3D printing cambridge uk

3D Printing | Dyson Centre for Engineering Design

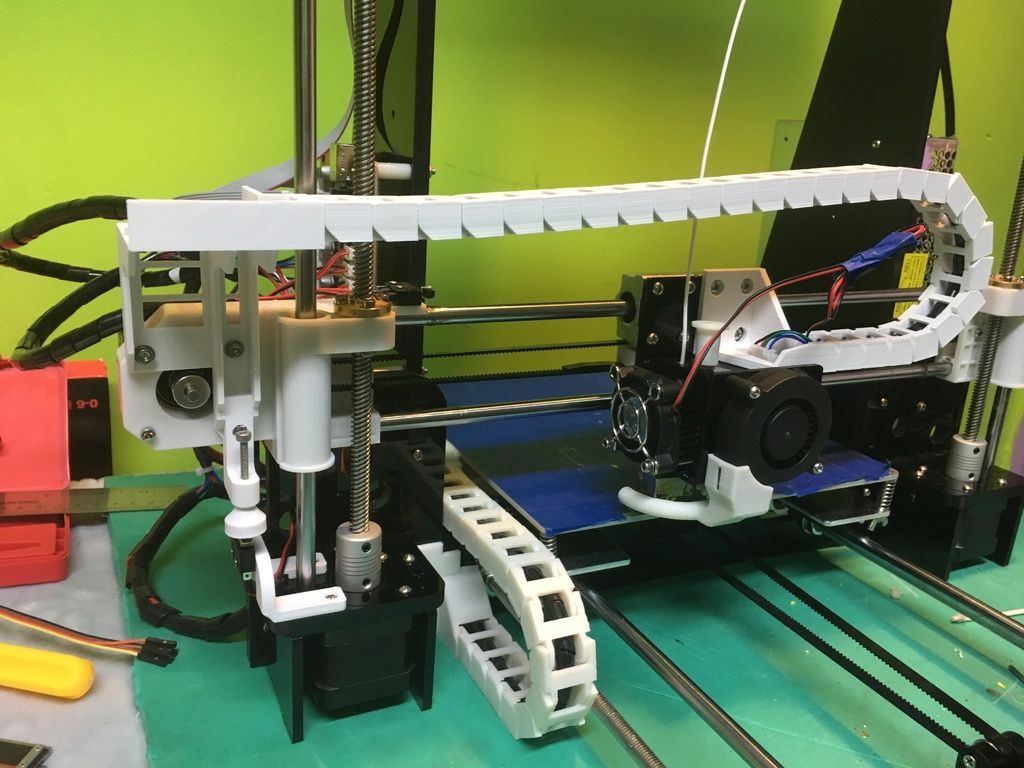

OverviewThe current list of 3D printers which have available in the Dyson Centre 3D printing area, for use by undergraduates is:

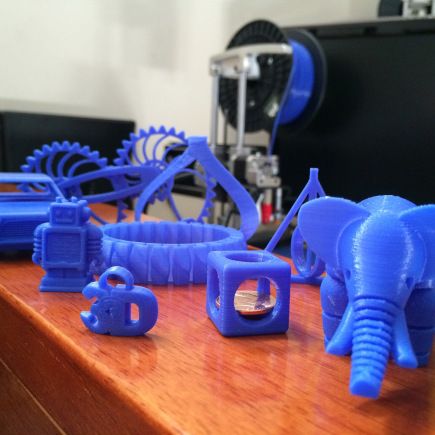

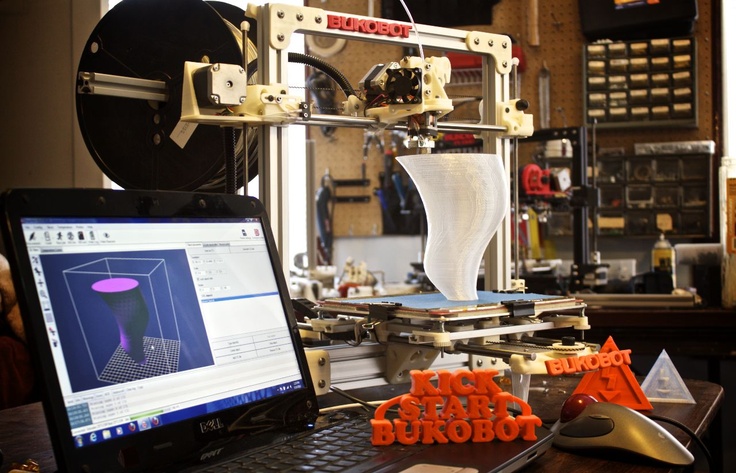

- Five IdeaWerk/RS 3D printers (plus a number of spares) - [above left image]

- Two Ultimaker 2+ Extended 3D printers - [above centre image]

- One Ultimaker 3 Extended 3D printer - [above right image]

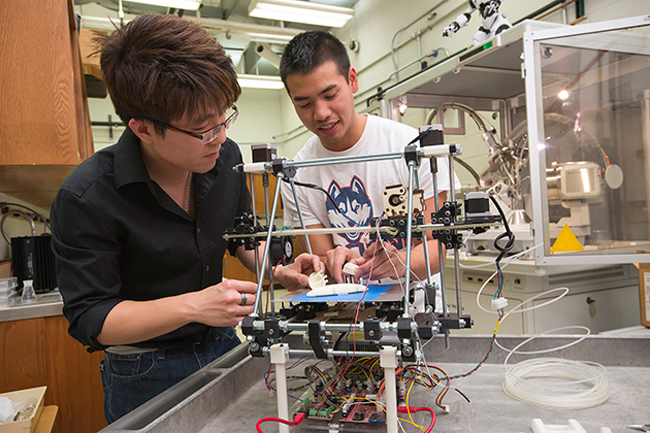

Undergraduates are able to operate the RS/IdeaWerk and Ultimaker machines if they have been shown how (by a Technician from the Dyson Centre Desk, the 3D Printing Society, or a friend familiar with using and paying for 3D printing in the Dyson Centre). The slides or manuals below could also be used for guidance (note the manuals are quite detailed as they cover everything we think you might need to know).

- Summary, single side of A4 leaflet on Dyson Centre 3D Printing (PDF) (DOCX)

(Researchers and Members of Staff may be able to use the 3D printers if there is spare capacity and Staff time available to assist, though there are additional charges for using the machines for research purposes to cover the machine maintenance, replacement and Staff costs - please enquire at the Dyson Centre desk. The priority, though, remains use by undergraduates.)

Ideawerk/RS 3D Printers (Aimed at Novices/Faster/Smaller Prints)

- How to 3D Print in the Dyson Centre lecture slides (PDF) (PPTX-less-video) (PPTX-Google)

- Dyson Centre manual for Ideawerk/RS 3D printer (PDF) (DOCX)

- Software for generating files for IdeaWerk/RS 3D printers (known as Doraware-P) installed on all computers in the Dyson Centre or download here from Google Drive - for use on Windows machines only.

- See "Paying for your 3D prints" below.

Ultimaker 2+ Extended (Aimed at More-Experienced-Users/Larger Prints)

The Ultimakers produce more high definition print and have more options and are therefore more complex to both use and create the file to use with them. We would recommend using the RS Ideawerk printer before using these.

- Dyson Centre manual for "Ultimaker 2+ Extended" 3D printer (PDF) (DOCX)

- CURA software for use with Ultimaker machines installed on all computers in the Dyson Centre, or download from Ultimaker's website.

- See "Paying for your 3D prints" below.

Ultimaker 3 Extended (Aimed at Experts/Disolvable-Support-Material)

- Dyson Centre manual for "Ultimaker 3 Extended" 3D printer (PDF) (DOCX)

- See "Paying for your 3D prints" below.

Paying for your 3D prints

To pay for your 3D prints use EPOS by clicking on the link below:

www.dysoncentre.eng.cam.ac.uk/pay

Printing charges for undergraduates are:

- Ideawerk/RS printer: £1 per every 30g, rounded up to the next highest whole pound.

- Ultimaker printer: £1 for every 20g, rounded up to the next highest whole pound.

Don't forget to also fill out a charge sheet (in the 3D printing area) indicating 'EPOS payment', and drop this in the box on the Dyson Centre desk.

Special and Other Filaments

- What sort of colours of filaments are available?

- An example of a 3D printing bureau service

- Find out about STL files here

RLR20, 28 April 2022

3D printing service available for Cambridge UK

Professional 3D Solutions

for business that needs a specialist service.

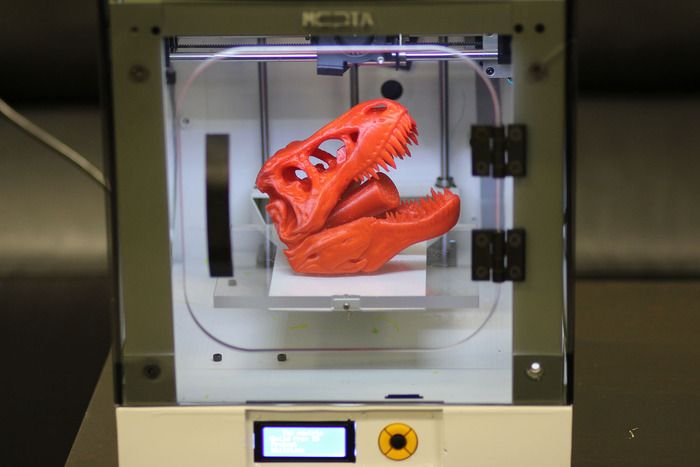

Our 3D Printing Service offers fast, accurate and affordable 3D Printing for Prototyping and Batch Production. Upload your 3D file and get an instant 3D printing quote today!

GET AN INSTANT ONLINE QUOTE

BENEFITS OF USING OUR SERVICE:

- Rapid prototyping service :

Precise Prototype Production , 1 off Prints

- On-demand 3D Printing Service : Upload your 3D file and get an instant quote

- Batch production : Low Volume Batch Production,Order Parts when Required! 1 – 10,000 Parts,

- No Tooling Costs, No Set Up Fee

-

- All production completed on Industrial grade 3D Printers

New paragraph

image/svg+xmlRAPID PROTOTYPING & SMALL BATCH PRODUCTION

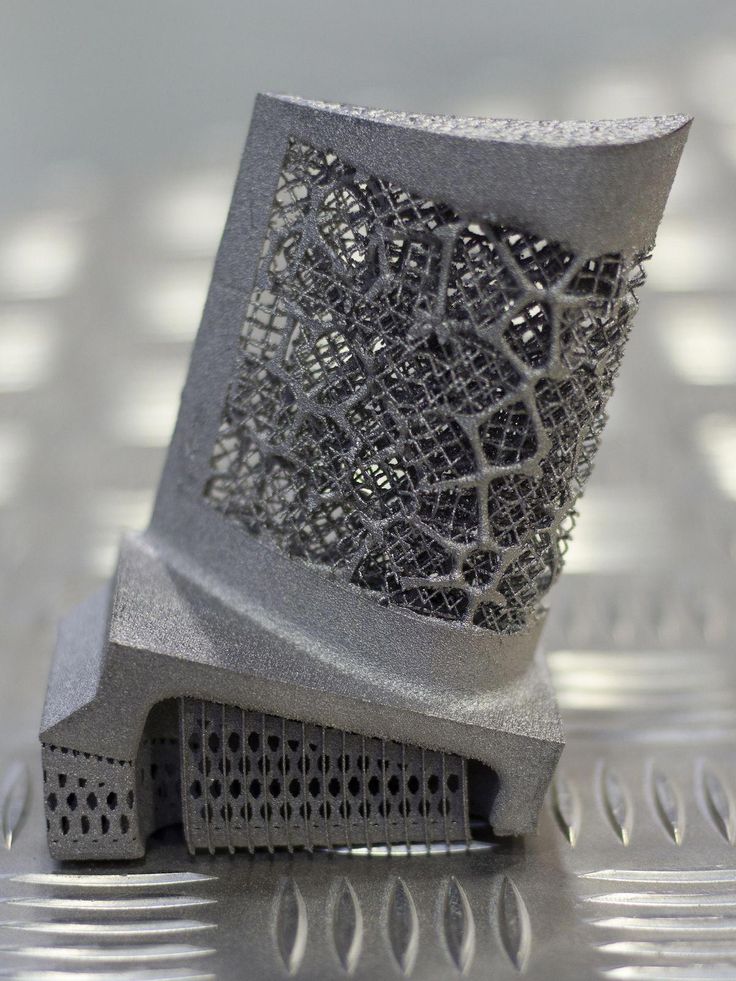

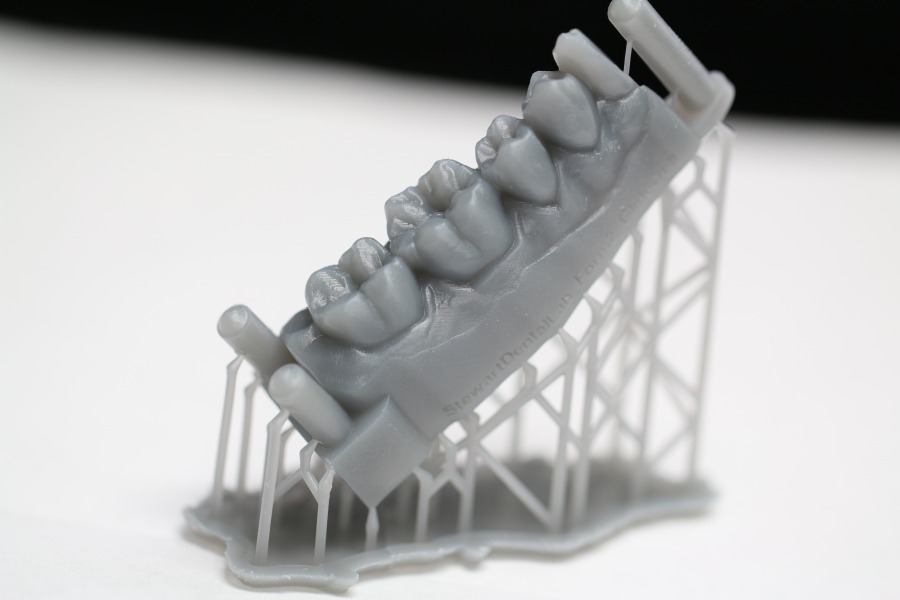

3D printing can be used to create complex shapes that can be printed as a single part or integrated into your build. This rapid prototyping technology can save you time and money.

INSTANT ONLINE QUOTES

Looking for a pricing model that can give you an instant quote? Our online quoting system is quick and easy to use, and will give you an exact price for your product in seconds. Just upload your STL file, select the material, and you'll see what you'll pay - with no hidden costs.

image/svg+xmlPRODUCTION LEAD TIME : 5 - 10 WORKING DAYS

The impact of lead time in the supply chain can be significant. In a client project that needs to be done right, getting models quickly and 3D printing new iterations as needed for final feedback and production can make a big difference.

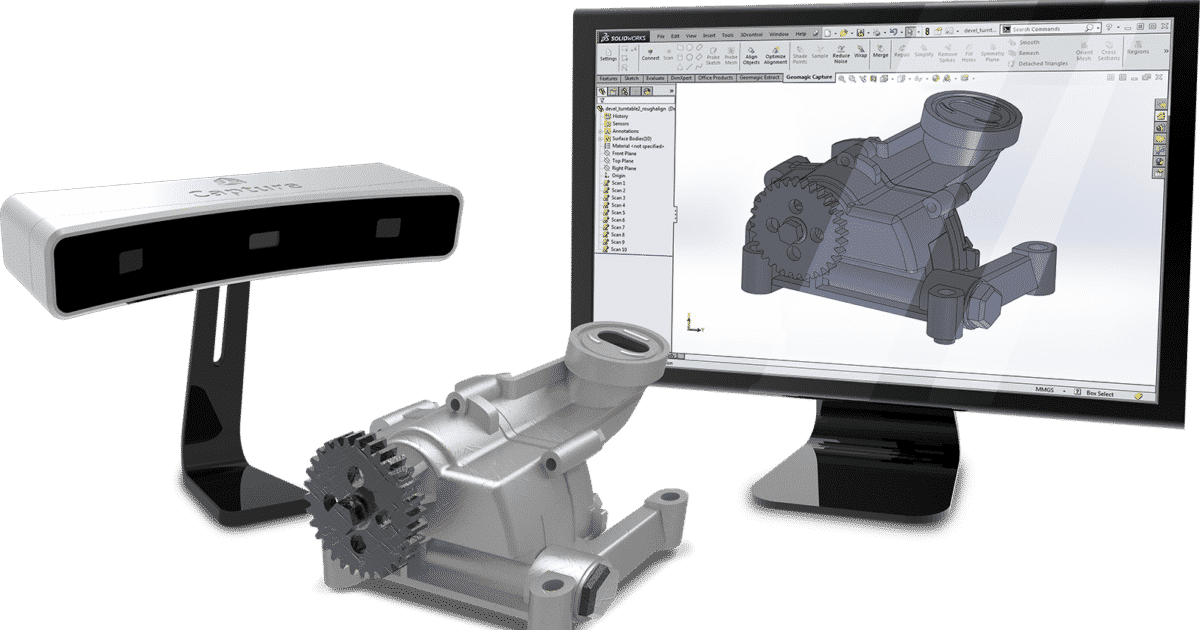

image/svg+xmlCAD DESIGN & REVERSE ENGINEERING

Reverse engineering has many advantages, including the ability to create more efficient processes, experienced 3D printers, and better quality control through inspections. By reverse engineering products, you can create a better design that meets the specific needs of your customers..

If you need spare parts and are looking for a 3D printing partner that can handle your batch runs with ease, our team of experts is here to help.

We have manufacturing partners located in New York, Belgium, Netherlands, and the Midlands UK, so we can ship your parts to any location in the world with a lead time of 5 to 10 working days.

In addition, we offer a wide range of 3D printing services, including design, prototyping, and production.

We also offer a variety of metal 3D printing options, including aluminum, stainless steel, and titanium.

Get an instant quote today.

INSTANT ONLINE QUOTE

CLICK HERE TO LISTEN TO OUR LATEST NEWS AND UPDATES

-

What is the cost of a 3D Print?

The cost of a 3D print is typically based on the size and complexity of the print, as well as the type of material used.

Generally, smaller and less complex prints will be less expensive, while larger or more complex prints will be more expensive.

The most common type of material used for 3D printing is plastic, which can range in price from £10 to £100 per kilogram, depending on the quality and type of plastic.

-

Can I upload STL files with different components in one file?

Yes, you can upload STL files with different components in one file. However, keep in mind that each component will be 3D printed separately, so you'll need to make sure that they're properly positioned and orientated in the file before uploading it.

-

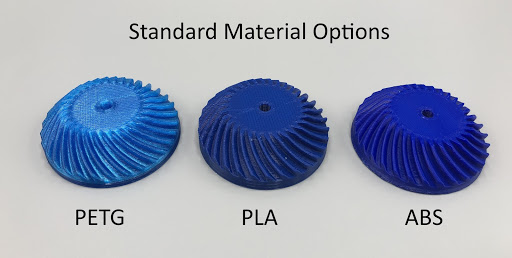

Which materials are available for 3D Printing Service?

- ABS

- PLA

- PET

- PETT

- Nylon

- PVA

- Sandstone

- Wood

- Metal

- HIPS

- Magnetic Iron

- Conductive

- Carbon Fiber

- TPE Filament

- Glow in the Dark

- Amphora

- ASA

- Stainless Steel

- Copper

-

What objects can you 3D print?

- Aircraft Bracket

- Automotive spare

- motorcycle spare

- Pump Impeller

- Sprocket

- End Effector

- Soft Jaws

- Welding Fixture

- CMM Fixture

- Assembly Jig

- Brake Lever

- Metal Bracket

- Stainless Steel Clevis

- Motor Housing

- Engine Block Model

- Oil Pan

- Gear Set

- Spaceship Model

- Vase

- Jewelry

- Water Bottle

-

Which industries use 3D printing?

- Automotive

- Aerospace

- Architecture

- Military

- Marine

- Construction

- Manufacturing

-

What are the benefits of Functional Prototypes?

Functional prototypes offer several benefits over traditional, non-functional prototypes.

Perhaps the most significant benefit is that they allow for early testing of a product or system.

Perhaps the most significant benefit is that they allow for early testing of a product or system.By creating a working prototype, engineers and designers can get feedback on the design much earlier in the development process. This can save significant time and money by identifying and addressing potential problems early on.

In addition, functional prototypes can be used to demonstrate the feasibility of a design to potential investors or customers. A working prototype can be a powerful marketing tool, helping to generate interest and support for a new product or system.

Finally, functional prototypes can help to ensure that a final product meets the needs of its users.

By testing a prototype with actual users, designers can gather valuable feedback that can be used to improve the design. This can help to create a better, more user-friendly

-

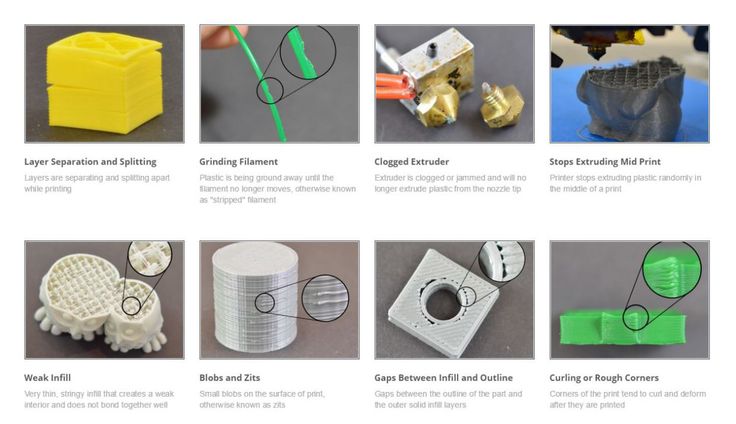

How do you ensure that all 3D prints are of the highest quality?

3D printing quality assurance can be a challenge, particularly when working with multiple filaments, printers, and materials.

Here are a few tips to help ensure that your 3D prints are of the highest quality:

1. Use the best quality filament you can find. There are a lot of different filament manufacturers out there, so do your research and find the best quality filament for your needs.

2. Print with a higher resolution whenever possible. This will help to ensure that your prints are as detailed and accurate as possible.

3. Use support material sparingly. Too much support material can negatively impact the quality of your print, so only use it when absolutely necessary.

4. Calibrate your printer regularly. This will help to ensure that your prints are coming out exactly as you intended them to.

5. Inspect your prints carefully. If you notice any defects, try to correct them before proceeding with the print.

By following these tips, you can help to ensure that your 3D prints are of the highest quality.

-

Do you offer a 3D printing service with full colour?

Yes, we offer full color 3D printing services.

We use a variety of different technologies and materials to produce high-quality, realistic prints in full color.

We use a variety of different technologies and materials to produce high-quality, realistic prints in full color. We can print your designs in a wide range of sizes and shapes, and we can even customize the colors to match your specific needs.

Cambridge

3D modeling and rendering is the perfect way to see your ideas in action. Whether you're creating a new product or redesigning an old one, 3D modeling and rendering is the perfect way to see your ideas in action. Rendering is another term used for monetarily showcasing these models through various methods such as still images/ animations etc.

One of the advantages of 3D modeling and rendering is that it allows you to see your ideas before they are created. This means that you can make changes to your design without having to start from scratch. You can also create different versions of your design so that you can compare them side by side.

3D modeling and rendering is also a great way to create prototypes of your products. This can be extremely helpful when you're trying to sell your product to a company or raising money for your startup. A 3D model can help potential investors or customers see what your product looks like and how it works.

This can be extremely helpful when you're trying to sell your product to a company or raising money for your startup. A 3D model can help potential investors or customers see what your product looks like and how it works.

3D modeling and rendering is a complex process, but there are a few steps that you can follow to make it easier. First, you need to decide what you want to create. This will help you choose the right software and find the right tutorials.

Once you know what you want to create, you need to find a software that you're comfortable with. There are many different 3D modeling and rendering software programs out there, so take some time to explore your options. Once you've found a software that you like, you can start watching tutorials and practicing.

As you become more comfortable with the software, you can start experimenting with different textures, lighting, and materials. The more you experiment, the better your results will be.

If you want to create a truly lifelike model, you should consider using 3D scanning technology. This technology can scan real-world objects and turn them into 3D models. This is a great way to create accurate models of people, animals, or other real-world objects.

This technology can scan real-world objects and turn them into 3D models. This is a great way to create accurate models of people, animals, or other real-world objects.

3D scanning is also a great way to create models of existing products. This can be helpful if you're trying to improve upon an existing product or create a new version of it. By scanning the existing product, you can get a detailed 3D model that you can use to make changes or additions.

3D modeling and rendering is a great way to bring your ideas to life. By following these steps, you can create stunning models that look just like the real thing.

-

City skyline

Photo By: John Doe

Button

-

3D Printed Ceramic Cups

Photo By: John Doe

Button

-

3D Printed Machine Jig

Photo By: John Doe

Button

-

3D Printed Trainer

Photo by: John Doe

Button

Bring your designs to life with Rendering software. With realistic textures and lighting, you can create truly lifelike models that look just like the real thing. Whether you're creating a new product or redesigning an old one, Rendering is the perfect way to see your ideas in action.

With realistic textures and lighting, you can create truly lifelike models that look just like the real thing. Whether you're creating a new product or redesigning an old one, Rendering is the perfect way to see your ideas in action.

Rendering is another term used for monetarily showcasing these models through various methods such as still images/ animations etc

What are the Benefits

1. With rendering, you can create realistic-looking models of anything you like!

2. This software uses three dimensions to represent objects, making for a more lifelike end result.

3. You can use it to create models of anything, from everyday items to imaginary creatures or landscapes.

Cambridge is one of the most beautiful and historic cities in England. Located in the east of the country, it is home to the world-famous University of Cambridge, as well as a number of other important tourist attractions.

The city is built on the River Cam, which flows through the center of the city. The river is popular with tourists and locals alike, and there are many boats that offer trips along the river.

The river is popular with tourists and locals alike, and there are many boats that offer trips along the river.

The university is made up of a number of different colleges, each with its own unique architecture and atmosphere. The oldest college, Peterhouse, was founded in 1284, while the most recent, Robinson College, was founded in 1977.

The university also has a number of museums and libraries, which are open to the public. The most famous of these is the Fitzwilliam Museum, which houses a collection of art and antiquities from around the world.

Cambridge is also home to a number of parks and gardens, including the Cambridge University Botanic Garden, which is one of the largest in Britain.

If you are looking for a place to relax and enjoy the beauty of nature, Cambridge is the perfect destination.

Latest Articles

Understanding Stainless Steel: Grades, Properties, and its Versatility in 3D Printing

by Dwight Mitchell • 07 Jan, 2023 •

Stainless steel is a widely used material for its strength and corrosion resistance, making it ideal for a variety of applications.

3D Printing Technology, Metal & Reverse Engineering

by Dwight Mitchell • 03 Jan, 2023 •

Everything you have to know about the new additive manufacturing applied sciences inside the Origin One, Stratasys h450 and Stratasys F770.

What Advances Have We Seen in 3D Printing Technology This Year? A Closer Look at 2022

by Dwight Mitchell • 31 Dec, 2022 •

2022 has been a year of rapid advancement in 3D printing technology. Major strides have been made in the development of more precise, reliable and cost-effective 3D printer models, as well as a wide variety of new materials and applications of 3D printing.

10 Highly Useful Things You Can 3D Print To Improve Your Automobile and Home

by Dwight Mitchell • 30 Dec, 2022 •

3D printing is a revolutionary technology that is taking the world by storm. It has immense potential to make life easier and improve everyday items.

A Comprehensive Guide to 3D Scanning an Object

by Dwight Mitchell • 28 Dec, 2022 •

3D scanning an object has become increasingly popular as technology advances and 3D scanning apps become more widely available.

Potential of 3D Full Colour Printing

by Dwight Mitchell • 27 Dec, 2022 •

3D full colour printing has been a revolutionary force in many industries, from engineering and prototyping to medicine and manufacturing.

Exploring the Latest Developments in 3D Metal Printing Technology

by Dwight Mitchell • 23 Dec, 2022 •

3D metal printing technology is revolutionizing the way products are created and manufactured.

What You Need to Know: A Comparison of Stainless Steel Printing vs Resin 3D Printing

by Dwight Mitchell • 22 Dec, 2022 •

3D printing is a powerful, versatile technology that has revolutionized the way we think about manufacturing and product design.

How to Get a Functional Prototype Example from a 3D Printing Shop Near me

by Dwight Mitchell • 21 Dec, 2022 •

Having a functional prototype is essential for any product designer, engineer, or maker. It’s the best way to bring your ideas to life and test the viability of a product before investing in mass production.

It’s the best way to bring your ideas to life and test the viability of a product before investing in mass production.

Put Your Customers First and Create a Memorable Experience

by Dwight Mitchell • 19 Dec, 2022 •

In an ever-changing and competitive business world, it is essential to put the customer first and provide them with a memorable experience

Show More

Nufood 3D Printed 5-Course Dinner at Eat Cambridge Food Festival

News

It's no secret that 3D printed food is increasingly showing up at food festivals around the world, and there are even entire conferences dedicated to 3D printed food, like the Dutch 3D Food Printing Conference last month. And this week, the Eat Cambridge food and drink festival kicked off in the UK, where local design studio and innovation lab Dovetailed will unveil its Nufood 3D food printer. nine0003

Nufood's 3D printer, which may well be one of the most user-friendly 3D food printers on the market due to its small size, manages to produce edible designs from flavored liquids. For example, he can give the shape of a star to drops of lemon juice, with each drop encased in a thin film. Or the shape of a banana with drops of orange juice. Such droplets will become an unusual decoration for a cocktail or salad.

For example, he can give the shape of a star to drops of lemon juice, with each drop encased in a thin film. Or the shape of a banana with drops of orange juice. Such droplets will become an unusual decoration for a cocktail or salad.

The idea of creating a compact 3D food printer came to the mind of the Lithuanian Vaiva Kalnikaite, the founder of Dovetailed, a few years ago. Then her team took part in a food hackathon, where designers, technical experts and representatives of the gastronomy world were looking for new ways to prepare dishes. nine0003

Kalnikaite recalls: “For two whole months we tried to come up with a machine that allows you to create food from liquids. In the end, we got the first prototype - it seemed just huge! - and we made raspberries on it from raspberry juice. And then we thought, why make raspberries from raspberry juice? Why not choose some other juice like orange?..”

After a series of experiments, the Nufood 3D printer became much smaller and could print tasty little things in a matter of minutes. Although it is not suitable for making large-scale dishes, it can be used to beautifully decorate snacks, desserts and even drinks. He not only knows how to give a beautiful shape to his creations, but also to add different flavors. “The main advantage of Nufood is that this 3D printer can create things that do not exist in nature, for example, strawberries with a strip of cream inside,” says Kalnikaite. nine0003

Although it is not suitable for making large-scale dishes, it can be used to beautifully decorate snacks, desserts and even drinks. He not only knows how to give a beautiful shape to his creations, but also to add different flavors. “The main advantage of Nufood is that this 3D printer can create things that do not exist in nature, for example, strawberries with a strip of cream inside,” says Kalnikaite. nine0003

The founder of Dovetailed also believes that this technology is suitable for preserving fruits and vegetables, it is enough to collect them in the summer-autumn season, make juice from them, freeze it, and then load it into a 3D food printer. And voila, you have strawberries and tomatoes on your table in winter. Maybe then people will start buying products from local producers, which will help the economy, and refuse imported plastic vegetables and fruits that are sold in supermarkets. nine0003

At the Eat Cambridge Festival, the Dovetailed team plans to use Nufood to create a five-course dinner for 17 lucky people. Each dish will have its own 3D printed element. “People can't wait to see Nufood,” says Kalnikaite. “They do not believe us and want to see with their own eyes how it works. Every time we demonstrate its capabilities, there is a whole line of people who want to try his fragrant masterpieces.”

Each dish will have its own 3D printed element. “People can't wait to see Nufood,” says Kalnikaite. “They do not believe us and want to see with their own eyes how it works. Every time we demonstrate its capabilities, there is a whole line of people who want to try his fragrant masterpieces.”

If you're looking to put your own Nufood 3D food printer in your kitchen, then you might be happy to hear that Dovetailed is planning to launch a crowdfunding campaign to raise money for its development this summer. If you pre-order, then Nufood will cost you from 290 to $725 (depending on option selected).

Source

Subscribe to author

Subscribe

Don't want

Scientists 3D printed corals

1793

Bookmark

University of Cambridge researchers (UK) and University of California San Diego (USA) printed on a 3D printer artificial corals, which can grow dense populations of microscopic algae. in detail technology is described in an article published in magazine Nature Communications , reports briefly press office of the University of Cambridge.

in detail technology is described in an article published in magazine Nature Communications , reports briefly press office of the University of Cambridge.

In the ocean, corals and algae live in complex symbiotic relationship. Coral provides algae are home, and algae produce sugar for coral through photosynthesis. These relationships underlie one of the the most diverse and productive ecosystems on Earth - coral reef.

Researchers printed coral structures and used them in as incubators for algae growth. They checked different types of microalgae and found that growth rates were 100 times higher than in standard liquid nutrient media. nine0003

To create the complex structures of natural corals, scientists used a fast 3D bioprinting method, originally designed for bioprinting artificial liver cells. Scientists scanned using optical coherence tomography corals to use their computer models for 3D printing.

The team also developed artificial tissue and coral skeleton with a combination of polymer gels and hydrogels, which include added cellulose nanomaterials to mimic optical properties of living corals. nine0003

nine0003

“Cellulose is a rich biopolymer; it scatters light very well and we used it to optimize light delivery in photosynthetic algae,” said Dr. Silvia Vignolini (Silvia Vignolini), leader of the study. printed corals have proven to be very effective at redistributing light - just like their natural counterparts.

The new technology has many applications. For example, with Printed corals can be used to grow algae for production of bioproducts in developing countries. Also authors works hope that their development will have a real impact on algae biosector and will ultimately reduce emissions greenhouse gases that are killing coral reefs. nine0003

[Photo: UNIVERSITY OF CAMBRIDGE]

Author Material Designed by Tatyana Matveeva

3D printing seaweed artificial corals coral reef corals photosynthesis cellulose

Source: www.cam.ac.uk

Information provided by the Information Agency "Scientific Russia". Mass media registration certificate: IA No. ФС77-62580, issued Federal Service for Supervision of Communications, Information Technology and Mass Communications on July 31, 2015. nine0003

Mass media registration certificate: IA No. ФС77-62580, issued Federal Service for Supervision of Communications, Information Technology and Mass Communications on July 31, 2015. nine0003

SCIENCE FOR CHILDREN

Russian and Brazilian scientists have investigated the largest source of microplastics entering the World Ocean

14:00 / Ecology

How have New Year celebration traditions changed? Lecture by Candidate of Historical Sciences Maryana Arkhipova

13:00 / History, Science and Society, Ethnography

“Keepers of cultural heritage”: a new project on how Russian scientists protect our culture

12:00 / History, Science and Society

Where did the image of the Snow Maiden come from?

10:30 / Leisure

Scientists have developed biodegradable non-woven materials for accelerated wound healing

14:00 / Medicine, Chemistry

The most Christmas fairy tale. Ernst Theodor Amadeus Hoffmann, "The Nutcracker"

13:00 / Leisure, Person, Reading

A cold snap for 10 thousand years "expelled" the Neanderthals from the North-Western Caucasus

12:00 / Archeology, Climate

“Kolyada was born on the eve of Christmas”.