3D printer printing houses

3D Printed Houses: Top Projects from Around the World

3D printing news News 3D Printed Houses: A Closer Look at Completed Projects from Around the World

Published on July 29, 2022 by Carlota V.

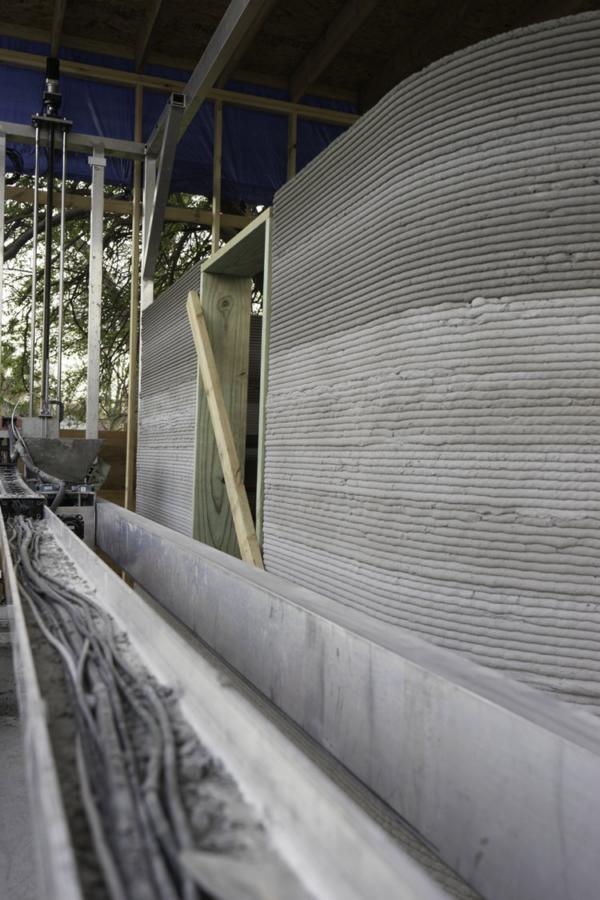

As you may know, additive manufacturing is becoming increasingly important in the construction market. The new technologies make it possible to create more complex shapes, build walls faster, and reduce labor costs. Many construction companies have already started to 3D print buildings or houses. Be careful, however, with the term 3D printed house: In most cases, only the walls are made by a 3D concrete printer, that prints them layer by layer. That in itself is already quite an innovation that has made it possible to build homes in hard-to-reach, disadvantaged, or conflicted areas. These days, we are starting to see more and more 3D-printed houses being inaugurated and the first families are starting to move in. Yet, at this point, it is still difficult to assess the sustainability of such a structure, and only time will show if this manufacturing method is more viable altogether. However, we can already share with you some 3D printed house-projects that have been completed around the world.

A 3D Printed House in Japan

In less than 24 hours and for less than $25,500, the company Serendix designed this small house with 3D printed walls. Even if it’s hard to imagine that anyone could live in it, the project is still interesting and shows all the agility of 3D concrete printing. With a surface area of only 10 square meters, the structure has a honeycomb shape and no reinforcements. Serendix’s objective is to create emergency housing in times of crisis, as earthquakes and typhoons regularly hit the country. It took three hours to assemble the different 3D printed parts and a total of 23 hours and 12 minutes to get the final result.

Alquist 3D and the Virginia Project

U.S.-based Alquist 3D recently announced the launch of one of its new projects for 3D printing homes. Located in the state of Virginia, the 200 homes that make up the project will be created through additive manufacturing with the aim of reducing the overall cost of infrastructure in communities with economic problems. According to the company, which specializes in 3D printing houses with concrete, this initiative is intended to be one of the largest housing construction projects, with Pulaski and Roanoke being the first cities to be chosen for it, due to the growth in demand for housing that these areas have experienced in recent years. After completing the project for Habitat for Humanity, this new idea now aims to help the company expand further into the 3D construction market.

According to the company, which specializes in 3D printing houses with concrete, this initiative is intended to be one of the largest housing construction projects, with Pulaski and Roanoke being the first cities to be chosen for it, due to the growth in demand for housing that these areas have experienced in recent years. After completing the project for Habitat for Humanity, this new idea now aims to help the company expand further into the 3D construction market.

The Fibonacci House, the First 3D Printed House on Airbnb

The next house on our list is interesting not just for its design but because it holds the distinction of being the first fully 3D printed house to be listed on Airbnb. Twente Additive Manufacturing (TAM), one of the leading companies in concrete 3D printing, created this home in a spiral shape following the Fibonacci sequence, a famous mathematic sequence also known as the golden ratio that often occurs naturally, giving the home its name. The spiral allows for the progression of space from the wide-open exterior to the closed and warmer space in the tightest part of the spiral. The tiny home is available for rent for a minimum of two nights in Proctor, British Columbia, Canada on Airbnb for about $128 a night..

The tiny home is available for rent for a minimum of two nights in Proctor, British Columbia, Canada on Airbnb for about $128 a night..

Mvule Gardens is Africa’s Largest 3D Printed Housing Project

Continuing the trend of 3D printed houses being used for affordable housing, Mvule Gardens is a neighborhood consisting of 52 houses, it is Africa’s largest 3D printed affordable housing project. Built by 14Trees, a joint venture between Holcim, a global leader in sustainable construction solutions, and CDC Group, the UK Government’s impact investor, the project hopes to address the housing shortage in Kenya. The homes were built using the BOD2 printer from COBOD and a 3D printable dry mortar called TectorPrint from Holcim, ensuring that the houses are adequately strong and can be made with a reduced carbon footprint. Both two-bedroom and three-bedroom homes are available and 14Trees notes that they hope they will help to make green, low-income and affordable housing a reality for Africa.

Azure 3D Printed Homes for Sustainable Construction

With the goal to develop homes faster, more economically, and with less environmental impact, Ross Maguire and Gene Eidelman brought Azure 3D Printed Homes to life in 2019. By combining years of experience in building and developing properties all over the world, the company has already been able to 3D print several environmentally friendly houses. The company uses recycled waste materials to create the structure of the houses, which are then produced with a large-scale 3D printer in only 24 hours. Azure 3D Printed Homes offers a variety of backyard offices and homes, one example is its Azure Marina Model. This 360 SQ/FT studio consists of a bedroom, kitchen, and bathroom, and can be customized and ordered on the company’s website.

Habitat for Humanity Uses AM For Homes in Low-Income Areas

Atlanta-based nonprofit organization Habitat for Humanity has been able to support millions of people all over the world by helping to construct and preserve houses and shelters. Last year, in 2021, the organization finalized its first house using 3D printing technologies. The 1,200-square-feet house that is located in Williamsburg, Virginia, was the first 3D printed house to be owner-occupied in the United States. To create the house, Habitat for Humanity partnered with 3D printing home construction company Alquist 3D, which used a large-scale 3D concrete printer to produce the house in only 28 hours. The home features a kitchen, three bedrooms, and two full bathrooms. The nonprofit also has been working on building 3D printed houses in other states including Arizona.

Last year, in 2021, the organization finalized its first house using 3D printing technologies. The 1,200-square-feet house that is located in Williamsburg, Virginia, was the first 3D printed house to be owner-occupied in the United States. To create the house, Habitat for Humanity partnered with 3D printing home construction company Alquist 3D, which used a large-scale 3D concrete printer to produce the house in only 28 hours. The home features a kitchen, three bedrooms, and two full bathrooms. The nonprofit also has been working on building 3D printed houses in other states including Arizona.

House 1.0, Europe’s First 3D Printed Tiny House

The House 1.0 is the first 3D-printed Tiny House in Europe. It was made by Danish 3D printing startup 3DCP Group using concrete 3D printers. The company’s goal with this house is to build better, faster, greener, and reduce the amount of effort required in the construction process. The Tiny House is designed to be as cost-effective as possible and to provide owners with all the necessary amenities despite its small size of only 37 m2.

SQ4D Puts the First 3D Printed House on the Market

SQ4D is a company that has completed the construction of the world’s largest known 3D printed house. The house, which was printed and built entirely on-site, is approximately 180 m2 in size and required only forty-eight hours of printing time, which was spread over a period of eight days. The materials used in the manufacturing process had a total value of less than $6000. The company continues to strive for innovation and plans to cut the printing time in half for subsequent projects in the future.

Prvok, the 3D Printed Houses in the Czech Republic

Whether in the countryside, in the city, or even on water, the 3D-printed house called Prvok was born in the Czech Republic and was created through the collaboration of Buřinka, a visionary company from the construction sector, and sculptor Michael Trpák. Built of concrete, the house can be printed in just 22 hours due to the printing speed of 15 cm per second – and with a size of 13.35 m x 3.5 m x 3.1 m. The robot arm thus produces a living area of 43 m2. With a total of three rooms – a bathroom with toilet, a living room with kitchen area, and a bedroom – the building can even be solidified on a floating hollow body, making it habitable on the water all year round.

Built of concrete, the house can be printed in just 22 hours due to the printing speed of 15 cm per second – and with a size of 13.35 m x 3.5 m x 3.1 m. The robot arm thus produces a living area of 43 m2. With a total of three rooms – a bathroom with toilet, a living room with kitchen area, and a bedroom – the building can even be solidified on a floating hollow body, making it habitable on the water all year round.

Viliaprint, the Project Combining AM and Conventional Construction

This project combines additive manufacturing and conventional techniques for building houses. The project called Viliaprint was inaugurated in June of this year in the French city of Reims, more precisely in the eco-district there called Réma’Vert. A total of five houses, with each having living spaces ranging from 77 to 108 m2, were built thanks to the collaboration of stakeholders. The promising project aims at improvements in social, economic, and sustainable aspects. In the 3D printing process, which did not take place directly on site, the designers behind the 3D printed homes placed particular emphasis on concrete that dries as quickly as possible after each layer is applied so that it can hold its own weight.

COBOD and PERI Partner for Incredible Houses Build Using AM

PERI is a company founded in 1969. In 2018, the group acquired a minority stake in COBOD, a leader in 3D design, and since then the two companies have been working together. In 2020, they built the first 3D-printed house in Germany and the largest apartment building in Europe. The house, printed in the Rhineland region of North Westphalia, is a 160-square-meter, two-story single-family home with three-layer insulated cavity walls. The COBOD BOD2 printer was used for the construction, which is characterized by its ability to extrude concrete at a speed of up to 100 cm per second, resulting in the desired project size, smooth and straight walls, and the highest quality requirements. With the CODOB printer, it is possible to build up to 300 square meters on 3 floors at an unprecedented speed. PERI firmly believes that 3D printing will one day, revolutionize the construction industry.

Project Milestone, the 5 3D Printed Homes in the Netherlands

This next housing project is located in the city of Eindhoven in the Netherlands. It consists of five 3D-printed concrete houses. Although the houses have already been sold, you can rent them from a real estate company. Each of them is made of 24 individual concrete pieces that took 120 hours to print layer by layer. These 24 pieces were then moved to the location where the house is currently located and assembled, attached to the foundations, and fitted with a roof, windows, and doors. The buildings have a futuristic design, which makes the houses look like they are abandoned, reminiscent of rocks in an oasis surrounded by trees. The houses meet the ultimate comfort needs and were built in a sustainable and energy-efficient way. The surrounding area is bright, yet quiet, and provides a great place to relax.

It consists of five 3D-printed concrete houses. Although the houses have already been sold, you can rent them from a real estate company. Each of them is made of 24 individual concrete pieces that took 120 hours to print layer by layer. These 24 pieces were then moved to the location where the house is currently located and assembled, attached to the foundations, and fitted with a roof, windows, and doors. The buildings have a futuristic design, which makes the houses look like they are abandoned, reminiscent of rocks in an oasis surrounded by trees. The houses meet the ultimate comfort needs and were built in a sustainable and energy-efficient way. The surrounding area is bright, yet quiet, and provides a great place to relax.

What do you think of these different projects? What is the impact of 3D printing in the construction sector? Let us know in a comment below or on our Facebook and Twitter pages! Sign up for our free weekly Newsletter, all the latest news in 3D printing straight to your inbox!

What It’s Really Like to Live in a 3D-Printed Home

This year’s South by Southwest (SXSW) festival saw its usual lineup of bands and films, but another more pressing topic was on the table. "It’s existentially urgent that we find new ways to shelter ourselves," says Jason Ballard, cofounder and CEO of Icon, an Austin-based construction start-up. "The homes and buildings of our future have to be profoundly different than they are today." For Icon and other disruptors in the construction industry, the solution isn’t about optimizing human labor or materials, but rather, building with robots.

"It’s existentially urgent that we find new ways to shelter ourselves," says Jason Ballard, cofounder and CEO of Icon, an Austin-based construction start-up. "The homes and buildings of our future have to be profoundly different than they are today." For Icon and other disruptors in the construction industry, the solution isn’t about optimizing human labor or materials, but rather, building with robots.

Icon’s large-scale 3D printers build up architectural forms through an additive process using a proprietary material called Lavacrete, a high-strength concrete that is mixed on-site based on climate conditions and construction needs.

Ballard and his company are imagining a future where all our housing needs are 3D printed using advanced tech. "It’s time for the built environment to join the digital automated robotic revolution that has brought so much good to other industries," Ballard says.

Four years ago, Icon unveiled the world’s first permitted 3D-printed home at SXSW. That house was designed as a prototype affordable housing unit, and it was later translated into several tiny home villages that the company has helped to build. This year, Icon presented their latest achievement, House Zero.

That house was designed as a prototype affordable housing unit, and it was later translated into several tiny home villages that the company has helped to build. This year, Icon presented their latest achievement, House Zero.

Icon unveiled their latest 3D-printed home, House Zero, at SXSW earlier this year. Designed by Lake Flato Architects, House Zero explores new design opportunities for 3D printing in residential construction.

Designed by Lake Flato Architects in the likeness of a ranch-style residence, the model home is arguably the most advanced formal expression of 3D-printed residential design to date. Its undulating, textural printed concrete walls are interspersed with windows that stretch from floor to ceiling, where a flat traditional timber roof caps it off. "It’s important to do deliberately provocative houses like House Zero," says Ballard. "It’s about shifting people’s imaginative window about what modern housing can be."

Inside, House Zero looks and feels like a traditional home, but with undulating 3D-printed exterior walls that offer an element of texture and movement to interior spaces.

"To us, it’s important to do deliberately provocative houses like House Zero," says Jason Ballard, cofounder and CEO of Icon. Ballard hopes House Zero will help shift the general mindset about what a 3D-printed home can look and feel like.

While it’s good to invite people to dream, what about 3D-printing’s promise to actually create and provide shelter? Is this something people want or need? And what kind of shelter is it, exactly?

For a select group of global citizens who’ve found themselves living in a 3D-printed homes, while the reality may not be quite as glamorous as House Zero, it’s nevertheless been surprisingly comfortable.

Shawn and Marcus Shivers stand among the beginnings of their new home in Tempe, Arizona, which was built using an on-site gantry 3D printer and is targeting LEED Platinum certification.

Seventy-five percent of the Shivers’ home was 3D printed, including all of the interior and exterior walls, with the remainder—including the roof—built using traditional construction methods.

"I was worried," admits Phoenix, Arizona, resident Marcus Shivers about his initial reaction to hearing he could be moving into a 3D-printed home. "It looked like a nice house in the mock-ups, but my main concern was that the technology was new—I wondered who would actually know how to work on the house if something went wrong."

Marcus and his wife, Shawn, were motivated by the chance to stay in the Tempe neighborhood where they’d lived for decades (but were swiftly getting priced out of), so they took the leap and signed on to take ownership of the home, which was recently completed by Habitat for Humanity Central Arizona.

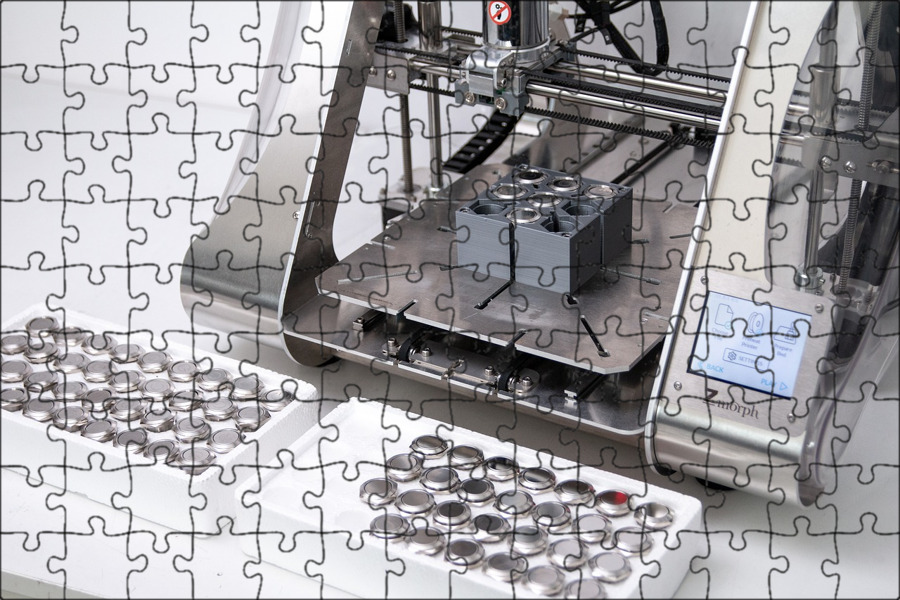

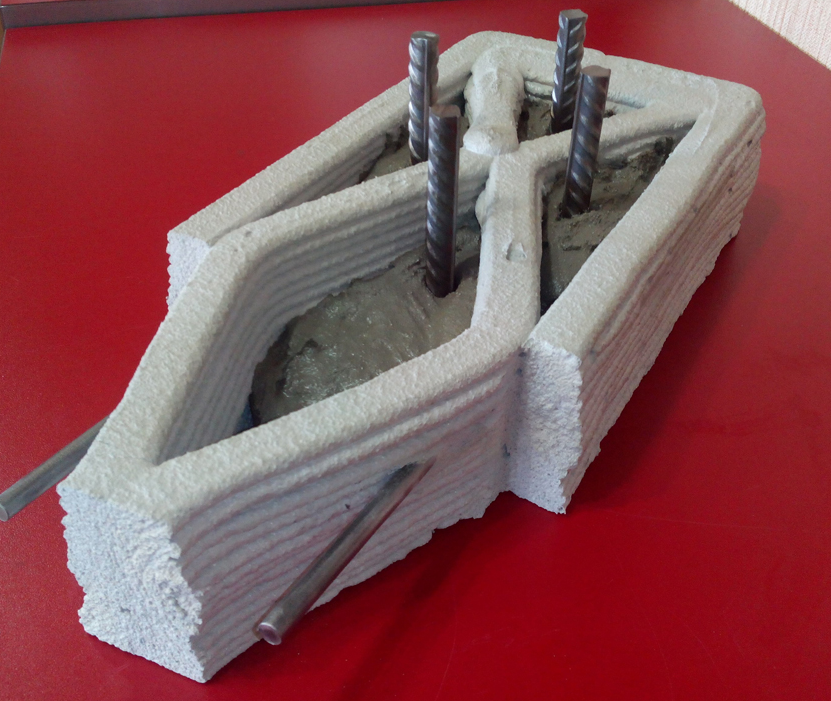

Habitat for Humanity Central Arizona used a Build on Demand Printer (BOD2) shipped from Germany-based PERI Group, which is designed in such a way that builders can work in the print area during the printing process, optimizing efficiency.

The BOD2 printer uses a composite concrete material called Laticrete in its additive construction process. Successive layers are built up to form interior and exterior walls.

Successive layers are built up to form interior and exterior walls.

Targeting LEED Platinum, the Shivers’ new residence is Habitat for Humanity’s first 3D-printed house in the nation—and the nonprofit hopes to scale the design to produce other homes in Tempe and beyond. All of the three-bedroom home’s walls were formed by on-site gantry printers using Laticrete, a composite concrete material, while the ceiling and roof were built via traditional construction methods.

Now that they’re moved in, the Shivers’ initial hesitations have given way to elation. "It’s so energy efficient and tight, and the walls are so thick," says Marcus. "We rarely have to turn on the air-conditioning, and when we do, we turn it off five minutes later." Shawn agrees: "It feels like a fortress, but it’s not too closed-in. You can’t hear through the walls at all, and I like the safety and strength of the structure," she says.

The cave-like quality of 3D-printed homes has made some potential homeowners wary, particularly when designers embrace the organic, undulating forms that 3D printing naturally yields (à la House Zero). In Holland, architects from Houben / Van Mierlo designed the world’s first legally habitable property with 3D-printed load-bearing walls, which takes the shape of a giant boulder with rounded walls and roof forms. Completed in 2021 by Project Milestone, the two-bedroom bungalow is currently home to Elize Lutz and Harrie Dekkers, who were intrigued from the outset by its unique form.

In Holland, architects from Houben / Van Mierlo designed the world’s first legally habitable property with 3D-printed load-bearing walls, which takes the shape of a giant boulder with rounded walls and roof forms. Completed in 2021 by Project Milestone, the two-bedroom bungalow is currently home to Elize Lutz and Harrie Dekkers, who were intrigued from the outset by its unique form.

Elize Lutz and Harrie Dekkers are currently living in this Flintstones-style home in Eindhoven. Completed by Project Milestone, it was the first legally habitable house in Europe with 3D-printed load-bearing walls.

The home has 94 square meters (1,011 square feet) of living space, with an open-plan living, dining, and kitchen area and two bedrooms.

"For 40 years, we had a shop selling contemporary jewelry, so we liked looking at design, and the form of this building interested us," says Elize. "It’s like a bunker, but cozy inside." Harrie agrees, but notes that he never feels closed in. "It feels very safe inside, like a cocoon—but when the doors are open, you can see all the way through the house, and it’s a very open feeling," he says. Now, Project Milestone is at work on the second and third of their five planned homes in Eindhoven, which are slated to finish construction by end of year.

Now, Project Milestone is at work on the second and third of their five planned homes in Eindhoven, which are slated to finish construction by end of year.

EYRC Architects is partnering with Oakland-based construction company Mighty Buildings on a new 3D-printed community in Desert Hot Springs, California. Construction on the first unit began earlier this year, and the initiative uses a kit-of-parts approach to 3D print wall panels which are then assembled on-site.

Los Angeles–based architect Mathew Chaney’s firm EYRC Architects is working with construction company Mighty Buildings to design and construct a new 3D-printed community in Desert Hot Springs. He notes that this type of volumetric fabrication is ideal for tapping the full potential of 3D printing. "Organic shapes have more inherent form stability, making them better for 3D printing," he explains. "However, 3D printing is typically a hybrid of organic shapes and conventional residential architectural forms because, for example, you can’t print a concrete roof very easily. "

"

Unlike other 3D printing outfits, Mighty Buildings uses a resonated stone composite called Light Stone Material in their printers, which hardens when exposed to UV light and is highly durable and thermally stable.

As companies like Icon continue pushing the envelope on technology to unite 3D-printed forms with typical architectural elements, residents of 3D-printed homes find them remarkably comfortable. Tim Shea, who moved into an Icon house in 2020 in the Community First! Village, a 51-acre development aiming to provide homes for unhoused people in Austin, has been pleased by how livable and cozy he’s found his 400-square-foot home. "There are no sharp corners in the house, and the roundness is embracing," he says. "It feels warm, secure, and comforting inside—it’s like I’m being hugged by my house."

These 400-square-foot dwellings were designed by Logan Architecture for a 51-acre development called the Community First! Village that aims to provide homes for unhoused people in Austin. Icon 3D printed the houses on-site using its Vulcan II printers.

Icon 3D printed the houses on-site using its Vulcan II printers.

Inside Tim Shea’s 3D-printed home, cozy furnishings and textiles complement the layered 3D-printed walls. "When I was asked if I’d be willing to explore the possibility of moving into a 3D-printed home, I went through the roof and jumped at the opportunity," says Shea. "It’s been nearly two years in my beautiful home, and I just love it. It’s a space that I enjoy and feel comfort in."

While it remains to be seen whether 3D printing will be able to deliver on its promise to provide adequate housing for the world, for the few currently living in 3D-printed homes, the experience has been eye-opening. "This home is a new way of thinking about how to build and what a house can be," says Elize Lutz, who, along with her partner Harrie, have just extended the lease on their Eindhoven home because they’re so content.

For Icon’s Jason Ballard, the tech has always been a means to an end—one that strives for the most comfortable, resilient, and dignified homes possible. "Right now, we believe 3D-printed houses are the best houses," says Ballard. "But I promise if we thought of a better solution tomorrow, we’d start doing that."

"Right now, we believe 3D-printed houses are the best houses," says Ballard. "But I promise if we thought of a better solution tomorrow, we’d start doing that."

Related Reading:

At SXSW, a 3D-Printed House Tests a New Vision for Home Building

ICON Just Unveiled Plans for a Massive Neighborhood of 3D-Printed Homes

A Dutch Couple Are the First Tenants of This Boulder-Shaped 3D-Printed Home

Have a Look at the World’s First 3D-Printed Home Made Entirely of Clay

Published

Last Updated

Topics

Home TechDesign News

3D Printing Technologies - Antar Printing House in Khabarovsk

Automated production of three-dimensional figures based on their computer model was implemented quite a long time ago, back in the last century. After all, CNC milling or turning machines to some extent solved this problem. But 3D printing is considered a breakthrough in the technology of creating objects based on a virtual three-dimensional image. It is based on a completely different principle, when an object is formed not by processing the original workpiece, but by recreating it layer by layer in various ways.

After all, CNC milling or turning machines to some extent solved this problem. But 3D printing is considered a breakthrough in the technology of creating objects based on a virtual three-dimensional image. It is based on a completely different principle, when an object is formed not by processing the original workpiece, but by recreating it layer by layer in various ways.

This technology appeared quite a long time ago, in the 80s, and is now used almost everywhere. This is due to its significant reduction in price. If the first 3D printers were built tens and hundreds of thousands of dollars, now they have reached the level of almost household devices available to any consumer.

The history of 3D printing. Stereolithography

The study of this direction in technology began with the research of the American Charles Hull, who got excited about the idea of creating three-dimensional figures back in the late 40s. A method that he was able to patent only at 1986, was called stereolithography, and it was based on the process of creating objects using the photopolymerization of a liquid substance. The first industrial 3D printer was called that - a stereolithographic installation. This technology involved "growing" an object by superimposing layers of fractions of a millimeter on a continuously moving platform. The units produced by the Hull-founded 3D System were commercially successful, but limited in demand due to their considerable cost and bulkiness.

The first industrial 3D printer was called that - a stereolithographic installation. This technology involved "growing" an object by superimposing layers of fractions of a millimeter on a continuously moving platform. The units produced by the Hull-founded 3D System were commercially successful, but limited in demand due to their considerable cost and bulkiness.

Modern 3D printing technologies

And only in the current century, around 2012, did a breakthrough occur in the 3D printer market, when compact and cheap consumer-grade models appeared. Buying them now is no problem, you can even order in the online store. The aforementioned 3D System company also started their production, but its printing technology is far from the only one.

LOM - sheet printing

Back in 1985, another method was proposed - by forming objects from thin sheets, connected using a heated press. It was invented by Mikhailo Feigen, and not only plastic, but also paper was used as a material. The three-dimensional models of the earth's surface created with its help look very impressive. However, this method, referred to as LOM, has some disadvantages associated with insufficient strength of the resulting sample.

The three-dimensional models of the earth's surface created with its help look very impressive. However, this method, referred to as LOM, has some disadvantages associated with insufficient strength of the resulting sample.

SLS - powder plus laser

Around the same time, in 1986, a more advanced technology appeared that uses a laser and powder as a raw material. The principle of operation lies in its layer-by-layer sintering by a laser beam along a given contour in a special chamber. Accordingly, this technology is designated SLS, that is, selective laser sintering. The powder used can be made from polymers, ceramics, metal or foundry wax.

The advantage of this method, proposed by Carl Descartes, can be considered not only the use of various materials, but the possibility of simultaneous production of several items. The disadvantages include the porous structure of the obtained samples, as well as the need for regular cleaning of the chamber.

SGS - UV Curing

This method was developed by Gubital in Israel a year later. In it, as in stereolithography, photopolymerization is used, however, the technological process itself involves the preliminary formation of a template that covers a thin layer of photopolymer. After its exposure to ultraviolet irradiation, the material solidifies selectively (only under the template), the process is repeated cyclically.

In it, as in stereolithography, photopolymerization is used, however, the technological process itself involves the preliminary formation of a template that covers a thin layer of photopolymer. After its exposure to ultraviolet irradiation, the material solidifies selectively (only under the template), the process is repeated cyclically.

The advantage of this technology is the possibility of stopping it, for example, to check the quality of workmanship. The disadvantage is the use of unique high cost polymers. The installation itself also costs a lot - hundreds of thousands of dollars. For this reason, 3D printers of this class have not received distribution in our country.

FDM - Filament Printing

In the early 90s, this technology made a splash in the market when Stratasys offered consumers $50,000 3D printers. Inventor Scott Crump received a patent for it at 1988, and the installation itself is somewhat similar to a conventional inkjet printer. After all, it uses a real print head, through which the melt of plastic, metal or wax (in the initial state - in the form of a thread) flows down and forms an object in even layers. The transition to the next layer is carried out after lowering the platform on which the sample is located.

The transition to the next layer is carried out after lowering the platform on which the sample is located.

Currently, all of the above methods are used for 3D printing, however, the invention of Charles Hull is considered the most promising. This is due to the fact that stereolithography has significantly less restrictions on the materials used. Regardless of the method used, the most important factor in the development of this technology is its penetration into various spheres of human activity. Today, they are not limited to industry, and 3D printing is confidently taking its place in construction, medicine, and even culinary.

We can safely say that this is technology of the XXI century .

3D printing: the possibilities of additive technologies

Additive technologies or 3D printing is the process of creating an object that exactly corresponds to a three-dimensional model by applying material layer by layer. This innovation has become a global trend. The main advantage of the technology is resource saving. Losses of useful substance tend to zero.

The main advantage of the technology is resource saving. Losses of useful substance tend to zero.

Area of use

3D printers have not yet penetrated into every home, but they are already present in all key areas of human life. 3D printing is in demand in the automotive industry, energy, medicine, food industry, construction/design, fashion industry.

In resource- and labour-intensive industries, the development of a product prototype costs a lot of money. With traditional casting or machining technologies, this takes weeks, months. Using the possibilities of volumetric printing, the work is done many times, and sometimes dozens of times, more quickly. At the same time, the quality does not suffer at all and the parameters of the product remain extremely accurate. By the way, the strength of the prototype is more than 20% higher than that of the classic production.

In medicine, the possibilities of 3D printing are used to design dentures, skeletons, and even internal organs. Additive technologies make it possible to create a medical instrument with certain parameters for specific patients with pathologies and anatomical features. This allows you to take a huge step forward in training and preparation for operations.

Additive technologies make it possible to create a medical instrument with certain parameters for specific patients with pathologies and anatomical features. This allows you to take a huge step forward in training and preparation for operations.

In 2011, a kidney was “drawn” on a 3D printer. Scientists have created an exoskeleton to support atrophied muscles. There are even special “pens” that “draw” living cells on injured skin areas.

On 3D printers, models of premises are created with a visual study of interiors, buildings and entire residential areas with details of houses, utilities, and infrastructure facilities.

In the field of science and education, the benefits of 3D printing are expressed in the creation of visual aids with which the learning process becomes easier and more efficient.

3D printing is in demand in the fashion world. On the printer, you can create shoes, clothes, perfume bottles. While this process is expensive, therefore, it is not used in mass production. However, piece products made on 3D printers are already presented on the catwalks.

However, piece products made on 3D printers are already presented on the catwalks.

Creative 3D Printed Sandals

The advantage of introducing AF technologies into the light industry is the ability to create products for a specific physique/foot shape. This is especially true for athletes, people with deviations of the anatomical structure. For example, designer Ross Berber introduced the world to shoes printed on a 3D machine. His collection includes 5 pairs.

3D printing allows for a breakthrough in innovation. Before a product can be mass-produced, a prototype must be tested and repeatedly tested. This is done on 3D models. You can create them in minutes.

Three-dimensional technologies are used in jewelry, when creating maps of the area, making souvenirs, customizing finished products (applying a pattern, logo).

How does a 3D printer work?

A classic 3D printer is a 3D printing device that works on the principle of FDM (Fusion Deposition Modeling). On three-dimensional equipment, you can create an object of almost any shape, with curves, a relief surface. The product "increases" simultaneously in the horizontal and vertical direction.

On three-dimensional equipment, you can create an object of almost any shape, with curves, a relief surface. The product "increases" simultaneously in the horizontal and vertical direction.

Printers work with various materials: plastic, metal, and so on. With their help, you can create parts that can withstand a significant load. In order for the printer to print three-dimensional figures, it is equipped with:

- extruder - for heating and forcing plastic through the printheads;

- motors (usually linear) - set in motion the mechanisms;

- work surfaces - the platforms on which everything happens;

- sensors for fixing moving parts;

- Cartesian robots - devices moving along three axes.

Printers work differently, but the classic sequence of actions can be described by a single algorithm. First, a 3D image is created. This requires specialized software. After that, the model is “cut” into horizontal layers. A special program (G-code generator) is also provided for this. The computer converts the codes into information that the 3D printer can recognize. The next step is to recreate the model.

A special program (G-code generator) is also provided for this. The computer converts the codes into information that the 3D printer can recognize. The next step is to recreate the model.

Smartprint HB-8 3D printer

3D Printing Technologies

There is monochrome and color 3D printing - more than a dozen technologies (plus their modifications). Among the most common:

- SLA - stereolithographic laser printing. The technology provides the creation of models with high detail. Its essence is the layer-by-layer application of a photopolymer material. It hardens under the influence of a laser. Then the working platform is lowered. A translucent composition is used as a photopolymer: it is easy to process, paint, glue.

- SLS - the technology is suitable for working with plastics and metals. The reagent is sintered under the laser beam. The products are very durable.

- HPM - printers work with thermoplastic, auxiliary soluble materials.

The latter are used to create complex multilevel models with cavities and functional holes. Finished products may have a different shape. They are durable, resistant to stress, mechanical and chemical stress.

The latter are used to create complex multilevel models with cavities and functional holes. Finished products may have a different shape. They are durable, resistant to stress, mechanical and chemical stress. - DLP is a relatively new 3D modeling technology. The printers that support it print with photopolymer resin. The material hardens when exposed to light.

The most progressive technologies are EBM and SLM. The first involves the impact on the material with an electron beam, and not with a laser, the second works with metals.

Equipment for 3D printing is produced by companies from the USA, Europe, and Asia. Among the famous ones are Photocentric, 3D systems, Makerbot, Azuma Engineering Machinery Inc. and others.

3D model of the ship strikes with realism

Advantages of additive technologies

The advantages of 3D printing include:

- Resource efficiency.

Products are "grown" from scratch, that is, the production is completely waste-free. For comparison: when creating a blank using traditional methods, material losses sometimes reach up to 85%.

Products are "grown" from scratch, that is, the production is completely waste-free. For comparison: when creating a blank using traditional methods, material losses sometimes reach up to 85%. - Efficiency. The time from the development of the layout to the receipt of the product can be reduced several times, or even tens of times, without compromising quality.

- Mobility. The equipment is compact, layouts can be transferred online.

- Precision. Layered synthesis ensures absolute compliance with specified technical parameters.

- Strength. The indicator is 25–30% higher than that of products obtained by traditional methods (forging, casting).

- Weight. This is an important advantage for industry, aircraft and mechanical engineering. The mass of individual products is reduced by 40–50% without loss of strength.

Souvenirs and toys are successfully printed in Russia using 3D printing technology

3D printing is also used in advertising printing.