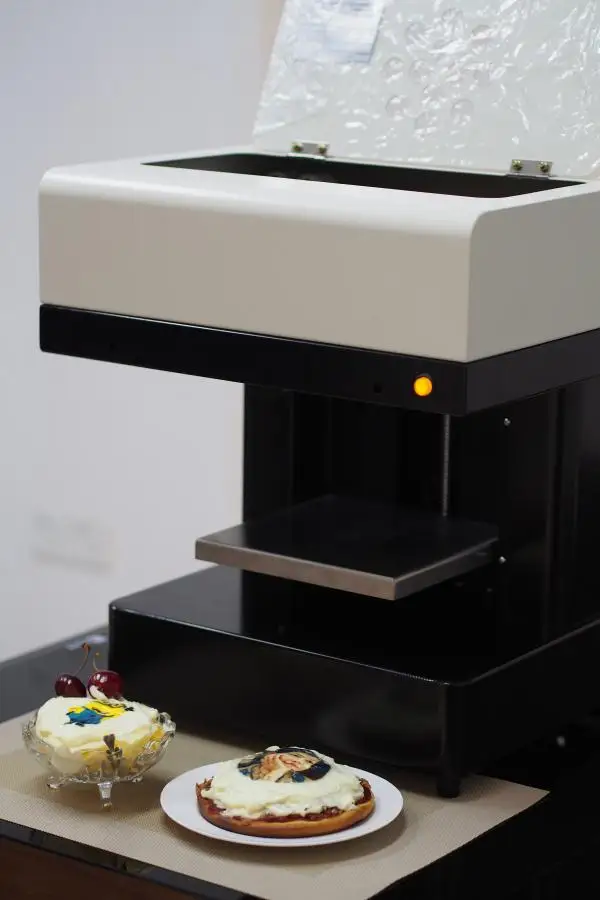

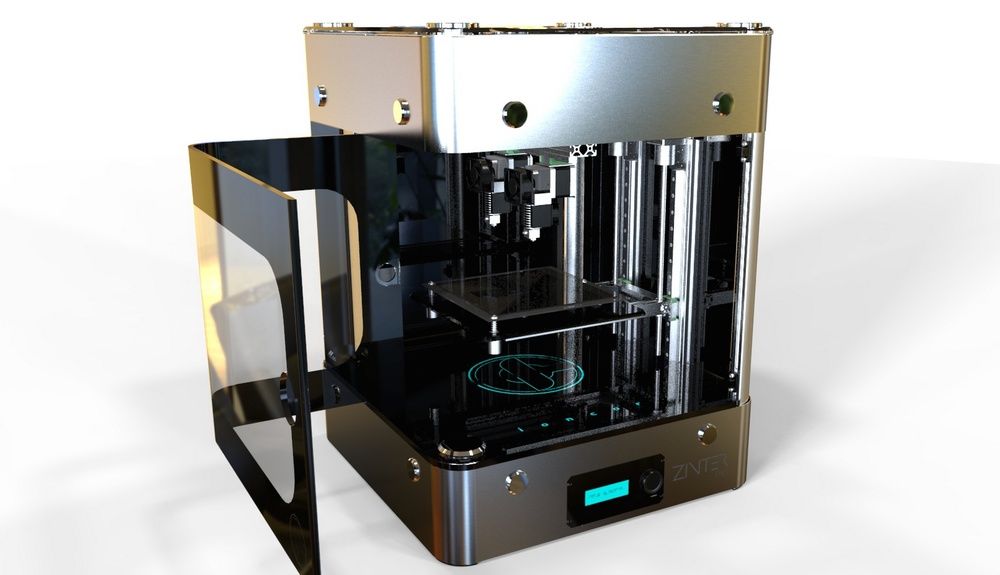

Chef jet pro 3d printer

3D Systems ChefJet Printers

There are a number of 3D food printers on the market, promising to print everything from pasta to Nutella. But most simply create shapes from pre-prepared ingredients.

One company, however, has gone a different direction, designing 3D printer that turns sugar into gorgeous geometric confections in your own kitchen.

“They work a lot like making frosting,” Liz von Hasseln, co-inventor of 3D Systems' ChefJet, told Business Insider. “If you’ve ever made frosting and left the bowl overnight in the sink, you’ll know that it gets quite hard and that’s essentially what happens inside the ChefJet Printer.”

The geometric designs created with a ChefJet printer. Courtesy of 3D Systems The project started when von Hasseln and her husband Kyle, who were graduate students at the Southern California Institute of Architecture, forgot that they were supposed to bake a birthday cake for a friend. Their tiny apartment didn’t have an oven, but they did have the 3D Systems printer they were using for their thesis project.

After tweaking the existing technology to print layers of sugar, they printed their friend’s name as a cake topper and a business was born. The von Hasselns quickly realized the potential of their invention and established Sugar Lab, designing and printing 3D candies in flavors like mint, sour cherry, and vanilla.

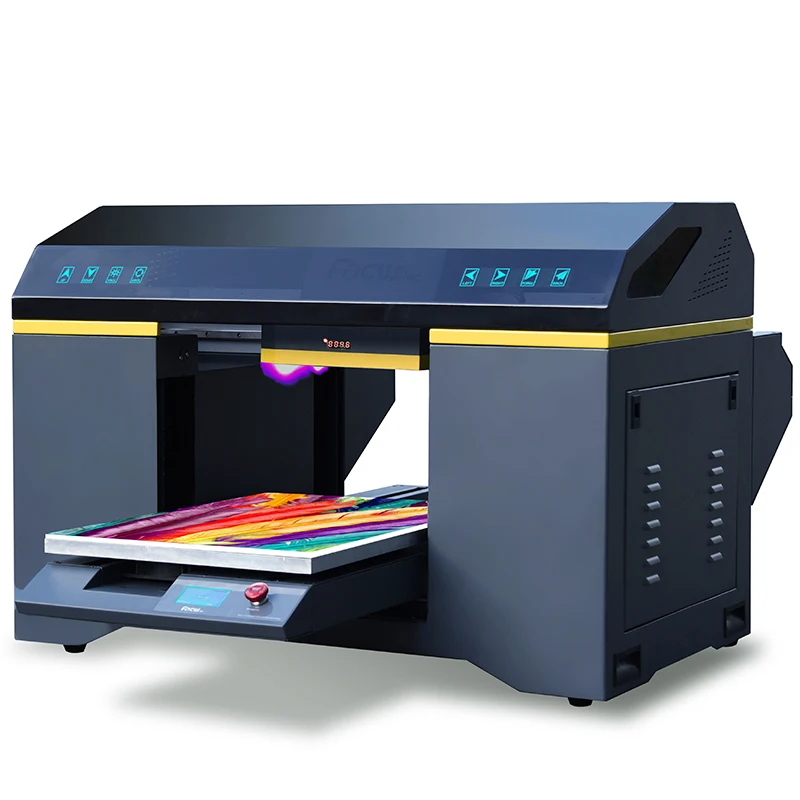

The printer can create 3D candies in a variety of flavors such as mint, sour cherry, and vanilla. Courtesy of 3D Systems Sugar Lab was purchased by 3D Systems last year, and now the von Hasselns are the company's Creative Directors of Food Products. Later this year, they will unveil their sleek ChefJet, which prints in black and white, and slightly larger ChefJet Pro, which can print in color, with prices ranging from $5,000 to $10,000.

Later this year, they will unveil their sleek ChefJet, which prints in black and white, and slightly larger ChefJet Pro, which can print in color, with prices ranging from $5,000 to $10,000.

The machines are roughly twice the size of a microwave and look like something one would see on a futuristic cooking show hosted by Spock.

The ChefJet printers can create sugar structures in cocktail glasses for mixologists. Courtesy of 3D Systems And the possibilities with sugar have gone far beyond the candies Sugar Lab originally printed. “We’ve done everything from drink sweeteners to complicated toppers for elaborate wedding cakes," von Hasseln said. "We even did a cake stand for a wedding cake. When you 3D print the frosting, it becomes a structural component of the dessert other than just an embellishment.”

"We even did a cake stand for a wedding cake. When you 3D print the frosting, it becomes a structural component of the dessert other than just an embellishment.”

The end results are gorgeous, geometric creations — especially with the ChefJet Pro, which can make such exact color designs that the end product resemble expensive china.

The technology is still limited to sugar, but the ChefJet and ChefJet Pro come with a sort of “digital cookbook” that’s organized by food types. If you’re working on a wedding cake, there’s a cake section. If you’d like to make sugar cubes or candy, there’s a section for that, too.

If you’re working on a wedding cake, there’s a cake section. If you’d like to make sugar cubes or candy, there’s a section for that, too.

“We want to enable people to be able to create beautiful, customized things that they can print on the ChefJet without having to learn 3D dimensional digital modeling from scratch,” von Hasseln said. “We’re working hard to make sure they’re very user friendly and intuitive right off the bat.”

But don’t expect to run out and buy a ChefJet or ChefJet Pro anytime soon. In its current iteration, ChefJet is meant for the professional market, to be used alongside other industrial kitchen equipment by pastry chefs, molecular gastronomists, and mixologists.

In its current iteration, ChefJet is meant for the professional market, to be used alongside other industrial kitchen equipment by pastry chefs, molecular gastronomists, and mixologists.

“We are looking at the ChefJet printer as a professional-grade machine,” von Hasseln said. “The ChefJet and ChefJet Pro are really the only printers on the market that are appropriate for that level. They’ll be the first kitchen-certified 3D printers, meaning they’ll be used in commercial, professional settings. No other 3D printers have done that.”

No other 3D printers have done that.”

In other words, this is not the next microwave — yet. But as the science continues to evolve, von Hasseln does see additional practical uses for her invention.

The sugar cubes can also be made in flavors like chocolate. Courtesy of 3D Systems “We think that sugar is a great place to start 3D printing food,” Liz said. “But beyond sweets, we see tons of potential for other edible substrates. We’re really excited to continue to experiment with starches, spices, or even proteins down the line. And even further down the road, we see potential for things like personalized nutrition and pharmaceuticals. "

"

“We’re at the very beginning of 3D printing,” she added. “This is a very exciting time.”

Courtesy of 3D Systems3D Systems' ChefJet Pro Helps Serve Up a 3D Printed Edible Palace of Versailles - 3DPrint.com

Marie Antoinette, who famously did not say ‘let them eat cake’ when told about the inability of France’s poor to afford bread, is perhaps one of the most polarizing figures from the French Revolution. While she wasn’t directly involved in the events that led to the storming of the Bastille fortress in the wake of the growing French Revolution, Antoinette found herself an easy target for the revolutionaries’ rage. Not only because of her Austrian heritage, but because of her efforts to maintain the power of the monarchy throughout the transition.

While historians continue to separate fact from propaganda and revisionist history, one thing has always been clear–Antoinette never would have told the poor to eat cake; had she said anything, she would have told them to eat brioche. The extremely rich, expensive and decadent bread was usually served to French nobility and well out of reach for the average citizen. During an exceptionally long period of scarcity of bread and flour, a frustrated and hungry mob stormed the Palace of Versailles and forced the king and queen to return to Paris and address the growing resentment of their subjects. So it seems that regardless of the accuracy of the quote, bread still played an important role in the abolition of France’s monarchy.

So when the cooking lab at Modernist Cuisine in Bellevue, Washington was contacted by 3D Systems to team up and produce an elaborate 3D printed food creation, they decided to pay tribute to the historic palace and the infamous bread. The cooking lab was already close to perfecting their recipe for brioche, so they decided to design a 3D printed sugar structure shaped like Versailles as an elaborate decoration for the dessert bread. Modernist Cuisine started with a hand drawn sketch of a simplified version of the iconic palace. Conceived by their head chef Francisco Migoya, the elaborate dessert included a 3D printed sugar structure, meringue topiaries, as well as an elaborate acrylic base cut to resemble the gardens of Versailles. Once Migoya was happy with his design, he passed his sketch on to 3D Systems Culinary to be converted into a 3D model, and ultimately 3D printed from pure white sugar using 3D Systems food 3D printer the ChefJet Pro.

Modernist Cuisine started with a hand drawn sketch of a simplified version of the iconic palace. Conceived by their head chef Francisco Migoya, the elaborate dessert included a 3D printed sugar structure, meringue topiaries, as well as an elaborate acrylic base cut to resemble the gardens of Versailles. Once Migoya was happy with his design, he passed his sketch on to 3D Systems Culinary to be converted into a 3D model, and ultimately 3D printed from pure white sugar using 3D Systems food 3D printer the ChefJet Pro.

The structure needed to be able to fit completely around a brioche while still maintaining the look and feel of Versailles. Because the ChefJet is based on powder 3D printing technology, the team at 3D Systems Culinary was able to design and print a very detailed recreation of the château’s Baroque architecture, distinctive windows and ornate gates. Realistically, the sugar structure’s complex geometries could only be created in sugar using a 3D printer like the ChefJet. In order to maintain such a high level of detail in an object printed in such a fragile material, massive supports would have needed to be included in order to even try to use a typical extrusion style printer. However the ChefJet Pro uses technology very similar to an inkjet printer to print a design on thin layers of sugar. The geometry is completely supported by the excess material, which is then simply blown away using compressed air.

In order to maintain such a high level of detail in an object printed in such a fragile material, massive supports would have needed to be included in order to even try to use a typical extrusion style printer. However the ChefJet Pro uses technology very similar to an inkjet printer to print a design on thin layers of sugar. The geometry is completely supported by the excess material, which is then simply blown away using compressed air.

“Once the 3D printed sugar structure was delivered by the 3D Systems Culinary team, head chef Migoya baked an incredibly rich brioche. True to the project, it’s totally decadent—eggy, buttery, subtly sweet, and utterly delicious. He began construction by coating the brioche in a glaze of pectin and water, then topped it with gold leaf as a nod to the façade of Versailles. Gold leaf is safe to eat and has been consumed throughout history; ancient Egyptian royalty mixed gold in with their food, even incorporating it into breads,” Modernist Cuisine explained on their blog.

Here is a video showing the dessert Palace of Versailles being constructed:

Once he had all of the various components for his dessert in one place, Migoya assembled his eatable palace just in time for France’s Bastille Day. He glazed the acrylic base and coated it with green panko to simulate grass and added several meringue bushes. Migoya placed the gold leaf topped brioche at the center of the base and covered it with the 3D printed details.

His brioche recipe is just as decadent as history tells us that it was back in the 18th century. With its rich and slightly sweet taste, brioche is not the type of bread that you make a ham sandwich out of. You probably could, and it would probably be delicious, but before you could tell anyone about your dessert bread sandwich your heart would probably seize.

Migoya and the rest of the cooking lab served the dessert the same way that it would have been served in 18th century France, topped with a generous heaping of whipped cream. Although they also went ahead and added some raspberries for the pop of color. And because fresh berries make everything better, especially desserts. So how delicious does this modern reinterpretation of the traditional French dessert look? Let us know over on our ChefJet Pro 3D Printed Palace of Versailles forum thread at 3DPB.com.

Although they also went ahead and added some raspberries for the pop of color. And because fresh berries make everything better, especially desserts. So how delicious does this modern reinterpretation of the traditional French dessert look? Let us know over on our ChefJet Pro 3D Printed Palace of Versailles forum thread at 3DPB.com.

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 3d food printer • 3d printed food • 3d systems • ChefJet Pro • food 3d printing • Modernist Cuisine • palace of versailles • sugar 3d printer • versailles

Please enable JavaScript to view the comments powered by Disqus.

| 3DNews Technologies and IT market. 3D Technology News The Chef Jet 3D printer will be able to print. The most interesting in the reviews 01/15/2014 [02:13], Dmitry Prikhodko 3D Systems booth attracted enough attention at the last CES 2014. The company decided that it was time to create real edible masterpieces that will be taken not from the oven, but from the 3D printer. The junior model of the printer - Chef Jet and its advanced version with the Pro index are real culinary devices. Modern 3D printers already have a fairly wide range of applications, from confectionery to gas turbine parts. The MakerBot CEO called the Replicator Mini unveiled at CES the ultimate breakthrough in 3D home printing. He even suggested that the model would mimic the iPhone when it first entered the mobile device market. Such a development of the industry was unimaginable a few years ago. Now, 3D printing technology could make it possible to produce fuel injectors for aircraft, a full-fledged sport bike, and even decorative alcohol patterns in jelly. Chef Jet and Chef Jet Pro, announced by up-and-coming 3D Systems for edible 3D printing, are representative of the relatively recent trend in safe 3D food printing. Both printers have passed all the necessary certifications and are ready to appear in the kitchens of the world's most famous restaurants this year. The material that culinary 3D printers predominantly work with is sugar. Candies can also be printed from edible ingredients that harden quickly, such as starch. The most popular material for a rather exotic way of making confectionery masterpieces promises to be chocolate with coconut powder. Both devices are aimed at professional bakeries and pastry shops, restaurants and chocolate makers. The Chef Jet and Chef Jet Pro are still devices not for home use by amateur enthusiasts. 3D printers will become part of professional kitchen equipment. Unlike modern devices that reproduce models not from food components and present the finished product mainly in one or several colors, the Chef Jet can work like a real color printer, using the entire range of food coloring to create an object. The procedure itself is quite clear and unpretentious. First, the workpiece, which is a layer of fine dried sugar, is treated with a jet of water from the printer's print head to those parts that should harden in accordance with the concept of the future sugar model. As a result, thanks to the recrystallization of sugar, the edible object is durable, as far as the material allows. After the sculpture has an almost complete appearance, the excess sugar is cleaned. Both Chef Jet and Chef Jet Pro printer models will be available in the second half of 2014. The simpler model will cost about $5,000, while the Pro version will cost the buyer twice as much - about $10,000.0007 Source: If you notice an error, select it with the mouse and press CTRL+ENTER. Related materials Permanent URL: https://3dnews.ru/794394 Headings: News Hardware, 3D technologies, Tags: hardware, 3d printer, 3d, ces 2014, printing ← В past To the future → |

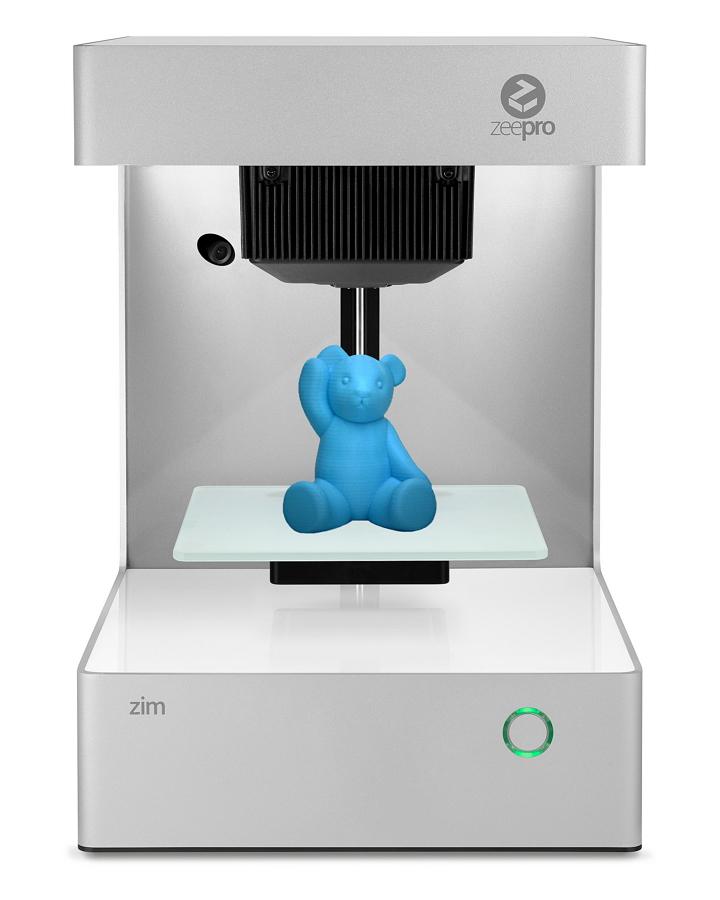

What does 3D printer steak taste like? - such a question is no longer from the category of fantasy.

Israeli startup Redefine Meat has learned how to 3D print steaks that look like real meat. In mid-February, the startup completed another round of funding to start shipping its printers around the world. According to the plan, the expansion was supposed to begin last year, but the pandemic prevented it: the startup intends to promote the product first through restaurants.

Israeli startup Redefine Meat has learned how to 3D print steaks that look like real meat. In mid-February, the startup completed another round of funding to start shipping its printers around the world. According to the plan, the expansion was supposed to begin last year, but the pandemic prevented it: the startup intends to promote the product first through restaurants. Many companies produce artificial meat from soy and pea protein, coconut fat, sunflower oil, natural colors and flavors. But even if they taste like real minced meat, they lack the main thing: the texture and look of the steak. Redefine Meat founder Eshkhar Ben-Shitrit figured out what to do with it. His printer prints three types of voxels, or millimetric three-dimensional pixels. Some copy muscle, others fat, others blood. Each stake consists of an example of 3 million voxels. By changing the recipe and collecting them in different sequences and proportions, you can reproduce tenderloin, ribeye, picanha and other types of steaks. And most importantly - they copy not only the taste, but also the type of meat, and even sensations. “A steak is basically muscle, fat and blood in a complex structure that affects how it feels in the mouth and how it is cooked. The taste depends on how the marbled veins of fat melt when you cook,” Ben-Shitrit told Israel21c online.

And most importantly - they copy not only the taste, but also the type of meat, and even sensations. “A steak is basically muscle, fat and blood in a complex structure that affects how it feels in the mouth and how it is cooked. The taste depends on how the marbled veins of fat melt when you cook,” Ben-Shitrit told Israel21c online.

How Ben-Shitrit met cows

Ben-Shitrit grew up on a kibbutz where his mother ran a dairy farm. He loved meat since childhood. And at the age of 13, he learned how to cook the perfect steak when he went to work part-time at his uncle's restaurant in Tel Aviv in the summer.

He received a law degree from the Hebrew University of Jerusalem, worked for a year and a half as a clerk of the Israeli Supreme Court, and in 2011 changed careers to become a product manager for Hewlett-Packard. Responsible for printing on cardboard boxes. His next job was at the Israeli company Highcon, specializing in cardboard packaging. In 2015–2017 he was its vice president of marketing.

So, Ben Shitrit loved meat. But when his first child was born, he was surprised to find that he could no longer eat beef. There were memories of his childhood on a dairy farm, where he saw firsthand how cows take care of their calves. Ben-Shitrit tried many meat substitutes, but none of them looked like a real steak. Then he had the idea to print meat on a printer to copy its texture. He quit and in February 2018 founded Jet-Eat, which was later renamed Redefine Meat.

“The company was engaged in R&D for almost two years before [in the fall of 2019] we first raised serious investments and recruited a team - in nine months the staff grew from 6 to 25 people,” Ben-Shitrit told Business Insider and last July . Now, judging by the information on the startup's website, it employs 36 people.

The startup developed its products in collaboration with scientists from the Israeli Institute of Technology Technion, using its laboratories for experiments. In September 2019The company received $6 million in seed funding from CPT Capital, a venture fund that also includes stakes in other artificial meat producers, Impossible Foods and Beyond Meat. In February of this year, Redefine Meat raised $29 million in a Series A round in which new investors joined CPT Capital - Losa Group, Sake Bosch, K3 Ventures.

In February of this year, Redefine Meat raised $29 million in a Series A round in which new investors joined CPT Capital - Losa Group, Sake Bosch, K3 Ventures.

1/5 cow per day

Redefine Meat already has something to boast about. Last June, the company officially unveiled the world's first plant-based 3D printed steak, then began testing its product in high-end restaurants in Israel, and Ben-Shitrit became a hero in the Israeli media with the phrase "We print steaks on a 3D printer ".

True, the fastest printer at his disposal prints about 6 kg of meat per hour. With three cartridges to recharge (artificial meat, fat and blood) and maintain the machine, on good days it produces about 90 kg of meat per day. Beef cows can weigh about half a ton, but meat can account for 60–70% of the total weight.

No meat in meat, no milk in chocolate

Not only meat becomes vegan. In mid-February, Nestle announced that it would launch the first vegan milk chocolate, called KitKat V. The product will roll out to several countries, including the UK, and if successful, will expand to other markets. It took about two years to develop the bar. The main problem was that soy and almond substitutes do not mix well with cocoa and sugar, and as a result, the desired creamy structure is not obtained. KitKat V replaced milk with rice mix. This is not the first product to replace animal ingredients. Last year, Nestle launched meat-free sausage, veggie ground meat, dairy-free ice cream, and animal food with insect protein and bean and millet meat protein substitutes.

The product will roll out to several countries, including the UK, and if successful, will expand to other markets. It took about two years to develop the bar. The main problem was that soy and almond substitutes do not mix well with cocoa and sugar, and as a result, the desired creamy structure is not obtained. KitKat V replaced milk with rice mix. This is not the first product to replace animal ingredients. Last year, Nestle launched meat-free sausage, veggie ground meat, dairy-free ice cream, and animal food with insect protein and bean and millet meat protein substitutes.

Now the startup is completing the construction of the first production line, which will assemble a new printer model, designed for 10 kg of meat per hour. “It’s not yet an industrial machine, we call it semi-industrial,” Ben-Shitrit told Business Insider.

Machines will be installed directly at customers' premises to enable them to sell fresh meat. The technology that Redefine Meat is developing could disrupt the global food supply chain, Ben-Shitrit shared his thoughts with The Times of Israel online edition. 3D printers that produce meat near the points of sale make it unnecessary to buy meat in other countries, he said.

3D printers that produce meat near the points of sale make it unnecessary to buy meat in other countries, he said.

Redefine Meat was supposed to hit restaurants late last year, but the coronavirus got in the way. During the pandemic, Redefine Meat signed contracts with several organizations interested in introducing artificial meat into the assortment. For example, in January of this year, Redefine Meat announced a strategic agreement with Israeli meat distributor Best Meister. The partner will supply not only to restaurants in Israel, but also to butcher shops. The agreement was signed after a blind tasting of alternative meats in Tel Aviv (both companies claim that it was the largest in the world - it was attended by about 600 people), which showed that 90% of meat eaters like fake meat. The company wants to conduct the same test with chefs in other countries and is preparing to enter markets in Europe, Asia and North America later this year. “This is a step towards becoming the world's largest alternative meat company by 2030,” Ben-Shitrit told The Times of Israel.

What the startup hopes for

Ben-Shitrit is going to sell his meat at the price of the real one. He believes that now is the best time to bring the product to market - many large meat companies are investing in meat alternatives for vegans, flexitarists, etc.

According to Euromonitor, global sales of meat substitutes reached $19.5 billion in 2018. In 2019, investment bank UBS predicted that the plant-based meat market would reach $85 billion by 2030. And Barclays named meat substitutes as the fastest growing segment of the food industry and estimated their market by 2030 at $ 140 billion. A large contribution to its popularity is the demand from people concerned about healthy eating, animal cruelty and climate change. Ben-Shitrit says that his equipment can in the future create analogues with the structure of chicken, pork, lamb and tuna. But he started with beef for two reasons. “Beef has the biggest business potential, it's the $500 billion industry, and it's the most environmentally damaging,” he told Food Ingredients First online.

..

..