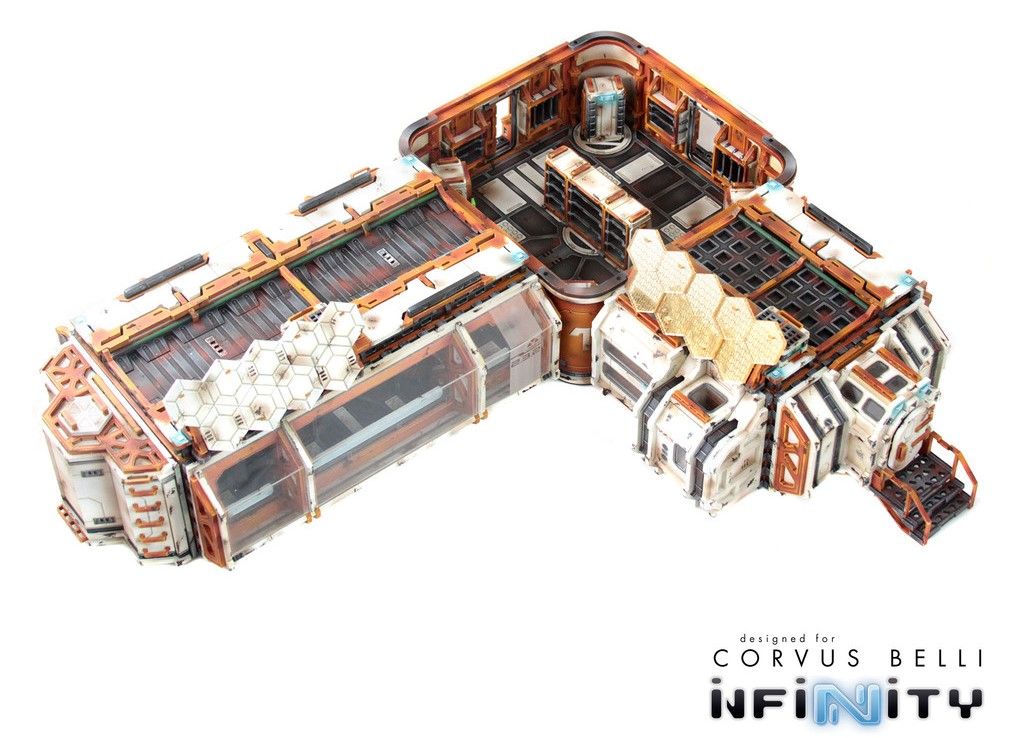

3D printed infinity terrain

Corvus Games 3D Wargaming Terrain Digital STL Files – Tagged "infinity"– Corvus Games Terrain

Skip to contentDownloadable 3D wargaming terrain STL digital files of our models for you to print on your own 3D printer. Print as many copies as you like. Perfect for Warhammer 40K, Kill Team, Gaslands, Marvel Crisis Protocol, Space Hulk, Necromunda, Infinity, and Star Wars Legion.

85 products

85 products

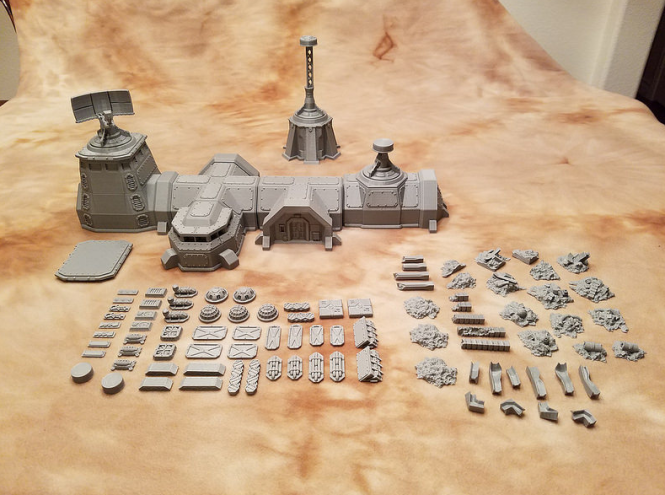

Sci-fi Splinter's Edge Mining Outpost Digital STL 3D Printable

€10.00

Sci-fi Modular Floor Tiles Addons Digital STL 3D printable

€8.00

Sale

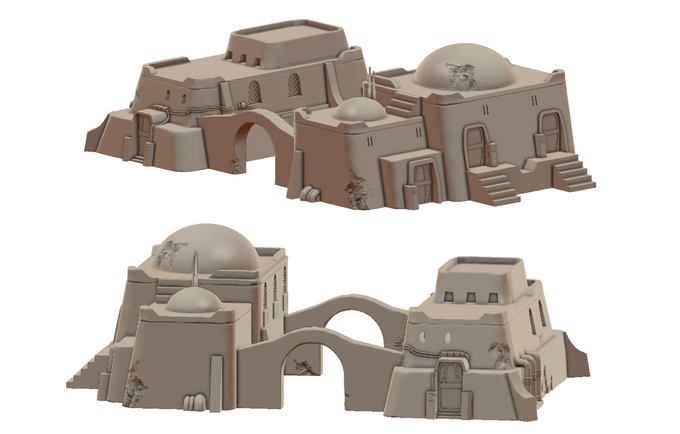

Sci-fi Atreus Settlement Bundle Digital STL 3D Printable

Regular price €72.00 Sale price€55.00 Save €17.00

Sci-fi Transmat Array Digital STL 3D Printable

€5.00

UnderNidus Container Shanty Village Buildings Digital STL 3D printable

€8. 00

Sci-fi Atreus Settlement Water Fountain Digital STL 3D Printable

€6.00

Sci-fi Atreus Settlement House 'A' Digital STL 3D Printable

€8.00

Sci-fi Atreus Settlement Market Building 'A' Digital STL 3D Printable

€8.00

Sci-fi Atreus Settlement Nobles House Digital STL 3D Printable

€13.00

Sci-fi Atreus Settlement Pavilion Digital STL 3D Printable

€6.00

Sci-fi Atreus Settlement Archway Bridge Digital STL 3D Printable

€11.00

Sci-fi Atreus Settlement Temple Tower Digital STL 3D Printable

€9.00

Sci-fi Atreus Settlement Goverment Building Digital STL 3D Printable

€11.00

Cyberpunk Monorail Digital STL 3D printable

€9.00

Cyberpunk Garbage Truck Vehicle Digital STL 3D printable

€7.00

Infinity Continuum Miniatures Bases Digital STL 3D printable

€7. 00

00

Cyberpunk Chatsubo Building Digital STL 3D printable

€7.00

Sale

MidRim City Phase 2 Bundle Digital STL 3D printable

Regular price €33.50 Sale price€24.00 Save €9.50

MidRim City Parlor Bar Digital STL 3D Printable

€8.00

Sci-fi W1Va Repulsor Bikes Digital STL 3D printable

€6.00

Sci-fi Mumhan Industrial Miniatures Bases Digital STL 3D printable

€6.00

Sci-fi Modular Urban Ground Tiles Digital STL 3D printable

€8.00

Sci-fi HoverBotz STL 3D printable

€6.00

Sci-fi Junk Piles Scatter Digital STL 3D printable

€8.00

Builder's Greebles Pack '3' Digital STL 3D printable

€4.00

Sci-fi Uladh Starport Buildings Bundle Digital STL 3D printable

€19.00

Sci-fi Uladh Starport Miniatures Bases Digital STL 3D printable

€6. 00

00

Infinity City Miniatures Bases Digital STL 3D printable

€7.00

OBJ file Infinity Terrain・3D printable design to download・Cults

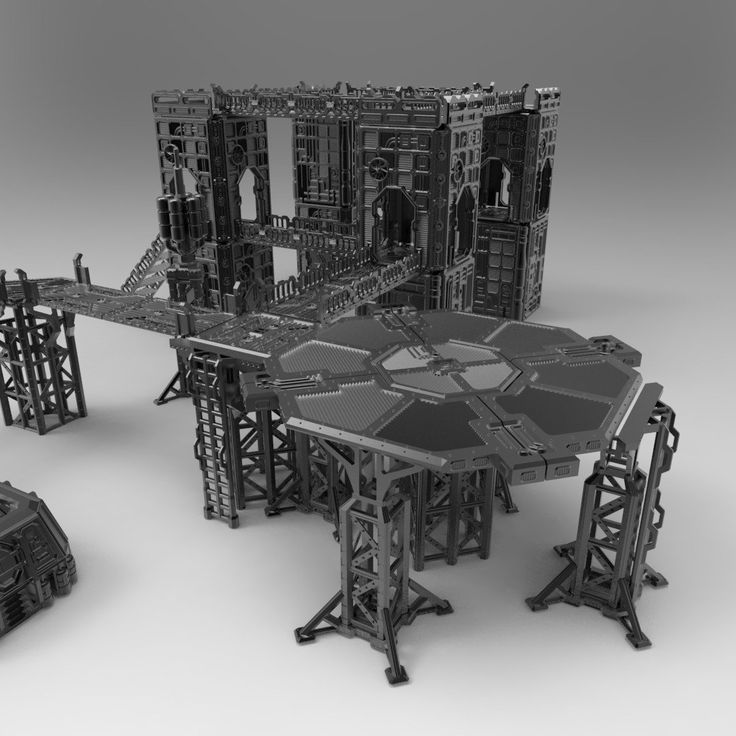

Necromunda terrain compatible with OpenLOCK

€15

furniture for mansion of madness

€5

terrain futuristic warhammer 40k

€5

circular bases 28mm

€3

28mm circular bases

€3

Column destroyed

€3

cryogenic capsule

€3

fences futuristic apocalypse

€3

Best 3D printer files of the Game category

Sleepy Cat toy

€2. 82

82

FAT ROOK BOX M

Free

Playmobil table leg

Free

Lao Hiho it2

€5

TRAIN STATION for BRIO wooden railway

€0.99

SWITCH CARTRIDGE CASE

€2.10

Pascal from Animal Crossing

Free

Model-T Bomber

€78

Best sellers of the category Game

Iron Legionnaires: Security Detail

€15

Lazy Cat

€3.76

Cenobite Catafrac Destroyers

€12.66

Dirt Bike

€1. 40

40

Nice Flexi Dragon

€1.77

Octopus 2.0

€3.76

Your Pal, Cappin' Corey Swain

€4.01

Space She-Hulk Interior - Action Boarding and Killer Team Terrain

€9.43

Articulated Dragon

€3.76

Voidwalker Exosuits Truescale

€14.85

RC 1/10 Dodge Challenger

€7.50

Vurgalis

€11.31

SPACE BUGS NICOLETTI

€30

UPSCALED rivet armor fire squad - fully posed

€12.50

Derelict damaged space ship compatible Murder team or small corridor games

€13. 92

92

Heavy Armored Thicc Boi of Brutality

€12.61

💖 Would you like to support Cults?

You like Cults and you want to help us continue the adventure independently? Please note that we are a small team of 3 people, therefore it is very simple to support us to maintain the activity and create future developments. Here are 4 solutions accessible to all:

ADVERTISING: Disable your banner blocker (AdBlock, …) and click on our banner ads.

AFFILIATION: Make your purchases online by clicking on our affiliate links here Amazon.

DONATE: If you want, you can make a donation via Ko-Fi 💜.

WORD OF MOUTH: Invite your friends to come, discover the platform and the magnificent 3D files shared by the community!

Construction 3D printing is waiting for a breakthrough The first construction projects using this technology appeared only in 2014.

We are talking, first of all, about the so-called small architectural forms (benches, flower beds, fences). They never even dreamed about building houses. But already in 2015, the Russian startup Apis Cor made a splash - it printed a whole house in the Moscow region. Since then, news about new 3D printed houses has periodically appeared. However, despite the fact that the technology proved to be very promising in terms of the speed of construction of housing and the reduction in the cost of construction, no mass implementation followed.

We are talking, first of all, about the so-called small architectural forms (benches, flower beds, fences). They never even dreamed about building houses. But already in 2015, the Russian startup Apis Cor made a splash - it printed a whole house in the Moscow region. Since then, news about new 3D printed houses has periodically appeared. However, despite the fact that the technology proved to be very promising in terms of the speed of construction of housing and the reduction in the cost of construction, no mass implementation followed. Construction is the world's number one market. And, if many technological innovations are being introduced in the field of high-rise construction, then little has changed in the field of low-rise construction over the past decades. The last 30 years have seen the availability of the Internet, mobile phones, mobile internet, robotics taken to a new level, etc., but when you get to a house construction site, you are unlikely to find many technological innovations. Automation is practically non-existent, and manual labor prevails. 2020 was a test of strength for the whole world, and also led to the highest level of inflation, which, first of all, hit the construction market, there was a dramatic change in prices for metals, cement, wood and much more.

Automation is practically non-existent, and manual labor prevails. 2020 was a test of strength for the whole world, and also led to the highest level of inflation, which, first of all, hit the construction market, there was a dramatic change in prices for metals, cement, wood and much more.

This Internet meme shows what happened to the cost of building materials in just a year. And the process is still going on. At the same time, there is a serious rise in the cost of labor, and there is an acute shortage of it. All this leads to a sharp rise in the cost of building houses. No matter how strange it may sound, statistics show that the growth of automation does not occur when everything is fine, but precisely in crisis situations, during increased competition, reduced demand and the need to urgently look for new technologies to increase production efficiency. So it happened this time, and after some stagnation, construction 3D printing received a new impetus for development.

Preparing to write an article, I turned to the founder of Arkon - Boris Kozlov y. Arkon was established in 2020 and is engaged in the production of construction 3D printers, both a workshop type for creating prefabs (prefabricated houses) and a portal one capable of printing a two-story house. I asked Boris the key, in my opinion, question:

Arkon was established in 2020 and is engaged in the production of construction 3D printers, both a workshop type for creating prefabs (prefabricated houses) and a portal one capable of printing a two-story house. I asked Boris the key, in my opinion, question:

- Construction 3D printing appeared in 2014, but no mass introduction of this technology followed in 7-8 years. Why do you think this happened, and why is there a surge of new projects right now?

- It seems to me that the reason is the snowball effect. The technology had to mature, grow from a hypothesis to a pilot implementation, and finally to commercialization and scaling (what is happening now). In addition, it should be borne in mind that construction is one of the most conservative industries, where, unlike even aviation and the automotive industry, there is still an extremely low introduction of digital solutions and automation in the field of the production process itself - the construction itself.

The issue of regulation and certification also plays an important role - this process is long and creates an additional lag.

In 2014-2016 the first samples of building 3D printers and prototypes of printed buildings appeared. The concepts of various form factors of construction 3D printers and types of printing materials were tested.

In 2017-2018 in the world, the first notable investments were made in a number of construction 3D printing start-ups. Further, by 2020, these investments "rolled" in the form of reaching a certain level of technology maturity - the first commercial products (3D printers and houses) appeared.

Finally, in 2020-2022 it became clear that the hypotheses of the effectiveness of construction 3D printing were justified (cheaper, faster, more environmentally friendly), and large investments began in the industry. A striking example is the investment of GE (the French division of General Electric) in the Danish COBOD or the achievement of a capitalization of $ 2 billion by the American company ICON.

In 2022-2023 over 1,000 buildings will be printed worldwide already, scaling from single buildings/pilot projects to entire villages and major infrastructure/reinforced concrete implementations. In addition, in a number of countries, by now, a regulatory framework has been created or is being actively created for the introduction of additive technologies in the construction industry.

Thus, I believe that the specified time period is a fairly natural cycle of technology development, which is likely to experience exponential growth in the next decade.

According to ResearchAndMarket report, the global construction 3D printing market is valued at USD 354.3 million in 2022 and is projected to reach USD 11068.1 million by 2027, growing by 99.04%.

Various market processes affect the prices and behavior of participants in the global 3D construction printing market. They create price signals that are the result of changes in the demand and supply curves for a product or service. They can be associated with both macroeconomic and microeconomic factors. Even human emotions can also drive decisions, influence the market, and create price signals.

They can be associated with both macroeconomic and microeconomic factors. Even human emotions can also drive decisions, influence the market, and create price signals.

Now let's take a quick look at what the construction 3D printer is. Without delving too deeply into the technology, we can say that construction 3D printers are very similar to classic FDM/FFF printers that print with plastic, but instead of plastic, the material here is a cement mixture, which is fed directly into the nozzle and forms an object by layer-by-layer overlay. Printers are also portal, on the basis of a flying boom, with a robotic arm.

Pictured left is a construction printer based on a boom. The figure on the right is a gantry construction 3D printer

In the figure above, a construction 3D printer in the form of a robot arm installed on a mobile platform.

Everything changed completely when, in the summer of 2021, the American company ICON, which was trying to introduce 3D printing into the construction of various auxiliary facilities, signed a contract with one of the largest American developers, Lennar, to build a village of 100 houses in Texas and immediately became a unicorn , having received 200 million dollars of investments from several investment funds.

At the same time, the Danish company COBOD, created by the world's largest construction formwork company PERRI, began selling its gantry 3D construction printers and participating in construction projects around the world. In the photo below, a modern two-story house built in Germany and a school building in Malawi, built in record time with a minimal budget.

Few things unite developed, developing and poor countries, everywhere their problems and tasks, but Affordable housing shortage is a global agenda . If in poor countries there is an acute problem with the increase in the number of homeless people due to a lack of housing, as such, then in developing countries it is necessary to dramatically accelerate the number of new housing being built to meet the needs of a growing population. In developed countries, the problem is primarily in the cost of housing, which has risen in price to such an extent that it has become practically inaccessible to young people. And with the simultaneous increase in life expectancy in these countries, this problem is only getting worse.

And with the simultaneous increase in life expectancy in these countries, this problem is only getting worse.

At the same time, the trend towards "green agenda " is developing, reducing CO2 emissions, building with more environmentally friendly materials, etc. But, unfortunately, so far the construction industry is the absolute leader in CO2 emissions, as well as in the amount of garbage that each construction site leaves behind. This is not to say that construction 3D printing solves all these problems, but at least it is moving in the right direction. Let's look at this with a few illustrative examples.

3D printed walls. Today, when we talk about 3D printing houses, we are talking about printing walls. Everything else (foundation, windows, doors, ceilings and roof) is done in the traditional way. 3D printed walls are built as fixed formwork, which significantly saves the amount of cement used , and this, in turn, reduces the cost of construction and reduces the environmental impact of cement production. In addition, with this method of construction, no additional waste is produced, the strength of the structure does not suffer. It can be reinforced, as shown in the photo on the left, and engineering communications can be immediately laid, as shown in the photo on the right, which also affects the final speed of the construction of the object. At the same time, the total weight of the structure is reduced, the remaining cavities can be filled with lightweight foam concrete, insulation, straw or any other available material. Such a lightweight design can use a lighter foundation. The construction method itself is more economical in terms of material, and therefore environmentally friendly.

In addition, with this method of construction, no additional waste is produced, the strength of the structure does not suffer. It can be reinforced, as shown in the photo on the left, and engineering communications can be immediately laid, as shown in the photo on the right, which also affects the final speed of the construction of the object. At the same time, the total weight of the structure is reduced, the remaining cavities can be filled with lightweight foam concrete, insulation, straw or any other available material. Such a lightweight design can use a lighter foundation. The construction method itself is more economical in terms of material, and therefore environmentally friendly.

Eco-concrete with the addition of polymers is being actively developed, the production of which reduces CO2 emissions from 30% to 100%. The Apis Cor company mentioned at the beginning of the article, which built a house in the suburbs in 2015, is now based in hot Florida, plans to start using this material in its projects.

Another startup from Russia, Mighty Buildings, headquartered in California, initially relied on a polymer with the addition of mineral chips. And while the company doesn't build entire homes, it only makes wall panels, it has won numerous design awards, as well as a $400 million valuation in several investment rounds.

As a result, with a rough calculation, we can say that the total savings on the construction of walls can reach 30%, and the total cost of the house can be reduced by 10%. This is true for houses designed for conventional construction. And if you initially design with 3D printing, you can improve this ratio by optimizing the laying of communications, the ability to immediately print interior walls, bookmark niches for bathrooms, fireplaces, built-in wardrobes and kitchens, as was done in the house built by COBOD in Germany.

"There are spots on the sun." Despite all the advantages of construction 3D printing, has several significant disadvantages of . The main one is layering, which cannot be avoided at the current level of technology development.

The main one is layering, which cannot be avoided at the current level of technology development.

The photo above shows the layering of the 3D printed walls.

This task can be worked in several directions:

-

Ribbed walls can be plastered, painted and played with as a design element. That's how ICON does it in the US, for example their latest project House Zero is done that way and has won a number of design awards.

-

Use special "shutters" on the print head that allow smooth layers, as COBOD and other manufacturers do. The photo below shows that this does not ensure the complete absence of layering.

-

Fully sand the surface to get the usual smooth wall for plastering, painting, wallpapering or other finishing. It is possible, but it will require huge labor costs, which can reduce the overall efficiency of using 3D printing.

Pictured above is a 3D printed wall sanded smooth.

The second problem is the required temperature. Ideally, printing should take place at temperatures between +5C° and +30C°. Humidity is also important. Using additives, you can push these boundaries, but not indefinitely. At strong sub-zero temperatures, printing will be possible in the field only if the construction site is covered with a dome and the required temperature is reached inside with the help of heat guns. In conditions of intense heat, it is preferable to print at night. Another solution could be to print the wall panels in the shop and assemble them on site. Of course, each of these decisions will have a negative impact on the economic efficiency of the project.

Building 3D printing can be useful not only for the construction of houses . With its help, you can solve many other problems, and there its disadvantages will not matter. For example, the American concern GE uses COBOD printers to build towers for wind turbines in the shop. Ribbed surface and temperature restrictions in this case do not play any role. Construction takes place in the shop, after which the object is transported to the installation site.

Construction 3D printing, or, as it is also called, additive construction, has just appeared, and I want to believe in its bright future. There are many prerequisites for this, but a lot still needs to be done for success. First of all, it is necessary to develop principles for designing houses for building 3D printing. Then it is necessary to attract top architects to create landmark projects, which can be followed by the mass introduction of a new and very promising technology. Construction 3D printing could help solve the global housing shortage and bring more automation to other areas of construction.

Alexander Kornveits

Expert in the field of additive technologies and 3D printing, head of Tsvetnoy Mir company

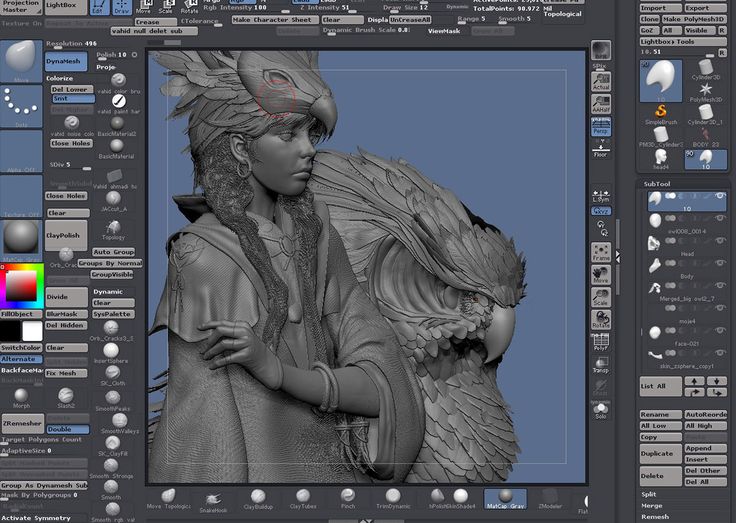

3D printer for an architect and designer, pros and cons, examples of use

3D technologies are becoming good helpers in various fields. In architecture and design, 3D printers are successfully used mainly to create architectural models.

Illuminated layout

Architectural layouts can be divided into several types:

Layouts can be used for a variety of purposes:

-

Visualization for buyers or to coordinate the project with the client. Many customers find it much more difficult to perceive a digital layout of a building or interior. 3D printing allows you to quickly and inexpensively produce, for example, a miniature apartment model with a furniture model. The client himself will be able to visually see a variety of interior options and choose the one he likes the most.

-

Project presentation. A presentation with a beautiful layout looks much more colorful and effective, for example, a building or an entire microdistrict. But making an architectural model in the classical way is a long and painstaking, often manual, work.

What if you need multiple layouts? A 3D printer can significantly speed up and reduce the cost of production of a layout.

The cost of the layout depends on several factors - this is the complexity of manufacturing and artistic value. The use of a 3D printer allows you to speed up and significantly simplify the production of complex and simple layouts. For example, making a layout of modern buildings with non-linear geometry becomes a real headache for layout designers. 3D printing allows you to quickly and accurately reproduce an exact copy of any building, regardless of its geometry.

Building layout with non-linear geometry

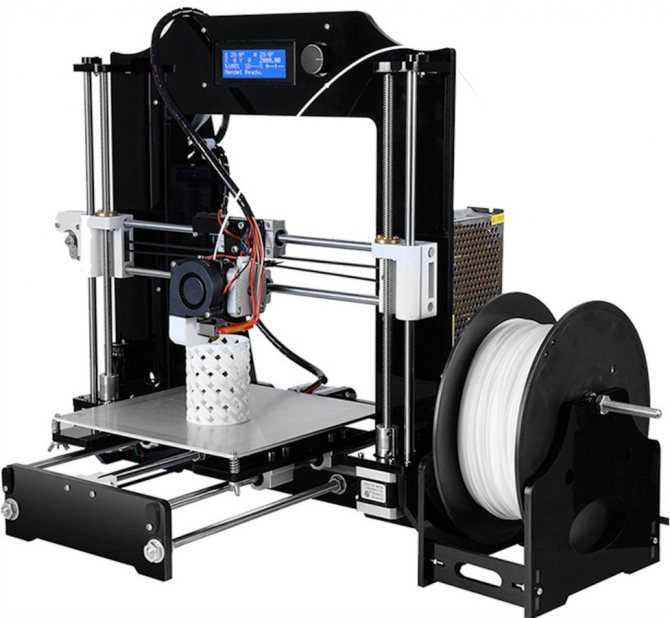

FDM printers for architecture and design

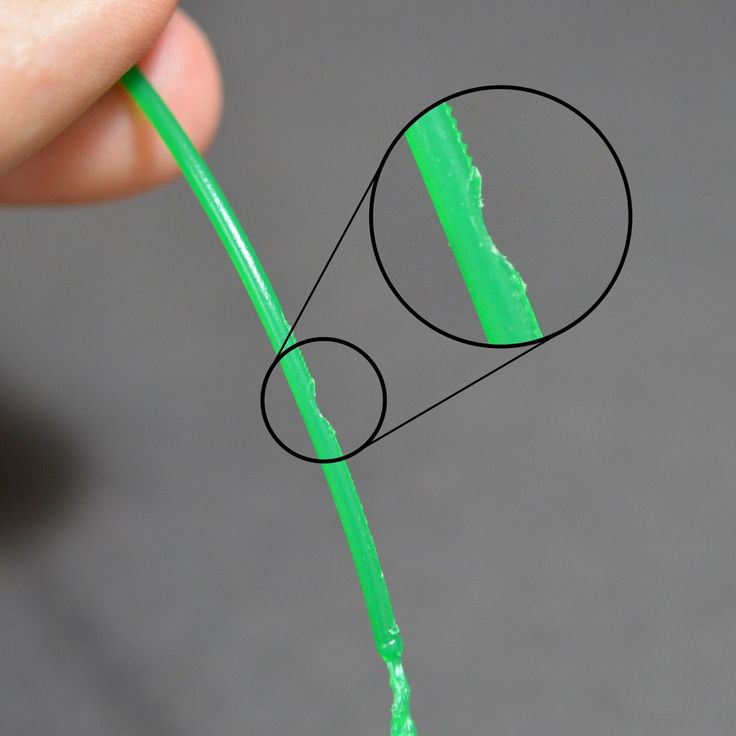

FDM is a technology for layer-by-layer deposition of plastic to obtain a physical model. As a consumable material, a plastic thread is used - a filament.

FDM printers are very popular due to their large working area, printing speed and inexpensive consumables.

The choice of printer model depends on what needs to be produced. Some devices are poorly designed to work with some engineering plastics.

Pluses and minuses

pros

Models of 3D printers appeared with an “infinite” printable area along one of the axes. These printers use a conveyor belt instead of a printtable. Such printers are suitable for mass production.

For the manufacture of simple layouts, you can give preference to models with a single extruder. But if a 3D printer is required to solve a variety of tasks, then models with two extruders and a closed chamber should be preferred. Such devices are universal and can print on almost any material.

Minuses

Application and printing examples

Model of the city of Astana. Production took 1 month.

Building kit

Prefabricated house model

Layout San Francisco

Furniture and interior elements made on a 3D printer

Layout of the floor of the building for arranging furniture

Printer Rating

CreatBot D600 Pro

CreatBot D600 Pro

Features:

Print technology: FDM/FFF

Workspace size: 600x600x600

Number of extruders: 2

Max. extruder temperature: 420 degrees

Closed Camera: Yes

Heated table: Yes

Plastic type: ABS, ABS+, PLA, PLA+, PETG, Flex, Nylon (Nylon), ASA, Carbon, PEEK, Decorative plastics, others

CreatBot D600 Pro is a professional device that has many options that will be useful not only for a beginner, but also for an experienced user. Two extruders with a high heating temperature and a closed chamber allow you to print on all available types of plastics. And automatic table calibration using the BL-Touch sensor eliminates the need to level the table plane.

Raise3D E2

Raise3D E2

Features:

Print technology: FDM/FFF

Working area size: 330 * 240 * 240 mm - when printing with the 1st extruder

295x240x240 mm - when printing with 2 extruders

Number of extruders: 2

Max. extruder temperature: 300 degrees

Closed Camera: Yes

Heated table: Yes

Plastic type: ABS, ABS+, PLA, PLA+, PETG, Flex, Nylon (Nylon), ASA, Carbon, Decorative plastics, others

Raise3D E2 is a small device with unusual kinematics. Raise3D E2 has two independent extruders that allow the printer to work in several modes:

In addition, Raise3D E2 is equipped with a convenient touch screen, automatic table calibration, an assistant for calibrating the height of extruders relative to each other and other nice features that do not affect the final print, but make working with the printer easier and more comfortable.

Raise3D Pro2 and Pro2 Plus

Raise3D Pro2 left and Pro2 Plus right

Features:

Print technology: FDM/FFF

Stage size: Raise3D Pro2

305x305x300 mm - when printing with the 1st extruder;

280x305x300 mm - when printing with 2 extruders

Raise3D Pro2 Plus 305x305x605 mm - when printing with the 1st extruder;

280x305x605 mm - when printing with 2 extruders

Number of extruders: 2

Max. extruder temperature: 300 degrees

Closed Camera: Yes

Heated table: Yes

Plastic type: ABS, ABS+, PLA, PLA+, PETG, Flex, Nylon (Nylon), ASA, Carbon, Decorative plastics, others

As you can see from the specifications, the only difference between Raise3D Pro2 and Pro2 Plus is the size of the workspace in height. Pro2 Plus has twice as much.

The Raise3D Pro2 series has proven itself in various fields. These are reliable workhorses with a set of all the necessary options for high-quality printing, and the presence of two extruders allows you to make models of any complexity.

PICASO 3D Designer XL Pro

PICASO 3D Designer XL Pro

Characteristics:

Print technology: FDM/FFF

Working area size: 360 x 360 x 610 mm

Number of extruders: 2

Max. extruder temperature: 410 degrees

Closed Camera: Yes

Heated table: Yes

Plastic type: ABS, ABS+, PLA, PLA+, PETG, Flex, Nylon (Nylon), ASA, Carbon, PEEK, PC, Decorative plastics, others

PICASO 3D Designer XL Pro is a Russian-made professional printer with an enlarged working area. Designer XL Pro is equipped with automatic table calibration, plastic feed control sensor and other nice features.

Photopolymer printing in architecture and design

The principle of operation of a photopolymer printer is based on the illumination of a special resin using directional UV radiation. Photopolymer printers can work on one of three technologies:

Photopolymer printers allow you to get a product with an ideal surface. It is not for nothing that LCD, DLP and SLA devices are actively used in the jewelry and dental industries, where accuracy and the ideal surface of the finished model are important.

Currently, LCD technology has gained particular popularity due to its availability and inexpensive printers.

Pluses and minuses

pros

Minuses

-

After printing, it is necessary to rinse and dry the product in a UV chamber. After printing, it is necessary to wash off excess polymer from the surface of the finished print. For this, isopropyl alcohol is usually used, although resins have now appeared that can be washed with plain water. In order for the photopolymer to gain the declared strength, it must be additionally illuminated under an ultraviolet lamp or in a special box.

Application and printing examples

Miniature model of building

Model of the Cathedral of the Intercession of the Most Holy Theotokos on the Moat (St. Basil's Cathedral)

City map

Miniature "extras" for the layout

Printer rating

Prismlab RP400

Prismlab RP400

Features:

Print Technology: DLP/LCD/SLA

Material: Photopolymer resin

Construction area size: 384x216x384 mm

XY positioning accuracy: 100/67/50 microns

Z-axis positioning accuracy: 100/50 microns

Prismlab RP400 is a professional photopolymer machine with a large printable area. Humidity and temperature sensors in the build chamber allow Prismlab to adjust print settings for the best print quality, while open source software allows the use of third-party photopolymer resins.

Peopoly Phenom XXL

Peopoly Phenom XXL

Characteristics:

Print Technology: DLP/LCD/SLA

LCD display resolution: 3840x2160 (23. 8", 16:9, UHD 4K)

Material: Photopolymer resin

Construction area size: 527x296x550 mm

XY positioning accuracy: 137 µm

The Peopoly Phenom XXL is a large format photopolymer printer with a huge printable area. The improved monochrome LCD matrix allows you to quickly and accurately produce large models or small batches of small products.

Phrozen Sonic MEGA 8K

Phrozen Sonic MEGA 8K

Features:

Print Technology: DLP/LCD/SLA

LCD resolution: 15" 8K Mono LCD

Material: Photopolymer resin

Build area size: 330 x 185 x 400 mm

XY Positioning Accuracy: 43 µm

Sonic Mega 8K is the first LCD printer with a matrix resolution of 8k, but the accuracy of printing depends on the resolution of the matrix. Sonic Mega 8K allows you to produce large models with amazing clarity, without “blurring” or smoothing small elements.

Construction printers

Construction printers are just groping for their niche for application, and the technology itself is still far from ideal. But the projects already implemented allow us to imagine a possible future where it will be possible to print entire houses.

Application and printing examples

Bridge in Shanghai.

In Shanghai, using a construction 3D printer, a whole bridge was printed and installed over a pond in the Baoshan area. The new bridge is 26.3 meters long and 3.6 meters wide.

Bridge in Shanghai

Before making a concrete, full-size model, a reduced copy of the bridge 1: 4 was printed for testing the strength and safety of the structure. 3D printing took 450 hours. A load and deformation monitoring system was installed in the finished bridge. This allows you to explore the properties of printed concrete elements in real time.

Up close, you can see the concrete layers that appeared due to the peculiarities of printing

Bridge in Amsterdam

In Amsterdam, a printed steel bridge was installed. It connects the embankments of the Oudesijds Achterburgwal canal. The length of the finished bridge is 12.2 m, the width is 6.3 m, and the weight is 6000 kg.

Bridge in Amsterdam

Sensors were installed in the bridge to track the deformation of the structure and count the number of people passing through it. For the manufacture of a modern "crossing" 4 robots for 6 months layer-by-layer made a construction of stainless wire.

Bridge manufacturing process

Printed house in Germany

In Germany, builders built an entire house using a 3D construction printer. The house is designed for 5 families, the total area is 380 sq.m.

Almost finished house

In the model of the house, cavities are initially laid for all communications, which the builders will later install. Thus, while the printer is building walls, the workers are solving other tasks.