3D printed sports equipment

The Top 3D Printing Applications in Sports

Published on June 11, 2021 by Jamie D.

3D printing technologies are becoming increasingly popular. This becomes particularly clear when taking a look at the all the industries that are now using additive manufacturing. These include not only those you would expect, like aerospace, construction and medicine, but also the sports industry. The use of 3D printing in sports is not limited to only a few, isolated sports – on the contrary, ranging from surfboards and golf clubs to sports and ski boots, there is something for almost every sports fan. However, additive manufacturing is most often used for the production of various types of protective equipment due to its ability to be fully customized to the wearer, offering significantly better protection. Read on and discover what innovations have already been realised thanks to 3D printing in the sports sector.

3D printed prosthesis for a cyclist

Denise Schindler and her 3D printed prosthesis

The importance of 3D printing technologies and their advancement in the sports industry, also came to light at the 2016 Summer Paralympics. Denise Schindler, a German competitive cyclist, was able to snag a silver and bronze medal in the individual time trial and road race categories, respectively, at the 2016 Paralympics in Rio – and she did it with a 3D-printed prosthesis! Together with the American software company Autodesk and her prosthesis manufacturer Reha-Technik Wellmer, she developed a process in which the residual limb of amputees can be digitally measured and modeled thanks to laser scanning. A prosthesis can then be produced using 3D printing.Denise now works with the web-based Mecuris Solution Platform, which 3D prints her prostheses. Together with her prosthetist, she can design the foot exactly the way she wants it.

Chevrolet Race Cars with 3D Printed Parts

In 2020, Chevrolet announced that by October, their race cars with incorporated 3D parts had covered 80,000 miles or approximately 130,000km over the course of the season. The automaker has taken its cue from its parent company, GM, and increasingly uses additive manufacturing at the heart of its development, in both prototyping and end production phases. In 2020 alone, two new corvettes entered the racetrack, each with 75 3D printed parts, including oil tanks, fuel tank inlets and caps, drivers’ cooling boxes and the integrated hydration systems. The brand’s racing teams – Corvette, INDYCAR, NASCAR Camaro and Silverado – have been driving vehicles with 3D printed components, proving their durability. The two new Corvette C8.4s alone covered 9000 miles in seven races.

In 2020 alone, two new corvettes entered the racetrack, each with 75 3D printed parts, including oil tanks, fuel tank inlets and caps, drivers’ cooling boxes and the integrated hydration systems. The brand’s racing teams – Corvette, INDYCAR, NASCAR Camaro and Silverado – have been driving vehicles with 3D printed components, proving their durability. The two new Corvette C8.4s alone covered 9000 miles in seven races.

Cavendish Imaging’s 3D Printed Football Mask

Cavendish Imaging is a London-based company that produces masks in order to allow athletes who have suffered injuries to their face, such as a fractured nose or cheekbone, to continue playing. Using 3D software, the company are able to scan the athlete’s face and create a model based on which a custom protection mask can be 3D printed. This innovation reduces the period of inactivity related to an injury, and also prevents further harm to the injury whilst it heals. The mask has been used by several professional football and rugby players, including, their first client and former captain of Chelsea, John Terry as well as Sergio Ramos.

The HEXR 3D Printed Bike Helmet

Most bike helmets are made of foam, which actually doesn’t provide as much safety in a fall as it should. Jamie Cook, Co-Founder and CEO at HEXR, thought that it was time for something to change. And that’s exactly why he launched HEXR, a new type of helmet made from polyamide 11 (PA 11) and 3D printed to provide more protection. The helmets are personalized and can be customized through a 3D scan of the head shape, resulting in optimal comfort. HEXR even provides an app that can be used to try on helmets on your own. All you need is a tight-fitting cap and a friend who can help you scan your own head.

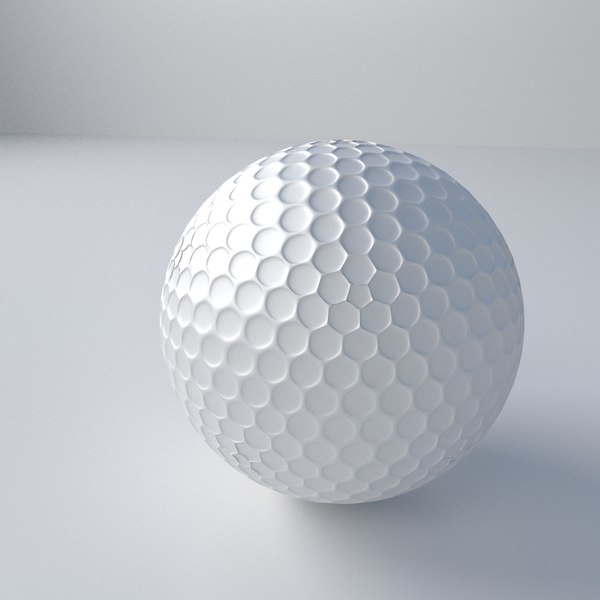

KING Supersport-35 3D printed golf club

The KING Supersport-35 is a 3D printed golf club made from 316 stainless steel, created by Cobra Golf in partnership with HP and SIK golf. While its 3D printed body and lattice design ensures that the putter possesses optimal weighting, producing the highest MOI in a blade shape, thanks to SIK Face Technology the putter is able to produce the most consistent and accurate roll for every putting stroke. Created using HP Metal Jet Technology, Cobra Golf’s first ever 3D printed club is certainly a feat.

Created using HP Metal Jet Technology, Cobra Golf’s first ever 3D printed club is certainly a feat.

3D Printed Bicycles from Superstrata

If you are a cycling fan, you are going to like this next project from Superstrata! They have created a carbon monocoque bike, all printed in 3D using Arevo’s composite machine. Entirely adapted to the cyclist’s morphology, the frame is designed with carbon fiber, a material renowned for its lightness and strength. This makes the bike easier to handle: the company claims that the frame weighs less than 2 bottles of water or more exactly 1.3 kg. For the moment, two versions are available, one of which is electric.

Wyve, 3D Printed and environmentally friendly surfboards

Another sport in which you can find 3D printing is surfing! Last year, we conducted an interview with the Wyve team, a French startup dedicated to the development of surfboards through additive manufacturing. The peculiarity of this project lies in the production process of the boards since, in addition to being customizable, they have a very original transparent design. The company states that they produce the boards from recycled plastic waste which, through 3D technologies, offers the user a more optimal and resistant solution. An original way to combining eco-friendliness and innovation in the same project.

The peculiarity of this project lies in the production process of the boards since, in addition to being customizable, they have a very original transparent design. The company states that they produce the boards from recycled plastic waste which, through 3D technologies, offers the user a more optimal and resistant solution. An original way to combining eco-friendliness and innovation in the same project.

3D printed running shoes

3D-printed sports shoes are now no longer isolated cases. More and more sporting goods manufacturers, including Nike or Reebok, are using 3D printing technologies to produce their shoes. Adidas’ 4D Fusion, launched in January, is also among the 3D-printed shoes. The reason why the use of 3D printing is increasing in this field is simple: there is the possibility of personalization. 3D technologies can be used to scan the consumer’s foot, develop a 3D model and print it in record time. The result is a shoe that is customized to the consumer’s morphology, needs and style.

Tailored Fits, 3D Printed Ski Boots

When it comes to ski boots, often skiers are forced to choose between high-performance and comfort, boots that are too loose, while more comfortable, are unable to provide the same amount of control. Using state-of-the-art 3D printing technologies, Tailored Fits have developed ski boots that combine comfort and performance. Thanks to 3D scan measuring technology, Tailored Fits are able to 3D print an inner boot specific to the individual, ensuring an incredible direct power transmission. Moreover, the buckle-less design guarantees blood circulation meaning that not only is the user able to get a better feel of the slopes, but also no more cold toes!

Riddell SpeedFlex Precision Diamond Helmet

Safety is key when it comes to helmets, even more so when engaged in a high contact sport like American Football. For this reason, Riddell along with Carbon, a 3D printing technology company, partnered to create The Riddell SpeedFlex Precision Diamond Helmet, featuring the first-ever 3D printed football helmet liner. Currently ranked one of the NFL’s best-performing helmets, the helmet features a 3D printed lattice liner that can be digitally manufactured using Carbon’s proprietary Digital Light Synthesis™ (DLS™) technology. Part of the reason it is so effective is because it uses Riddell’s Precision-Fit head scanning and helmet fitting process to create a customized, 3D printed helmet liner precisely contoured to the athelete’s head. The project moved from the prototype stage to serial 3D production of the liners with the help of OECHSLER, one of the largest manufacturers in the additive industry, who have produced and delivered thousands of the parts to Riddell using their more than 150 Carbon L1 printers in three continents.

For this reason, Riddell along with Carbon, a 3D printing technology company, partnered to create The Riddell SpeedFlex Precision Diamond Helmet, featuring the first-ever 3D printed football helmet liner. Currently ranked one of the NFL’s best-performing helmets, the helmet features a 3D printed lattice liner that can be digitally manufactured using Carbon’s proprietary Digital Light Synthesis™ (DLS™) technology. Part of the reason it is so effective is because it uses Riddell’s Precision-Fit head scanning and helmet fitting process to create a customized, 3D printed helmet liner precisely contoured to the athelete’s head. The project moved from the prototype stage to serial 3D production of the liners with the help of OECHSLER, one of the largest manufacturers in the additive industry, who have produced and delivered thousands of the parts to Riddell using their more than 150 Carbon L1 printers in three continents.

A 3D printed mouthguard

Guardlab is an American company dedicated to the additive manufacturing of mouthguards for athletes in various fields (boxing, soccer, field hockey, etc). They have different varieties of models ranging from low contact, to training or high contact. They use a 3D scanner to obtain a three-dimensional model of the athlete’s jaw. This precise data helps in the development of the protector, always depending on the degree of protection needed to avoid the impact of blows. Once the 3D model is obtained, the person will be able to customize it to his or her liking. Protective gear like mouthguards are some of the most popular ways that 3D printing is now being used in the sports industry.

They have different varieties of models ranging from low contact, to training or high contact. They use a 3D scanner to obtain a three-dimensional model of the athlete’s jaw. This precise data helps in the development of the protector, always depending on the degree of protection needed to avoid the impact of blows. Once the 3D model is obtained, the person will be able to customize it to his or her liking. Protective gear like mouthguards are some of the most popular ways that 3D printing is now being used in the sports industry.

The NFL Approved 3D Printed Hockey Helmet

In another project from Carbon, CCM Hockey and Carbon worked together to revolutionize the design of hockey helmets, largely unchanged for the past 50 years. Using the Carbon Digital Light Synthesis™ (DLS™) technology and CCM Hockey’s Nest Tech, the companies created the first NHL certified 3D printed helmet, the Super Tacks X with NEST Tech. According to the companies, the digitally printed lattice-structured liner offers superior breathability, premium comfort and elite protection and is fully customized to fit an athlete’s head. The custom-fit helmet will be available to all NHL players ahead of the 2021 season, though in the 2020 NHL season three professional players, Austin Matthews and John Taveres from the Toronto Maple Leafs and Seth Jons from the Columbus Blue Jackets, played in the helmet. CCM will release a 3D-printed retail helmet for customers in Spring 2021.

According to the companies, the digitally printed lattice-structured liner offers superior breathability, premium comfort and elite protection and is fully customized to fit an athlete’s head. The custom-fit helmet will be available to all NHL players ahead of the 2021 season, though in the 2020 NHL season three professional players, Austin Matthews and John Taveres from the Toronto Maple Leafs and Seth Jons from the Columbus Blue Jackets, played in the helmet. CCM will release a 3D-printed retail helmet for customers in Spring 2021.

What do you think about the role of 3D printing in sports? Let us know in a comment below or on our Facebook and Twitter pages! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!

The 3D printed sports equipments are here!

3D Learning Hub

See all categories

Contents:

- Introduction

- The benefits of 3D printing for sports

- High-Performance 3D Printing Materials: What opportunities exist for sports?

- 3D printing for sports: The best sports equipments

Introduction

3D printing in sports is possible. We saw in a previous blogpost that 3D printing is a major asset for winter sports: it has even been used during the Olympics. Indeed, additive manufacturing is allowing mass customization, and it is actually a great asset for this industry. We are going to see in this blogpost how the additive manufacturing technology can revolutionize the sports field. Then, we are going to check what the best sports equipments made with 3D printing are.

We saw in a previous blogpost that 3D printing is a major asset for winter sports: it has even been used during the Olympics. Indeed, additive manufacturing is allowing mass customization, and it is actually a great asset for this industry. We are going to see in this blogpost how the additive manufacturing technology can revolutionize the sports field. Then, we are going to check what the best sports equipments made with 3D printing are.

The benefits of 3D printing for sports

Aerospace, medical, architecture, a lot of different industries are using 3D printing technology. Why couldn’t athletes also make the most of it?

Prototyping

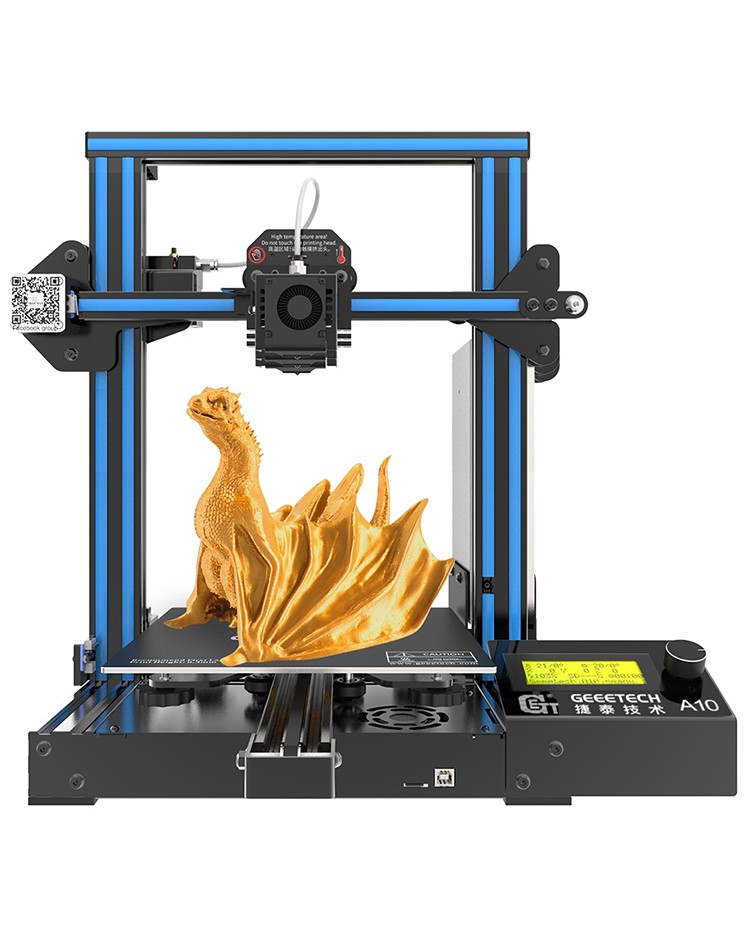

Additive manufacturing is an amazing method to 3D print for just any industry. Indeed, this technique allows making many iterations at lower costs. The process is quite simple: you just have to modify your 3D file with a 3D modeling software to print a brand new version of your future product! You will obviously save time using additive manufacturing for your prototyping process.

Production

You can also use 3D printing to produce your finished products. 3D printing technology allows manufacturing products with a really good quality. It is also possible to print really complex designs in just one part with this technology. Additive manufacturing can help you to optimize your product, as it is allowing to work on complex designs that are not feasible with traditional manufacturing processes.3D printing allowing mass customization

One of the most interesting advantages of 3D printing for sports is obviously mass customization. Indeed, 3D printing technology is perfect to create customized items, and it could totally benefits athletes, that obviously need the best equipment to focus on their performances and give the best of themselves. It is a good news for athletes with a handicap. Indeed, 3D printing is already well used in the medical industry to manufacture prostheses perfectly adapted to their morphology, to their handicap but also to their sport. It could allow them to forget the handicap and focus on what they are doing without being disadvantaged.

It could allow them to forget the handicap and focus on what they are doing without being disadvantaged.High-Performance 3D Printing Materials: What opportunities exist for sports?

With the development of advanced Additive Manufacturing materials, the sports industry can enjoy new opportunities for more functional equipment.

Ultrasint® TPU01 & Ultrasint® TPU 88A

Ultrasint® TPU 88A and Ultrasint® TPU01 are two thermoplastic polyurethanes presenting a high elasticity. The former is grey and was developed for MJF technologies, while the latter is white, and was designed for SLS technologies. As elastomers, TPU materials present very high fatigue resistance, energy return, and shock absorption capabilities, which make them ideal picks for all applications where flexibility is needed.

Their advantages for sports equipment

Lightweight and durability are two key standards for sports equipment manufacturing, and this is where materials such as Ultrasint® TPU 88A and Ultrasint® TPU01 find utility. Indeed, their flexibility and shock absorption properties meet the damping requirements needed for sports protection equipment and footwear. But other than these properties, sports goods manufactured with these materials can also enjoy the superior design potential of 3D printing. With lattice structure designs, high-performance sports equipment can be achieved with a much lighter weight than with other manufacturing technique. Along with weight, design for Additive Manufacturing allows to enhance the properties of these high-performance materials, hence to make the most of 3D printed helmets, shinguards, soles, shoes, and much more.

Indeed, their flexibility and shock absorption properties meet the damping requirements needed for sports protection equipment and footwear. But other than these properties, sports goods manufactured with these materials can also enjoy the superior design potential of 3D printing. With lattice structure designs, high-performance sports equipment can be achieved with a much lighter weight than with other manufacturing technique. Along with weight, design for Additive Manufacturing allows to enhance the properties of these high-performance materials, hence to make the most of 3D printed helmets, shinguards, soles, shoes, and much more.

3D printing for sports: The best sports equipments

3D printed running shoes

Additive manufacturing is a great asset for the footwear industry. Brands like New Balance, Adidas or Nike are already using this mass customization technique. For example, Adidas used Carbon resins to create 3D printed soles for running shoes. Smaller businesses such as Feetz are also making the most of this technology, offering to their clients soles adapted to their feet. For sport, it allows to make shoes adapted to the athletes morphology. Moreover, this process allows to avoid months-long processes, as the additive manufacturing technology is really a time saving manufacturing process. It is possible to get an adapted pair of shoes in no time!

Smaller businesses such as Feetz are also making the most of this technology, offering to their clients soles adapted to their feet. For sport, it allows to make shoes adapted to the athletes morphology. Moreover, this process allows to avoid months-long processes, as the additive manufacturing technology is really a time saving manufacturing process. It is possible to get an adapted pair of shoes in no time!

crédit: https://www.engadget.com/2015/11/19/new-balance-3d-printed-running-shoe/

3D printing for cycling

At Sculpteo we wanted to show our clients that it is possible to create a whole bike using 3D printing and laser cutting. And we made it. We developed a bike with 70% of parts created with digital manufacturing, using our online laser cutting and 3D printing service. But it is also possible to create bike equipment using additive manufacturing! For example, one of our clients at Sculpteo developed the Kupol project, a fully 3D printed bike helmet made with the HP Multi Jet Fusion PA 12 black plastic. Check out this video presentation:

Check out this video presentation:

Custom made golf clubs

Each golfer is unique, and Grismont Paris really understood that. That is why they decided to develop custom made clubs. These clubs are useful, adapted to the player and his playing technique, but they also have incredible designs. The founder is a golf passionate interested in additive manufacturing. He is now working with engineers, craftmen, club makers and artists to build impressive golf clubs, able to fit any golfer’s specifications with style.

credit: 3Dnatives

The 3D printed glove for wheel racing

Arielle Rausin developed her own 3D printed gloves for wheelchair racing. This equipment is so useful and durable that other 3D printed gloves will certainly be printed for the whole team. The 3D printing technology really allowed her to design gloves that were perfectly fitting her hands, to feel at ease and become even more efficient during the races.

The 3D printing technology really allowed her to design gloves that were perfectly fitting her hands, to feel at ease and become even more efficient during the races.

credit: http://publish.illinois.edu/digitalmaking/tag/3d-printing/

Cycling with a 3D printed leg

Denise Schindler lost one of her legs in an accident. Thanks to a 3D printed prosthesis she is able to compete in the Olympics. What are the advantages of this prosthesis for Denise Schindler? Actually, the prosthesis has been cheaper to develop than a traditional prosthesis, and it has been manufactured in no time. Last but not least: this leg is perfectly adapted to the rider, and to the bike!

credit: https://uk.reuters.com/article/uk-olympics-rio-germany-paralympics-idUKKCN0XV2AQ

3D printed protection mask

Custom made protections are essential for athletes. This 3D printed equipment is particularly dedicated to footballers suffering from recent facial injuries.

This mask is looking like a Zorro mask, but it allows them to play while recovering from a bone fracture, a broken nose, etc. How is it made? Simply with a 3D scan of the player’s face, made using Cavendish Imaging. It is allowing to get a custom made mask for the player to protect its injuries.

crédit: http://www.dailymail.co.uk/

3D printed mouthguards

Athletes have to wear mouthguards for the practice of some sports. These have to become even more accessible. Indeed, the Center for Disease Control and Prevention (CDC) reported that each year, 600 000 emergency visits are due to dental injuries. 26% are sports-related. The science-based company Royal DMS based in Netherlands made a partnership with 3Dmouthguards . Their will is to create 3D printed, sustainable protection gears for athletes, combining comfort and safety. A flexible thermoplastic is used to create these mouthguards. Thanks to accurate 3D scanning methods its is now possible to make adapted mouthguards. For example, companies like Damage Control developed their own scanning process (the 3 Shape Lab Scanning) and are able to get a digital version of your teeth, to create mouthguards and 3D print them. Check out this video to see how they manufacture instantly 3D printed mouthguards:

For example, companies like Damage Control developed their own scanning process (the 3 Shape Lab Scanning) and are able to get a digital version of your teeth, to create mouthguards and 3D print them. Check out this video to see how they manufacture instantly 3D printed mouthguards:

It is now possible to use 3D printing to get customized products and the sports sector is really making the most of this technology. Indeed, the future of 3D printing seems really promising in this field. As you can see, 3D printing has many advantages for different industries and sports is one of them! What do you think about using 3D printing for sports? Let us know! Are you a sports manufacturer? Start using 3D printing now! Upload your file right here, or contact our sales team to see how our 3D printing service could help you with your project If you want to get the latest news about all the possible 3D printing applications, be sure to subscribe to our weekly newsletter!

Related Topics

- Return to Top

Get the latest 3D printing news delivered right to your inbox

Subscribe to our weekly newsletter to hear about the latest 3D printing technologies, applications, materials, and software.

Creative 3D: 3D printer that produces sports protection

Sports can not only improve the quality of our lives, but also play an important role in improving the quality of our lives. However, some active sports can also harm our body and mind. Therefore, we must continue to research some equipment to improve our safety. By 2025, the market value of sports safety equipment will exceed US$90 billion, and 3D printers will become a major investment for many manufacturers. So how do we use 3D printers to manufacture and protect our equipment? Let's take a look!

Why do we use 3D printers to make protective equipment? First of all, 3D printers have reached a whole new level of customization, we can forget about the standard sizes S, M, L. Through 3D printing technology, we can provide athletes with high-precision personalized protectors that can be used to perfectly fit different parts of the body, providing them more protection and comfort than ever.Another reason is that 3D printers are produced very quickly. Considering that athletes must change their protective equipment regularly and personal protective equipment is relatively complex. With a 3D printer, you only need to upload a 3D scan of, for example, a player's chin, adjust the 3D model if necessary (for example, due to an injury) and immediately 3D print a new mouthguard. 3D printers can lower production costs for you. Especially small-scale production, such as parts with individual requirements, is much cheaper. This process does not include mold making, such as injection molding, so you only need a fast and very accurate 3D scan, and the 3D model can be easily customized to suit the user's needs. This does not require additional tools, it not only reduces the time spent on the design process, but also reduces costs. Now that you know the benefits of using 3D printers to make sports protective gear, let's talk about real life examples of using 3D printers to make sports protective equipment.

1. The 3D printer produces baseball bats and shoes. American baseball player Cory Kluber is the first pitcher to 3D print baseball bats and his shoes have also been 3D printed for him. The researchers studied Klaber's biomechanical movements and his use of different areas of the foot while playing to provide better protection for the foot and produce efficient 3D printing data. The 3D printed shoe has an additional blocking plate to prevent the athlete's foot from twisting, while the left shoe implements a curved wall to keep the toes stable while the midfoot and heel rotate to protect Krupp from slipping.

2. 3D printed chest protector. Hockey players often get seriously injured. To help them stay safe, researchers at the University of Zagreb in Croatia have developed 3D printed breast protectors for men and women. They use a variety of 3D technologies to improve their work, from 3D scanning to 3D modeling and 3D printing. First, the player performs a 3D scan in different locations, and based on the collected data, a 3D simulation of the chest protector is performed.This is very important because the researchers took into account the differences in the bodies of women and men, as well as the different habits of each player.

Tri, 3D shin guard production printer Jakob Schmid, inventor of the Zweikampf Shin Guards, is a football fan but was unable to play due to chronic periostitis. Looking for a solution to continue enjoying football, he created a team of experts and opened the shin guard manufacturer Zweikampf-3D. In his innovative product, 200 3D scans of a human lower leg were taken and then 3 individual layers were developed. The custom layer uses a 3D printed shell made using SLS technology. Because the 3D printer makes the body very strong, it also has a high performance structure and light weight, so it can be well protected.

4. Making football helmets on a 3D printer.

CLIP technology is a revolutionary 3D printing technology that uses liquid resin to make parts and hardens them layer by layer with light. Riddle, a leader in the football equipment industry, sees the potential of using CLIP for sports protective equipment. They partnered with Carbon to develop the next generation of football helmets.

Riddle, a leader in the football equipment industry, sees the potential of using CLIP for sports protective equipment. They partnered with Carbon to develop the next generation of football helmets.

The most important aspect of using 3D printing is how they can make helmets with a lattice structure that absorbs shock and provides the best head protection. 3D printing production also provides the opportunity to use 3D scanning and 3D modeling for the production and measurement of protective equipment.

Five Teeth Protection 3D Printer From basketball to swimming, athletes in a wide variety of fields suffer jaw injuries. To protect them and allow them to use better aligners, GuardLab uses 3D scanning to give their customers the best fit, then 3D models them, and finally uses a 3D printer to make the final denture guard. Thanks to 3D technology, their products fit perfectly with consumers, allowing their mouthguards to be completely personalized.

As you can see, 3D printing technology has greatly improved sports protective equipment.It is thanks to the strong lattice structure and 3D scanning that manufacturers can produce customized protective devices that fully meet the needs of users and provide them with maximum protection against damage. 3D printing technology has completely changed the protection of the head, legs and other parts of athletes needed to prevent injury. Source: Creative 3D https://www.cxsw3d.com/

3D printing helps Paralympians improve athletic performance / +1

Society

Technology makes assistive devices more accessible

Photo: iStock Athletes with various disabilities participate in the Paralympic Games. Many of them use assistive devices: prostheses, wheelchairs, special gloves. 3D printing technology is increasingly being used to manufacture these devices. University of Queensland and University of Technology Sydney researchers James Novak and Andrew Novak note that this is an affordable way to improve athletic performance and keep athletes safe. Scientists warn that some competitors have access to more advanced tools, and this gives them a certain advantage.

Scientists warn that some competitors have access to more advanced tools, and this gives them a certain advantage.

Back at the Paralympic Games in Rio de Janeiro in 2016, German cyclist Denise Schindler performed with a 3D-printed prosthetic leg. She lost the lower part of her right leg as a child in a car accident and started playing sports at 18. The custom-made prosthesis was made by the American company Autodesk, which develops solutions for 3D design, design, graphics and animation. The cyclist and her team interacted with the company using the Fusion 360 cloud product modeling software. The developers came up with over 50 prosthetic designs before it was printed.

The product is made of polycarbonate (polymer plastic. — Approx. Plus-one.ru) and weighs less than 1 kg, while its carbon fiber counterpart is 1.5 kg. The production of a prosthesis can take from five days to ten weeks, the cost is from £ 3.5 thousand to 12 thousand. This year at her third Paralympic Games in Tokyo, 35-year-old Denise Schindler, who is called Killerbiene (from German - “bee killer"), won a bronze medal in the 3,000 m individual pursuit in classes C1-3.

New Zealand athlete Anna Grimaldi wears a 3D printed prosthesis. A girl who was born without an arm won first place in the long jump competition at the Paralympics in Tokyo. The prosthesis was made for her by Zenith Tecnica, a company based in Auckland, which specializes in titanium 3D printing and manufactures products for the medical, aerospace and other industries. The company said that the production process of the prosthesis, including the processing of digital models and printing itself, took only a few hours. Anna Grimaldi received the product thanks to High Performance Sport NZ. It is funded by the New Zealand government and works with national sports organizations to improve the performance of competitors.

From sports to manufacturing

James Novak and Andrew Novak also talk about athletes who have started making their own assistive devices. One of them is American track and field athlete, wheelchair racer Ariel Rauzin. In 2003, at the age of 10, she was paralyzed as a result of a spinal cord injury sustained in a car accident. In 2012, Ariel started wheelchair racing, and in 2016 she founded Ingenium Manufacturing, a company that 3D printed gloves for wheelchair athletes. The girl came up with an idea for a business as part of one of the tasks while studying at the University of Illinois at Urbana-Champaign. The company's website emphasizes that the gloves made of plastic are comfortable to use and strong enough to withstand serious force. The company produces gloves not only for professional athletes, but also for beginners. They cost $150, but buyers under the age of 18 can get a discount: Ariel Rauzin is sure that the high cost of equipment can be an obstacle to starting a sports career. In 2019In 2018, the track and field athlete reported that over 4,000 pairs of gloves had been sold to athletes from 31 countries in three years.

In 2012, Ariel started wheelchair racing, and in 2016 she founded Ingenium Manufacturing, a company that 3D printed gloves for wheelchair athletes. The girl came up with an idea for a business as part of one of the tasks while studying at the University of Illinois at Urbana-Champaign. The company's website emphasizes that the gloves made of plastic are comfortable to use and strong enough to withstand serious force. The company produces gloves not only for professional athletes, but also for beginners. They cost $150, but buyers under the age of 18 can get a discount: Ariel Rauzin is sure that the high cost of equipment can be an obstacle to starting a sports career. In 2019In 2018, the track and field athlete reported that over 4,000 pairs of gloves had been sold to athletes from 31 countries in three years.

Another athlete who decided to launch his own production of various auxiliary products is the British paratriathlete, participant in the Paralympic Games, World Championships, and Ironman races (long-distance triathlon competitions. — Approx. Plus-one.ru) Joe Townsend. The man served in the British Royal Marines and lost both legs in 2008 in an explosion in Afghanistan. He started triathlon in 2011. At some point, Townsend discovered that there was practically no equipment on the market with optimal performance for athletes at an affordable price. One of the products that Joe Townsend decided to focus on was a bicycle crank that transmits power from the pedals to the wheels. Parts are made from composite compounds, such as MarkForged's Onyx material, which consists of nylon and chopped carbon fiber. They are printed on a Markforged Mark Two printer and reinforced with continuous fibers. Products are lightweight, durable and impact resistant. Their design can be adapted to the individual needs of each athlete - both amateur and professional.

— Approx. Plus-one.ru) Joe Townsend. The man served in the British Royal Marines and lost both legs in 2008 in an explosion in Afghanistan. He started triathlon in 2011. At some point, Townsend discovered that there was practically no equipment on the market with optimal performance for athletes at an affordable price. One of the products that Joe Townsend decided to focus on was a bicycle crank that transmits power from the pedals to the wheels. Parts are made from composite compounds, such as MarkForged's Onyx material, which consists of nylon and chopped carbon fiber. They are printed on a Markforged Mark Two printer and reinforced with continuous fibers. Products are lightweight, durable and impact resistant. Their design can be adapted to the individual needs of each athlete - both amateur and professional.

Joe Townsend 3D prints other items, such as gloves and special handles (one of the parts of hand-operated bicycles. - Approx. Plus-one.ru). Gloves come in different stiffness: for example, a tough athlete uses during competitions to improve results, and more comfortable soft ones during training. Handles are made to order. The buyer receives plastic granules, which can be turned into a prototype of the desired shape with the help of hot water. The hardened part is sent to the manufacturer, who will print the desired component.

Handles are made to order. The buyer receives plastic granules, which can be turned into a prototype of the desired shape with the help of hot water. The hardened part is sent to the manufacturer, who will print the desired component.

Photo: Instagram / @ingenium_manufacturing

3D scanning and technology ethics

3D scanning is also used to manufacture assistive devices for paraathletes. It allows you to create three-dimensional models of various parts of the athlete's body and make equipment that is exactly the right size and shape. Back in 2016, the design studio of the German car, motorcycle and engine manufacturer BMW Designworks used 3D scanning technology to produce gloves for wheelchair athletes. The studio made 3D models of the athletes' accessories and then printed them on a 3D printer. This made the gloves lighter and more accurate.

3D-scanned Australian basketball and tennis player Dylan Olcott's wheelchair has also been created. It is made of carbon fiber and follows the body shape of a parasportsman. The seat, like other parts of the stroller, including the aluminum frame, was developed at the Australian Institute of Sport (Australian Institute of Sport, an educational and scientific institution. — Approx. Plus-one.ru). Compared to analogues, the stroller weighs less, has great maneuverability and is easy to repair.

It is made of carbon fiber and follows the body shape of a parasportsman. The seat, like other parts of the stroller, including the aluminum frame, was developed at the Australian Institute of Sport (Australian Institute of Sport, an educational and scientific institution. — Approx. Plus-one.ru). Compared to analogues, the stroller weighs less, has great maneuverability and is easy to repair.

James Novak and Andrew Novak note that these technologies are becoming more accessible. Already now, everyone can buy surf fins, various bicycle accessories, including bottle cages, bicycle chain guides, coasters, as well as sneakers with printed soles. Adidas has teamed up with American industrial 3D printing startup Carbon to develop an athletic shoe called the Futurecraft 4D.

Researchers warn that some athletes still have more resources and opportunities, which means they are much more likely to perform well during competition. By the way, the International Paralympic Committee emphasizes that all athletes should have access to equipment that primarily ensures their safety and protects their health.