3D print lifting off bed

9 Ways How to Fix 3D Prints Warping/Curling – PLA, ABS, PETG & Nylon – 3D Printerly

Most people who’ve worked with 3D printers are familiar with warping and it’s a problem that plagues many users. You’ll be happy to know there are a series of methods to reduce warping to the point where you can get consistently successful prints without experiencing warping.

This article will show you precisely, how this problem is solved for good.

To fix warping/curling in 3D prints, use an enclosure to control the ambient printing temperature and any rapid cooling that causes shrinkage in your prints. Use a good build plate temperature for your filament, make sure your build plate is clean and use adhesives so the print sticks to the build plate properly.

There’s more detail behind fixing 3D prints that warp so keep on reading for more.

What is Warping/Curling in 3D Prints?

Warping or curling in 3D prints is when the base or bottom of a 3D print starts to curl upwards and lift away from the build plate. It results in 3D prints losing dimensional accuracy and can even ruin the functionality and looks of a 3D model. It occurs due to shrinkage in the material from rapid temperature changes.

What Causes Warping & Lifting in 3D Printing?

The main causes of warping and curling is from temperature changes which causes shrinkage in your thermoplastic filament, along with a lack of adhesion to the build surface.

Below are some specific causes of warping in 3D printing:

- Rapid temperature changes from hot to cold or room temperature too cold

- Bed temperature too low or uneven heating on bed

- Drafts blowing cold air onto model, no enclosure

- Bad adhesion to the build plate

- Cooling settings not optimized

- Build plate not leveled

- Build surface is dirty with grime or dust

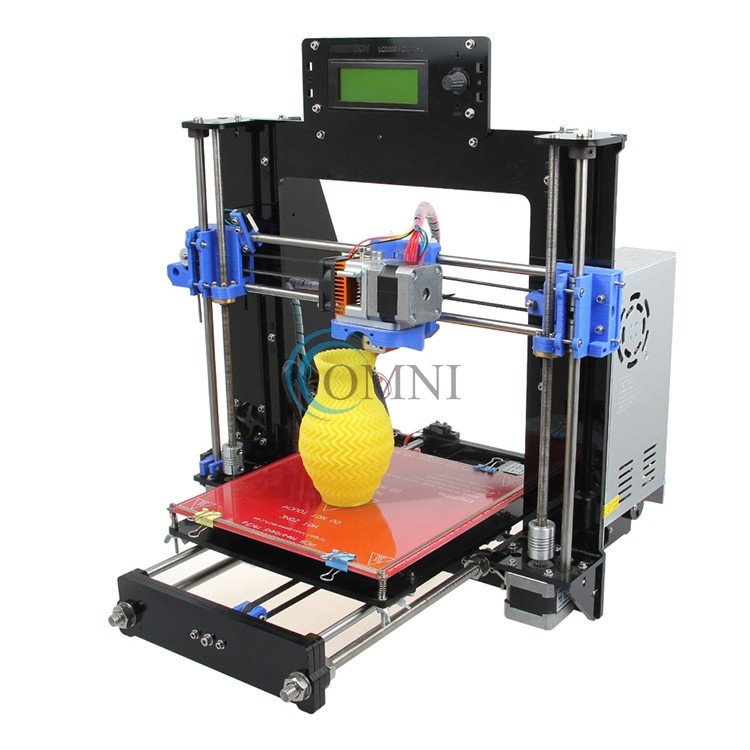

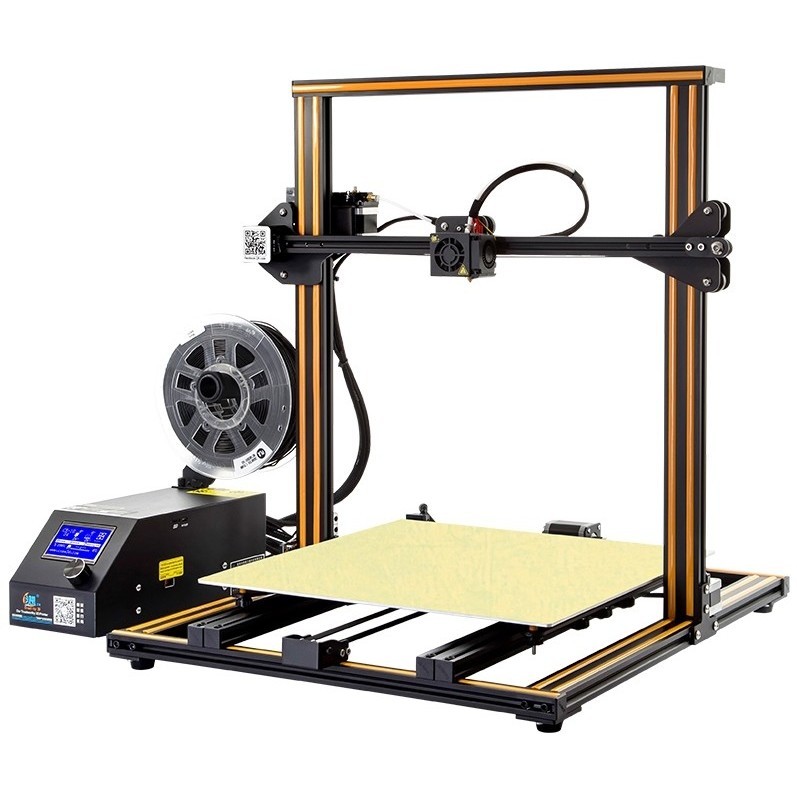

Whether your PLA is warping mid-print, warping on a glass bed or heated bed, the causes and fixes will be similar. Many people who have a 3D printer like an Ender 3 or Prusa i3 MKS+ experience warping, so let’s look into how to fix it.

Many people who have a 3D printer like an Ender 3 or Prusa i3 MKS+ experience warping, so let’s look into how to fix it.

How to Fix Warping in 3D Printing – PLA, ABS, PETG & Nylon

- Use an enclosure to reduce rapid changes in temperature

- Increase or lower your heated bed temperature

- Use adhesives so the model sticks to the build plate

- Ensure cooling is turned off for the first few layers

- Print in a room with a warmer ambient temperature

- Make sure your build plate is properly leveled

- Clean your build surface

- Reduce drafts from windows, doors, and air conditioners

- Use a Brim or Raft

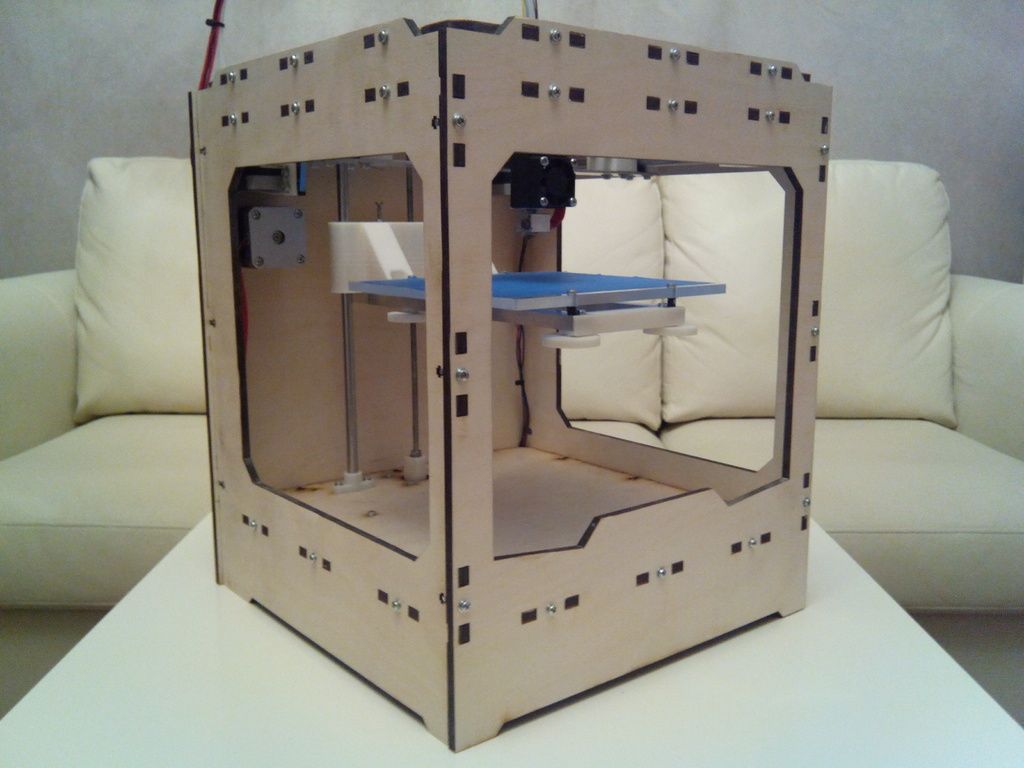

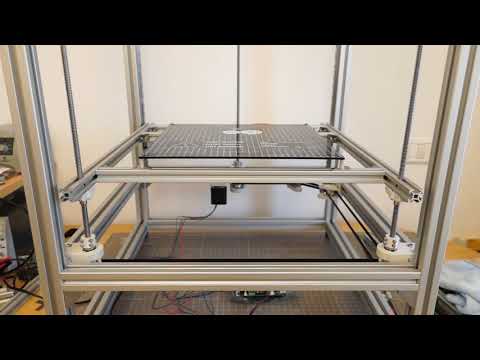

1. Use an Enclosure to Reduce Rapid Changes in Temperature

One of the best methods to fix warping and prevent it happening to your 3D prints is to use an enclosure. This works because it does two things, keeps a warmer ambient temperature so your print doesn’t cool rapidly, and also reduces drafts from cooling your model.

Since warping usually occurs due to temperature changes, an enclosure is a perfect fix to preventing warping happening to your 3D prints. It should fix a lot of the issues but you may still need to implement some other fixes to get rid of warping once and for all.

I’d recommend getting something like the Comgrow Fireproof & Dustproof Enclosure from Amazon. It has plenty of positive reviews from other 3D printer users mentioning just how effective and useful the enclosure is.

One user mentioned that after they started using this enclosure, they no longer has prints warping on the corners, and adherence to their heated glass bed got a lot better. It also even slightly cuts down on noise pollution, so you don’t disturb others or yourself as much.

There are other temperature-related defects that 3D prints go through, so having this enclosure helps with many problems at once. Setup is pretty easy and it looks good overall.

3D prints that warp on one side can be quite annoying, so getting an enclosure can help to solve this issue.

2. Increase or Lower Your Heated Bed Temperature

Usually, increasing your bed temperature helps to reduce warping because it stops that rapid change in temperature since the heat emits nicely on the model. Follow your filament recommendation for bed temperature, but try increasing the bed temperature on the higher end.

Even for a filament like PLA, 60°C can work well even though many people recommend 30-50°C, so give different temperatures a try and see how it works for you. There are many types of 3D printers out there, as well as personal printing environments that can affect these things.

Check out my article on How to Get the Perfect Build Plate Adhesion Settings & Improve Bed Adhesion for more info.

One bed temperature for one user might work well, while it doesn’t work too well for another user, so it’s really down to trial and error.

You can also have a bed temperature that’s too high that can lead to warping due to rapid temperature changes, possibly due to having a cool ambient temperature.

If you have tried increasing your bed temperature, you can also try lowering it to see if it has a positive effect on reducing warping.

3. Use Adhesives so the Model Sticks to the Build Plate

Since warping is a movement that shrinks material, especially corners of your 3D prints, sometimes having a good adhesive on the build plate can stop the material from moving away.

Many people have fixed warping or curling in their 3D prints by simply applying a good adhesive and letting it do its magic.

There are plenty of adhesives out there that work for 3D printer beds. The most popular type of adhesive I’ve seen in the 3D printing community has to be glue sticks.

I’d recommend going with something like FYSETC 3D Printer Glue Sticks from Amazon.

A few coats of glue stick on the bed should give you a lovely foundation for your model to stick to so it doesn’t warp and shrink away from the build plate.

You can also take it to the next level and use a 3D printer specific adhesive like LAYERNEER 3D Printer Adhesive Bed Weld Glue from Amazon.

I wrote an article called Best 3D Printer Bed Adhesives – Sprays, Glue & More.

4. Ensure Cooling is Turned Off for the First Few Layers

Your slicer should have default cooling settings that turn the fans off for the first few layers, but you may want to turn it off for more layers if you are getting warping. I’d usually recommend trying out the other fixes before you do this because cooling contributes to better 3D print quality.

For a material like PLA, they usually recommend your cooling fans being on 100% so you may not want to turn it down for that.

If you are experiencing warping on a material like PETG or Nylon, you want to try adjusting your cooling settings to be lower so the material isn’t cooling too quickly.

You can change the layer height that your 3D printer fans start their regular speed directly in your Cura settings. If you get warping early on, it could be worth delaying where you start the fans.

Check out How to Get the Perfect Print Cooling & Fan Settings for more details.

5. Print in a Room with a Warmer Ambient Temperature

Similar to the fixes above, the main thing is having a better control on your temperature, especially the ambient temperature. If you are printing in a cold garage in the winter, you are a lot more likely to experience warping in your models, compared to printing in a warm office.

Be aware of the general temperature of where your 3D printer is placed so it’s not in an environment that’s too cool.

As mentioned above, an enclosure here can help. Some people have reduced warping by even using a space heater near their 3D printer, or placing the printer close to a radiator.

6. Make Sure Your Build Plate is Properly Leveled

Warping usually happens due to pressure from the rapid cooling and shrinking of material, but this can be countered by making sure your build plate is leveled better.

In addition to using adhesives like a glue stick, when your build plate is leveled nicely, it improves the adhesion of material to the build plate.

If your build plate isn’t leveled very well, the foundation and adhesive is going to be weaker than usual, increasing the chances that you experience warping.

Follow the video below by Uncle Jessy to level your build plate nicely.

For more details, check out my article How to Level Your 3D Printer Bed – Nozzle Height Calibration.

7. Clean Your Build Surface

Just like leveling your build plate is important for adhesion which helps to reduce warping, cleaning your build surface is equally as important.

We want to provide strong adhesion to the material extruded from the nozzle, but when the build plate is dirty or grimy, it doesn’t stick so well to the bed surface, especially with glass beds.

If you want to reduce warping in your 3D prints, make sure your build surface is nice and clean.

Many people would do something like clean it with isopropyl alcohol and a cloth, or even do a full clean with dish soap and warm water. You can also get sterile pads to help clean your beds, it’s really up to you what you do.

I wrote an article How to Clean a Glass 3D Printer Bed – Ender 3 & More that goes into more depth.

The video below shows you how to clean a print surface on the Ender 3 using a sock and some 70% Isopropyl Alcohol.

8. Reduce Drafts From Windows, Doors, and Air Conditioners

If you don’t have an enclosure, you definitely want to stop cool air and drafts from blowing on your 3D printed parts. I remember I had a strong draft due to having a window and a door open while 3D printing, and it resulted in really bad warping.

I remember I had a strong draft due to having a window and a door open while 3D printing, and it resulted in really bad warping.

Once I closed the door and stopped the draft from blowing around the room, that warping quickly stopped and I successfully created my 3D model.

Try to identify where any gusts of wind are coming from, even from something like an air conditioner or air purifier, and try to reduce it or the impact on the 3D printer.

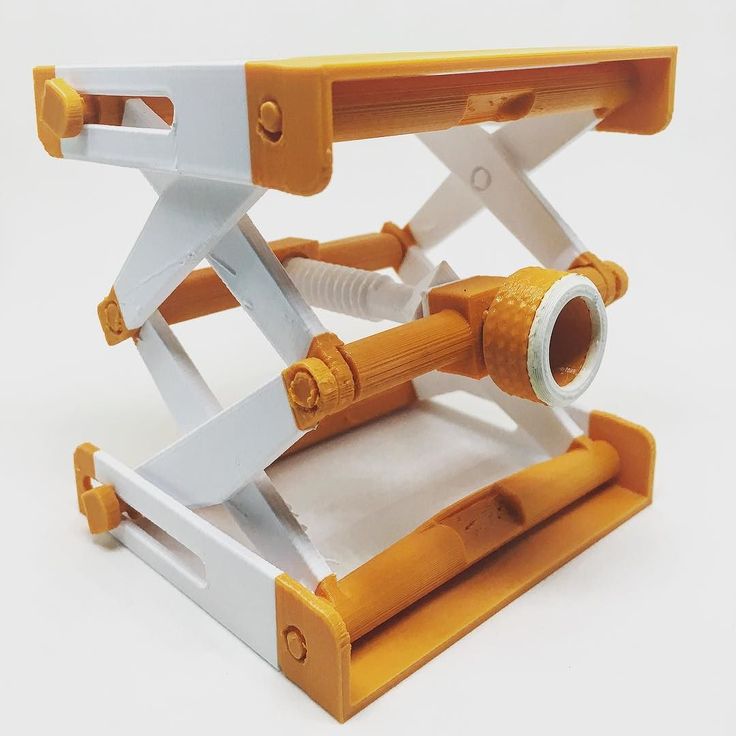

9. Use a Brim or Raft

Using a Brim or Raft focuses on the adhesion side of warping. These are simply extra layers of extruded material that provide a foundation around your 3D model.

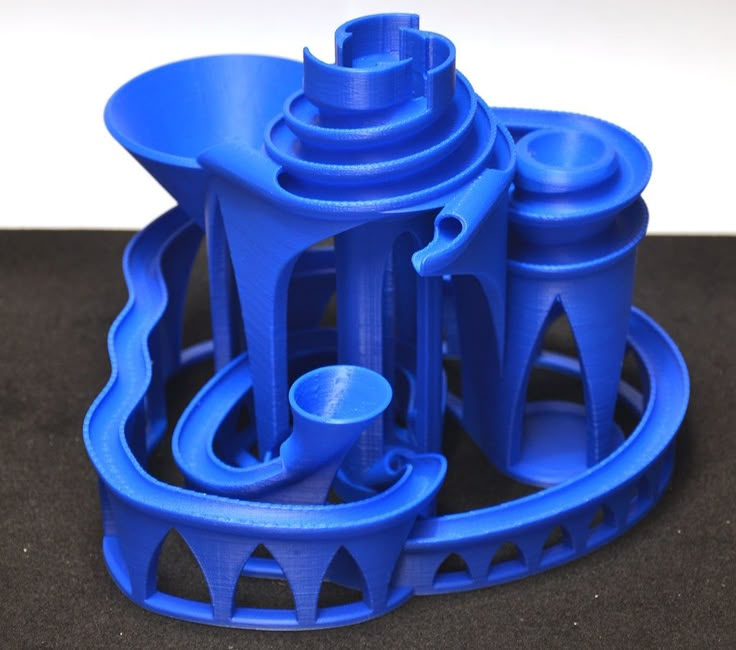

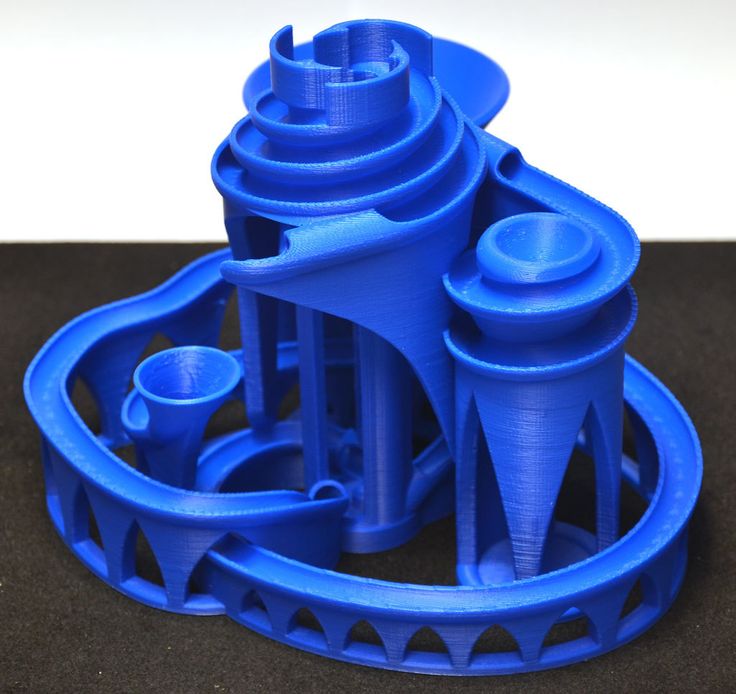

Here is a Brim around a calibration cube. You can see how the Brim would help reduce warping since the actual model isn’t on the outside, so the Brim would warp first before the warping can reach the actual model.

Here is a Raft around a calibration cube. It looks very similar to the Brim but it is actually placed around and underneath the model, along with being thicker and having more settings to customize.

I usually prefer to use a Raft versus a Brim because it does the job better and you actually have a great foundation to remove your print from, but Brims still work well.

Check out my article about Skirts Vs Brims Vs Rafts – A Quick 3D Printing Guide for more details.

How to Fix a 3D Print That Has Warped – PLA

To fix a 3D print that has warped, try using a method of heat and pressure. Get a large metal surface like a frying pan which your 3D print can fit into the same way it came off the build plate. Take a hair dryer and heat up the 3D model all around evenly for about a minute. Now hold the print down and bend it flat.

The model will need to be held for a few minutes until it cools down, then repeat this process until your print is back to the shape you desire. Remember to heat up the model evenly with the hair dryer each time you do this. It requires you reach the glass transition temperature so it can be molded.

This method from RigidInk has worked well for many users to fix a warped 3D print, so it’s definitely worth a try.

As long as the warping on your model isn’t too bad or your 3D print isn’t too thick, it’s possible to save it.

You can also try this method in the video below with hot water by Make Anything.

How Do You Stop PETG 3D Prints From Warping?

To stop your PETG 3D prints from warping or curling, you should:

- Make sure the active cooling fans are turned off, at least for first layers

- Use a better build surface for adhesion like BuildTak

- Use a good adhesive substance for your build plate – hairspray or glue sticks

- Print slowly on your first layer

- Try decreasing your printing temperature and increasing your bed temperature

- You can also dry your PETG filament to reduce its moisture content

Using a combination of the solutions above should help you with your PETG warping. It can be a fairly stubborn filament to work with, but once you get a good routine going, you’ll start to enjoy plenty of successful PETG prints.

It can be a fairly stubborn filament to work with, but once you get a good routine going, you’ll start to enjoy plenty of successful PETG prints.

There isn’t necessarily a PETG warping temperature, so you can try different bed temperatures to reduce warping.

How to Keep Nylon Filament From Warping

To keep Nylon filament from warping, get yourself a heated enclosure and try using a smaller layer height. Some people have success by slowing down their print speed to around 30-40mm/s. Make sure your heated bed is hot enough for your specific brand of Nylon filament. PEI build surfaces work well for Nylon.

You can also try 3D printing a raft in a different material like PETG, then switching out for your Nylon filament to help reduce warping. PETG is a good material to use since it shares a similar printing temperature with Nylon.

One user mentioned that they overcame warping by printing a really large brim. Nylon sticks quite well to Blue Painter’s Tape according to some users, so that could work well to reduce warping.

Turning off your cooling fans should help to reduce warping in Nylon filament.

How to Fix PLA Warping on PEI

To fix PLA warping on a PEI bed surface, clean your bed surface with rubbing alcohol. For larger 3D prints, you can try turning on the bed for an extra few minutes so the heat has enough time to travel through the bed, especially if you have glass. Lightly sanding the PEI surface with 2,000 grit sandpaper can work.

9 Ways How to Fix PETG Warping or Lifting on Bed – 3D Printerly

PETG lifting or warping from the print bed is an issue that many people experience when it comes to 3D printing, so I decided to write an article detailing how to fix this.

Why Does PETG Warp or Lift On Bed?

PETG warps/lifts on the print bed because when the heated up filament cools down, it naturally shrinks, causing the corners of the model to pull upwards off the bed. As more layers are printed on top of one another, the tension on the bottom layer increases, and warping becomes more likely.

Below is an example of how warping can ruin a 3D print’s dimensional accuracy.

PETG warping off bed from 3Dprinting

CNC Kitchen did a quick video explaining some of the reasons why 3D prints in general warp, which you can check out below.

How to Fix PETG Lifting or Warping on Bed

The main ways to fix PETG lifting or warping on bed are to:

- Level the bed

- Clean the bed

- Use adhesives on the bed

- Increase Initial Layer Height and Initial Layer Flow settings

- Use a Brim, Raft, or anti-warping tabs

- Increase print bed temperature

- Enclose the 3D printer

- Turn off cooling fans for first layers

- Reduce printing speed

1.

Level the Bed

Level the BedOne method that works for fixing PETG lifting or warping from the bed is to make sure your bed is properly leveled.

When you don’t have good bed adhesion, the shrinking pressure that causes the warping makes it more likely to happen. Good bed adhesion can fight against those warping pressures that occur during printing.

A well-leveled bed helps the first layer squish into the bed which improves adhesion.

One user said he uses more of a gap when 3D printing with PETG since it likes to be laid down rather than smushed like PLA:

Comment from discussion BloodFeastIslandMan’s comment from discussion "PETG Shrinking / warping and pulling off bed during print.".

Check out the video below to see how to properly level your 3D printer’s bed.

2.

Clean the Bed

Clean the BedAnother useful method to fix warping or lifting with PETG filament is to clean your 3D printer’s bed properly.

Dirt and grime on the bed can prevent your model from properly sticking to build plate, so cleaning the bed improves adhesion.

You should ideally clean the bed once or twice a week for the best adhesion. It is important to try to make a habit out of this, as cleaning the bed regularly is an essential part of 3D printer maintenance and will make your print bed last longer in the long term.

To clean the print bed, most people suggest using isopropyl alcohol. Wipe the bed surface with a cloth with some of the alcohol on it. Make sure the cloth does not leave any lint behind.

For removing thin layers of plastic leftover from prints, some people suggest heating up the bed to around 80°C and wiping it off by rubbing the surface with the lint-free cloth.

Another user suggested using a metal scraper or razor with the bed heated up to 80°C for PLA and that should come right off.

If you are using any sort of adhesives on your bed, such as glue stick, it’s a good idea to make sure a build up is cleaned off the bed, so you can apply a fresh layer of adhesive.

For glue stick for example, warm water will help you remove most of it, and then isopropyl alcohol will help you clean the bed further.

For 3D printers that use a magnetic sheet on a fiberglass board, you will want to also wipe the underside of the sheet and the board underneath, to remove any dust that might create an uneven printing surface.

Have a look at this video that shows how to clean the printing bed of a 3D printer.

3. Use Adhesives on the Bed

Another method to fix PETG warping from the bed is to use adhesives to help the print stay in place and not warp.

Sometimes, the specific PETG filament roll you have may not stick to the bed properly even after leveling and cleaning the bed surface. In this case, there are many types of 3D printing adhesives you can use, from hair spray to glue sticks or sticky tape.

I usually recommend going with a simple glue stick like the Elmer’s Disappearing Glue Stick from Amazon. I’ve used this for many 3D prints and it works really well, even for many prints.

You can also go with a specialized 3D printing adhesive like the LAYERNEER 3D Printer Adhesive Glue from Amazon. Parts stick nicely when it’s hot and release after the bed cools down. It dries fast and isn’t tacky so you won’t experience clogs in your nozzle.

You can print several times on just one coasting by recharging it with a wet sponge. There is an in-built foam tip that makes it easier to apply the coating to your bed surface without spilling.

They even have a 90-day manufacturer guarantee that says if it doesn’t work, you have three months to get a full refund.

Some people have success with using tape such as Kapton Tape or Blue Painter’s Tape, which simply goes over your print bed and you 3D print on the tape itself.

One user who said he’s tried other tapes said they didn’t work as well, but after trying the Duck Clean Blue Painter’s Tape, it worked really well without leaving a residue behind.

For the Kapton Tape, after one user did a lot of research to find the best value for tape, he tried the APT Kapton Tape and it worked really well to hold PETG plastic down to the build plate which is known to be difficult, even with just a 60°C since that is his 3D printer’s max.

With just one layer of this tape, he has 3D printed around 40 hours without issues. It’s still easy to peel off when you want to so this is a great product to help with your PETG warping or lifting from the bed.

This video tests and reviews some interesting adhesive alternatives for a glass bed using only household items, for both PLA and PETG.

4. Increase Initial Layer Height and Initial Layer Flow Settings

To get better adhesion and reduce the risk of warping or lifting off the bed you can try increasing the Initial Layer Height and Initial Layer Flow settings.

Having a higher Initial Layer Height means that more material will extrude on the first layer, leading to better adhesion to the bed surface. It’s the same thing with the Initial Layer Flow to have more material to stick to the bed, which increase contact surface area and improves adhesion.

You can find these settings in Cura by simple searching for “initial”.

The default Initial Layer Height in Cura is the same as your Layer Height, which is 0.2mm for a 0.4mm nozzle. I’d recommend increasing that to around 0.24mm or 0.28mm for better adhesion, which reduces warping or lifting from the bed.

I’d recommend increasing that to around 0.24mm or 0.28mm for better adhesion, which reduces warping or lifting from the bed.

For Initial Layer Flow, you can try increasing this by a few percentage points like 105% and seeing how it goes. It’s all about testing different values to see what works for you.

You also have another setting called the Initial Layer Line Width which comes as a percentage. One user recommended increasing this to 125% for better adhesion results for PETG warping.

5. Use a Brim, Raft, or Anti-Warping Tabs

Another method for fixing PETG that warps or lifts from the bed is to use better bed adhesion features such as a Brim, Raft, or Anti-Warping Tabs (also known as mouse ears) that you can find in Cura.

These are basically extra material that is extruded around your 3D model that adds more surface area to improve adhesion.

Brims are a single flat layer area around the base of your model, while Rafts are a thick plate of material between the model and the bed. Rafts provide the highest level of adhesion, but do take longer and use up more material, especially for large models.

Rafts provide the highest level of adhesion, but do take longer and use up more material, especially for large models.

Check out the video below for more details on Brims and Rafts.

Anti-Warping Tabs are small discs that you manually add to warp-risk areas such as corners and thin areas that make contact with the bed. You can see an example in the picture below.

Once you import a model into Cura and select it, the left toolbar will show. The bottom icon is the Anti-Warping Tab which has settings such as:

- Size

- X/Y Distance

- Number of Layers

You can adjust these settings to your liking and simply click on the model where you want to add the tabs.

CHEP made a great video that walks you through this useful feature.

6. Increase Print Bed Temperature

Another potential fix or PETG warping is increasing the printing bed temperature. When your bed temperature is too low for your material, it makes warping more likely since it doesn’t have the optimal adhesion to the build plate.

A higher bed temperature will melt the PETG better and help it stick to the bed more, while also keeping the material warm for longer. This means the PETG doesn’t cool off too quickly so it shrinks less.

Try raising your bed temperature in 10°C increments until you see better results.

Most users that 3D print with PETG recommend a bed temperature anywhere between 70-90°C, which is higher than a lot of other filaments. While 70°C can work great for some, it may be too low for others, especially depending on what brand of PETG you have.

One user said that using a bed temperature of 90°C worked best for his setup. It’s always a good idea to do your own testing to see the best value for you. Another said an 80°C bed and a layer of glue stick works perfectly.

This user prints with an 87°C bed and also offers some other tips on printer settings that worked well for his PETG prints.

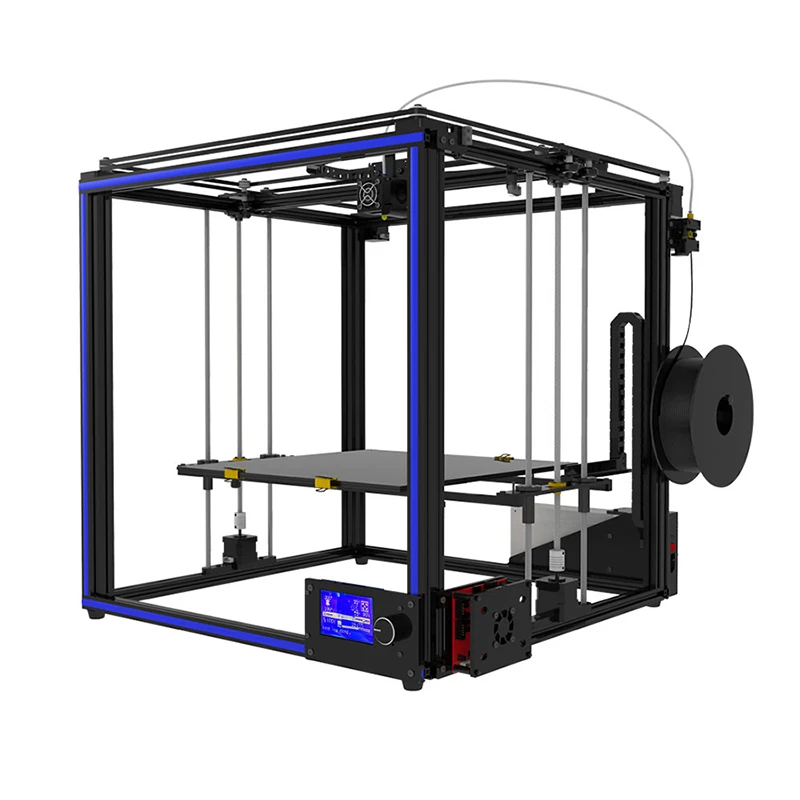

7. Enclose the 3D Printer

Many people suggest printing in an enclosure to prevent the PETG from shrinking and lift off the bed or warp.

If the difference between the temperature of the PETG and the room temperature is too high, the plastic will cool down too quickly and shrink.

Enclosing your printer reduces this temperature difference and basically keeps the plastic warmer for a longer period of time, so it can cool down properly and not shrink.

One user mentioned that simply opening the door of the enclosure for too long caused their print to warp, while another said that tuning in the settings, turning off the fan and using an enclosure seemed to have fixed their issue.

If you can’t use an enclosure, then at least make sure that there are no windows or doors open, as they cause air drafts and increase the temperature difference of your filament, which leads to shrinkage and warping.

Here is a more detailed overview of enclosures and also some advice on how to build your own.

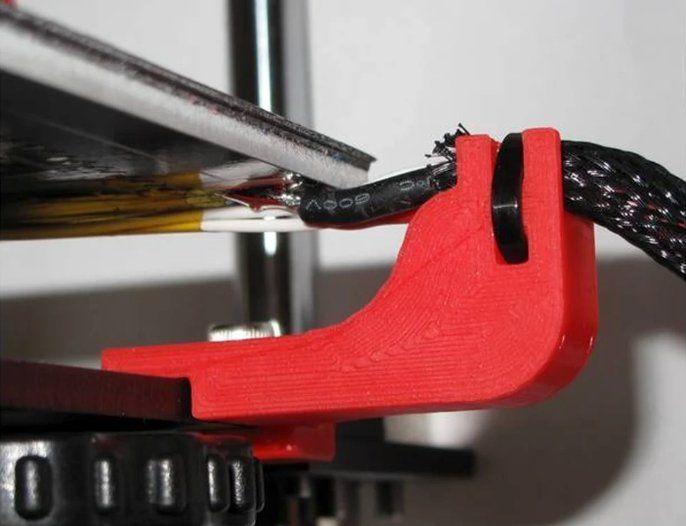

8. Turn Off Cooling Fans for First Layers

Another strong recommendation from many PETG users is to turn off the cooling fans for the first few layers, to make sure the filament doesn’t cool down too fast and shrink.

Some people suggest disabling cooling throughout the entire printing process, while others prefer to reduce it or only disable it for the first few layers.

One user mentioned that cooling leads to massive warping for them, so they don’t use it. Someone else also mentioned that turning off cooling made the most significant difference in reducing warping and shrinking for them.

Generally, most people who use PETG disable the cooling fan for at least the first few layers.

Having the cooling fan low has worked well for one user who uses just 30% for PETG, while another had success with 50%. It’s going to be down to your specific set up and how well the air is directed to your 3D print.

If you have a fan duct that directs air to the front of your part, that temperature change can cause shrinkage which leads to the warping you are experiencing.

This video explains different cooling fan settings and tests whether they make PLA and PETG stronger and more stable.

9. Reduce Printing Speed

Reducing printing speed can improve layer adhesion and give the filament time to melt properly and stick to itself, so it doesn’t pull on the lower layers and cause them to lift from the bed.

One user sets his printing speed to 50mm/s with success, alongside a few other settings, such as a 60°C bed temperature – lower than most people would recommend – and 85% cooling – a setting which most users suggest not using at all.

In this case, the lower printing speed worked well without having to turn off or even reduce cooling too much.

Another user mentioned they are using 60mm/s, with a travel speed of 120mm/s. They also suggested that you could increase the speed after the printing starts to reduce printing time.

It’s usually recommended to use a Print Speed of between 40-60mm/s, then having an Initial Layer Print Speed of 20-30mm/s for the best results.

How to Fix PETG First Layer Warping

To fix PETG first layer warping, turn your cooling fan off or 30% and below. Make sure your printing temperature and bed temperature is optimal according to your filament manufacturer’s recommendations. Level your bed accurately so the PETG filament slightly squishes to the bed. Glue sticks work well on the bed too.

When leveling the bed, it can be a good idea to fold up your normal piece of paper so it’s thicker than normal leveling or the filament might squish too much to the print bed which isn’t ideal for PETG.

Some people also recommend that you dry your filament since PETG can absorb moisture from the environment. I’d recommend going with something like the SUNLU Filament Dryer from Amazon to dry filaments.

How to Fix PETG Infill Warping

To fix PETG infill warping upwards, you should decrease the Infill Print Speed within your settings. The default Infill Print Speed is the same as the Print Speed so reducing this can help. Another thing to do is to increase your Print Temperature so you get better layer adhesion throughout the model.

The default Infill Print Speed is the same as the Print Speed so reducing this can help. Another thing to do is to increase your Print Temperature so you get better layer adhesion throughout the model.

Several users pointed out that a printing speed too high for the infill can result in poor layer adhesion and cause your infill to curl.

One user is working with a travel speed of 120mm/s, a printing speed of 60mm/s and an infill speed of 45mm/s. For one user, reducing the printing speed and reducing the layer height solved the infill issue they experienced.

You should also make sure the bed is not too high, as this could cause the material to overflow during printing.

One user suggested a series of steps that helped them fix the issue:

- Deactivating cooling throughout the entire print

- Decrease the infill printing speed

- Clean the nozzle to avoid under-extrusion

- Make sure the nozzle parts are tightened properly

How to Fix PETG Raft Lifting

To fix PETG rafts lifting, the main solution is to 3D print using an enclosure to control the temperature within the printing environment. You can also follow the main steps for PETG warping since that works for the raft also such as leveling the bed, increasing print temperature, and using adhesives.

You can also follow the main steps for PETG warping since that works for the raft also such as leveling the bed, increasing print temperature, and using adhesives.

The raft lifting off the bed or warping occurs for mostly the same reasons that the normal printed model warps: poor layer adhesion and temperature differences causing the PETG to shrink and the corners to lift.

Sometimes, the layers of the print can pull the raft up as well, especially if the model is quite compact. In this case, you may also try to orient the print differently, to reduce the tension on the bottom layer, and potentially with support material.

Have a look at this video for a comprehensive explanation of PETG and the best ways to print it without facing any issues.

Techno Print 3D Company

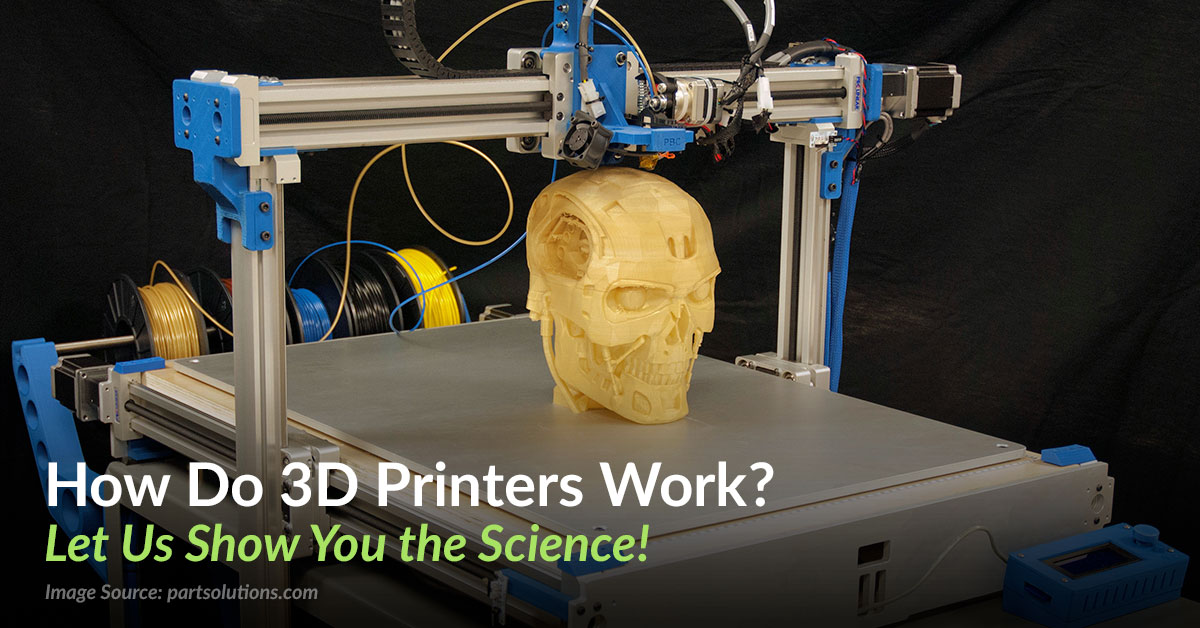

This is our first review of the most popular and inexpensive 3D printers for 2020. The list will include the best-selling devices in two price ranges (up to 30 tr and up to 60 tr). Printers working with both plastic filament (FDM) and photopolymers (LCD/DLP) will be presented. This list will always be up to date, as it is periodically updated and supplemented. Read more→

The list will include the best-selling devices in two price ranges (up to 30 tr and up to 60 tr). Printers working with both plastic filament (FDM) and photopolymers (LCD/DLP) will be presented. This list will always be up to date, as it is periodically updated and supplemented. Read more→

The Chinese company Dazz3D announces the launch of the project on KickStarter and accepts pre-orders for Dazz3D Basic and Dazz3D Pro 3D printers. These revolutionary new devices are aimed at both the professional and amateur markets. Read more→

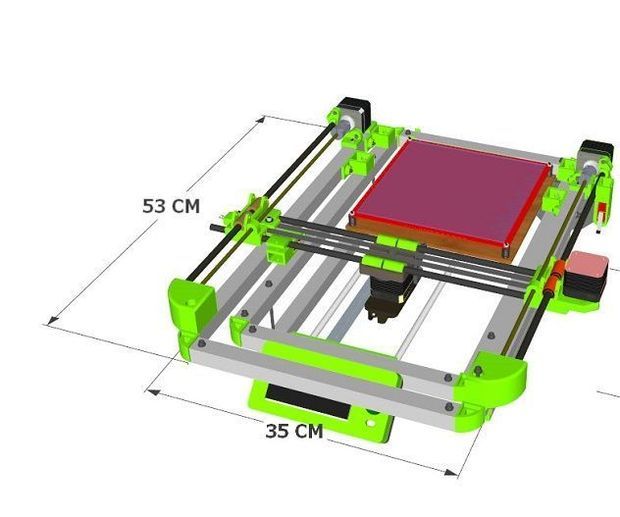

We all know that precise calibration of the 3D printer desktop is the foundation and the key to successful printing on any FDM printer. In this article we will talk about the main and most popular ways to level the "bed". So, as mentioned above, 3D printing without desktop calibration is impossible. We face this process Read more→

It's hard to go through a day today without hearing about 3D printing technology, which is bursting into our lives at an incredible speed. More and more people around the world are becoming addicted to 3D printing technology as it becomes more accessible and cheaper every day. Now almost anyone can afford to buy a 3D printer, and with the help of Read more→

More and more people around the world are becoming addicted to 3D printing technology as it becomes more accessible and cheaper every day. Now almost anyone can afford to buy a 3D printer, and with the help of Read more→

The FormLabs Form 2 and Ultimaker 3 are perhaps the most popular 3D printers today, capable of high quality printing with incredible surface detail. Moreover, these two devices use completely different technologies, and therefore, there are a lot of differences between them. Many will say that it is wrong to compare them or Read more→

XYZprinting, best known for its daVinci line of desktop 3D printers, is bringing five new devices to the professional and industrial environment. One will use laser sintering technology, the second full color inkjet printing and three DLP machines. First of all, the novelties will be of interest to dentists and jewelers. Read more→

Cleaning the nozzle of a 3D printer is a fairly common process that any user of such a device has to deal with. This is not at all a complicated procedure that anyone can handle. You can complete this task in 15 minutes, using only handy tools and accessories. Read more→

This is not at all a complicated procedure that anyone can handle. You can complete this task in 15 minutes, using only handy tools and accessories. Read more→

Acetone steam polishing of ABS plastic is a process for smoothing the surface of 3D printed models. The result of this treatment makes your printed products look as if they were made by a professional mold casting method. If you want to understand how this is done correctly, then read this article. Aceto Read more→

Techno Print 3D Company

This is our first review of the most popular and inexpensive 3D printers for 2020. The list will include the best-selling devices in two price ranges (up to 30 tr and up to 60 tr). Printers working with both plastic filament (FDM) and photopolymers (LCD/DLP) will be presented. This list will always be up to date, as it is periodically updated and supplemented. Read more→

The Chinese company Dazz3D announces the launch of the project on KickStarter and accepts pre-orders for Dazz3D Basic and Dazz3D Pro 3D printers. These revolutionary new devices are aimed at both the professional and amateur markets. Read more→

These revolutionary new devices are aimed at both the professional and amateur markets. Read more→

We all know that precise calibration of the 3D printer desktop is the foundation and the key to successful printing on any FDM printer. In this article we will talk about the main and most popular ways to level the "bed". So, as mentioned above, 3D printing without desktop calibration is impossible. We face this process Read more→

It's hard to go through a day today without hearing about 3D printing technology, which is bursting into our lives at an incredible speed. More and more people around the world are becoming addicted to 3D printing technology as it becomes more accessible and cheaper every day. Now almost anyone can afford to buy a 3D printer, and with the help of Read more→

The FormLabs Form 2 and Ultimaker 3 are perhaps the most popular 3D printers today, capable of high quality printing with incredible surface detail. Moreover, these two devices use completely different technologies, and therefore, there are a lot of differences between them.