Can you use any filament in a 3d printer

Can You Use Any Filament in a 3D Printer? – 3D Printerly

Being able to use any filament in a 3D printer is a question that people want to know, so I decided to write an article answering that, along with related questions.

If that’s something you want to learn, keep reading through to learn the answers.

Can You Use Any Filament in a 3D Printer?

No, you cannot use any filament in a 3D printer. You need to specifically have a filament 3D printer to use filament since resin 3D printers don’t use filament. The filament also needs to be the correct size for your 3D printer. The standard filament size is 1.75mm, but there are also 3mm filaments as well.

You should know that exposure to sunlight or a humid environment can degrade any filament. Avoid using expired or older filaments because they can make the 3D prints brittle.

Here are some other factors that you need to consider for using filament in a 3D printer:

- Type of 3D printer

- Presence a heated bed or heat chamber

- Type of nozzle material

- Diameter of the filament

- Melting point of the filament

Type of 3D Printer

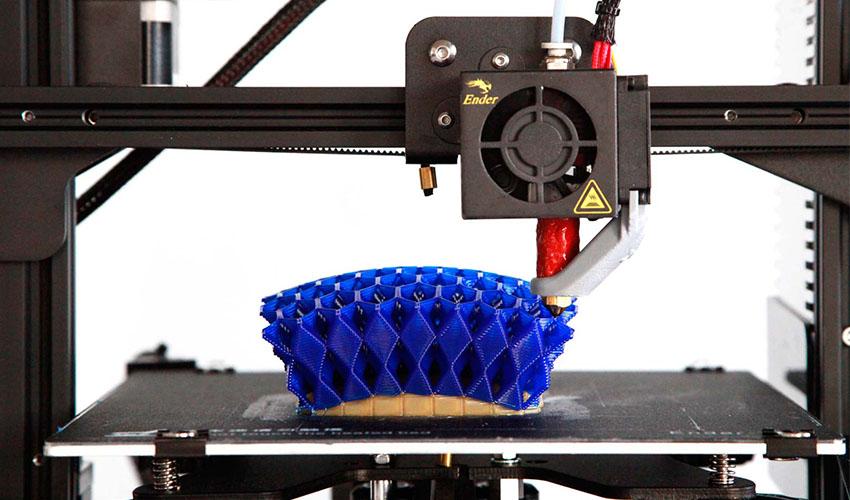

Most 3D printers can use PLA, PETG and ABS as they are popular amongst users in 3D printing. A standard Ender 3 printer can use most standard filaments, but not some high-level ones.

The Creality Ender 3, along with most other Creality 3D printers use a 1.75mm diameter filament.

The diameter size of the filament to be used with your 3D printer should be included in its manual or specifications.

You should note that not all 3D printers use filaments. Some 3D printers use only resins. An example of resin-based printer is the Elegoo Mars 2 Pro printer which wouldn’t be able to use filament.

Many users prefer filament-based 3D printers over resin-based ones, but it depends on what types of 3D prints you want to create. Filament 3D printers are better for functional, stronger models, while resin printers are best for high quality, decorative models.

Check out the video below for a comparison between resin and filament printers.

Presence of Heated Bed or Heat Chamber

Some popular filaments like PLA, PETG and ABS can be printed by most 3D printers because these filaments have low melting point. A standard Ender 3 or filament 3D printer would be capable of 3D printing these materials, as long as it had a heated bed and decent hotend.

A standard Ender 3 or filament 3D printer would be capable of 3D printing these materials, as long as it had a heated bed and decent hotend.

PLA is the most commonly used filament because it doesn’t require a heated bed or a high printing temperature. It’s also the easiest filament to print with successfully.

For advanced filaments such as Nylon and PEEK with higher melting points, a high bed temperature and sometimes a heat chamber is required to maintain high temperature while printing the filament.

PEEK has a melting point of about 370 – 450°C and therefore requires a high-end 3D printer to be used. PEEK requires a minimum of 120°C bed temperature. It commonly used in aerospace and automotive engineering.

Most users like PEEK because it is incredibly strong but claim it is impractical for an average user because of its very high cost.

The video below shows an example of the Instasys Funmat HT printing PEEK.

Type of Nozzle of the 3D Printer

If you have a brass nozzle and you wish to use your 3D printer with tougher filaments like Nylon, Carbon fiber PLA or any abrasive filament, you should replace the brass nozzle with a stronger nozzle. Most people recommend a hardened steel nozzle or even the special Diamondback Nozzles.

It allows you to 3D print standard filament and abrasive filament without having to change out the nozzle.

Diameter of the Filament

Filaments are available in the two standard diameters of 1.75mm and 3mm. Most Creality 3D printers and the Ender 3 series of printers use a 1.75mm diameter filaments while Ultimaker printers such as the Ultimaker S3 use 3mm diameter filaments (also known as 2.85mm).

Most users people prefer 1.75mm diameter filament to 3mm diameter filament because it has more extrusion accuracy. It is also cheaper, less prone to snapping and more common than 3mm diameter filaments

It is also cheaper, less prone to snapping and more common than 3mm diameter filaments

Most users don’t advise using filament diameter size different from the 3D printer manufacturer’s recommendation as it involves replacement of some printer’s parts such as its hotends and extruder.

You can watch the video below for a comparison between 1.75mm and 3mm diameter filaments.

Printing Temperature of the Filament

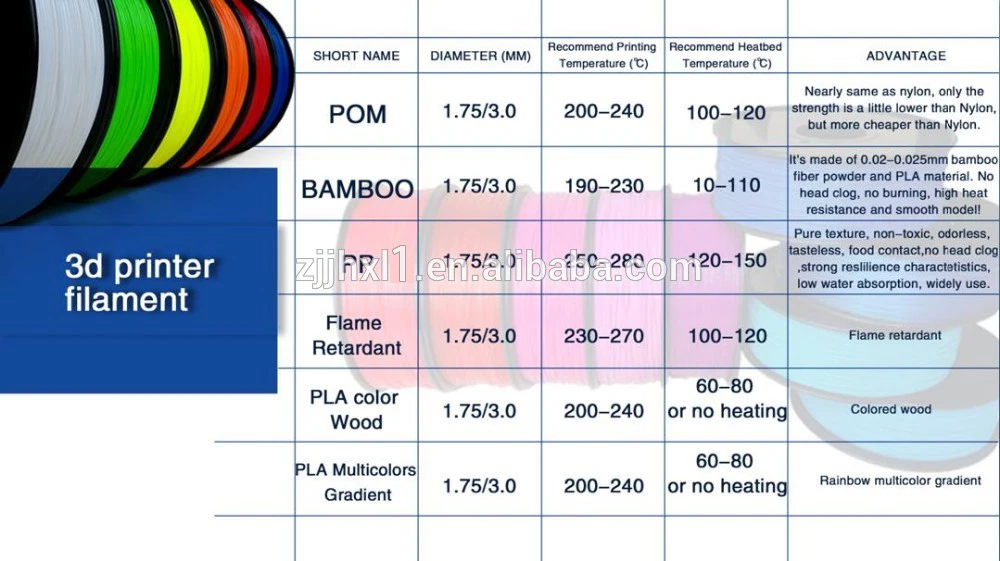

Each type of filament has its own melting point. All standard filament 3D printers can print PLA because of its low melting point, as well as ABS and PETG for machines with a heated bed.

For a tougher filament like Nylon with a printing temperature of around 220-250°C or PEEK at about 370-450°C, an Ender 3 printer wouldn’t work as they can only reach around 260°C with adjustments.

To effectively print PEEK, you need professional 3D printers like the Intamsys Funmat HT or Apium P220, which are expensive.

Most users suggest buying a more powerful printer rather than upgrading parts if you plan to use High Temperature filaments.

A user replaced the extruder housing with Carbon-PC material, hotend, heater and thermistor of his Prusa MK3S 3D printer just to print PEEK.

Check out this CNC Kitchen video for a comparison between PLA, PETG and ASA filaments.

Can You Use 3D Printer Filament in a 3D Pen?

Yes, you can use 3D printer filament in a 3D pen. They both use the standard 1.75mm filament, while some older 3D pen models use 3mm filament. Most people recommend to use PLA filament for 3D pens since they have a lower melting point. You can also use ABS which is a stronger filament, but it has a strong odor.

Most people recommend to use PLA filament for 3D pens since they have a lower melting point. You can also use ABS which is a stronger filament, but it has a strong odor.

A great 3D Pen to use is the MYNT3D Super 3D Pen from Amazon. It comes with PLA filament refills with multiple colors and a mat kit to create objects on. There are speed controls for better flow regulation, as well as a temperature adjustability for PLA and ABS.

Can You Make Your Own 3D Printer Filament?

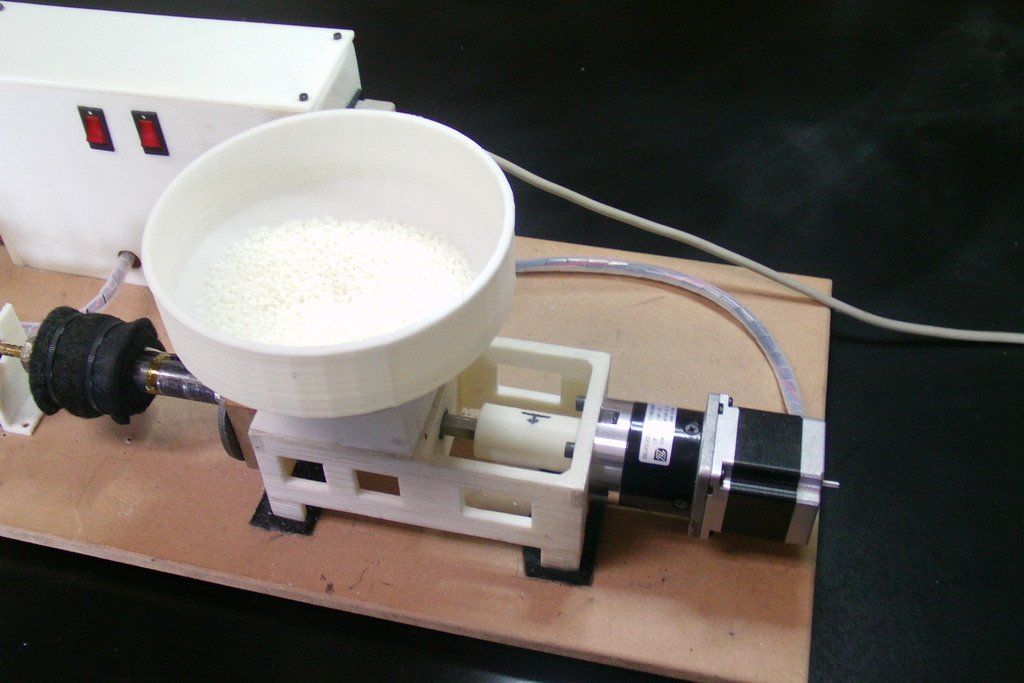

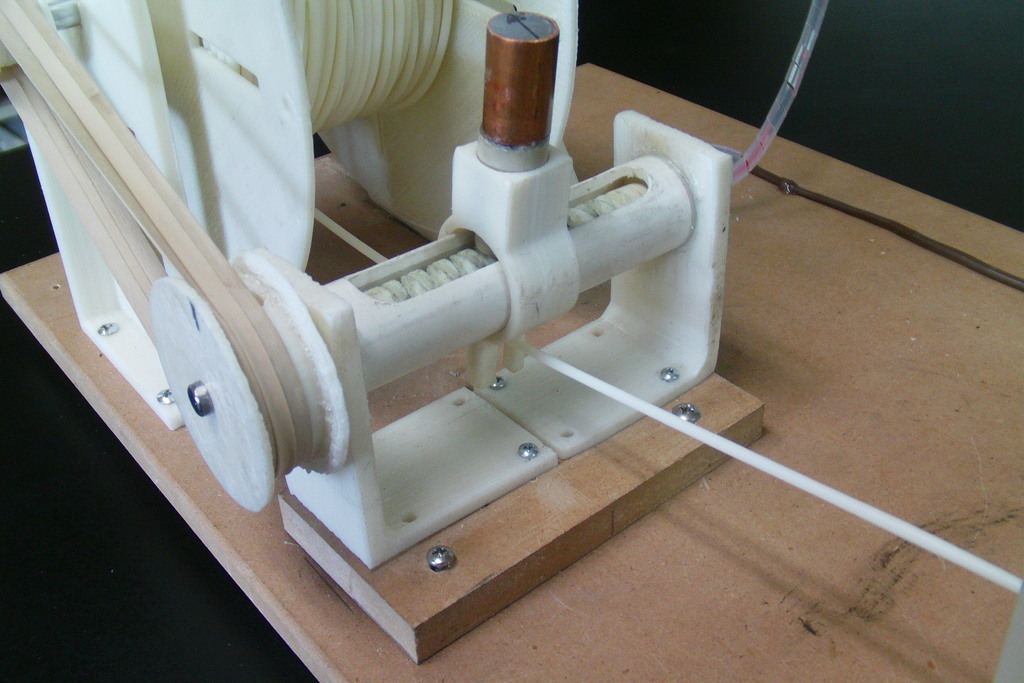

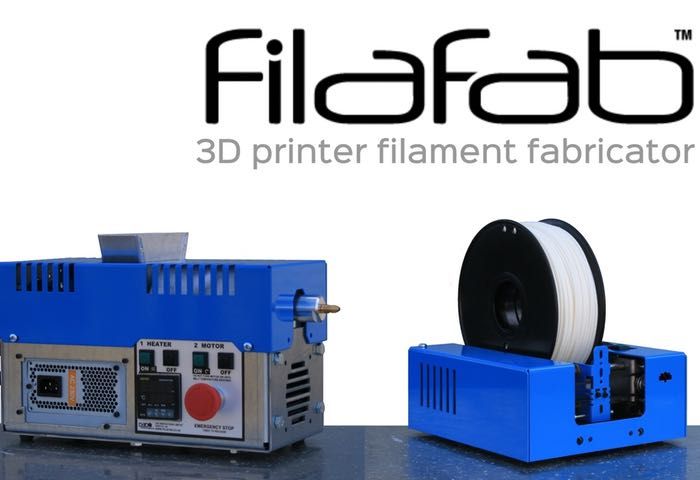

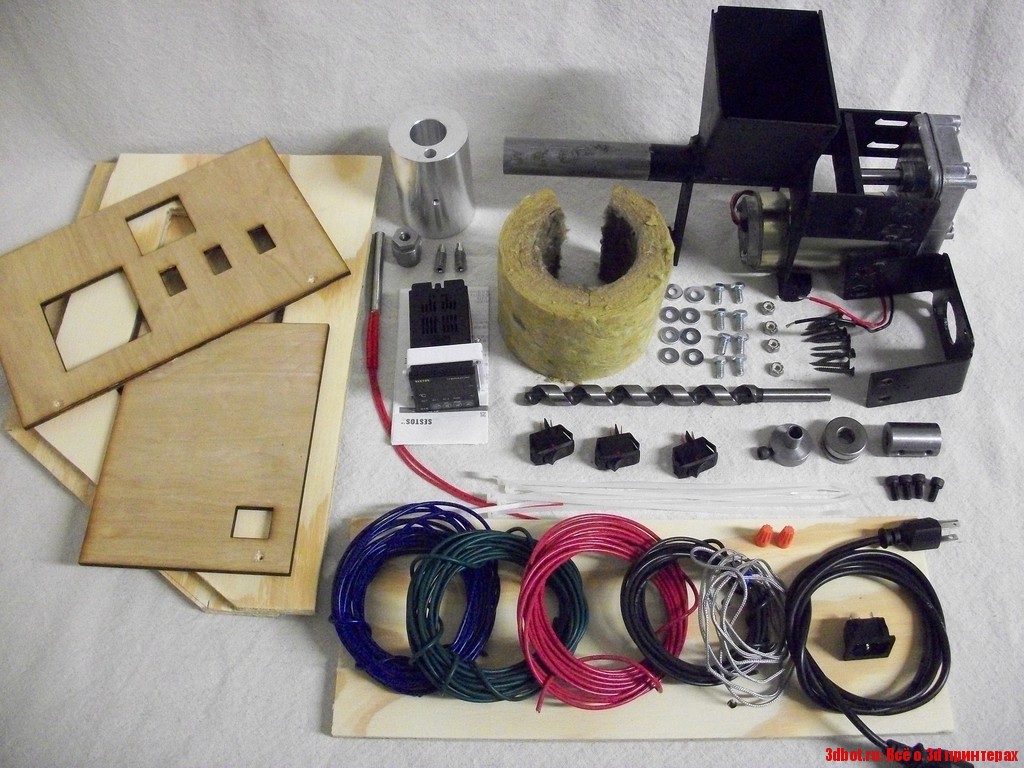

Yes, you can make your own 3D printer using a specialized filament extruder like the 3DEvo Composer and Precision Filament Makers, along with plastic pellets that get melted down and extruded through the machine to create filament.

So, you’ll need:

- Filament Extruder

- Plastic Pellets

Each item is explained below:

Filament Extruder

This is the machine that processes the pellets into filament.

The Filament Extruder heats the plastic pellets until it becomes molten. The molten pellets then come out of the nozzle of the machine and is the pulled to the user’s selected diameter (either 1.75mm or 3mm). The machine has a holder unto which a roll can be attached for spooling the filament.

The molten pellets then come out of the nozzle of the machine and is the pulled to the user’s selected diameter (either 1.75mm or 3mm). The machine has a holder unto which a roll can be attached for spooling the filament.

Creating your own filament isn’t really a beginner-friendly option since it requires consistency and a large scale to make it worth your while. If you have been 3D printing for a while and you know you need a lot of filament, this could be a worthy investment.

One user mentioned that you’d be spending a lot of money and hours tinkering with things to get it to work up to standard. You might be able to save around $10 per KG of filament, which doesn’t save you much unless you’re printing a lot.

Check out this really cool video from CNC Kitchen on making your own filament from home.

Plastic Pellets

This is the raw material fed to the filament extruder to be processed.

Each filament type has its corresponding plastic pellets. The most common types of pellets used to made filaments are PLA and ABS plastic pellets.

Plastic pellets are cheaper when compared to filaments, but it could be a hassle to get it processed to an ideal filament for 3D printing. It may also be difficult to acquire some types of pellets. An example of difficult pellets to acquire is Masterbatch pellets.

To get colored filament, you have to mix the plastic pellets with a small percentage of Masterbatch pellets before filling it into the hopper of the filament extruder.

Some users recommended Alibaba to order the uncommon plastic.

How to Take Filament Out of a 3D Pen

To take filament out of a 3D pen, follow the following instructions in order:

- Make sure the 3D pen is powered on

- Make sure the 3D pen’s extruder is at the appropriate temperature. The temperature is indicated on a digital screen on the pen, accompanied by two buttons to adjust the temperature.

Press and hold extrude button to preheat the 3D pen to the selected temperature. Most 3D pens use indicators to show the user that the 3D pen has reached the selected temperature. For most 3D pen this indicator is a green light.

Press and hold extrude button to preheat the 3D pen to the selected temperature. Most 3D pens use indicators to show the user that the 3D pen has reached the selected temperature. For most 3D pen this indicator is a green light. - Press and hold the extrude button. The extrude button is the button that releases molten filament from the nozzle of the 3D pen.

- Pull on the filament slowly until it freely moves out of its hole.

- Release the extrude button

You can watch the video below to learn the basics of a 3D pen.

Can 3d printers use any type of filament? – 3D Solved

If you already own a 3d printer, you are surely aware of PLA and even ABS. Perhaps, you already tried printing other less popular filaments, like PETG, TPU, and ASA, among others. Before you buy a spool of these, you may find it usefull to know if your 3d printer is compatible with that specific thermoplastic.

Before you buy a spool of these, you may find it usefull to know if your 3d printer is compatible with that specific thermoplastic.

In short, what types of filaments can you print with a regular 3d printer?

Both Bowden-Type and Direct Drive 3d printers are able to print ABS, PLA, PETG, ASA, TPU, and PTE, although Bowden printers generally have a tougher time printing with flexible filaments because they can’t as easily be pushed through the Bowden Tube. It is also usually recommended to use more resistant nozzles to print with abrasive filaments

Table Of Contents

- Filaments most consumer-grade printers can print

- Filaments you can use with Bowden and Direct Drive extruders

- Filaments you can print without an enclosure

- Filaments that require higher extrusion temperatures

- Filaments you can use with the most common nozzle types

- Check out our recommended products section

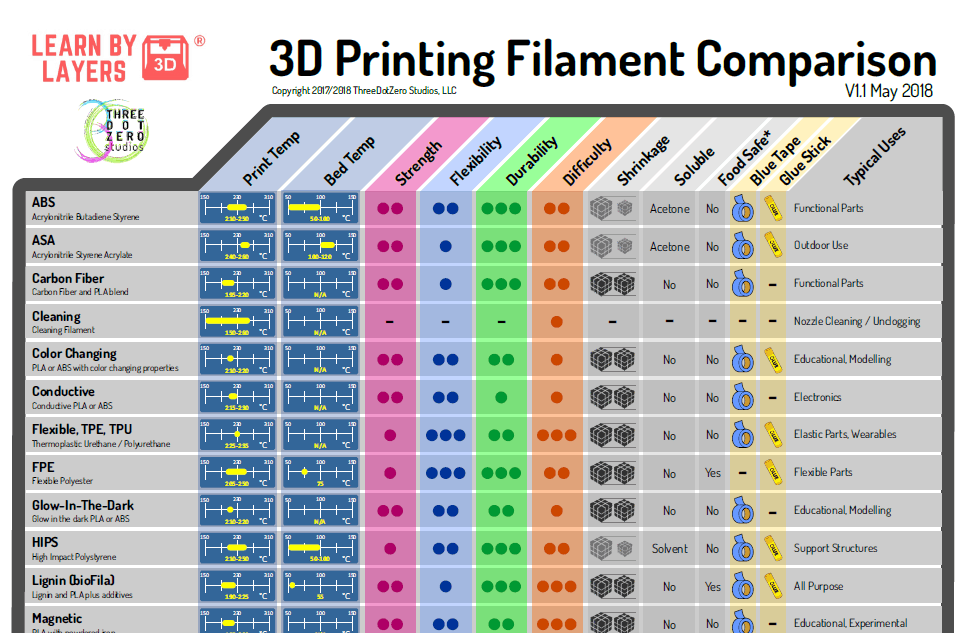

Filaments most consumer-grade printers can print

The kind of filament that you’ll be able to use for your printings will highly depend on your extruder type, nozzle material and if you are using an enclosure or not. Nonetheless, there is a broad spectrum of popular thermoplastics that almost any printer setup will be able to successfully print

Nonetheless, there is a broad spectrum of popular thermoplastics that almost any printer setup will be able to successfully print

These would essentially be PLA and ABS, PETG, for printers such as the Ender 3 and other similar desktop 3d printers. Other materials such as Nylon, Polycarbonate, and even TPU are definitely printable on these types of machines but generally require some modifications like changing from Bowden to Direct Drive extruders, replacing the hot end for one that can achieve higher temperatures, getting a more durable nozzle, and using an enclosure for the printer.

You should always take into consideration the temperature at which your filament melts. Most PTFE tubes that come with the printers that use a Bowden setup can’t sustain high temperatures for prolonged periods and can turn black and get ruined, so if you are going to be printing over 240°C in most cases you will need to replace the factory PTFE tube with a higher quality one for high temperatures. That won’t be a concern if you are using a Direct Drive setup.

That won’t be a concern if you are using a Direct Drive setup.

Here’s a quick list of the filament brands I’d recommend:

- Sunlu PLA

- Polymaker ABS

- Sunlu PETG

Filaments you can use with Bowden and Direct Drive extruders

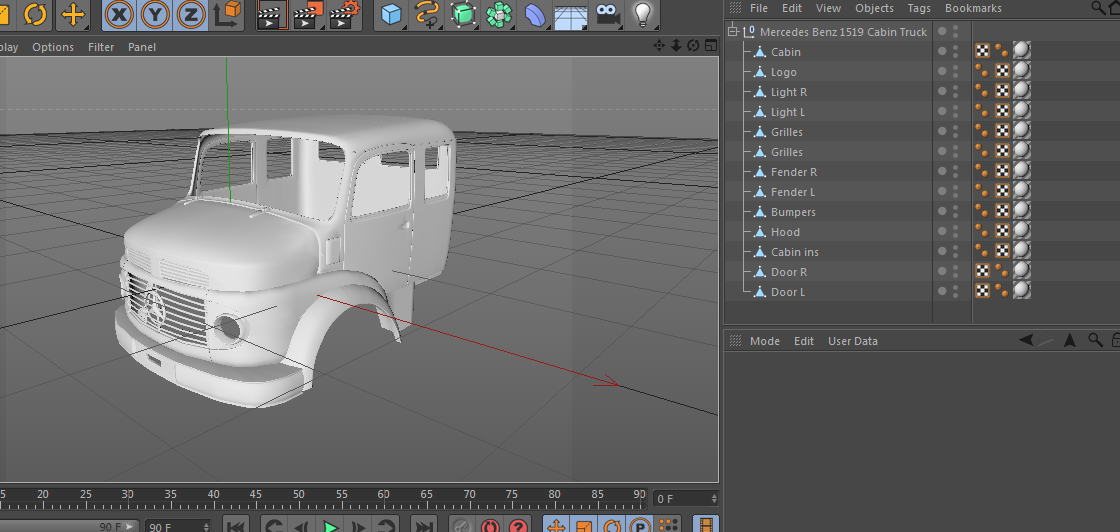

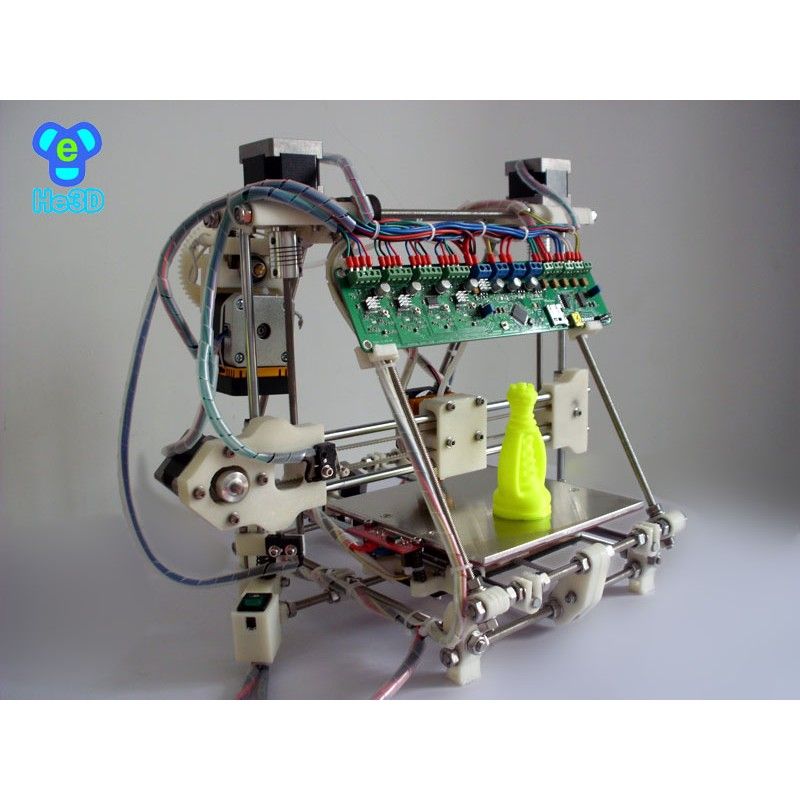

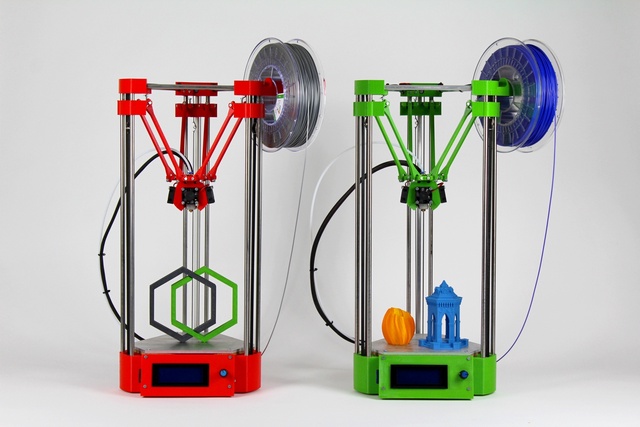

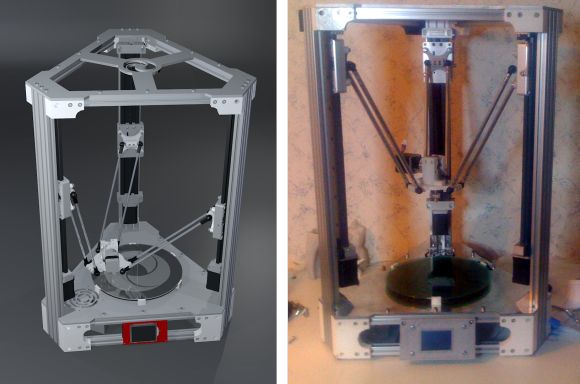

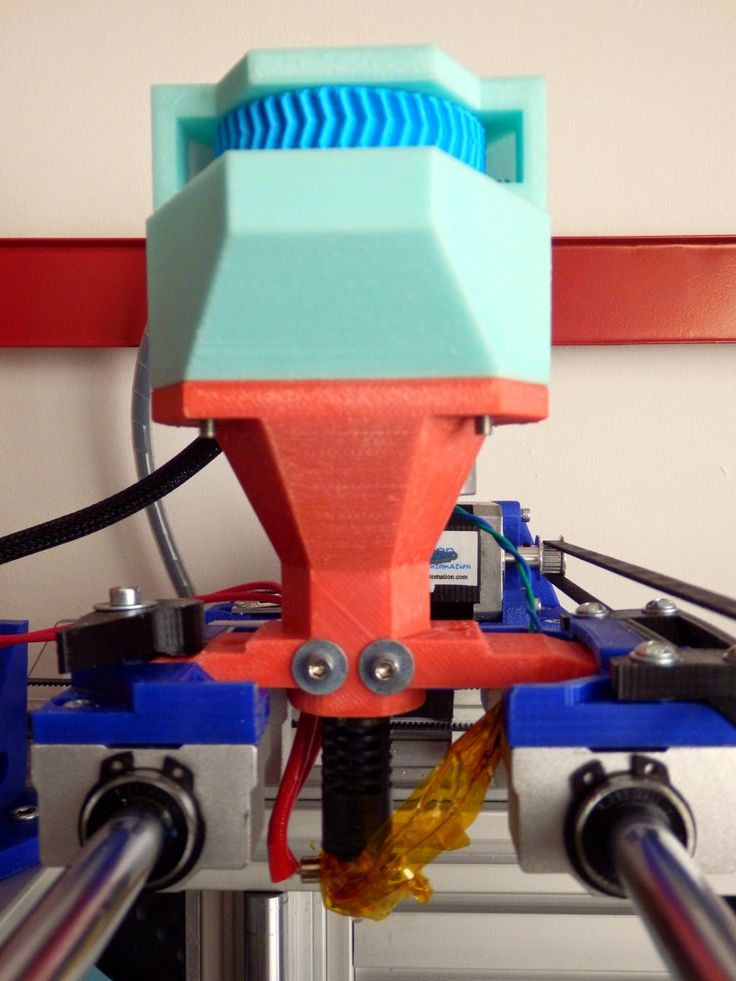

A visual representation of a Bowden Type and Direct Drive 3d printerIf you own a Fused Deposition Modeling (FDM) printer, you either have a Bowden or Direct Drive extruder setup. In a Bowden system, the drive gears and the hot end are separated. The drive gears are usually mounted on the printer’s frame and push the filament through a PTFE tube into the hot end.

On the other hand, a Direct Drive system has the drive gears mounted on top of the hotend and from there it pushes the filament directly into the nozzle. They both accomplish the same function but every system has its own advantages and disadvantages.

Bowden systems usually require more acceleration and retraction to compensate for the friction in the PTFE tube but since the drive gears and the hot end are separated there is much less weight on the nozzle resulting in faster and more precise prints. The downside of a Bowden system is that it is more limited when it comes down to the different types of filament you can use since abrasive and flexible filaments can stick and damage the PTFE tube.

The downside of a Bowden system is that it is more limited when it comes down to the different types of filament you can use since abrasive and flexible filaments can stick and damage the PTFE tube.

Direct Drive setups have heavier printheads since the drive gears are mounted over the hot end thus causing more wobble and sometimes inaccuracy in movements. On the other hand, Direct Drive extruders have fewer extrusion or retraction-related issues and can use a wider range of filaments.

In a nutshell, and although it is possible to obtain good results, Bowden-type printers are not suitable for printing flexible or abrasive filaments. The most popular flexible in the 3d printing space is currently Thermoplastic polyurethane, better known as TPU. By “abrasive filaments” I mean thermoplastics that have some percentage of other materials, such as wood or some type of metal.

It’s worth noting, however, that not all TPU is created equal and there are some harder TPU’s that you can print with a Bowden extruder, but you will have a hard time printing something like NinjaFlex since it’s almost like a rubber band, and try pushing that through the tube.

I have an entire guide on how to print TPU with an Ender 3 (Bowden-type printer) that you should absolutely check out.

Filaments you can print without an enclosure

Most consumer-grade 3D printers are designed and shipped without an enclosure as it reduces the costs, weight, and size of the machine. An enclosure protects your prints from drafts and temperature changes as well as keeping the dust away and containing the fumes emitted by some of the filaments when printing. The stable temperature inside the enclosure is very helpful to print with some filaments but it isn’t a requirement for many of them.

You can perfectly print PLA, PETG, TPE, and TPU without an enclosure. On the other hand, filaments like ASA and ABS are recommended to be printed with an enclosure, but you can still print small models with those filaments. Larger models printed with ASA or ABS will most likely warp without an enclosure.

If you’re looking for an affordable and non-flammable enclosure, then I’d recommend trying this one by Creality.

Filaments that require higher extrusion temperatures

Different printers have different maximum printing temperatures and mainly determine how hot the hotend can get. This which will determine the array of filaments that a given 3d printer print (as will the nozzle, and if it’s Direct Drive or Bowden). The higher temperatures a hot end can achieve, the more filament types you will be able to print with.

Although the manufacturer specifications often state high temperatures, such as 280°C for the Ender 3, there are other limiting factor that will limit the range. For example, if you use a Bowden-Type printer, printing at temperatures over 240°C or 250°C should be avoided if you are using a low-quality PTFE tube.

If you are willing to replace your hot end with one that can get higher temperatures, you will most likely need to also adjust the restrictions on your printer’s firmware to be able to raise the max temperature safety feature. Also, some hot ends distance the PTFE tube from the heat block with a heatbreak so you don’t have to worry about the PTFE tube getting damaged.

Also, some hot ends distance the PTFE tube from the heat block with a heatbreak so you don’t have to worry about the PTFE tube getting damaged.

Most hobbyist 3d printers, even the ones that are in the “prosumer” category, are not able to achieve the required temperature for printing PC-ABS, Polycarbonate, and other popular thermoplastics used by industrial-grade 3d printers.

Filaments you can use with the most common nozzle types

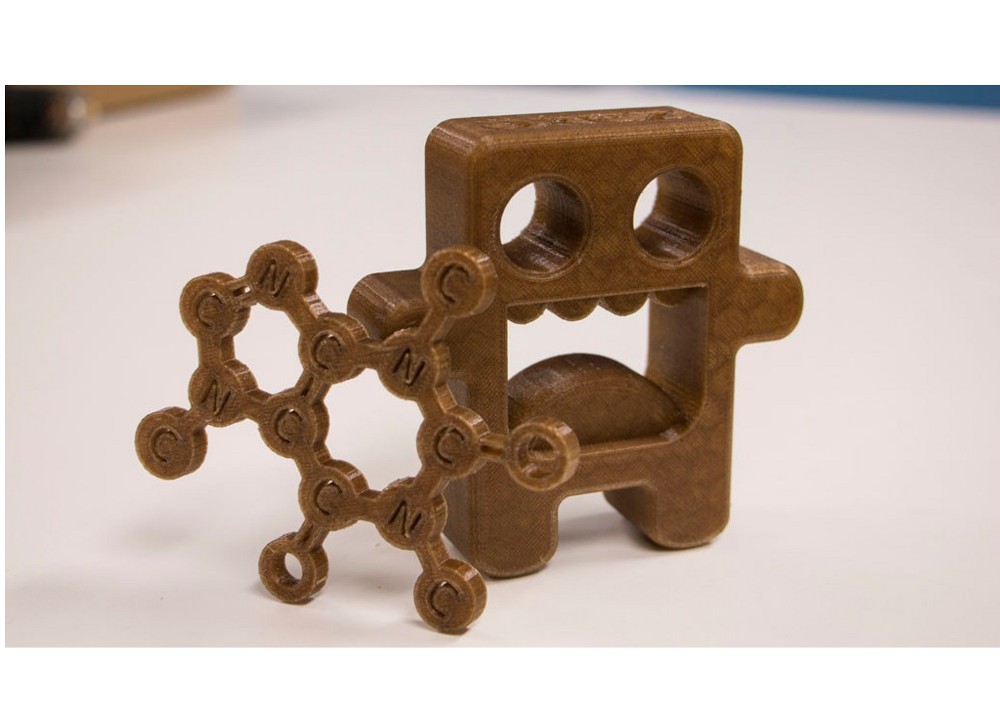

An Elephant printed with Wood-Fill Filament. Its composition makes it an abrasive thermoplasticIf you’ve never heard about different nozzle types, you probably have a brass nozzle installed on your 3d printer. You may be interested in knowing that nozzles are also made from stainless steel, hardened sttel and even ruby. Each nozzle type serve a different purpose, and obviously comes at a different price tag.

Different nozzle types are also better suited for printing with different filaments, so I find it important to briefly go through each one of them.

Brass Nozzle

Brass nozzles are the most commonly used nozzles. Brass is a great heat conductor so the temperature of the nozzle will be much closer to the temperature of the heater block making it easier to print with this nozzle.

On the downside, brass is also a relatively soft metal so you should avoid any abrasive filaments as they will damage the nozzle and decrease the printing quality, even to the point where the nozzle is no longer usable.

Unless you want to print with an abrasive filament, a good quality brass nozzle is definitely the go-to choice, since they are cheaper, faster, and produce outstanding prints. I always recommend brass nozzles when printing with PLA, ABS, PETG, NYLON, and TPE.

Stainless steel nozzle

Stainless steel nozzles are more durable than brass nozzles, and can therefore be used to print with abrasive filaments (although they aren’t as good as the hardened steel ones for this purpose).

Their thermal conductivity falls short when compared to brass nozzles, which means that you will probably need to adjust your temperature settings and perform some tests until you arrive at the right parameters. Additionally, I also recommend first trying to print with lower movement speeds.

Additionally, I also recommend first trying to print with lower movement speeds.

Most importantly, stainless steel nozzles have been declared food-safe by the FDA, so you can use them for projects where food will be involved. Stainless steel nozzles can be used for any filament but it is still not recommended for heavy and repeated use of abrasive filaments.

Hardened steel nozzle

Hardened steel nozzles are extremely durable and can sustain heavy printing sprints with abrasive filaments for long periods before you will need to replace them.

On the downside, these nozzles have even lower thermal conductivity than stainless steel nozzles, which means that they will take longer to achieve the desired temperature and thus you will need to adjust temperature settings. The inside of these nozzles is not as smooth as the others, resulting in a lower printing performance when compared to other nozzle types.

You should consider using hardened steel nozzles to print with abrasive filaments like NylonX, Wood-Filled, Metal-Filled, Ceramic-Filled, Wax-Filled, and glow-in-the-dark filaments.

Special mention: Olsson Ruby Nozzle

A closeup of an Olson Ruby NozzleThe Olsson Ruby nozzle is not a common nozzle at all. These nozzles have a brass base with a ruby in their tip. While the brass base allows for good thermal conductivity, the ruby tip is very resistant and can be used with any type of filament even the most abrasive ones.

Given that these nozzles have excellent performance and durability, they are expensive. You should only consider using them if you have very specific printing needs that require almost only abrasive filaments. If you only use abrasive filaments sporadically and mostly print with PLA or ABS, it would be extremely cost-inefficient to use a ruby nozzle.

We created a recommended products section that will allow you to remove the guesswork and reduce the time spent researching what printer, filament, or upgrades to get, since we know that this can be a very daunting task and which generally leads to a lot of confusion.

We have selected just a handful of 3D printers that we consider to be good for beginners as well as intermediates, and even experts, making the decision easier, and the filaments, as well as the upgrades listed, were all tested by us and carefully selected, so you know that whichever one you choose will work as intended.

(There is a solution) Can any filament be used with any 3D printer?

print material tpu

I recently heard that the 3D printing lab at my college can do fused sputtering with ABS and PLA, but I would like to use TPU for more flexibility.

Can TPU filament be fed into the same machine built for ABS/PLA? Or is there no difference? Let's assume that the diameters of the threads are the same.

@William R. Ebenezer, 👍3

Talk

3 answers

Best Answer:

▲ 3

Can TPU filament be fed into the same machine built for ABS/PLA? Or is there no difference? Let's assume that the diameters of the threads are the same.

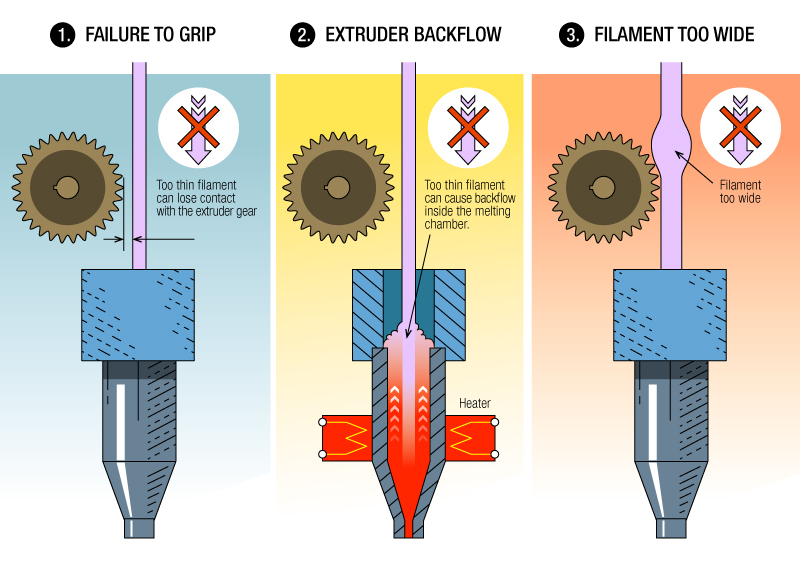

The question is not what the machine is built for, but how it is built . Let's break down some things on why some threads work better than others and the problems with them.

Temperature range

The first obstacle is the temperature range of the printer. For example, if the printer's extruder can't get over 220°C, you can't print ABS. You must ensure that your printer can match the temperature range of your intended filament.

TPU usually prints around between the same temperatures for PLA and ABS, so it should work from that range.

Heated Bed

Most filaments work best with a heated bed, but some are nearly impossible to print without. For TPU, a heated table should be used, but this is not necessary. nine0003

Heated Chamber

Some filaments cannot be printed without a heated chamber, others like ABS benefit greatly from it. As far as I know, TPU is ambivalent about this.

Extruder Unit

There are basically 3 extruder units. Pellet extruders are very rare so we don't worry about them. The other two are Direct Drive and Bowden. In direct drive, the extruder motor sits directly above the hotend and pushes the filament directly into it. In a Bowden setup, the hotend and extruder motor are connected via a Bowden tube. Both have their advantages and disadvantages:

In a Bowden setup, the hotend and extruder motor are connected via a Bowden tube. Both have their advantages and disadvantages:

Bowden makes the carriage lighter, resulting in faster print speeds. Direct drive has far fewer problems with elastic threads and handles retraction much better.

TPU is one thread that works much better with direct drive.

Other Considerations

Some print services print with presses set to one filament only because it prevents nozzle cross-contamination, especially when high temperature media is left in the nozzle the next time low temperature is printed. If, for example, some ABS is left in a printer that is running PLA next, this can lead to very severe clogging. nine0003

, @ Trish

▲ 1

Most printers can print most filaments. However, some of the more exotic filaments are not suitable for all printers:

-

To print a flexible filament such as TPU, the path of the filament from the extruder must be well constrained.

The Bowden extruder is generally less good at handling flexible filaments than the straight extruder. Some straight extruders without a well defined filament path may also be unsuitable. nine0003

The Bowden extruder is generally less good at handling flexible filaments than the straight extruder. Some straight extruders without a well defined filament path may also be unsuitable. nine0003 -

A printer without a heated bed will not be able to print filaments that tend to warp, such as ABS.

-

A printer without a (heated) housing will not be able to print filaments that tend to warp such as polycarbonate

-

A printer with a PTFE lined hot end will not be able to print filaments that require higher temperatures. PETG is on the high end of what can be (safely) printed with a PTFE-lined hot end, while filaments like polycarbonate require temperatures well outside of their usable range. nine0003

-

A printer with a standard brass nozzle will not be able to print (at least not long) abrasive filaments such as glow-in-the-dark filaments.

It is likely that the printer in your lab will handle TPU just fine. If it's a Bowden printer, then you might have some difficulty printing, but it might still work depending on how precise the soft filament is and how well the filament path is constrained.

If it's a Bowden printer, then you might have some difficulty printing, but it might still work depending on how precise the soft filament is and how well the filament path is constrained.

, @ Tom van der Zanden

▲ 3

Regarding your specific question about TPU, any machine that can print PLA should be able to print TPU. The table temperature is even lower, and the required nozzle temperature is about the same. The only potential difficulty is that if the entire path from the extruder to the hotend is not tightly constrained, the soft filament may bend and not advance properly. However, this is not a show stopper - it can almost always be solved with printable upgrades to restrict the path. nine0003

If your printer is equipped with a Bowden extruder, you will have to work quite slowly with the TPU because there is so much room between the extruder gear and the nozzle for the filament to compress that the reaction to advance and retract of the extruder is delayed. But this can largely be resolved by updating the printer firmware to one with a "linear advance" or "pressure advance" feature that compensates. I can print TPU very well at 30mm/s on my Ender 3 firmware updated to Marlin 2.0 with a whopping 5.0 as the linear spring constant. nine0003

But this can largely be resolved by updating the printer firmware to one with a "linear advance" or "pressure advance" feature that compensates. I can print TPU very well at 30mm/s on my Ender 3 firmware updated to Marlin 2.0 with a whopping 5.0 as the linear spring constant. nine0003

, @ R.. GitHub STOP HELPING ICE

How to use leftover 3D printer filament

top sellers

-

Bearing 604UU U604ZZ

U-bearing U604ZZ 604UU 4*13*4

35.00 UAH nine0003

-

Thermal mat for 3D printing 200 x 200 mm

3D printing thermal pad

150.

00 UAH

00 UAH -

Buy epo3d+ 3D printer nine0016

Epo3d+ Ukrainian FDM 3D printer on HIWIN rails. Thanks to reliable...

UAH 35,000.00

-

ABS granules

ABS granules for extrusion

400.00 UAH nine0003

-

PLA

PLA environmental plastic from Plexiwire. 100% advance payment....

UAH 375.00

-

Buy ABS plastic (ABS) nine0016

ABS plastic from Plexiwire.

100% prepayment. Free shipping...

100% prepayment. Free shipping... UAH 220.00

-

Mini motor reducer 12v 100 rpm

high torque mini electric motor. Its size...

150.00 UAH

-

Nozzle for 3D printer 1.75 mm, for E3D and MK8 hotends

Nozzle for 3D printer 1.75 mm 0.2/0.3/0.4/0.5

35.00 UAH

nine0073 -

PETG plastic for 3D printer

PETG plastic from Plexiwire. 100% prepayment. Free...

UAH 360.00

-

SHF-20 shaft support nine0016

SHF-20 shaft support is used for CNC

60.

00 UAH

00 UAH -

A4988 stepper motor driver

35.00 UAH

nine0070

Buy epo3d 3D printer

Ukrainian epo3d 3D printer built on the basis of modern kinematics...

UAH 18,000.00

All best sellers

Information nine0003

How to use the leftover plastic filament for a 3D printer

The leftover thread has accumulated, which is a pity to throw away and is not enough for a full-fledged model, read this article and maybe you will find a use for them. Here are some helpful tips for using small pieces of filament.

1. Recycling

If you properly sort the 3D filament by type, you can recycle it. The first thing to do is break up the pieces. You can use the manual method with wire cutters and scissors, but this is a very labor intensive process, or use a shredder such as a minishredder. Then you will need an extruder, with its help you will get a solid thread. Now you can safely print any model. Plastic recycling is also suitable for unsuccessful models that are usually thrown away. nine0003

The first thing to do is break up the pieces. You can use the manual method with wire cutters and scissors, but this is a very labor intensive process, or use a shredder such as a minishredder. Then you will need an extruder, with its help you will get a solid thread. Now you can safely print any model. Plastic recycling is also suitable for unsuccessful models that are usually thrown away. nine0003

2. Welding plastic

The 3D pen is a great way to join two parts of the same model. Use the remnants of the thread as a material for welding, even small pieces will be enough. If you don't already have a 3D printing pen, use a soldering iron like in the picture below. Then a little processing, in the form of grinding, and the seam will be almost invisible.

3. Pins and loops

One way to connect parts of a 3D model is to use wooden or metal staples, but if these are not available, you can replace them with pieces of filament. A 3cm diameter would work better for this task, but 1. 75cm is fine, it just takes a bit of experimenting with the hole sizes. nine0003

75cm is fine, it just takes a bit of experimenting with the hole sizes. nine0003

4. Replacing the filament

Just because you don't have a big enough piece for the model you want is not a reason to cancel everything. We have several solutions.

- Completely manual method. This is the most risky option, because it is very easy to miss a break. To signal the end of the filament, hook some object from its other end, and when it falls, you will know that the thread will soon end, but this option takes a lot of time, because you need to be constantly on the alert. I prefer not to use this option as it requires a lot of attention so as not to miss the time for a replacement. nine0073

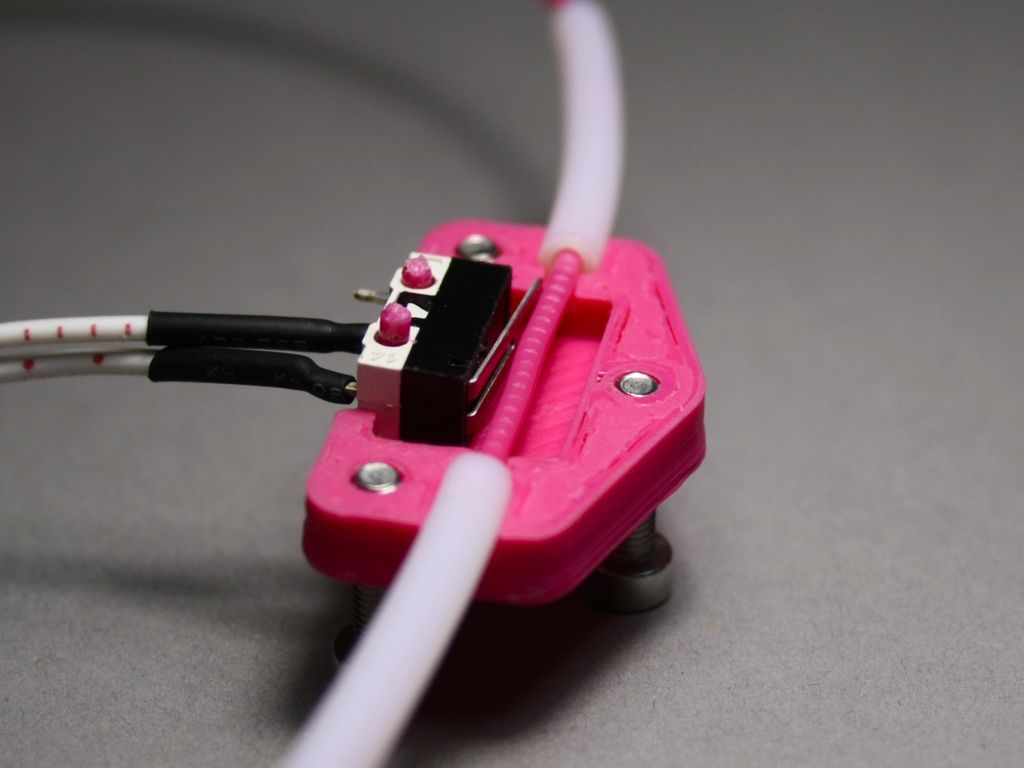

- Break sensor. It is much more efficient to install a break sensor for a 3D printer that will signal when the filament runs out and automatically stop printing. Printers with multiple extruders sometimes have a function to automatically switch the working extruder

- Mosaic palette.

Learn more