3D printed specialized saddle

Saddle Mirror | Specialized.com

THE PERFECT REFLECTION OF YOU

Mirror Technology

It’s our obsession to improve the ride through our Body Geometry method that breeds innovation. That obsession led to Mirror technology—a 3D printed matrix with a density that can be infinitely tuned in a way impossible with foam. Mirror saddles deliver the greatest combination of performance and pain relief of any saddle we’ve ever created, all validated by science.

Shop Now

THE PERFECT REFLECTION OF YOU

Mirror Technology

It’s our obsession to improve the ride through our Body Geometry method that breeds innovation. That obsession led to Mirror technology—a 3D printed matrix with a density that can be infinitely tuned in a way impossible with foam. Mirror saddles deliver the greatest combination of performance and pain relief of any saddle we’ve ever created, all validated by science.

Shop Now

UNPRECEDENTED SIT BONE SUPPORT

Mirror Variable-Density Matrix

SOFT TISSUE RELIEF

Supportive Cut-Out

S-WORKS

Carbon Rails and Base

PRO

Ti Rails and rCF Base

How Mirror Works

Unlike traditional single-density foam, Mirror technology allows for infinite density tuning with a single material. Using Body Geometry methodology and Retül data, the 3D printed matrix is tuned to support the sit bones across a greater area, creating a hammock effect that lets the saddle support your weight, not the tissue around your sit bones.

These high-resolution pressure maps show the same rider in the same conditions on traditional foam saddles versus saddles with our Mirror technology. Mirror creates an extended surface of support that significantly reduces the overall pressure and relieves pain, validated by science.

These high-resolution pressure maps show the same rider in the same conditions on traditional foam saddles versus saddles with our Mirror technology. Mirror creates an extended surface of support that significantly reduces the overall pressure and relieves pain, validated by science.

These high-resolution pressure maps show the same rider in the same conditions on traditional foam saddles versus saddles with our Mirror technology. Mirror creates an extended surface of support that significantly reduces the overall pressure and relieves pain, validated by science.

These high-resolution pressure maps show the same rider in the same conditions on traditional foam saddles versus saddles with our Mirror technology. Mirror creates an extended surface of support that significantly reduces the overall pressure and relieves pain, validated by science.

Our Best Reviewed Saddle Ever

“The most comfortable high-end saddle I've ridden! I have not felt that comfortable after a long ride since being 26 years old. ”

”

- Trace

“The Mirror is beyond my expectations. Checks all of the boxes. Treat yourself to the top-of-the-line saddle.”

- Mike

“This is the best saddle ever made. Probably one of the most impactful purchases I have made in years.”

- EMD

“Without question the BEST saddle on the Market.”

- 6453Nsider

MADE IN RACING

Working With World Class Athletes

We work hand in hand with the world’s best riders on Body Geometry product innovation to help them excel at the toughest races in cycling. Mirror technology is a direct result of countless hours of athlete input, feedback, and testing in the lab and on the road.

IDENTIFY A PROBLEM, SOLVE IT WITH DESIGN, VALIDATE IT WITH SCIENCE

Body Geometry

It all started in 1997 when we solved erectile dysfunction issues facing male cyclists with the Body Geometry saddle—the first ergonomically designed, scientifically tested saddle in history. Since then, we’ve been obsessed with ensuring the contact points where female, male, and non-binary riders become one with their bikes never hurt.

Learn More

TOWARDS SUSTAINABILITY

RCF - Reclaimed Carbon Fiber

The Power Pro with Mirror's carbon base is built with our all-new reclaimed carbon process. Using carbon scraps from factory production combined with injected nylon, we're building a more sustainable carbon base. This is our first step on the road to closed-loop production.

Learn More

HELPING RIDERS MAKE DECISIONS USING DATA

Retül

Cutting-edge Retül technology at Specialized retailers helps personalize Body Geometry gear to ensure you’re riding with more power and less pain, so you can truly be one with your bike. Learn how to choose your perfect saddle with Retül’s Digital Sit Bone Device.

Learn More

Review: new 3D-printed Specialized Power Pro with Mirror saddle is more affordable & partially recycled

Home > Bike Types > Gravel Bikes > Review: new 3D-printed Specialized Power Pro with Mirror saddle is more affordable & partially recycled

Jordan Villella

Support us! Bikerumor may earn a small commission from affiliate links in this article. Learn More

Learn More

The new Power Pro with Mirror is nearly the same as the S-Works but swaps out carbon rails for titanium ones, adding a few grams but keeping all the comfort. The Specialized Power Mirror saddle is now available with hollow titanium rails and is $125.00 cheaper than its S-Works brethren.

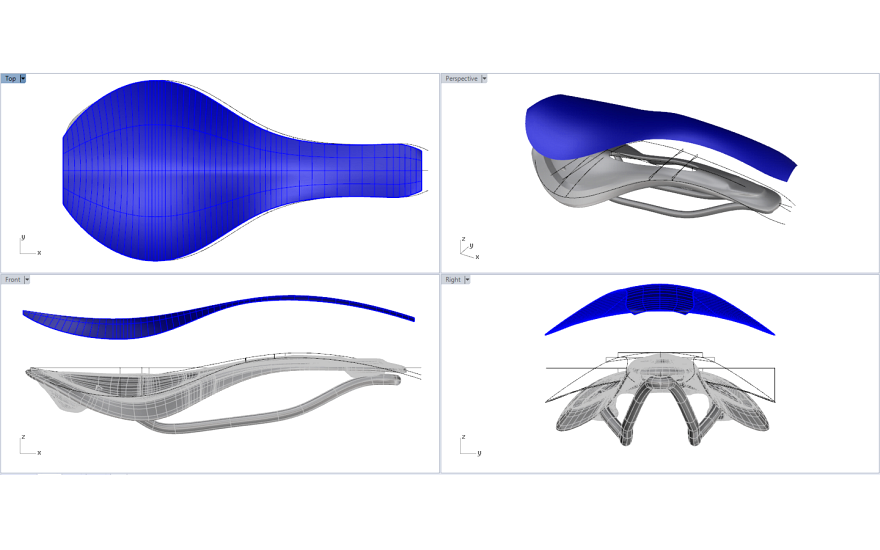

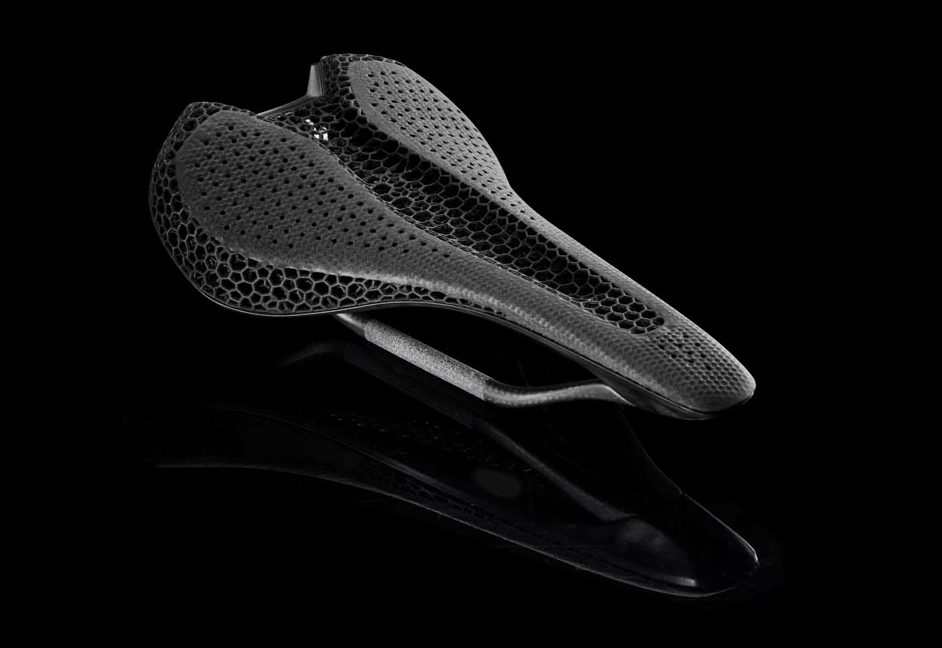

For those unfamiliar with the Specialized Mirror saddles — let me catch you up. The base of the saddle is the sturdy and well-respected Specialized Power shell and uses the same overall shape. The top pad is 3D printed using a liquid polymer to create an infinitely tunable honeycomb structure; it conforms to and supports all the bits while you sit. Hows does it work? A patent-pending matrix of 14,000 struts and 7,799 nodes can be tuned individually to deliver unprecedented sit bone comfort — very plush.

Specialized Reclaimed Carbon

For all intents and purposes — the Specialized Power Pro with Mirror is the S-Works version with rails that can take more abuse and a carbon shell that utilizes a new sustainable 15% reclaimed carbon fiber.

The saddle’s carbon base is built with an all-new reclaimed carbon process. The method uses carbon scraps from factory production, combined with injected nylon, building a more sustainable carbon base. This process is the first step on the road to closed-loop production for Specialized — creating less waste while maintaining product integrity. We’re optimistic that Specialized will eventually use this new process and shell for most of its saddles.

Hollow titanium rails?

Like most all of the Pro models in the Specialized saddle ecosystem, the new Power Pro with Mirror arrives with Titanium rails. The round titanium rails offer more options for seat post compatibility and added resilience to damage. The swap adds roughly 61g to the overall weight of the saddle, coming in at 235g for our 144mm version. *The S-Works model weighs in at 192g in the same width.

Specialized Power Pro with Mirror Key Features

- Patented Body Geometry design is lab-tested to ensure blood flow to sensitive arteries.

- Mirror technology utilizes 3D printing from liquid polymer to create a one-of-a-kind honeycomb structure that offers superior sit-bone support and comfort.

- Reclaimed carbon fiber and nylon-injected base with 15% reclaimed carbon fiber.

- Hollow Titanium rails fit many different seatpost and droppers

- SWAT-compatible mounts molded into the saddle base allow for a sleek and integrated storage solution

- Sizes: 143mm, 155mm

- Weight: 253g (143mm width)

- Available: Now

- Price: $325

Ride impressions — Specialized Power Pro with Mirror saddle

This review was my first time riding any Specialized Power saddle with Mirror. I’ve ridden other 3D printed saddles, but this was the first for a saddle that I ride daily — the S-Works Power is my preferred saddle.

As for fit, I set the new saddle up with the exact fit measurements as the S-Works Power it replaced on my cross country bike, same tilt, and same height. The padding on the nose and the pad, in general, is much more responsive than the S-Works Power with traditional foam.

The padding on the nose and the pad, in general, is much more responsive than the S-Works Power with traditional foam.

The most notable difference is the response and suppleness of the pad. Think of the traditional Power as a traditional casing clincher and the Power Pro with Mirror as a super supple tubular. My changes to the saddle placement were minor. I adjusted the tilt-up slightly (I usually ride the Power at a – 3°), the padding is very responsive, and I felt like I was sinking in a bit more than usual.

Another thing that took some getting used to was the feel of the liquid polymer outer used for the 3D honeycomb printing process. The traditional Power saddle has a smooth surface, one that’s easy to adjust your posterior on and migrate to other sections of the saddle. The Power Pro with Mirror has a tacky feel, not sticky but more like a “locked and loaded” feel. Depending on your choice of shorts, sensations could be a bit different. It took some time but I ultimately adjusted to the new sensation and now prefer it to my traditional Power saddle.

The new Power Pro with Mirror made its way from bike to bike, gravel to the road, and back again for review. The impressions were the same with different bike disciplines; the is a very comfortable saddle, and the titanium rails keep it simple, so you don’t have to swap out the seatpost ears or the post altogether.

I enjoy plenty about this saddle, but there are some shortcomings. The mega-complex structure of the 3D-printed honeycomb can act as a mud trap and clog up on wet rides. The 3D printing could create a slight problem for anyone that frequently rolls around in the mud or gross wet gravel. I’m confident that Specialized didn’t intend this to be their new cyclocross saddle, but the sky can open at different points, and a dry XC course can become peanut butter, just like the US Pro Cup Fayetteville last weekend. The mud (and pebbles) will eventually disappear, but it can take some thoughtful washing and more high-pressure spraying than is customary.

Final thoughts

After spending lots of time on the Power Pro with Mirror, I can undoubtedly say it’s one of the most comfortable saddles I’ve ridden.![]() The fit and comfort are hard to match; the price tag is still more than most saddles on the market, but can you put a price on comfort? Having ridden this saddle on all manner of disciplines and intensities, I can say it’s now my go-to saddle. I’ll go back to the traditional Power for ‘cross season, but until then, the Power Pro with Mirror is the perch for me.

The fit and comfort are hard to match; the price tag is still more than most saddles on the market, but can you put a price on comfort? Having ridden this saddle on all manner of disciplines and intensities, I can say it’s now my go-to saddle. I’ll go back to the traditional Power for ‘cross season, but until then, the Power Pro with Mirror is the perch for me.

If you’re looking for a new saddle and like the feel on a short nose or are a current Power saddle user, I recommend trying the Specialized Power Pro with Mirror. It might mean a longer ride or less posterior pain in the long run.

For more information check out: Specialized.com

Jordan Villella is a staff writer for BikeRumor.com, specializing in cross country mountain, gravel, road, and race tech. He has been writing about the bicycles and bike culture for over ten years with no signs of stopping.

Prior to BikeRumor, Jordan raced at the professional level and wrote for MTBR and now-defunct Dirt Rag Magazine. He’s covered races, including World Championships and World Cups — where he loves to report what the pros are riding.

He’s covered races, including World Championships and World Cups — where he loves to report what the pros are riding.

Based in Pittsburgh, PA — Jordan spends his time coaching cyclists of all abilities with Cycle-Smart, racing bikes around North America, and adventuring with his family.

3D printed bicycle saddles

14.00

Normal

0

false

false

false

false

RU

X-NONE

X-NONE

using Carbon Digital Light Synthesis (DLS) technology.

14.00

Normal

0

FALSE

FALSE

FALSE

RU

X-None

X-None

In the photo Specialized saddle Power-Carbon S-Works

Recall that at the end Silicon Valley announced that it has teamed up with an American bicycle manufacturer specializing in creating a 3D printed bicycle saddle that provides superior comfort and protection. The saddle, called the S-Works Power Saddle, is made using "Mirror Technology," which is a combination of Carbon 3D printing, materials, and a complex lattice structure designed to absorb shock and improve stability. nine0005

The saddle, called the S-Works Power Saddle, is made using "Mirror Technology," which is a combination of Carbon 3D printing, materials, and a complex lattice structure designed to absorb shock and improve stability. nine0005

About a week later, Carbon announced a second partnership with the Italian cycling company fizik and introduced a jointly developed range of adaptive saddles. This bike saddle is also made with Carbon DLS technology and EPU 41 material and is designed to offer riders superior power transfer and cushioning. The adaptive saddle is said to overcome many of the issues associated with using foam saddles and will eventually be offered as a custom product. nine0005

Both bike saddles - although different in style and shape - are based on the idea that a 3D-printed, flexible, custom-structured mesh can outperform existing foam materials.

Grille 3D printed with Carbon and fizik

Comfort is key

As with shoes and helmets, cycling comfort is important, but most cyclists will tell you there's a lot of room for improvement. Most saddles have yet to find the perfect balance between comfort, performance and stability. To make matters worse, a bad saddle can have very real consequences, such as nerve pain, numbness, and urinary problems. nine0005

Most saddles have yet to find the perfect balance between comfort, performance and stability. To make matters worse, a bad saddle can have very real consequences, such as nerve pain, numbness, and urinary problems. nine0005

In the case of Specialized's S-Works Power Saddle, the combination of 3D printing, intelligent design and pressure mapping helped improve the saddle in every direction. 3D printed grating based on pressure mapping data provides fast rebound. The grille has also been designed for breathability, to improve comfort and reduce weight (only 189 grams).

Looking at the adaptive fizik saddle, we use many of the same tactics: 3D printing, grille geometry and pressure mapping data combine to create a streamlined saddle with zoned cushioning designed to transmit and support power. In addition, fizik plans to collect pressure mapping data from selected customers to eventually produce custom 3D printed saddles in the near future. nine0005

What do cyclists think?

In many cases, cyclists reported a more comfortable ride in which they even forgot about the seat. In one review of the S-Works Power saddle, cyclist Dave Everett noted that the softness of the saddle was a pleasant surprise compared to regular saddles.

In one review of the S-Works Power saddle, cyclist Dave Everett noted that the softness of the saddle was a pleasant surprise compared to regular saddles.

The main stumbling block at this stage is the cost. With a price well above most standard bike saddles (around $500), one wonders if the saddle's higher cost is worth the increase in performance and comfort. For recreational cyclists, the answer may be no, but for elite cyclists, the opposite may well be true. nine0005

A recent review of Philipp Schwabb's printed fizik Adaptive 3D saddle said that the saddle's comfort was immediately noticeable and that it provided "excellent internal damping" even on long rides. The main criticism of the 3D printed fizik saddle was that it collected water and mud in bad weather due to the lattice structure and was harder to clean than a traditional saddle.

Fizik series adaptive seat

Professional athletes, even those who compete in the Olympics, have already advertised 3D handlebars and other bicycle components for their light weight and customizability. 3D printed saddles could be the next step for professional or elite cycling, where even the slightest competitive advantage is critical.

3D printed saddles could be the next step for professional or elite cycling, where even the slightest competitive advantage is critical.

When the first printed bicycle saddles hit the market, it will be interesting to see how widely they will be used. The fizik Antares Versus Evo 00 adaptive saddle is already available for order starting from € 390. Specialized's 3D printed saddle is currently being tested by several partner bike companies and is expected to be available later this year.

Author Tess Boissono

Retrieved

Attention!

We accept news, articles or press releases

with links and images. [email protected]

3D-printed ear transplanted to patient for the first time / Sudo Null IT News0001

Specialists from the American biotechnology company 3DBio Therapeutics for the first time were able to transplant an organ printed on a 3D printer into a human. For a 20-year-old patient with a deformity of the right ear, a special ear implant was made from her own cells.

According to independent medical experts who evaluated the technology's first clinical trial, this transplant was a breakthrough in tissue engineering. nine0005

A patient from Mexico was born with microtia, a rare birth defect that deforms the pinna or outer part of the ear.

The 3D printing manufacturing process typically involves a computer-controlled printer applying material in thin layers to create the precise shape of an object. The new ear implant from 3DBio Therapeutics combines several patented technologies, starting with a method to turn a small sample of a patient's cells into billions of cells. The company's 3D printer uses collagen-based "bio-ink", which is safe for the body and ensures the sterility of all materials. nine0005

A surgeon removed 0.5 g of cartilage from a woman's deformed ear. Chondrocytes, the cells responsible for cartilage formation, were then isolated from a tissue sample and grown in a proprietary suspension of nutrients. Live cells were mixed with bioink. Collagen was injected through a syringe into a specialized 3D bioprinter, which extruded the material from the nozzle in an even, thin stream, moving in a circle, creating a small oblong shape that was a mirror image of the patient's healthy ear. The entire printing process took less than 10 minutes. nine0005 3DBio Therapeutics Ear Implant Sample / The New York Times

Live cells were mixed with bioink. Collagen was injected through a syringe into a specialized 3D bioprinter, which extruded the material from the nozzle in an even, thin stream, moving in a circle, creating a small oblong shape that was a mirror image of the patient's healthy ear. The entire printing process took less than 10 minutes. nine0005 3DBio Therapeutics Ear Implant Sample / The New York Times

The printed ear shape was then placed in a protective biodegradable shell and placed in the refrigerator overnight. The next day, it was implanted under the patient's skin just above the jawbone. As the skin tightened around the implant, the shape of the ear appeared.

3DBio Therapeutics notes that their implant is more cosmetic. According to them, after transplantation, the ear will independently regenerate cartilage tissue, acquiring the appearance of a natural organ. nine0005

The company's specialists estimate the probability of implant rejection as low, since the cells for printing the organ were taken from the patient's own tissues.