Rosemount 5708 3d solids scanner

Rosemount 5708 Series 3D Solids Scanner | Level Transmitters

Skip to Main Content

Low frequency acoustic waves deliver accurate volume and level measurements of bulk solids and powders. Learn more...

Rosemount 5708 Series 3D Solids Scanner- Rosemount 5708 Series 3D Solids Scanner

- Rosemount 5708 Series 3D Solids Scanner

- Rosemount 5708 Series 3D Solids Scanner Basic Configuration Guide

- osemount 5708 Series 3D Solids Scanner Installation Guide

Retired products cannot be ordered

The Rosemount 5408 Radar Level Transmitter is the recommended replacement

View Company Reviews Trustpilot

Manufactured

- By Rosemount

Includes

- FREE Ground Shipping

- FREE Lifetime Tech Support

Product Manual Product Specs

Overview

Features

- Dead band is 19.

6in (0.5m) from top of antenna

- Up to 230ft (70m) measurement range

- Minimum bulk density of 12.5lb/ft3 (200kg/m3)

- Process fitting thread, angle adapter

- 2.3 to 7kHz emitting frequency

- Polyurethane covered aluminum housing material

- 4-20mA & RS-485 with Modbus signal output

Description

The Rosemount 5708 series 3D solids scanner uses a multiple point measurement technology to deliver accurate volume and level measurement of bulk solids and powders regardless of material type, product characteristics, storage silo type, size, or harshness of the storage environment. The 5708L, 5708V, and 5708S models enable efficient process measurement and true inventory management of bulk solid materials used in industrial applications including:

- Large open bins

- Bulk solid storage rooms

- Stockpiles and warehouses

- Loads that randomly form over time inside silos

The device includes an integral array of three antennas that generate unique dust-penetrating low frequency acoustic waves

and receive echoes from the contents. Using these antennas, the unit measures not only the time/distance of each echo, but also

its direction.

Using these antennas, the unit measures not only the time/distance of each echo, but also

its direction.

Collecting multiple echoes from different directions and distances enables the scanner to accurately calculate the volume of stored material. It also enables the 3DVision software to generate the 3D visualization of the material.

The acoustic waves combined with self-cleaning capabilities prevent material from adhering to the internal workings of the antenna array, ensuring long-term reliable performance with very low maintenance requirements, regardless of harsh dusty conditions.

Documents

Spec Sheets

- Rosemount 5708 Series 3D Solids Scanner Datasheet PDF (3.5 MB)

Manuals

-

Rosemount 5708 Series 3D Solids Scanner Manual PDF

(34.

1 MB)

1 MB)

Other

- Rosemount 5708 Series 3D Solids Scanner Quick Start Guide PDF (25.6 MB)

- Instrumart's Level Application Form PDF (141 KB)

Accessories

Service Options

$2,294. 56

56

Starting at $4,800.00

Accessories

Please consider these optional accessories.

Starting at $2,605.51

Starting at $6,368.43

Starting at

$1,120. 51

51

Need Help? Call a Calibration Engineer at 1-800-884-4967

We're open 8:00 am to 5:30 pm ET

Mark D.

Applications Engineer

11 years at Instrumart

Mike K.

Cal & Pressure Engineering Lead

11 years at Instrumart

Angelo S.

Applications Engineer

3 years at Instrumart

Mike C.

Senior Applications Engineer

21 years at Instrumart

Shawn S.

Senior Applications Engineer

27 years at Instrumart

John A.

Applications Engineer

16 years at Instrumart

Brynn O.S.

Applications Engineer

Recently Viewed

Rosemount 5708 3D Solids Scanner

Brochures

Brochure: Rosemount Level Measurement Solutions

Certificates & Approvals

Certificate: Rosemount 5708 3D Solids Scanner EC-type Examination

Certificates & Approvals

Certificate: Rosemount 5708 3D Solids Scanner PESO Intrinsic Safety

Certificates & Approvals

Certificate: Rosemount 5708 Hazardous Location Electrical Equipment

Certificates & Approvals

Certificate: Rosemount 5708 Hazardous Location Electrical Equipment per Canadian Requirements

Certificates & Approvals

Declaration of Conformity: Rosemount 5708 3D Solids Scanner

Data Sheets & Bulletins

Configuration Data Sheet: Application Evaluation Form Rosemount 5708 3D Solids Scanner

Data Sheets & Bulletins

Product Data Sheet: Rosemount 5708 Series 3D Solids Scanner

Drawings & Schematics

Type 1 Drawing: Rosemount 5708 Solids Scanner, 2D DXF

Drawings & Schematics

Type 1 Drawing: Rosemount 5708 Solids Scanner, 2D PDF

Drawings & Schematics

Type 1 Drawing: Rosemount 5708 Solids Scanner, 3D PDF

Drawings & Schematics

Type 1 Drawing: Rosemount 5708 Solids Scanner, 3D SAT

Drawings & Schematics

Type 1 Drawing: Rosemount 5708 Solids Scanner, 3D STP

Manuals & Guides

Manual Supplement: Rosemount™ 5708 Series 3D Solids Scanner Integration with DeltaV™

Manuals & Guides

Manual: Rosemount 5708 Series 3D Solids Scanner

Manuals & Guides

Manual: Rosemount™ 5708 3D Solids Scanner Integration with Ovation™

Manuals & Guides

Quick Start Guide: Rosemount 5708 Series 3D Solids Scanner

Manuals & Guides

Quick Start Guide: Rosemount™ 5708 3D Solids Scanner Manhole Mounting Tool Kit

Software Downloads & Drivers

Device Descriptors: 5708 (5708L, 5708V, 5708S) | Rosemount

Software Downloads & Drivers

Device Install Kit: Emerson 3D Vision 3. 0.020 Exe File | Rosemount

0.020 Exe File | Rosemount

Software Downloads & Drivers

Device Install Kit: Rosemount 5708L 4.5.340 wrapped

Software Downloads & Drivers

Device Install Kit: Rosemount 5708V S 4.5.340 wrapped

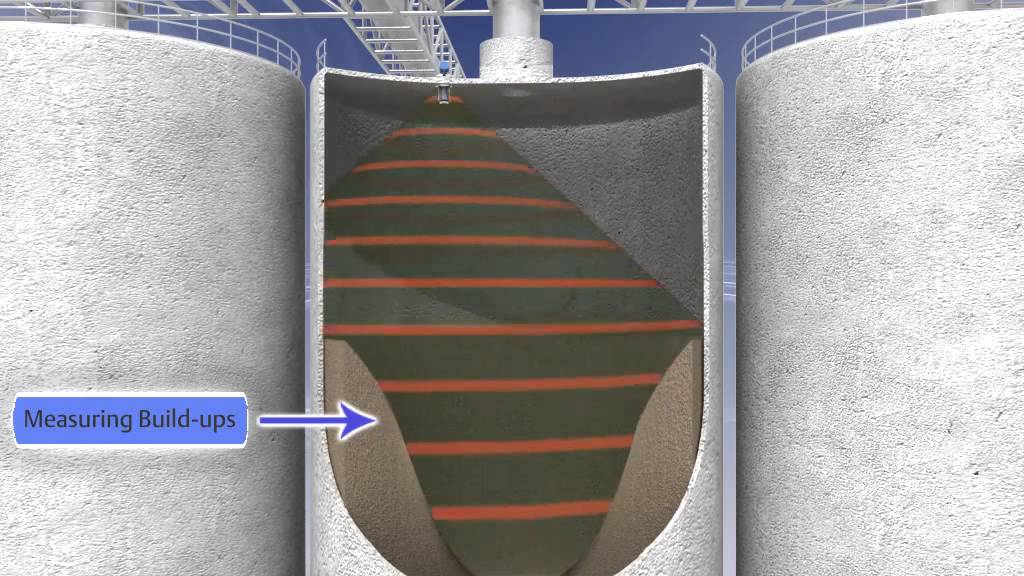

PJSC Acron Level measurement of bulk solids

The task of measuring the level of solid bulk solids is fundamentally different from measuring the level of liquid media. First of all, solid products are characterized by the inhomogeneity of substances in volume, associated with the presence of a space between solid particles filled with gas. The degree of heterogeneity depends on the particle size and directly affects the physical properties of the material, which complicates the use of level measurement methods that use certain physical properties of the medium.

First of all, solid products are characterized by the inhomogeneity of substances in volume, associated with the presence of a space between solid particles filled with gas. The degree of heterogeneity depends on the particle size and directly affects the physical properties of the material, which complicates the use of level measurement methods that use certain physical properties of the medium.

The next difficulty in level measurement is due to the limited mobility of the particles due to the action of friction and cohesion between the particles, resulting in the absence of a horizontal gas-material interface. The surface of the bulk material is located to the horizontal at an angle of repose, and this angle may be different when filling or emptying the container. The limited mobility of the particles also leads to surface irregularities, which affect the normal operation of the measuring devices.

Bulk materials are characterized by stickiness and abrasion. The dust content of the phase space can complicate the operation of level gauges, which affects the electrical properties of the medium, and also imposes increased requirements on ensuring the explosion safety of measuring instruments.

Acron specialists faced the task of measuring the volume of bulk media: apatite in cylindrical tanks 26 m high and 11 m in diameter. These media are corrosive. It was also necessary to understand the relief of the surface of the granular medium.

To solve this problem, Promsensor engineers used an acoustic level gauge Contour 3D manufactured by Magnetrol (Belgium).

Most level gauges measure from the installation site to a single point on the surface. Whereas Contour 3D measures many points on a surface. This is achieved by using 3 antennas with a beam angle of 70°, each of which sends an acoustic signal and receives its reflections, thereby forming an accurate measurement of the volume above the surface of the medium.

Medium volume = tank volume - volume above surface This is the accuracy of measuring the level of bulk materials. Contour 3D measures volume as well as minimum, maximum and average levels of stored materials. As a result, the customer received accurate volume and level measurements, based on which he monitors production, process control, inventory management and consumption forecasting. Precise inventory control has reduced the safety stock and reduced the cost of maintaining surplus.

Precise inventory control has reduced the safety stock and reduced the cost of maintaining surplus.

Thanks to the 3D visualization in the software, the material distribution inside the tank can be fully seen. This solves the security issue. After all, due to uneven loads on the side wall caused by the accumulation of bulk material, or when filling / emptying the tank, the tank could collapse. The use of Contour 3D allows you to increase safety and avoid material and human losses.

During operation, Acron specialists noted another interesting feature of the Contour 3D - the self-cleaning function. The instrument uses acoustic vibration energy to remove buildup from the antenna, ensuring reliable operation in dusty environments. High reliability is ensured by the absence of moving parts. The instrument is virtually maintenance-free, reducing downtime and labor costs. There is no need for regular dismantling and manual cleaning of the device.

Always clean antenna

After trial equipping with this volumetric level gauge of apatite tanks at Akron PJSC, based on the positive results of the work, all apatite storage tanks were equipped.

In addition to these media, Promsensor engineers recommend using the Contour 3D volumetric level transmitter for the following applications:

- Energy – coal, fly ash and biomass;

- Chemical treatment - calcium carbonate, soda ash and

- manufacture of detergents;

- Cement and aggregates - production of clinker and concrete;

- Food processing - cocoa processing and production of cereals, vegetable oil, dough, beer, flour and sugar;

- Mining - production of potash, talc, lime and salt, and processing of iron ore and coal.

Calculation of the volume of bulk materials using a Heron Lite mobile 3D laser scanner (Heron Light)

January 13, 2020 has long exceeded thousands of measurements per second. With the advent of Heron mobile 3D scanning systems based on SLAM algorithms and a high-performance laser scanner from Velodyne, it became possible to scan directly in the process of passing through an object (by hand, from a car) and not depend on satellite signals (GNSS). Thus, a new tool Heron Lite (Heron Light) has appeared at our disposal, which allows us to obtain a high-density point cloud (up to 1 cm) with geodetic accuracy (3-5 cm) in the shortest possible time for almost any object of arbitrary shape, regardless of its location (outdoors or indoors).

Thus, a new tool Heron Lite (Heron Light) has appeared at our disposal, which allows us to obtain a high-density point cloud (up to 1 cm) with geodetic accuracy (3-5 cm) in the shortest possible time for almost any object of arbitrary shape, regardless of its location (outdoors or indoors).

Survey process

All this makes mobile 3D laser scanning technology indispensable for bulk material volumes. To perform work, it is not necessary to bring the object of shooting to the correct geometric shapes, the scanning range of the laser scanner (up to 100 m), as well as its field of view (360x30 degrees horizontally and vertically) and a speed of 300,000 points / sec, allow you to get comprehensive information about the measurement object.

The configured scanning data processing technology, which includes algorithms for classifying the "ground" surface, removing re-reflected and points of moving objects (people, equipment) and TD, allows you to reliably calculate the volume in the shortest possible time and obtain all the necessary information in the form of plans, digital elevation models, cartograms of works.

Scan process

Cloud of points, gradation in height

Points

Automatic classification

Surface

9000 9000 Details about Heron Lite 3D laser scanner All articles Accurate and detailed three-dimensional data on terrain, infrastructure: structures, roads, highways, bridges and other objects can be obtained using laser scanning technology using terrestrial and mobile laser scanners based on LiDAR sensors. ... With the extraction of natural resources, mining has become a market segment covering a wide range of Russian enterprises. This includes research, planning, collection and processing of data obtained in the field, with the calculation of the results of geological exploration. Other publications

Learn more