3D print curling corners

What Causes 3D Print Warping and How to Prevent It

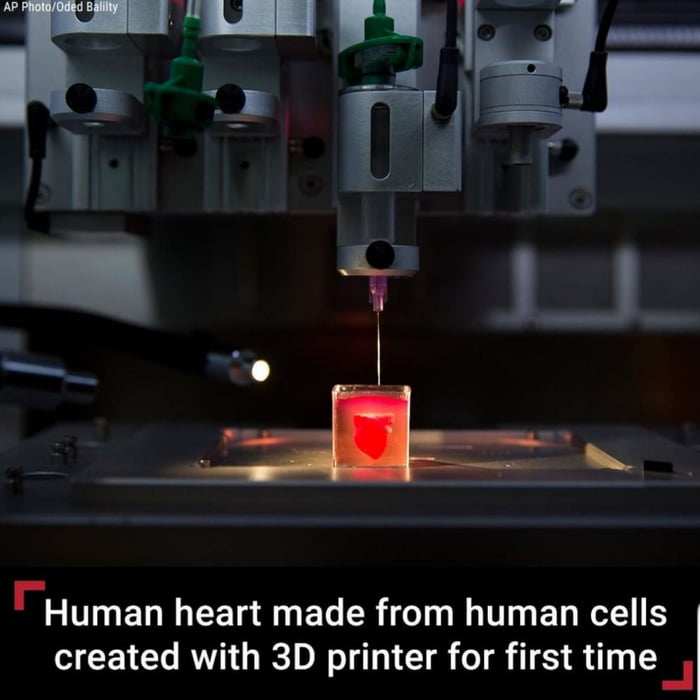

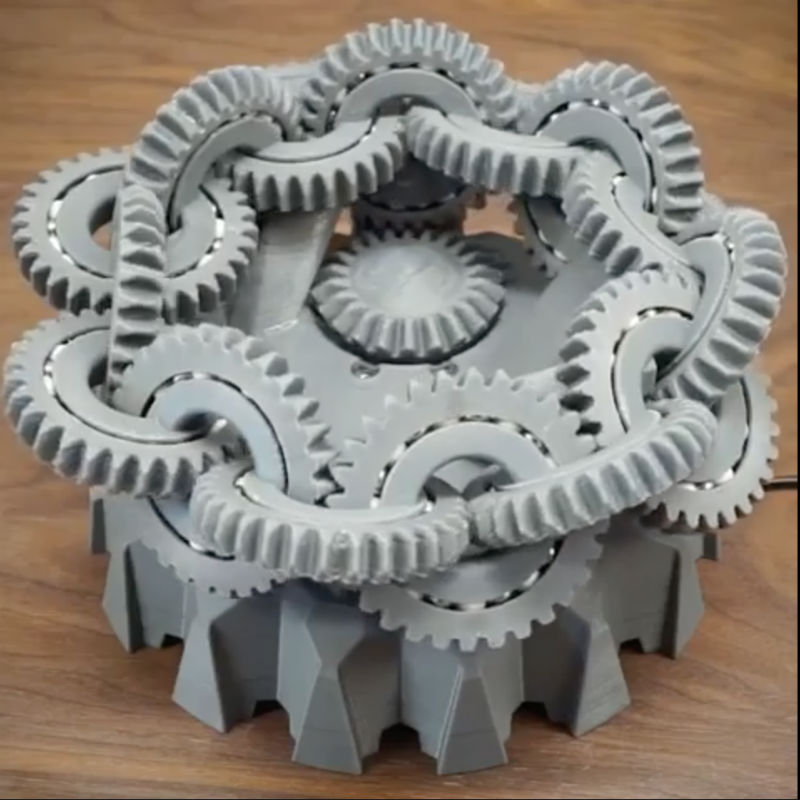

3D print warping is a common problem in fused deposition modeling (FDM) that causes parts to deform on the print bed. If you’ve ever noticed that the base of your 3D print is curling up and the corners are unsticking from the build plate, that’s warping. The good news is that there are several tips and tricks to prevent warping and improve your chances of a successful, warp-free 3D print.

What causes 3D print warping?

3D print warping happens when extruded filament layers on the 3D printer build plate cool too quickly and shrink. This causes the plastic material to contract and pull away from the build plate, resulting in warping (or curling, as it is sometimes known).

We can understand the problem of warping better if we zoom out a bit and look at the FDM process on the whole. In FDM 3D printing, a heated extruder deposits melted filament onto a print bed. This filament is made from a thermoplastic, a type of material characterized by its ability to melt into liquid form and resolidify when cooled. This means that in the printing process, as each layer is deposited, the filament hardens as it cools, but it also shrinks.

Thermoplastic filament shrinks as it cools; if it shrinks too quickly it can lead to warping

Warping occurs when the cooling process happens too quickly or unevenly and 3D printed layers shrink and pull on less solidified layers, ultimately lifting the first layer off the build platform and causing deformation. Though it is possible to experience warping with any type of 3D printed part, it is more common when 3D printing larger parts or parts with a large surface area. Certain 3D printing filaments are also more prone to warping than others. Typically, materials with a higher printing temperature, like ABS, suffer more from shrinkage because the temperature difference as they cool is more extreme.

How to fix 3D printer warping?

Fortunately, the chances of 3D print warping can be mitigated and 3D print outcomes can be improved using a few key techniques.

Bed Adhesion

One effective way to minimize the risk of 3D print warping is to improve your 3D printer’s build plate adhesion. Good bed adhesion will keep your 3D printed part stuck to the build surface and prevent the first layers of the print from curling up as they cool.

Bed adhesion can be achieved in a few ways. For example, there are dedicated 3D printer adhesives that can be applied to the build plate before printing. Many also opt for more DIY adhesives, like glue sticks and hairspray. A third option is tape, which is placed on the build plate surface. Painter’s tape is a popular option because it can be removed easily and the porous texture of the non-stick side keeps filament stuck down.[1] Kapton tape is also commonly used to encourage bed adhesion.

If you are using adhesives on your 3D printer, be sure that the print surface is clean before and after printing. Glue residue can cause an uneven print surface, potentially impacting calibration and the quality of future prints. It is also a good idea to try a test print if you are using a new adhesive to ensure it keeps the bottom layer of the print down but can also be easily unstuck when the print is done.[2]

It is also a good idea to try a test print if you are using a new adhesive to ensure it keeps the bottom layer of the print down but can also be easily unstuck when the print is done.[2]

An enclosed build chamber can reduce the risk of warping by maintaining a stable print temperature.

Temperature

Because cooling filament too quickly is what causes shrinkage and warping, it is key to control the temperature of your build as much as possible. 3D printer temperatures can be regulated using different methods or a combination of approaches. One of the most effective tricks for improving bed adhesion is to use a heated build plate. Each type of filament will have its own recommended bed temperature for good adhesion—for example, PLA works best with a heated bed at a temperature of between 60 and 70°C, while ABS requires a hotter print bed of between 100 and 120°C.[3]

Using an enclosed print chamber can also help to maintain an ambient temperature throughout the printing process and stop 3D printed layers from cooling too quickly. Many 3D printer models have a built-in enclosed chamber, but those that don’t can still benefit from a DIY enclosure. Other ways to improve temperature consistency in your 3D printer are to adjust cooling fan speed settings (especially for the first layers of a print) and keeping your room temperature as ambient as possible (i.e. keeping cold air out by closing windows).

Many 3D printer models have a built-in enclosed chamber, but those that don’t can still benefit from a DIY enclosure. Other ways to improve temperature consistency in your 3D printer are to adjust cooling fan speed settings (especially for the first layers of a print) and keeping your room temperature as ambient as possible (i.e. keeping cold air out by closing windows).

Brim or Raft

Brims and rafts are tried and true techniques for boosting bed adhesion, especially for ABS and other high-temperature filaments. These 3D print features are added in slicer software right before printing and have several functions.

Specifically, a brim is a 3D printed border that connects to and goes around the edges of a 3D printed part. Brims are typically a few millimeters wide and consist only of 1-2 layers. They increase the footprint of the 3D printed part and anchor its edges to the build platform. A raft is similar, only it is also printed under the 3D printed part, acting as a base for it.

Brims and rafts are especially beneficial for 3D printed parts with unbalanced geometries or small footprints, as they can stabilize the print and secure it to the build surface. Both brims and rafts must be removed after printing, either by hand (by peeling them off) or using a tool. Printed parts with brims or rafts may require additional post-processing to achieve a smooth first layer.

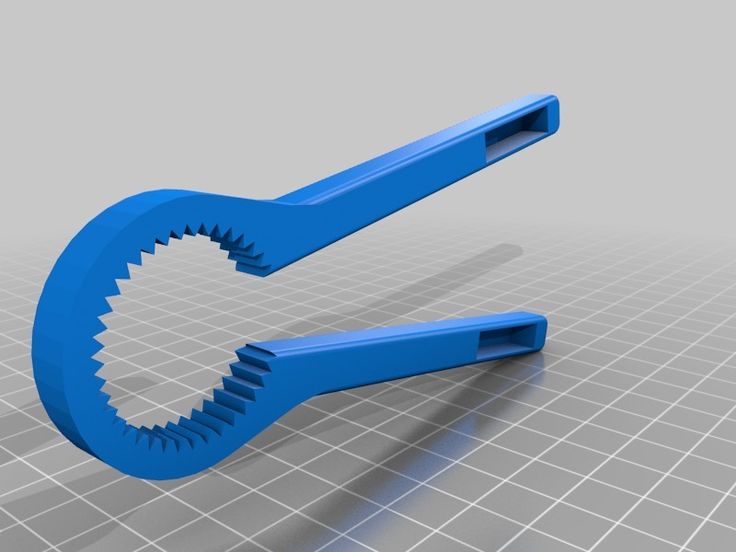

3D printed brims can help to anchor the printed part down to the build platform.

Slicer settings

The risk of warping can also be reduced substantially by implementing the right print settings for the first layers of the printed object. Most slicer software programs allow you to adjust the print speed and layer height specifically for the first layer. A slower print speed for the first printed layer of a build will help to ensure that the filament sticks to where it has been deposited and is not pulled by the nozzle as it moves. Choosing a slightly thicker layer height for the first layer can also improve bed adhesion and help reduce any leveling inconsistencies.

Another print setting that can influence warping is fan speed. Fans are built into some FDM 3D printers and ensure the build space does not get too hot. By tweaking fan speeds you can maintain closer control over print cooling. For example, fans can be programmed to turn on only after the first few layers of a print have been deposited. This helps the first layers cool slowly and evenly on the print bed.

Conclusion

3D print warping is a frustrating problem most makers will encounter at some point or another. By following the tips and methods laid out in this article, however, you can ensure good bed adhesion, consistent printing temperatures, and ultimately reduce warping and improve print quality overall.

References

[1] TapeManBlue, 2022. “The Complete Guide to Blue Tape for 3D Printing”. [Internet]

https://tapemanblue.com/blogs/tips-tricks/blue-tape-for-3d-printing [Accessed March 31, 2022].

[2] Ultimaker, November 10, 2020. “Build plate adhesion: How to get your print to stick to the build plate”. [Internet] https://support.ultimaker.com/hc/en-us/articles/360012015680 [Accessed March 30, 2022].

[3] Simplify3D, 2022. “Warping”. [Internet] https://www.simplify3d.com/support/print-quality-troubleshooting/not-sticking-to-the-bed/ [Accessed March 30, 2022].

how to easily fix it! – 3D Solved

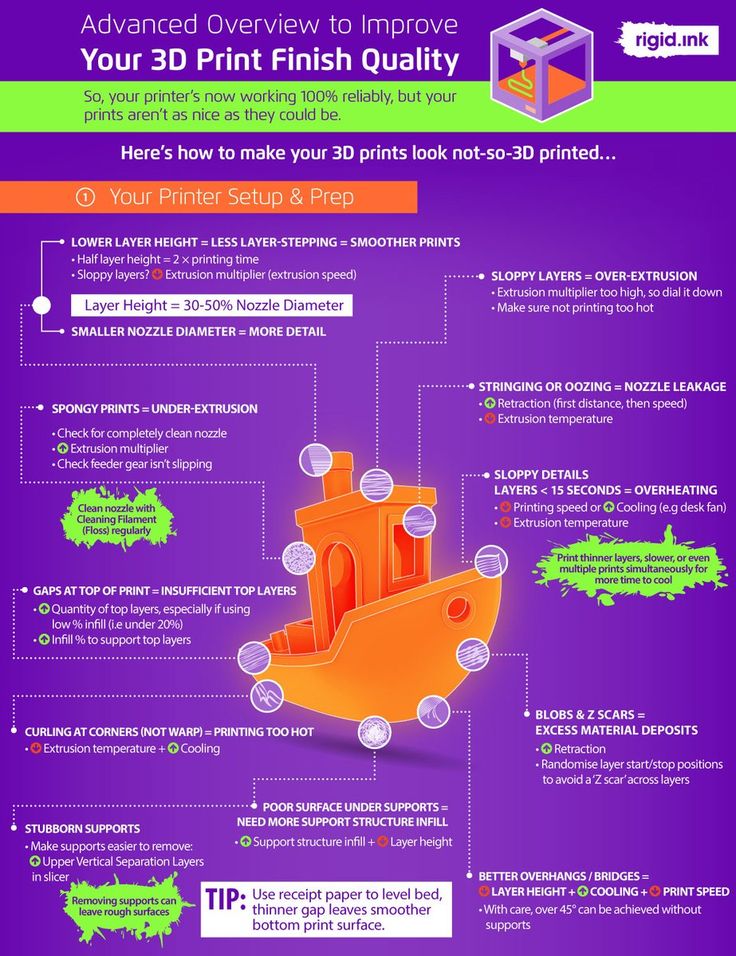

Both novice and experienced 3D printing enthusiasts have to deal with printing issues on a regular basis in order to finally achieve rewarding and good-looking prints. The main difference between both type of users is that the experienced ones typically can look at a print and quickly troubleshoot and determine what went wrong and what should be changed in order to solve it. As we will find out in this article, knowing the root cause of an issue is the hardest and most important step.

Let cut right to the chase and find out how we can solve over extrusion (curling) on the corners!

In order to fix over extrusion or curling on the corners, it is recommended to lower the extrusion temperature, turn on the layer fan to its maximum capacity and increase the time minimum time per layer to around 15 seconds, thus reducing movement speed on smaller layers. Curling on the corners is commonly mistaken with over extrusion, but in contrast to that problem, the issue only occurs on the corners of the object instead and not on the entirety of the outer shell.

Curling on the corners is commonly mistaken with over extrusion, but in contrast to that problem, the issue only occurs on the corners of the object instead and not on the entirety of the outer shell.

By differentiating both issues, it is possible to isolate the problem and determine that the cause of curling on the corners is not caused by over extrusion but by slow cooling down of the deposited thermoplastic.

Due to the nature of this problem, it is very easy to wrongly determine the cause of the issue. This is why I will try to help you differentiate curling on the corners from general over extrusion, and also from warping on the first few layers. Let’s get started!

Table Of Contents

- How to fix curling on corners

- How to fix over extrusion

- Do these problems affect all filament types equally?

- Check out our recommended products section

Curling only on corners versus over extrusion everywhere

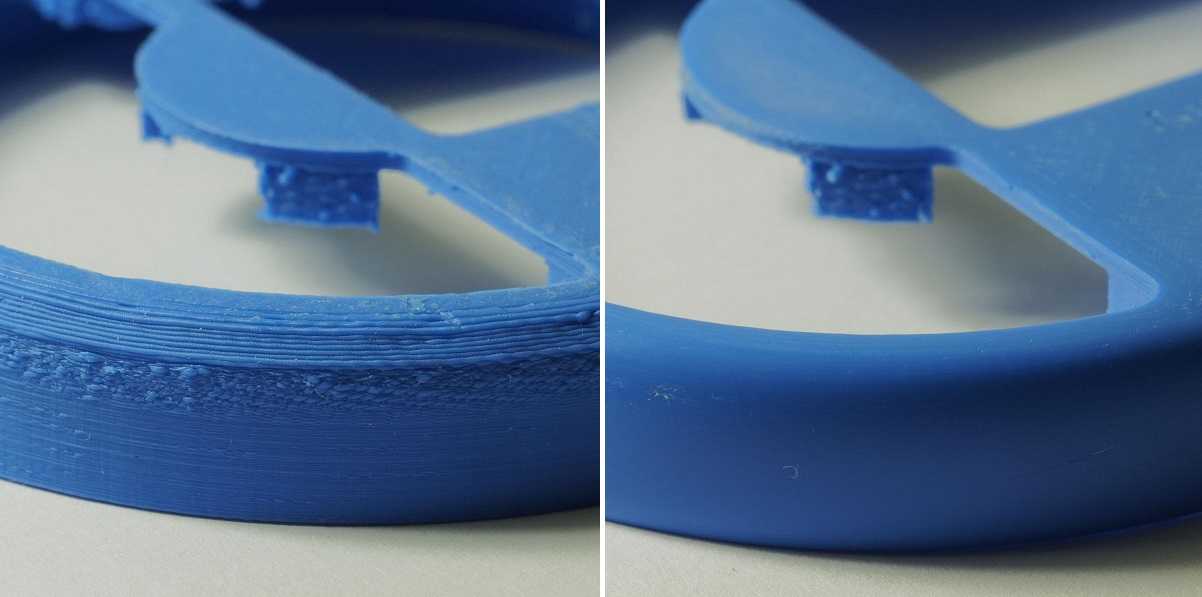

On the left: curling on the corners (Source)On the right: Overextrusion (Source)

The problem of curling in the corners is often associated with over extrusion, although this is not always the cause. Many people try to fix this by modifying the flow parameters, making the printer extrude less material, but while this can sometimes help, it doesn’t eliminate curling entirely.

Many people try to fix this by modifying the flow parameters, making the printer extrude less material, but while this can sometimes help, it doesn’t eliminate curling entirely.

One way to differentiate in which cases the curling is produced by over extrusion is verifying the size and shape of the vertical walls of the object. When the extruder provides more material than necessary, this defect can be observed throughout the part, not only in the corners.

Now that we know how to differentiate both issues, let’s focus on curling. The biggest difference is that overextrusion occurs throughout the piece, while curling occurs in areas where the object needs a greater supply of material, such as a sharp corner.

Curling consists of a lifting of the last printed layer, which occurs in certain sharp areas. It happens because the material contracts when it cools down, and the areas where there is more material drag the corners in, causing them to rise.

The problem gradually increases on each layer when the extruder passes through the raised area again, since the contact of the hotend with the bent corner produces undesirable deformations in the perimeters of the part.

Worst of all, if the plastic curled and cooled down before the next layer, the nozzle could hit that corner and unstick the entire part. Also, the stepper motor could lose steps and displace the next layers of the print. There is no way to fix this problem since 3d printers don’t have a closed-loop control system.

Curling on corners vs warping

Warping. Different to curling on the edges because it only occurs on the bottom layers. SourceIt is easy to confuse curling with warping, and although they have points in common, their causes and ways of solving them are different.

Warping only occurs at the base of the part, because it is a problem of adhesion to the heated bed. It is similar to curling because both happen in corners, and the sharper they are, the more noticeable this defect will be.

The chances of the part coming off the bed are much higher when warping occurs and starts lifting one of the object’s corners. The solution to warping is rather straightforward: raise the temperature of the heated bed, or enclose your 3d printer. Cold air currents are also very harmful and lead to warping issues.

Cold air currents are also very harmful and lead to warping issues.

Curling, on the other hand, also occurs in the upper layers, so the temperature of the heated bed has little or no influence on this problem. In order to fix it, you’ll have to consider other things, such as lowering nozzle temperature, installing a layer fan, or reducing printing speed.

How to fix curling on corners

We could say that curling is mainly produced by excessive extrusion temperatures of the filament. As the material comes out of the nozzle very hot, it stays limp for a longer time. This excessive time, combined with the shrinkage of the material, causes the corners to lift up.

For this reason, we will focus on the temperature parameters of the hotend in order to solve it definitively. To prevent curling, we are going to modify the following parameters on our slicer software:

Nozzle temperature

Many times, when we have problems with jams or underextrusion, some people recommend raising the printing temperature. This action sometimes improves our prints but does not solve the original problem. Although the filament flows better, the extruder may have another problem and we´re only hiding the problem under a rug by raising the temperature.

This action sometimes improves our prints but does not solve the original problem. Although the filament flows better, the extruder may have another problem and we´re only hiding the problem under a rug by raising the temperature.

In the long run, raising the printing temperature too much comes along with other defects such as curling or burning the inner PTFE tube. To avoid this, we will try to use the lowest possible temperature, and thus give less time for the material to shrink. This test will help assist us in determining the optimal temperature of our printer for a specific filament type.

Another way to know if you are setting too high of a temperature when printing with PLA is paying attention to your prints’ brightness. The object gets brighter as the temperature is higher. Reduce it if the piece looks too shiny.

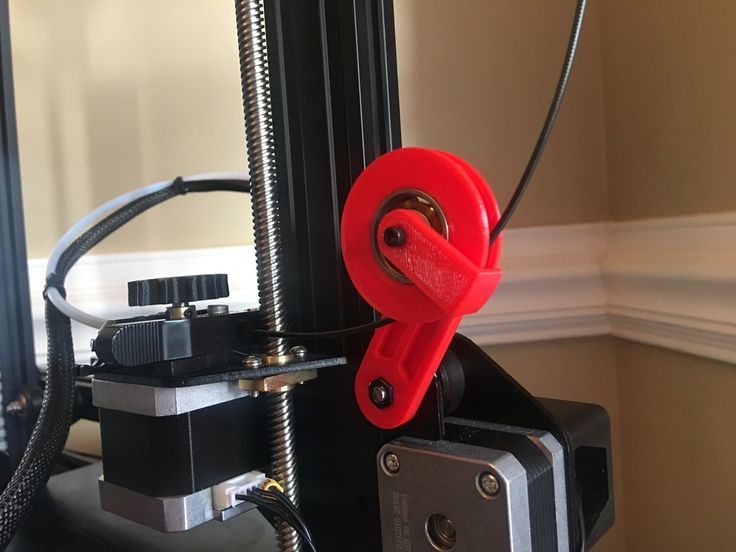

Cooling

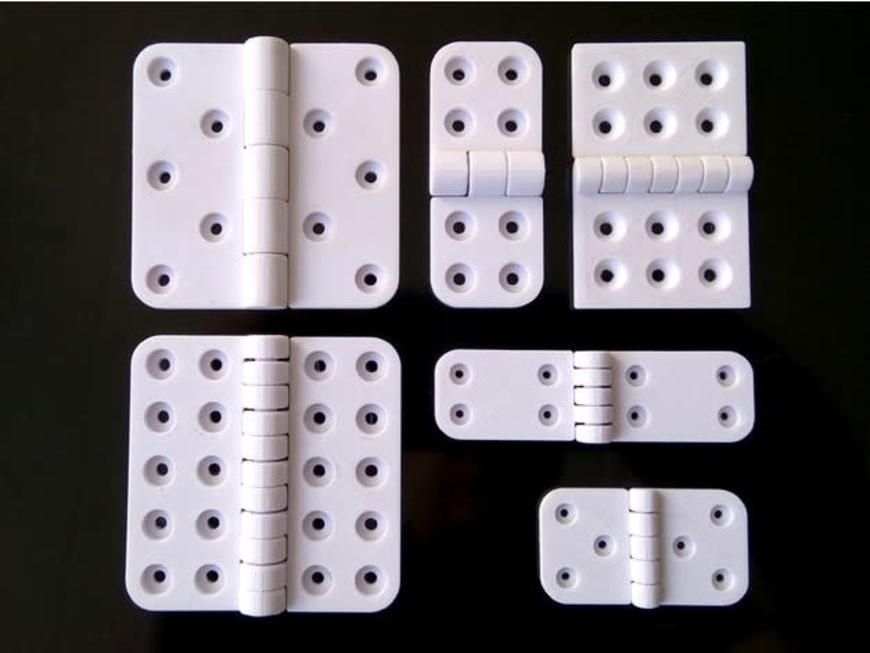

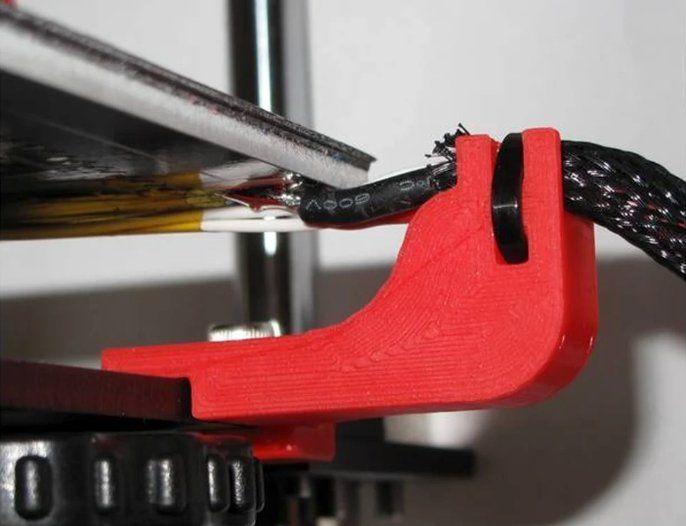

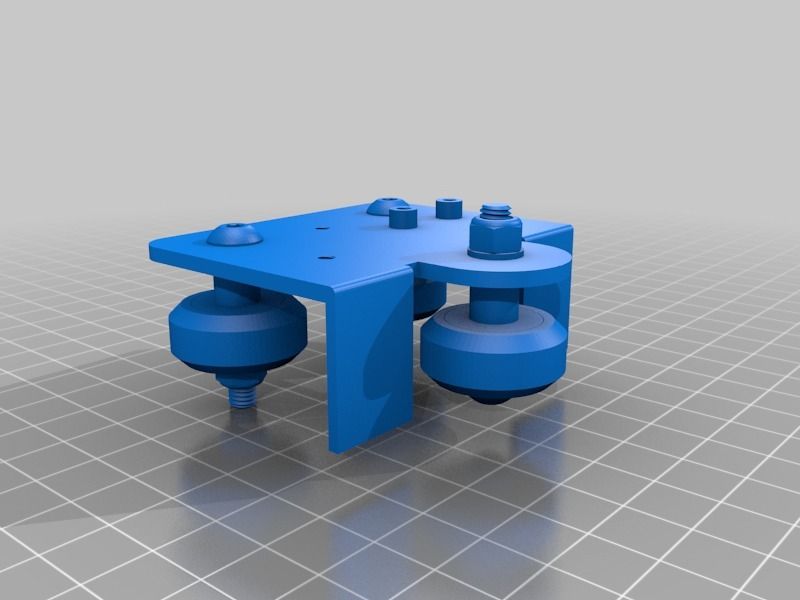

A dual blower model for improving layer fan performance. SourceIf your printer doesn’t have a layer fan installed, it’s time to install one. This fan dramatically decreases material cooldown times, preventing corners from having time to bend up. You just have to be careful not to activate it during the first layers, as it could lead to warping.

This fan dramatically decreases material cooldown times, preventing corners from having time to bend up. You just have to be careful not to activate it during the first layers, as it could lead to warping.

These fans can change their speed during printing, as they are controlled by PWM (pulse with modulation). This feature allows you to turn them on whenever you need, and at a precise speed.

One of the things to keep in mind when using a layer fan is its orientation. It may be incorrectly positioned, which would cool down the nozzle, causing temperature errors and printing stops.

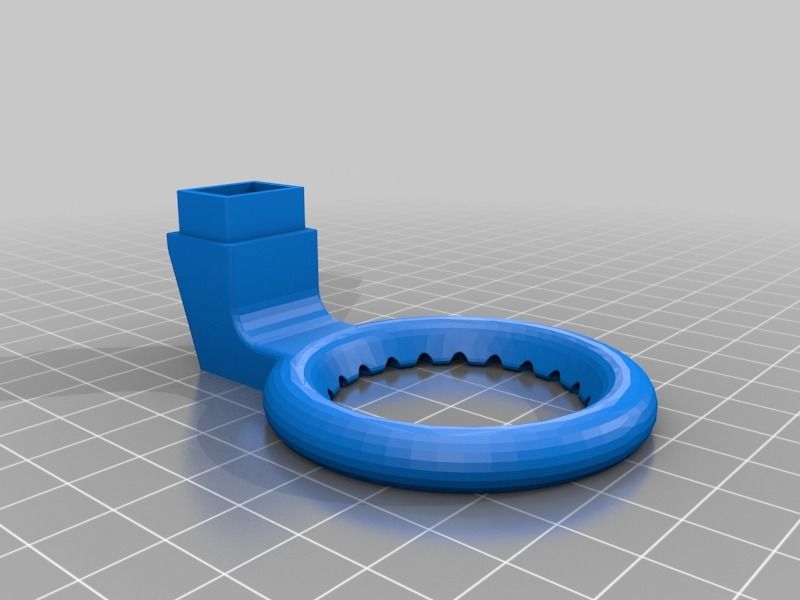

It may also happen that, due to the orientation of the object, the layer fan only cools down one side of the object. You can tell if this is the case when the curling always occurs on the opposite side of the layer fan. There are radial ducts that blow air evenly in all directions. On the off chance that you own a GeeTech i3 Pro B, you should definitely print and install this Air Duct. Here is another one that is compatible with the Tevo Tarantula

Printing speed

In some small pieces, a new layer might start printing on top of one that is still hot, so it never fully solidifies. To help prevent this, slicers come with an option to determine the minimum time it should take to produce each layer. By doing so, the printing speed is decreased during smaller layers. A typical value is about 15 seconds per layer.

To help prevent this, slicers come with an option to determine the minimum time it should take to produce each layer. By doing so, the printing speed is decreased during smaller layers. A typical value is about 15 seconds per layer.

If you still have issues related to curling, lower the printing speed by 10 mm/s until you get better results.

How to fix over extrusion

An extreme case of overextrusion. SourceIf the walls look “squirted”, as if the material is falling out of the object, then you will most likely have to set the extrusion parameters correctly.

This configuration mainly includes calibrating the extruder steps, so that the exact amount of material required is provided. The procedure is very simple, and there are several tutorials on the web on how to do it.

One easy test you can do consists of drawing marks along the filament before it gets extruded. The hotend is then heated and the 3d printer is commanded to extrude 10 cm of material. If the steps are correct, the next mark drawn on the filament should be located exactly at the entrance of the extruder (at the same point the previous mark was located).

If this mark ends up inside the extruder, it means that the printer thinks it is extruding 10 cm but is actually extruding more material (over extrusion). When this happens, the excess material deposited will squash against the previous layer and drip down to the sides of the object’s outer shell, leaving an unsightly finish.

Another parameter to check, after calibrating the extruder steps, is the flow rate. This allows you to multiply or reduce the volume of filament supplied. It is a more direct way of controlling the flow provided by the extruder, depending on the different densities of each material. Unlike step calibration, this parameter is variable. It is not the same to use ABS, PLA or TPU in your printer, so it is advisable to vary the flow rate according to the material used. You can use this test to quickly adjust the flow rate.

It contains instructions for performing the test using a caliper or micrometer. Be sure to read them before starting the test.

Do these problems affect all filament types equally?

There is a property that is common to all materials used in 3d printing: they expand when heated and contract when cooled. So technically any filament can present warping or curling problems. The difference is that not all materials expand and contract at the same rate or at the same speed.

So technically any filament can present warping or curling problems. The difference is that not all materials expand and contract at the same rate or at the same speed.

PLA is the most widely used material nowadays because, in addition to being cheap, its shrinkage ratio is one of the lowest, making it is easier to print in broader conditions than most filaments. PETG also features a low shrinkage ratio, but it needs a heated bed to be printed.

Other plastics (like nylon or ABS) shrink a lot, so the use of an enclosed printer is practically mandatory if you want to get acceptable results.

Why does ABS need a heated bed?

ABS is a thermoplastic that definitely shrinks a lot when it cools down. Without the presence of a heated bed to keep the first layers warm at 90°C, the difference in temperatures along the piece will lead to a contraction that lifts up the corners of the piece.

ABS warping is very common and difficult to eliminate. You can minimize the risk by properly leveling your bed and enclosing your printer. Additionally, when ABS curls and cools down, it becomes harder than PLA, increasing the risk of losing the entire print if the nozzle hits the object.

Additionally, when ABS curls and cools down, it becomes harder than PLA, increasing the risk of losing the entire print if the nozzle hits the object.

Keep in mind that, unless there is a technical aspect that requires the print to be produced in ABS, most of your problems can automagically disappear by switching to PLA!

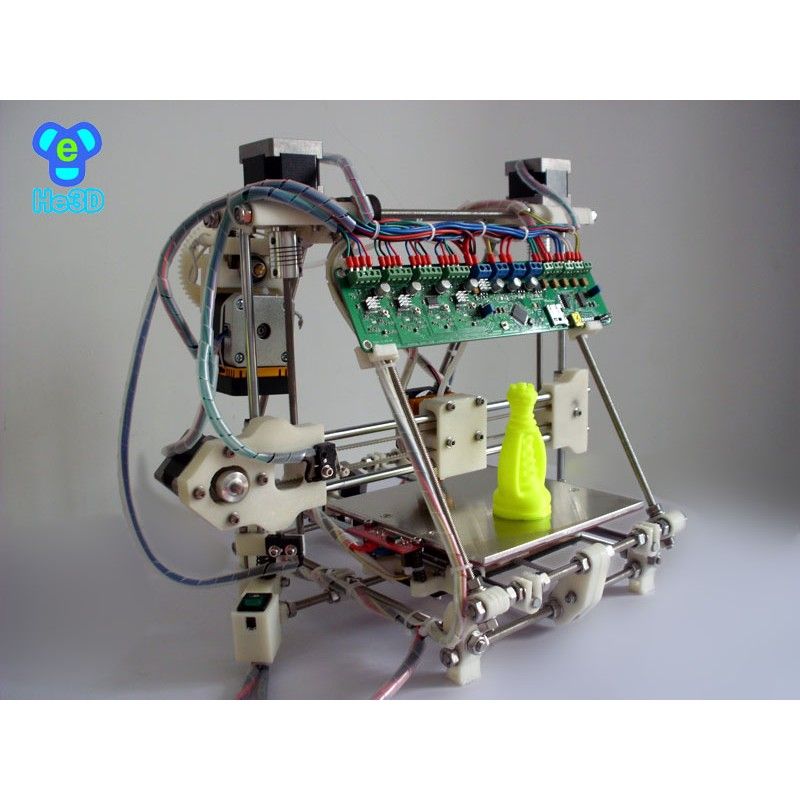

We created a recommended products section that will allow you to remove the guesswork and reduce the time spent researching what printer, filament, or upgrades to get, since we know that this can be a very daunting task and which generally leads to a lot of confusion.

We have selected just a handful of 3D printers that we consider to be good for beginners as well as intermediates, and even experts, making the decision easier, and the filaments, as well as the upgrades listed, were all tested by us and carefully selected, so you know that whichever one you choose will work as intended.

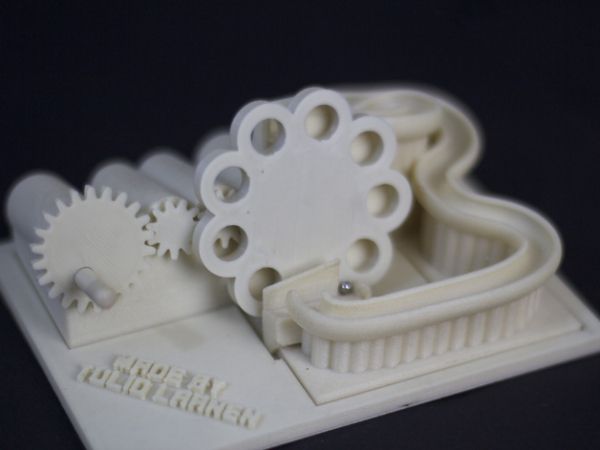

Troubleshooting 3D Printing・Cults

This article should help you identify various 3D printing related issues. Find the image or description in this list that best describes the problem you're experiencing. We offer some tips that should help you solve this problem.

Find the image or description in this list that best describes the problem you're experiencing. We offer some tips that should help you solve this problem.

As you know, 3D printing is an empirical process and it is through mistakes that you learn to understand, set up and use your machine. With the help of this list, you should be able to resolve the major bugs. If you are still experiencing issues or have additional tips to add to this list, feel free to contact us and let us know! nine0004

#1 Drooling

Symptom

Thin threads are woven into gaps between different parts of a 3D printed part.

Common Name: oozing

Possible Cause

Plastic continues to leak out of the head as it moves due to residual pressure in the heater and fluidity of the molten plastic.

Suggested remedies

Increase filament retraction length in Slic3r, retraction distance in CuraEngine. Retracting the filament will cause the pressure in the print head heater to drop. The effect can be modulated by adjusting the retraction speed directly in the slicer. nine0003 Increase print head speed. This allows the melted plastic to spread less time and leave marks between the printed parts.

Retracting the filament will cause the pressure in the print head heater to drop. The effect can be modulated by adjusting the retraction speed directly in the slicer. nine0003 Increase print head speed. This allows the melted plastic to spread less time and leave marks between the printed parts.

Reduce the extrusion temperature of your plastic. If it is too high, the plastic becomes more fluid and flows out of the extruder faster.

#2 It is collapsing

Symptom

Collapse or poor quality of the overhanging surface, leaving small bumps.

Common name: overhang

Possible cause

The plastic deposited on the periphery of the protrusion does not solidify fast enough, so the deposited filament moves before it solidifies. The phenomenon is repeated or emphasized from one layer to another.

Suggested fixes

Vent the deposited plastic more efficiently, for example by adding a fan to the extruder or directly with a portable fan. nine0003 Create print supports under the overhangs.

nine0003 Create print supports under the overhangs.

Change part orientation to avoid overhangs.

#3 Flaking on the sides or top

Symptoms

Contours not bonded enough.

Flat surfaces are not completely covered.

Possible cause

Not enough material is deposited. Too narrow, the deposited wires do not touch each other enough and therefore do not stick to the adjacent wire. nine0003 There is dirt in the nozzle, which prevents the passage of the melt.

The extrusion temperature is too low, the wire dries out too quickly or shrinks and therefore does not stick to the adjacent wire.

Suggested Tools

Calibrate the extruder to obtain material flow according to data received from the slicer.

Unlock the extrusion nozzle.

Increase extrusion temperature.

Increase the blending speed in your slicer. nine0004

#4 There is not enough material on thin parts

Symptom

The edges of a very thin area are not strong enough, there is not enough material.

Possible cause

Recycling or reworking is not effective enough.

Incorrect filament solidification.

Thread drive slippage during retraction.

Suggested remedies

Reduce the retraction speed and length while printing. nine0003 Increase "extra leg length when retracting" when using Slic3r.

Increase the spring pressure on the driven gear.

#5 Blisters

Symptom

Blisters, mismatched geometry, such as small bumps that are seen mostly in areas with a small surface area.

Possible cause

The filament is too hot during extrusion or the filament cooling system is not effective enough. nine0004

Suggested media

Place more parts on the plate while printing. In this case, the nozzle will print more objects and therefore allow more time for the part to cool before passing over it again.

Improve the cooling of your 3D printed object by adding cooling systems.

#6 Thin walls delaminate

Symptom

At a thin wall without filler, the threads diverge, they are not glued together on the sides. nine0004

Possible Cause

The walls of your 3D print are too thin or not adapted to such a small size.

Suggested remedies

Draw thicker walls to adapt to the thread thickness.

In the slicer settings, set a sludge width that is a sub-multiple of the wall width while remaining consistent with the extrusion diameter and layer height.

Change slicer.

#7 Layer shifts horizontally

Symptom

The layer is shifted in the X or Y axis (or both).

Possible Cause

Print head or plate movement problem.

Suggested fix

Reduce the acceleration on the axis that has the problem.

#8 Layers shift evenly

Symptom

Layers almost always shift along the X and/or Y axis after a certain print height. nine0004

nine0004

Possible Cause

Head or plate offset failure due to overheating of motors going into safe mode.

Suggested fix

Cool engines with cooling systems (fans).

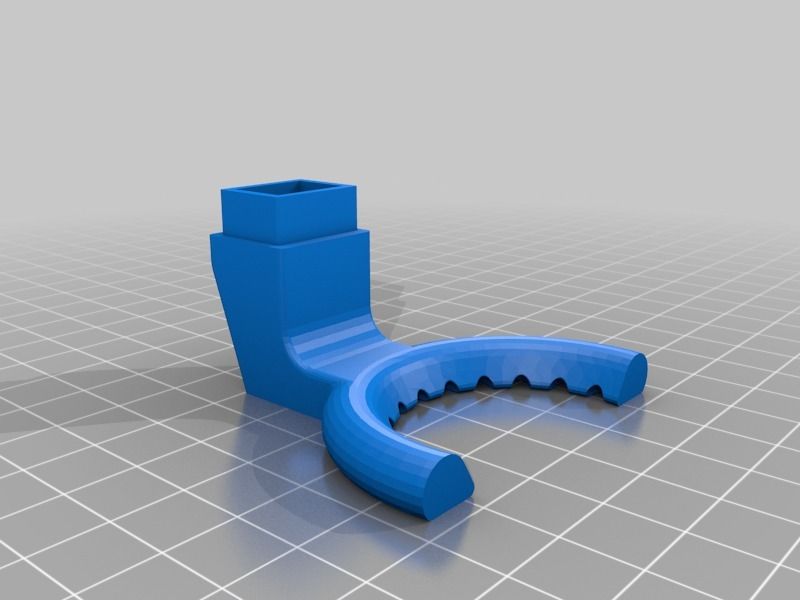

#9 Corners curl up

Symptom

Deformation in the Z direction during 3D printing. This figure increases in case of a strong overhang.

Common name: curling

Possible cause

Poor solidification, shrinkage effect due to temperature difference of the wire deposited on the previous cooled layer.

Suggested remedies

Increase the slope in the 3D part to reduce overhang.

Further cooling of the deposited plastic using a ventilation system.

Add print supports to affected areas.

#10 Corners fall off

Symptom

The corners of the printed object are peeling off the plate, creating an uneven base.

Common name: warping

Possible cause

Poor fit between the workpiece and the insert.

Material shrinkage factor too high.

The first layer is not pressed enough against the board.

Suggested remedies

Change media as PLA is less likely to warp.

Apply adhesive to the printing plate (glue, tape, varnish, etc.). nine0003 Correctly adjust the plate height before printing.

Apply a thinner first coat to further crush the deposited wire.

Add a bezel under the first layer.

Heat up the stove.

Clean and degrease the base.

Change the filling strategy. Fill the bottom concentrically instead of linearly, then fill the inside in a honeycomb pattern to avoid any shrinkage effect.

Reduce the internal fill density of your 3D printed object.

#11 Extrusion density too low

Symptom

Incorrect material density.

Possible cause

Material consumption too low

Suggested remedies

Unlock the extrusion nozzle.

Filament blocked upstream of extruder (e.g. knot in spool)

Check thread drive (e.g. knurled screw problem)

Corners #12 not forming correctly

Symptom

The corners are not straight enough, they can even stick out and increase the size of the part.

Possible cause

Too much material is deposited in the corner due to the nozzle slowing down too much as it passes through the corner.

Suggested remedies

Intentionally soften the corner of the part in the 3D modeling software.

Increase the "jerk" on your 3D printer's axis controller.

#13 There are black drops

Symptom

Burnt (blackened) plastic in some areas of the printed object.

Possible Cause

Poor nozzle seal causing burnt PLA or ABS to drip around the nozzle.

Suggested fix

Remove the nozzle and close it again.

#14 Layers poorly welded

Symptom

Part breaks at the attachment point between two printed layers. nine0004

Possible cause

Too much cooling, the deposited layer does not adhere well to the previous layer, because it was not hot enough during the deposition.

Suggested remedies

Reduce fan speed during printing.

Increase the minimum print speed in the slicer.

#15 Bubbles form on the first layer

Symptom

The first layer comes off the plate locally in the form of bubbles. nine0004

Possible Causes

Moisture in the material which gradually evaporates on contact with the heating plate.

Insufficient heating plate temperature for the material being used.

Suggested products

Store raw material rolls in a dry place, in closed packaging, with a desiccant bag.

Dry damaged material: place in a rotary oven at 40°C for approximately 3 hours. Be careful not to heat above 45°C or 50°C as this may cause the threads to stick together in the bobbin and even lose their cylindrical shape. nine0003 Increase the temperature of the heating plate.

Printing on tape or special adhesive.

#16 Fragile top and bottom

Symptom

Horizontal sides too thin and brittle.

Possible Causes

Insufficient material thickness above and below thin fill print. The laid threads have too few support points and break between the threading ribs.

Suggested remedies

Place at least 2 or 3 fully filled layers ("Solid layers" option in Slic3r) for the "top" and "bottom" faces.

Increase the fill of your object.

#17 Hole tops collapse

Symptom

Horizontal center hole top wires collapse during construction.

Possible causes

Plumb line too horizontal.

Mismatch between nozzle temperature, wire cooling and speed. nine0004

Suggested fixes

Reduce or eliminate this overhang area by modifying the 3D file geometry. An example is in the large hole in the photo, shaped like a drop of water, not a cylinder.

Add print supports below this area if the overhang is too difficult for the 3D printer.

Avoid too much slowdown in this area, even if the layer print time is short.

#18 Color or transparency varies

Symptom

The color or transparency of the material changes in different areas during 3D printing.

Possible causes

Different crystallization of the material due to different cooling rates. This may be due, for example, to the printing time of individual parts of the object or to the power of the fan.

This may be due, for example, to the printing time of individual parts of the object or to the power of the fan.

Radiation from the nozzle can affect the thermal cycle of the previous layer and thereby change its appearance.

The applied layer is too hot because the underlying layer has not cooled down. nine0004

Be careful, the physical-mechanical properties of the part may change due to these differences in crystallization!

Suggested fixes

Better control of cooling with slicer settings: change fan power based on plate cooling time or slow print speed in proportion to plate surface.

Reduce extrusion temperature for faster and more uniform phase transition.

#19 Layers are delaminating

Symptom

Some layers are bent and cracks appear between the different printed layers.

Possible causes

Twisting phenomenon due to the effect mentioned in #9 the above happens between layers.

The wire cools too quickly at the exit of the nozzle, it does not weld properly with the previous layer.

Severe contraction of the material during cooling or phase change.

Some materials extruded at high temperature (ABS, PC...) may present a significant shrinkage phenomenon. nine0004

Suggested remedies

Change the extrusion temperature.

Change the media.

Avoid blowing on a wire that has been set aside, reducing fan power, or placing the printer in a draughty room.

Close the assembly area in a controlled cabinet at a temperature close to the glass transition temperature of the material.

#20 Drops appear

Symptom

Drops of material are deposited at various points on the side of the 3D printed object. nine0004

Possible Causes

Excessive extrusion when resuming extrusion after stopping extrusion when moving from one point of the part to another or when changing layers.

Suggested Remedies

Some slicers have a setting that after a pause in printing, request that more be pushed in before resuming normal printing than was removed by retraction.

#21 Bowden extruder salivation

Symptom

The Bowden extruder is either running too hard or not running enough. First impressions of your extruder are not great, too much extruded material, bridges between different areas in motion where extrusion should stop.

Possible cause

Insufficient thread shrinkage to compensate for the gap in the Bowden tube. Depending on the diameter of the tube and filament, as well as the length of the body, the motor must draw a certain length of filament through the bends of the tube before the filament is drawn out of the heating head. nine0004

Suggested fixes

Increase the "pull" distance in the slicer. The detail on the left was printed with 1. 5 mm of indentation, which was clearly not enough. When the pull-in distance was increased to 6mm, the center part was printed. Too much shrinkage causes hot material to enter the thermal break, the temperature of the thermal break gradually rises, and the melting thread eventually gets stuck in the thermal break. The engine is no longer able to effectively push it. Reducing the retraction distance to 4 mm results in the part shown on the right. nine0004

5 mm of indentation, which was clearly not enough. When the pull-in distance was increased to 6mm, the center part was printed. Too much shrinkage causes hot material to enter the thermal break, the temperature of the thermal break gradually rises, and the melting thread eventually gets stuck in the thermal break. The engine is no longer able to effectively push it. Reducing the retraction distance to 4 mm results in the part shown on the right. nine0004

#22 Streaks or regular patterns on extrusion

Symptom

Repeating patterns appear on the walls of 3D prints.

The pattern may change depending on the direction of movement of the motors.

Possible cause

Incorrect extruder drive setting

This problem can occur if the extruder is set to the wrong current. If the extruder has insufficient power, the extrusion will not be constant. nine0004

Suggested remedies

Adjust the extruder driver with a multimeter. Be careful not to short circuit during the measurement, use a ceramic screwdriver.

Be careful not to short circuit during the measurement, use a ceramic screwdriver.

Artwork by Philippe, Pierrot and Franck and originally posted on LOGre

This page has been translated using machine translation. Suggest the best translation

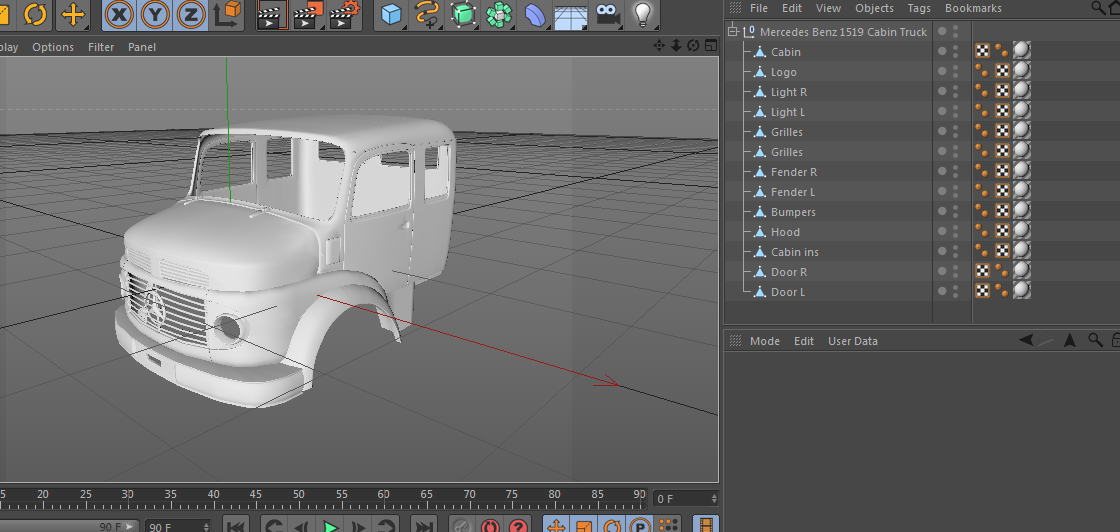

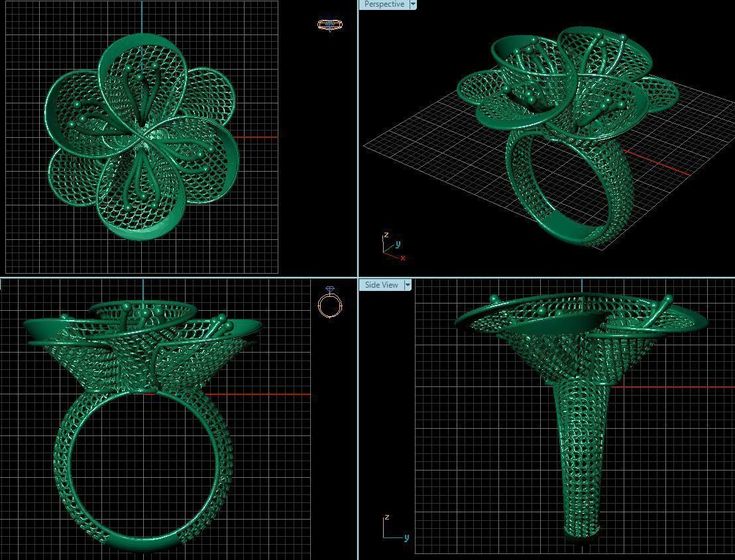

Basics of 3D Modeling for 3D Printing / Sudo Null IT News0001 KolianM

Working with 3D graphics *Prototyping *DIY or DIY 3D printers

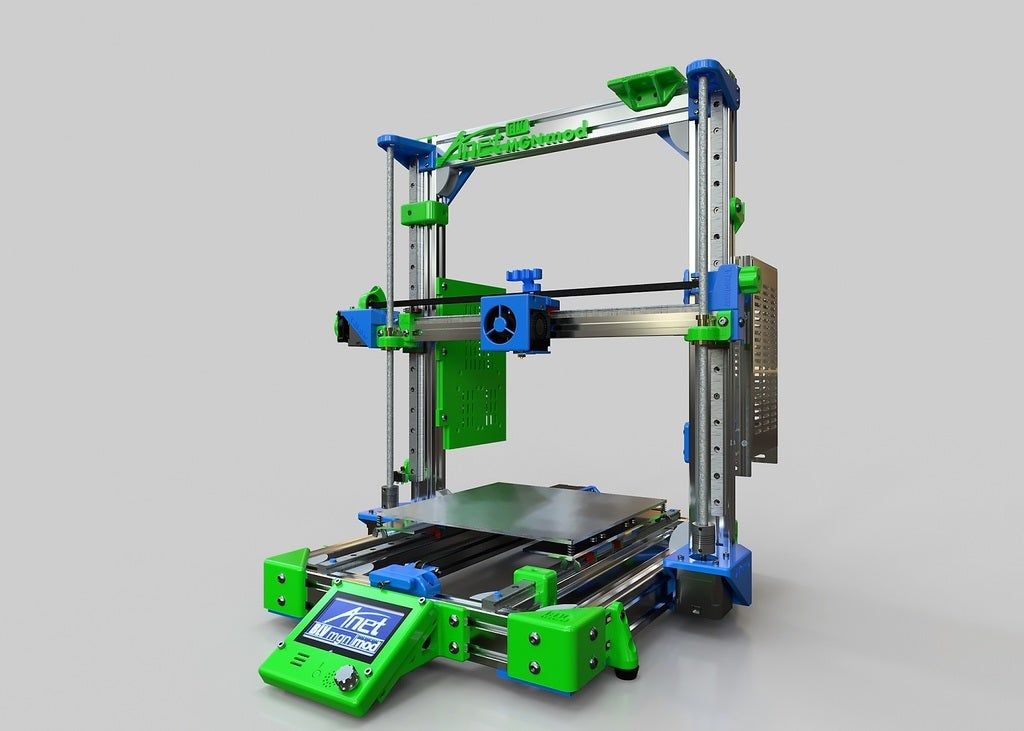

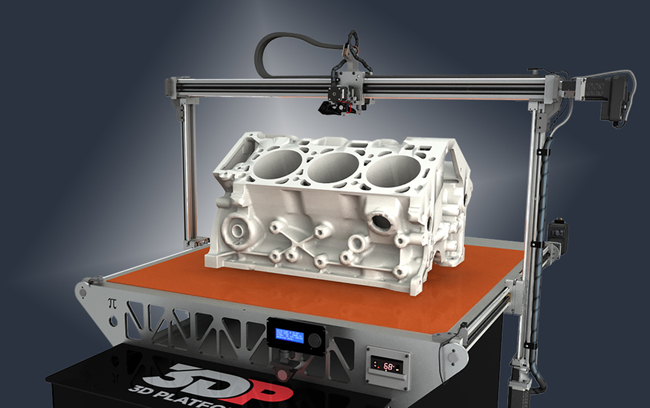

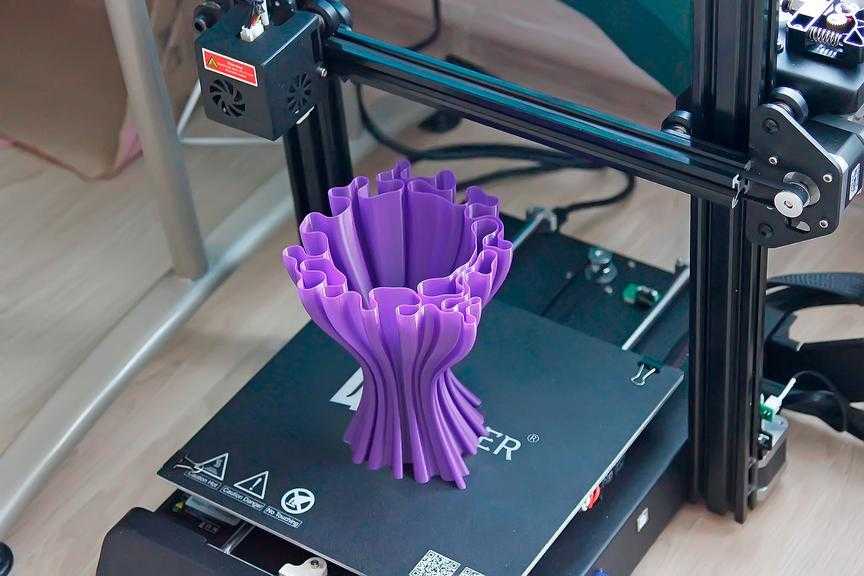

casting or milling. This is due to the technical features of the 3D printer, from which you need to either squeeze the maximum benefit, or adjust to the disadvantages of printing.

As a reservation, I note that these recommendations relate mainly to the FDM (FFF) 3D printing method, in which a plastic rod is heated by a moving extruder that forms the part layer by layer. nine0004

nine0004

Development of a 3D model starts with a sketch. It can be a drawing on paper, a material prototype, a mental image, etc. What is important to pay attention to when creating such a sketch and the model itself, we will analyze in detail.

Part strength

Here and further down the text there are several sub-points that must be taken into account at the same time, kept in mind from the very beginning.

- Be aware of the layering or anisotropy of the material: it is much easier to break a part in layers than across. This must be taken into account in advance, given the location of the 3D model on the 3D printer table. nine0003

- Add fillets. The leg of the stool and the tabletop at the junction should have a rounded corner. At the same time, the larger the radius of curvature, the stronger the leg will be fixed on the table top. Similarly for various body parts. Modeling a box All right angles are rounded.

It doesn't matter what plane they are in. Even where a right angle is needed, we make a radius of 0.5 mm. The printer will pass through such a section more easily than an unrounded one, there will be no impact from a sharp stop of the extruder, the part will not sway, and other pluses. nine0003

It doesn't matter what plane they are in. Even where a right angle is needed, we make a radius of 0.5 mm. The printer will pass through such a section more easily than an unrounded one, there will be no impact from a sharp stop of the extruder, the part will not sway, and other pluses. nine0003

- Wall thickness and filling. The maximum strength at 100% infill is a fact, but if you need to lighten the part or save plastic, you can make a much larger wall thickness in the print settings, while setting the infill much lower. This works with parts that have holes for fasteners. When creating machine code for a printer, absolutely all the outer walls are thick, so the fastener will be surrounded by a reliable thick layer of plastic of your part.

- Support. This element affects the strength in that the layers supported by the support are not always ideal in structure. This can be solved by increasing the wall thickness, filling, but it is better not to do support at all.

Support is added by the slicer depending on the angle between the part wall and the table plane. Often the default is 60 degrees, sometimes 45. This setting is selected experimentally for each 3D printer. You can check this with the help of special test parts. For example, https://www.thingiverse.com/thing:2806295 - do not forget to turn off support to check the real quality of 3D printing in its absence. For example, you need to print a T-piece for tubes. Cast products are made in a T-shape. 3D printing makes the product L or even Λ-shaped. In the second case, support can even be avoided, and the part will be stronger due to the layers located at an angle of 45 degrees to the tubes. We, in the workshop, set up slicers for each machine and ask the client about the strength requirements, and, depending on this, choose a 3D printer to print. nine0003

Support is added by the slicer depending on the angle between the part wall and the table plane. Often the default is 60 degrees, sometimes 45. This setting is selected experimentally for each 3D printer. You can check this with the help of special test parts. For example, https://www.thingiverse.com/thing:2806295 - do not forget to turn off support to check the real quality of 3D printing in its absence. For example, you need to print a T-piece for tubes. Cast products are made in a T-shape. 3D printing makes the product L or even Λ-shaped. In the second case, support can even be avoided, and the part will be stronger due to the layers located at an angle of 45 degrees to the tubes. We, in the workshop, set up slicers for each machine and ask the client about the strength requirements, and, depending on this, choose a 3D printer to print. nine0003

Geometric restrictions

- The wall thickness is limited from below by the size of the 3D printer nozzle.

Its diameter is constant and in the vast majority of cases it is 0.4 mm. Smaller thickness - long 3D printing for most parts. The larger the nozzle, the bonds between the layers are less strong, the steps between the layers are more visible. And in general, the wall thickness should be a multiple of 0.4 mm, then the 3D printer will be able to accurately make the wall in two passes (0.8 mm), in 3 passes (1.2 mm), etc. Other thicknesses will cause the 3D printer to leave a gap or overflow, which negatively affects the strength and appearance of the printed part. nine0003

Its diameter is constant and in the vast majority of cases it is 0.4 mm. Smaller thickness - long 3D printing for most parts. The larger the nozzle, the bonds between the layers are less strong, the steps between the layers are more visible. And in general, the wall thickness should be a multiple of 0.4 mm, then the 3D printer will be able to accurately make the wall in two passes (0.8 mm), in 3 passes (1.2 mm), etc. Other thicknesses will cause the 3D printer to leave a gap or overflow, which negatively affects the strength and appearance of the printed part. nine0003

- 3D printing of thin cylinders and "needles". For 3D printing of such products, special 3D printer settings are needed: low 3D printing speed, allow time for cooling, otherwise such a structure will bend. Vertically standing thin elements are best avoided at all costs. Even if they are printed, they will be very fragile. It makes sense to leave them only for decorative purposes, but you must be prepared that their quality will be worse than the quality of other elements of the 3D part.

- 3D printed holes. I note that if the hole is straight and through, then it can be drilled, if it is curved and requires support, then it may turn out that it will be impossible to get support.

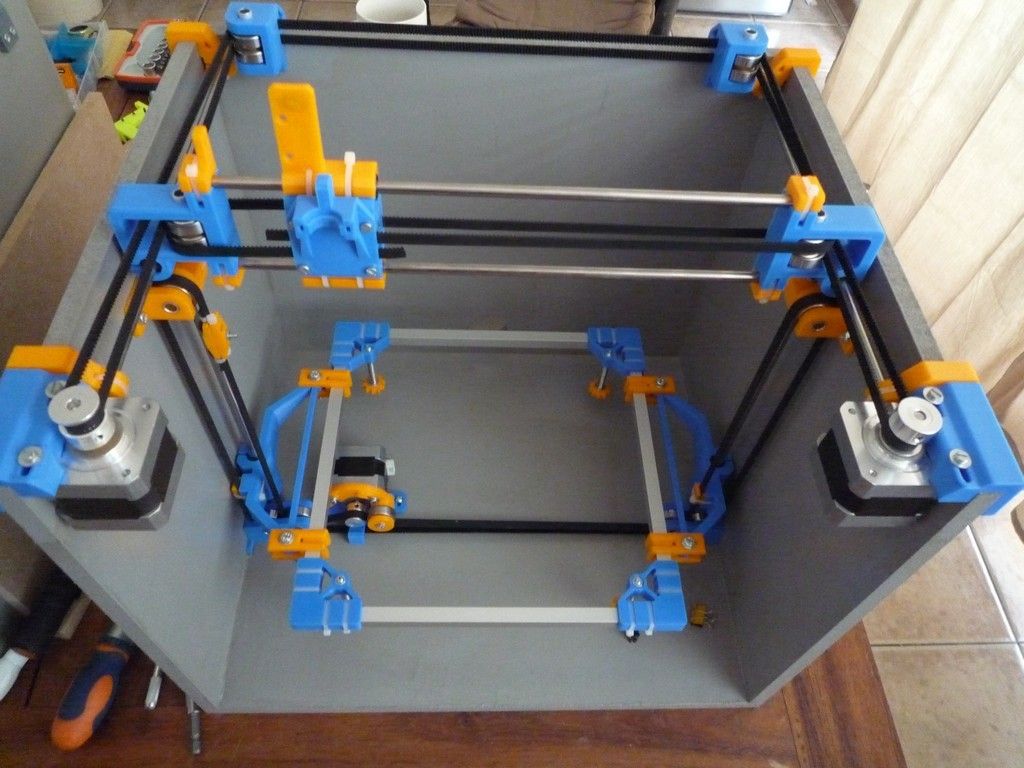

- When 3D modeling, it is important to consider the overall dimensions of the 3D printer. We use convenient 3D printers, table 250x250 mm, diagonal 353 mm. This is where you need to enter the dimensions, if possible. Otherwise, you need to order either an industrial 3D printer with a large print area, or use gluing, but assembly is better, so the assembly process will be controlled by the developer, and not by the 3D printing master. nine0003

- Large footprint may cause edges to peel off the table. We use special glue, but this does not always help. We are periodically approached with a complaint about colleagues in the workshop that for them such “minor” defects as a folded edge are not a reason to restart 3D printing, take it as is. But an engineer who 3D models a part can take this into account in his work, and make either assemblies or thin-walled flat 3D parts that “do not have enough strength” to compress the outer contour and, as a result, raise the edge.

nine0003

nine0003

- Tall and thin "towers" may not work well due to vibrations that occur when the 3D printer is running closer to the top, and layer shifts are also possible.

Dimensional stability, accuracy

- Precise 3D printing is quite rare. I don’t want to speak in engineering terms here, but the likelihood that a complex composite structure will assemble the first time is very low. Here, rather, you need to take into account the fact that you can then mechanically refine the details. nine0003

- Holes for fasteners are best done with a margin of 0.5 mm in diameter. This will not reduce strength, the fasteners will also not dangle due to tightening forces, but if you do it without a margin, you will definitely have to drill it out. Reducing the size of a large shaft, >10mm sandpaper is much easier than making a hole, which requires a huge drill that cuts into the plastic walls and breaks the part, or gets stuck in it.

It is also important to consider that when drilling, the plastic melts and the drill can melt into it so that it cannot be removed. There have been cases. nine0003

It is also important to consider that when drilling, the plastic melts and the drill can melt into it so that it cannot be removed. There have been cases. nine0003 - Heat shrinkage is not always compensated, more precisely, it is very difficult to catch it, it is not the same in different directions, so it is extremely difficult to take it into account. It's easier to print a test version, and then make adjustments.

When looks matter

- Think about how the craftsman will orient the part on the 3D printer table. 3D printing proceeds in layers, which is clearly manifested when printing surfaces that are at a small angle from the horizontal of the table. Skinning will be long and painful, because you will have to cut this "ladder" to the deepest depressions of the "steps". It is better to place such surfaces either horizontally, for example, put on a table, or increase the angle. In some cases, even adding support that spoils the wrong side of the wrong side saves time and effort on post-processing.

nine0003

nine0003

- Support. First, the surface it supports has significantly more defects than without it. Secondly, thin and high support is weak, wobbly, which leads to the fact that the supporting part may have serious defects, or not work at all.

- First layer quality improvement. You need to add a bevel. Even where a sharp corner is not needed, I recommend adding a chamfer of 0.5 mm. It will not be clearly visible, but the edge will be neat. nine0003

What you need to know in order not to make a mistake when ordering 3D printing

When appearance is important

- Location of the part on the table. Remember about anisotropy.

- Wall thickness and filling. What you can run into here: the filling is 20% cells, which are either visible through a thin outer wall, or the filling slightly tightens the outer wall during shrinkage, but at the same time it is visually easy to determine that there is support inside.

Here, first of all, an increase in the thickness of the outer wall, or an increase in the filling density, helps. Please take this into account when ordering. nine0003

Here, first of all, an increase in the thickness of the outer wall, or an increase in the filling density, helps. Please take this into account when ordering. nine0003

Postprocessing

The elimination of stepping is achieved by mechanical and chemical methods. It is possible to use putty. Acrylic paint available. If the part has a complex color structure, then we use the ProJet 4500 printer, which works on a different technology. He glues the powder particles together with colored ink glue. It turns out well.

Morality

In conclusion, I would like to note that these recommendations and the accumulated experience will make it possible to produce parts by 3D printing, which in their properties will not be inferior to cast ones, which makes it possible to save significant funds in the presence of a customized printer and small production volumes. From my own experience, I note that fiddling with the printer, debugging it, knowing “all the cracks” is a separate topic, which I will talk about later.