3D print media

3D Printing for Visual Marketing » 3D Printing Media Network

By introducing 3D printing technologies to visual marketing, companies are now able to create large and small visual advertising products that are not just images on a wall but real 3D representations of a product, often supersized. This has become possible with the emergence of more affordable, large format 3D printing technologies, including filament extrusion and – even more so – Massivit’s unique gel dispensing technology.

Because marketing models don’t need to be durable or possess particular mechanical properties, the quality of the materials used is irrelevant. Materials need to be first and foremost affordable and fast do print. By cagtering to these two primary demands, a few 3D printer manufacturers which also include HP and its full color 3D printing systems, have effectively created a new segment of 3D printing and marketing.

Key adopters in this segment are 2D digital printing services and studios that decide to venture into offering 3D capabilities. This transition is not an easy one, as physical 3D representations present a series of challenges that need to be overcome in terms of assembling and finishing a product, however more than a few companies around the world have already begun to embrace this revolution and the results have often been quite stunning.

In this AM Focus, we will examine some of these fascinating marketing projects and the potential of this new vertical segment of the additive manufacturing industry, with contributions from some of the key players in this field.

-

Mimaki’s 3D printing business has been intertwined with Israeli technologies from the start. The Japanese company is a leader in large format 2D inkjet technology just like many of the firms involved in the evolution of companies like Objet, which later became Stratasys.

Read More After launching the only credible material jetting…

After launching the only credible material jetting… -

Anouk Wipprecht, one of the best-known tech-fashion designers making intensive use of 3D printing technologies, has worked with “bionic” singer Viktoria Modesta on the latest Rolls Royce Campaign. Anouk has collaborated with Viktoria on several projects in the past, transforming the singer’s prosthetic leg in a stylish augmentation. This time…

Read More -

One Piece manga fans had a chance to get interactive with their favorite One Piece characters 3D printed in huge sizes for the publication’s 20th Anniversary celebrations. Fans used the event app’s augmented reality videos to film themselves together with the 24 giant 3D printed props and to customize the…

Read More -

Perhaps one of the most exciting developments in the field of visual communications is the adoption of large-format 3D printing. The power of this technology to wow audiences and draw them in is immense.

Read More I mean, what could be cooler than an 8-foot baseball player mannequin in a sporting goods…

I mean, what could be cooler than an 8-foot baseball player mannequin in a sporting goods… -

Working with graphic studio Construction Effects for Nespresso, Australia-based digital design studio Composite Images 3D printed two incredible oversized milk splashes to celebrate the new Vertuo machines. The studio created two models: the larger of the two was displayed in the Nespresso George Street, Sydney store window, while the smaller one…

Read More -

New York City startup Graft Milk has launched the world’s first 3D printing filament designed specifically for the creative arts, known as Art Filament. Graft Milk’s first line of high-quality PLAm Art Filament has been specifically formulated to capture every detail of the most intricate designs and elevate printed artwork to…

Read More -

When exploring the new developments, opportunities and challenges of additive manufacturing, mass production and especially manufacturing dimensions represent a significant obstacle.

Read More During Formnext 2018, we had the opportunity to discuss such challenges with Dr. Ricardo Osiroff, VP Industrial Solutions of Massivit 3D. The large format print industry is a highly…

During Formnext 2018, we had the opportunity to discuss such challenges with Dr. Ricardo Osiroff, VP Industrial Solutions of Massivit 3D. The large format print industry is a highly… -

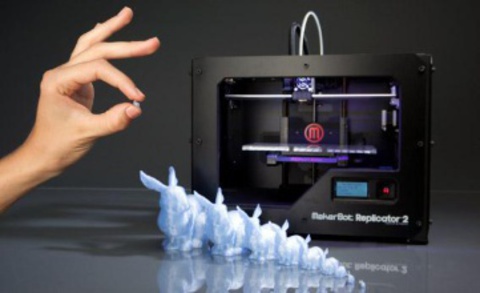

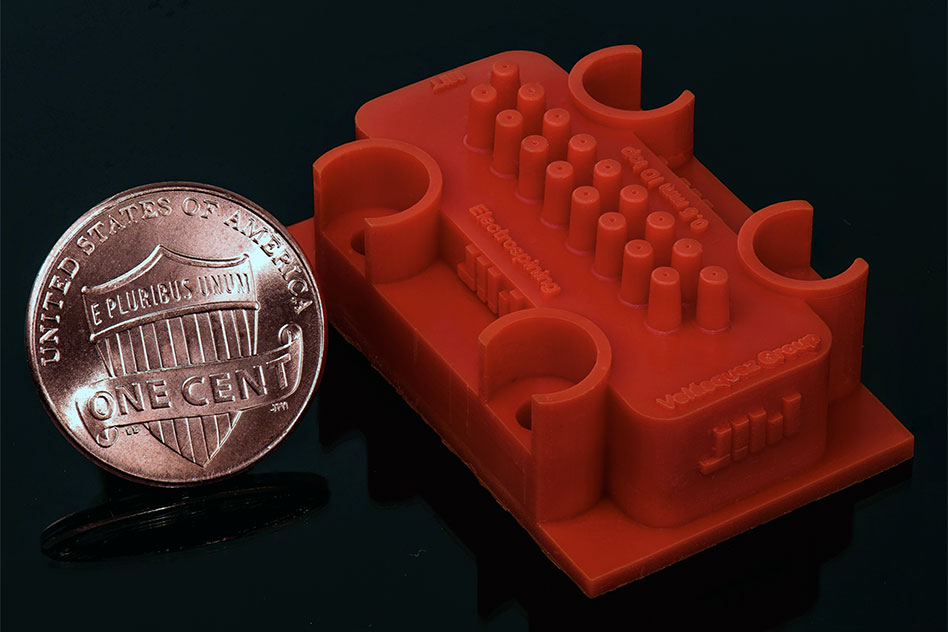

While 2D renderings can help to communicate a product concept well enough, there is something to be said about seeing a concept as a physical, three-dimensional object. This marketing reality has not been lost on manufacturers and designers, who are increasingly turning to additive manufacturing to tactilely visualize design and…

Read More -

Deko 3D by Sépia has installed a Massivit 1800 3D printing solution in a bid to secure new business and overcome the constraints of traditional production processes. The Grenoble-based specialist provider of large format 3D applications, a subsidiary of Sépia Signalétique, was founded as a full-service 3D service bureau. “After several years…

Read More -

Boston-based 3D printing company RIZE Inc.

Read More today announces a slew of new products, including the brand new XRIZE industrial desktop 3D printer with full-colour capabilities. In addition to the 3D printer launch, the company has also introduced a range of new materials, including RIZIUM CARBON and RIZIUM ENDURA, as well…

today announces a slew of new products, including the brand new XRIZE industrial desktop 3D printer with full-colour capabilities. In addition to the 3D printer launch, the company has also introduced a range of new materials, including RIZIUM CARBON and RIZIUM ENDURA, as well…

Load More

Davide Sher, Author at 3D Printing Media Network

- Financial Reports

Davide SherNovember 14, 2022

It’s not eactly a great moment for some leading US-based digital manufacturing service providers. Their real businesses are doing rather…

Read More

- Executive Interviews

Davide SherNovember 11, 2022

Clear aligners continue to increase in demand and 3D printing has proven to be an ideal technology to produce these…

Read More

- Financial Reports

Davide SherNovember 10, 2022

The good news for Markforged Holding Corporation (NYSE: MKFG), a company looking to enable industrial production at the point of…

Read More

- 3D Printer Hardware

Davide SherNovember 7, 2022

As additive manufacturing continues to grow, one of the most challenging and high-potential segments of AM, that of reactive thermoset…

Read More

- Automotive

Davide SherNovember 5, 2022

As anticipated by 3dpbm in July 2022, the Cadillac CELESTIQ, described by GM “as the most technologically advanced Cadillac ever”,…

Read More

- 3D Printer Hardware

Davide SherNovember 5, 2022

The Bosch Group has shown a growing interest for additive manufacturing over the past few years.

The company owns Dremel…

The company owns Dremel…Read More

- Metal Additive Manufacturing

Davide SherNovember 2, 2022

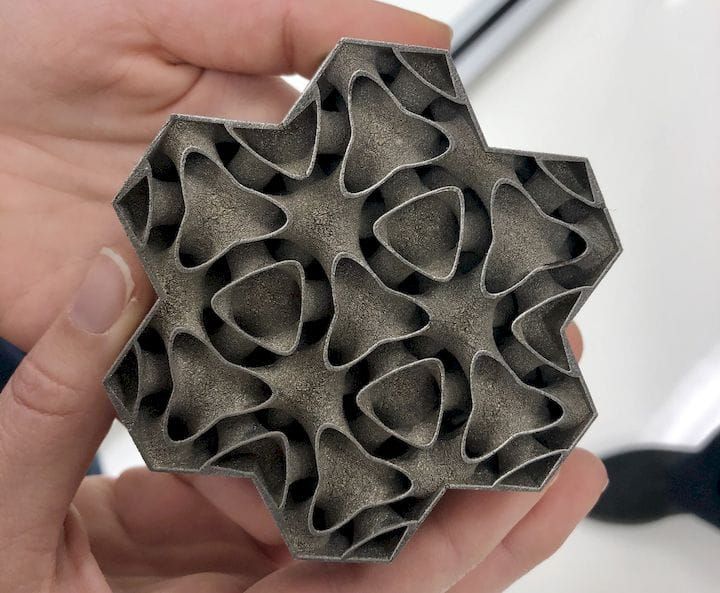

Metal binder jetting technology, now also known by the acronym MBJ, is, at the same time, the first and the…

Read More

- Automotive

Davide SherOctober 26, 2022

Sauber Motorsport will be the strategic partner of Audi’s F1 program as per a new agreement signed by Audi AG…

Read More

- Automotive

Davide SherOctober 21, 2022

Mass customization, consumer 3D printing, on-demand, local, digital manufacturing. These are no longer just far away goals of 3D printing:…

Read More

- piùAdditive BIMU

Davide SherOctober 20, 2022

PiùAdditive, the first additive manufacturing exhibit created by AITA, the Italian association of AM companies, wrapped up its first edition…

Read More

Load More

Relativity Space tests 3D printed launch vehicle

News

-printed components in the current iteration is already 85% and according to the developers' plans it will reach 95%.

During testing, nine first stage engines ran for twenty seconds ( see video ). The Aeon 1 power plants are 3D printed and run on methane and oxygen. The company uses various 3D printing technologies, including selective laser sintering of metal powders on 3D printers manufactured by the German company EOS and laser-plasma deposition of aluminum alloys in the form of welding wire on an additive system of its own design called Stargate.

Terran launchers will be able to launch up to 1250 kg of payload to low Earth or up to 900 kg into sun-synchronous orbit. The first flight will take place this year, although the exact date is still unknown: the company planned to launch in June, but the schedule has shifted to the right.

The first non-commercial launch will take place from Cape Canaveral, from Launch Complex 16, leased from the US Air Force and previously used to test Titan ICBMs and Pershing short-range ballistic missiles.

In the long term, Relativity Space expects to reduce production times to two months through automation and the widespread use of additive technologies. The cost of a single launch of Terran 1 is estimated at twelve million dollars. By 2024, it is planned to complete work on a heavier Terran R launch vehicle with a payload capacity of up to twenty tons. Read more about production at the facilities of Relativity Space in the material at this link.

Space Relativity Space Terran 1

Follow author

Follow

Don't want

4

Article comments

More interesting articles

fourteen

Subscribe to the author

Subscribe to the author

Don't want to

This used to happen in cases of revocation of airworthiness certificates for storks and poor harvest of cabbage children. ..

..

Read more

7

Subscribe to the author

Subscribe

Don't want to

One of the key technological challenges of our time is the need for a multiple reduction in time...

Read more

82

Subscribe to the author

Subscribe

Don't want

Collaboration 3D

We are pleased to present you our joint development with Speci...

Read more

90,000 Russian cruise launch vehicles plan to equip 3D-print enginesNews

Subscribe to

Subscribe

I do not want

4

Multiral hypersonic level of “Kryllo-SV” unified family of new lungs launch vehicles are planned to be returned using a 3D-printed MGTD-150 jet engine developed under the Tantalum project.

“The MGTD-150 engine developed as part of the project is also planned to be used as a return flight engine for the Krylo-SV reusable rocket and space system,” said Deputy General Director and Head of Chemical, Biological and Medical Research at the Advanced Research Foundation Alexander Panfilov in an interview with RIA-Novosti.

The Krylo-SV system is being developed by the Myasishchev Experimental Machine-Building Plant as a hypersonic reentry stage with a rotary wing. The project of the failed promising cruise missile "Baikal" ( in the illustration above ), developed by the Khrunichev Research and Production Center. For flights at high speeds, the Whirlwind engine is being created, and the MGTD-150 3D-printed jet engine will be responsible for the return of the stage. The first flight of the return stage in subsonic mode is scheduled for the end of next year, full-fledged tests of the flight demonstrator will take place approximately in 2023.

“The system is designed to launch a payload of up to 600 kilograms into a sun-synchronous orbit. The scheme of operation of the product provides for the separation of the first stage of the launch vehicle at a height of 59-66 kilometers and its return to the launch area with landing on a regular runway. In the basic design of the return unit, a large-span rotary rectangular wing and a classic tail unit will be used. Within the framework of the project, it is planned to develop a complex of scaled flight experimental demonstrators of reusable blocks. A separate project includes work on the creation of a demonstrator of a dual-mode liquid-jet engine running on liquefied natural gas and oxygen. The main goals of the program are to demonstrate the technical feasibility of creating reusable retrievable cruise missile units and to confirm the level of technology readiness for creating a unified model range of light class launch vehicles of various payloads,” the Advanced Research Foundation reports.

MGTD-10

The creation of a family of small-sized 3D-printed jet engines is carried out by the Design Bureau named after MP Simonov with the participation of the Advanced Research Foundation (FPI) and the All-Russian Research Institute of Aviation Materials (VIAM). The first flight tests of the A30 light unmanned vehicle with a 3D printed MGTD-20 engine took place in July of this year, and in September, a more powerful version of the MGTD-125E launched another drone, the Dan-M air target. At the same time, it was reported that the start of mass production of small-sized gas turbine engines in the thrust class of 10, 20, 125 and 150 kilogram-forces is scheduled for 2021-2022, taking into account the completion of the stage of development work in the interests of the state defense order.

Do you have interesting news? Share your developments with us, and we will tell the whole world about them! We are waiting for your ideas at news@3Dtoday. ru

ru

Rocket VIAM FPI MGTD Baikal Wing-SV

Follow author

Follow

Don't want

4

Article comments

More interesting articles

ten

Subscribe to the author

Subscribe

Don't want

The leaders of the business accelerator of Rosatom "InnoHub" and LLC "Incarnation" signed an agreement on the pre...

Read more

four

Subscribe to the author

Subscribe

Don't want

Employees of the Institute of Laser and Welding Technologies (ILIST) of the St.