Polyvinyl alcohol 3d printing

Ultimate Materials Guide - Tips for 3D Printing with PVA

Overview

PVA, or Polyvinyl Alcohol, is a soft and biodegradable polymer that is highly sensitive to moisture. When exposed to water, PVA will actually dissolve, which makes it a very useful support structure material for 3D printing. When printing extremely complex shapes or ones with partially enclosed cavities, PVA supports can be used and easily removed by dissolving in warm water. Standard supports may have been difficult to print or remove in these situations. PVA can also be used as a model material if there is a need to make quick prototypes.

- Great water dissolvable support material

- No special solvents required

- No additional hardware required

- Moisture sensitive

- Airtight storage containers required

- Greater chances of clogging if the nozzle is left hot when not extruding

- Expensive

Hardware Requirements

Before 3D printing with PVA make sure your 3D printer meets the hardware requirements listed below to ensure the best print quality.

Bed

Temperature: 45-60 °C

Heated Bed Optional

Enclosure Not Required

Build Surface

PEI

Painter’s Tape

Extruder

Temperature: 185-200 °C

No special hotend required

Cooling

Part Cooling Fan Required

Best Practices

These tips will help you reduce the chances of common 3D printing issues associated with PVA such as absorbing moisture, warping, and fumes.

Take Precautions for Filament Storage

Since PVA is highly reactive to water, storing the filament in a moisture-free container is mandatory. PVA that has absorbed water from the air will tend to bubble and crack during printing, which will ruin the quality and strength of the finished part. When you are done with the PVA spools, be sure to remove them from your printer and place them in air-tight containers along with a desiccant to remove any moisture from the container. If your filament has already absorbed too much moisture, the filament can be dried using a commercial dehydrator, or an oven set to the lowest possible temperature for a few hours. This will draw the water out of the filament without melting it, allowing it to print smoothly and without bubbles.

This will draw the water out of the filament without melting it, allowing it to print smoothly and without bubbles.

Use an Ooze Shield

When using PVA as a support material for your PLA prints, consider adding an ooze shield with at least two outlines. This will have the benefit of priming the PVA extruder after every tool change, which will ensure this extruder is ready to print at the start of the layer. Additionally, the ooze shield will catch any oozing from both nozzles to prevent these plastic deposits from reaching your part. Once the print is completed, the ooze shield can be removed and discarded. If you find the ooze shield is too weak or tends to separate easily, consider adding an additional ooze shield outline to thicken the protective shield.

Use Dense Support Layers

PVA can be rather expensive, so you want to minimize the amount of material that is used for your support structures. Simplify3D includes a useful feature called Dense Supports, which allows you to use the PVA material only at the interface layers between your part and the supports. This can easily offer a PVA material savings of 90% or more, while still allowing the supports to easily be dissolved and separated from the part. The dense supports also create a nearly solid interface layer, which improves the surface quality on the underside of your print. If you have never used this feature before, there is a great video explaining the process, which can be found here: How to Use Dense Supports.

This can easily offer a PVA material savings of 90% or more, while still allowing the supports to easily be dissolved and separated from the part. The dense supports also create a nearly solid interface layer, which improves the surface quality on the underside of your print. If you have never used this feature before, there is a great video explaining the process, which can be found here: How to Use Dense Supports.

Pro-Tips

- In multi-extruder setups, cooling down the PVA hotend during idle times can prevent oozing and clogging

- Set the support upper separation distance to zero layers for a better surface finish. The PVA will be dissolved away, so it doesn’t matter if it bonds to the part while printing. This same technique can be used for your PVA rafts.

Get Started with PVA

Now that you understand the basics of printing with PVA, you are ready to try your first print! We’ve put together some sample project ideas and even a list of popular filament brands to help you get started.

Common Applications

- Removable supports or rafts

- Dissolvable/Disintegratable applications

- Decorative parts

Sample Projects

- Hilbert cube

- Spring

- Parrot Pendant

Popular Brands

- Ultimaker PVA

- Matterhackers PVA

- eSun PVA

- HobbyKing PVA

PVA: All You Need to Know for 3D Printing

Published on June 6, 2022 by Madeleine P.

PVA, or polyvinyl alcohol, is a material widely used in the 3D printing industry due to its ability to dissolve in water. In particular, it is used for the creation of print supports when using FDM dual extruder machines. This offers users greater design freedom for parts with complex geometries, without affecting print quality. The more details and cantilevered parts the design has, the more supports the part will require in order to be manufactured. This guide will help you better understand the properties of this material, as well as its role in 3D printing in obtaining the best results in each manufacturing process.

Characteristics of PVA in 3D Printing

On a technical level, PVA is part of the synthetic polymer family, with the particularity that it is biodegradable. It is created by polymerizing vinyl acetate, which is then hydrolyzed to obtain the material in filament form for 3D printing. It has a transparent to off-white appearance and is highly resistant to oil and grease. In addition to having very good adhesive properties similar to other thermoplastics such as PLA, CPE or Nylon, this material has a high tensile strength and flexibility. In order to obtain good substrate results, PVA requires preheating the printing tray to between 45 – 60ºC and bringing the extruder to a temperature of between 180 – 200ºC. It is also odorless, non-toxic and, as mentioned, biodegradable, making it safe for humans, animals and the environment.

PVA is a soluble material used as printing support (photo credits: Ultimaker)

Among its main advantages is, as mentioned, its ability to dissolve. Linked to this, the most remarkable thing is that it only needs water to remove the support material, i.e., it does not require solvents with more complex components. Furthermore, it does not require any additional hardware. However, it is also worth mentioning some of the disadvantages of PVA, though they are generally applicable to other soluble materials. One of these is the high sensitivity to moisture, which can directly affect the material. In order for its properties not to be altered, it will be necessary to keep it in areas where the air is highly controlled. PVA is also more likely to generate clogging if the nozzle is left hot when not extruding. To this can be added that many users consider it to be an expensive filament for what it is, as it ultimately is not used in the final parts being printed, but rather dissolves in post-processing.

Linked to this, the most remarkable thing is that it only needs water to remove the support material, i.e., it does not require solvents with more complex components. Furthermore, it does not require any additional hardware. However, it is also worth mentioning some of the disadvantages of PVA, though they are generally applicable to other soluble materials. One of these is the high sensitivity to moisture, which can directly affect the material. In order for its properties not to be altered, it will be necessary to keep it in areas where the air is highly controlled. PVA is also more likely to generate clogging if the nozzle is left hot when not extruding. To this can be added that many users consider it to be an expensive filament for what it is, as it ultimately is not used in the final parts being printed, but rather dissolves in post-processing.

Use and Applications

As a soluble material, PVA is ideal as a complement in the manufacture of parts with complex geometries, as well as internal cavities, conceptual models and molds. 3D printed supports offer improved surface quality and also allow the part to be oriented to optimize its mechanical properties. An important point to consider when working with this material is the configuration of the extruders. Cooling the PVA hotend while idle will prevent the oozing and clogging mentioned above. In addition, it is recommended to set the top support clearance distance to 0 layers for a more optimal surface finish. Since the supports will dissolve, it does not matter if they adhere to the final part during the fabrication process.

3D printed supports offer improved surface quality and also allow the part to be oriented to optimize its mechanical properties. An important point to consider when working with this material is the configuration of the extruders. Cooling the PVA hotend while idle will prevent the oozing and clogging mentioned above. In addition, it is recommended to set the top support clearance distance to 0 layers for a more optimal surface finish. Since the supports will dissolve, it does not matter if they adhere to the final part during the fabrication process.

By allowing 3D printing of all types of parts, no matter how complex the design, PVA is a material widely used in the art world to create decorative models. However, it is not the only sector that is taking advantage of this filament. Even the most advanced industries that work with FDM technology to create tooling or prototypes are also increasingly integrating the soluble materials to create supports. Among the companies offering PVA filaments we can find Ultimaker, eSun, MatterHackers or Polymaker, among many others. If you want to learn more about other 3D printing filaments, you can consult our guide HERE.

Among the companies offering PVA filaments we can find Ultimaker, eSun, MatterHackers or Polymaker, among many others. If you want to learn more about other 3D printing filaments, you can consult our guide HERE.

What do you think of the characteristics of PVA in 3D printing? Let us know in a comment below or on our Linkedin, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: Zortrax

REC Wiki » PVA - print parameters, features and properties

REC PVA is a special filament capable of facilitating the 3D printing of complex parts. It is a specialized support material that is soluble in water and does not require mechanical processing.

Features PVA

PVA or PVA is a polyvinyl alcohol widely used in films, adhesives, cosmetics, medicines, food emulsifier, carbon dioxide barrier material in PET bottles, and more. Polyvinyl alcohol should not be confused with polyvinyl acetate: they are related materials, both are used in the production of adhesives (the well-known PVA adhesive is based on polyvinyl acetate, hence the name), and in Latin both are abbreviated PVA, which leads to confusion. However, they are different materials. In 3D printing, polyvinyl acetate (PVA) glue is often used as an adhesive coating applied to tables for better adhesion of products to the work surface, and filaments are already made from polyvinyl alcohol (PVA). This article will focus exclusively on PVS.

Polyvinyl alcohol should not be confused with polyvinyl acetate: they are related materials, both are used in the production of adhesives (the well-known PVA adhesive is based on polyvinyl acetate, hence the name), and in Latin both are abbreviated PVA, which leads to confusion. However, they are different materials. In 3D printing, polyvinyl acetate (PVA) glue is often used as an adhesive coating applied to tables for better adhesion of products to the work surface, and filaments are already made from polyvinyl alcohol (PVA). This article will focus exclusively on PVS.

Example 3 D- of a printed product with supports from REC PVA

With all its capabilities, we are interested in one particular property of polyvinyl alcohol: at room temperature and during 3D printing, PVA behaves like ordinary , although a fairly soft thermoplastic, it is readily soluble in water, allowing the use of polyvinyl alcohol as an easily removable backing material. Unlike conventional supports printed with the main consumable material, supports made of PVA do not require mechanical removal, do not leave marks and allow printing products of exceptionally complex geometric shapes, including those with delicate structures vulnerable to mechanical damage. Moreover, this material itself is biodegradable and non-toxic, which is important from a safety point of view.

Unlike conventional supports printed with the main consumable material, supports made of PVA do not require mechanical removal, do not leave marks and allow printing products of exceptionally complex geometric shapes, including those with delicate structures vulnerable to mechanical damage. Moreover, this material itself is biodegradable and non-toxic, which is important from a safety point of view.

Example 3 D- of a printed product with supports from REC PVA

PVA has two disadvantages - high hygroscopicity (as it should be for a water-soluble material) and rather high cost. However, with proper storage and use of special slicer settings, which we will discuss below, both disadvantages are effectively leveled.

PVA 3D Printing Preparation Guidelines

One mandatory and self-evident requirement when 3D printing PVA support structures is that the 3D printer has at least two extruders. There are no special requirements for the extruder, assemblies used to work with ABS, PLA, PET-G and other popular materials are quite enough. There are only three things to keep in mind.

There are only three things to keep in mind.

First, make sure the material is dry before threading the filament. Since it is a water-soluble material, PVA easily absorbs moisture and becomes more elastic and sticky. At the very least, this can lead to filament feeding problems, but even if the extruder is able to cope with this task, other problems are possible, including the formation of bumps and bubbles in the laid layers, uneven melt feeding and reduced interlayer adhesion.

The second point is the temperature regime directly during 3D printing. The hot end allocated for PVA, of course, must be warmed up to a temperature in the recommended range (190-240°C), but for optimal conditions it is desirable to warm up the table as well. The problem is that the base material may have completely different requirements for the temperature of the working surface. In such cases, the platform should be heated to a temperature that is optimal for the base material. PVA is relatively picky in this regard.

Finally, remember that PVA is not suitable for all base materials. The base resin and PVA need to bond well during 3D printing to work successfully. In this regard, PVA is well suited to work in conjunction with REC PLA (polylactide), REC Flex (thermoplastic polyester elastomer), REC Easy Flex and REC TPU D70 (thermoplastic polyurethane-based filaments), and also sets well with REC Relax (filament made of PETG). With REC HIPS (high impact polystyrene), REC Rubber (synthetic rubber filament) and REC PP+ (polypropylene), polyvinyl alcohol does not adhere well. Unfortunately, PVA does not work with the popular ABS plastic, so when working with this polymer, it is better to print support structures from high-impact polystyrene (REC HIPS) dissolved in limonene.

Detailed information about the adhesive properties of REC PVA and other materials in multi-material 3D printing is available here.

PVA 3D Printing Guidelines

When switching from base to base material and back during 3D printing, it is desirable to run the material by printing junk turrets or separate outlines around the model. On the one hand, this will help to prepare the activated hot end for material laying, and on the other hand, it will help to get rid of “snot” in case of insufficient retraction on a deactivated extruder. The ingress of PVA into the layers of the base material is highly undesirable, as this will lead to the formation of defects after the removal of polyvinyl alcohol.

On the one hand, this will help to prepare the activated hot end for material laying, and on the other hand, it will help to get rid of “snot” in case of insufficient retraction on a deactivated extruder. The ingress of PVA into the layers of the base material is highly undesirable, as this will lead to the formation of defects after the removal of polyvinyl alcohol.

To save PVA, you can use special modes at the stage of G-code preparation in the slicer. For example, the Simplify3D slicer has a Dense Supports function, with which 3D printing can be configured so that the bulk of the supports are printed with the base material, and PVA is placed only at the junctions between the supports and the model, forming a separating layer. This option is worth trying out if relatively cheap base plastic is used to build the model. Detailed instructions are available in the video at this link.

Recommended settings for 3D printing with REC PVA material:

- Nozzle temperature: 190-240°C

- Table temperature: 50°C

- Airflow: desirable

- Recommended adhesives: blue tape, The3D adhesive

- Minimum nozzle diameter: 0.

1 mm

1 mm

Removal of REC PVA

After 3D printing, areas of the support material must be removed, and here the PVA comes into its own. It is enough just to keep the part in a container with the most ordinary water for several hours, after which the sections of polyvinyl alcohol will get wet and will be easily separated from the main model. The best option is to simply leave the part in water overnight, and in the morning the PVA will dissolve completely or almost completely. It remains only to rinse the product in clean water.

Warm water and occasional stirring can be used to speed up the process, but with one caveat: do not forget the heat resistance of the base material. If, for example, we are talking about PLA plastic, it can melt in hot water. Accordingly, make sure that the water temperature does not exceed 50 ° C, and for greater safety it is worth limiting to 35 ° C. Softening temperatures are different for different plastics, so be guided by the characteristics of specific polymers and do not use boiling water, only warm or hot.

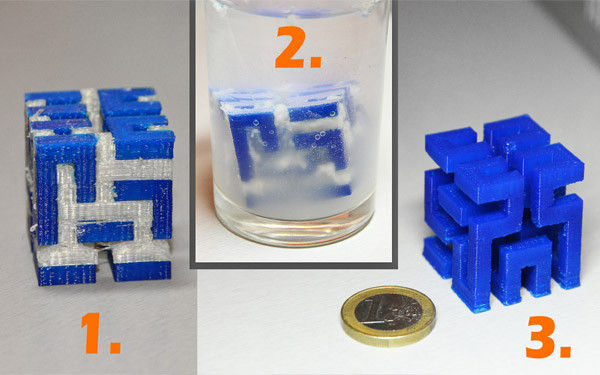

3 D- printed product with supports from REC PVA before, during and after soaking in water

bubbles in the water, and help separate and wash out the remaining polyvinyl alcohol. When using ultrasonic baths, be careful with the settings for frequency, power, and exposure time, as the wrong mode can adversely affect the strength of 3D printed products.

Storage PVA

Due to its water solubility, PVA is extremely hygroscopic, meaning it easily absorbs moisture. To prevent this from happening, store the filament in a tightly sealed plastic bag or container with dry silica gel inside. Just in case, drying the filament just before 3D printing won't hurt either. To do this, you can use fruit dryers, an electric oven or specialized equipment. The filament should be kept at 60°C for at least four hours.

If the specified storage conditions have not been met and dust has accumulated on the filament, in addition to drying, it is necessary to clean the material before feeding it to the hot end, otherwise carbon deposits may form. To clean the filament right during 3D printing, you can use a simple homemade foam filter (for example, this or that).

To clean the filament right during 3D printing, you can use a simple homemade foam filter (for example, this or that).

For more information about storing and drying filaments of different materials, see the articles at the links below:

Storing filament

Drying plastic

Safety REC PVA

In terms of safety, REC PVA should not cause any inconvenience. Polyvinyl alcohol is non-toxic and is even used in the food and pharmaceutical industries. However, while 3D printing, we still recommend that you follow the basic safety rules - work in a well-ventilated area, if possible equipped with an exhaust hood near the 3D printer. In case of contact with the PVA solution in the eyes or on the skin, thoroughly rinse the affected areas with running water.

Safety certificates are published in a special section of our website.

Printable PVA

Polyvinyl alcohol or "PVA plastic" is a unique consumable that greatly expands the possibilities of 3D printing when using printers with a dual extruder. PVA is soluble in water, which makes it completely unsuitable for creating durable products, but allows it to be used as a support material when printing models of complex geometric shapes.

PVA is soluble in water, which makes it completely unsuitable for creating durable products, but allows it to be used as a support material when printing models of complex geometric shapes.

An example of using temporary supports. Removing such elements manually

is time consuming and can degrade the quality of the finished model

One of the limitations of 3D printing is the inability to "print in the air", which makes it difficult to create attachments. Technologies such as selective laser sintering (SLS) solve this problem by using powdered materials distributed over the entire area of the working chamber - the unused material of one layer serves as support for the elements of the next layer.

In the case of FDM printing, the material itself is applied selectively. Accordingly, hinged elements may not have sufficient support - it all depends on the angle of deviation and print resolution, but even with the optimal resolution, printing long horizontal elements (the so-called "bridges") is only possible at the expense of quality or impossible at all. In such cases, artificial temporary structures called "pillars" or "supports" are created to be removed when printing is complete.

In such cases, artificial temporary structures called "pillars" or "supports" are created to be removed when printing is complete.

Hilbert cube printed with ABS (grey) and PVA (white)

Unfortunately, the mechanical removal of such structures leaves marks on the finished model, which leads to the need for subsequent machining. In the worst case, the supports may even be out of reach of mechanical tools. The latter is possible when creating models with a complex open internal structure.

As an illustrative example, you can use the Hilbert cube. Building such a model with standard supports will turn into a nightmare when you try to remove them. Fortunately, owners of dual printhead FDM printers have a smarter option: printing a composite model with water-soluble plastic supports, that is, PVA.

In this case, the PVA serves as a void filler supporting the layers of ABS performance. The finished model will need to be kept in ordinary water until the PVA plastic is completely dissolved.

ABS/PVA Composite Water Cured

Curing time can be quite long, up to several hours. The period depends on the size of the model and the temperature of the water, but can be reduced by intermittent or constant stirring of the solution.

PVA plastic is supplied in standard spools of 1.75mm or 3mm thread. The recommended extrusion temperature is 160-175°C. Exceeding this temperature may lead to pyrolysis.

PVA is produced from various raw materials, including ethylene gas (released during the ripening of some fruits and vegetables), ethyl alcohol (the same, drinking) and petroleum products, but in any case, when prepared, it is non-toxic and does not pose a health hazard.

Being water-soluble, the material is hygroscopic (easily absorbs moisture), which should be taken into account when printing. We recommend drying the media before printing to avoid distortion or steam.

Finished Hilbert Cube without PVA filling

Drying can be done even in an ordinary oven: about six hours at 80°C should be enough for a stale coil.