.

- You can remove the printed product from the table.

The photo below shows the disassembled extruder.

Imagine an ordinary printer. He prints on paper. The 3D printer does the same. He delivers the molten material to the table. The only difference is that the regular printer does not move up, but the 3D printer moves along the Z axis, laying down the material in layers, one on top of the other.

He prints on paper. The 3D printer does the same. He delivers the molten material to the table. The only difference is that the regular printer does not move up, but the 3D printer moves along the Z axis, laying down the material in layers, one on top of the other.

Important questions for a newbie to 3D printing

Below is a list of questions that I asked myself before buying Anet A8 and the answers to them.

- I'm new to the world of 3D printing... Can I assemble and use it? Relax, you can. There are step-by-step instructions and support from a large community. Just be patient and feel free to ask questions.

- Because I can't create 3D models. Don't worry. You don't have to be able to. There are a huge number of online resources where you can say 3D printable models for free.

- Is it safe to use Anet A8 in an ordinary apartment? It's safer if you use PLA as it doesn't release toxic substances during printing unlike ABS.

- Can Anet A8 cause a fire? Yes, like any other electronic device, the 3D Printer can cause a fire. This is not a toy, so be extremely careful. To improve the security of use, there is a whole list of improvements. You should not invent a wheel, but just google and subscribe to the relevant groups on Facebook.

- What media should I use? It's better to start with PLA plastic. It is easier to learn from it. Once you get comfortable, you can switch to other materials.

- Is it necessary to connect to a personal computer? You can control from a personal computer by connecting via USB, but Anet A8 can work as a completely independent device, reading model information from an SD card.

- Noisy 3D printer ? You will definitely hear how it works. There are Anet A8 upgrade options that will reduce noise and vibration.

- How firm are the printed objects ? It depends on the material used and the filling of the model.

- Can other materials be used? If you want to try something other than PLA or ABS, it is recommended to upgrade your 3D printer.

Before the arrival of my 3D printer Anet A8...

I wanted to get ready. Especially after the scary stories on the Internet about burned houses and apartments, I didn’t want to get stuck in the same one.

The first thing I did was to join two popular Facebook groups of Anet A8 owners. To be honest, it was not easy to find useful information in these Facebook communities. As a result, it all came down to surfing the Internet and tons of YouTube videos. YouTube has been especially helpful for me.

I also recommend you to educate yourself. Yes, you won’t be able to avoid all mistakes, but as a result, you won’t fall for many of them.

What's in the box?

When the 3D printer arrived, I was absolutely delighted. Anet A8 arrived in a large box that weighs about 10 kg. When you open it, make sure you do it from the front so that the parts do not fall out.

When you open it, make sure you do it from the front so that the parts do not fall out.

Box contains 3 layers of smaller plastic boxes. These boxes contain all the parts needed for assembly. There are really a lot of details. And it was especially nice.

The manufacturer also packs a screwdriver, 4 hex keys, pliers and even an SD card with a USB adapter. There is no specific sequence in the packaging of the parts, so it doesn't matter how you mix them when you take them out. Below is a list of Anet A8 parts.

Everything is packed very well.

The first thing that started to alert me was that there was no printed assembly instruction. But it turned out that it is on the MicroUSB card that comes with the kit.

Manual is written in Chinese and English. Consists of several folders on the SD card. The only printed part is an A4 sheet with a diagram of connecting electrical equipment to the control board. Everything else you will find in digital form.

Before starting assembly, you can check if all parts and assemblies are missing. Personally, I printed out a complete list of parts and checked everything. It turned out that there were even more screws and nuts than it should be.

It is also worth noting that in addition to the parts from the list, there were 10 meters of white PLA plastic in the kit. Since it's not in the parts list, I'm not sure if it comes in every box with the Anet A8. In any case, this will not last long, so you need to take care of the printing materials yourself. I'll talk more about the materials later.

Anet A8 assembly

I'll be honest with you. Seeing all the details, I was scared. How do I collect all this? In fact, it turned out that it is not as difficult as it seemed at first glance. You will need time, patience and focus. This is quite enough, even if you have never held a screwdriver in your hands.

In addition to the instructions on the flash drive, Anet has published three video instructions for assembling and getting started with the Anet A8.

- Assembly Video - Part 1 (Printer Frame Assembly)

- Assembly Video - Part 2 (Remaining Assemblies and Electronics)

- Assembly Video - Part 3 - setup (this video shows the process of calibration and the first 3D printing)

The quality of the videos is quite good. According to them, it is quite possible to assemble a printer by 80%. The remaining 20% must be specified in the instructions, because sometimes not everything is transparent. In general, if you are assembling from a video, I recommend checking all your steps with the instructions.

It took me 3 days to build Anet A8. Yes, 3 days. On the first day, I checked the presence of all components and parts and removed the protective films from all acrylic parts. After that, I started to assemble the frame. The process did not go as smoothly as expected. I assembled a few parts incorrectly because I ignored the instructions. After that, even despite the apparent obviousness, I still consulted the instructions. Probably, on the first day I spent 3-4 hours in total.

Probably, on the first day I spent 3-4 hours in total.

On the second day I wired up the electronics and added the rest of the frame. This is the hardest part. It took me 5-6 hours in total. Good thing you don't have to solder anything. All electronics and wires are connected directly to the main board.

Although I put everything together in 2 days, I turned on my 3D printer for the first time only on the third day. At the time, I hadn't watched the instructional videos, so when I turned on the printer, it put me in a slight stupor. I didn't really know what to do with him. How to calibrate it, when can I start printing? In general, if you are a beginner, be sure to watch the third video.

There are already some 3D printing files on the SD card. I recommend you start small, like Box-1.75mm PLA-A8 or something similar. I made the mistake of starting to print a large part that took a long time to print and used a lot of material.

In general, a day passed and Anet A8 was finally ready to print.

Important note. It turns out that there is a mistake in the first part of the assembly video. The metal H frame is installed incorrectly, causing the drive belts to be out of parallel. If you flip the frame, the straps will be parallel. In my experience, this has reduced the noise. Look at the photo below.

My first 3D print with Anet A8

After calibrating with the video instructions, I started the first print. In the photo below, you can see the result, which turned out to be (literally) too hot :).

I couldn't tear the result off the table. I didn't understand what happened either. In general, I turned off the 3D printer and went to Google.

So what happened? It turned out that the thermistor, a small wire that measures the temperature of the extruder, had come off. As a result, it sent incorrect data to the main board and the nozzle heated up to 230 degrees. Since the optimal temperature for printing PLA plastics is 180-220 degrees, nothing good came of it.

By the way, the thermistor is one of the dangerous components that can cause a fire. So be very careful with him. Well, "the first pancake came out lumpy", but that's all - an invaluable experience for a beginner. It is unlikely that many people have such problems, but anything can happen.

After fixing the first problem, I started 3D printing again and watched closely. The beginning was inspiring, but at some point my model started to move... Now what???

Google told me my desk was not calibrated well. He also suggested to me that this is a standard mistake for beginners. As a rule, everyone wants to type faster and does not pay much attention to such seemingly trifles. But without calibration, you won't succeed. In general, this error was not a jackpot, which is already good.

Manual table calibration is the most boring and most important part for Anet A8 to work correctly. If the first layer does not fit well, then the part may come off at any stage. It is especially sad when this happens at 70-80 percent of the press.

It is especially sad when this happens at 70-80 percent of the press.

Well, the first time it took me about 20 minutes to calibrate. I was guided by the third video assembly instruction.

The third run was a success! It's hard to convey my delight when I saw that 3D printing runs smoothly, without failures. The model was printed for about 7 hours (mainly due to the fact that 100% filling is set).

During printing, I realized that the plastic would not be enough and I would have to change it without interrupting the 3D printing. Again, Google helped. The solution turned out to be very simple - just pause the print, take out the old plastic and add a new one. Resuming printing.

After 7 hours of waiting/watching, the model was ready. It looks, of course, far from ideal, but it was printed!

After the first success, I realized that it is better to print something less bulky first. So I downloaded a small Pikachu model (you can download free 3D printable Pokemon models if you're interested), scaled it up and sent it to print. It took 30 minutes.

It took 30 minutes.

I later realized that this waviness of the surface was due to insufficient tension on the belts.

That's it, I was ready to conquer the new, wonderful world of 3D printing. I was very inspired by the idea of modernizing my new miracle. Print parts to improve yourself? The concept is good, isn't it?

These were my next experiments. I printed two upgrades - button cap and a filament guide. After that... Another problem is my extruder got clogged . The material stopped coming out of it. Want to know what I did next? Yes, the Internet is still a wonderful thing...

In general, I had to take everything apart. In the photo below you can see what happened.

Do you think I fixed it quickly? Of course not. Like a real noob who ignores guides and instructions, I only made the situation worse.

If in a few sentences: the material is stuck, I tried to use tweezers to get it out. Naturally. I broke it and somewhere inside there stuck a small piece. My next step was the most fatal: I tried to melt it with a lighter and naturally singeed a teflon tube (English - ptfe tube) . Although this tube seems like a small thing, you won't be able to print without it. I cut off the burnt part, installed it back, but there was a slippage effect during printing. All in all, things got really bad.

My next step was the most fatal: I tried to melt it with a lighter and naturally singeed a teflon tube (English - ptfe tube) . Although this tube seems like a small thing, you won't be able to print without it. I cut off the burnt part, installed it back, but there was a slippage effect during printing. All in all, things got really bad.

This little tube is important! Its task is not only to guide the material in the extruder, but also to provide the right temperature so that the material does not melt before it reaches the nozzle.

What is the solution? I had to buy a new Teflon tube. But besides her, I immediately ordered more additional parts and assemblies that belong to the "must have" category.

Parts list below. If you are going to drink Anet A8, I recommend that you order these too. Most are the things $1-2 :

- ptfe tubes (highly recommended)

- 6X different size tips (highly recommended)

- Timing belt (highly recommended)

- Print head

- Thermistor Last - not necessarily.

- Make sure the thermistor is connected;

- Table calibration is very important - this is what caused most of my problems during 3D printing;

- Belt tension is important. With poor tension, the model is obtained with a wavy surface;

- Buying consumables will save a lot of time and solve many problems in the future;

- Every little detail counts (eg Teflon tube). Do not consider yourself the smartest and be extremely attentive to details;

- The same material from different suppliers melts at different temperatures. So when you start using a new plastic, print this model first to check the optimum print temperature.

- Semi-Circular Anet A8 Fan Duct - improves air circulation;

- Extruder Button Anet A8 - after that you will not have to suffer from pain every time you press the metal screw of the extruder;

- Filament Guide Horizontal - guides material more precisely into the extruder;

- Filament Guide - also guides your material into the extruder more accurately;

- T Corners - adds stability and reduces vibration;

- Improved X belt tensioner - helps to adjust the tension of the belts along the X axis. Much better than the basic design;

- Improved Y belt tensioner - Helps to adjust the tension of the belts along the Y axis. Much better than the basic design;

I bought it just in case and still have a basic thermistor.

I bought it just in case and still have a basic thermistor. What can you learn from my mistakes?

Anet A8 improvement

Several months have passed since the purchase of Anet A8 until this article was written. During this time, I learned a lot of information about my printer and 3D printing in general. And although I haven't done everything I wanted yet, many upgrades for the Anet A8 are already printed and in use.

And although I haven't done everything I wanted yet, many upgrades for the Anet A8 are already printed and in use.

After the modification, the print quality of the Anet A8 has really improved.

Below is a list of upgrades you can download for free from Thingyverse:

Of all the improvements listed above, I noticed the best result after replacing the belt tensioner. The video tutorial shows that the belts should not be too tight. But it's not. The stronger the tension of the belts, the less wavy surface of the 3D model at the output.

The video tutorial shows that the belts should not be too tight. But it's not. The stronger the tension of the belts, the less wavy surface of the 3D model at the output.

Plans to try other types of belts, such as fiberglass belts.

3D printed quality

In the photo below, I am proud to present you the 3D printed models. All of them are printed on Anet A8, with minor modifications and upgrades. If you compare them with the first results, the difference is huge.

This fish skeleton has moving parts. At the same time, it is printed as one model. Low bow to the author of the 3D model.

Empire State building 3D model is what I'm most proud of right now.

You can print functional models. For example, stand for Kindle Paperwhite.

Another example of functional models - a printed holder for flash drives. Well, the last experiments with print quality.

The dragon on the left is the first experiment with painting a 3D model.

Software

You don't need 3D modeling skills to use the 3D printer. I am sure that if you create a 3D model yourself and then print it, the process becomes much more pleasant. But don't worry, it's not necessary.

The process is quite simple. You go to a website with 3D models. Probably the most popular one I've used is Thingyverse. After you have found a suitable 3D model and downloaded it, you need to unzip it.

Some 3D models are printed in one setup. Others consist of separate parts, which are then assembled or glued. Your next task is to import the model or individual part into the program's slicer. A slicing program is software that adjusts your model for your 3D printer.

Cura recommended for beginners. See the Anet A8 manual for information on how to set up Cura 14.07 to work with your 3D printer. I recommend starting with this version of Cura, as there is an instruction explaining how to set it up to work with Anet A8.

The first picture below shows the Cura 14. 07 interface, the second picture shows Cura 2.3.1.

07 interface, the second picture shows Cura 2.3.1.

In a slicing program, you can do a lot of things. Scale your 3D model, change print quality, speed, etc. A very useful feature - you can find out how much material you need, how much it will weigh as a result and how long it will take to 3D print. Naturally, these are approximate values.

All settings affect print quality to some extent. A very important parameter is the speed of printing. The higher the speed, the faster the part will be printed, but the quality will be worse. Here it is necessary to find the golden mean.

The photo below shows models printed at different speeds.

Can a newer version of Cura be used with the Anet A8?

Yes, you can update your software. Personally, I started with version 14.07, but when I got a little comfortable, I switched to version 2.3.1. There were no problems with this. The only thing is to update the settings. As a rule, the latest versions are better than the previous ones. Using Cura as an example, I noticed that version 2.3.1 renders objects much faster than 14.07. And the interface is nicer too.

Using Cura as an example, I noticed that version 2.3.1 renders objects much faster than 14.07. And the interface is nicer too.

Anet A8 display user interface

The Anet A8 is said to be suitable for beginners, but the display user interface is not as simple as one would like. Even after 2 months of relatively regular 3D printing, I can't remember all the features that are displayed on the screen. Probably, the manufacturer should pay attention to this and make the interface more intuitive.

Conclusions

My adventure with the Anet A8 can be described as a love-hate game. I really hate that I love my Anet :). There were moments when I just wanted to pull out my hair from the fact that you don’t understand what went wrong. And there was such that I literally jumped around for joy, marveling at the quality of the printed models.

But it's worth noting that most of the problems I've encountered are due to my ignorance in the world of 3D printing and overconfidence (for example, the situation with a lighter and plastic stuck in the nozzle).

Yes, before buying I read and tried to learn theoretically, but as always, the best way to learn is to solve practical problems.

I can confidently say that the Anet A8 is a 3D printer that will take some time to assemble and master, but you can achieve very good printing results. Would I recommend this model for a beginner on a budget? Definitely yes. But again, do not forget that for a good 3D printing result, you will have to spend some time and effort. You will have to slightly modify the base model and set up printing for material from a specific manufacturer.

The developers of Anet managed to overcome a very important barrier that was between the consumer and the manufacturer. Now you don't have to pay $700-2000 for a 3D printer. Apparently, 3D printing is becoming an increasingly competitive marketplace, which means that prices will fall and the number of innovations will increase every day.

Another big advantage of the Anet A8 (besides the price) is the large user community.