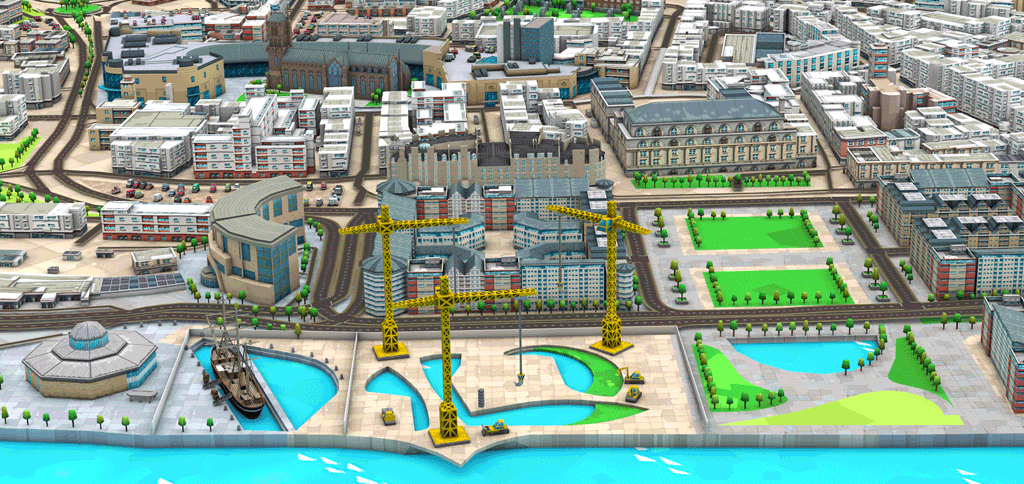

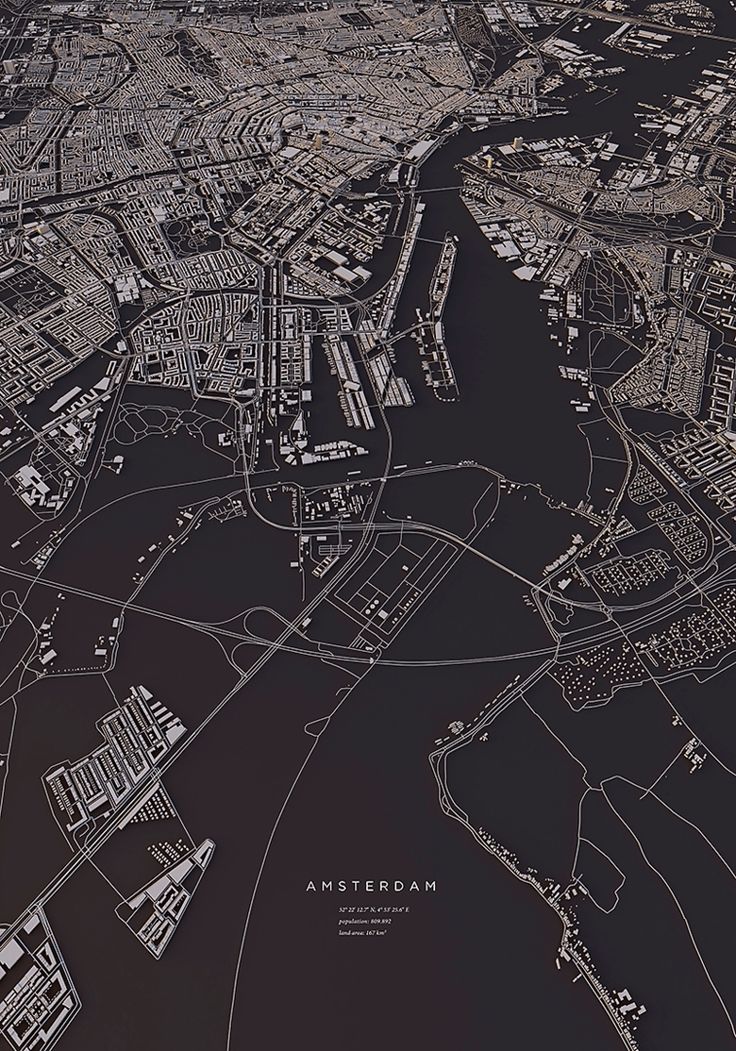

3D print city from google maps

How to Create 3D Printable Maps Using Touch Mapper

Summary

This blog post will explain how to use Touch Mapper to create maps that can be printed on a 3D printer.

Touch Mapper is a website that enables you to create tactile maps. You can create maps that can be printed on a 3D printer, tactile graphics embosser, or swell paper. This post focuses exclusively on maps that can be 3D printed. It explains how to create and download an STL file that contains a map for a specific address. Loading an STL file into 3D printing software and printing it is beyond the scope of this post.

The maps you create using Touch Mapper may contain buildings, roads, sidewalks, and water features such as streams, rivers, and lakes. The objects represented in a map may vary by location based on the contents of the underlying data source which is Open Street Maps.

Touch Mapper supports many options. This is true for most products. Lots of options means lots of flexibility. However, lots of options also creates complexity which can be overwhelming. For example:

- How do I choose between all of the options?

- How can I use the product to solve specific problems?

- If I use the product to solve a specific problem, what options should I use and how should I use them?

Based on my initial experimentation with Touch Mapper, I think it works well for at least one use case that I’ll discuss in this post. I may include additional use cases in the future.

USE Case: Large scale map of a destination

Description

This use case produces a map of a destination such as a building as well as the area immediately surrounding the building. The surrounding area may include roads, intersections, and sidewalks.

Benefits to Map Creator

This use case requires only a few simple options. You do not need to use any advanced options.

Benefits to pedestrians with visual impairments or blindness

The map may enable pedestrians with VIB to create a mental map of the building and the surrounding area. The mental map can be very helpful if the pedestrian is travelling to the destination for the first time or they need to refresh their memory of the destination.

The mental map can be very helpful if the pedestrian is travelling to the destination for the first time or they need to refresh their memory of the destination.

Pedestrians with VIB may be able to discern the following information from the map:

- The approximate size and shape of the building.

- The location of entrances to the building.

- The location of the building in relation to nearby roads and intersections.

- The existence of nearby buildings as well as their size and shape.

- The path of sidewalks that approach the building.

- The location of sidewalks in relation to adjacent roads and intersections. For example, is there a sidewalk on both sides of Main Street? Note that sidewalks are higher than roads.

Limitations

The biggest limitation of Touch Mapper is that the map does not include any text or labels. As a result, the map has limited value by itself. Therefore, I recommend that the map creator also creates a written description to accompany the map. Together, the map and a thoughtful written description can enable independent exploration by pedestrians with VIB. See guidance below regarding written descriptions.

Together, the map and a thoughtful written description can enable independent exploration by pedestrians with VIB. See guidance below regarding written descriptions.

Step 1: Create the map

- Go to https://touch-mapper.org/en/.

- Enter the address of the destination in the text field and click Search.

- For printing technology, choose 3D printing.

- For print size, choose the largest size your 3D printer will support. Don’t worry about the price that is listed for each size. It is free to download the map and print it yourself.

- For map scale, choose 1:1800. See the note below about this item.

- Do not check hide buildings.

- Click the Create Tactile Map button. Note that it might take a few minutes for your map to be created.

Note: I recommend the 1:1800 map scale for a few reasons. First, this scale seems to provide enough spacing that it is possible to differentiate features that are close together, e. g. a sidewalk and a road that are parallel to each other. Second, at this scale one inch on the map is equal to 50 yards on earth. That’s a round number that is relatively easy to remember. I also encourage you to teach your students how to estimate distances in using yards because a yard is roughly equal to one step for an adult walking at a normal speed. If you do this, one yard equals one step. Hence, one inch on the map equals 50 steps.

g. a sidewalk and a road that are parallel to each other. Second, at this scale one inch on the map is equal to 50 yards on earth. That’s a round number that is relatively easy to remember. I also encourage you to teach your students how to estimate distances in using yards because a yard is roughly equal to one step for an adult walking at a normal speed. If you do this, one yard equals one step. Hence, one inch on the map equals 50 steps.

Step 2: Download the STL file

- After the map is created, click the Download the Map Yourself radio button.

- Click the Download Printable STL File link. That will initiate the download of the STL file to your browser’s Downloads folder.

Step 3: Print the map

This step is outside the scope of this post. It assumes you have access to a 3D printer and you know how to use 3D printing software. If that is not the case, try to find a local maker space or science teacher that has access. In my experience, most Touch Mapper maps require four to five hours to print. This time may vary widely depending on your 3D printer.

This time may vary widely depending on your 3D printer.

Step 4: Finish the map

Notice the map has no writing on it whatsoever. I recommend that you immediately label the map so you will be able to recall what it shows. If you’re sighted, you can do this by writing on the back of the map. If you’re blind, you can braille the description on a large envelope and store each map in its own envelope. At a minimum, your label should include the address of the destination and the map scale.

Place the printed map on a table in front of you. Notice the map has a raised border on each edge. There should be a raised dot on one corner. That is the Northeast corner of the map. I recommend that you orient the map properly so the North edge of the map actually faces North and you also orient your body so you are facing North. In my experience, this practice reduces confusion.

Notice there is a cone in the center of the map. That cone can be very sharp. I recommend that you use a file to round off the top of the cone to prevent injury.

Finally, write a description of the map for your students. The description must include the name and/or address of the destination building and the map scale. In this case, the map scale should be express in terms the student can easily understand. I also recommend that you use cardinal directions to describe objects in relation to the destination building.

Here’s an example description:

- One inch on the map equals 50 yards on earth.

- The North Carolina Museum of Natural Sciences is in the center of the map. The address is 11 West Jones Street, Raleigh, NC.

- Jones Street is just to the north of the museum. It runs east-west.

- Edenton Street is to the south of the museum. It also runs east-west.

- Salisbury Street is to the west of the museum. It runs north-south. It is a one way street in which traffic flows south.

- Centennial Plaza is immediately to the east of the museum. It is a pedestrian plaza that runs north-south between Jones Street and Edenton Street.

- The main entrance of the museum is on the east side of the museum facing Centennial Plaza.

- Wilmington Street is on the eastern edge of the map. It runs north-south. It is also a one way street in which traffic flows north.

By Ed Summers

SHARE THIS ARTICLE

How to print maps, terrains and landscapes on a 3D printer

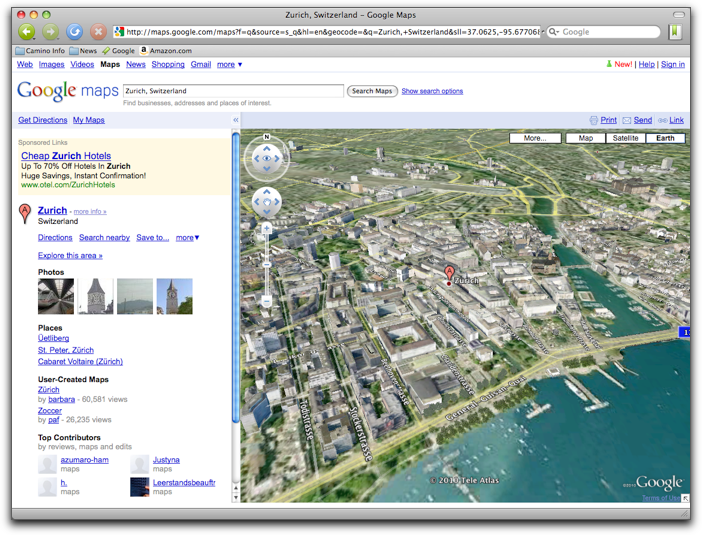

From time to time, every 3D printer owner is asked the same question: “Why is the printer really good and useful? I cannot imagine what would I use it for.” I did not find a satisfactory answer to this simple question at first, because I don’t consider printing figures and statues as the right example. That’s why every time the 3D printing technology is applied in practical use, I’m excited! Today, I’ll show you how to print a 3D map, that can serve in a number of situations not only using our Original Prusa i3 MK3 printer. How about a plastic model of terrain for school education, a small-scale version of a national park, a model that shows the overview of a real-world race track, or perhaps a tiny version of a mountain you climbed in the past. Thanks to these models, we can see the landscape from a bird’s eye view. Input data will be topographic maps that are most interesting for 3D printing purposes.

Thanks to these models, we can see the landscape from a bird’s eye view. Input data will be topographic maps that are most interesting for 3D printing purposes.

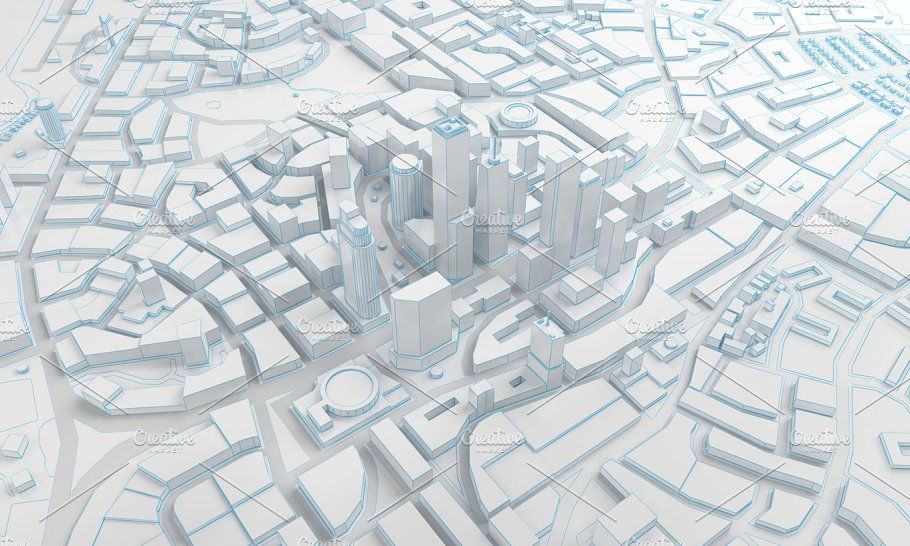

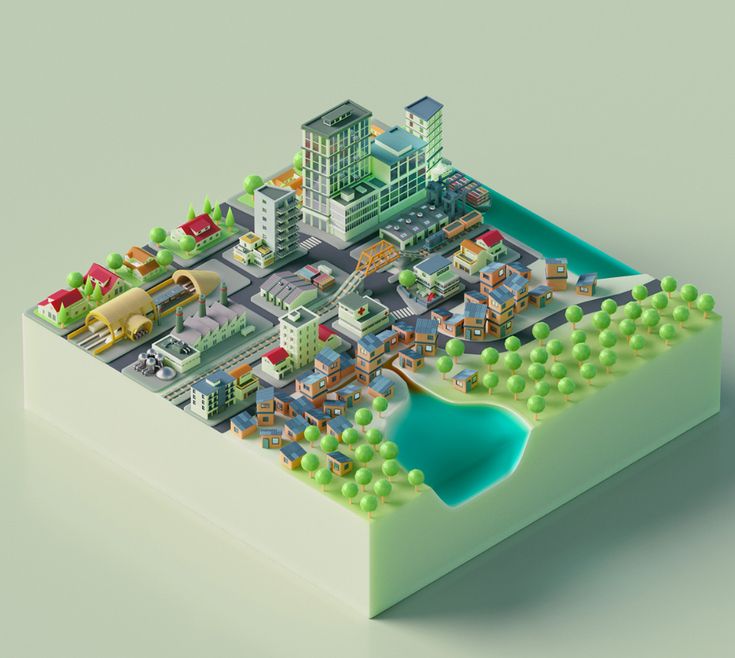

Models based on maps can be divided into two groups:

- Printing a terrain model – ideal for mountain ranges, volcanoes or abysses. So where there are well-known elevations.

- Printing a terrain model including buildings – ideal for cities and areas with buildings.

Terrain models

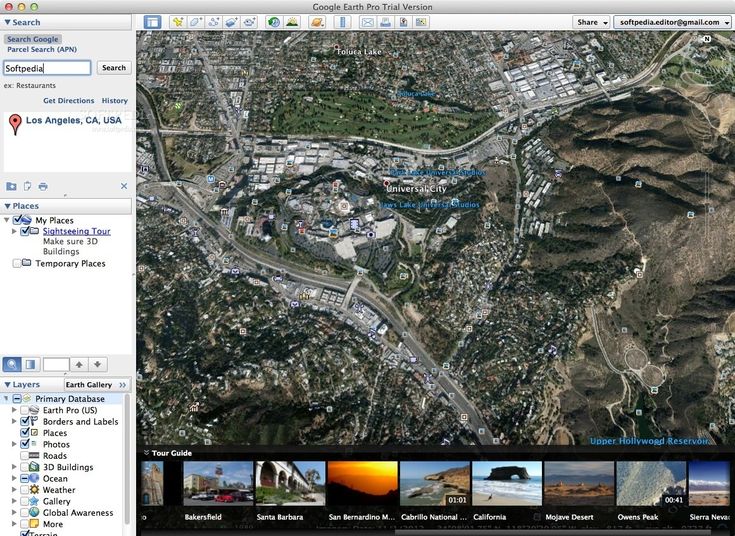

A 3D terrain model (without buildings) can be obtained simply and for free with the Terrain2STL web application.

- Find a place on the map. Rugged terrain works the best.

- On the Location tab, press Center to View. This will show a selection rectangle on the map.

- On the Model Details tab, adjust the size of the selected area by moving the Box Size slider. The selection can be moved in the map.

If the resulting model is very flat, it is possible to scale it on the Z axis. This is done in the Model Details by using the Vertical Scaling slider. However, keep in mind that the resulting model will differ from reality.

If the resulting model is very flat, it is possible to scale it on the Z axis. This is done in the Model Details by using the Vertical Scaling slider. However, keep in mind that the resulting model will differ from reality. - On the Water and Base Settings tab, set the desired model base height.

- Press the Generate Model button. Then click the Download button and download the model.

Does a square or rectangular shape feel way too ordinary? Let’s take a look at how to work with some more complex shapes. Naturally, one of the basic ideas is to use borders of existing countries. For the sample print, I chose the Czech Republic – the home of Prusa Research. A good start is to successfully obtain the STL terrain model from the previous step. However, the disadvantage of the Terrain2STL application is that it is not possible to change the shape of the selection. So, if you want to work with a larger area, you will need to cut the STL model first using a 3D editor and then work with it. This is because the Tinkercad software we want to use limits the size of the imported file to 25MB. A better solution is to use a similar tool like Terrain2STL. The TouchTerrain project allows you to select any aspect ratio on the map. I recommend aligning the map, for example, in the upper left corner for a simpler placement of the shape for the cutout.

This is because the Tinkercad software we want to use limits the size of the imported file to 25MB. A better solution is to use a similar tool like Terrain2STL. The TouchTerrain project allows you to select any aspect ratio on the map. I recommend aligning the map, for example, in the upper left corner for a simpler placement of the shape for the cutout.

How to do it:

- Find and download the desired shape in .SVG format. Ideally, it should be on a white or transparent background. To make searching easier, I recommend adding the keyword “silhouette“.

- In a web browser, open the Tinkercad tool and sign in (or create a free account).

- Create a new design by pressing the Create new design button.

- Create a block (use the “Box” tool on the right) and change the dimensions so it stretches across the entire Workplane.

- Import the downloaded .SVG file with the shape using the Import button in the top right corner.

When the import is complete, the image is automatically converted to a 3D object. Change the shape type to “Hole“.

When the import is complete, the image is automatically converted to a 3D object. Change the shape type to “Hole“. - Click the object with the right mouse button and first adjust its height in the Z-axis so that it is higher than the block. Then, adjust the size of the model by dragging any corner to fit the block. To keep the aspect ratio hold the Shift key.

- Now select both objects (Ctrl + A), group them with the Group button (Ctrl + G) and change to the “Hole” type. This creates a negative shape, which then cuts the terrain.

- Import the terrain model using the Import button in the top right corner and wait for it to finish.

- Adjust the size of the terrain model and place it in the right place in relation to the carved shape.

- Deselect the selection of objects by pressing the mouse outside the print area.

- Export the object using the Export button in the top right corner of the .STL format.

- The model is ready to be sliced, for example, in Slic3r, where it can be scaled in the Z-axis if needed for better terrain visualization.

Download link: The Czech Republic 3D terrain model on PrusaPrinters

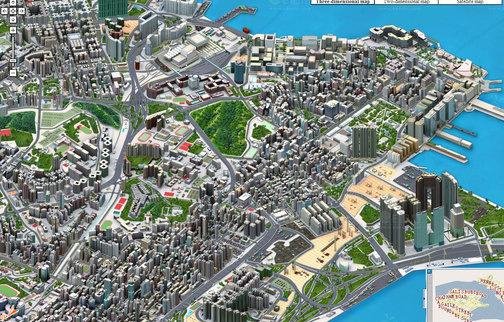

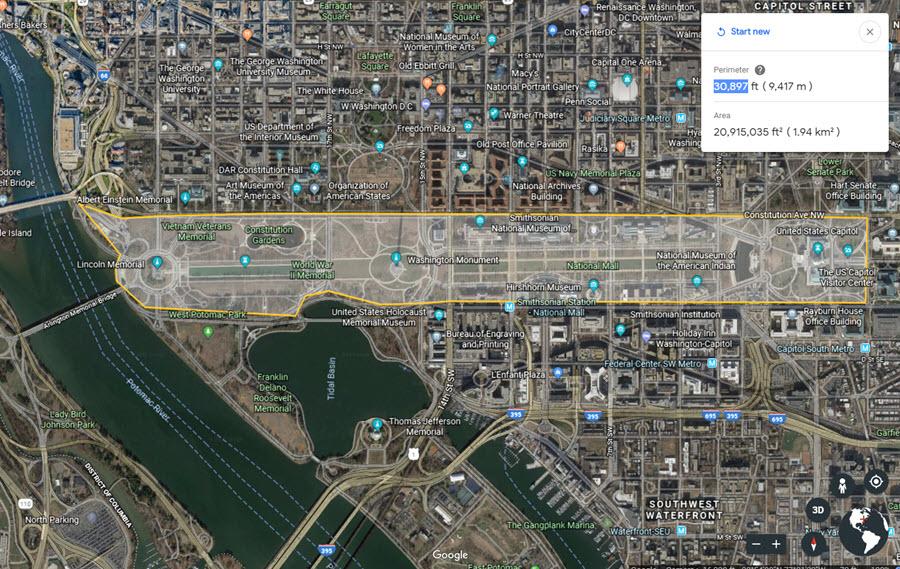

City model with terrainIn this case, the procedure is a little more complex than the terrain itself and more tools need to be used. To get the model, we use the CADMAPPER web tool, which uses freely available maps from OpenStreetMap as a source. The tool allows you to download a 3D model up to 1 km² area for free. Larger areas are paid. In most cases, 1 km² is perfectly fine. By covering the entire print area (25 x 21 cm), we get the ideal scale for the model (approximately 1: 4000 to 1: 5000).

- Open CADMAPPER tool in the browser and click Create a map.

- Select the desired area up to 1 km² (or larger and buy the model).

- Select the output format for SketchUp 2015+.

- Include Topography and 3D Buildings in the output model and choose the height of buildings for which the height in the map is not defined.

- Press the Create button to start generating.

- Press the Download button to download a generated zip file that contains the .SKP file.

The downloaded file is not yet fully prepared for slicing. What we need to do is to create an object under the terrain. In addition, we can simply change the height of buildings in this tool, especially those that have a default value from CADMAPPER. We will use SketchUp Pro for editing, which is free to download in the trial version.

Eneroth Terrain Volume extension is useful when you want to create a solid object under the terrain easily. Download this extension as well.

Add extensions using the Window -> Extension Manager. Press the Install Extension button and select the downloaded file from the previous step.

Now we have everything ready and we can start editing the model.

- Run SketchUp, open the downloaded file from CADMAPPER (File -> Open).

- On the right side of the application window, expand the Layers section and remove all layers except buildings, topography and Layer0. Press the “Delete content” icon. The content of the deleted layers is not easily printable, that’s why we’re deleting them. However, you can play around with the content of deleted layers and see if something interesting comes out of it – we won’t be using them in our guide, though.

- Click anywhere on the terrain to select it. In the top menu of the app select Extensions menu -> Eneroth Terrain Volume. This creates a solid object under the terrain.

- If you want to change the height of the base or buildings, you must explode the model (select the whole model, right mouse button, Explode option), and then the Push / Pull tool to increase or decrease the height of the buildings or the base under the model.

- Export the model using File -> Export -> 3D Model.

The file is now ready for 3D printing. Open it in the Slic3r PE and adjust the size to fit the print area. For an area of 1 km², the approximately square shape of the model is reduced to about 20% of the original size. So we get the model on a scale of cca 1: 5000. We recommend a PLA material and a layer height 0.15mm.

1:5000

1:2500

1:1000

Download link: Prague Castle area on PrusaPrinters

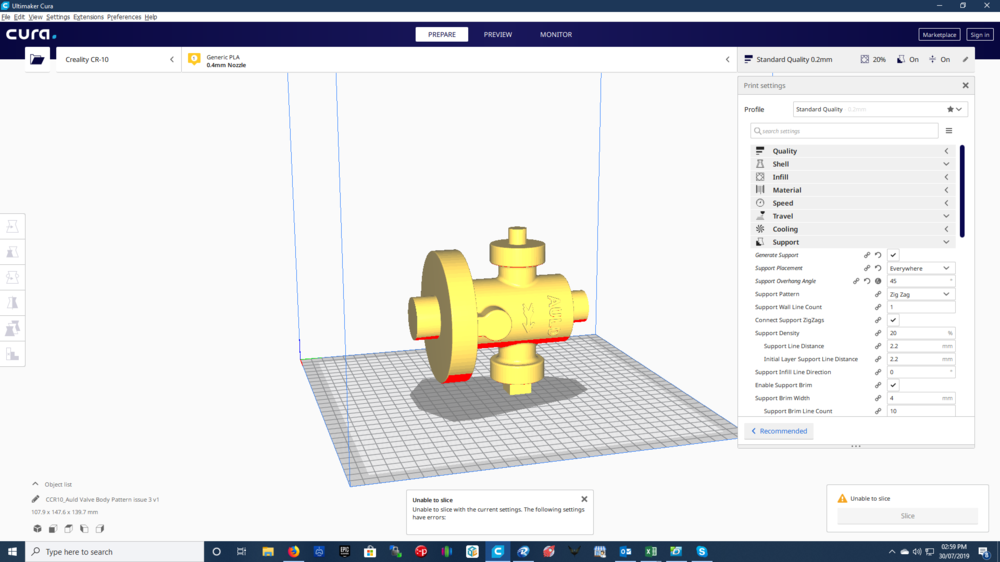

Preparing the model for printing and correct orientationUse Slic3r PE or your favorite slicer tool to generate the gcode file.

Terrain models with at least one straight edge can be printed in two ways, either horizontally or vertically. Each of these orientations has its pros and cons and for each model, it is necessary to decide which orientation to choose. Let’s look at the main differences.

The horizontal positionThis position is natural in the real world. In this position, we are able to print almost any model. In the Z-axis, however, we are limited by the height of the layer. The lowest height of the extruded material is about 0.05mm and the most commonly used nozzle diameter is 0.4mm. The relatively large diameter of the nozzle alone causes “drops” on the peaks. The nozzle diameter also affects edge sharpness.

In this position, we are able to print almost any model. In the Z-axis, however, we are limited by the height of the layer. The lowest height of the extruded material is about 0.05mm and the most commonly used nozzle diameter is 0.4mm. The relatively large diameter of the nozzle alone causes “drops” on the peaks. The nozzle diameter also affects edge sharpness.

We recommend selecting a layer height of 0.15mm and a 15% to 20% infill.

Pros:

- you can print almost any model

- there are horizontal lines on the model that represent contour lines (some may consider this a con)

Cons:

- infill is necessary (longer printing time)

- drops on peaks

- there may be strings between the peaks/buildings

In the vertical position, the biggest advantage is that no “drops” of material on the peaks will be created, and the peaks will be smoother. This makes the surface more detailed and looks much better. The vertical orientation is suitable for models where there are no areas that make an angle with the print area less than about 45°. Supports for such models is not a solution we would recommend.

The vertical orientation is suitable for models where there are no areas that make an angle with the print area less than about 45°. Supports for such models is not a solution we would recommend.

Vertical orientation is also not suitable for printing city-building models, because almost every building would have a perimeter wall parallel to the print surface and therefore the model would be non-printable without supports.

With vertical orientation, it is advisable to choose the most suitable area on which the model will be placed. Choose the one that will touch the bed with the largest possible area. Use the Place on the face button to rotate the model.

We recommend selecting a layer height of 0.15mm and a 0% infill. Infill is not needed in most cases. The printing time will be almost half and you save some material. For best results, use PLA filament.

Pros:

- print without support and infill

- there is no stringing between peaks

- the terrain looks smoother than the horizontal print position

Cons:

- can not be used to print city models

- there’s a chance that it will become loose and that the print will fail

The difference of print in horizontal and vertical orientation is shown in the pictures below.

Our tips for color models:

- Use ColorPrint to change the color of the filament depending on the altitude. Learn how to use ColorPrint in this article.

- Print the model with a single filament and paint it afterward. It depends only on your imagination.

- If you already have Original Prusa Multi Material Upgrade 2.0, you can try to create a color model to distinguish terrain, buildings, waterways and roads.

Feel free to experiment, try various changes and edits, and don’t forget to share the results in our forum.

Mexico has the world's first 3D printed residential area

Not far from a city in southern Mexico, a ten meter printer has recently printed walls for the world's first 3D printed residential area.

At the beginning of December, the printed houses received a roof, windows and interior decoration. New Story, a charity behind the project, believes 3D printing can bring affordable housing to people in the poorest parts of the world. “We believe we were able to prove the reality of this idea by taking this device to rural Mexico where there is seismic activity and being able to print the first houses with it,” says Brett Hagler, CEO and co-founder of New Story.

“We believe we were able to prove the reality of this idea by taking this device to rural Mexico where there is seismic activity and being able to print the first houses with it,” says Brett Hagler, CEO and co-founder of New Story.

Founded five years ago, his company provides housing for people living in extreme poverty. The organization has already built more than 2,700 houses in the traditional way in Bolivia, Mexico, El Salvador and Haiti.

Photo: New Story

After the 2010 earthquake in Haiti, it was difficult to rebuild houses after the destruction, but New Story improved the construction process so that housing could be built faster. The organization realized that with the help of new technology, it was possible to work faster and at less cost. Two years ago, she partnered with Icon to develop a 3D printer capable of printing even under the most difficult conditions.

The printer is called Vulcan II. This is not the first device that can print an entire house. However, a new residential area in Mexico of 50 printed houses will be the first place where this technology has been used on such a scale. Other companies have experimented with building printed houses, but all trials have been conducted in controlled environments or locations with a low risk of natural disasters.

However, a new residential area in Mexico of 50 printed houses will be the first place where this technology has been used on such a scale. Other companies have experimented with building printed houses, but all trials have been conducted in controlled environments or locations with a low risk of natural disasters.

Initially, the New Story team planned to print houses in another part of Mexico, but ran into difficulties - for a long time the organization could not obtain a building permit from the government. Therefore, it was decided to print houses further south, in Tabasco, a state bordering Guatemala. The new location had a higher risk of earthquakes, so the design of the houses had to be finalized.

Photo: New Story

After successful testing, the printer was trucked to the state, but it got stuck in customs for three months. “The device is brand new, obviously it doesn’t exist [in the database],” Hagler explains. When the 3D printer arrived at its destination, the rainy season began. At some point, the entrance to the construction site was flooded, and no one could get there for a week.

At some point, the entrance to the construction site was flooded, and no one could get there for a week.

However, the most important test—whether the printer can print on site at home—succeeded. The printer lays out the concrete mixture in layers, and the floors and walls are obtained. The program monitors the weather conditions and adjusts the mixture accordingly. “The weather can be dry in the morning and wet in the evening, so you have to change the viscosity of the mixture to keep the print quality the same all day,” explains New Story co-founder Alexandria Lafzi.

The printing process is autonomous, the team can only make minor adjustments to the scheme. In this case, you can print several houses at the same time. The first two houses printed at the same time, the total printing time was 24 hours, but it lasted several days because the team only wanted to work during the day. In the future, the authors of the project hope to be able to run the printer for longer periods to speed up the construction process.

The resulting houses have two bedrooms, a living room, a kitchen, and a bathroom, much better than the simple huts the locals live in. Families who will live in printed houses earn an average of $76.50 a month. “For many families, this will be the first home with a toilet outside the yard and a full sewer,” says Lafzi. And, unlike huts, such houses are able to withstand an earthquake. The charity is partnering with the local government to provide land and infrastructure to build roads and provide electricity to 50 families who need housing the most. When New Story finishes printing all the houses, new tenants will immediately move into them.

Photo: New Story

Some families have already inspected the resulting houses and noted that they do not leak during heavy rain. “When it rains, the roof of our house starts to leak, and the worst thing is when it happens at night,” says Candelaria Hernandez, who lives in a one-room hut with seven members of her family. “We have to wake up and arrange the pans so that things don’t get wet.”

“We have to wake up and arrange the pans so that things don’t get wet.”

“The construction industry needs a paradigm shift,” says Alex Le Roux, co-founder and CTO of Icon. “We don’t have to choose between affordability and reliability.” The company plans to print more new houses and develop its technology. Many representatives of local governments in Latin America have already shown interest in the project and even visited the current construction site. “Once people see our project with their own eyes, it no longer seems like a crazy idea to them,” says Hagler.

Source.

95% cheaper: why 3D printing is effective for today's business

Unfortunately, even industry experts do not fully understand the potential of using additive technologies in their work. Because of the high-profile headlines that a car or even a house was printed on a 3D printer, the whole essence of the technology and its advantages over traditional working methods are lost. After all, for the most part, it is needed to replace routine processes and make the final product cheaper than when working with traditional means.

From stone carving to additive manufacturing – why do businesses need 3D printing?

For any business that produces a physical product, a prototype is essential. Previously, the processes were labor-intensive - prototypes had to be sculpted from clay or carved from stone, which took a lot of time, and if you made a mistake somewhere or something needs to be changed, you had to redo the whole form again.

Today, thanks to additive technologies, businesses have the opportunity to automate these processes and reduce not only the time spent on a project from several days to hours, but also the funds invested in the product.

Thus, different departments in companies benefit from the introduction of technology:

- R&D employees begin to do their work faster, as the production of a prototype is automated and takes less time;

- Designers can quickly prepare new iterations, since all work is completely digital;

- Everyone who demonstrates their products - from sales to top management - can convince customers and business partners with the help of visual prototypes;

- Marketing departments can demonstrate prototypes to focus groups to prepare a final product that meets the needs of the client, and additionally make small souvenirs for promotional purposes.

In-house and outsourcing - 3D printing methods

There are three main methods of prototyping in terms of additive technologies: outsourcing work to a 3D printing company, printing with your own industrial printers, or working with your own desktop printers. The choice of method depends more on the scope of work in the company and its financial capabilities.

Consider the advantages and disadvantages of each method.

3D Printing Bureau are best suited for small complex jobs. It is worth contacting the bureau when you have less than five orders per month, but they require non-standard materials. Bureaus are also useful when different materials are needed to make each item. In other cases, this is the slowest and most expensive option.

Advantages:

- Bureaus work with several 3D printing technologies at once, such as SLA, FDM and SLS;

- The bureau has more materials in stock, including rare or very expensive ones;

- The Bureau will advise on materials and their limitations;

- If contractors do not work well, then you can quickly terminate the contract and find new ones.

Drawbacks:

- The cost of a prototype will be ten times higher than when working with our own desktop and industrial 3D printers;

- Much slower than native 3D printing (may take weeks instead of one day).

In-house industrial 3D printers are a reliable option for large productions (200 items per week or more). Products are made of one material, and their size is more than 30 cm³. This option may suit the R&D centers of the largest companies. However, businesses often do not use industrial printers in affordable volumes, which is why the cost of equipment will take a long time to “fight back”.

Advantages:

- Allows deep immersion in technology;

- Work faster than in cooperation with the bureau;

- The production of a product at high throughput will be cheaper compared to a bureau.

Drawbacks:

- Installation costs about $30,000 for an entry-level system, $300,000 for a full-fledged production system;

- Complete production systems require separate specialists to work with them, as well as more than 30 m² of production areas, industrial HVAC systems, finishing stations, cleaning stations, etc.;

- At low throughput, this will cost more than service bureaus and desktop 3D printers;

- Higher cost per part and total cost of ownership compared to desktop 3D printers, even in large scale production

- Limited range of materials compared to service bureaus;

- The cost of materials per kilogram is higher than for desktop printers.

Desktop 3D printers are great for business when it has a lot of projects and speed is important. For small companies, you can get one desktop printer to get a newly developed prototype within a few hours.

For small companies, you can get one desktop printer to get a newly developed prototype within a few hours.

A larger business that manufactures more than 200 items a week assembles a farm of several printers - for them it is cheaper than installing industrial ones. Such farms will also give more flexibility and provide access to several materials at the same time. Sometimes companies can use the services of a 3D printing bureau when larger parts or rare materials are needed for work.

Advantages:

- The cost of a printer to get started is 10 times less than a commercial one;

- Cost per part and total cost of ownership is the most affordable of the in-house manufacturing options;

- Allows deep immersion in technology;

- Compact, resulting in less space requirements.

Drawbacks:

- Low reproducibility compared to industrial machines;

- There will not be many manufactured products in one batch;

- Not all desktop 3D printer manufacturers provide long-term warranties and support.

How Lush saves on 3D printing

Lush is one example of how the company is using 3D printing with its own desktop printers. The company has located its farm in an R&D center in the south of England, where employees come up with ideas for new forms of cosmetics.

The R&D center itself also offers support to Lush's global manufacturing sites in the UK, Japan, Australia, Croatia and Germany. They can order the right molds and special tools to give cosmetics their whimsical look.

3D printing on their own printers has opened the way for Lush employees to creatively solve problems and quickly respond to customer requests.

The team now designs a product and launches production in less than a day, with 4.5 hours spent printing a new mold. This was also the case with Lush, a charity project to help wildlife in Australia during last year's wildfires, which brought the new product to market within a week.

With access to the full range of digital manufacturing tools, the R&D center completed 580 projects in the first half of 2020. This saved a significant amount of time and labor. In doing so, they were able to respond more quickly to the pandemic and prioritize projects that clients needed in a volatile year.

The process of 3D printing itself turned out to be several times cheaper than traditional methods of work when delegating them to outsourcing - an average of 95%.

Comparison of in-house and outsourced 3D printing costs Source - Lush and Formlabs calculations

| Product | The cost of outsourced work | Cost of printing on a 3D printer (including labor) | Saving |

| Thank You Coin Mold | £114 | £6 | 95% |

| Architectural model of the R&D center | £15,000 | £900 | 94% |

| Special tooling for production | £99 | £4. |