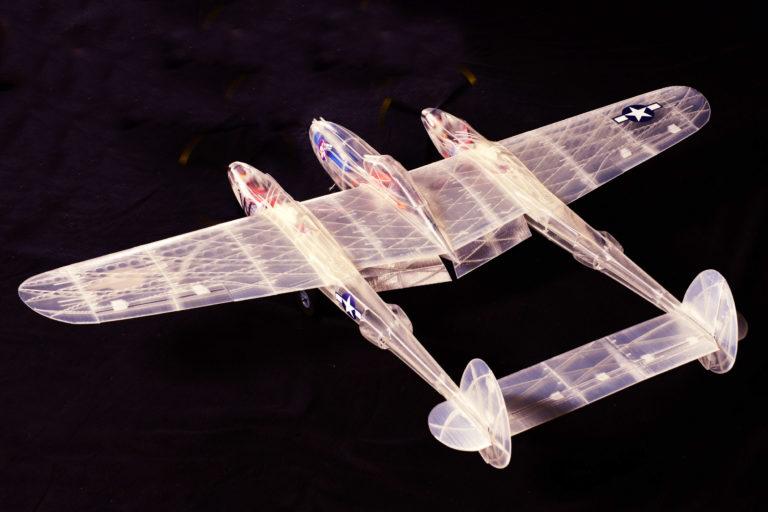

3D printed aircraft models

✈️ Best 3D files for 3D printing of planes and aircrafts ・Cults

✈️ Best 3D files for 3D printing of planes and aircrafts

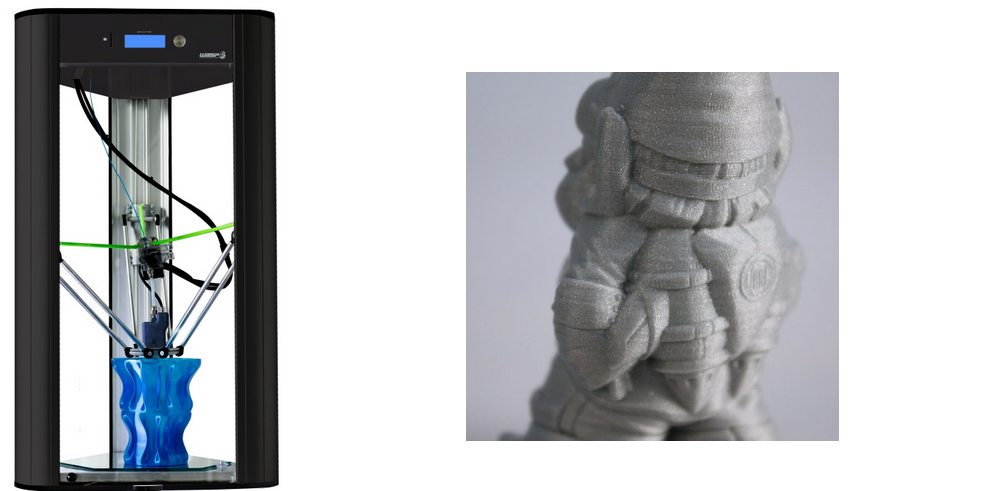

Take altitude with this selection of 3D files perfectly optimized for 3D printing. You can print beautiful airplane models to decorate your home or even do model making. The result of your aircraft 3D printed and associated with various parts can even fly for real. A great way to show how an aircraft works to your child and educate on the different models: CESSNA, Airbus, Boeing, etc.

RC plane - Eclipson model A free version by Eclipson

Free

Easy to print F5 Tiger aircraft scale model 1/64

Free

Free RC airplane

Free

Pilot Baby - 3D Printable Vintage RC Sports Model Reproduction.

Free

Build Your Own Jet Engine

Free

RAF WW II Spitfire

Free

Easy to print T-38 Talon aircraft scale model (esc: 1/64)

Free

Plane

Free

RC airplane Wing - Eclipson Model Y

Free

F117 Nighthawk

Free

MD80 AIRCRAFT SCALE MODEL

Free

RC plane fuselage - Eclipson model Z

Free

Airbus A220-100 - 1:144 - Free

Free

Zlin Z-242 frame model (esc: 1/64) (No 3D print, CNC routing)

Free

Cessna 172 Skyhawk 1:72

€2

Turboprop Engine

Free

Ultimate Biplane 10-300S

Free

Easy to print Cessna Citation SII 1/64 aircraft scale model

Free

Porco Rosso Savoia S.

Free

Aero Commander 500S

Free

Model plane

Free

SOFIA, the Stratospheric Observatory for Infrared Astronomy

Free

Das Liddle Stik RC Airplane

Free

Antonov An-225

Free

Aircraft

Free

Easy to print Aero L-39 Albatros aircraft scale model

Free

Lancer B1 Bomber

Free

PIPE ECHAPEMENT SPITFIRE

Free

WW II RAF Spitfire Sliced

Free

A02 Plane C-3D

Free

P-51D Mustang - Sally AURI

Free

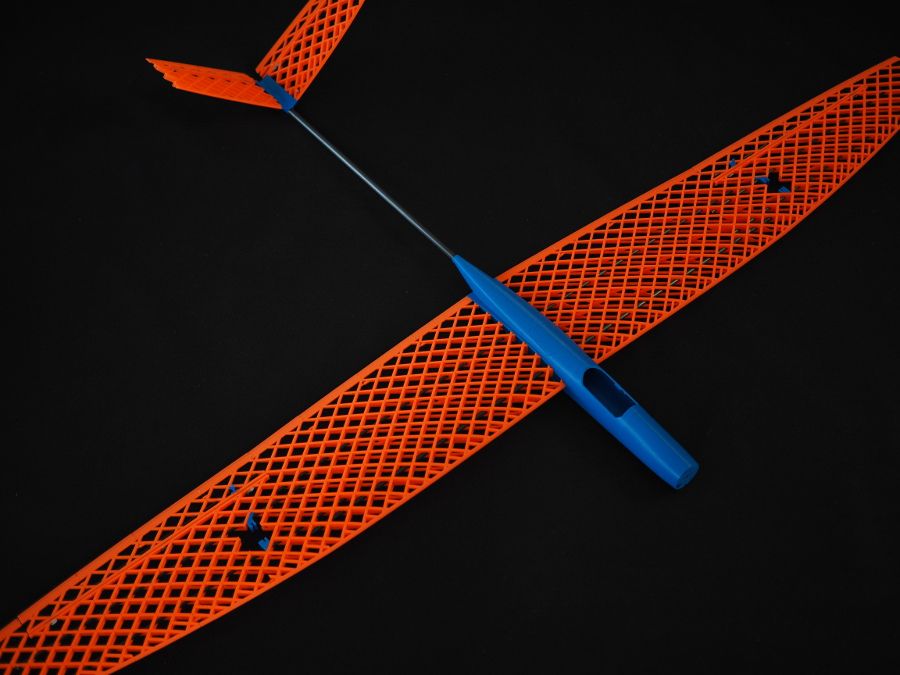

First Take Off of a fully printed (FDM) sailplane.

Free

Ercoupe Golden Age Aircraft

Free

RAF Mosquito WW II

Free

Le Rhone spinning radial dummy engine for RC planes

Free

Little Jet Plane

Free

RAF Lightning

Free

Floonda - free 3d printed Freestyle Glider 1335mm Wingspan (Vasemode)

Free

Red Barron Mobile

€2.42

Transport Aircraft Toy Puzzle

Free

Speedy "Red Mini Wing" RC Plane

Free

"Red Swan" the biggest fully printed Flying Wing

Free

Antonov An-32

Free

Antonov An-124

Free

Touristic plane

Free

EL-39 - Semi scale RC jet for 120 mm EDF

€17. 01

01

Skewer Fighter Jet (F-86 Sabre)

Free

Bi Plane

Free

Hawker Tempest V WW2 Fighter Plane

Airbus A220-100 - 1:144 - Free

Airbus A220-100 - 1:144 - Free

Aichi D3A2

Here is our selection of the best 3D files of planes, all these magnificent machines are from the 3D files library Cults and are perfectly 3D printable.

This collection includes Free 3D files of all kinds of aircraft. There are many models of aircraft from the most prestigious brands such as Boeing, Airbus, Cessna or Antonov.

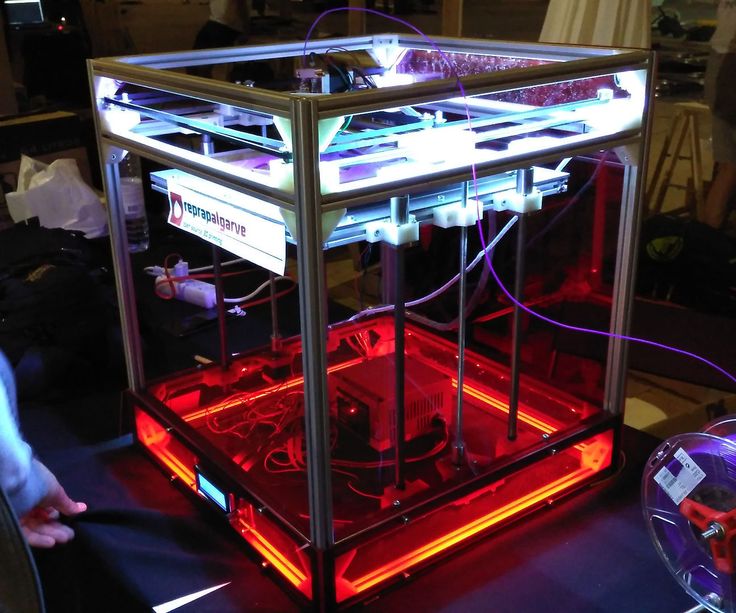

The professional 3D printing has greatly developed in the world of aeronautics mainly for very specific applications. For example, this technology makes it possible to create very strong and much lighter parts than more traditional manufacturing processes.

For example, this technology makes it possible to create very strong and much lighter parts than more traditional manufacturing processes.

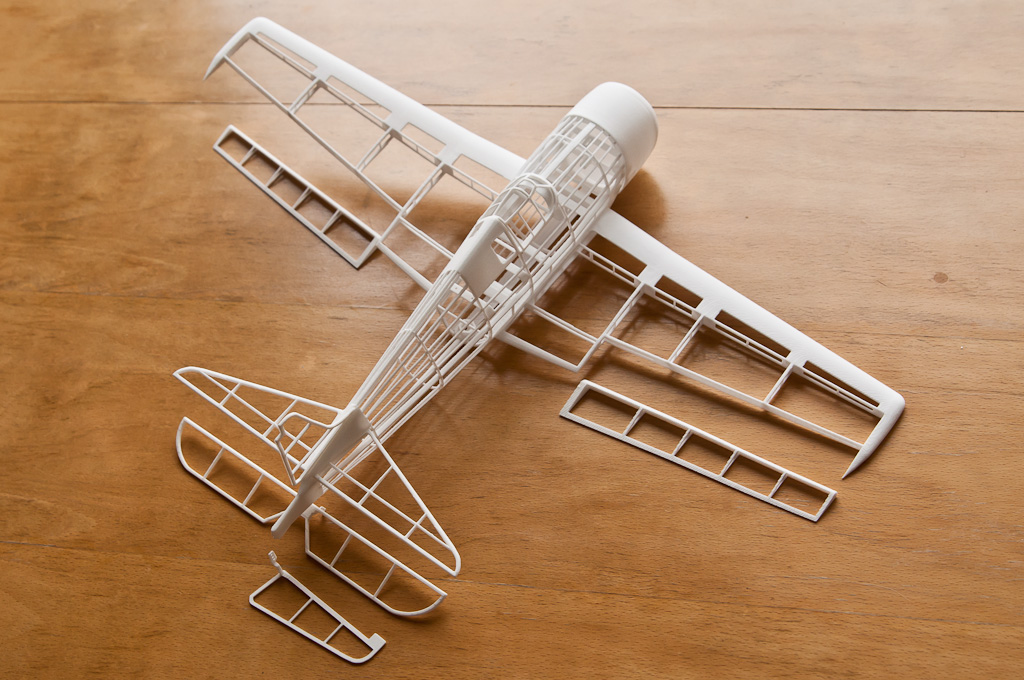

Obviously, you won't find parts of real planes here, but you will discover many plane models in 3D. For the fans of modelism, you will be able to 3D print your own plane or glider!

Materials for 3D printing planes – 3DLabPrint

Choice of material is very crucial for a successful result. We tried many different materials and here’s our experience.

Recommended materials are:

- PolyAir 1.0

- PolyLight 1.0

- PLA

- LW-PLA

Materials tested, not recommended:

- LW-ASA

- HT-PLA

- PETG

- ABS

- Carbon filled materials

PolyAir 1.0 (highly recommended)

Advantages:

- More resistant to impact!

- Improved layer adhesion

- Easier to cut with a knife – doesn’t break that easily

- Easy to print – prints even better than regular PLA

- Stiff – as stiff as regular PLA to handle high G forces

Disadvantages:

- Lower glass transition temperature

Our new in-house PLA based four compound material, developed specifically for printing thin-wall planes. Improved impact resistance and layer adhesion are crucial for a longer lifespan of 3D printed RC planes. It prints as easy as a regular PLA, so you can use your trusted print profiles or our pre-compiled gcodes on compatible printers. A sophisticated production line ensures a constant diameter with tight tolerance.

Improved impact resistance and layer adhesion are crucial for a longer lifespan of 3D printed RC planes. It prints as easy as a regular PLA, so you can use your trusted print profiles or our pre-compiled gcodes on compatible printers. A sophisticated production line ensures a constant diameter with tight tolerance.

The printing temperature remains at 230°C without cooling.

As with the regular PLA, the glass transition temperature remains around 50°C, so avoid exposing the model to higher temperatures on direct sunlight or leaving the model in a car.

PolyLight 1.0 (highly recommended)

Active foaming lightweight LW-PLA material. Depending on hotend temperature, the material increases its volume more than twice during extrusion resulting in very lightweight parts. Suitable especially for smaller models and parts where strength is not so critical.

Suitable especially for smaller models and parts where strength is not so critical.

Pros:

- Less than half the weight of standard PLA

- More than double the print volume from a single spool

- Strong inter-layer adhesion

- Controllable active foaming

- Easy to clean and sand any imperfections

- Easy to glue with CA

- Less visible layers

- Not translucent

Cons:

- Less stiff than PLA – can be controlled by extrusion multiplier and temperature

- Lower glass transition temperature, but with lower volumetric density, less prone to warping on a Sun

- Foaming during travel moves means more stringing, however, easily removable

Great for LW Planes or weight reduction of any model

PolyLight 1.0 is recommended especially for our LW Planes models designed to be printed in single-pass (vase) mode with reduced travel moves but used wisely it can also be used as a complement to the PolyAir to improve the wing loading of any of our models. For example, every gram saved on tail parts counts more than twice in the need to balance the model improving weight distribution.

For example, every gram saved on tail parts counts more than twice in the need to balance the model improving weight distribution.

Printing recommendations

A basic Simplify3D FFF profile for printing LW-PLA on Prusa MK3 and compatible printers: 3dlabprint_LW_1per

Recommended hotend temperature is around 230-240°C, Bed temperature 50-60°C, Set multiplier in a range of 0.4 – 0.5 to achieve a wall width around 0.6 mm. If you find the parts are hard to fit into each other, slightly lower the flow or multiplier.

Set retractions to 0 mm distance, but keep the extra restart distance to compensate for oozed material on travel moves. Where possible, we’re trying to minimize the number of travel moves in geometry, but stringing can be quite easily removed with a snap knife, scalpel or sanded down. Don’t expect the print to be perfectly clean.

Cost-effective

Since the filament foams up when being printed, a single spool lasts for more than twice the amount of parts in volume, compared to non-foaming filaments. Lowered wing loading results in lower stall speed and impact energy when things go sideways. That means the model is less prone to damage and it actually saves costs.

Lowered wing loading results in lower stall speed and impact energy when things go sideways. That means the model is less prone to damage and it actually saves costs.

Suitable for painting

We chose to make the material in light grey colour, that’s the most universal base colour for painting. Models printed in light grey are not translucent and therefore it’s easier to create a good-looking scale paint job. Parts can be easily sanded to make a nice surface finish.

PLA (recommended)

Advantages:

- Stiff (wing can handle higher Gs)

- Low shrinking

- Easy to print

- Easy to glue with CA

Disadvantages:

- Lower glass transition temperature

Standard PLA is our most commonly used and recommended material to print 3DLabPrint planes. If not specified otherwise, the planes are designed and tested with standard PLA filament. If you’re new to 3D printing RC planes, please always start with a standard PLA with a consistent diameter. At least you’ll have something to compare to while experimenting with others.

At least you’ll have something to compare to while experimenting with others.

We’re using higher than usual temperature (by default 230°C) and no cooling to achieve good inter-layer adhesion. The PLA softens at temperatures higher than 50°C, that is its glass transition temperature. To achieve sufficient heatbed adhesion, we use temperature 50-60°C any higher will result in warped bottom part caused by the weight of the part.

Darker colours warp on direct sunlight as the temperature of the surface builds up fast. To avoid this, use bright, single-wavelength colours like yellow, orange, lime-green, etc…

Don’t leave printed planes in a car on hot summer days, as the temperature can easily rise above 50°C

LW-PLA (recommended)

Advantages:

- half the weight of standard PLA

- Low shrinking

- Easy to print

- Controllable foaming

- Easy to clean and sand any imperfections

- Easy to glue with CA

- Less visible layers

Disadvantages:

- Less stiff than PLA – can be controlled by extrusion multiplier and temperature

- Lower glass transition temperature, but with lower volumetric density, less prone to warping on a Sun

- No use of retractions on travel moves causing cosmetic imperfections

A basic FFF profile for printing LW-PLA on Prusa MK3 and compatible printers: 3dlabprint_LW_1per

This revolutionary material is using active foaming technology. I.e. it’s gaining volume when being printed. The higher the temperature, the more it foams. With this feature we can use half extrusion multiplier to get the same wall width, reducing the overall weight to half. Can be used to lighten any of our planes, LW-Planes are designed to be printed from this material explicitly.

I.e. it’s gaining volume when being printed. The higher the temperature, the more it foams. With this feature we can use half extrusion multiplier to get the same wall width, reducing the overall weight to half. Can be used to lighten any of our planes, LW-Planes are designed to be printed from this material explicitly.

With extrusion multiplier and temperature we can control how stiff the resulting part will be. Leaving extrusion multiplier at 1 will result in strong walls, but the internals could pronounce to the outer shell. Normally we are using 0,5 multiplier at 230°C making the walls same thickness as standard PLA parts to reduce weight.

Since the material foams inside the nozzle, it’s oozing faster than standard PLA. Increasing retractions may cause clogs, so we decided to turn off the retractions at all. This results in hairy internal trussing, but it’s very lightweight and it’s just a cosmetic issue.

The resulting parts are less stiff, so it’s not recommended to use this material for the whole plane. It is very suitable for printing less stressed parts to reduce all-up-weight of the plane though. Tail parts, wing-tips, control surfaces, hatches, scale accessories, etc…

It is very suitable for printing less stressed parts to reduce all-up-weight of the plane though. Tail parts, wing-tips, control surfaces, hatches, scale accessories, etc…

The material is distributed directly by ColorFabb. At first glance higher price tag is reduced by the fact, we need just a half of it compared to any other material, making it no more expensive than any other premium filament.

A comprehensive LW-PLA review by CNC Kitchen

LW-ASA

Advantages:

- Active foaming, similar to LW-PLA

- Higher temperature and UV resistance compared to LW-PLA

Disadvantages:

- Shrinking

- Worse inter-layer adhesion compared to LW-PLA

- Possibly hazardous fumes when being printed

Another promising foaming filament by ColorFabb, however more tricky to print than LW-PLA. The only advantage for our purpose is higher temperature resistance. Contains styrene, so printing can produce toxic fumes. You’ll probably need a ventilated heated enclosure to print LW-ASA.

The only advantage for our purpose is higher temperature resistance. Contains styrene, so printing can produce toxic fumes. You’ll probably need a ventilated heated enclosure to print LW-ASA.

HT-PLA

Advantages:

- Higher glass transition temperature compared to PLA

Disadvantages:

- Lower inter-layer adhesion – brittle

- Some brands require to be annealed to gain the thermal resistance

- Usually more expensive

Printing HT-PLA requires more precise tweaking of hotend temperature. The glass transition temperature is slightly higher depending on the brand used, but this is for a price of lower inter-layer adhesion, which means more brittle planes. This often ends with broken wing mid-flight and mishaps on landing.

It can be possibly used on motor mounts that are glued to the fuselage, but it’s not always necessary.

PETG

Advantages:

- Higher glass transition temperature compared to PLA

- Less brittle

Disadvantages:

- Lower tensile strength (more flexible)

- Harder to glue

- Harder to print – oozing

- Higher shrinking rate

The PETG printed planes may look less brittle in the beginning, but less strong glue joints and lower tensile strength (higher flexibility) makes the planes more prone to fail mid-flight due to higher G forces. Use this material only when you know what you’re doing. Not recommended for beginners.

Use this material only when you know what you’re doing. Not recommended for beginners.

It is a good material to print some motor mounts, wheel discs and even springs. Always watch for good layer adhesion when printing PETG. It’s not recommended for parts that require to be glued to hold together.

ABS

Advantages:

- Lower density – lower overall weight

- Higher glass transition temperature

Disadvantages:

- Hard to print

- High shrinking rate

- Requires an enclosure with a controlled ambient temperature

- Possibly hazardous fumes when being printed

Printing thin-wall from ABS is very tricky. It requires enclosed printing volume with precisely controlled ambient temperature. Any draft will cause the layers to separate and warp.

Printing ABS is recommended only for skilled and well-equipped modellers with enclosed and vented printers.

Carbon fibre filled filaments

Advantages:

- Smooth surface

Disadvantages:

- Abrasive

- No real advantage in strength or thermal resistance

We tested several carbon fibre-filled filaments as well. They eat the standard brass nozzles alive and there’s no advantage in any of important parameters for our purpose.

They eat the standard brass nozzles alive and there’s no advantage in any of important parameters for our purpose.

✈️ Best Aircraft & Aircraft 3D Printing 3D Files ・Cults

✈️ Best Aircraft & Aircraft 3D Printing 3D Files

Climb with this collection of 3D files perfectly optimized for 3D printing. You can print beautiful airplane models to decorate your home or even do some modeling. As a result of 3D printing and connecting various parts, your aircraft can even fly for real. This is a great way to show your child how an airplane works and talk about the different models: CESSNA, Airbus, Boeing, etc.

RC plane - Eclipson model A free version by Eclipson

Free

F5 Tiger 1/64 easy to print scale model

Free

Free RC Airplane

Free

Pilot Baby - 3D printed reproduction of a vintage RC sport model.

Free

Build your own aircraft engine

Free

RAF WW II Spitfire

Free

Easy to print T-38 Talon aircraft scale model (esc: 1/64)

Free

Plane

Free

RC airplane Wing - Eclipson Model Y

Free

F117 Nighthawk

Free

MD80 AIRCRAFT SCALE MODEL

Free

RC plane fuselage - Eclipson model Z

Free

Airbus A220-100 - 1:144 - Free

Free

Zlin Z-242 frame model (esc: 1/64) (No 3D print, CNC routing)

Free

Cessna 172 Skyhawk 1:72

2 €

Turboprop Engine

Free

Ultimate Biplane 10-300S

Free

Easy to print Cessna Citation SII 1/64 aircraft scale model

Free

Porco Rosso Savoia S.

21 Aircraft

21 Aircraft Free

Aero Commander 500S

Free

Model plane

Free

SOFIA, the Stratospheric Observatory for Infrared Astronomy

Free

Das Liddle Stik RC Airplane

Free

Antonov An-225

Free

Aircraft

Free

Easy to print Aero L-39 Albatros aircraft scale model

Free

Lancer B1 Bomber

Free

PIPE ECHAPEMENT SPITFIRE

Free

WW II RAF Spitfire Sliced

Free

A02 C-3D aircraft

Free

P-51D Mustang - Sally AURI

Free

First Take Off of a fully printed (FDM) sailplane.

Free

Ercoupe Golden Age Aircraft

Free

RAF Mosquito WW II

Free

Le Rhone spinning radial dummy engine for RC planes

Free

Little Jet Plane

Free

RAF Lightning

Free

Floonda - free 3d printed Freestyle Glider 1335mm Wingspan (Vasemode)

Free

Mobile device Barron Red

2.42 €

Transport Aircraft Toy Puzzle

Free

Speedy "Red Mini Wing" RC Plane

Free

"Red Swan" the biggest fully printed Flying Wing

Free

Antonov An-32

Free

Antonov An-124

Free

Touristic plane

Free

EL-39 - RC half-scale jet for 120 mm EDF

17. 01 €

01 €

Skewer Fighter Jet (F-86 Saber)

Free

Bi Plane

Free

Hawker Tempest V WW2 Fighter

Airbus A220-100 - 1:144 - Free

Airbus A220-100 - 1:144 - Free

Aichi D3A2

Here is our selection of best 3D aircraft files , all these great machines from the Cults and 3D file libraries are perfectly 3D printable for .

This collection includes free 3D files of all types of aircraft. There are many aircraft models of the most prestigious brands, such as Boeing , Airbus , Cessna or Antonov .

Professional 3D printing of has gained a lot of development in the world of aeronautics mainly for very specific applications. For example, this technology makes it possible to create very strong and much lighter parts compared to traditional manufacturing processes.

For example, this technology makes it possible to create very strong and much lighter parts compared to traditional manufacturing processes.

Of course, you won't find real aircraft parts here, but you will find lots of 3D aircraft models . For lovers of modeling, you can 3D print your own airplane or glider!

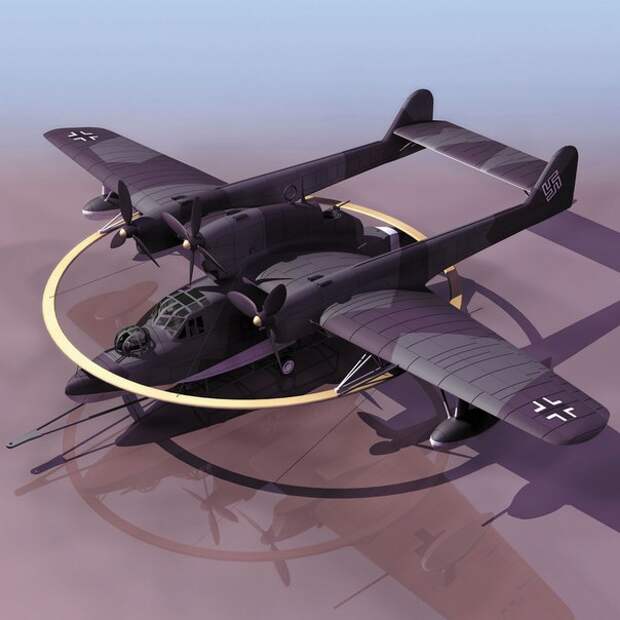

Aircraft 3D printing: An engineer's story Boeing

Each Boeing 787 passenger aircraft has about 30 3D printed parts. Combined, Boeing Commercial Airplanes (jet airliners and business jets) contain 25,000 printed parts. And military aircraft F-15 and F / A-18 - about 40,000. Most of the components are components of air ducts, but there are engine parts and parts of the interior of the cabins.

Boeing spokesman Bernardo Malfitano spoke at the EAA AirVenture Oshkosh forum of aviation enthusiasts and spoke about how 3D printing is being used in the aircraft industry today.

Mechanic, tester, aircraft builder and pilot

Bernardo Malfitano has been with Boeing since 2007. In his career, he was engaged in the repair and maintenance of the air fleet, analyzed the wear and tear of aircraft. Now he is involved in the development of new aircraft.

In his career, he was engaged in the repair and maintenance of the air fleet, analyzed the wear and tear of aircraft. Now he is involved in the development of new aircraft.

According to the expert, all popular 3D printing methods are now used in the aerospace industry: laser stereolithography (SLA), deposition method (FDM), selective laser sintering (SLS) and direct metal deposition (DMD). Unlike traditional techniques, in which the cost of a part depends on the circulation (the higher it is, the lower the price for each spare part), 3D printed products cost the same: it doesn’t matter if you ordered 10 or 1000 pieces. Therefore, it is advantageous to use this technology for small circulations.

Where are printed parts on airplanes?

Air ducts are the part of the aircraft where 3D printed parts are most widely used today. In modern aircraft, circulating air maintains a comfortable temperature for a person and a safe pressure. 3D printed duct connections are used in the Boeing 787, F/A-18 and F-35 fighters, and Bell 429 helicopters.

3D printed duct connections are used in the Boeing 787, F/A-18 and F-35 fighters, and Bell 429 helicopters.

Power units. There are also 3D printed parts in the systems that propel the aircraft. As a rule, these are metal products made by laser sintering or metal deposition. So, in the Boeing 777, the compressor is connected to the temperature sensor using a 3D-printed adapter. And in the F-15K Slam Eagle military aircraft, casings for turbines were made using volumetric printing. This reduced the cost of the part from $34,000 to $2,550 and halved its production time.

Interior details . Shelves, brackets and various fixtures in passenger aircraft cabins are often printed in plastic. For example, the popular Boeing A350 has over 500 of these parts on board.

Small parts. End caps, parts of seats and instrument cases - all this can also be made using the 3D printing method. In the Boeing A300 passenger ship, brackets and seat belt buckles for crew seats are produced in this way.

Advantages of 3D printing for aircraft construction

Additive technologies attract aircraft designers not only because they are economical. They make it possible to optimize the shape at the model stage and significantly reduce the weight of the product. So, by replacing the cast metal bracket with a plastic one printed on a 3D printer, the designers managed to reduce its weight from 918 grams to 326. Of course, there is more than one bracket on the plane, so the total gain in weight is several kilograms. For passenger aircraft, lightening the design means reducing fuel consumption, which reduces not only the costs of the airline, but also environmental damage.

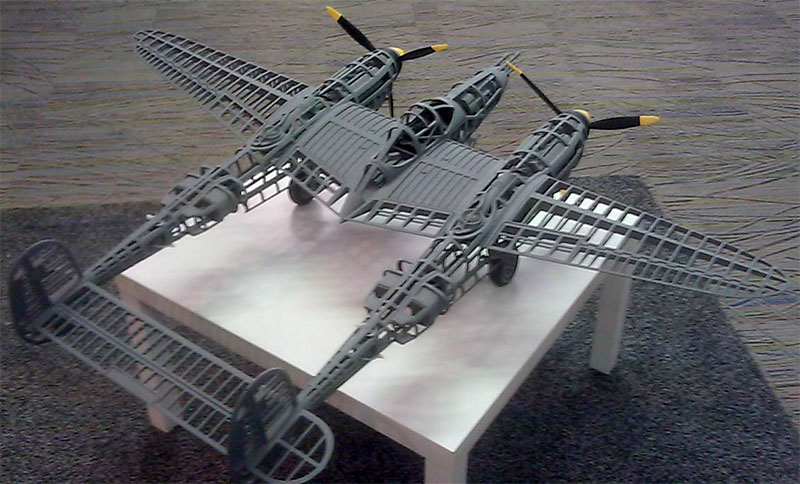

Parts with mesh and honeycomb structure are lighter than monolithic ones, but at the same time they do not lose strength. Each new sample introduced in the aircraft industry undergoes multi-stage tests, especially if it is a functional part.

Is it possible to print the entire aircraft?

If additive technologies are so good for 3D printing, is it possible to print an entire airplane? Bernardo Malfitano is sure that now it is impossible.

Today, 3D printing is successfully used to make drone bodies and working models of aircraft. At the Berlin Air Show in 2016, visitors saw the Airbus Thor, a remote-controlled aircraft about 2 meters long. All of its parts were 3D printed.

But to create the hulls of large aircraft - passenger liners, cargo planes, fighter jets - modern 3D printing technologies are not reliable enough.

Malfitano explained that the US has statutory manufacturing standards. The aircraft industry is governed by 14 CFR Part 25 (“Airworthiness Standards: Transport Category Aircraft”). It says that the structure of the materials must be strong, and the details must be reliable, which must be confirmed by certain tests. Meanwhile, testing parts created by 3D printing often reveals defects and inhomogeneities.

The second factor is the price. Aircraft manufacturing is mass production, so it is now more profitable to use traditional techniques at most nodes.

Bernardo Malfitano's entire presentation can be viewed here.

Learn more