3D printed robot car

Ford rolls out autonomous robot-operated 3D printers in vehicle production

0Shares

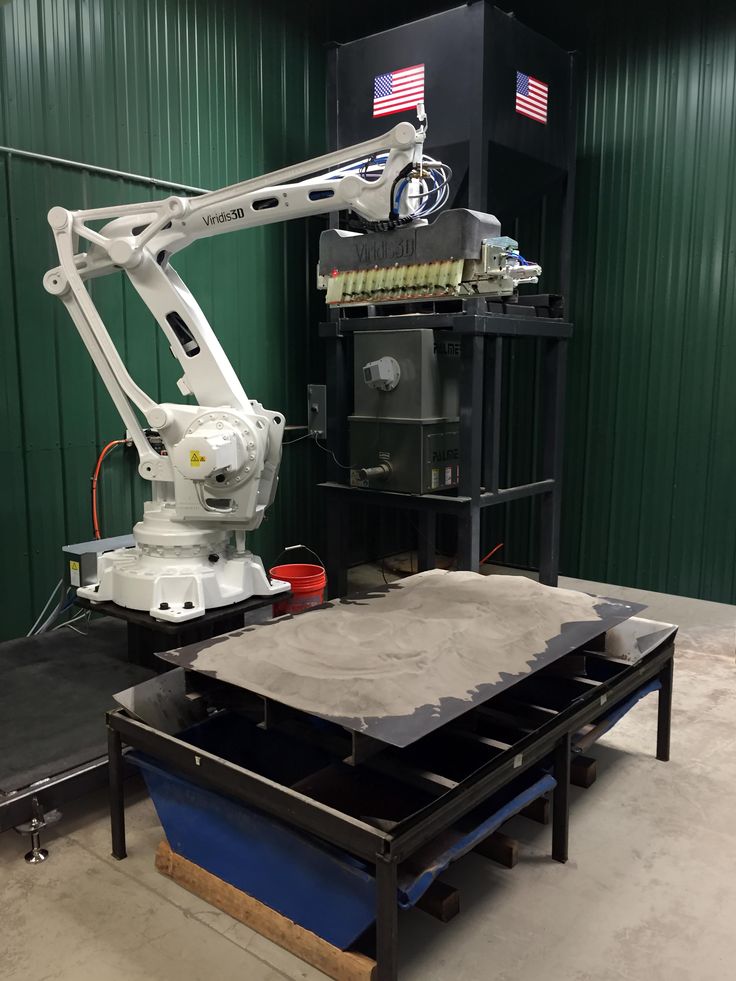

Multinational automotive manufacturer Ford has begun using an autonomous robot within its production line to 3D print end-use parts for its vehicles.

Leveraging an in-house-developed interface, Ford has managed to get the KUKA-built bot to ‘speak the same language’ as its other systems, and operate them without human interaction. So far, the firm’s patent-pending approach has been deployed to 3D print custom parts for the Mustang Shelby GT500 sports car, but it could yet yield efficiency savings across its production workflow.

“This new process has the ability to change the way we use robotics in our manufacturing facilities,” said Jason Ryska, Ford’s Director of Global Manufacturing Technology Development. “Not only does it enable Ford to scale its 3D printer operations, it extends into other aspects of our manufacturing processes – this technology will allow us to simplify equipment and be even more flexible on the assembly line. ”

3D printing at Ford’s innovation hub

Since acquiring an SLA 3 system back in the late 1980s, Ford has consistently sought to integrate 3D printing into different aspects of its vehicle production process. As revealed in a recent interview with AMUG keynote speaker Ellen Lee, the firm uses the technology, not just within fluid flow visualization and wind tunnel testing, but in the creation of jigs, fixtures and end-use components for its cars.

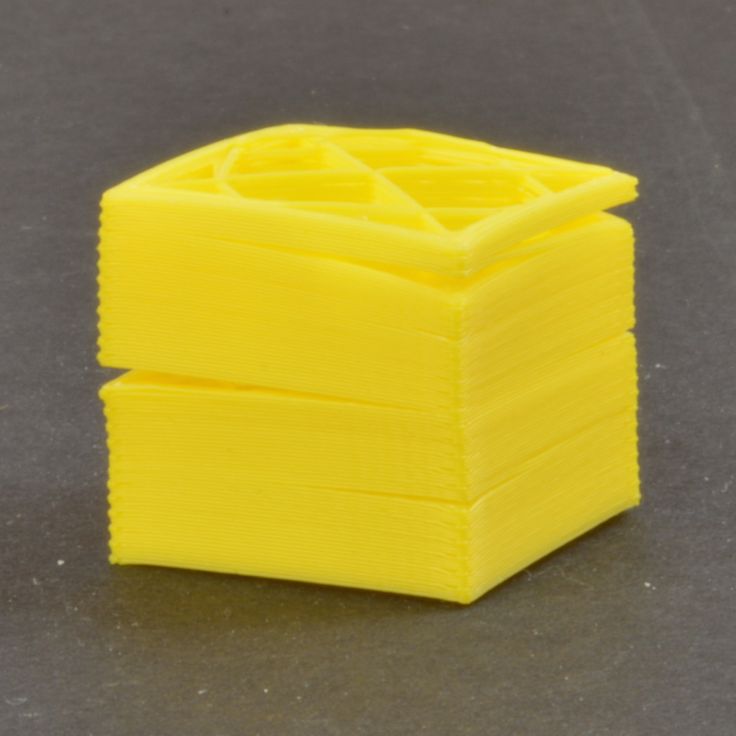

Much of Ford’s work around 3D printing takes place at its Advanced Manufacturing Center (AMC), a facility that now houses SLA, FDM and SLS systems, among a range of other advanced machinery. While the AMC team spends a lot of time verifying the feasibility of printed parts or assessing how technologies like 3D printing can be better utilized, their work has yielded a number of recent breakthroughs.

Just last month, Ford released CAD files that enable its customers to 3D print pickup truck accessories such as cup holders or phone mounts, and through working with HP last year, it developed a means of recycling 3D printing waste into F-250 parts.

Going further back, the company also partnered with DLS specialist Carbon in 2015, as a means of initially expediting its prototyping workflow, but with the longer-term goal of using the technology for part production. With the news that it has developed an automated Carbon 3D printing workflow, it now appears that Ford has passed this milestone, and set its sights on driving efficiency from the process.

A set of Carbon DLS 3D printed automotive parts. Photo via Ford.Interfacing with autonomous robots

Like most companies, Ford utilizes systems at its production facilities that have been developed separately from one another, hence they don’t run the same interface and can’t usually communicate back and forth. However, the firm has now shifted this paradigm, by developing a unique application interface program that enables systems of different makes to send constant feedback to each other.

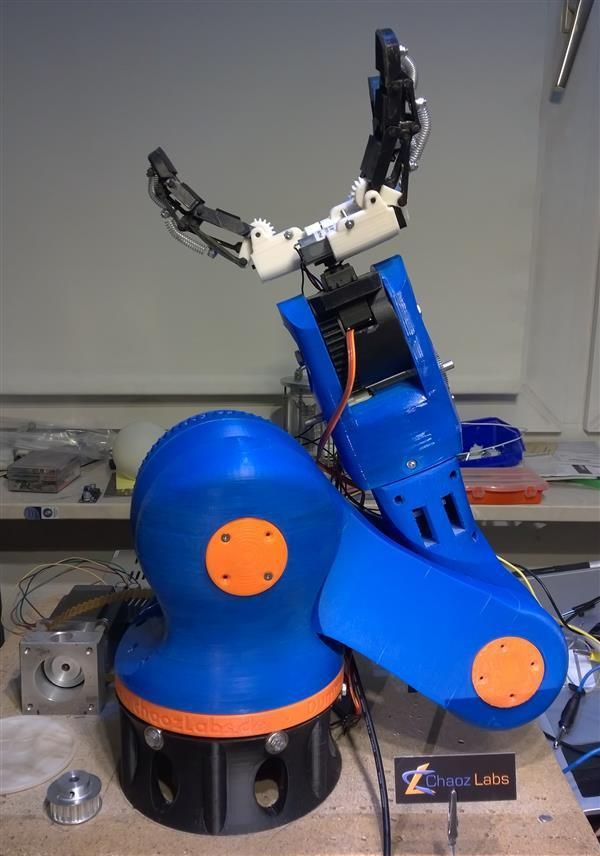

When applied to the robotic arm on wheels housed at Ford’s AMC, which it has nicknamed ‘Javier,’ the software essentially allows it to ‘talk to’ the Carbon 3D printers there. As a result, the bot is now able to tell when the center’s additive manufactured parts will be finished, as well as when they’re ready for pick-up, operating autonomously all night long without requiring any human input at all.

As a result, the bot is now able to tell when the center’s additive manufactured parts will be finished, as well as when they’re ready for pick-up, operating autonomously all night long without requiring any human input at all.

Although Ford admits that its operators are still responsible for uploading designs to the printer and maintaining machinery, it says its approach does unlock higher part throughputs and reduces related costs. The firm also claims to have used Javier’s feedback to reduce the margins of error within its processes, allowing it to “achieve great accuracy” in production despite the bot not having the vision systems to ‘see.’

At present, the company is utilizing its setup to make low-volume, custom parts such as a brake line bracket for the Performance Package-equipped version of its Mustang Shelby GT500. Moving forwards though, Ford believes its program could be applied to make other robots in its production line more efficient as well, and it has filed several patents, not just on its interface, but the positioning of its KUKA bot.

The competitive world of automotive AM

Due to the highly-competitive nature of the automotive industry, we may not know the full extent to which many leading manufacturers utilize 3D printing, but now and then they do provide us with a glimpse of the way it’s used behind the scenes.

Back in June 2021, it was revealed that Volkswagen has adopted binder jetting at its main plant in Wolfsburg, Germany. Working as part of a project that reportedly made it the first car maker to deploy the technology within its production process, the firm has partnered with HP and Siemens with the aim of driving greater efficiency and part throughput there.

Similarly, fellow car-manufacturing multinational Groupe Renault has announced plans to integrate 3D printing capabilities into its new sustainable automotive ‘Re-Factory.’ Specifically, the company says that the complex, which is set to focus on reducing waste by recycling and retrofitting vehicles, will feature a spare part additive manufacturing service.

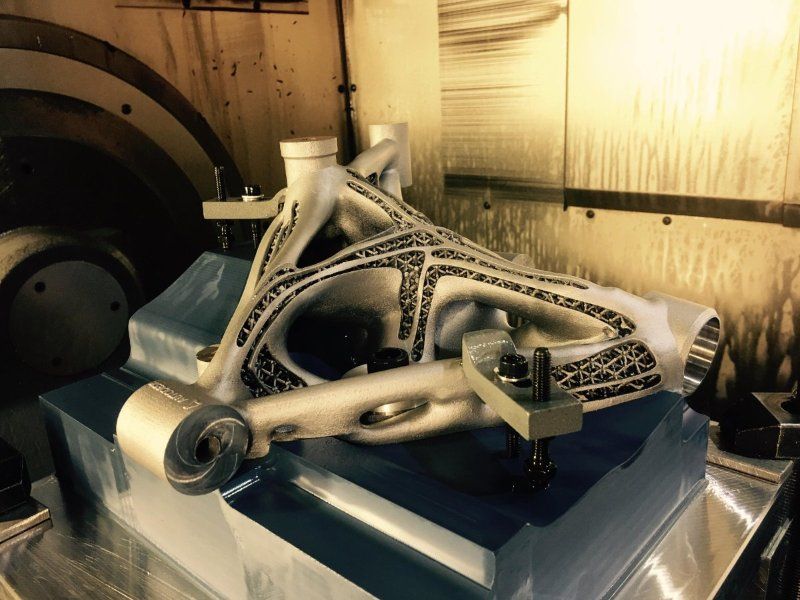

At Audi’s Metal 3D Printing Centre in Ingolstadt, meanwhile, its engineers have begun ramping up their deployment of EOS technologies to 3D print hot form tooling. In doing so, the firm says it’s now able to produce twelve different segments of four hot forming tools at the facility, which are later used to assemble car models like the A4 saloon.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Ford’s ‘Javier’ autonomous 3D printing robot. Photo via Ford.

Photo via Ford.

Tags Audi Carbon Ellen Lee EOS Ford Groupe Renault HP Jason Ryska Kuka Mustang Shelby GT500 Siemens Volkswagen

Paul Hanaphy

Paul is a history and journalism graduate with a passion for finding the latest scoop in technology news.

3D file M Second - Robot Car・3D printable model to download・Cults

Smartphone Stand for Video Recording

€2.06

Tablet Stand (iPad)

€0.98

Hand Free Door Opener - Keychain19

€1.07

Laptop Riser Stand

€1.97

PS4 and Xbox Controller Stands

€1.96

Face Shield with eyes top cover

€1.08

Face Shield

€0.91

Toy House

€0. 98

98

Best 3D printer files of the Gadget category

Sony DSC RX100VA RX100M5A Bracket Grip Extension

Free

- 5.8 cm high X 4 cm wide X 2 cm thick. - 2h 2min the printing time. - You don't need support.

€2

Boomy The BoomBox

Free

Pi Touch Case

€1.96

Cute Fishes - Phone Stand / Card Holder

Free

Desktop Headphone Stand

€4.90

NERF arrow shaft

Free

Best sellers of the category Gadget

Mechanical Spinning Top Dice Box

€3. 87

87

App to create switchable business cards

€3.56

DJI AVATA GoPro Mount

€2.50

Perritos fantasma / Spooky dogs

€3.30

JEEP WRANGLER PEN HOLDER - 3-IN-1

€1.85

ENGINE CYLINDER BLOCK - WALL KEY HANGER

€1.85

Owl - Wall Key Holder

€1.85

Fidget Pumpkin Keychain - Halloween

€1.89

App to create dual text illusion

€3.56

Writing Machine V2.0 - 2D Pen Plotter

€6.69

WALL KEY HOLDER - EYE (ENTIRE COLLECTION)

€1.88

Pumpkin duck

€1. 25

25

PIXEL 7 case (two designs)

€0.96

wall key holder (dragon ball)

€1.25

AR-15 LOWER MULTI CAL. REINFORCED STRUCTURE

€8.50

Jack the fidget Zombie - Halloween

€2.29

Would you like to support Cults?

You like Cults and you want to help us continue the adventure independently? Please note that we are a small team of 3 people, therefore it is very simple to support us to maintain the activity and create future developments. Here are 4 solutions accessible to all:

ADVERTISING: Disable your AdBlock banner blocker and click on our banner ads.

AFFILIATION: Make your purchases online by clicking on our affiliate links here Amazon.

DONATE: If you want, you can make a donation via PayPal.

WORD OF MOUTH: Invite your friends to come, discover the platform and the magnificent 3D files shared by the community!

3D Printed Robo Insect Jumps Without Power And Without Wires

06/11/2016Alexey Boyko (ABloud)

robots, scientific robots

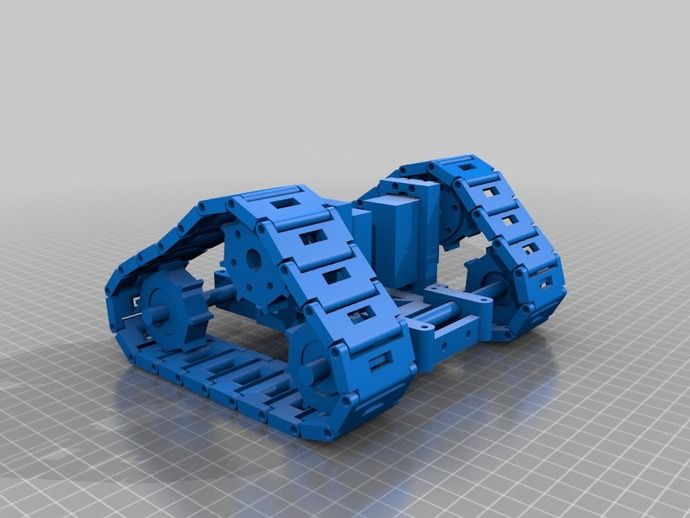

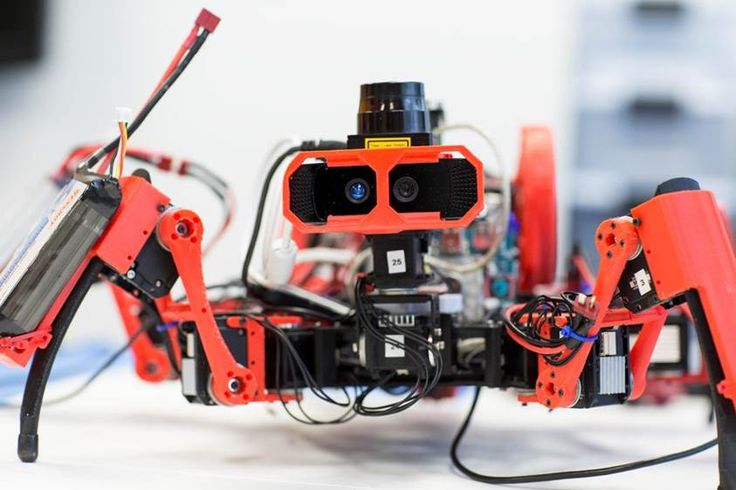

Researchers at the University of Maryland, USA have used 3D printing to create miniature robots with four limbs that can traverse rough terrain. Measuring 20mm long and 5.6mm wide, the 3D printed robots weigh less than 2 grams and can move in a variety of styles: trot, walk, waddle, roll, hop and bounce. Once again, the developers were inspired by the bionic approach - ideas for such designs can be gleaned from insects.

Robot designed by Ryan St. Pierre and Sarah Bergbreiter Professor at the University of Maryland. In May, the developers presented the characteristics of the robotic insect at the International Conference on Robotics and Automation (ICRA) in Stockholm, Sweden.

The peculiarity of the robot is that it is printed on a 3D printer, which is called "in one pass". After that, four cube-shaped magnets are installed in the robot - one for each leg. The rotation of a large magnet nearby causes the microrobots to move. The orientation of each magnet determines the gait of the bot.

Previously, the inventors have already tried to create a robot with 6 legs, acting on the same principle - it was similar to the Robotic Autonomous Crawling Hexapod (Roach), developed at UC Berkeley in 2009. In experiments at the University of Maryland, the legs of the hexapods intermittently blocked each other. I had to give up a pair of legs.

Researchers have studied various combinations of initial magnet setups, as well as various actuator rotation speeds. It turned out that the best results were obtained if the actuator worked at a frequency of 10 Hz - in this case, the robot moved at an average speed of 78 mm/s, i.e. about 4 body lengths per second. Depending on the type of surface, different styles of movement turned out to be optimal. For example, "antelope jumping" when the robot was launched into the air gave the fastest movement in the case of a normal and slightly uneven surface on which the robot was moving, while other styles gave the best results in the case of a heavily rough surface.

Depending on the type of surface, different styles of movement turned out to be optimal. For example, "antelope jumping" when the robot was launched into the air gave the fastest movement in the case of a normal and slightly uneven surface on which the robot was moving, while other styles gave the best results in the case of a heavily rough surface.

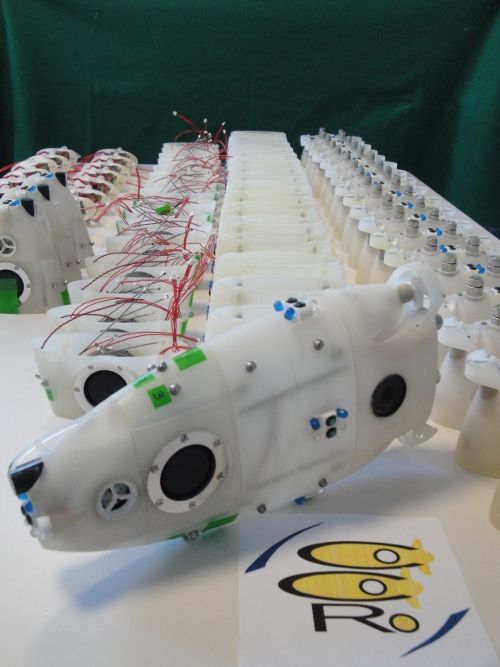

The scientists intend to continue their research. Despite the simplicity of the design, they can experiment with different "leg" designs, gait, body shape, and so on. Conveniently, with the help of a 3D printer, it is not difficult to create a whole swarm of such robots. And also the fact that using the same principle, you can create even smaller robots.

Developers are already building a robot that is only 2.5 mm long. Such robots will be able to get to places where traditional robots cannot get.

+ +

Source: 3ders. org

org

See related Robopedia articles:

- Bionics and robotics

- Bionic robots

- Microrobots and nanobots

- Scientific robots

- Advanced technologies and robotics 9004

A mechanical engineer 3D printed a working gearbox for a Toyota engine (+ video)

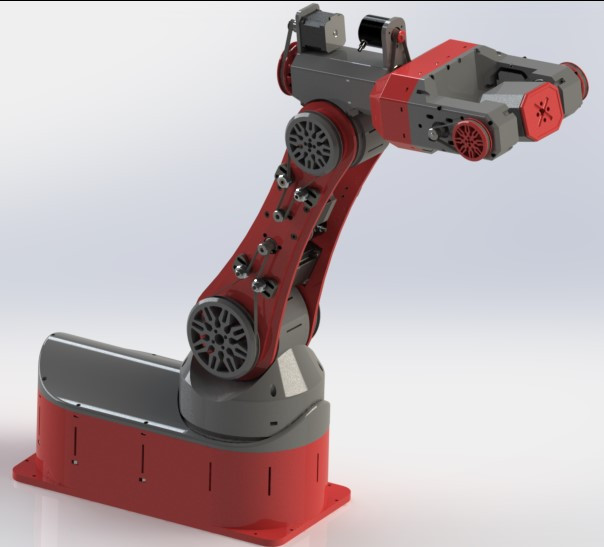

One of the unusual novelties is a 3D printed five-speed gearbox for a Toyota 22RE engine. The author of the work is mechanical engineer Eric Harrell from the city of Santa Cruz in California. His brainchild not only looks convincing, but is also a fully functional model.

In January, Harrell had already reverse-engineered a Toyota engine from scratch using a 3D printer (in other words, analyzed and reproduced its design). Thingiverse users and the American media have positively evaluated Harrel's project, and he decided to take his creation to the next level by supplementing the engine with a gearbox, also printed on a 3D printer. Harrell's two designs can work together to create a unique piece of 3D printed mechanical construction.

“The success of my first project, a four-cylinder Toyota engine, inspired me to get into the gearbox business,” says Harrell. “It's amazing how many people are interested in my work. I never thought that my design could generate such interest and, moreover, that people would actually print and assemble it, simply because it is a complex and time-consuming process. To date, eight people have already assembled the engine, and many are now working on it.”

In general, it will take approximately 48 hours of printing on a 3D printer to make all parts of the gearbox. After printing all the components, you need to assemble the structure according to the drawings provided by Harrell. The engineer recognizes that assembling a gearbox is not an easy task, so he is available to answer questions from those who have encountered any difficulties in the process.

“Anyone who puts together one of my designs—a gearbox or an engine—will get a pretty good idea of how they actually work, because my models are exactly replicas of real mechanisms,” Harrell explains. “And it’s amazing because most people who are interested in 3D printing are unlikely to ever get the opportunity to actually recreate an engine or gearbox.”

“And it’s amazing because most people who are interested in 3D printing are unlikely to ever get the opportunity to actually recreate an engine or gearbox.”

Although most parts of the gearbox are 3D printed, some small parts cannot be printed on a personal 3D printer. We are talking about such details as a rod with a diameter of 3 mm, 628ZZ bearings, washers with a diameter of 3 mm and several other small elements that serve mainly for fasteners. At the same time, Harrell does not guarantee that all parts can be 3D printed in the correct scale - some of them may have to be adjusted to fit the rest of the structure. On the other hand, the author of the project notes that instead of resizing the parts in the project, you can simply file them as necessary after printing.

“The transmission works exactly like most manual transmissions in cars or trucks,” Harrell says. “Nevertheless, I can hardly explain how it works. This is very difficult to understand until you assemble the gearbox yourself, or at least watch a cutaway video of the mechanism in operation.