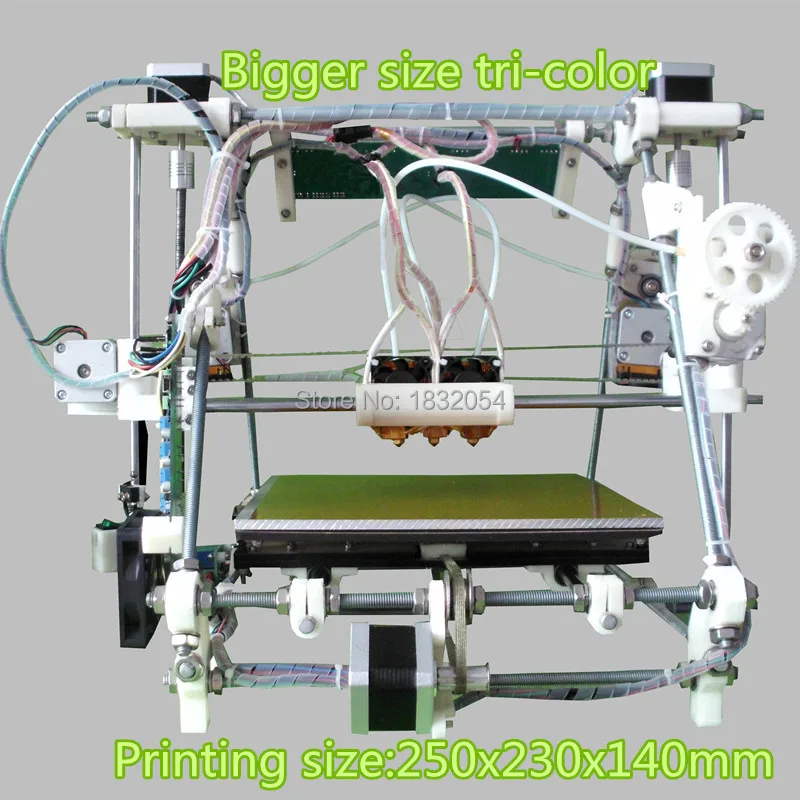

Cyclops 3d printer

CLEARANCE - E3D Cyclops+ Air Cooled Dual Extrusion Hotend - 1.75mm (12v)

- Home

- Store

- 3D Printer Accessories

- 3D Printer HotEnds

- Browse by Hotend Assembly

- Self Assembly Hotend Kits

Clearance

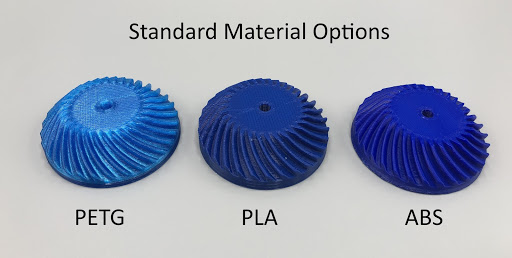

This experimental dual extrusion nozzle has got the 3D printing world excited by its potential possibilities! This 2 in 1 out extruder takes two materials in and prints through one nozzle, alternating between the different filaments. With the ability to swap between air and water cooled versions, the Cyclops+ hotend system is more versatile than ever before.

Remove from wishlist Add to wishlist loading...

Product No. M-26T-4AAW

| List Price: | $150.08 |

|---|---|

| Price: | $104.20 |

| Price: | $... |

| Order Now: | Ships calculating. |

Please note, all Clearance Item purchases are final and are not covered by the MatterHackers Return Policy - this excludes Refurbished 3D printers and machines which have at least a 6-month warranty.

Reason for Clearance: This item is being discontinued.

One nozzle, two materials

The Cyclops+ hotend features a unique two into one filament path that blends two separate inputs into a single heater block and extrudes them from a single nozzle. The ecosystem supports either air or liquid cooling, and this kit includes the air cooled heatsink. One of the major calibration pains with dual extrusion is configuring nozzle offset and the Cyclops makes it easy thanks to a single, shared nozzle for both.

Two materials, one nozzle

Easily swap components

The E3D Dual Extrusion + ecosystem features only two heater blocks; one for air cooling and one for liquid. Both utilize heat breaks that secure via set screws and both the Cyclops and Chimera heaters are compatible with either cooling system. With either heatsink installed, it's a quick swap between Cyclops and Chimera.

Both utilize heat breaks that secure via set screws and both the Cyclops and Chimera heaters are compatible with either cooling system. With either heatsink installed, it's a quick swap between Cyclops and Chimera.

Which E3D Hotend is right for you?

From the mainstay v6 to the diabolical quad-extrusion Kraken, E3D has a hotend to suit your needs. The v6 is the king of single extrusion with a wide variety of nozzle sizes and materials available, including the Volcano system. The Cyclops+ brings dual extrusion with a single, shared nozzle to maintain easier leveling and calibration. To mix and match nozzle sizes and types the Chimera+ uses two v6 or Volcano hotends together. Easily run a 0.4mm nozzle for fine detail perimeters and a 0.8 for fast and strong supports or mix brass for low temp and Nozzle X for high temperature materials. Kraken is the ultimate in multi-extrusion with four individual nozzles. Setting up Kraken is no simple task, but for the maker/hacker looking for the ultimate test it's truly the top of the mountain. Check out this graphic for a visual overview of all these options.

Check out this graphic for a visual overview of all these options.

What's in the box?

Air Cooled Cold Side:

- Air cooled heatsink

- 2 black plastic collets

- 2 blue plastic collet clips

- Cyclops+ fixings kit (compatible with Cyclops+ and Chimera+)

- 800mm PTFE bowden tubing

- 12v fan

Cyclops+ Hot Side:

- 0.4mm brass Cyclops nozzle

- Cyclops+ heater block

- 2x Cyclops+ Heat Breaks

- Cyclops+ Hot Side fixings kit

- Thermal compund

- 12v 30w Heater Cartridge

- Thermistor Cartridge

E3D Online releases upgraded Chimera and Cyclops 3D printer hot-ends

0Shares

E3D Online, a UK-based manufacturer of 3D printer components has released a new range of dual-extrusion hot-ends for 3D printing. The upgraded Chimera and Cyclops hot-ends are available in versions suitable for both air-cooled and water-cooled dual extrusion.

Customers can choose whether to have a Chimera+, Chimera Aqua+, Cyclops+, or Cyclops Aqua+ heater block kit and then add on an air or water-based cooling system, each with a 12 or 24 V fan.

With this launch, E3D continues its efforts bring water-cooled 3D printing to the hobbyists as well as the professional markets, following the release of the Titan Aqua water-cooling system in 2017.

The Cyclops+ hot-end. Photo via E3D Online.The Chimera+ and Chimera Aqua+ for multi-material 3D printing

The Chimera+ handles two separate filaments, extruding them via two different nozzles. Because it the two nozzles can each be heated to two different temperatures, the Chimera+ hot end is optimized to 3D print two separate materials (and can also 3D print two different color filaments).

With a slim design, it is also possible for the dual extrusion Chimera+ to perform as a single-extrusion hot-end. A variant of the Chimera+, the Chimera Aqua+ can be attached to a separately-sold water-based cooling system and function as a water-cooled hot-end.

The easy customizability of the Chimera+ and Chimera Aqua+ hot-ends means that they can be further upgraded with E3D online’s range of copper blocks and nozzles to handle even higher temperatures.

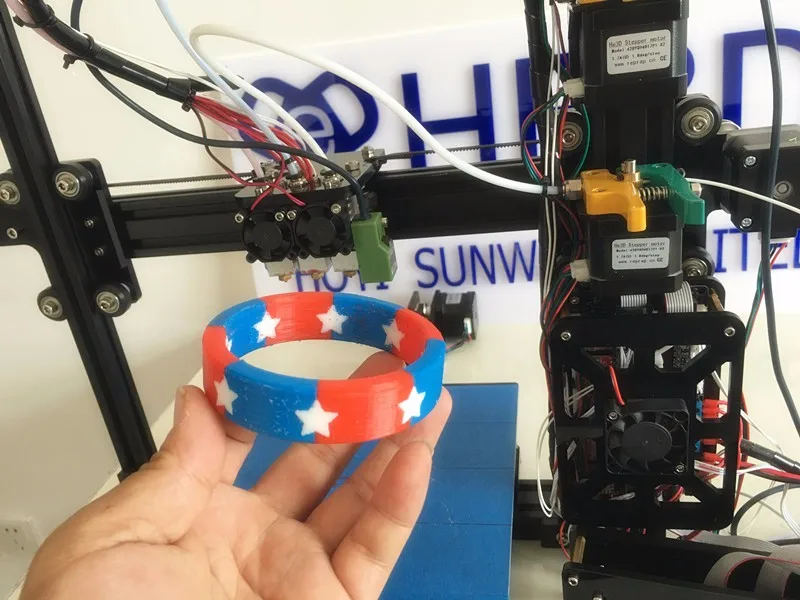

The Cyclops+ and the Cyclops Aqua+ for multicolor 3D printing

The Cyclops+ hot-end is an upgrade to its predecessor, the Cyclops. The redesigned heater block has had its redundant material removed, reducing the amount of radiant heat generated by the hot-end onto the print.

The single extruder receives one single filament at a time and has two extrusion nozzles, making the Cyclops+ ideal 3D printing designs with two different colors. Like the Chimera+, the Cyclops+ is also available as a modified Cyclops Aqua+ hot-end, suitable for water-cooled extrusion.

One distinct advantage of the single extruder design is that there is no idle nozzle that oozes whilst the other nozzle is in operation. This means that there is no need for an ooze-shield or height calibration.

Both the Chimera+ and the Cyclops+ use the same heatsink design, meaning that it is also possible to swap between air-cooled and water-cooled heatsinks. An external heatsink fan ensures that there is no sudden change in the air of the build chamber, which reduces the possibility of warping.

An external heatsink fan ensures that there is no sudden change in the air of the build chamber, which reduces the possibility of warping.

Tell us who what you think the most innovative 3D printer add-on has been this year. There is only a week until nominations for the 3D Printing Industry Awards 2018 close. Submit your choices now.

For more stories on 3D printing and the extruder technology, subscribe to our free 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Featured image shows the Cyclops+ and Chimera Aqua+ extruders with some multicolor designs. Photo via E3D-Online.

Tags Chimera Aqua+ Chimera+ Cyclops Aqua+ Cyclops+ E3D Online Titan Aqua V6

Rushabh Haria

Rushabh Haria is a writer at 3D Printing Industry. Hailing from South London, he has a degree in Classics. His interests include 3D printing in art, manufacturing design, and education.

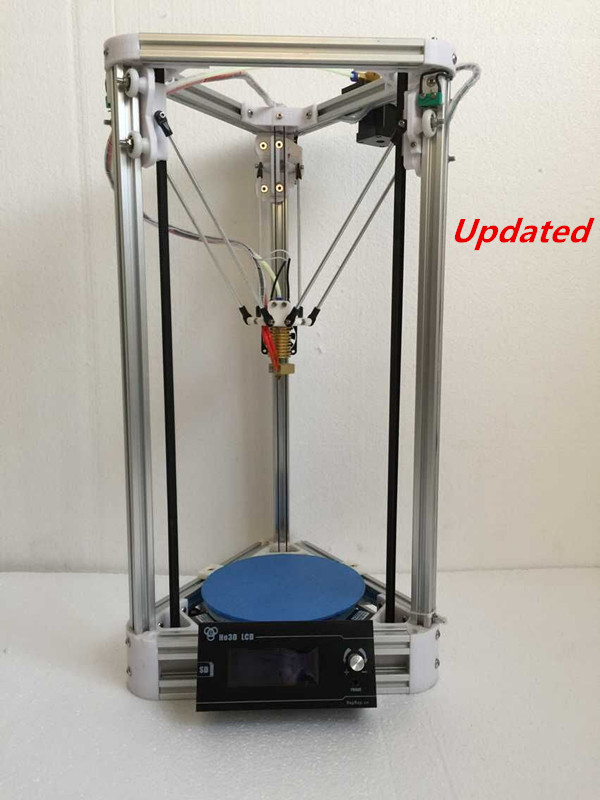

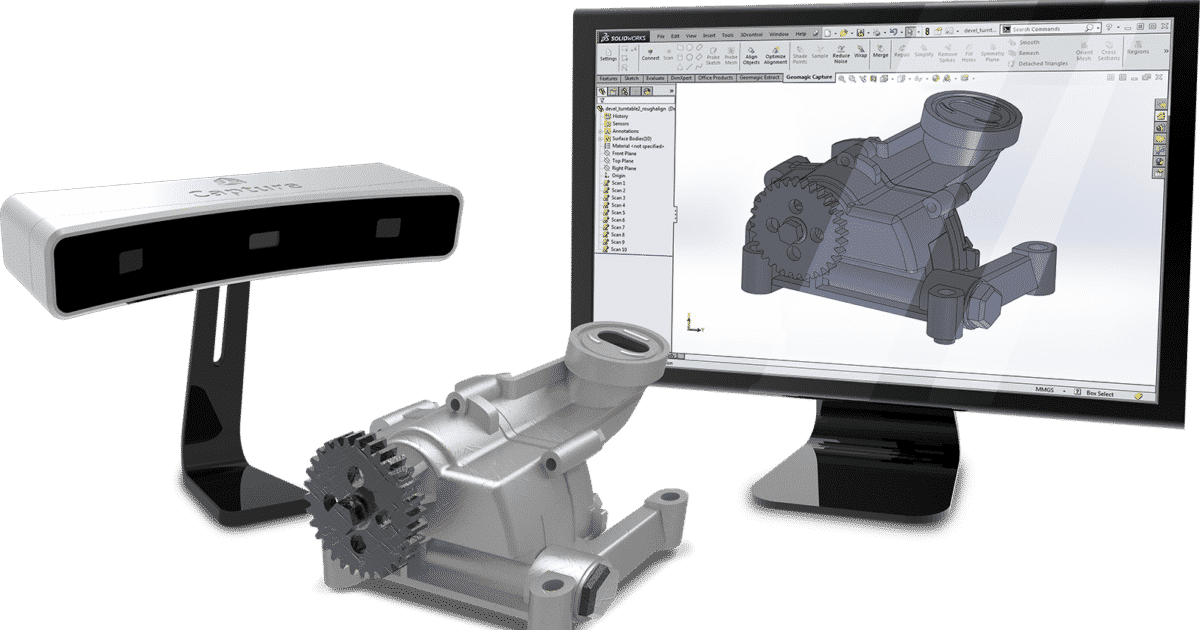

Read ""How to defeat the Cyclops": how to assemble and debug the 3D scanner that was installed in your school" - Dmitry Usenkov

Cyclops, or, more precisely, Ciclop is a 3D scanner for scanning small objects. This model (with a turntable and one or two lasers - Fig. 1) has been developed for a long time and is used by many "home-made people" - especially since all the plastic parts of the structure are printed on a 3D printer. It was these scanners made by the Spanish company BQ that were delivered to Moscow schools in the summer of 2017 along with Hephestos 3D printers under the Technosphere of the Modern School project (read about this project and the assembly of Hephestos 3D printers in another brochure of this series - "The Taming of Hephaestus": how to assemble and debug a 3D printer that was delivered to your school - https://www.litres.ru/dmitriy-urevich-usen/ukroschenie-gefesta-kak-sobrat-i-otladit-3d- printer-k&lfrom=508959676 ).

The principle of operation of the scanner is quite simple: a laser beam in the form of a thin vertical strip hits the original object mounted on a rotating table, and due to the surface irregularities of the object (protrusions or depressions), the light strip is distorted, becomes bent, broken or broken. Software (program Horus - this time the developers decided to turn to ancient Egyptian mythology instead of ancient Greek) processes the image coming from the webcam and, due to changes in brightness and contrast, highlights this bright line against the general background. And then, according to the shape of this line, the corresponding section of the surface of the object is determined (calculated). At the same time, the table rotates with a stepper motor, and the scanner gradually “copies” this object into a digital model, forming a point cloud. (In principle, one laser is enough for scanning, but you can use two at once to speed up the work and increase the accuracy of the scan.)

Software (program Horus - this time the developers decided to turn to ancient Egyptian mythology instead of ancient Greek) processes the image coming from the webcam and, due to changes in brightness and contrast, highlights this bright line against the general background. And then, according to the shape of this line, the corresponding section of the surface of the object is determined (calculated). At the same time, the table rotates with a stepper motor, and the scanner gradually “copies” this object into a digital model, forming a point cloud. (In principle, one laser is enough for scanning, but you can use two at once to speed up the work and increase the accuracy of the scan.)

Like the Hephaestus, the Cyclopes were delivered to schools as a set of parts, in the expectation that there would be specialists in schools who could assemble and set up this equipment - therefore, in most cases, this equipment is most likely gathering dust somewhere in a warehouse . However, assembling and setting up a Ciclop scanner is not that difficult (and much easier than a 3D printer anyway). Let's get on with it.

Let's get on with it.

1. Assembly

We note right away: unlike the Hephestos 3D printer kits for the Ciclop scanner, there is no printed (paper) assembly instruction. There are only electronic manuals that can be found on the manufacturer's website - BQ:

- assembly manual for the whole structure and turntable - https://storage.googleapis.com/bqcom15.statics.bq.com/prod/resources/manual/Ciclop_QSG_01_EN-1484575721.pdf

End of introductory fragment.

Text provided by LitRes LLC.

Read this book in its entirety by purchasing the full legal version on LitRes.

You can safely pay for the book with a Visa, MasterCard, Maestro bank card, from a mobile phone account, from a payment terminal, in an MTS or Svyaznoy salon, via PayPal, WebMoney, Yandex.Money, QIWI Wallet, bonus cards or in another way convenient for you. nine0007

Cronos Cyclops. One-eyed brother of god with a sickle. Part one. Unboxing » Profitable 3D printing studio

A funny thing, Greek mythology. Family ties there are so mixed up that it takes a long time to figure out who is to whom what kind of relative. And all the relatives are among the gods. ))

Family ties there are so mixed up that it takes a long time to figure out who is to whom what kind of relative. And all the relatives are among the gods. ))

So the one-eyed children of the Cyclopes were born to the god Uranus and Gaia. And so that they would not overthrow dad, he threw them into Tartarus.

And then Kronos was born to them, who castrated his father with a sickle, with which he is shown on the frescoes, and he himself came to power. nine0007

In general, it turns out that if the parents are alone, then Kronos and the Cyclopes are brothers. This is such a fun name for a new Russian 3D printer.

But enough fairy tales. Let's get to the main point.

Appearance of Cronos to the people

Last week I received a healthy plywood box weighing over 50 kg. It turned out to be a 3D printer from the Russian company Cronos from Surgut, called Cyclop.

To get it, I had to unscrew something like 20 screws. Of course, it took time and a little stress. But the packaging of the printer inspires respect. In this form, the printer will definitely not be damaged during transportation. And you do not need to order a special rigid packaging from a transport company. Inspires! nine0007

But the packaging of the printer inspires respect. In this form, the printer will definitely not be damaged during transportation. And you do not need to order a special rigid packaging from a transport company. Inspires! nine0007

All this can be seen in the photo.

I will not describe the complete set. Because this is a test sample and only the wires for connection and the sd card are included. Nothing extra. We will see in the near future what the printers will be equipped with when selling.

I also warn you, since this is a test sample, there will be traces of operation in the photo, in which the Plastmaska comrade can be blamed. From him, I understand, the “ErichKrause” glue stick also appeared in the kit. )))

Therefore, in this initial mini-review - a photo of the external / internal view and a few impressions.

Appearance

First, a standard photo with a kote to estimate the dimensions of this unit.

The printer is quite large and heavy. Only metal, only hardcore.

Only metal, only hardcore.

The front door is not hinged but is removable and hangs on bolts. This can be seen in the photo.

Back wall

The thickness of the metal from which the case is made is respectable. Hence the weight. And immediately Boris-Razor comes to mind, with his unforgettable phrase about weight. nine0007

Kinematics

The printer itself is built, as you can see from the photo according to the H-Bot scheme on rails. For the "worried" - Hiwin rails.

Those nasty elements of construction.

Extruder

To insert the plastic, press the lever and direct the plastic inward.

View of the left side of the extruder.

Right side view.

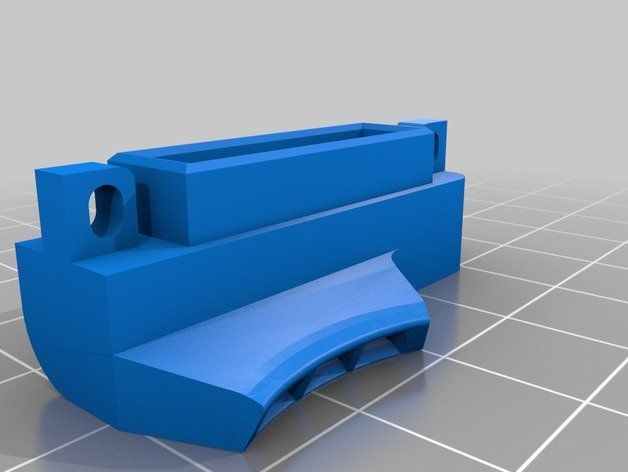

As you can see from the photo - an extruder with a gearbox. Metal carriage. Two fans. One cooler per thermal barrier. The second is for cooling the part.

Air is directed through the printed duct.

Well printed, by the way. I even thought it was cast.

Table

Heated table. With a glass surface that is easy to remove by pushing the two holders.

It heats up quickly.

The main feature is auto-calibration. That is, complete. And not as it happens semi-automatic, when you need to turn the turntables. nine0007

The extruder passes over several points. Pulls out the dipstick and voila! All is ready.

If you use ready-made slicer profiles from the manufacturer, the same operation is carried out automatically before starting printing.

The manufacturer took care of the user and did everything to support the print-out-of-the-box format.

Screen and control menu

And our screen is not a standard “reprapovsky”. A graphic a la Ultimeyker. Menu items are standard.

There is some screen lag. But everything looks nice.

The text is readable both in bright light and in the dark.

The control of the “turntable” is convenient.

The location of the SD card on the front panel is convenient. No need to squirm and insert the card into some “back place”. nine0007

Noise

Virtually no noise. There is a quiet whistle when moving. The rest is quite comfortable in terms of noise level.

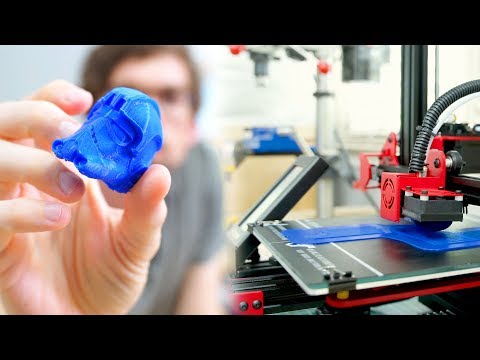

My approach to testing new technology is simple. First, the settings (software) from the manufacturer are loaded and everything is printed by default. It's like I'm a new user who knows nothing and does everything according to the instructions.

In this case, there was a profile for Symplify3D on the manufacturer's website. I uploaded it. nine0007

Shove white #ABS plastic from Strimplast. He, like #PLA from this manufacturer, is excellent. Already exhausted about two kilograms of each.

Uploaded the cube model I liked - https://www. thingiverse.com/thing:2251743

thingiverse.com/thing:2251743

Here's what came of it.

Everything turned out great! Except one BUT. I, as I wrote above, used the default settings from the manufacturer and did not uncheck the support box. As a result, the lower part was printed incorrectly, with supports. nine0007

I will test this point in the future.

First impressions

Cronos Cyclop 3D printer is well made. In every detail you can see the desire to make everything powerful, reliable. No backlash, squeaks. There is nothing loose that can be torn off or damaged.

Attention to the user - auto-calibration, user-friendly menu. It seems like a trifle, but it greatly simplifies the work. Especially for a beginner.

Another useful feature. After the end of printing, well, as usual, the extruder is parked and the table is lowered. And the backlight turns off, the fans turn off and the printer “turns off”. Well, that is, it gets into sleep mode when it does not make a sound, but by pressing a button it “can be awakened”.