3D printed electric guitar

10 3D Printed Guitars You Can Download & Print At Home

Guitars are the first thing many people think of when they hear the words ‘musical instrument.’ While anyone can go out and buy one that can already be found in thousands of homes, a lot of people have taken their hobby to the next level with 3D printed guitars.

Any musician will tell you that the only thing that makes music more satisfying is playing it on an instrument you’ve made yourself, so 3D printed guitars have increased in both popularity and function in recent years.

Guitars are complicated instruments, and so they’re more than a simple click and print job. Many designers have shared their cool and unique creations online, many of which come with detailed instructions and information on where to buy the parts that can’t be easily 3D printed.

Here, we’ll look at some of the coolest looking and sounding 3D printed guitars, pics, and accessories available online, most of which are free!

- See also: our ranking of the coolest 3D printable musical instruments.

- We also have a guide to the coolest things you can 3D print.

The Electric Guitar Project – Amazing Electric 3D Printed Guitar

This design, simply titled ‘Electric Guitar Project’, comes courtesy of a user who claims to be passionate about two things: 3D printing and music.

The Electric Guitar project is a fully playable 3D printed guitar with one of the coolest designs around. The classic Les Paul shape combined with the minimalist body makes for one cool looking 3D printed guitar you can really play!

After much trial and error, the designer was pleased enough to upload all files and information for free, so anyone can 3D print this guitar themselves. If you don’t believe us, check out the video above to hear how it sounds.

Along with the files found here are links to the extra pieces such as strings and an output jack to ensure you have everything you need. Many of these come with video tutorials so you can be as confident as possible when 3D printing this guitar yourself.

The Geartar – 3D printed guitar with gears

One look at the aptly named Geartar, and you’ll have trouble believing it came from a joke request from the designer’s friend.

The shape was copied from the designer’s neglected guitar, and reworked to fit small, battery-powered gears that really turns heads.

Alongside the files for this guitar are in-depth instructions from the designer, including sizes and infill recommendations. As the Geartar was printed using a 1:1 scale of a store-bought model, it can be shrank or grown to any size.

When it comes to 3D printed guitars, the fewer prints the better, but the designer of the Geartar explains that smaller 3D printers can handle this project as long as post-print assembly is done carefully.

All files and instructions for both the Geartar are available for free here, and the gears (which were taken from a different design), can also be downloaded free of charge here.

The AMGP – The Thing of the Week!

The AMGP (or Adapter Modular Guitar Pro) is a guitar made for both guitar aficionados and ‘wannabes’ who are looking for an old school, but no less cool, rock guitar with built in, replaceable pic holster.

This 3D printable guitar is a popular choice for anyone wanting to put their own spin on an old look.

While the instructions and files can be found for free on Thingiverse, the designer recommends going here to ensure the files are as up to date as possible.

The Giger Guitar – Out of This World

The works of H.R. Giger are recognizable to many at a first glance. Their dark, twisted shapes have inspired many artists, but his work is perhaps best known through the Xenomorph of the classic sci-fi horror ‘Alien.’

Musical instruments weren’t to be left out of his influence, thanks to the designer of the Giger Guitar, a 3D printed guitar with Giger’s work (most prominently the alien themself). Any fan of Giger or Ridley Scott’s immensely popular film will definitely want to add this guitar to their 3D print list.

With the files found here, simply follow the laid-out instructions and you’ll have your own 3D printed guitar that’s sure to turn a few heads. The user comments alongside these files show overwhelmingly positive results in both look and playability.

The Black Widow – Deadly Licks

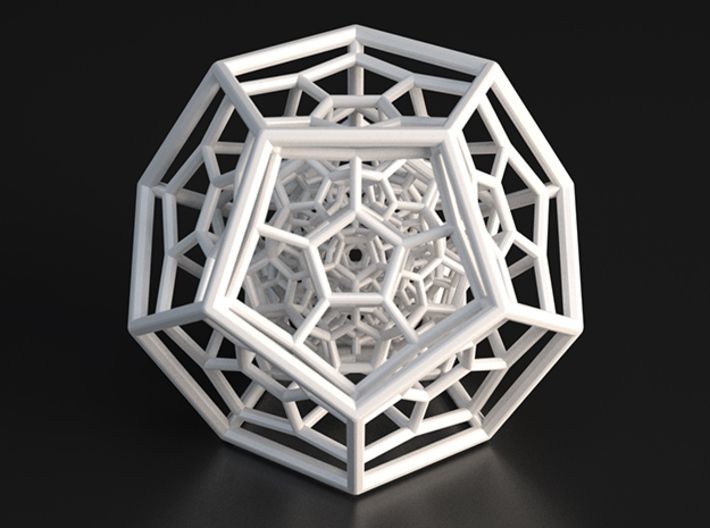

Few guitars, let alone 3D printed guitars, look as cool as The Black Widow. From its meshed design to its light weight, it is without a doubt one of the most attractive 3D printed guitars available online, and the designer has been gracious enough to make the files available for free!

The Black Widow is made from a simple PLA filament, and has a relatively simple post-print assembly. This makes it an ideal first project that’s far less complicated than it looks.

With just a few purchased add-ons, The Black Widow makes an attractive, elegant, and extremely metal guitar!

The Black Widow 3D printed guitar even made it on to our list of the coolest 3D printed musical instruments!

The Compact Bass

Bass guitars may be the definition of cool, but they are known for being larger and heavier than most other kinds of guitar. And so one designer came up with this 3D printed compact bass guitar that’s fully playable and has even been used in gigs!

Like the other guitars on this list, the files are completely free and come with assembly instructions and necessary add-ons to turn this design into a working 3D printed instrument.

They do suggest caution, however, as this 3D printable guitar’s pickup wire has proven to be fragile.

Playable Mini Guitars

Something on an honorable mention on this list are these mini guitars that are still tunable and playable with nothing more than a few rubber bands.

By adjusting the tension on these miniatures, you can change the pitch of the tune played. With enough practice (and some finger strength) you’ll be able to string out a basic tune, strum for a relaxing noise, or tinker and toy away to see what tunes you can play.

While not ‘guitars’ per se, these 3D printed mini guitars are great for musically-inclined fidgeters.

3D Printed Guitar Accessories

Every guitar needs a place to live. For many, this is as simple as buying a case, but for something as special as a 3D printed guitar, you’re going to want a stand or a mount to make sure it’s in view. Fortunately, they can also be 3D printed!

Or, why not make your own 3D printed guitar pick to complete the collection and make each strum that much more your own?

There are plenty of 3D printed guitar stands, mounts, picks, and add-ons to choose from, here we’ll look at some of our favorites.

3D Printed Guitar Stands

Guitar stands are simple structures that keep your guitar stood upright for easy access and even to double as a part of a room’s décor.

This design is a simple print-and-place 3D printed guitar stand for electric guitars that don’t fit comfortably in normal stands.

Acoustic guitar owners may also like this 3D printed guitar stand with a wider base and secure back rest to ensure the instrument heft doesn’t exclude it from being an attractive decoration when not in use.

Guitar Mounts

Whether trying to save space or just prefer the look, 3D printed guitar wall mounts are a cool way to display your instrument in style.

Whether 3D printed or not, a guitar’s wall mount needs to be sturdy and strong. This design for a wall bracket comfortably holds an instrument of 4kg (about 8.8lbs), and can hold a variety of guitars in different sizes.

For a more whimsical look, this Incredible Hulk wall mount is adjustable to wall mount that can hold just about anything, including guitars.

3D Printed Guitar Picks

What guitar player doesn’t want a personal pick to go with their instrument? 3D printed guitar picks are simple, customizable, and always add a personal touch to your sessions.

From this simple design for a standard guitar pick, to this pick complete with spider engraving, 3D printed guitar picks can be made in any color, size, and thickness to match you and your instrument.

For something more creative, these Queen of Hearts guitar picks are beautiful multicolored designs that easily stand out. Their design also allows for the picks to be worn as necklaces or charms which not only looks cool, but also makes them difficult to lose.

Speaking of, guitar picks are notorious for vanishing into thin air. It’s not uncommon to carry spares or wearable ones to ensure they stay on you and in sight, but another way is to make your own 3D printed guitar pick holders.

These holders range from small boxes like the one found here, to this creative design for a 3D printed guitar pick stand that looks like an actual guitar!

13 of the most amazing 3D-printed guitars

Introduction

If weird guitars are your game, forget mahogany, alder and maple: 3D-printed guitars are the future of ambitious axe design, and they're here to stay.

We've scoured the globe to bring you 13 of the most intricate, awe-inspiring designs; they're not cheap, but in some cases you can download the specs and – providing you have the requisite equipment (we don't, sadly) – you can print them yourselves.

Don't Miss

These awesome movie-inspired electric guitars combine celluloid and nitrocellulose

Elephants, racing cars and more: how to make 13 weird noises with your guitar

The 8 best guitar innovations of 2015

$4,000

ODD Guitars Americana

We could fill this gallery entirely with ODD Guitars man Olaf Diegel's off-the-wall creations, but the Americana is perhaps the most detailed of his efforts.

A Duraform nylon-like body is complemented by a wooden inner core (with a choice of wood), which links the Warmoth maple neck to the bridge for customisable sustain and tone.

Most impressive are the replicas of New York landmarks hidden inside the guitar – everything from the Empire State Building to the Statue of Liberty and the Yankee Stadium are crammed into the body. Take a closer look below.

Take a closer look below.

$3,500

ODD Guitars Atom

More ODD Guitar action: the Atom's body is “inspired by the patterns of oil coalescing on water”, while it also features an internal atom with spinning electrons.

Again, Duraform PA provides the bulk of the body, while a wooden inner core adds sustain and tone. Seymour Duncan Jazz SH-2 (neck) and JB SH-4 (bridge) fill the pickup cavities.

£1,500

Customuse RodeoMuse

Shortly after Customuse's inception in 2014, Klaxons began playing their guitars live – a real testament to the quality of these University of Sheffield graduates' designs.

The RodeoMuse rather boldly claims to be “the ultimate country and blues guitar”, with an oak leaf pattern and 3D-printed wagon-wheel volume and tone knobs really hammering the point home.

Buyers do get a choice of centre block tone wood, while a pair of Seymour Duncan Alnico Pro 2 pickups are the finishing touch.

£1,500

Customuse NecroMuse

A fine example of the kind of eye-popping designs 3D printing makes a reality, the NecroMuse is a terrifying creation, boasting an intricate rib cage, rippling spine and grinning skulls, all made out of a durable polymer.

Like other Customuse designs, a wooden centre block retains sustain and resonance, and there's a choice of Seymour Duncan pickups, but best of all, the guitar's output jack is actually one of the skull's eye sockets – ouch.

Francesco Orrù Lovecraft-inspired guitar

This Italian 3D artist living in London has a wealth of incredible 3D-printed designs to his name, and this bonkers example pays homage to the artwork of HP Lovecraft.

ZBrush software provided the basis for the design element, based on Lovecraft's Godfish and Necronomicon works, then the guitar was 3D printed in eight different parts over 80 hours using a Delta Wasp 3D printer. Phewph.

Animal 4theswarm guitar

Yes, it's Francesco Orrù again, this time with a stunning guitar depicting a lion, eagle and shark.

It doesn't look like this one ever got completed with the requisite neck, pickups and hardware, but you can download the template and print and finish one yourself.

3D Printing Solutions Guitar Project

Designed and printed in four parts on the UP Box 3D Printer, this instrument from Australia's 3D Printing Solutions combines a Telecaster-like look with a cool playing card suite motif.

A maple neck and mahogany body keep traditional guitar credentials in check, but this 3D innovation is so designed that you can change to different 3D printed bodies in under 45 minutes.

Print one yourself here!

3FM Serious Request guitar

Right, bit of a weird story behind this beauty, which starts thusly: Dutch radio station 3FM Serious Request raises money for charity by locking three of its DJs up for six days a year, forcing them to live on a juice-only diet.

In 2014, Dutch company ASSEMBL3D (see what they did there?) and guitar builder Eugen Wulff bolstered funds by creating a 3D-printed guitar, which made references to the city of Haarlem, the site of that year's DJ lock-up.

The resulting guitar encompassed references to architecture, painters and Serious Request, and impressed a number of famous Dutch artists (so we're told) – watch Arnold van Dongen strut his stuff below.

The whole process took 76 hours, including the classy rust finish, but it was worth it, as the final instrument sold for €5,750, which went to female victims of war and sexual violence.

Scott Summit 3D-printed acoustic

With the help of 3D Systems, 3D artist Scott Summit produced this awe-inspiring matt black strummer.

Printed using a fine nylon powder, Summit's guitar utilised a whopping $3,000 worth of plastics – so, it's certainly not a cheap option for designing your own guitar – but as sceptical as most guitarists are of a non-wood instrument, Summit claims, “It’s rich and full and has a great tonal range. ”

”

Back in 2012, Summit and 3D Systems were looking to advance the production of this one, but we haven't heard anything since.

Widows Web 3D Printed Guitar

Looks like this body had a chance encounter with a meteor shower, but Jessie Sasser's Widows Web design – recently showcased at CES 2016 – certainly encapsulates its title.

Built out of six different pieces printed on a Robo 3D R1 and assembled using LocTite plastic bonder, the Widows Web also features a Fender-style neck and electronics – we like the red strings, too.

Jessie details the build in the video below, and you can download the design from Thingiverse.

$4,000

ODD Guitars Steampunk

While the shape is total Telecaster, the Steampunk's design and execution is pure Wild Wild West: and yes, all those cogs actually move!

Ignoring the incredible airbrushed paint job, the most impressive part of this guitar is that the whole lot – cogs 'n' all – is printed as a single component.

A maple core gives the guitar its tone and sustain, while DiMarzio Area-T and Fast Trick single coils offer a range of T-type tones – it's all printed using selective laser sintering (SLS) by 3D Systems, on an sPro 230 SLS machine out of Duraform (nylon) material.

Jeff Kerr 3D-printed acoustic

There's not a whole lot of info on this one out there, but this acoustic seems to have its own internal LED light, which accentuates the unusual internal bracing, itself used to support the thin exterior.

More impressive still is that not only did The Foundry's Jeff Kerr design and make the guitar, but he designed the printer that printed it, too. The man's some kind of genius – watch him jam on his creation below.

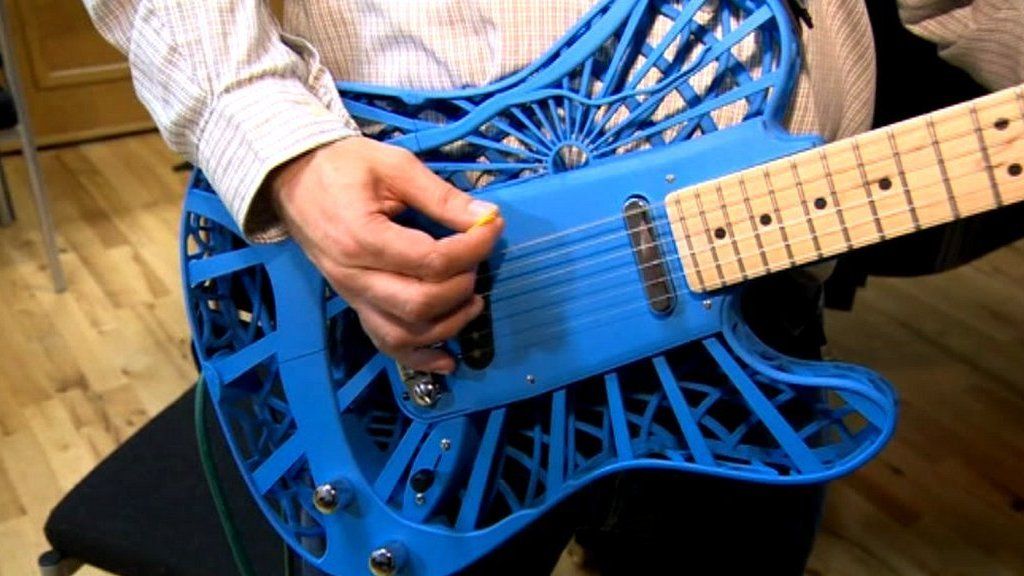

Shapespeare Fully Printed Electric Guitar

Now, while this isn't one of the most remarkable 3D-printed body designs, this, ahem, blue print from Thingiverse user Whitney Potter is notable for being entirely 3D printed – including the neck and fingerboard (but not the hardware, pickups, knobs and strings, natch).

Whitney notes that, “The first one printed plays, although not well, so this should be considered a work in progress and maker beware. I designed this as a 'could it be done' exercise more than anything.”

Carbon fibre reinforcement provides the neck with the stability to cope with the string tension, while the printed fingerboard includes printed slots for fretwire.

Don't hold your breath for an influx of 3D-printed necks in the future, though, as Whitney says, “At this point it is fairly pointless to print the neck as far superior stock guitar necks are available for less than the cost of the materials.”

You can download the design on Thingiverse.

Don't Miss

These awesome movie-inspired electric guitars combine celluloid and nitrocellulose

Elephants, racing cars and more: how to make 13 weird noises with your guitar

The 8 best guitar innovations of 2015

Mike is Editor-in-Chief of GuitarWorld. com , in addition to being an offset fiend and recovering pedal addict. He has a master's degree in journalism, and has spent the past decade writing and editing for guitar publications including MusicRadar, Total Guitar and Guitarist, as well as a decade-and-a-half performing in bands of variable genre (and quality). In his free time, you'll find him making progressive instrumental rock under the nom de plume Maebe .

com , in addition to being an offset fiend and recovering pedal addict. He has a master's degree in journalism, and has spent the past decade writing and editing for guitar publications including MusicRadar, Total Guitar and Guitarist, as well as a decade-and-a-half performing in bands of variable genre (and quality). In his free time, you'll find him making progressive instrumental rock under the nom de plume Maebe .

A guitar on a 3D printer or a summer project

Good afternoon, dear readers. Today's article will no longer be an overview, but a creative and practical one, dedicated to hobbies and hobbies.

Introductory lyrics.

In my student years, I happened to play the rhythm guitar in a musical group whose work was in the style of Heavy / Speed Metal (in a simple way - they played ROCK).

Every year, I and probably many of you think that life flies by, accelerating and accelerating, and somewhere far away there are dreams and there is absolutely no time for their fulfillment. But nostalgia and the desire not to give in to despair sometimes help make dreams come true or return to a long-forgotten hobby. This happened to me as well. I managed to escape from the working routine, and pick up the guitar again. Having acquired a tool, I began to restore long-forgotten skills.

But nostalgia and the desire not to give in to despair sometimes help make dreams come true or return to a long-forgotten hobby. This happened to me as well. I managed to escape from the working routine, and pick up the guitar again. Having acquired a tool, I began to restore long-forgotten skills.

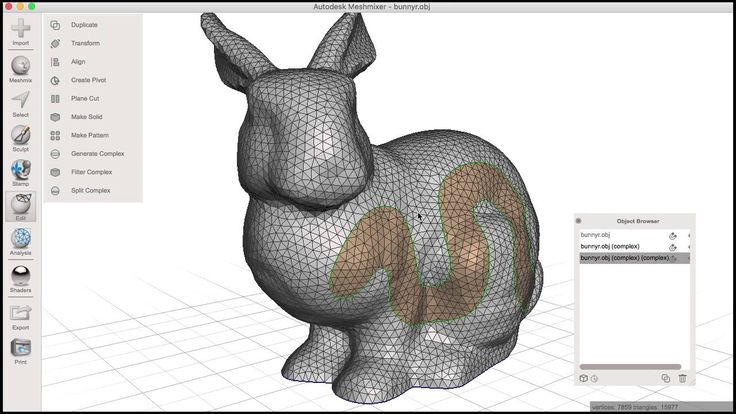

At one fine moment, the instrument became "not enough" and I wanted to buy something else that sounded different. I considered various options, and at some point the thought came - why not assemble the guitar myself. There is a 3D printer, there are filaments, examples of manufacturing are in plain sight. So the idea of a 3D printed guitar slowly began to flicker, until an interesting project caught my eye:

Why not, I said to myself. Found the description of the project on thingiverse. The body of this instrument was based on the design of guitars from the "state" manufacturer Strandberg guitar. Exactly what is needed! But without backlight - it's superfluous.

Preparation

"Wishlist" is not enough to make wishes come true, so a rough list of everything needed for manufacturing was compiled:

3D printer

Picaso Designer Classic. None of them were suitable for the project, because did not have enough printable area for those models that are hosted on Thingiverse. There was no desire to break / saw the finished models, especially the central part of the guitar, to which the neck was to be attached, the pickups were to be placed, and also where the tremolo was installed. This is the most loaded part of the case and should have been printed in its entirety without breakdown.

As a result, after turning and twisting the models in slicers, it was decided to print on Picaso, because in principle, everything was placed at an angle, except for the central part, and the quality of the printed wall on this machine was quite suitable for my tasks. It was decided to print the central part at a printing studio or ask friends with larger printers.

Printable plastic

The author of the project on Thingiverse made a guitar from PLA plastic, but I did not like this option at all, since in this case the guitar would have to be primed and painted. My task was to make a tool without post-processing and painting, so that it could be seen that it was made using 3D printing, but at the same time, it did not have a completely collective-farm look. After looking through the reviews of plastics on 3Dtoday, I decided to focus on composites, especially since I had a shareware promo reel of FormaX composite from REC3D. Once, at one of the 3D printing exhibitions, I happened to turn a part made of this material in my hands, and then I also noticed an interesting visual effect that hides layers and makes the surface of products pleasant to the touch. An additional plus in this solution was the presence of carbon fiber additives in the filament, which should create additional shielding (so that the guitar does not "start" when played).

Donor guitar

Inventing a printed neck is, of course, beyond the bounds, so only the body should be printed, but let's look for the neck, and at the same time all the electronics from the donor guitar will come in handy. There were a lot of options on avito, and in the end, Jackson, who had seen life, was purchased as a donor:

At home, the guitar was immediately dismantled, the neck was washed, polished and put in order. (guitars need to be looked after, of course).

Electronics from the guitar was also included in the project. I really liked the black and white combination of pickups. Yes, and FormaX is also black. The only thing that didn't fit the project from the donor was the tremolo bridge - "that iron thing with twists on the body, to which the strings are attached."

In a music store I picked up an inexpensive option + they also gave me cheap Olympia strings as a gift:

Test printing and fitting of the model x).

This thermoblock allows you to work at high temperatures with most materials with a working temperature up to 410°C. We install it according to the instructions from the PICASO 3D website - it takes no more than five minutes, calibrate the printer, refill the plastic, get the instruction from REC3D technical support on FormaX printing and run it for test printing - a piece of the rec company symbol. At the same time, we evaluate the wall of the model.

This thermoblock allows you to work at high temperatures with most materials with a working temperature up to 410°C. We install it according to the instructions from the PICASO 3D website - it takes no more than five minutes, calibrate the printer, refill the plastic, get the instruction from REC3D technical support on FormaX printing and run it for test printing - a piece of the rec company symbol. At the same time, we evaluate the wall of the model.

Pleasant enough structure.

Another test - printing a piece of the central part of the guitar to assess the strength with a given infill.

Print settings:

- Nozzle temperature: 280°C.

- Table temperature: 95 °C.

- No airflow

- Table adhesive: PICASO 3D printing adhesive.

- Supports strictly from the table (otherwise the internal communication channels will be flooded)

Nozzle in thermoblock steel: 0.5 mm.

The model shows a defect on the wall. Most likely the reason is in the feed - the material is abrasive and can get stuck in the nozzle. Therefore, we will play with temperatures and retracts during further printing.

Most likely the reason is in the feed - the material is abrasive and can get stuck in the nozzle. Therefore, we will play with temperatures and retracts during further printing.

Also during the test prints with "formax" it became clear that in order to obtain a better surface, it is better to place the part at an angle. In this case, the top, covering layers (which are the front side of the case) will be just as perfect as the side ones.

Running a little ahead of the story , I show a photo with examples of printing the same part printed at an angle (left) and just on a table (right). The question of further orientation of the model on the table immediately disappeared.

The right part was printed by the PICASO 3D 3D printer farm on the PICASO Designer XL PRO printer at my request. By my mistake in the TOR - the location of the part was flat on the platform and using supports not only from the surface, which led to the fact that the internal cavities for laying communications were filled with plastic, and the surface itself had an unpresentable appearance. I will write about the left part a little later - but I managed to fit it into PICASO Classic and it was printed at an angle.

I will write about the left part a little later - but I managed to fit it into PICASO Classic and it was printed at an angle.

As a result of all the trials and tests, it was decided to print all parts at an angle and spend plastic on supports (walk, walk) - I didn’t want to stop the project. To celebrate, another FormaX coil was purchased.

The first quality print result met all expectations:

From different angles, the plastic plays with both color and texture.

Here are some photos of the rest of the print:

All photos are attached in the original size - you can click the mouse and look closer. The material is absolutely fantastic. After it, I don’t want to look in the direction of PLA and ABS.

I had to stop printing several times due to problems:

As a result, I got parts for assembling as many as two guitars. In the photo below, parts rejected for various reasons.

As for the central part of the guitar - I still managed to fit it on the table in the slicer at a certain angle, but when printing, the corner of the model was "eaten", although everything should have fit.

The problem was found during communication with the representative of PICASO, Kapiton (very competent specialist) . It turned out that with the declared height of the print area, in fact, almost half a centimeter is missing. As it turned out, there was a special revision of the part that protects the coupling under the table screw, and the one that was installed on my printer was larger. They promptly sent me an STL model, I printed it from ABS and replaced it - everything immediately began to fit in height)

Such a stunning surface of parts made from this material. Without post-processing:

While the parts were printed and reprinted, I gutted the donor:

Everything was neatly disassembled, cleaned and set aside for further assembly of the printed version.

During the work, a problem was found in the central part - the neck did not fit into place. He crawled onto the body and covered the part of the pickup with an overlay:

I did not want to cut the neck and it was decided to increase the size of the platform on which it is attached. Since I'm not good at editing STL, I asked Ivan (Plastmaska) for help.

Thanks to Ivan, the printing of the third version of the central part of the body was launched on the same day and the next I had the opportunity to join the parts and evaluate what happened:

Next, the parts were fastened together with using 7 screws M3x10 and 2 screws M3x20 and followed by the assembly of electronics, wiring, installation of the tremolo bridge and neck:

Here I ran into the problem that the power of my "children's" soldering iron for soldering electronics is not enough. I had to call out in 3D chats and Ivan Kashirin (known to many printers in St. Petersburg) came to the rescue. The guitar was carefully transported to Vanya's office and all the electronics were carefully soldered:

Petersburg) came to the rescue. The guitar was carefully transported to Vanya's office and all the electronics were carefully soldered:

After assembly and soldering, it remained to put the strings, set their height, adjust the scale and install printed covers that cover the technological connectors on the back of the case.

Tuning and maintenance of the guitar was handled by Mikhail Marchenko, a professional in his field. I highly recommend those. who needs to put the instrument in order - https://vk.com/marchenko_mikhail.

A few photos:

Surely many people have a question - why did the project take the whole summer. In general, everything could be done slowly in 3-4 days, but summer is vacations, summer cottages, a lot of work for yourself and that guy, and there wasn’t much time to get down to business.

Well, a quick video. Happy listening everyone.

World's first guitar printed on 3D printer! 3D printed guitar!

May62016

3D printed guitar!

3D printed guitar!

Aluminum is the most abundant metal on earth and the third most abundant element after oxygen and silicon. Due to its low density, corrosion resistance and ability to easily combine with other metallic substances, aluminum is one of the most valuable industrial metals and is an indispensable material in the production of components for the aerospace and automotive markets. In addition, it has found application in the field of 3D printing, being one of the materials suitable for use in a 3D printer using selective laser sintering technology.

Due to its low density, corrosion resistance and ability to easily combine with other metallic substances, aluminum is one of the most valuable industrial metals and is an indispensable material in the production of components for the aerospace and automotive markets. In addition, it has found application in the field of 3D printing, being one of the materials suitable for use in a 3D printer using selective laser sintering technology.

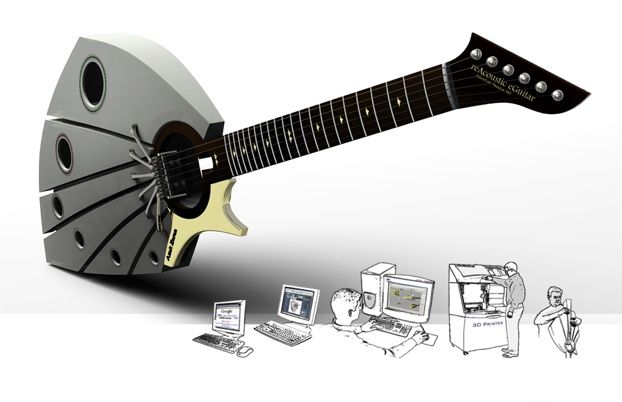

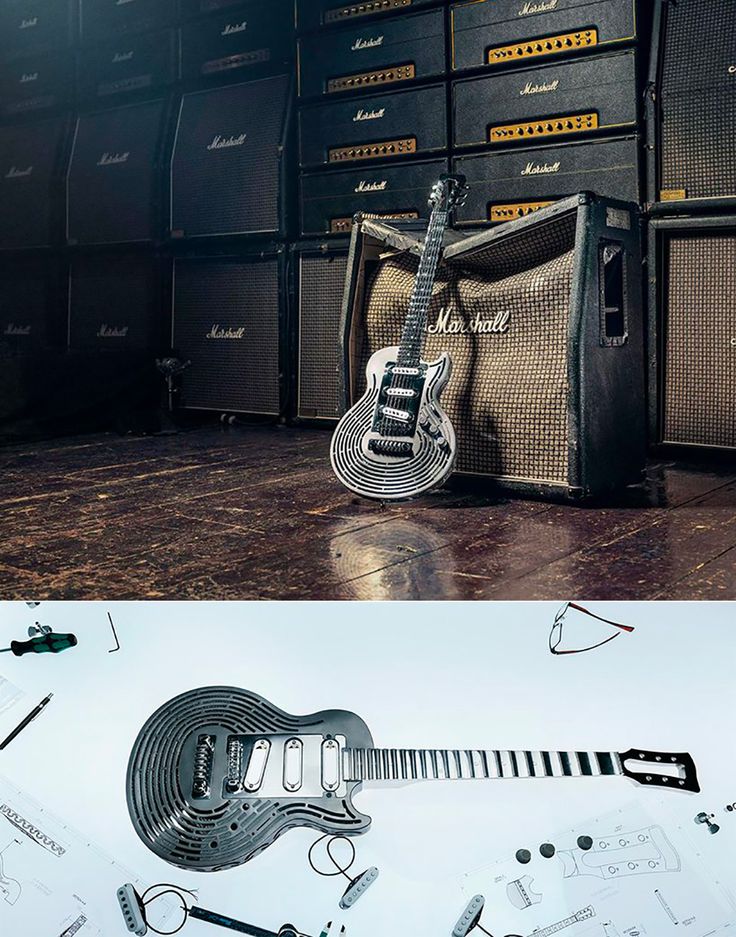

Aluminum is able to recreate almost any geometry of a product, which makes it an invaluable material for the manufacture of some advanced metal parts. However, no one could have imagined that someday he would be involved in such an unusual project as 3D printing of a guitar. Yes, yes, it was from aluminum that the Swedish artist and designer Olaf Digel decided to create his next exclusive musical instrument. Digel is known worldwide primarily for a range of original design guitars made using a 3D printer. Almost all 3D printed guitars that can be found on the web today are the creation of his hands.

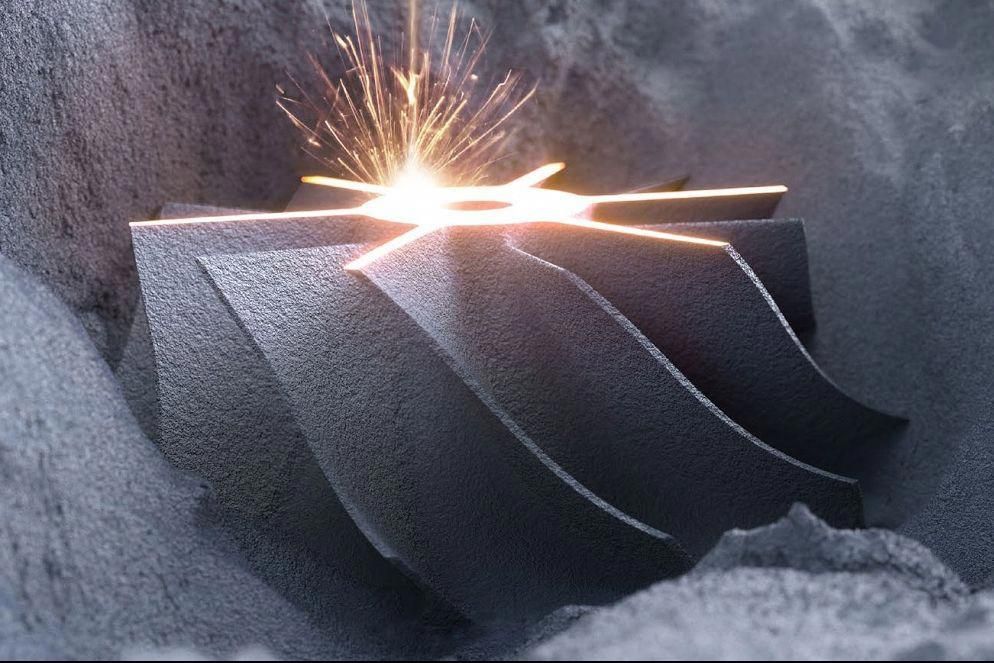

The designer's new project was inspired by the massive possibilities of 3D printing: Olaf was interested in what additive manufacturing technology with metal as the active material can do. In addition, Digel wanted to better understand the intricacies of the process itself, from design and 3D modeling to 3D printing itself. I didn’t have to think long about the name of this product, it suggested itself. Heavy Metal is the name of Olaf Diegel's new creation, inspired by the body shape of the legendary Fender Telecaster electric guitar.

3D printed guitar!

The front and back plates of the body are replaced by imitations of barbed wire, all pointed parts of which are directed away from the performer. 3D modeling of the product was carried out in CAD Solidworks, and the Dutch 3D printing service Xilloc helped the designer to reproduce the model in three dimensions. The aluminum body of the guitar was created on the basis of the EOS M400 additive manufacturing machine using preformed material melting technology.

3D printed guitar!

Due to the extreme heat during printing, the product needs additional supports which must then be removed. Upon completion of 3D printing, the elimination of all auxiliary materials occurs using various devices suitable for this purpose. However, in this case, Diegel wished to clean the sample himself from excess elements, which took him about four days, which is largely due to the complexity of the design of the artistic product.

A lot of effort was put into getting a smooth, beautiful surface that is pleasant to the touch, which further enhances the value of this product. After four days of polishing the guitar, it took another day to install the electronics. But the work done was worth it - its result is really amazing. Olaf Diegel's reputation as the manufacturer of the most beautiful 3D printed musical instruments is fully confirmed and it is clear that the artist does not intend to give up. And the great design of Heavy Metal is close to pushing the limits of metal 3D printing.