3D printed house recycled plastic

LA Startup Is Using Recycled Plastic to 3D Print Prefab Homes

Photos: LA Startup Is Using Recycled Plastic to 3D Print Prefab Homes Search iconA magnifying glass. It indicates, "Click to perform a search". Insider logoThe word "Insider".US Markets Loading... H M S In the news

Chevron iconIt indicates an expandable section or menu, or sometimes previous / next navigation options.HOMEPAGE Save Article IconA bookmarkShare iconAn curved arrow pointing right.Download the app

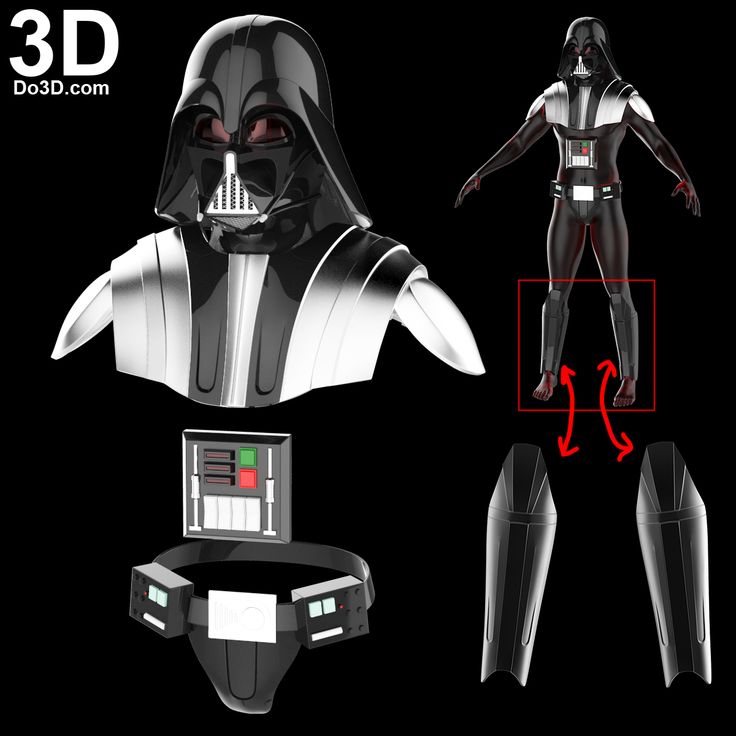

Azure Printed Homes- Los Angeles-based startup Azure is using recycled plastic to 3D print prefab homes.

- The startup is now selling several models ranging from a backyard studio to a two-bedroom ADU.

- Azure says it can build homes 70% faster and 30% cheaper than "traditional home construction methods."

Thanks for signing up!

Access your favorite topics in a personalized feed while you're on the go.

Why "reduce, reuse, recycle" when you can just turn your plastic waste into homes?

A worker stands in front of a pile of plastic waste as machinery processes it at a facility in Japan. Makiko Tanigawa/Getty Images

Makiko Tanigawa/Getty Images This may sound like a far-fetched idea, but that's exactly what one 3D printing home construction startup in Los Angeles is trying to do.

Azure Printed HomesIn April, Azure unveiled what it called the world's first 3D printed "backyard studio" made with recycled plastic materials.

Azure Printed Homes

Azure Printed Homes Source: Azure

And its plastic-printed studios and accessory dwelling units (ADUs) are now available for preorder as the startup prepares to ramp up its production line in the Culver City neighborhood of Los Angeles.

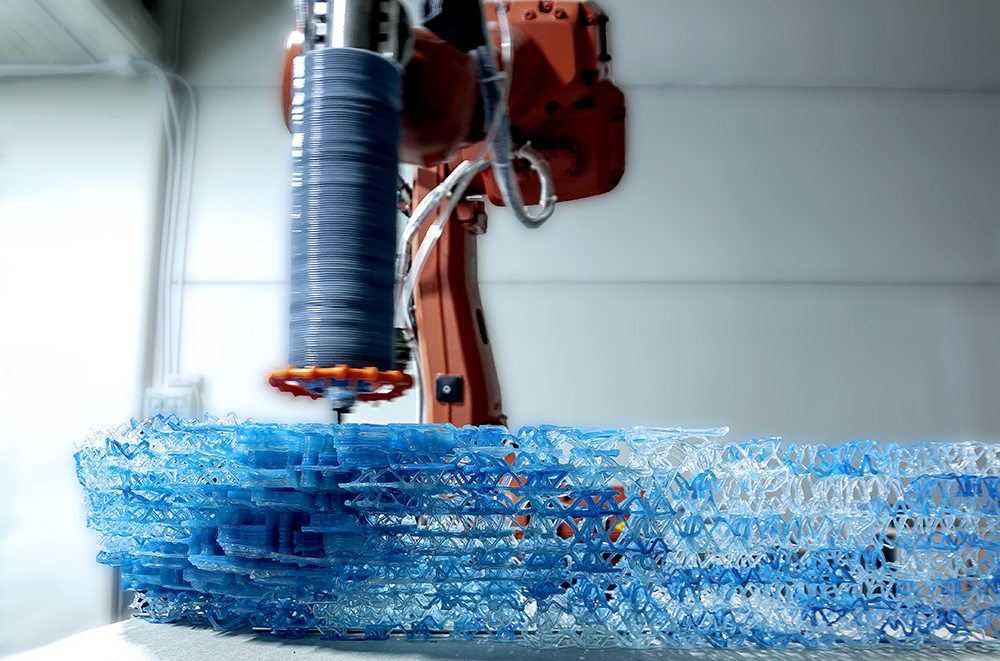

Azure Printed HomesMost 3D printing home builders currently use a form of concrete to create their homes, whether it be a proprietary mix or pure concrete.

3DCP Group

3DCP Group Source: Insider, Insider

But Azure is saying goodbye to this drab grey look by taking a more sustainable approach …

Azure Printed Homes… giving a second life to plastic once destined for landfills or incineration.

Azure Printed Homes

Azure Printed Homes Over 60% of Azure's printing material will use the inherently waterproof plastic polymer often found in plastic bottles and packaging for food, according to the startup.

Azure Printed HomesSource: Azure

It's currently working with three suppliers to source "post-industrial plastic" for its printing mix, Ross Maguire, who cofounded Azure to make construction more efficient and sustainable, told Insider.

Azure Printed Homes

Azure Printed Homes But in the future, the goal is to use post-consumer plastic: "Our supply chain should never be short in our lifetime," he said.

A volunteer with Dominion Tabernacle Ministries prepares cold water bottles to hand out in Dallas, Texas on June 12, 2022. Shelby Tauber/ReutersEven without the use of recycled plastic, the nascent 3D printing homebuilding industry has already been heralded as a more sustainable and efficient construction method.

Alquist

Alquist According to its biggest proponents, by using printers instead of people, homes can be built more efficiently using less waste, materials, and time.

Mense-KorteSource: Insider

And Azure will be no different: The startup says it can build homes 70% faster and 30% cheaper than "traditional home construction methods" by 3D printing the floor, roof, and walls of its models inside its factory.

Azure Printed Homes

Azure Printed Homes Source: Azure

And with the help of prefabrication, before a unit leaves Azure's 10,000-square-foot factory in Los Angeles, 99% of its finishes will be complete, Maguire said.

Azure Printed HomesSo when it arrives on site via a flatbed truck, the only necessary on-site work will be to connect the home to its foundation and utilities.

Azure Printed Homes

Azure Printed Homes Azure currently has several customizable models ranging from small studios to 900-square-foot two-bedroom ADUs.

Azure Printed HomesAnd these builds are now available for pre-order to be delivered as soon as early November.

Azure Printed Homes

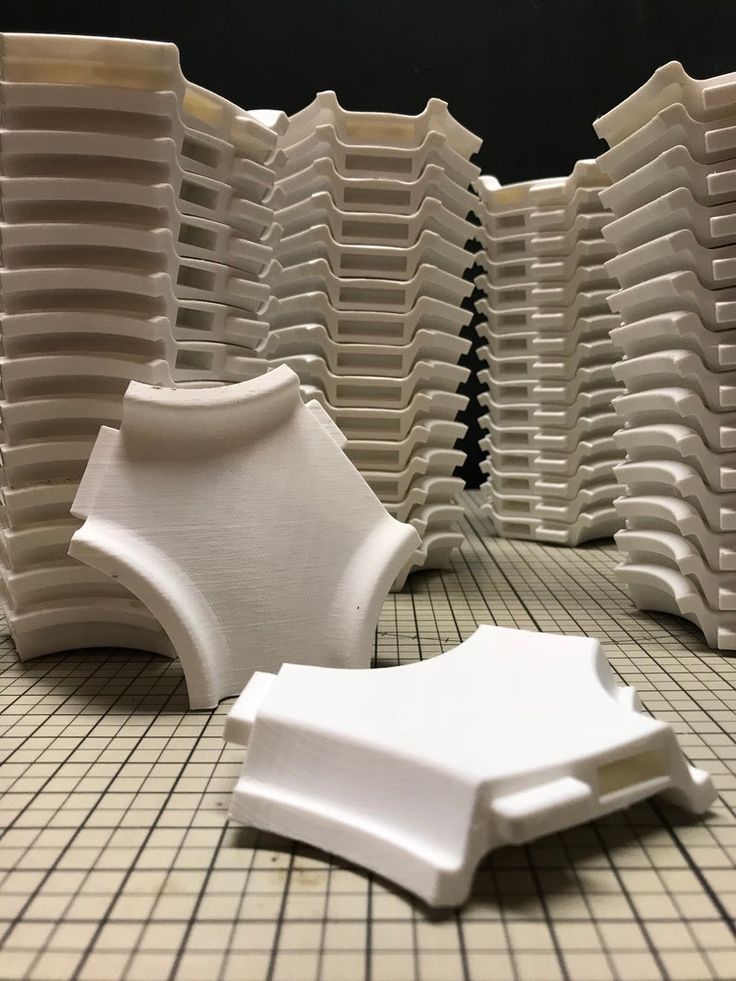

Azure Printed Homes But no matter the model or size, these units will all be prefabricated and built using connectable modules that can each be printed in under 24 hours.

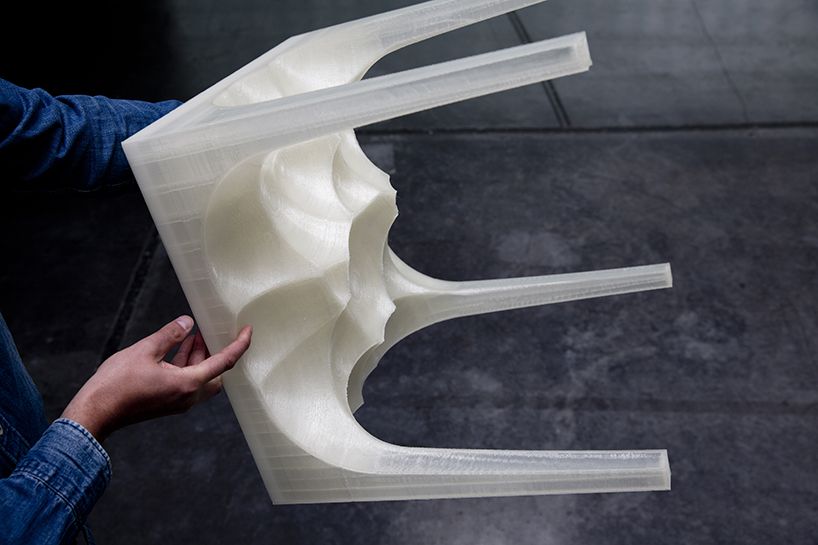

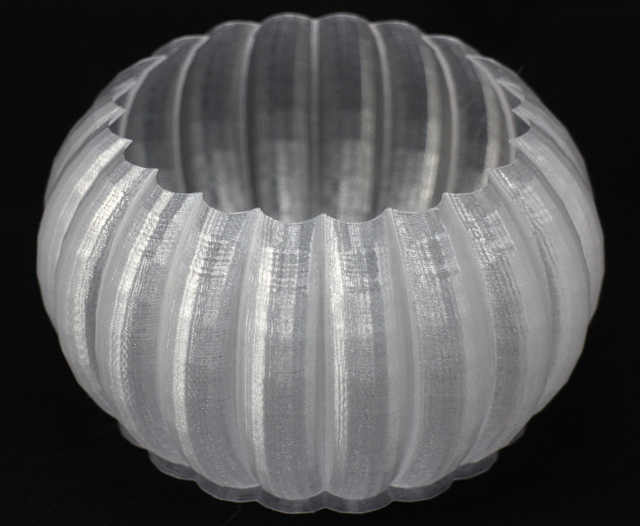

Azure Printed HomesThe floor and ceiling are connected by a flowing wall with curved corners, a trademark of 3D printers.

Either side of the unit is then encased with glass walls, giving the studio a clean and futuristic look. Azure Printed Homes

Either side of the unit is then encased with glass walls, giving the studio a clean and futuristic look. Azure Printed Homes Given its smaller size, these studios can be printed within day one, wired by day two, insulated by day three, and then delivered on-site in two weeks, Maguire told Insider.

Azure Printed HomesBut if you're looking for something more substantial, Azure also prints ADUs, which skyrocketed in popularity in 2020.

Azure Printed Homes

Azure Printed Homes ADUs extend the square footage of the main home by serving as a backyard guest home or Airbnb.

Azure Printed HomesAnd Azure's comes in multiple sizes: a studio, one-bedroom, or two-bedroom.

Azure Printed Homes

Azure Printed Homes These units range from 180 square feet to 900 square feet…

Azure Printed Homes… although the smallest $39,900 option already has a three-month waitlist, according to local news reports.

Azure Printed Homes

Azure Printed Homes Source: Spectrum News 1

Inside, there are spaces like a bedroom, living room, bathroom, and even a laundry room in the larger builds.

Azure Printed HomesThe smaller ADU has a more traditional appearance with a pointed roof (shown below), while the size up features the same futuristic aesthetic as the backyard studio.

Azure Printed Homes

Azure Printed Homes When the startup debuted the former look, it saw a "big rush of preorders," Maguire told Insider.

Azure Printed HomesAnd moving forward, he believes the company will sell more of this traditional-passing ADU.

Azure Printed Homes

Azure Printed Homes Azure has only printed one model so far, although it does have another in the works.

Azure Printed HomesBut next month, the startup will receive the last bits of equipment it needs to begin rolling out the production line .

.. Azure Printed Homes

.. Azure Printed Homes ... which should help address its "big backlog of orders" that has already been overloading its one printer, Maguire said.

Azure Printed HomesAnd in 2024, the startup will begin rolling out larger homes.

Azure Printed Homes

Azure Printed Homes Further down the line, Azure may also explore printing housing for the unhoused or for overseas clients …

Azure Printed Homes… and in the future, if the company decides to expand, you could find a pop-up-like Azure production line near you.

Azure Printed Homes

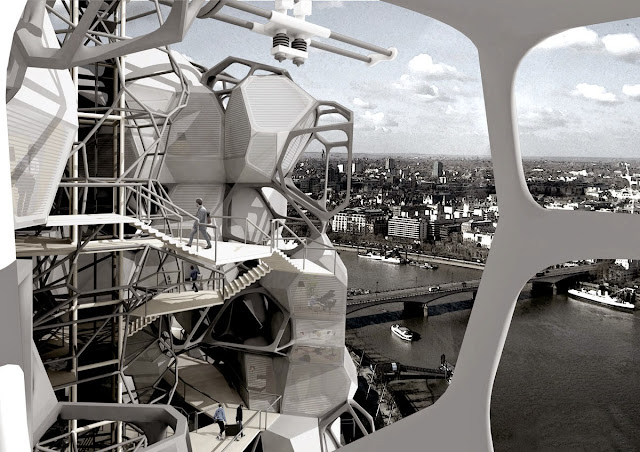

Azure Printed Homes "3D printing is a more efficient way of building and it should only get better as we develop the processes, technology, and materials further," Maguire said. "I can only see it becoming more and more prominent in [construction] as we move forward."

Azure Printed HomesRead next

FeaturesThese Sleek Houses Are 3D Printed From Recycled Plastic.

Prices Start at $26,900

Prices Start at $26,900The US has a housing shortage problem. We also have a plastic waste problem. What if we could solve both these problems simultaneously with an unexpected two birds/one stone innovation? If you’ve ever longed to live in a small house made out of 100,000 recycled plastic water bottles, your lucky day is just around the corner.

If, like most of us, living in a water-bottle house isn’t on your list of life goals, but this still sounds like an intriguing idea, bear with me.

3D printed houses can’t quite be called “commonplace” yet, but they’re growing in popularity and springing up everywhere from New York to Virginia, California to Texas and in between. If putting down layers of cement wasn’t innovative enough, a company called Azure is making good use of the material that’s both a boon to our consumer society and the bane of our (and the planet’s) existence: plastic.

Los Angeles-based Azure Printed Homes was founded by entrepreneurs Ross Maguire and Gene Eidelman, who believe they can build homes 70 percent faster, at a cost 20 to 30 percent less expensive than traditional construction methods—and far more sustainably to boot.

Azure’s 3D printed studios and accessory dwelling units (ADUs) have been available for preorder since August, and this fall the company was chosen by real estate development company Re-Inhabit to build 10 rentable homes in southern California.

“California, like many states, needs to find more innovative ways to speed up the time it takes to build,” said Re-Inhabit cofounders Rudy and Kim Dvorak in a press release. “Azure is doing something really special with their approach to the problem. Repurposing materials and 3D printing a complete structure in a fraction of the time is something that is a game changer for us.”

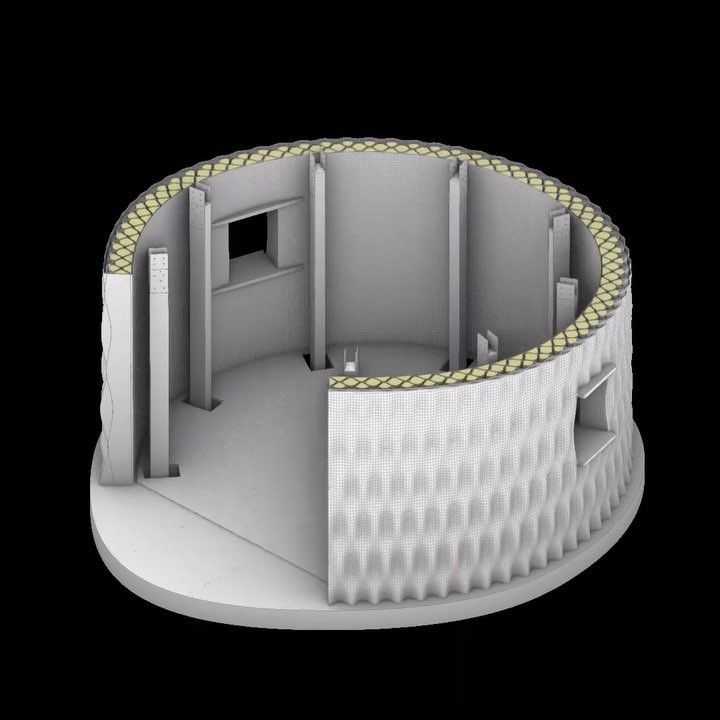

Azure’s process differs a bit from that of existing 3D printed concrete homes. Because concrete is much heavier than plastic, it makes the most sense to bring a giant 3D printer—most of which either move around the print area on rails or hang gantry-style from a frame—to the home’s location and build onsite. This adds cost and time, though, because the building company needs to move its construction equipment around and set it up all over again at each new home site.

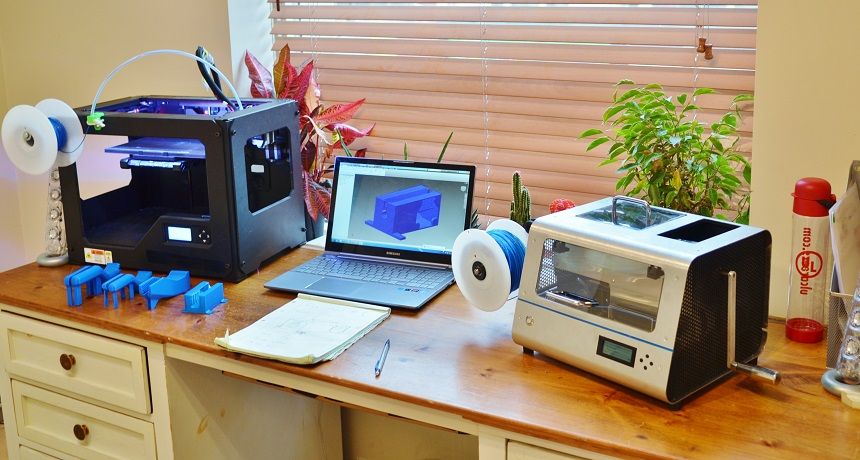

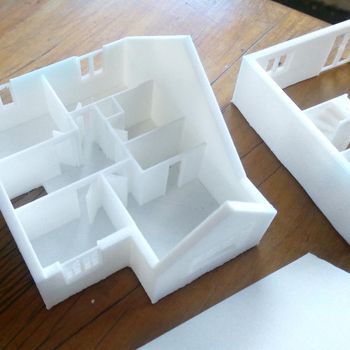

Azure is taking a more centralized approach. They 3D print the floor, roof, and walls of their homes in their 10,000-square-foot factory in Culver City (outside LA). By the time a home leaves the factory, it’s 99 percent complete; it gets shipped to its site on a flatbed truck, and all that’s left to do is connect the modules to one another and to the foundation and utilities.

Azure’s 180-square-foot ADU. Image Credit: Azure Printed HomesAs for the printing portion, it only takes a day. Over 60 percent of the printing material is recycled plastic, which is combined with other materials to add strength and durability. Azure is currently using post-industrial plastic, but hopes to use post-consumer plastic in the near future. Either way, there’ll be plastic to spare; “Our supply chain should never be short in our lifetime,” Maguire told Business Insider. Not in the next lifetime, either.

On top of putting recycled plastic to good use, Azure is making the homes themselves environmentally friendly by incorporating solar panels and heat pumps. The company has reportedly already received over $16 million worth of pre-orders and has a waitlist three months long. Its lowest-priced offering is a 120-square-foot studio that costs $26,900, while its most expensive and largest home is a 900-square-foot two-bed that goes for $204,900 (these prices don’t include the land, foundation, delivery, or utility hookup costs).

The company has reportedly already received over $16 million worth of pre-orders and has a waitlist three months long. Its lowest-priced offering is a 120-square-foot studio that costs $26,900, while its most expensive and largest home is a 900-square-foot two-bed that goes for $204,900 (these prices don’t include the land, foundation, delivery, or utility hookup costs).

Azure’s planning to start delivering studios by the end of this year, and will move on to accessory dwelling units and homes in 2023. Maguire has nothing but optimism about the future of 3D printing in construction. “3D printing is a more efficient way of building and it should only get better as we develop the processes, technology, and materials further,” he said. “I can only see it becoming more and more prominent in [construction] as we move forward.”

Image Credit: Azure Printed Homes

3D printed plastic trash houses

News

Apparently, we are talking about the use of an extrusion 3D printer and granular polymers.

The new factory in Culver City covers almost 1,500 square meters, including the additive manufacturing facility. The startup relies on a special process using a large-format 3D printer that prints with recycled materials. The authors of the project are confident that the company will be able to build residential structures 70% faster and with savings of up to 30% compared to traditional construction methods, and the use of plastic waste will help reduce their carbon footprint.

“The construction industry is the world's leading consumer of raw materials, responsible for about twenty percent of carbon dioxide emissions. Our responsibility to consumers and future generations is to use the most sustainable practices available,” says Eugene Adelman, co-founder of Azure Printed Homes.

“We're driving efficiency gains not only by leveraging advances in 3D printing, but by designing and manufacturing in as little as twelve hours. We produce all of the structural, cladding, waterproofing, exterior trim, utility embeds, and interior resurfacing at a fraction of the time and cost required in conventional construction,” explains Ross Maguire, co-founder of Azure Printed Homes.

The company is already accepting pre-orders for ancillary buildings with the intention of starting 3D printing full-fledged residential buildings from 2023. Additional information is available on the official website.

Do you have interesting news? Share your developments with us, and we will tell the whole world about them! We are waiting for your ideas at [email protected].

construction FGF Azure Printed Homes

Follow author

Follow

Don't want

1

More interesting articles

ten

Subscribe to the author

Subscribe

Don't want

Igor Kostusev, an employee of the Arktika shipbuilding enterprise, received the Lomo Regional Prize. ..

..

Read more

four

Follow the author

Subscribe

Don't want

An upgraded version of the Ender-5 system with MakerBot kinematics is positioned as the new flagship and...

Read more

56

Subscribe to the author

Subscribe

Don't want

Dear friends!

3D printers, makers and just caring people in Russia connect...

Read more

Startup 3D prints tiny houses from recycled plastic

Recently, many projects have been implemented using recyclable materials to ensure sustainability. One such project was implemented by the Los Angeles-based architecture startup Azure.

Azure uses recycled plastic to 3D print prefabricated houses. The startup currently sells a variety of home models, from a backyard studio to a two-bedroom ADU.

The startup currently sells a variety of home models, from a backyard studio to a two-bedroom ADU.

“The construction sector is the world's largest consumer of raw materials, accounting for approximately 11 percent of the world's total carbon emissions. Our responsibility to our customers and future generations is to use the most sustainable practices imaginable,” said Ross Maguire, CEO of Azure.

That same month, Azure also unveiled what it called the world's first 3D printed "backyard studio" made from recycled plastic materials.

Plastic 3D Studios and Additional Living Units (ADUs) — that is, legal and regulatory terms for a secondary home or apartment that shares a lot with a larger main home — are now available for pre-order as the startup prepares to ramp up production in the Culver City area In Los Angeles.

Faster, cheaper and greener homes with 3D printing

Azure helps build homes 70% faster and 30% cheaper than "traditional home building methods. " As reported by Business Insider, most 3D home builders use a form of mixed or pure concrete to build the house. However, Azure "says goodbye" to this by using environmentally friendly materials.

" As reported by Business Insider, most 3D home builders use a form of mixed or pure concrete to build the house. However, Azure "says goodbye" to this by using environmentally friendly materials.

According to the startup, Azure's print materials are made from a waterproof polymer plastic commonly found in plastic bottles and food packaging.

“We've achieved improved manufacturing efficiency not only through advances in 3D printing, but by creating a design and process that is completed in as little as 20 hours. Compared to conventional construction, we produce the entire structural frame, outer skin, control barrier, outer. finishing, passages for utilities and grounding for interior decoration in a very short time. By transforming the new era of home building with our sustainable, automated and precise manufacturing processes, we have a very, very exciting future ahead of us,” Maguire added in April, describing the startup’s goal.

Azure is changing the construction industry

Azure was founded by Ross Maguire and Gene Eidelman.