News article about 3d printing

3D Printing News

Bringing you the latest 3D printing news from industry, academia and government projects all around the world. Come join us, and learn about the hottest trends in additive manufacturing.

Engineers Print Strain Sensing Structures with Plastic

Researchers at Purdue University have created a patent-pending method of producing filaments that can be used to manufacture sensing plastic structures. The technology... read more »

23 hours ago

Filament

Engineers Develop Means of Printing Hybrid Metal Plastic Composites

Engineers from institutes in Singapore and Japan have developed a new means of 3D fabricating hybrid metal-plastic systems in complex shapes, using multi-material... read more »

2 days ago

Electronics

3D Printed Electroactive Plastics Give Life to Haptic VR Glove

A team of researchers from Switzerland have come up with a design for a haptic feedback glove for use in VR, and it. .. read more »

3 days ago

Electronics

ORNL Researches Ash Content in Biocomposites

Researchers from Oak Ridge National Laboratory have published a paper highlighting the effects of ash content in bioplastics, and have reached the conclusion... read more »

6 days ago

News

Shell 3D Prints Leak Repair Clamp

In the world of oil and gas, it is not always convenient to switch off pipe networks to seal up a potential leak.... read more »

1 week ago

3D Printing Metal

Printing with Quantica’s NovoJet Technology – A Closer Look

A few weeks ago we took our first look at the new multi-material jetting printer from Berlin-based 3D printing company Quantica. The company... read more »

1 week ago

3D Printers

Researchers Use Twin Robots for Printing 3D Structured Electronics

Engineers from Simon Fraser University, Canada have demonstrated the use of dual robotic arms for the printing of 3D structured electronics. With one... read more »

With one... read more »

1 week ago

Electronics

Football and 3D Printing – A Common Language

As fans from around the world unite during the FIFA World Cup, we see that football itself is a language that transcends national... read more »

1 week ago

News

AI + AM Used to Make Custom Finger Joint Implants

Joint conditions such as rheumatoid arthritis, or those resulting from injuries can cause physical misery and even ruin the careers of professionals requiring... read more »

1 week ago

Medical

Engineers Demonstrate LPBF Microstructure Modification with Secondary Laser Pass

The microstructure of metals printed with LPBF methods can be modified by tweaking certain process parameters while the printing process is underway. Researchers. .. read more »

.. read more »

2 weeks ago

3D Printing Metal

Johns Hopkins Team Prints Ultra-high Temperature Carbide Ceramics

Using commercially available systems, a group of researchers from The Johns Hopkins University have managed to fabricate Ultra-high-temperature ceramics (UHTCs). The materials have... read more »

2 weeks ago

Ceramics

3D Systems Partners with WeMatter for Small Footprint SLS

SLS machines are typically fairly hefty things and are often a wee too big for your average small workshop or office space. But... read more »

2 weeks ago

3D Printers

Engineers Develop Contactless Powder Spreading

When using powder bed fusion methods of printing, the fresh layer of powder at the top is typically deposited before being evened out. .. read more »

.. read more »

2 weeks ago

3D Printing Metal

Maxfilament Teams with Flashforge Poland Bringing Industrial Filaments to Creator 4

Maxfilament, the Polish manufacturer of industrial filaments, has teamed up with a leading distributor of Flashforge printers to bring some interesting industrial filaments... read more »

2 weeks ago

Filament

Printed Nanocluster-based Composite Could Protect Delicate Aerospace Components

A team of Stanford University researchers have published details of a new nanoscale 3D printing material. The paper, published in the journal Science,... read more »

2 weeks ago

News

Experimental Printhead Demonstrates Combined FFF + Melt-blowing Process

A group of researchers from Budapest, Hungary have developed a novel means of 3D printing objects made from a combination of nano-/microfibers and. .. read more »

.. read more »

2 weeks ago

News

Researchers Print Flexible Circuit Tracks on Curved Surfaces

Researchers from North Carolina State University (NC State) have published their findings in a new paper demonstrating a method for printing flexible circuits... read more »

3 weeks ago

Electronics

Spanish Company to 3D Print Plant-based Car

Santa Pola based automobile manufacturer Liux has recently unveiled their new electric vehicle, dubbed the Animal. The Animal is an electric vehicle capable... read more »

3 weeks ago

Automotive

Up to 60% Off in Geeetech Black Friday Sale

Black Friday is upon us again and Geeetech has some bargains bargains BARGAINS for you! There are some great discounts on Geeetech’s range... read more »

3 weeks ago

News

MIT Researchers Strengthen Metal Prints with Induction Heating

Researchers from MIT have figured out a means of heat treating 3D printed metals so that they can be used in high temperature,. .. read more »

.. read more »

3 weeks ago

3D Printing Metal

3-D printing | MIT News

Industrializing 3D printing

VulcanForms, founded by an MIT alumnus and professor, has created digital production systems to manufacture complex metal parts at scale.

Read full story →

With new heat treatment, 3D-printed metals can withstand extreme conditions

A technique that transforms the metals’ microscopic structure may enable energy-efficient 3D printing of blades for gas turbines or jet engines.

Read full story →

UpNano joins MIT.nano Consortium

Provider of ultra-high resolution 3D printing becomes sustaining member of industry group.

Read full story →

A factory for FrEDs at MIT

Graduate students create on-campus assembly factory for fiber extrusion devices.

Read full story →

MIT team places 3rd in materials design competition with novel 3D printable metal

New material could be used by Tesla to produce all-electric vehicles with just a few massive parts.

Read full story →

Teachers learn radar basics in LLRISE outreach program

Esmeralda Hernandez and Liz Raine will bring lessons and hands-on activities from the Lincoln Laboratory Radar Introduction for Student Engineers back to their high schools.

Read full story →

New programmable materials can sense their own movements

Engineers 3D print materials with networks of sensors directly incorporated.

Read full story →

Using artificial intelligence to control digital manufacturing

Researchers train a machine-learning model to monitor and adjust the 3D printing process to correct errors in real-time.

Read full story →

Researchers 3D print sensors for satellites

Cheap and quick to produce, these digitally manufactured plasma sensors could help scientists predict the weather or study climate change.

Read full story →

Toward customizable timber, grown in a lab

Researchers show they can control the properties of lab-grown plant material, which could enable the production of wood products with little waste.

Read full story →

A helping hand for robotic manipulator design

With modular components and an easy-to-use 3D interface, this interactive design pipeline enables anyone to create their own customized robotic hand.

Read full story →

MIT engineers introduce the Oreometer

Mechanical engineers put an Oreo’s cream filling through a battery of tests to understand what happens when two wafers are twisted apart.

Read full story →

Festival of Learning centers on guiding students from surviving to thriving

The annual event aims to realize the promise of "new normal" education through community and technology.

Read full story →

New plant-derived composite is tough as bone and hard as aluminum

The material could pave the way for sustainable plastics.

Read full story →

Invisible machine-readable labels that identify and track objects

An MIT team develops 3D-printed tags to classify and store data on physical objects.

Read full story →

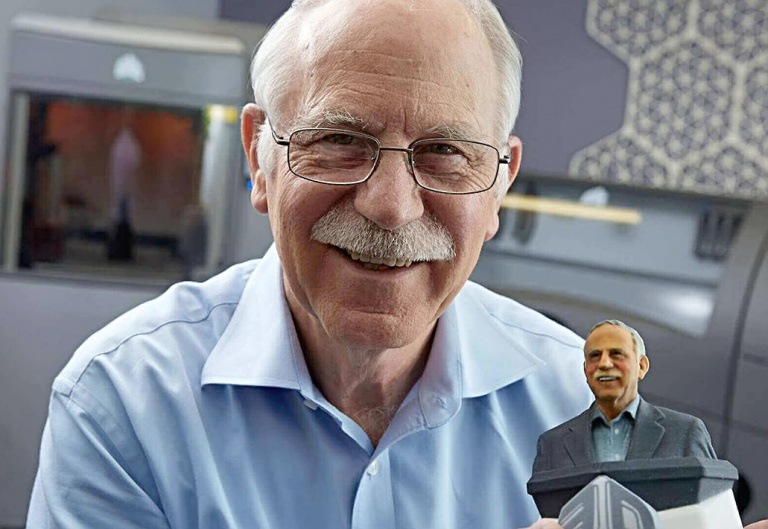

Harvard engineers develop true 3D printing technology

News April 23, 2022

Further

Alexander Sheremetiev news editor

Alexander Sheremetiev news editor

Researchers have developed a 3D printing technique that goes beyond the traditional layered bottom-up approach and eliminates the need for support structures. Description published in the journal Nature.

Description published in the journal Nature.

Read Hi-Tech in

A team of researchers led by scientists from the Rowland Institute at Harvard University has developed a new 3D printing technology. The engineers used a method of converting red light to blue and adding a photosensitive liquid to a resin used in 3D printers.

In traditional 3D printing, resin solidifies in a flat and straight line along the path of light. In their work, the researchers add nanocapsules containing special chemicals to the resin so that the resin reacts only to a certain type of light - blue light at the focus of the laser. Such a beam is formed in the process of frequency upconversion. The beam travels in three dimensions, so it doesn't need layering. As the researchers note, the resulting resin has a higher viscosity than the traditional method, so after printing it can stand without support.

“We designed the resin, we designed the system so that the red light does nothing,” says Daniel Congreve, co-author of the study. “But a small dot of blue light triggers a chemical reaction that causes the resin to harden and turn into plastic. What this basically means is that you have a laser going through the whole system and only in that little blue do you get polymerization, [and only there] do you get printing. We just scan that blue dot in three dimensions, and wherever that blue dot hits, it polymerizes and you get 3D printing.”

“But a small dot of blue light triggers a chemical reaction that causes the resin to harden and turn into plastic. What this basically means is that you have a laser going through the whole system and only in that little blue do you get polymerization, [and only there] do you get printing. We just scan that blue dot in three dimensions, and wherever that blue dot hits, it polymerizes and you get 3D printing.”

The researchers demonstrated their printer and created 3D Harvard and Stanford logos and a small boat. This is a standard test for 3D printers: the small size of the boat and many small details, such as overhanging windows and open spaces in the cabin, create a challenge.

The authors of the development believe that the technology can seriously change 3D printing. Traditional layering requires the use of props for overhanging elements to keep the resin from sinking and dripping down. Refusal of such structures will significantly speed up the process.

Engineers plan to continue developing the system to increase speed and print even finer details.

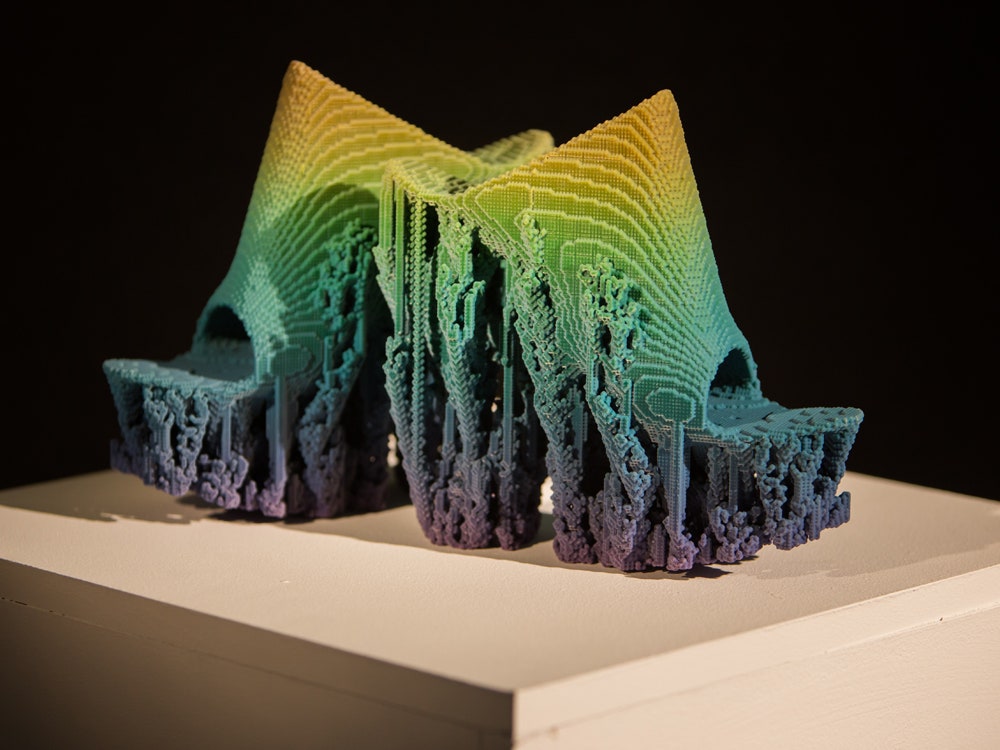

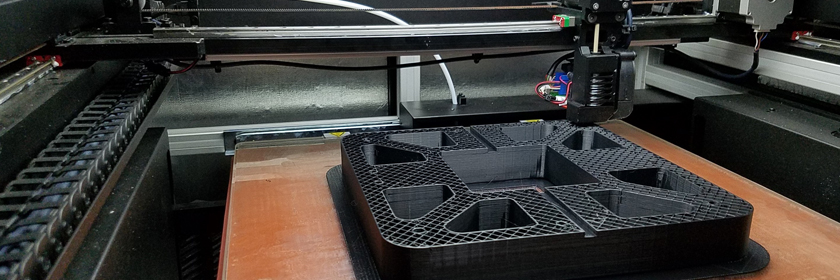

Photo: Dan Congreve, Stanford UniversityCover photo: An industrial 3D printer does not show the development described in the article.

Read more:

It has been hunted for centuries: what do we know about the planet Vulcan next to the Sun

Astronomers have found a planet near the Earth: it has a very strange orbit

Physicists figured out how to design and print the most delicious chocolate in the world

Read more

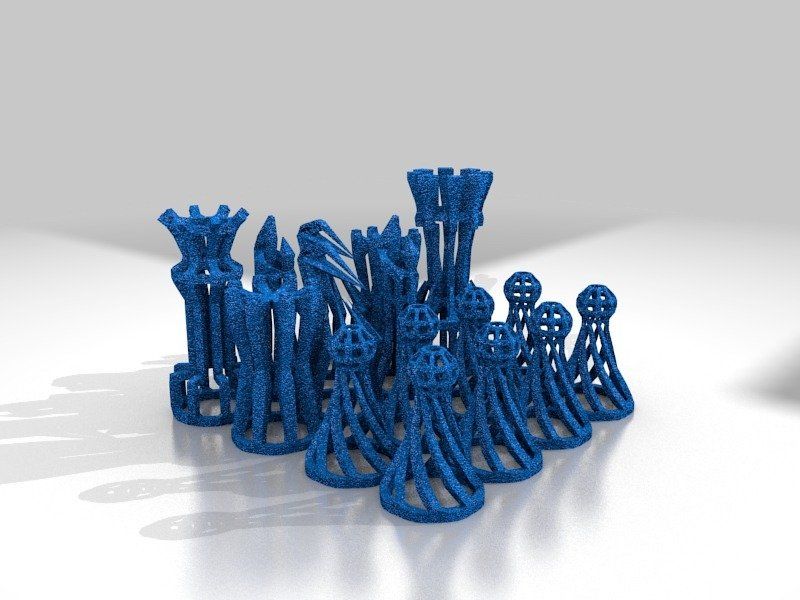

3D Printing Applications

3D printing is used for applications such as visualization of modeled designs, prototyping, metal casting, as well as in architecture, education, mapping, medicine, entertainment and retail.

In addition, 3D printing technologies can be used to reconstruct fossil objects in paleontology, create copies of the most valuable ancient artifacts in archeology, restore bones and body parts in forensic science, and reconstruct badly damaged evidence obtained during an on-site investigation. crimes.

crimes.

In 2007, it was proposed to use 3D printing to create art. Since then, sculptors, designers, and other visual artists have found various ways to apply 3D printing technologies.

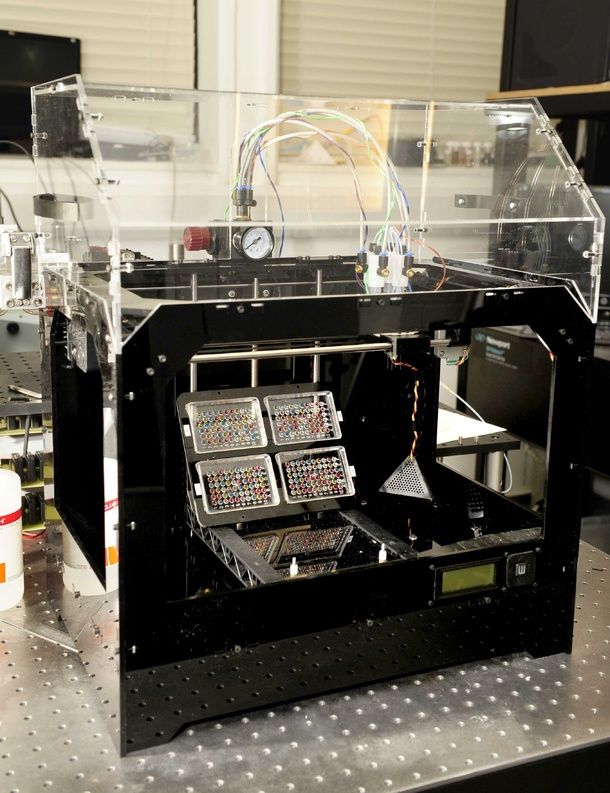

In addition, scientists and companies in the field of biotechnology are actively researching the use of 3D printing to create organs and tissues using inkjet printing. Such methods are reduced to the layer-by-layer introduction of living cells into a gel medium for the gradual production of a three-dimensional object. This area of development is called by various terms: printing of organs, printing with biomaterials, automated creation of tissues.

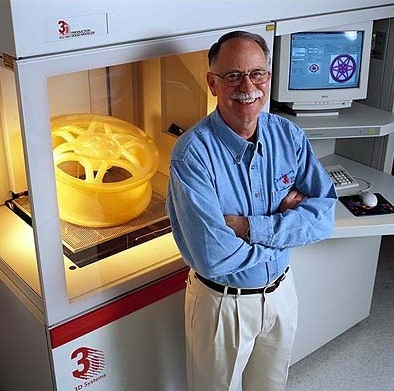

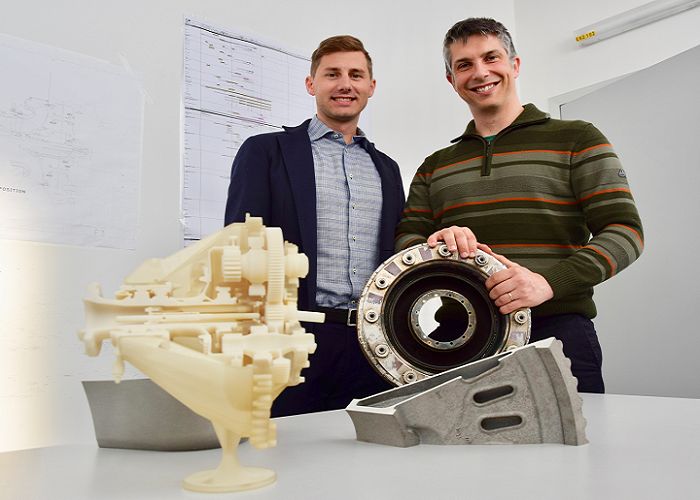

Industrial 3D printing

Over the past few years, 3D printing has become more known to the general public. However, most people still haven't even heard of this technology, even though it's been around for decades. In particular, in industry, 3D printing technologies have long been used to create prototypes in the development and design process, this process is called rapid prototyping.

The use of 3D printing for this purpose results in significant savings in time and money. A company can spend tens of thousands of dollars to install a 3D printer, but much more can be saved with rapid prototyping. Nike, for example, is using 3D printing to produce multi-colored athletic shoe prototypes. Prior to the introduction of 3D printing, the company spent thousands of dollars on prototyping and had to wait weeks for an order to be completed. Prototypes now cost hundreds of dollars to make, and if changes need to be made, they can be added to the computer model immediately and the modified prototype ready the same day.

In addition to rapid prototyping, 3D printing is also used for rapid production. The term refers to a new manufacturing method in which 3D printers allow companies to produce specialized and unique products in a short time frame. In other words, in this case, using 3D printing, you can get not a prototype, but the final product intended for the consumer. At the same time, modern technologies allow creating unique products that meet the specific requirements of the consumer.

At the same time, modern technologies allow creating unique products that meet the specific requirements of the consumer.

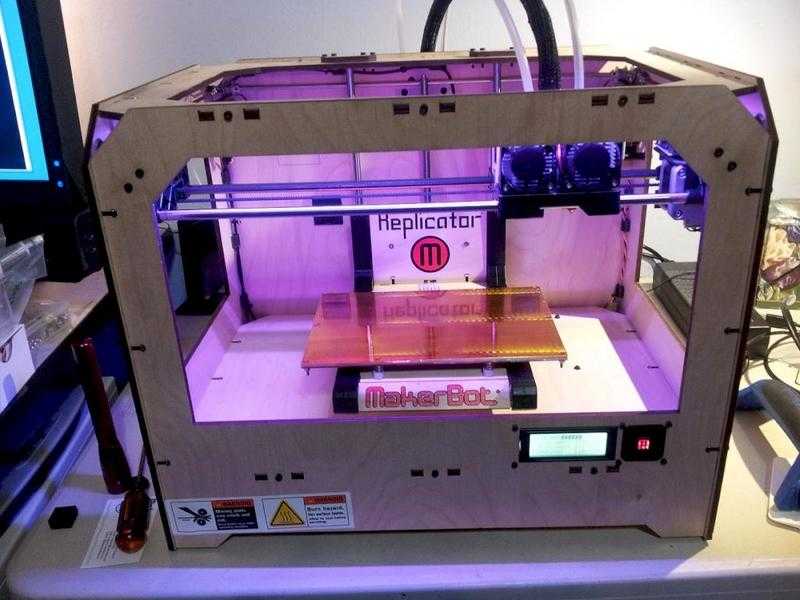

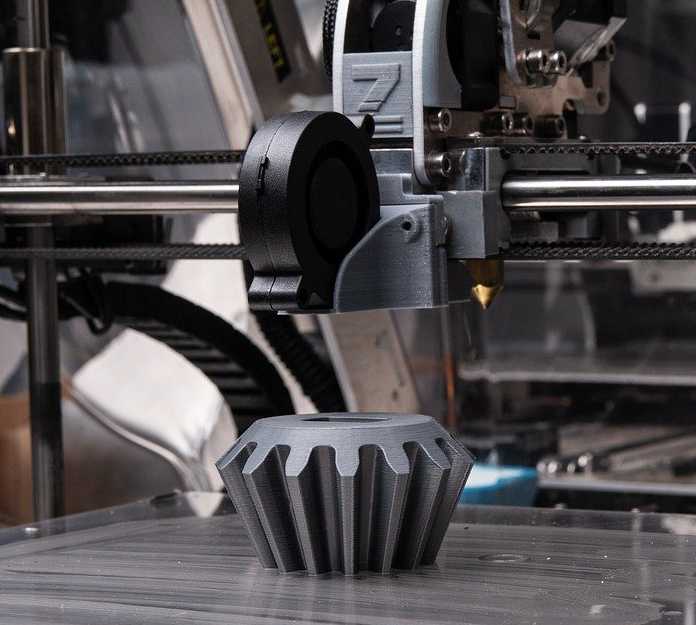

Personal 3D printers

Personal 3D printers designed for home use are mainly popular among hobbyists and enthusiasts. This segment of the market began to grow around 2011. Due to the rapid development of technology and increasing competition, prices for personal 3D printer models are constantly decreasing and today are in the range of $250 to $2,500. As devices become more affordable, 3D printing is becoming more widespread.

The hobbyist 3D printing market has been boosted by the creation of the open-source RepRap project. Consumers were able to purchase a RepRap kit for around $1,000 and build their own 3D printer with whatever modifications and additions they could think of and implement. The real driving force behind the project was the idea of openness of information. Everyone involved in RepRap shares their knowledge and experience with others so that the ideas are constantly refined and improved by the community.

The rapid development of open source 3D printers is of growing interest in both developed and developing countries. This approach allows not only to create a unique device that best suits the needs of an individual user, but also to share developments with a community of like-minded people through platforms such as Thingiverse and Cubify. This technology is also sustainable, as it can easily be used to create objects from available materials directly in the local community and in accordance with their needs.

3D printing services

Not everyone can afford or want to buy their own 3D printer. However, this does not mean that you cannot take advantage of the possibilities of 3D printing technologies. There are companies that provide 3D printing services such as Shapeways and Ponoko. For a relatively small fee, these companies will print and send you a 3D printed item based on a digital design that can be uploaded to the site using a simple system.