Bluecast 3d printer

High performance castable resin for 3d printers

ABOUT US

BlueCast is an Italian brand focused on the production of professional 3D printing consumables and machines. Since 2008, BlueCast is specialized on the production of castable resins for the jewelry industry. Thank to our experience, we are partners of main 3d printers manufacturers and we are available for OEM contracts.

All BlueCast products are certified 100% made in Italy and are dedicated to professional users. The BlueCast castable resin are absolutely safe for users and X10 is the first resin 100% monomers free. Customers from more than 50 countries define BlueCast resins as the Best Castable Resin of Market. The bournout cycle does not require any special tricks, the residue is less than 0.03% (internal test of x10 on PerkinElmer TGA 8000), and the expansion is negligible.

BlueCast also produces high tech resins for rubber molds or dental models. BlueCast has collaborated on the design and development of SLA 3d printers based on Galvo Laser, LCD and fast DLP technology for some world’s leading manufacturers. BC holds many patents into 3D technology. Today, BlueCast, produces 3d printers based on LCD or fast DLP technology dedicated to the jewelry industry. The company Is also involved in to the production of high technology ovens flask burnout (x-burn).

RESELLERS

map

list

Europe

3D GARAGE / BLUECAST

- ITALY

- website: www.

3dgarage.shop

3dgarage.shop - e-mail: [email protected]

3D SOLUTIONS STORE

- ITALY

- website: 3dsolutions.store

- e-mail: [email protected]

MODEL QUARTIER

- ITALY

- website: www.modelquartier.com

- e-mail: [email protected]

C.S.O. e G.

- ITALY

- website: facebook

- e-mail: [email protected]

BC ALBANIA

- ALBANIA

- website: www.facebook.com/BlueCast3d/

- e-mail: [email protected]

POLYBULL

- BELGIUM

- website: www.

polybull.be/

polybull.be/ - e-mail: [email protected]

3d COLOUR

- BULGARIA

- website: www.3d-colour.com

- e-mail: [email protected]

IMAKR

- DENMARK

- website: www.imakr.com

- e-mail: [email protected]

BC FINLAND

- FINLAND

- website: www.facebook.com/BlueCast3d/

- e-mail: [email protected]

3D-paja

- FINLAND

- website: www.3d-paja.net

- e-mail: [email protected]

ATOME 3D

- FRANCE

- website: www.

atome3d.com

atome3d.com - e-mail: [email protected]

HORBACH GmbH

- GERMANY

- website: www.horbach-technik.de

- e-mail: [email protected]

3D HUB

- GREECE

- website: www.3dhub.gr

- e-mail: [email protected]

DUTCHINNOVATIONGROUP

- HOLLAND

- website: www.dutchinnovisiongroup.com

- e-mail: [email protected]

FEPshop

- HOLLAND

- website: www.fepshop.com

- e-mail: [email protected]

3D NYOMTATO

- HUNGARY

- website: www.

3dnyomtato.shoppe.hu

3dnyomtato.shoppe.hu - e-mail: [email protected]

CBTOOLS

- NORWAY

- website: www.cbtools.no

- e-mail: [email protected]

SEB COMP

- POLAND

- website: www.drukarki3d.seb-comp.pl

- e-mail: [email protected]

ZORTRAX

- POLAND

- website: www.zortrax.com

- e-mail: [email protected]

BALANTEK

- PORTOUGAL

- website: www.balantek.pt

- e-mail: [email protected]

OPUS DENTAL

- ROMANIA

- website: www.

facebook.com/opus.dental.5

facebook.com/opus.dental.5 - e-mail: [email protected]

SUNTEM 3d

- ROMANIA

- website: www.filamente3d.ro/

- e-mail: [email protected]

UVELIRMAG

- RUSSIA

- website: www.uvelirmag.com

- e-mail: [email protected]

VOXELLAB

- SERBIA

- web site: www.voxellab.rs

- e-mail: [email protected]

UNISHAPE

- SERBIA / Grecia

- website: www.unishape.gr

- e-mail: [email protected]

3D PRINTERS SHOP

- SPAIN

- website: www.

3dprinters-shop.com

3dprinters-shop.com - e-mail: [email protected]

IMAKR

- UK

- website: www.imakr.com

- e-mail: [email protected]

- 2A Triangle Road, Hackney

- London E8 3RP, UK

PRO3D SHOP

- UK

- website: www.pro3dshop.com

- e-mail: [email protected]

CAD CAM CENTER

- UKRAYNA

- website: www.facebook.com/InterdentLAB/

America

PUVAH

- USA

- website: www.puvah.com

- e-mail: contact.

[email protected]

[email protected]

ULTIMATE 3D PRINTING STORE

- USA

- website: www.ultimate3dprintingstore.com

- e-mail: [email protected]

SPOOL 3d CANADA

- CANADA

- website: www.spool3d.ca

- e-mail: [email protected]

DIGITMAKERS

- CANADA

- website: www.digitmakers.ca/

- e-mail: [email protected]

VISION 3D

- ARGENTINA

- website: www.vision3d.tech

- e-mail: [email protected]

FESMO

- BRAZIL

- website: www.

fesmo.com.br

fesmo.com.br - e-mail: [email protected]

Studio 3d Resina

- BRAZIL

- website: @studio3dresina

- e-mail: [email protected]

Ultra Resinas 3D

- BRAZIL

- website: www.ultraresinas3d.com

- e-mail: [email protected]

UNIVERSO 3d

- COLOMBIA

- website: www.u3d.com.co

- e-mail: [email protected]

3dALQUIMISTA

- COLOMBIA

- website: @joyeria.3d

- e-mail: [email protected]

CLV MEXICO

- MEXICO

- website: www.

clvmexico.com

clvmexico.com - e-mail: [email protected]

LUXGOLD

- MEXICO

- website: www.luxgold.com.mx

- e-mail: [email protected]

CREAR4D

- PERU

- website: www.crear4d.com

- e-mail: [email protected]

LAKSMY

- VENEZUELA

- website: @inv.laksmy

- e-mail: [email protected]

Asia

DENTAL EXPERT LTD

- GEORGIA

- website: www.dentalexpert.ge

- e-mail: [email protected]

INFI JEWEL TECH

- INDIA-BANGALORE

- website: www.

infijeweltech.com

infijeweltech.com - e-mail: [email protected]

PCh4D

- INDIA

- website: www.pch4d.com

- e-mail: [email protected]

PROINNOV TEKNOLOGI

- INDONESIA

- website: www.pro-innovtech.com

- e-mail: [email protected]

BEYOND 3D

- ISRAELE

- website: www.beyond3d.co.il

- e-mail: [email protected]

SYSTEMATIC

- ISRAELE

- website: www.systematics.co.il

- e-mail: [email protected]

DENTAL BANK Co.

- JAPAN

- website: www.dentalbank.info

- e-mail: [email protected]

AYARD CORP

- JAPAN

- website: www.shop.ayard.jp

- e-mail: [email protected]

IS LTD

- JAPAN

- website: is-ltd.jp

- e-mail: [email protected]

DR PLAN _ DENTAL LAB

- KOREA

- website: www.facebook.com/doyunlee

- e-mail: [email protected]

3D Equip

- LEBANON

- website: 3dequip.com

- e-mail: sales@3dequip.

com

com

REMAS 3D

- PAKISTAN

- website: facebook.com/remas3d

- e-mail: [email protected]

MAKE IT 3D

- PHILIPPINES

- e-mail: [email protected]

- tel.: +639178980246

CubicSky - 3D Printing Products

- SAUDI ARABIA

- website: www.cubicsky.sa

- e-mail: [email protected]

PROINNOV TEKNOLOGI

- SINGAPORE

- website: www.pro-innovtech.com

- e-mail: [email protected]

IN2REAL3d

- THAILAND

- website: www.

in2real3d.com

in2real3d.com - e-mail: [email protected]

Siam 3d Tech Co. LTD

- THAILAND

- website: www.siam3dtech.com

- e-mail: [email protected]

SYNC

- THAILAND

- website: sync-innovation.com

- e-mail: [email protected]

BlueCast Production FZC

- UAE

- address: Saif Executive Office P8-10-65 _ Sharjah

- e-mail: [email protected]

Australia/Oceania

TOMIDENT

- AUSTRALIA

- website: www.tomident.com

- e-mail: info@tomident.

com

com

Africa

BC MAGHREB

- MAROCCO

- website: www.facebook.com/BlueCast3d/

- e-mail: [email protected]

OBERHOLZER

- SOUTH AFRICA

- website: www.oberholzerbj.co.za

- e-mail: [email protected]

WAX WORX

- SOUTH AFRICA

- website: www.3dwaxworx.co.za

- e-mail: [email protected]

PRODUCTS

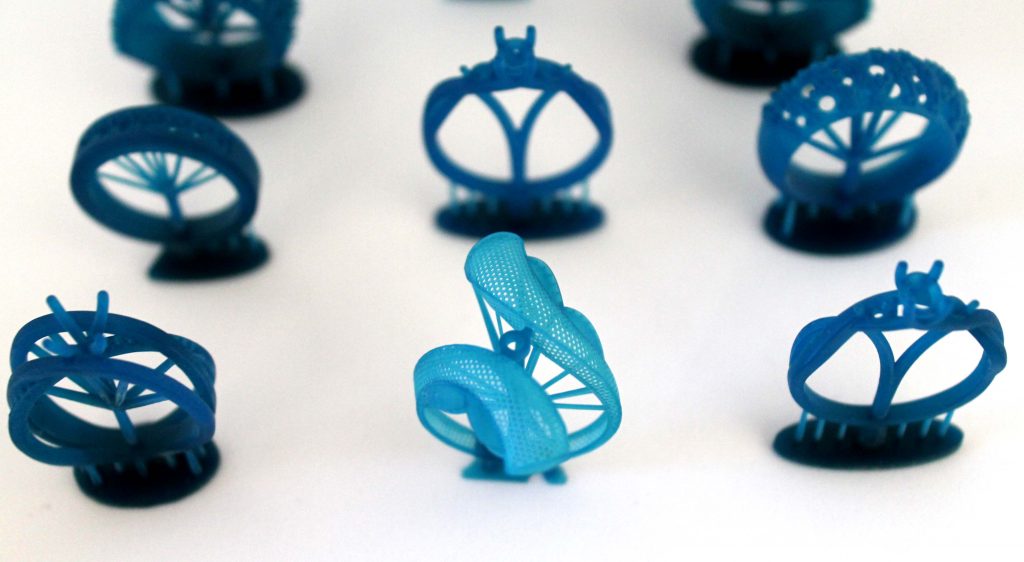

BLUECAST X-FILIGREE

X-Filigree® is the first castable resin developed in accordance with the needs of Middle East designers. Thanks to the polymer it ensures perfect printing properties with sharp details, excellent dimensional stability in time without shrinkage . X-filigree® was developed by BLueCast R&D in order to allow perfect filigree casting results with any kind of investments and burnout cycles. Standard wax burnout (12 hrs), Fast burnout ( 6 hrs), Ultra fast burnout (2 hrs).

X-filigree® was developed by BLueCast R&D in order to allow perfect filigree casting results with any kind of investments and burnout cycles. Standard wax burnout (12 hrs), Fast burnout ( 6 hrs), Ultra fast burnout (2 hrs).

Main features:

- No bleeding

- Excellent dimensional stability in time for all tickness. No shrinkage

- Low viscosity even at low temperature (easier to clean, easier to get back from patterns

- Strong adhesion to platform, no need to primer

BLUECAST ORIGINAL

BC Original is the most famous BlueCast resin. It is 100% ash-free in order to get perfect casting quality in jewelry manufacturing. BC BlueCast is available in different formulation for LCD/DLP and SLA machines and it is suitable for: Academy ring, Big pendent, Chevalier ring, Medals and Coins, Religious gold art, Solid bracelet, Engagement and wedding ring. BlueCast Original “is a Just cast it resin”. BlueCast was the first world castable resin don't need UV curing.

BlueCast Original “is a Just cast it resin”. BlueCast was the first world castable resin don't need UV curing.

Main features:

- Suitable for fast and standard burnout cycle

- Safe for health and no smell

- Developed for the professional jewellery production

- Exceptional weldability with wax sprues as all BC castable resins

- No need for post-curing

BLUECAST LS

BlueCast LS has been developed for filigree jewellery and it makes easier the creation of very light jewelry that is not feasible with traditional rubber molds. It has been formulated for high-details with thin walls and crisp features. LS allows perfect casting quality and this implies necessity of minimum post-process after casting. It works with any type of DLP or LED/LCD 3d printer n SLA machines.

Main features:

- High dimensional stability and low shrinkage

- Suitable for Jewelry and Dental casting

- Compatible with dental burnout cycle and dental investments

- Atoxic, solvent free, very low phospine content, very low skin irritant

- Post-curing needed

BLUECAST X5

BlueCast X5 has been designed in order to help jewelers in realizing difficult models where dimensional accuracy and structural qualities are required. X5 is raw material based on a synthetized oligomer produced by BlueCast, for which patent is going to be applied. Thank to this resin, it is possible reach outstanding direct casting quality with any type of investment. X5 fits all jewelry needs from filigree to medals as well dental ones. Printed parts are strong enough to be handled without post-cure process, allowing for a faster, simpler workflow.

X5 is raw material based on a synthetized oligomer produced by BlueCast, for which patent is going to be applied. Thank to this resin, it is possible reach outstanding direct casting quality with any type of investment. X5 fits all jewelry needs from filigree to medals as well dental ones. Printed parts are strong enough to be handled without post-cure process, allowing for a faster, simpler workflow.

Main features:

- Excellent casting of small engravings both positive and negative

- Fast and detailed

- No expansion during burnout, sublimation starts at 130 Celsius

- Burnout will not release aggressive chemicals to investment (80% of burnout is composed by carbon dioxide and water and oxygen that is used to complete combustion)

- No need of post-curing

BLUECAST X10

BlueCast X10 is the evolution of our well known X5 polymer and it is useful for direct investment casting of jewelry and dental patterns. It is a resin developed to give perfect casting using wax equipment as well normal gypsum bonded investments. An 80% wax-like filled photopolymer for reliable casting with zero ash content and clean burnout, highly accurate resin captures intricate features and offers the smooth surfaces. Its formulation is suitable for jewelry where huge quantity of metal is needed and/or high details are required.

It is a resin developed to give perfect casting using wax equipment as well normal gypsum bonded investments. An 80% wax-like filled photopolymer for reliable casting with zero ash content and clean burnout, highly accurate resin captures intricate features and offers the smooth surfaces. Its formulation is suitable for jewelry where huge quantity of metal is needed and/or high details are required.

Main features:

- Perfect surface, accuracy and print quality

- Less shrinkage – no ash even at lower temperature – improved detail

- Full burnout also at lower temperature (750 C°). The best solution for presetting stone

- Perfect smooth surfaces also for large surface jewelry

- 100% monomer free

- No need for post-curing

CR3A

Cr3a is the entry level castable resin by BlueCast. It is easy printable with all LCD printer and ensure consistent and excellent casting results. Differently from other monomer based resin that requires complex and tricky treatments our BC Crea just requires to be washed after print and cured in to BC CURING LIQUID we supply. No hot water wash required, no boiling, no overnight curing.

It is easy printable with all LCD printer and ensure consistent and excellent casting results. Differently from other monomer based resin that requires complex and tricky treatments our BC Crea just requires to be washed after print and cured in to BC CURING LIQUID we supply. No hot water wash required, no boiling, no overnight curing.

Main features:

- Consistent casting quality as BlueCast standard

- Low cost

- Negligible shrinkage

- No primer needed

- High resolution

- Very low odor

X-VEST

X-Vest is the most advanced synthetic investment for direct casting. Easy as gypsum bonded investment, reliable and performing as phosphatic one. X-Vest consistently provides extreme details and smooth casting surfaces for a variety of materials including standard injection waxes, resin patterns (DLP,SLA) and Hybrid wax / plastic patterns. X-Vest is the only synthetic gypsum based investment for ultrafast burnout and free expansion setting without steel flask.

X-Vest is the only synthetic gypsum based investment for ultrafast burnout and free expansion setting without steel flask.

For more info CLICK HERE

X-ONE

X-One® is the real meltable resin developed and produce by BlueCast® for DLP and Monochromatic LCD machines. Thanks to the low temperature melting polymer it ensures smooth surface finish and perfect lettering. X-One® was developed by BLueCast R&D in order to allow perfect casting results with any kind of investments and burnout cycles. X-One® is the first castable resin with 0% shrinkage and an extreme dimensional stability.

Main features:

- Finally, you can cast in any casting house/service every kind of pattern with text, engravings, micropavè etc.

- Perfect casting results with any kind of investments and burnout cycles. Low temperature burnout compatibility (even if we recommend 750°C last stage, everything is burned out at 680°C).

- Toxic and carcinogenic component free, Low fumes emission during burnout. Very low VOC and negligible smell.

GALLERY

CASTING / DESIGN SERVICE

We offer to our VIP customers precious metal casting service. We provide solutions for designers and companies, offering a customized, efficient and dedicated service. We are proud to guide and advise throughout the process so that partners receive an accurate product with satisfaction warranty. We work with the best casting materials on the market, in order to get the best finishing. We offer our castings in full range of metals: Yellow Gold - 9ct, 14ct, 18ct, White Gold - 9ct, 18ct, Silver 925, Brass or Bronze, Platinum, Palladium.

Our designers and CAD Technicians are also at disposal of sleek customers to create customized design. It is possible to modify existing designs, create a new model from a sketch or work with the client to create something completely new. The service includes consultation and advice, CAD drawings, creation of a resin model, casting in precious metal.

The service includes consultation and advice, CAD drawings, creation of a resin model, casting in precious metal.

BlueCast X-One - Castable resin - FEPshop

€140,59 DE VAT incl. 19%

Shipping today

BlueCast X-One - Castable resin quantity

SKU: 88597

- Product description

- Product specifications

- Downloads

- The first castable resin developed for the new LCD monochromatic generation and DLP printers.

- Perfect casting results with any kind of investments and burnout cycles. Low temperature burnout compatibility (even if we recommend 750°C last stage, everything is burned out at 680°C)

- Low temperature melting polymer ensures smooth surface finish and perfect lettering.

- Extreme accuracy and exceptional detail without shrinkage.

- No bleeding issue also on LCD machines.

- The first real meltable resin at low temperature.

- Excellent dimensional stability in time. No shrinkage (natural shrinkage will be compensated during print making polymer expand chemically).

- Low viscosity (easier to clean, easier to get back from patterns).

- Strong adhesion to platform (adhesion layers are exposure layers x4 or even x3), no need to primer.

- Toxic and carcinogenic component free, Low fumes emission during burnout. Very low VOC and negligible smell.

- Low fumes emission during burnout

- Finally, you can cast in any casting house/service every kind of pattern with text, engravings, micropavè etc.

- You can choice for chemical postcuring (longer washing in alcohol make a chemical reaction with X-One) or for traditional washing and UV oven postcuring. After chemical postcuring the color resin change from dark green to gray/white to permit you to check if the procedure was correct

- Compatible with most (Mono) LCD and DLP 3D printers

- Castable: Yes

- Castability: Extreme

- Before buy please check the printers compatibility.

- Washing mode and postcuring: Please check the Video tutorial.

- UV care: Not needed

- Shrinkage: Negligible

- Color: Dark green - White after curing

- Size: 500 gr

https://youtu.be/RNiUPQmUR4Y

NOTES:

- The resin is in dark green color but after post-processing, the models get light grey/white color

- Use Ethyl alcohol.

- Most (mono) LCD & DLP 3D printers like Wanhao, Elegoo, Anycubic, Epax, Zortrax, Prusa, Phrozen.

| Brand | BlueCast |

|---|---|

| Color | Green |

| Package Size | 0.5 KG |

| Product State | New |

| Material Group | UV Resin |

| Country Of Origin | Italy |

| External stock | Available in 1 to 2 weeks |

| Resin Wavelength (nm) | 405 |

| Material Types | Resins |

| Material Properties | Castable |

| Resin for | DLP, LCD, Mono LCD |

| Product application | Jewelry |

Product summary

| SKU | 88597 |

|---|---|

| Brand | BlueCast |

Product downloads

photopolymer Bluecast X One - Little Resin for Monochrome LCD 3D printers

Reviews

Subscribe to

Subscribe

Italian manufacturer - BlueCast X One.

- BlueCast X One - 0% ash content

- BlueCast X One melts and flows out of the mold like regular wax

- Melting point of BlueCast X One less than 300°C (recommended maximum shelf is 750°C, but will perform well even at 680°C)

- Excellent dimensional stability over time, no shrinkage extension)

- Free of toxic and carcinogenic ingredients

- Low smoke on burn-in

- BlueCast X One does not require primer (great adhesion to platform)

- BlueCast X One does not need any additives (excellent detail)

- Models can be cast by any foundry without any special preparation

BlueCast X-One resin is fully compatible with the new generation of monochrome LCD printers:

- Anycubic Photon Mono

- Anycubic Photon Mono X

- Anycubic Photon Mono SE

- Elegoo Mars 2 Pro (Mono)

- Elegoo Saturn Mono 4K

- Wanhao Duplicator 11 (Mono 4k)

Older generation RGB LCD printers will have much longer exposure times than base resins, making this resin almost impractical for older technology printers.

The manufacturer gives some recommendations for obtaining maximum detail:

It is recommended to use high quality FEP film. Poor quality FEP film greatly reduces print quality on this resin.

Before starting the Z-axis calibration, make sure that the printer platform is not painted, that is, it does not have a color coating, like the first models of Anycubic Photon or Elegoo Mars. This coating prevents the photopolymer from sticking. To fix this problem, you can sand it down with 150/200 sandpaper. Then calibrate the Z axis according to the manufacturer's instructions.

Due to the low temperature meltable polymer used, the resin hardens below 18°C, so heat the resin to 25 to 40°C before use. Best operating range is 20 to 30°C. BlueCast X One will remain liquid above 18°C.

Shake the bottle for one to two minutes before pouring resin into the resin tank. Then, to remove bubbles, let the resin sit in the resin tank for 5 minutes before printing. To speed up this process, you can filter the resin to remove air bubbles.

Due to the low melting point of the polymer, the supports must be larger than usual. You can design a gate in your model and use it as the main support. Never use contact points smaller than 0.4mm and try to support the shaft of the rings.

After each print, drain the resin tank from the printer, filter it and store it in the original bottle.

This resin prints are more brittle than other BlueCast resins, especially filigree and serrations. Handle it with care. Models are moderately softer, because the resin contains wax inside. Wash prints in 99% alcohol. If using a washer and dryer, run an 8/10 minute cycle. If rinsing by immersion in an alcohol bath, place the model for 12 minutes. After washing, dry the model with compressed air. The color of the resin will begin to change from dark gray to light gray/white. The more white the model becomes, the better the casting will be. If you don't have compressed air, you can dry the model with a hair dryer, but it will take longer to bleach.

The bleaching time of the resin is highly dependent on the alcohol used: the lower the quality of the alcohol or it has been used many times, the longer it will take. After rinsing, you need to give the alcohol time to evaporate before continuing to work.

Post-curing may speed up the evaporation of the alcohol and make the print harder. If you want to avoid a lengthy bleaching procedure, you can rinse the model quickly (maximum 1 minute), but then post-curing of the resin is required (minimum 15 minutes).

The first delivery of BlueCast X One resin to Russia is expected in early April 2021. The first batch will be in limited quantities, but pre-order is already available in our online store.

More interesting articles

3

Subscribe to the author

Subscribe

Don't want

Hi all printers, today I have a Chinese printer with two separate extruders on my desk (I. ..

..

Read more

3

Subscribe to the author

Subscribe

Don't want

Hello dear! If someone had told me half a year ago that I would buy myself a whale...

Read more

90

Subscribe to the author

Subscribe

Don't want

This post will cover the whole path from the idea of buying a 3D printer to the development of useful ...

Read more

Who creates the best work as a 3D printer client?・Cults

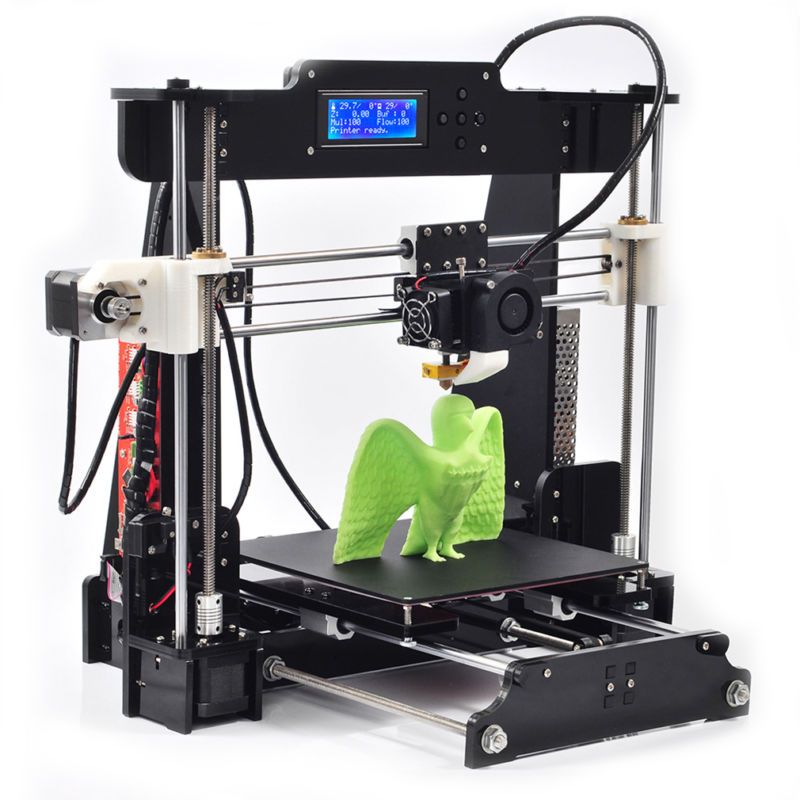

The BLU-5 is one of the most affordable desktop 3D printers we've ever made. It offers the largest print area of any TwoTrees 3D printer, the most consistent performance, and is suitable for users of all skill levels.

Its all-metal base and frame provide durable performance. Simple, elegant design combined with outstanding performance makes the BLU-5 a toy for DIY enthusiasts, as well as a professional printing machine for designers and factories.

Here is a video review made by Aurora Tech, you can search for other video reviews of the BLU-5 printer on Youtube (formerly known as BLUER Plus).

90% pre-assembled, easy to install

BLU-5 comes with 90% pre-assembled parts that require minimal installation. Most installations can be easily done with hex wrenches.

To ensure that users receive devices without printing problems, each device is assembled for a 3D cube printing test prior to shipment. Few factories test the print before shipping as it is time consuming and labor intensive.

90% Finished Desktop 3D Printer

Smart 3D Touch Sensor and Auto Leveling

The BLU-5 also has a built-in 3D touch sensor that allows the printer to check if the build platform is level and apply if necessary. adjustments.

adjustments.

After checking that each part is installed correctly, alignment is recommended and required before printing. The alignment and leveling function in Tool Settings (on the touch screen) allows you to move the nozzle and 3D touch sensor around multiple points and register the position of each one. If the distance between the dot, nozzle and print bed differs from other dots, the software automatically starts the alignment process.

Built-in 3D touch sensor

Large print area for more options

Compared to other TwoTrees consumer 3D printers, BLU-5 is the largest 3D printer with 300*300*400mm print area. It is also one of the best large-scale 3D printers available in the consumer market. The print size of 300*300*400mm provides enough space for most DIY projects and allows users to complete printing of multiple models in one print. If you're not sure what size you need, the BLU-5 is a good budget option if you take everything into account.

Large 3D Printer

Patent Development: Automatic Space Adjustment Function

The basic working principle of FDM 3D printing requires that the print head and print bed move in sync with the design file. Since 3D printing is extremely demanding on precision, any imperceptible defect can cause the print to fail or become distorted.

Patented auto-spacer kit with spring kits greatly reduces motion-induced vibration for high precision and smooth printing.

Auto interval function

Quiet operation: TMC2209 mute driver

One of the main disadvantages of using FDM 3D printers is annoying noise.

TMC2209 mute driver reduces running motor noise and makes 3D printing an enjoyable experience.

Dual Z-Axis and Synchronous Belt

Instead of a single Z-axis lead screw, the BLU-5 uses two lead screws with a synchronous belt for smoother movement and faster response.

This unique setting effectively reduces vibration and improves print accuracy and speed.

Z-Axis Dual Guide Screws

Transparent Dual Stage Extruder

Compared to single stage 3D printers, the BLU-5 uses dual stage extruders to provide greater stretching force to achieve more stable and smooth extrusion.

Transparent housing allows users to observe and control the entire process with the naked eye.

Packed PEI greenhouse

Although the PEI greenhouse is a basic accessory for 3D printers, users usually have to pay extra for it from most vendors.

To provide users with a print-ready desktop 3D printer, a PEI greenhouse is included with the BLU-5 printers.

Thanks to the resilient and wear-resistant surface, you can easily remove printed designs.

RJ45 jack

Instead of using other jacks, the BLU-5 uses the common RJ45 interface for connection, which is much more readily available in local stores and easier for users to find replacements on demand.

RJ45 is also more reliable and efficient in signal transmission.

RJ45 socket

Filament exhaustion detection and printing resume function when power is on

It is quite normal when filaments run out during printing, and restarting wastes a lot of time and money on filaments. To solve this problem, all TwoTrees 3D printers are equipped with an intelligent low filament sensor and a restart function.

Whether printing is interrupted due to a power failure or a broken filament, the printer will resume printing at the exact layer or position where it left off.

Thread flow detection

- X and Y belt tensioner allows users to make proper adjustments without the need for additional tools.

- Removable motherboard service cover makes motherboard replacement much more convenient.

- The 4.3-inch touch screen control panel provides a clear, simple interface and fast response to every touch.

- All-metal base and frame make the 3D printing machine strong and durable for long-term use.

Click to use promo code

(coupon code automatically added at checkout).

Established in 2017 as a manufacturer of 3D printer accessories, TwoTrees is fast becoming one of the most trusted companies in the world in developing, manufacturing and marketing desktop FDM 3D printers. In addition, TwoTrees is the pioneer of self-developed laser engraving machines in China. Today, our business includes FDM 3D printers, filaments, resins, as well as laser engraving machines and related accessories that have a global reach.

With R&D teams and a dedicated experimental studio, we promise to always maintain a customer-oriented concept to provide more cost-effective innovative products.

TwoTrees is pursuing its growth strategy as a highly dynamic company that expects continuous growth.

This page has been translated using machine translation.