3D printed arch supports

ME3D Custom Products | 3D Printed Arch Support

- Compare added products

PERSONALIZED

3D-PRINTED CUSTOM INSOLES

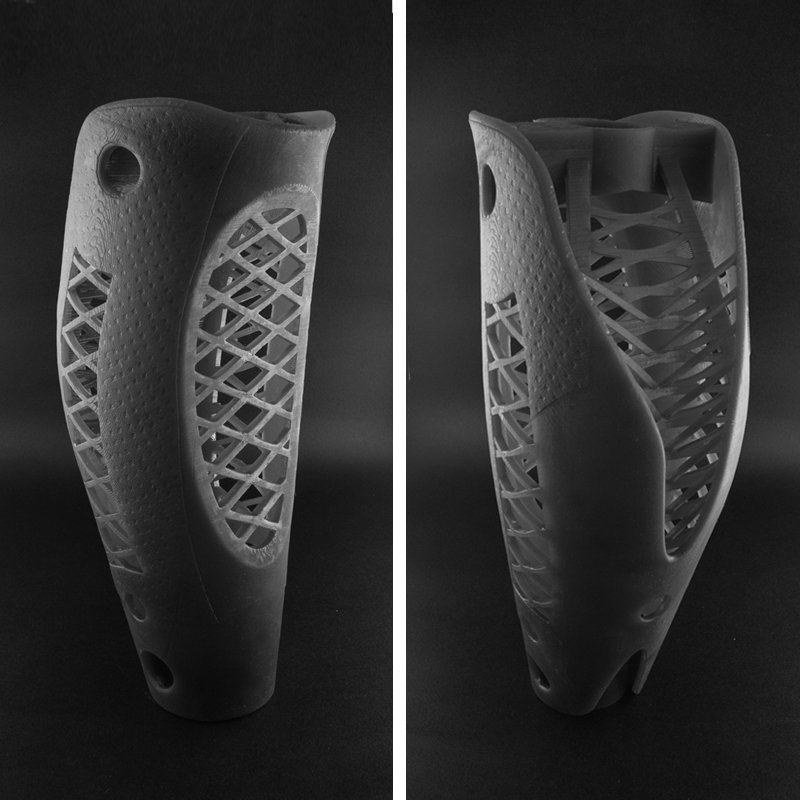

Your ME3D insoles are made with a personalized 3D-printed Superfeet shape for individualized support that moves with you. Created to match the geometry of each foot for truly personalized support. ME3D custom orthotic insoles are calibrated to each foot’s dynamic pressure pattern, with five independent support zones that adapt and respond to the way you move. Available in two style choices to dial in your perfect comfort feel.

PERSONALIZED

3D-PRINTED CUSTOM INSOLES

Your ME3D insoles are made with a personalized 3D-printed Superfeet shape for individualized support that moves with you. Created to match the geometry of each foot for truly personalized support. ME3D custom orthotic insoles are calibrated to each foot’s dynamic pressure pattern, with five independent support zones that adapt and respond to the way you move. Available in two style choices to dial in your perfect comfort feel.

NOW AVAILABLE IN TWO STYLES

Thin, high density foam for a slimmer fit

Premium dual-layer cushioning for plush support

MADE FOR YOU

Your biometric data insights are transformed into personalized insoles designed to match the geometry of each foot and your one-of-a-kind movement pattern, at a fraction of the cost of custom orthotics.

PERSONALIZED

SUPPORT

Custom arch support profile created to

match the geometry of each foot.

SUPPORT THAT

MOVES WITH YOU

Five independent zones tuned to adapt and respond to the way the foot moves.

VARIABLE FLEXIBILITY SCALE

DIRECTIONAL

FLEX LINES

Angled to provide guidance to your foot during the gait. Flex line angles on each insole cap are based on the distribution and timing of pressure during your dynamic scan.

Flex line angles on each insole cap are based on the distribution and timing of pressure during your dynamic scan.

MADE FOR YOU

A customized arch profile, independent flex zones, and directional flex lines create an insole that is perfect for your unique foot

PERSONALIZED SUPPORT

Custom arch support profile created to

match the geometry of each foot.

SUPPORT THAT

MOVES WITH YOU

Five independent zones tuned to adapt and respond

to the way the foot moves.

DIRECTIONAL

FLEX LINES

Angled to provide guidance to your foot during the gait cyle.

Angle based on the distribution and timing of pressure during your dynamic scan.

MADE IN THE USA

MADE IN THE USA

HOW TO GET YOUR ME3D PRODUCTS

Your next best move is only a few steps away. Find a ME3D retailer near you to measure each of your feet, analyze your gait and place your order. Using your unique biometrics, we’ll custom-create your ME3D insoles and ship them direct to you.

VISIT YOUR NEAREST

RETAILER

SCAN YOUR FEET

See your unique foot shape and gait profile, then

choose to create your personalized product.

PERSONALIZED

COMFORT, DELIVERED

In just over a week, your ME3D product will arrive

direct to you.

ERYONE Arch Support Insoles & Inserts

Important notice

[Note:Due to the COVID-19, delivery time might be delayed, but we will try and take care about on time]

Free shipping on all orders in Contiguous US.

[Note:Except few aresas.Normally we don't shipment this area.If you are from there and wants to buy our product please contact with us before order and know about the shipping fee.]

Handle Order

Time: We will handle the order in 3 days and send you the tracking information.

Cancel Order: Cancel the order within 24 hours after payment.

Out of stock: After your payment if the product out of stock we will let you know within 3 days. You can Change the product or You can wait until goods in stock or You can get Refund.

Warehouse

We have several warehouses located in US, CA, UK, EU and China.For US,CA,UK and EU friends we will fill the order from nearby warehouse.

For the other countries we will fill the order from "China".

Shipping rate from overseas warehouse

| Product | Shipping Rate "US" | Shipping Rate "CA" | Shipping Rate "UK" | Shipping Rate "EU" |

| Mailing Method | USPS,Fedex,DHL E-commerce | Chanada Post | Royal mail | DHL,DPD,GLS |

| Filament | Free | Free for some of areas. For some of areas need to pay but If you buy more than 4 rolls of filaments it will free shipment For some of areas need to pay but If you buy more than 4 rolls of filaments it will free shipment | Free | Free for some of areas.For some of areas need to pay but If you buy more than 4 rolls of filaments it will free shipment |

| Resin | Free | Free for some of areas.For some of areas need to pay but If you buy more than 6 Bottles of Resin it will free shipment | Free | Free for some of areas.For some of areas need to pay but If you buy more than 6 Bottles of Resin it will free shipment |

| 3D Printer Accessories | Free | Free | Free | Free |

Warmly Noted: Above illustration only use for Regular items(Without Discount Items),Owing to shipping fee raised up more and more fast, we will appropriately charge a little to each orders that enjoy discount(Pay shipping fee only Discount Collection Products,Some remote areas in Canada,shipping fee will higher a little)

Shipping rate from China

| Product | Shipping Rate "US" | Shipping Rate "CA" | Shipping Rate "UK | Shipping rate "EU" | Shipping rate Other countries |

| Mailing Method | China Post,4PX | China Post,4PX | China Post,4PX | China Post,4PX | China Post,4PX |

| 3D Printer | Free | Free | Free | Free | Free |

| Filament | 30$ | 30$ | 30$ | 30$ | 30$ |

| Resin | 30$ | 30$ | 30$ | 30$ | 30$ |

| 3D Printer Accessories | Free | Free | Free | Free | Free |

Warmly Noted: Above illustration only use for Regular items(Without Discount Items),Owing to shipping fee raised up more and more fast, we will appropriately charge a little to each orders that enjoy discount(Pay shipping fee only Discount Collection Products,Some remote areas in Canada,shipping fee will higher a little)

Shipping time from overseas warehouse

| Product | Ship to US | Ship to CA | Ship to UK | Ship to EU |

| 3D Printer | From US warehouse(3 to 8 busines days) | From CA warehouse(3 to 8 busines days) | From UK warehouse(2 to 4 busines days) | From EU warehouse(4 to 8 busines days) |

| Filament | From US warehouse(3 to 8 busines days) | From CA warehouse(3 to 8 busines days) | From UK warehouse(2 to 4 busines days) | From EU warehouse(4 to 8 busines days) |

| Resin | From US warehouse(3 to 8 busines days) | From CA warehouse(3 to 8 busines days) | From UK warehouse(2 to 4 busines days) | From EU warehouse(4 to 8 busines days) |

| 3D Printer Accessories | From US warehouse(3 to 8 busines days) | From CA warehouse(3 to 8 busines days) | From UK warehouse(2 to 4 busines days) | FFrom EU warehouse(4 to 8 busines days) |

Shipping time from China

| Product | Ship to US | Ship to CA | Ship to UK | Ship to EU | Ship to Other countries |

| 3D Printer | From China(5 to 7 busines days) | From China(5 to 7 busines days) | From China(5 to 7 busines days) | From China(5 to 7 busines days) | From China(5 to 7 busines days) |

| Filament | From China(5 to 7 busines days) | From China(5 to 7 busines days) | From China(5 to 7 busines days) | From China(5 to 7 busines days) | From China(5 to 7 busines days) |

| Resin | From China(5 to 7 busines days) | From China(5 to 7 busines days) | From China(5 to 7 busines days) | From China(5 to 7 busines days) | From China(5 to 7 busines days) |

| 3D Printer Accessories | From China(7 to 15 busines days) | From China(7 to 15 busines days) | From China(7 to 15 busines days) | From China(7 to 15 busines days) | From China(7 to 20 busines days) |

Delivery Guarantees

-

Order shipped in 3 business days.

-

Products (filaments, printers) are shipped from overseas warehouse, we guarantee that order will be delivered in 5-8 busines days, otherwise you can contact us to resend or refund if order isn’t delivered in 15 business days.

-

Accessories are shipped from China, we guarantee that order will be delivered in 7-15 business days, otherwise you can contact us to resend or refund if order isn’t delivered in 30 business days.

Contact us

[email protected]

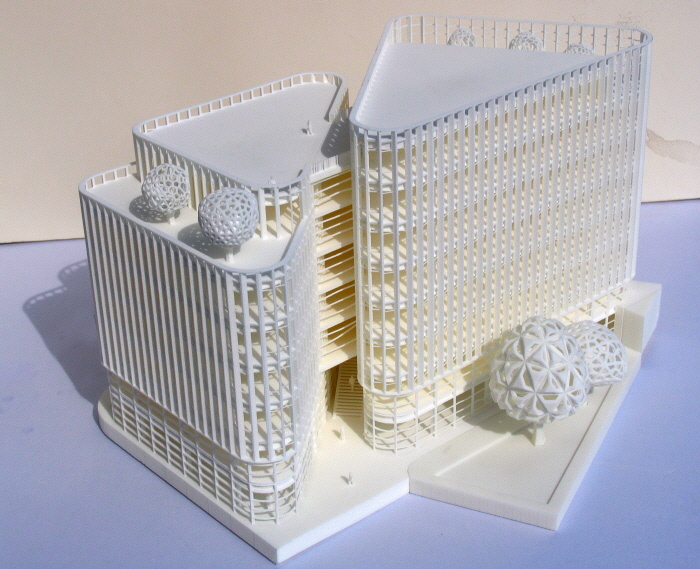

How to choose a 3D printer for your dental office or lab

Additive manufacturing is the final piece of the digital dentistry manufacturing process and has become a logical business choice for dental offices and laboratories due to its combination of high quality, low cost and streamlined workflows. The market is rapidly evolving, making this technology available to most businesses.

In this guide, we'll look at the various 3D printing technologies used in dentistry, as well as all the data you need to evaluate before investing in a dental 3D printer.

New to digital dentistry? Check out our guide to learn more about the difference between analog and digital processes and what goes into integrating 3D printing into your work.

sample

Would you like to see the resulting quality with your own eyes? Choose your material and we'll send you a free sample of the Form 3B 3D printed model for you to evaluate.

Request a free sample

Two 3D printing technologies are currently used in dental practices and laboratories: stereolithography (SLA) and digital light processing (DLP).

In stereolithography, the printed area on a container of liquid polymer is selectively exposed to a laser beam, whereby the polymer solidifies in specific locations. The Low Force Stereolithography (LFS) technology used in the Formlabs Form 3B Dental 3D Printer is the next evolution in SLA 3D printing, which reduces interlayer deformation on a part as it peels off the resin container, producing parts with incomparable smooth, clean and precise surface.

Digital Light Processing uses the same chemical process as SLA and LFS, but uses a digital projector rather than a laser as the light source to cure the resin.

The most common dental 3D printers selectively hit liquid polymer with a light source: SLA and LFS with a laser, DLP with a projector, forming very thin solid layers of plastic that fold into a solid object.

SLA, LFS, and DLP 3D printers work in the same way, and the differences in print quality, workflow, materials used, cost, and other characteristics are device-specific rather than technology-based.

Clear aligner, thermoformed from a 3D printed model on a Formlabs Form 3B dental 3D printer.

Webinar

Watch a Formlabs product demo and take a closer look at our new LFS dental 3D printer.

Watch the webinar now

Ensuring the high quality and accuracy of final models is the most important task for any dental practice and laboratory. Unfortunately, not all 3D printers on the dental market are capable of delivering the quality, precision, and accuracy required for dental products. In addition, comparing different dental 3D printers goes beyond comparing specifications.

Unfortunately, not all 3D printers on the dental market are capable of delivering the quality, precision, and accuracy required for dental products. In addition, comparing different dental 3D printers goes beyond comparing specifications.

Some manufacturers may try to confuse their potential customers with misleading claims and specifications. Most often, they pass off as "accuracy" the height of the layer, the size of the laser spot or pixel, although these characteristics do not directly affect the accuracy of the finished models. While most companies list accuracy as just one number (50 or 75 microns, for example), this is usually a marketing gimmick and most often indicates the ultimate resolution of a printer.

The basic units of the SLA and DLP processes are different shapes, making it difficult to compare different printers by numbers alone.

In essence, many different factors affect accuracy and accuracy: the quality of the 3D printer itself, the 3D printing technology, materials, software settings, post-processing, and how well all these systems are calibrated, so about 3D printing printer can only be judged by the final dental models.

Accuracy should always be judged from actual scan data of printed models. Better yet, order a free sample or a sample of your own design to check for fit or measure and compare with the original design.

Examining the accuracy of a complete arched model with stamps printed on a Form 3B LFS 3D printer. Dental 3D printers can produce a range of high quality custom products at low cost, providing exceptional fit and reproducible results.

The ease of use of a 3D printer is another important point. Eventually, you will have to learn how to operate the equipment and maintain it on a daily basis. Try to understand what the learning curve for a new 3D printer will look like by watching online videos, visiting an exhibition, contacting the sales team, or asking your colleagues to share their experience.

Fortunately, most of today's SLA and DLP desktop 3D printers are designed to be intuitive, so that offices and labs that will use this equipment as an outsourcer can easily become familiar with the process.

Review all types of day-to-day operations and maintenance that the printer will need after it has been started up and during operation. For example, automatic resin dispensing on the Formlabs SLA and LFS 3D printers means you never have to worry about running out of material.

Some printers come with their own 3D printing software, such as PreForm for Formlabs 3D printers, while others offer pre-built solutions. Different software tools have different features, for example, PreForm offers one-click print process customization, powerful tools for optimizing substrate density and size, adjustable layer thickness, and features that save materials and time.

Want to see how it works? Download PreFrom for free to test its features.

Models printed with SLA, LFS, and DLP require post-processing after printing.

First, the models must be washed in solvent to remove excess resin. In addition, biocompatible dental models require post curing. For SLA and LFS 3D printers, Formlabs offers solutions to automate these steps, saving time and labor, greatly improving the maintenance of a clean, low-maintenance production environment.

Finally, depending on the design, some models need to be separated from the supporting structures. To make this easier, the Formlabs Form 3B printer features easy-to-remove support structures that greatly reduce the need for finishing and costly manual labor.

The first 3D printers had a bad reputation because half the time was spent on their maintenance, and a large number of printed products went to waste, even if the printers worked fine. Fortunately, the latest generation of printers has much higher reliability. For example, users of the Formlabs 3D printer report success rates over 9 million attempts on tens of thousands of printers.5 %. Examine published reliability information in detail and make sure the manufacturer has the appropriate warranties and service offerings to make sure you get the proper attention if service is required.

If you are making a decision to implement a new technology, it should make sense for your business. The cost of dental 3D printers has come down significantly compared to the first models, and the systems on the market today have extremely low costs for a wide variety of applications.

For example, a practice or lab that prints their own surgical templates or dental models for thermoformed aligners can often reduce the cost of each model by 75-95% compared to outsourcing these operations to labs and service providers—enough to a few weeks to recoup a 3D printer, and over the years to save an amount many times higher than its price.

When comparing different 3D printing solutions for dentists, don't forget to consider:

-

upfront costs, including not only the cost of equipment, but also the cost of training, setup, and possibly the purchase of software;

-

operating costs, which are best estimated as costs per unit of material;

-

maintenance costs. Beware of mandatory service contracts that can cost up to 20% of the printer's original price per year.

INTERACTIVE

Try our interactive ROI tool to see how much time and money you can save by printing with Formlabs 3D printers.

Calculate Savings

Professional 3D printers are some of the most versatile tools available in dental offices and laboratories today, and specialty materials are the key to their versatility.

Media selection depends on the printer model. Some simple 3D printers can only produce diagnostic models, while more sophisticated systems can produce highly accurate models of crowns and bridges, surgical templates, and cast/pressed reconstructions; durable biocompatible dental products such as dental splints and retainers or digitally modeled dentures, as well as orthodontic brackets such as clear aligners and Hawley abutments by thermoforming 3D printed models.

Dental 3D printers enable cost-effective mass production of custom dental products.

Some 3D printers only work with their proprietary materials, which means your options will be limited to what the printer manufacturer offers. Other printers are so-called open systems, which means you can use third party materials.

However, when using third party materials, it is important to ensure that the results are clinically acceptable in terms of quality and accuracy. Moreover, the use of biocompatible materials on unproven 3D printers, which are considered "open" systems, violates application requirements and thus leads to the production of biologically incompatible products. Be careful and be aware of the risks your business is taking by using untested 3D printers and materials.

Surgical templates printed on a Formlabs Form 3B dental 3D printer.

Manufacturers release new materials regularly, so it's very likely that the printer you buy today will be able to create more and more dental products in the near future.

When talking about the speed of 3D printing, it is important to consider not only the printing speed itself, but also the productivity.

The overall print speed of SLA, LFS and DLP 3D printers is about the same. Since the projector exposes each layer in its entirety, the speed of DLP 3D printing is uniform and depends only on the height of the model, while the SLA and LFS 3D printers laser shape every detail. In practice, as a result, SLA and LFS 3D printers become comparable in speed or even faster when printing a single model or smaller models, while DLP 3D printers print several models faster, which almost completely fill the platform space.

In practice, as a result, SLA and LFS 3D printers become comparable in speed or even faster when printing a single model or smaller models, while DLP 3D printers print several models faster, which almost completely fill the platform space.

However, with DLP printers, there is a trade-off between resolution and working volume. Small DLP 3D printers are capable of printing fast, but you can only place a few models on the platform. Another high volume machine can print more detail, but only at a lower resolution, which means it may not be accurate enough to print restorative models or surgical templates that require higher precision.

The SLA and LFS 3D printers are able to do all of these in one device, giving dentists and labs the freedom to choose between optimal resolution, print speed or performance, as the case may be.

Another important detail, especially for labs, is whether to do all the work on one or more printers. Using multiple presses usually reduces the initial cost compared to larger format devices. By purchasing inexpensive equipment first, labs can test different production methods before eventually scaling up production to meet demand. This makes it possible to pay for production only as the need arises, rather than making large long-term investments in a rapidly developing market.

By purchasing inexpensive equipment first, labs can test different production methods before eventually scaling up production to meet demand. This makes it possible to pay for production only as the need arises, rather than making large long-term investments in a rapidly developing market.

Print cells also reduce risk through redundancy. If one printer needs maintenance, production can be split between the remaining print cells.

Print Cells allow you to 3D print multiple different models in parallel, spreading production needs and reducing risk through redundancy.

Whereas a few years ago 3D printers were only available to the largest dental laboratories and machining centers, now they are available in many dental offices and laboratories.

Consider the factors discussed above and the needs of your business: some solutions may work better than others. Be sure to do your research, consider the models you use, and try to avoid overspending.

Explore Formlabs dental offerings, get free guides, step-by-step guides, white papers, webinar training, and learn how to implement 3D printing in your lab or office.

Would you like to see the resulting quality with your own eyes? Choose your material and we'll send you a free sample of the Form 3B 3D printed model for you to evaluate.

Request a Free Sample

3D Printing Support Structures - Complete Guide

An Easier Approach to Caliper Structures

Caliper Structures for 3D Printing - The Complete Guide

Everything you need to know about caliper structures used in 3D printing. Feel free to use overhangs and bridges in your models!

Caliper Structures: If you have a lot of experience with FDM 3D printers (FDM - Fused Deposition Modeling), you may have found yourself in situations a couple of times in which you had to use structures like this. An FDM 3D printer creates a 3D object by sequentially applying layers of thermoplastic materials. In this case, each new layer rests on the layer below it. If the model has an overhang that is not supported from below, it will likely sink or even fall off, and you will need to print additional support structures to ensure successful printing.

Caliper structures are seen as a necessary evil in 3D printing. On the one hand, they are absolutely necessary for models with dangerous overhangs or bridges. On the other hand, the cost of materials rises, finishing work is added, and there is a risk of damage to the surface of the model. Therefore, proper application of printed caliper structures is a very important aspect of 3D printing complex models.

Caliper structures in 3D printing: 3 easy steps to success

In this article, we will cover everything you need to know about support structures used in 3D printing. Detailed explanations are provided later in the text.

WHEN DO YOU NEED THEM?

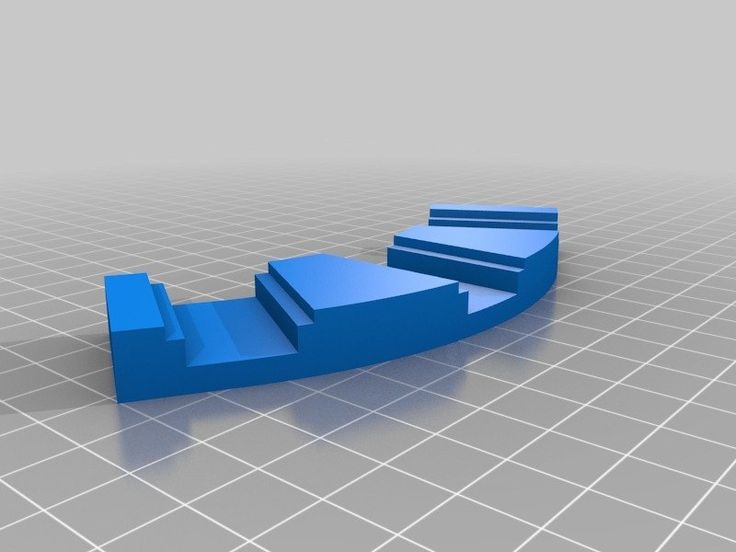

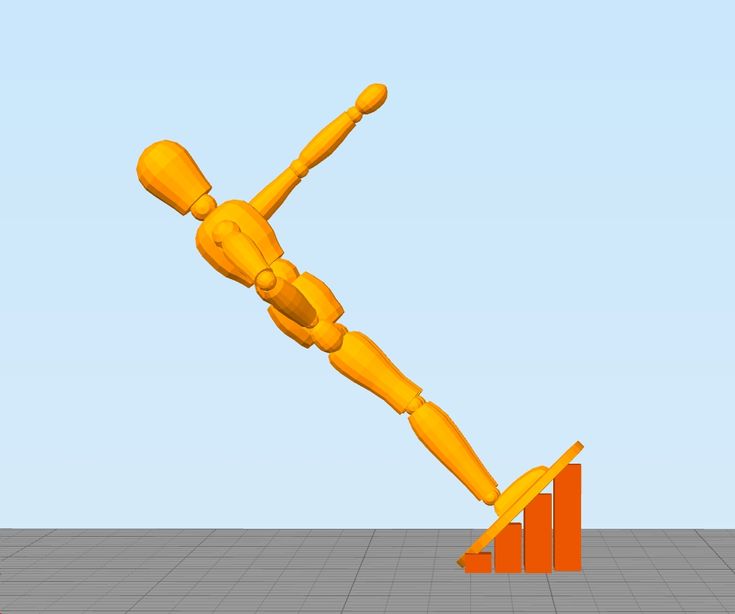

In general, when a model has an unsupported overhang or bridge, caliper structures may be required to enable 3D printing. The figure below shows overhangs and bridges using the letters Y, H and T as an example.

A classic example of overhangs and bridges using the letters Y, H and T as examples. 0003

0003

Caliper structures are not needed for all overhangs - 45 degree rule

Caliper structures are not needed for all eaves. As a general rule of thumb, if the overhang slopes less than 45 degrees from vertical, it can be printed without the use of caliper structures.

Support structures are required for overhangs greater than 45 degrees from vertical.

3D printers provide a slight (barely noticeable) horizontal displacement between successive layers, i.e., the applied layer is placed on the previous one with a slight displacement. This ensures that overhangs are printed that do not deviate too much from the vertical. Anything less than 45 degrees can be supported by previous layers, and anything above that number can't. A value of forty-five degrees is considered a break line.

This statement is best supported by the examples of the letters Y and T. The two slanted parts of the letter Y have an angle of less than 45 degrees with respect to the vertical. Therefore, if necessary, the letter Y can be printed without using any caliper structures performed by 3D printing.

Therefore, if necessary, the letter Y can be printed without using any caliper structures performed by 3D printing.

For overhangs in the letter Y, printing of support structures is not required. But for overhangs in the letter T - yes. (source: 3DHubs online production platform)

On the other hand, the protruding parts of the T are at an angle of 90 degrees from vertical. Thus, in this case, for the 3D printing of the letter T, the use of support structures is a necessary condition, otherwise the result will be a nightmare (see the figure below).

Without caliper structures, it is not possible to print the letter T properly (source: 3DHubs online manufacturing platform)

2

Not all bridges need supports - the 5 mm rule.

As with overhangs, supports are not required for all bridges. A rule of thumb that has been proven in practice is that if the bridge length is less than 5 mm, the printer is able to print it without the need for a caliper structure.

This uses the 'bridging' printing method, in which the printer stretches the hot material over short distances and prints it with minimal sagging.

However, if the bridge length is greater than 5 mm, this method does not work. In this case, it is necessary to additionally print support structures.

Bridges longer than 5 mm cannot be printed without support structures. Notice how they warp and deform.

TESTING PRINTER'S ABILITY TO PRINT OVERHANGS WITHOUT SUPPORT

The rule of thumb that if an overhang slopes less than 45 degrees from vertical, it can be printed without the use of support structures is just a rule of thumb. Much depends on the printer, its condition and the materials used. Printers that are in poor condition may not print 35 or 40 degree overhangs from vertical.

Before printing a model with overhangs, it is recommended that you evaluate the printer's ability to print small overhangs.

This is easy to do. Simply download the Massive Overhang Test print model from the Thingiverse website and print it. This model presents overhangs from 20 to 70 degrees in 5-degree increments.

Simply download the Massive Overhang Test print model from the Thingiverse website and print it. This model presents overhangs from 20 to 70 degrees in 5-degree increments.

Overhang print test model from Thingiverse website (Source: Thingiverse website)

Determine the angle at which the printer starts to print abnormally. This is the maximum overhang angle at which the printer can print without support. It is recommended to remember it for making further decisions on the need to use support structures.

DISADVANTAGES

Like many things in life, the use of support structures in 3D printing has certain weaknesses. There are several of them, so let's look at them.

1

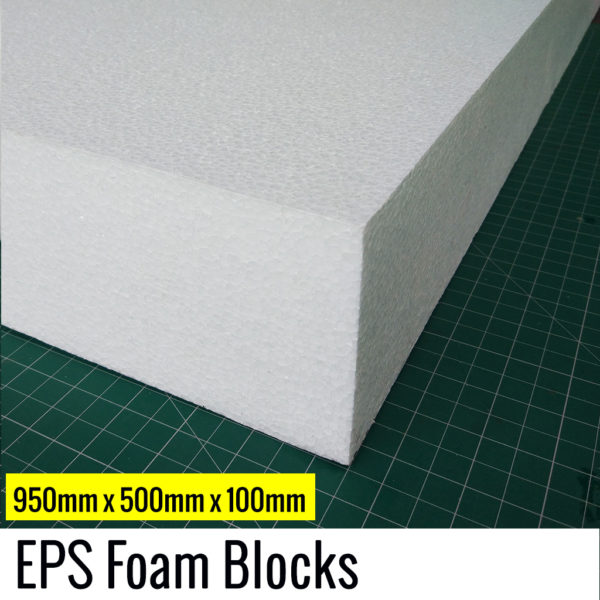

Increased material costs

Support structures require additional materials. In this case, these designs after printing must be removed and thrown into waste.

When using 3D printing at the manufacturing level, the focus may be on the cost per model. If this is your hobby and you are limited in funds, then, for sure, this is also not indifferent to you.

If this is your hobby and you are limited in funds, then, for sure, this is also not indifferent to you.

3D printing of support structures means an obvious additional cost per model. Caliper structures require material that is subsequently removed and discarded, so any 3D caliper structures go to waste, which increases the cost of the printed product.

2

Print time increase

3D printing of support structures also increases print time as the printer prints additional volumes. It is quite obvious that the additional time spent depends on the number and height of the caliper structures.

3

Additional finishing

Additional finishing is required when printing support structures. (source: Formlabs)

3D printed support structures are not part of the model. They are used as a support for parts of the model during printing. This means that at the end of printing, there is an additional need to remove these structures before the model is ready for use.

In a production setting, extra work means additional costs for the model.

4

Risk of product damage

Left: Printing with supports. Middle: Removal of calipers with product damage. Right: Removal of calipers without significant damage to the product. (source: 3DHubs online manufacturing platform)

3D caliper structures come into contact with the walls of products and often stick to them. They are the only means of providing support under overhangs and bridges. If care is not taken when removing 3D caliper structures, defects may remain on the surface of the product. In the worst case, part of the model may break off along with the 3D support structure.

In general, there are significant drawbacks when using support structures. Therefore, here's another tried-and-tested rule: Minimize the use of 3D support structures and add them only when necessary . The following sections will explore the application of this principle, starting directly from the computer-aided design (CAD) stage and ending with printing.

GEOMETRY OF THE CALIPER STRUCTURE

Two types of support structures are commonly used: tree-like (“tree”) and linear / “accordion”.

Tree calipers

The tree caliper is a tree structure that serves as a support for the overhangs of the model. Calipers of this type only come into contact with the overhang at certain points.

3D caliper tree structures (source: Flashforge)

The advantage of using a 3D caliper tree structure is that it can be removed more easily without significant damage to the underside of the overhang. However, it should be noted that this type of caliper is only suitable for non-flat overhangs, such as the tip of the nose, toe or arch. For flat overhangs, it does not provide sufficient stability.

Linear support or "accordion"

This is the most commonly used type of support in 3D printing. It consists of vertical posts that are in contact with the overhang over the entire surface. This type of caliper is suitable for any overhangs and bridges. However, it is more difficult to remove without damaging the surface of the model.

This type of caliper is suitable for any overhangs and bridges. However, it is more difficult to remove without damaging the surface of the model.

Linear 3D support structures (source: Flashforge)0141

Tear-off 3D support structures

Single-extruder printers use tear-off support structures by default.

If you have one extruder, you have to use the same material to 3D print the support structures that is used to print the model. Of course, the density of the caliper structures can be adjusted to be much lower than the density of the model, but this is the only remedy that can be applied to the material of the caliper.

Since the model and 3D caliper structures are made from the same material, the only way to separate them is to either break off the caliper by hand or carefully cut it off with a knife.

These removal methods carry a high risk of damage to the model, and during removal, you must use the proper methods and be extremely vigilant and careful.

2

Dissolvable 3D calipers

Dissolvable calipers are easier to remove, but requires a printer with two extruders.

If you have a dual extruder printer, you have a better choice. You can load one extruder with PLA for model printing and the other with water soluble material such as PVA or limonene soluble material such as HIPS (polystyrene) for caliper structure printing. At the end of printing, it is enough to simply remove the support structure by washing off by immersing the model in water or limonene.

This removal method reduces the risk of model damage and simplifies finishing, making it ideal for complex prints.

HOW TO REMOVE 3D RETAINABLE SUPPORT STRUCTURES

Because 3D Tear-Off Support Structures are difficult to remove and can damage the model, here are some tried and tested techniques for removing them properly.

- First you need to determine which support structures are completely open and can be easily reached with your fingers.

Try prying these calipers off with your fingers. Exercise caution. Extreme caution. If this operation is performed correctly, most caliper structures should come off without much effort.

Try prying these calipers off with your fingers. Exercise caution. Extreme caution. If this operation is performed correctly, most caliper structures should come off without much effort. - Then take a tool to remove 3D support structures that are difficult to reach. There are many opinions about which tools are best. You can use needle-nose pliers, a spatula, or a utility knife. You can also use all these tools together.

- When using a knife or scraper, it is a good idea to heat up the model or blade. This contributes to better delamination of the 3D support structures. A small butane torch will help, but care must be taken not to damage the model.

- Handle utility knives with care as they are very sharp.

- Sandpaper is also excellent for removal. When wet grinding with fine-grained sandpaper (from 220 to 1200), not only the removal of 3D caliper structures is performed, but also the model is polished. For best results, it is recommended to spray the part with water and sand in smooth, light strokes until the desired surface finish is obtained.

Wet sanding can be used to remove residual 3D caliper structures and smooth the surface of the model (Source: Formlabs) scratches and surface defects. Nail polish is great for partially or completely covering these marks.

If you are interested in how other users solve this problem, it is recommended that you view the web page on the best ways to remove supports, calipers and filament structures - Best ways to remove foundations, caliper structures and other external filaments.

MINIMIZING 3D CALIPER STRUCTURES WITH SMART DESIGN

Integrating 3D caliper structures into the model

One way to avoid the use of caliper structures in 3D printing is to use additional elements in the model that perform a similar function. Sculptors have been using this technique for centuries. As an example, consider the sculpture "Venus the Conqueror" by Antonio Canova.

"Venus the Conqueror", sculptor Antonio Canova

Here the right arm is an overhang but rests on pillows. The left leg is another overhang, but here the folds of the toga serve as a support.

The left leg is another overhang, but here the folds of the toga serve as a support.

The next example is the Guardian model by @fantasygraph. As a support for the legs and buttocks of the model, he guessed to use a dress flowing in folds. The left hand rests on the spear lowered down.

@fantasygraph's Sentinel is a prime example of how support structures can be integrated into a model.

Integrating 3D support structures into a design is more art than science. It is necessary to find such elements that fit into the overall design and at the same time can be a support for overhangs or bridges. If done correctly, the model will be more beautiful and the printing process will be freed from unnecessary 3D caliper structures, which means saving time, money and labor.

Bevels

Another way to get rid of 3D support structures is to use bevels. With proper chamfering, dangerous overhangs can be turned into innocuous structures with angles less than 45 degrees.

For example, if you have a smoothly falling or folded edge, you can replace it with an edge with an angle that does not require supports. Such an angular pattern is called a bevel.

Left: Gradually rounded edge that requires supports. Right: A beveled edge that can be printed without 3D caliper structures (Source: Rigid Ink)

Similarly, if your model has a hole, you can turn it into a beveled teardrop hole. For the most part, this won't ruin the overall aesthetic of the model, but will help reduce the amount of 3D support structures needed to print the model.

Beveled hole (source: Markforged)

. For example, it is much better to print the open box shown below with the open side up.

You can often minimize the use of 3D support structures by properly positioning the model on the build plate (source: Markforged)

Below is a more non-trivial example, again from designer @fantasygraph. This is a model of a man with a horizontally outstretched arm pointing forward and to infinity.

If you print the model as it is, you will need to support the left hand. And it, in fact, is a long overhang with an angle of 90 degrees.

Removing the supports will most likely leave imperfections on the underside of the arm. To avoid this, you can rotate the whole model by 45 degrees and simply add a support for its base. In any case, the quality of the basis of the model does not really matter. Thus, it is possible to print a model with fewer 3D caliper structures and save the left hand from damage.

A simple and ingenious solution. Maybe you can do it too?

PRINTING OVERHEADS AND BRIDGES WITHOUT 3D SUPPORT STRUCTURES

In the previous sections, attention was drawn to the fact that, if possible, you should try to use as little 3D support structures as possible. However, this means that it will often be possible to find yourself in a difficult situation in which the risk of model instability is inevitable. To minimize these risks, here are a few general tips.

To minimize these risks, here are a few general tips.

- Make sure the 3D printer is in optimal condition.

- Cool the printed material as quickly as possible. The longer the material cools, the more likely it is that the bridge or overhang will warp or fall off. To do this, it is necessary to maximize the cooling capacity of the layers by cooling fans. Also, reduce the print temperature to the lowest possible.

- Reducing the print speed also speeds up cooling and is especially helpful when printing longer bridges and complex overhangs.

- It is recommended to print with the minimum layer thickness. Less layer thickness means less weight applied with each pass of the print head. In addition, it contributes to faster cooling of the material.

SUPPORT STRUCTURE SETTINGS IN CURA PROGRAM

Sometimes you simply cannot do without 3D support structures. But even in this case, every effort must be made to ensure the stability of the 3D support structures, so that they do not consume a lot of material, they are easily removed and do not damage the surface of the model.

The layering manager has many additional functions for fine-tuning support structures. Most layering programs can automatically create calipers, but they also have a manual mode that lets you add or remove calipers anywhere. In addition, the layering manager has many different settings to control the following aspects of the caliper structures.

- Location of 3D supports

- Strength of 3D supports

- Easy removal after printing

- Damage to the printed surface

In this article, we decided to focus on Cura, one of the most popular free layering software.

Cura has a number of settings related to support structures located in the Support section of the Custom Settings menu. With the correct setting of these settings, you can create 3D support structures that meet most of the basic requirements.

1

Enable automatic creation of 3D support structures for unstable models

Let's start from the beginning. How can I check if a model needs additional supports?

How can I check if a model needs additional supports?

Cura makes this easy. Immediately after importing the model into Cura and placing it on the virtual working base, you should pay attention to the areas colored in red. These are the areas where Cura found instability. It should be noted that, possibly, areas without supports will not be visible until the camera is rotated.

If the bottom of the part is painted red where the model touches the work base, there is no need to worry that there is no support under this area. This problem will be solved by a working base. Small red areas at the top of holes or between two structures are called bridges and Cura will process them automatically.

You should start to worry if there are other parts highlighted in red. First you need to activate the automatic creation of support structures in order to ensure that these red areas are successfully printed. To do this, just check the Generate Support checkbox in the Support section.

So, the function of automatic creation of support structures is activated, but no external changes to the model occur. The reason is that Cura does not show support structures in the default Solid view. To view the generated 3D support structures, you must change the view mode to Layer View (View layers). The material of the calipers (lines and volume) will be displayed in turquoise. You need to move the layer slider up and down to see where the support is added to the model.

2

Selecting a tree or linear support

Tree support structures in Cura

Cura creates 3D linear support structures by default. Version 3.2 beta of Cura provides the option to use tree supports instead of the default linear ones.

3

Controlling the position of 3D supports

Two types of support structures in Cura: Everywhere and Touching Build plate

When you activate the option to create support structures, the Placement item automatically appears in the Support section. The Placement option provides the ability to control the approximate location of support structures. There are two options: Everywhere and Touching Build plate. The Everywhere option is selected by default.

The Placement option provides the ability to control the approximate location of support structures. There are two options: Everywhere and Touching Build plate. The Everywhere option is selected by default.

When the Everywhere option is selected, Cura 3D attempts to create support structures where they are needed. This means that not only 3D caliper structures will be created that will be placed on the working base, but also caliper structures that will be based on the details of the model. This is the rational choice for most cases, as it guarantees the necessary support for all unstable areas.

However, if you select the Everywhere option for very complex models, the model may be completely covered with the material used for the calipers. If there is no such intention, you just need to set the Touching Build plate option in the Placement settings. This option will create 3D caliper structures under the hanging parts of the model only between the working base and the model.

4

The Enable Support Roof option can improve the surface finish of overhangs, but will incur some additional cost.

Since the overhang of the model is always printed on top of the 3D support structures, the optimal surface finish of the parts is not always guaranteed. And in this case, the hidden setting Enable Support Roof can help.

The arch of the support is a dense layer in the upper part of the caliper structure, which does not detract too much from the quality of the surface of the overhangs. When this option is activated in the Cura 3D program, by checking the appropriate box, a better quality finish is obtained. But this improvement comes at a cost, as removing the caliper structures becomes more difficult than usual when choosing this option. This option is only recommended if the surface quality of the overhang is important to the finished part itself.

5

Prevent 3D support structures from damaging the outer walls of the model by using the Support X/Y Distance setting

wall and leave traces on the outer surface of the model. This can be avoided by using the hidden Support X/Y Distance setting in the Support section.

This can be avoided by using the hidden Support X/Y Distance setting in the Support section.

In Cura, the Support X/Y Distance setting generally controls the minimum allowable distance between the model's vertical walls and the support structure in the X-Y plane. If the 3D support structure damages or sticks to the walls, you can increase this value in 0.2 mm increments until the walls are smooth. However, it is highly recommended to ensure that there are no small overhangs protruding from the outer walls, which would be left unsupported by leaving a small distance between the support and the walls. With these small overhangs, you may even need to decrease the X/Y distance instead of increasing it. Otherwise, printing will fail.

6

Z Distance setting to allow easier removal of 3D support structures model layers. The Cura software creates this weaker connection by leaving a certain space between the top and bottom of the support structure and the model - this space is known as the Z distance.

By setting the hidden Z-Distance settings in the Support section, the 3D support structures can be more easily separated from the model. The default value of this setting is equal to the height of the layer. So if the layer height is 0.1mm, the default Z distance will also be 0.1mm.

If the support material is difficult to separate from the model, it is recommended to increase this value in increments of layer height until it separates cleanly. Cura may or may not provide additional support for any particular layer. Unfortunately, half layer values do not exist. That is, if the Z Distance value of 0.2 mm is too large for printing with a layer height of 0.1 mm, and the Z-Distance value of 0.1 mm is not enough, there are no other options for setting the Z Distance value.

7

Choosing the right 3D caliper structure to strike the right balance between strength and ease of removal

Support patterns in Cura

Cura provides one of seven 3D caliper patterns. The pattern can be changed using a hidden setting called Support Pattern in the Setting section.

The pattern can be changed using a hidden setting called Support Pattern in the Setting section.

In most cases, the default pattern, Zig Zag, provides the best balance between strength and ease of removal. Other scheme options: Triangles (Triangles), Lines (Lines), Grid (Lattice), Concentric (Concentric), Concentric 3D (Concentric 3D) and Cross (Cross). If the default schema doesn't work, you can experiment with other options. Each provides a different balance between strength and ease of removal.

Caliper structures are a necessary evil in 3D printing. They are needed to print complex overhangs and bridges on the model. But when soluble 3D support structures cannot be used, it is recommended to try to minimize their use. We've covered situations where 3D caliper structures aren't needed and mentioned a few creative tricks for printing without them.

However, often the overhang or bridge may be such that a support structure has to be used. In this case, you need to change the layering settings so as not to waste too much material and not damage the model during the removal of supports.