Diggro 3d printer

diggro alpha 3 3d printer - Buy diggro alpha 3 3d printer with free shipping

diggro alpha 3 3d printer - Buy diggro alpha 3 3d printer with free shipping | Banggood Shopping New ZealandBrands

SEE MORE

RC Drone Spare Parts

Printer Filament Material

Plug Type

Application

- Indoor (1)

SEE MORE

Color

- Black (1)

SEE MORE

Interface Type

Length

Material

Phone Model

Bag Type

Working Type

-

Home

- "" 470 Results

Price -

OK

Ship From

Filter for the right parts for your vehicle

Add vehicle

1 2 3 4 . .. 8

Total 8 pages

Go to Page

Go

Confirm your age

You must be at least 18 years of age to enter this section.

I AM UNDER 18 I AM OVER 18

STL file Diggro Alpha 3 sortie fil ameliorée・3D printer design to download・Cults

roller and axe for dish washer whirlpool mod ASF 66830W

€0.50

american pallet 1200x1000

€1

gas cap Ford KA 2001

€0.50

vertical tent tube hook

€1

horizontal tent tube hook

€1

piege pour escape game

€10

sel poivre et support mur

€2

volet prise 220v camping car

€1

Best 3D printer files of the Tools category

Milwaukee Charger mount (PEGBOARD REMIX)

Free

WALL OR CEILING HOLDER FOR MAKITA RAIL TRACK SAW GUIDE

€0. 99

99

PET-Machine, make Your own filament from plastic bottles at home!

€50 -66% €17

Pleat Maker Jig for Fabric Face Masks - Covid-19 -UPDATED

Free

Ski pole basket

Free

Cricut DIY Face Shield - Uses Binder Covers

Free

Teach a child to tell the time

Free

RobotDigg Kossel Mini V1.0

Free

Best sellers of the category Tools

3D Printer Tool Holder V3.0

€1.04

3D SCAN STAND

€2

Printer Drawers For Ikea Lack Table

€1. 99

99

Creality Sonic Pad Mount für Ender 3 S1

€0.99

Phone holder

€2.79

PRECISION DIAL INDICATOR 3D PRINTING DIY

€1.88

V4 AIR DUCT FAN 5015, ENDER 3 S1, S1 PRO, SPRITE, ACCELEROMETER, LED STRIP

€2.99 -15% €2.54

HOT END DUCT 4020 OR 5015 FAN, ENDER 3 S1, S1 PRO, SPRITE, PROBE NO Y OFFSET, ABL ADAPTER BETA

€2.28 -18% €1.87

Armadillo Flex EZR - Wire Management System

€1.68 -30% €1. 18

18

Sovol SV06 fan duct 4020 - CFD optimized

€3.75

Ender 3, 3 V2, 3 pro, 3 max, dual 40mm axial fan hot end duct / fang. CR-10, Micro Swiss direct drive and bowden compatible. No support needed for printing

€1.57

Creality Ender 3 S1 Pro Better Cable Management System

€1.50

Ratchet Holders - magnetic - toolbox organization stands

€2.68

SUPERBOX

€1.50

UNIVERSAL INDICATOR FOR BED LEVELING FOR ALMOST ALL PRINTERS

€2.37

ARTEMIS -> Magazine for Alligator 2 || 6.5" Arrows || Repeating crossbow

€6.25

💖 Would you like to support Cults?

You like Cults and you want to help us continue the adventure independently? Please note that we are a small team of 3 people, therefore it is very simple to support us to maintain the activity and create future developments. Here are 4 solutions accessible to all:

Here are 4 solutions accessible to all:

ADVERTISING: Disable your banner blocker (AdBlock, …) and click on our banner ads.

AFFILIATION: Make your purchases online by clicking on our affiliate links here Amazon.

DONATE: If you want, you can make a donation via Ko-Fi 💜.

WORD OF MOUTH: Invite your friends to come, discover the platform and the magnificent 3D files shared by the community!

Zmorph is the most multi-head 3D printer. Investigation from REC.

Hello everyone! Not so long ago, we got to see the unique multifunctional Zmorph platform. This article will tell you about our experience, observations and technical aspects revealed during 3D printing. However, since the Zmorph is not just a simple single extruder 3D printer, there will be additional articles about each interchangeable head describing the work, nuances and results.

General information about the device.

1. External dimensions - 530 mm x 555 mm x 480 mm.

2. Printable area - 250mm x 235mm x 165mm.

3. Number of printheads - 1

4. Weight is ~ 25 kg.

5. The printer is equipped with a thermal table, card reader, ethernet port and touch monitor.

6. Maximum nozzle temperature: ~260

7. Nozzle diameter: 0.4 mm, resolution: 200 to 70 microns

8. Build speed 60-150 mm/s

9. Printing materials declared by the manufacturer: PLA, ABS, PETG, Laywood, nylon, rubber, etc.

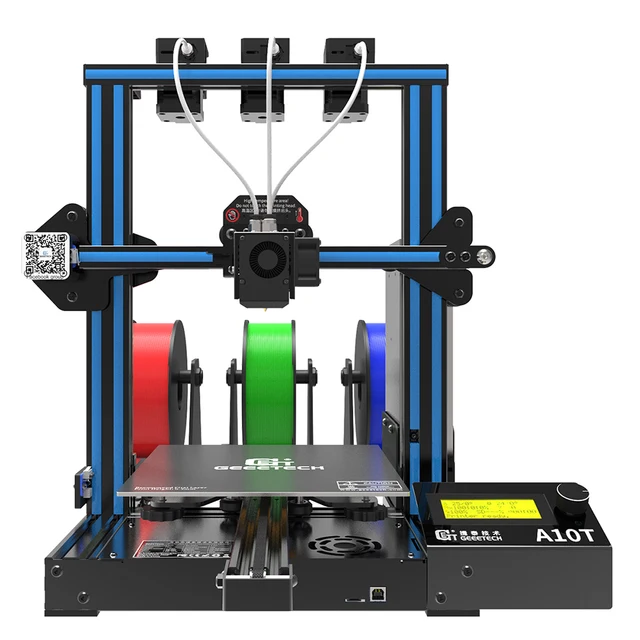

10) Features - the main bonus of this printer is interchangeable heads. In our kit there are 1.75 single extruder head, 1.75 double extruder head, milling cutter, laser and extruder-syringe,

11) The printer has its own software, called Voxelizer. The program provides all the options for the heads of this device and has many settings.

Review

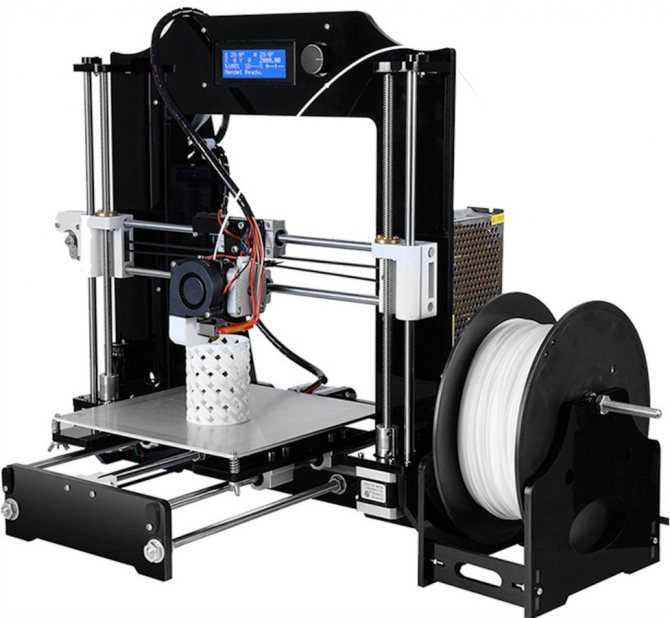

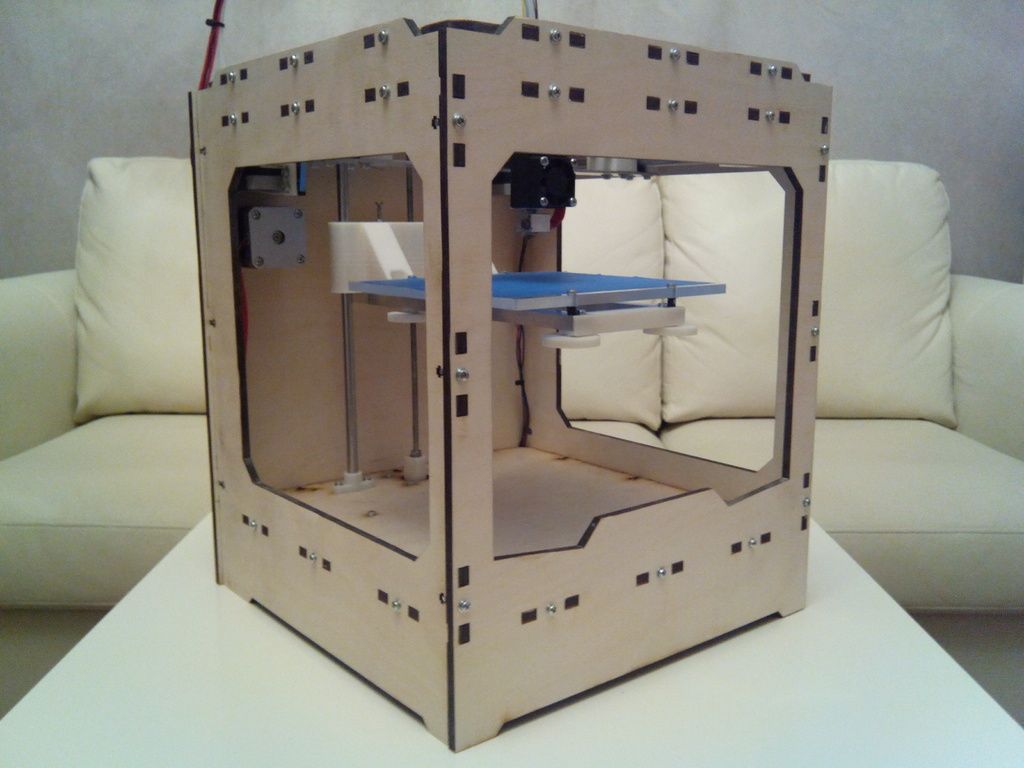

The printer itself looks quite serious, thanks to the metal and transparent plastic, it evokes the feeling of some kind of device from sci-fi films, although in principle we see a Prusa i2, but with a very rigid body.

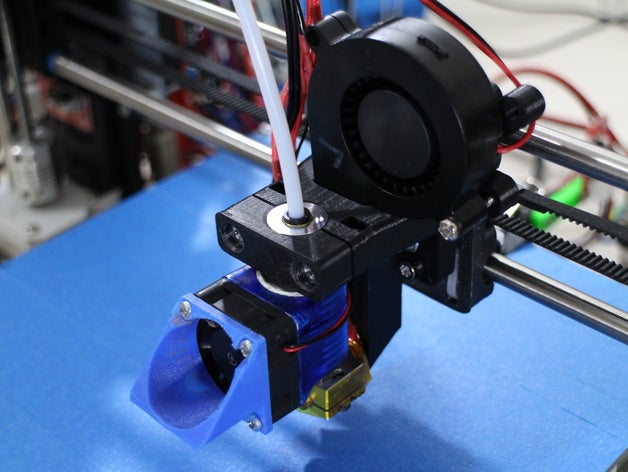

The extruder looks serious, the carriage itself is assembled from metal and a small number of printed parts. The airflow of the model is attached with magnets, which is very convenient.

Thermotable moves on two belts and rails, adjustable with 3 screws. Fastening is realized through magnets.

The axle guides are also made of sheet metal. No backlash, everything is very rigid.

The printer has a nice touch screen display with its own menu.

Cable management is perfectly arranged in the printer body itself. All wires are perfectly protected from breaking and bending. All connectors that the user will have to work with are signed and marked.

The printer has an interesting implementation of the spool attachment mechanism and the filament channel.

This is how 0 is implemented on the Z axis.

Very pleased with the highlighting and marking of important elements on a 3D printer. There is a feeling of working with an expensive industrial device.

Diode illumination of the printed model is a very nice element.

Like many other units, the outer protective case is also attached with a magnet.

Software

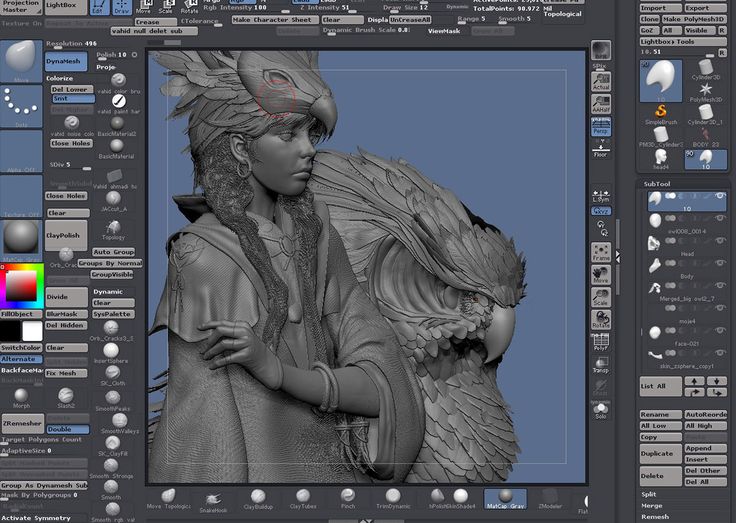

Voxilaser looks like this

this is the first menu of transformations and settings, here we place objects, set their sizes, and also select the work area. In this case, workflow costs as 3D printer.

press voxilase and go to voxel editor. It has the usual print settings for all of us.

after we click generate g-code

here we see the generated task, it remains to press play

save it to a USB flash drive and print it.

Print.

First print on a ZMorph 3D printer. A single extruder print head is used. Material natural REC PLA. Before printing, I had to calibrate the table.

Model can be found here: https://www.thingiverse.com/thing:1803617

Material red REC PLA plastic, print speed 90 mms

Material red REC PLA plastic, print speed 70 mms. (outer wall)

Relax

Material natural REC RELAX plastic, print speed 60 mm with 0.4 mm nozzle and 0.2 mm layer.

Bicycle pedals made of natural and white REC RELAX plastic. Layer height 0.15 mm, speed 30. In total, it took 48 hours to print, the result is stable.

Bonus

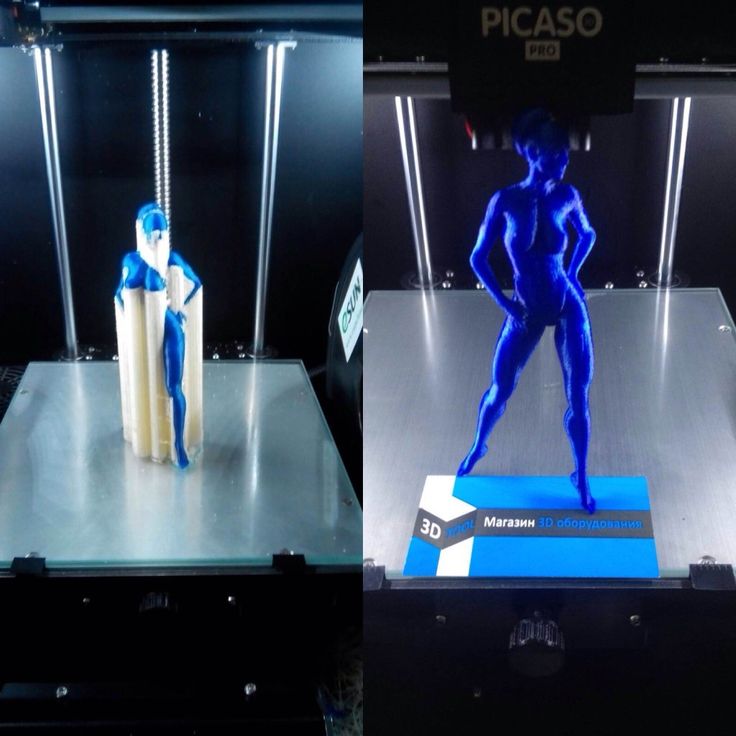

And now an unexpected bonus - ABS + HIPS printing test on the Dual PRO head.

It differs from the previous one by the ability to print two materials through one nozzle.

The slicing is not much different, all you need to do is set extruder 2 in some places. Thanks to the software, the head is able not only to create supports from another material or to imprint parts from different materials into each other, but also to mix them.

Now let's look at "two-color" printing.

The algorithm of actions is described here, but in general, it's very simple.

The result is just wonderful.

Now let's try blending. Let's fiddle a little with the settings again.

This tutorial describes how to do it.

Looking at the result

Unfortunately we overlooked the amount of pink ABS and ran out of it during the printing process, leaving most of the vase under extruded, but the resulting part shows that the mixing occurs without any problems according to the given program.

Anyway, we did it again.

And now the result:

Conclusions.

Pros:

- Rigid frame, good design and very high quality assembly and components.

- Very precise kinematics.

- The ability to quickly remove and put on additional elements such as protective screens, a model air cooler, a working head and even a heating table.

- Easy-to-learn software with lots of settings and features.

- Convenient printable area.

- The printer has all the necessary warnings and markings, heated table, extruder and powered Z and X axes are illuminated by diodes. The printed object itself is also illuminated, which helps to keep track of the printing process.

- User-friendly interface with a set of useful features. Fine-tuning printing is easy enough, all the icons are unambiguous and large enough not to miss them.

- The printer produces excellent results at low to medium speeds from PLA and RELAX

Cons:

- It is very easy to calibrate the table because of the magnetic mount, you will not only have to level the table plane but also very likely to set zero on the Z axis, after removing the part or detaching the table.

- This printer is conceived and designed as an MFP, not as a 3D printer, so it has a high margin of safety and rigidity, while at the expense of print speed there may be traces of underextrusion or, conversely, excessive drops on the surfaces of models, especially when it comes to a large number of retracts.

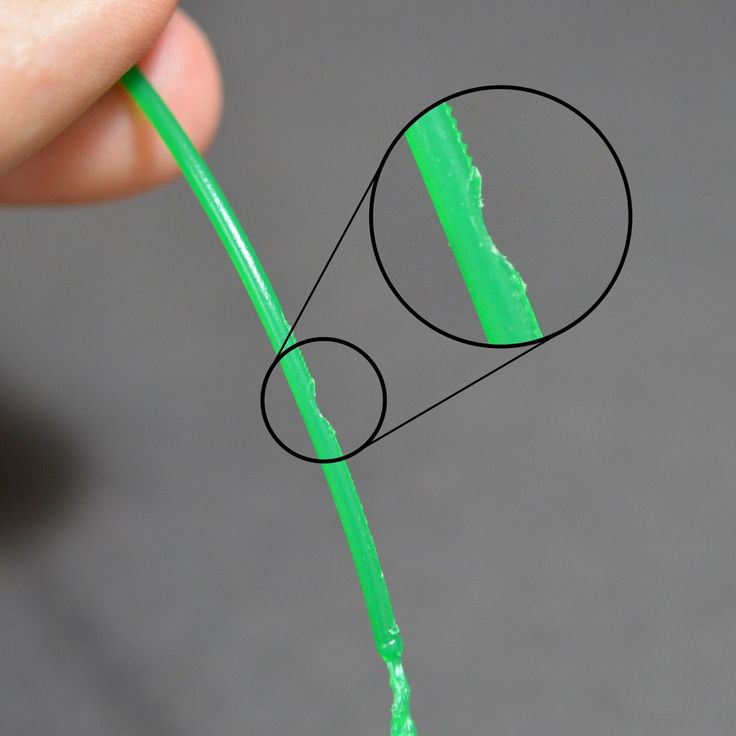

- The spool mounting on the printer is interesting, but practice has shown that the filament supply channels can get stuck in the case, stretch and thereby interfere with the plastic supply.

- The software calculates the print time very accurately, but not the amount of plastic required.

- Printing with flexible materials is difficult, again due to thermal distribution, difficulty in feeding the plastic through the tube, and too much pressure that compresses the bar.

Pro Dual PRO

This head has been tested for the main tasks conceived in the design. This system is capable of printing solvent-based supports in PLA+PVA and ABS+Hips combinations, and also allows two-color printing. and The ability to mix colors with a gradient comes as a special feature.

and The ability to mix colors with a gradient comes as a special feature.

Plug&play head, we installed it, filamented it, and started the job. Slicing in Voxeliser, even for this mode, is very simple and intuitive. If you don’t figure it out yourself, there are good tutorials on working in text and video format on the manufacturer’s website.

Conclusion.

Zmorph is a unique platform with many possibilities. Our practice of using it as a 3D printer has shown that this device requires very thoughtful use. This is also due to the software, in which the interface is very clear, but overloaded with elements, which makes it easy to miss something in the settings. It is worth noting a very tough and thoughtful case filled with useful features, markers and indicators. Despite its robust and simple design, the Zmorph printer is not one of the best offerings on the market, as it is built solidly and reliably to handle a range of versatile tasks, not just printing. Therefore, the printer is quite reliable, but not very fast in the additive manufacturing of objects.

Therefore, the printer is quite reliable, but not very fast in the additive manufacturing of objects.

At the same time, working with Zmorph is very simple, in order for the device to behave like a plug and play you just need to remove the printed models very carefully, trying not to pull the table off its mounts and thereby violate its calibration.

In general, the printer produced the best results at speeds from 30 to 70 mm s (infill and outer contour, travel from 120 to 180 mm s) with REC PLA and REC RELAX plastics. When printing ABS and ETERNAL, it is necessary to install protective screens, as they are enough to avoid delamination of the object.

Summing up, we note that Zmorph is a unique machine that will give the user great opportunities, and in return they will only ask you to follow the instructions. This device will find its well-deserved place in various workshops, design bureaus, and especially in educational institutions.

If you have any questions, write comments, call, contact us in the social.