3D printed bird beak

3D Printed Prosthetic Beak Saves Bird's Life

Published on April 20, 2022 by Clemens M.

Additive manufacturing has already proven to be a valuable asset to the medical department on countless occasions. In some cases, its use can even help to save lives, like in the recent case of Crescent, a Great Indian Hornbill from ZooTampa in Florida, shows. Doctors using Formlabs’ BioMed White Resin were able to create a 3D printed prosthetic beak in order to save the bird from a fatal cancer.

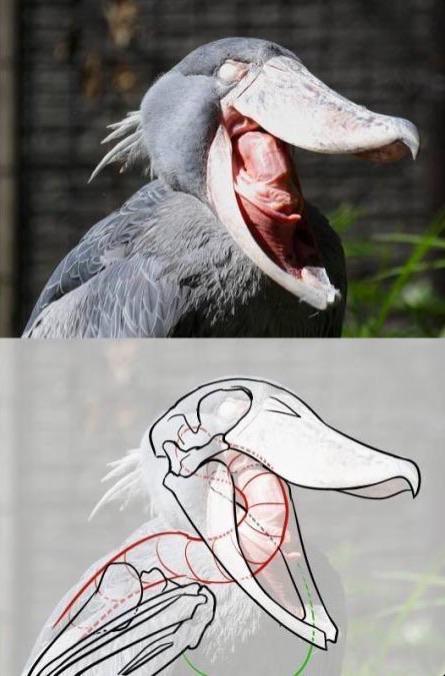

The story starts when caretakers at the Tampa Zoo first noticed a lesion on Crescents casque, which is the distinctive helmet-like portion on the upper beak. It was later discovered that the 25 year old bird had developed what veterinarians believed to be a squamous cell carcinoma. This is a common skin cancer also found on humans. While animals from this endangered species have a predisposition to this particular disease, a diagnosis is most of the time fatal. The veterinarians soon came to the conclusion that the only way to save her life was to get rid of the infected section of the beak entirely. By removing that area of the casque however, the then missing part would be leaving a big hole, resulting in her sinuses staying exposed.

The squamous cell carcinoma often ends fatal (photo credits: Formlabs)

In an effort to save Crescent, the veterinarians of ZooTampa turned to the University of South Florida (USF) medical team for help. Dr. Summer Decker, Director of 3D Clinical Applications at USF’s Radiology Department came up with the idea of 3D printing a prosthesis of the missing part. Already having used 3D printing for human prosthetics, Dr. Decker was convinced it would have the same positive outcome if used on the oversized bird.

In an amazing collaborative project, involving hospital physicians, veterinarians and biomedical engineers, the teams put together a complex plan to save the birds life. Before the actual surgery, the USF radiology team made CT scans of the casque to be able to 3D print an exact fitting prosthetic for Crescent. In addition, the scans were also used to develop and print a surgical guide, which made the procedure easier for the doctors performing the surgery. Following that, the surgeons took to the challenging task at hand, removing the tumour from the beak. In the next step, the doctors applied the 3D printed prosthetic using dental acrylic, before safely securing it with titanium screws.

Following that, the surgeons took to the challenging task at hand, removing the tumour from the beak. In the next step, the doctors applied the 3D printed prosthetic using dental acrylic, before safely securing it with titanium screws.

The 3D printed prosthetic covers the exact spot (photo credits: Formlabs)

Formlabs’ New Material Was Used in the Prosthetic Beak

To ensure the optimal use of 3D printing technology, the medical team got in contact with the specialists at Formlabs. The company, known for its leading role in the 3D printing industry, gladly contributed to the mission, providing technologies as well as a new special compatible material. Named BioMed White resin, the just recently developed material, which at the time had not even been officially released yet, proved to be optimal for the unique situation.

In order to be allowed in prosthetics or other 3D printed examples used on a living subject, the material has to fit exact standards. This particular high quality material, which is now also USP Class VI certified, provides high performance, biocompatibility and long term stability, all which is very important to ensure safe and long lasting results. It is furthermore designed for applications where opaque materials are preferred and functionality or aesthetic quality is demanded. These qualities made it optimal for the surgery, helping to contribute to its success.

It is furthermore designed for applications where opaque materials are preferred and functionality or aesthetic quality is demanded. These qualities made it optimal for the surgery, helping to contribute to its success.

The prothesis after surgery (photo credits: Formlabs)

Not long after the completed surgery, Crescent quickly recovered and has now gone back to her normal behaviour. The doctors were also pleased to see that she does not seem to think that the the prosthetic is abnormal, acting as healthy as ever. This specific procedure is the first of its kind performed in the United States, and the second in the entire world, being yet another great demonstration of how additive manufacturing can make our lives better. To find out more about Formlabs and it’s new biocompatible resin, you can visit the companies website HERE.

What do you think of the 3D printed beak prosthetic? Let us know in a comment below or on our Linkedin, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: ZooTampa

Mutilated toucan gets 3D-printed beak prosthesis

Published

Image source, Danielle Aires

Image caption,Tieta was rescued from an animal fair in Rio de Janeiro

By Luiza Bandeira

BBC Brasil

In a ground-breaking project, a Brazilian toucan which lost the upper part of its beak while being trafficked has been fitted with a prosthesis made with a 3D printer.

The female bird, named Tieta, was rescued from a wildlife animal fair in Rio de Janeiro.

It is not clear whether she lost the upper part of her beak after being mistreated by animal smugglers or in a fight with a bigger toucan she was locked up with inside a small box.

The project was co-ordinated by wildlife management group Instituto Vida Livre and involved three Brazilian universities.

Plastic replacement

The prosthetic is made of plastic, covered with nail polish and sealed with a special polymer made from the castor oil plant.

Image source, Gustavo Cleinman

Image caption,Researchers used the latest technology to design and produce the prosthesis

Image source, Gustavo Cleinman

Image caption,The beak is made of plastic and only weighs 4g

Taciana Sherlock from the Brazilian wildlife control agency Ibama said the toucan was rescued in March, malnourished and missing its beak.

Black-beaked toucans like Tieta, which are native to Rio and not endangered, can cost up to $5,000 (£3,180) when sold legally, according to Ms Sherlock.

She says that before the surgery Tieta was using the lower part of the beak to throw food into the air and trying to grab it.

She only succeeded once in every three attempts.

Hungry for maggots

Tieta was fitted with the prosthesis on 27 July.

"It took her three days to realise she had it again," says Instituto Vida Livre Director Roched Seba.

"We were feeding her fruit and she was ignoring the new beak. But when we gave her live animals, like maggots and cockroaches, she ate normally immediately," he explains.

"I believe she had that kind of food when she was free, before losing the beak. So it activated a core memory," he adds.

It took researchers three months to design the beak but it took only two hours for the printer to print it. - the beak weighs approximately 4g and it is 4cm (1.6in) long.

Image source, Gustavo Cleinman

Image caption,The prosthesis is 4cm long and replaces the upper part of the beak

Tieta herself only weighs 300g.

Designer Gustavo Cleinman from Rio de Janeiro's Federal University says the biggest challenge was to create a light and resilient prosthesis.

He used the beak of a dead animal as a model and adapted it to resemble Tieta's original beak more closely.

Hope for mating

The team was breaking new ground with this project.

Although another group of researchers was creating a prosthetic beak for another injured toucan in Sao Paulo, the two teams were unaware of each other's work.

In Costa Rica, a charity has raised $10,000 for a prosthesis for a toucan which also lost the upper part of its beak, but the surgery has yet to be performed.

Tieta's surgery only took 40 minutes to perform but was not without risks, veterinarian Thiago Muniz says.

This video can not be played

To play this video you need to enable JavaScript in your browser.

Media caption,The toucan lost part of its beak while being trafficked

He explains that the prosthesis will allow her to eat independently and also help her access glands on her body that keep her feathers waterproof.

With the help of the prosthesis, Tieta will also be able to feed any chicks she might have in the future.

But Ms Sherlock says that unfortunately it will not allow her to be released into the wild.

"She wouldn't be able to live an independent life, even in captivity," she says.

Wildlife control agency Ibama wants to send her to an educational zoo to create awareness about animal trafficking, but they have not yet settled on one.

What is certain is that wherever she is sent she will be joined there by another toucan, which was also rescued from animal traffickers and sent to Ibama.

The male bird also has a problem with his beak.

The researchers hope Tieta and the male toucan will eventually mate. Their chicks would be released into the wild, Ibama says.

Future: Science and technology: Lenta.ru

Frame: Formlabs / YouTube

1

Bird's beak printed using biocompatible resin in the USA

Scientists from the University of South Florida (USA) and Formlabs specialists performed a successful operation on replacement of part of the diseased beak of a rare bird. Doctors operated on a hornbill that lives in the Tampa City Zoo, Florida. The animal suffered from skin cancer, which is fatal to this type of bird; as a result of cancer, the part of the beak that covers the nasal sinuses was damaged. Specialists scanned the skull of the animal, made a prosthesis based on a special resin and installed it in place.

Doctors operated on a hornbill that lives in the Tampa City Zoo, Florida. The animal suffered from skin cancer, which is fatal to this type of bird; as a result of cancer, the part of the beak that covers the nasal sinuses was damaged. Specialists scanned the skull of the animal, made a prosthesis based on a special resin and installed it in place.

According to doctors, after the operation the bird quickly recovered, the surgical intervention did not affect her appetite and habits. After some time, the protective mask printed on a 3D printer acquired the color of a beak, which became possible due to the secretions of special glands produced by the body of hornbills. The inventors of a medical 3D printer and a biocompatible resin said that in the future it is possible to use prostheses and artificial organs created individually for each patient with a specific disease.

3D printed hornbill implant

Photo: ZooTampa at Lowry Park

2

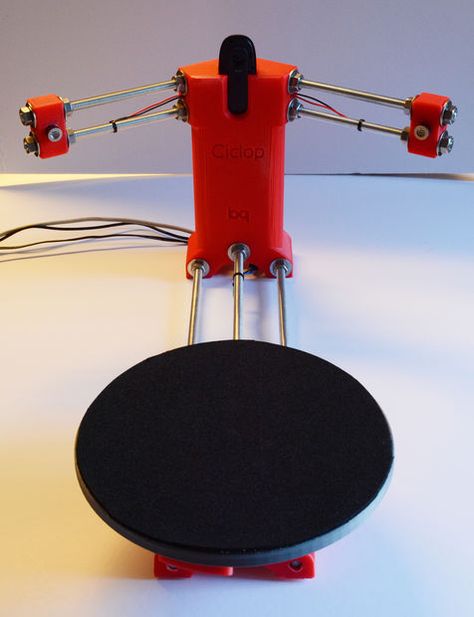

3D printing solves the problem of creating high-quality and affordable prostheses

Experts estimate that hundreds of thousands of people lose limbs and become waiting for a prosthesis. Mass-market prostheses are only available in a few sizes, so wearers have to adapt to the features of the medical equipment. In addition, they are short-lived and expensive to manufacture. 3D printing allows you to create an almost perfect prosthesis according to individual drawings. In this case, he can successfully replace the lost arm or leg.

Mass-market prostheses are only available in a few sizes, so wearers have to adapt to the features of the medical equipment. In addition, they are short-lived and expensive to manufacture. 3D printing allows you to create an almost perfect prosthesis according to individual drawings. In this case, he can successfully replace the lost arm or leg.

Prosthetic services are also commonly available to patients in the developed world with good medical insurance. Formlabs experts note that the problem lies in the lack of manufacturing processes that allow the production of non-standard parts at an affordable price. 3D printing could make prosthetics more affordable. For example, the non-profit initiative e-NABLE offers free blueprints, mockups, and open source programs to create medical devices using printers. In this case, the cost of one custom-made prosthesis can be only about $50.

3

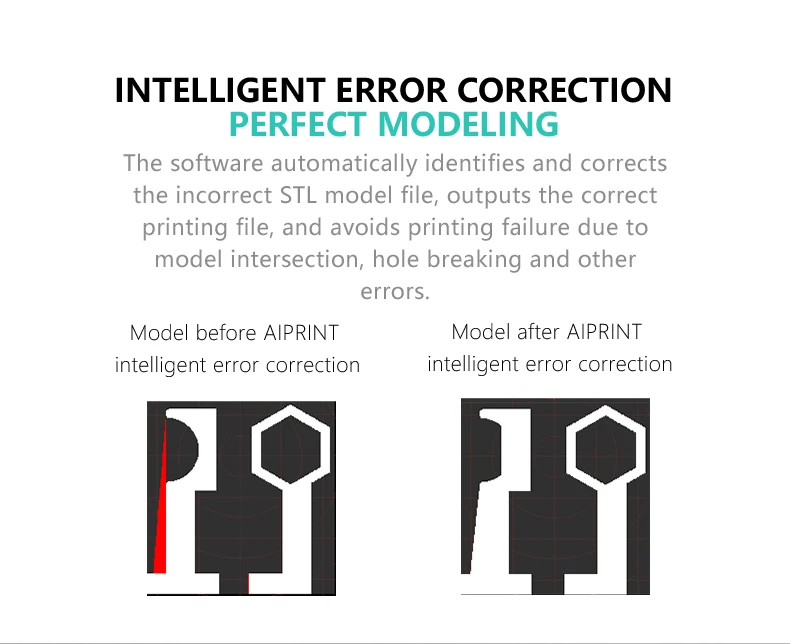

Medical 3D printing requires a special resin that is compatible with living organisms

Modern 3D printers print blanks based on photopolymer resin, a special liquid substance that hardens when exposed to light. In medical printing, everything is much more serious, since it is believed that a person will be in direct contact with an object created using a 3D printer for quite a long time. Scientists explain that printed prostheses must have an ideal shape, taking into account the structural features of the body, and also consist of safe materials that will not cause an allergic reaction or rejection.

In medical printing, everything is much more serious, since it is believed that a person will be in direct contact with an object created using a 3D printer for quite a long time. Scientists explain that printed prostheses must have an ideal shape, taking into account the structural features of the body, and also consist of safe materials that will not cause an allergic reaction or rejection.

“The importance of 3D printing in healthcare cannot be overestimated,” says Gaurav Manchanda, director of medical market development at Formlabs. For example, medical "live" resin essentially resembles the material for printing conventional 3D blanks, but differs in detail from them. Firstly, it allows you to print more accurate objects - about a hundred microns in size. Secondly, it is designed for prolonged contact with the skin or mucous membranes. Thirdly, the resin can be given absolutely any shade, which is especially important in dentistry. For example, Formlabs has BioMed Clear Resin, which has a high degree of transparency, which may be required to produce parts that show internal anatomy.

4

3D printing will eliminate organ transplants

When organ transplants are needed, patients may face the same problem as when creating a prosthesis: the supply of suitable biomaterials is extremely limited, and the cost of transplantation is very high. In addition, the body may not accept a new organ, in which case the efforts to find a donor and prepare the patient for surgery will go down the drain. Theoretical medicine proposes to create the necessary organs on order, literally printing them on the basis of the patient's biomaterial.

Experts describe the use of bio-ink, a special material and a kind of raw material for medical 3D printers. Bio-ink is created using tissue engineering techniques based on samples received from the patient. Doctors take a part of the patient's tissue and place it in a bioreactor, where, with the help of nutrients, the material acquires the mechanical and biological properties of organic tissue. Bioengineers can direct cell growth in such a way that the desired tissue or organ type is obtained as a result. The probability that the resulting organ will take root in the patient's body is extremely high. Also, scientists from around the world offer to grow organs in the body of animals. According to Genotek CEO Valery Ilyinsky, such technologies will become a reality in five to ten years. However, the production of individual kidneys, liver or heart based on the patient's biomaterial still seems to be a more reliable way to replace a damaged organ - due to the maximum compatibility of the printed organ and the patient's body. In this case, resorting to exotic methods of solving the problem - such as transplanting a pig's heart to a person - will not be required.

Bioengineers can direct cell growth in such a way that the desired tissue or organ type is obtained as a result. The probability that the resulting organ will take root in the patient's body is extremely high. Also, scientists from around the world offer to grow organs in the body of animals. According to Genotek CEO Valery Ilyinsky, such technologies will become a reality in five to ten years. However, the production of individual kidneys, liver or heart based on the patient's biomaterial still seems to be a more reliable way to replace a damaged organ - due to the maximum compatibility of the printed organ and the patient's body. In this case, resorting to exotic methods of solving the problem - such as transplanting a pig's heart to a person - will not be required.

At the moment, doctors can grow primitive parts of the tissues of the human body, and the technology for creating complex internal organs is still in the field of futurology. At the same time, scientists look much further - in the future, printing not only the heart, but also blood vessels. Experts remind that diseases of the cardiovascular system are now the number one cause of death in the world. “Creating blood vessels with 3D printing opens up the possibility of creating a ‘design’ of blood vessels that fits the patient,” says Dr Sam Pashneh-Tala from the University of Sheffield.

Experts remind that diseases of the cardiovascular system are now the number one cause of death in the world. “Creating blood vessels with 3D printing opens up the possibility of creating a ‘design’ of blood vessels that fits the patient,” says Dr Sam Pashneh-Tala from the University of Sheffield.

A prototype of an artificial heart created using a 3D printer by Israeli specialists

Frame: ColdFusion / YouTube

When people start mass printing organs and body parts

April 5

Lenta.ru

using biocompatible resin

Photo: Formlabs / YouTubeFormlabs / YouTube

Scientists from the University of South Florida (USA) and Formlabs specialists performed a successful operation to replace part of the diseased beak of a rare bird. Doctors operated on a hornbill that lives in the Tampa City Zoo, Florida. The animal suffered from skin cancer, which is fatal to this type of bird; as a result of cancer, the part of the beak that covers the nasal sinuses was damaged. Specialists scanned the skull of the animal, made a prosthesis based on a special resin and installed it in place.

Specialists scanned the skull of the animal, made a prosthesis based on a special resin and installed it in place.

Video of the day

According to the doctors, the bird recovered quickly after the operation, the surgery did not affect its appetite and habits. After some time, the protective mask printed on a 3D printer acquired the color of a beak, which became possible due to the secretions of special glands produced by the body of hornbills. The inventors of a medical 3D printer and a biocompatible resin said that in the future it is possible to use prostheses and artificial organs created individually for each patient with a specific disease.

ZooTampa at Lowry Park

3D printed hornbill implant

3D printing solves the problem of creating high-quality and affordable prostheses waiting list for a prosthesis. Mass-market prostheses are only available in a few sizes, so wearers have to adapt to the features of the medical equipment.

In addition, they are short-lived and expensive to manufacture. 3D printing allows you to create an almost perfect prosthesis according to individual drawings. In this case, he can successfully replace the lost arm or leg.

In addition, they are short-lived and expensive to manufacture. 3D printing allows you to create an almost perfect prosthesis according to individual drawings. In this case, he can successfully replace the lost arm or leg. Prosthetic services are also commonly available to patients in the developed world with good health insurance. Formlabs experts note that the problem lies in the lack of manufacturing processes that allow the production of non-standard parts at an affordable price. 3D printing could make prosthetics more affordable. For example, the non-profit initiative e-NABLE offers free blueprints, mockups, and open source programs to create medical devices using printers. In this case, the cost of one custom-made prosthesis can be only about $50.

Medical 3D printing requires a special resin that is compatible with living organisms

Modern 3D printers print blanks based on photopolymer resin, a special liquid substance that hardens when exposed to light. In medical printing, everything is much more serious, since it is believed that a person will be in direct contact with an object created using a 3D printer for quite a long time. Scientists explain that printed prostheses must have an ideal shape, taking into account the structural features of the body, and also consist of safe materials that will not cause an allergic reaction or rejection. “The importance of 3D printing in healthcare cannot be overestimated,” said Gaurav Manchanda, director of medical market development at Formlabs. For example, medical "live" resin essentially resembles the material for printing conventional 3D blanks, but differs in detail from them. Firstly, it allows you to print more accurate objects - about a hundred microns in size. Secondly, it is designed for prolonged contact with the skin or mucous membranes. Thirdly, the resin can be given absolutely any shade, which is especially important in dentistry. For example, Formlabs has BioMed Clear Resin, which has a high degree of transparency, which may be required to produce parts that show internal anatomy.

In medical printing, everything is much more serious, since it is believed that a person will be in direct contact with an object created using a 3D printer for quite a long time. Scientists explain that printed prostheses must have an ideal shape, taking into account the structural features of the body, and also consist of safe materials that will not cause an allergic reaction or rejection. “The importance of 3D printing in healthcare cannot be overestimated,” said Gaurav Manchanda, director of medical market development at Formlabs. For example, medical "live" resin essentially resembles the material for printing conventional 3D blanks, but differs in detail from them. Firstly, it allows you to print more accurate objects - about a hundred microns in size. Secondly, it is designed for prolonged contact with the skin or mucous membranes. Thirdly, the resin can be given absolutely any shade, which is especially important in dentistry. For example, Formlabs has BioMed Clear Resin, which has a high degree of transparency, which may be required to produce parts that show internal anatomy.

3D printing will eliminate organ transplants

When organ transplants are needed, patients may face the same problem as when creating a prosthesis: the supply of suitable biomaterials is extremely limited, and the cost of transplantation is very high. In addition, the body may not accept a new organ, in which case the efforts to find a donor and prepare the patient for surgery will go down the drain. Theoretical medicine proposes to create the necessary organs on order, literally printing them on the basis of the patient's biomaterial.

Experts describe the use of bio-ink, a special material and a kind of raw material for medical 3D printers. Bio-ink is created using tissue engineering techniques based on samples received from the patient. Doctors take a part of the patient's tissue and place it in a bioreactor, where, with the help of nutrients, the material acquires the mechanical and biological properties of organic tissue. Bioengineers can direct cell growth in such a way that the desired tissue or organ type is obtained as a result. The probability that the resulting organ will take root in the patient's body is extremely high. Also, scientists from around the world offer to grow organs in the body of animals. According to Genotek CEO Valery Ilyinsky, such technologies will become a reality in five to ten years. However, the production of individual kidneys, liver or heart based on the patient's biomaterial still seems to be a more reliable way to replace a damaged organ - due to the maximum compatibility of the printed organ and the patient's body. In this case, resorting to exotic methods of solving the problem - such as transplanting a pig's heart to a person - will not be required.

ColdFusion / YouTube

3D-printed artificial heart prototype by Israeli experts

At the moment, doctors can grow primitive parts of human tissue, and the technology for creating complex internal organs is still in the field of futurology. At the same time, scientists look much further - in the future, printing not only the heart, but also blood vessels.