Up plus 2 3d printer price

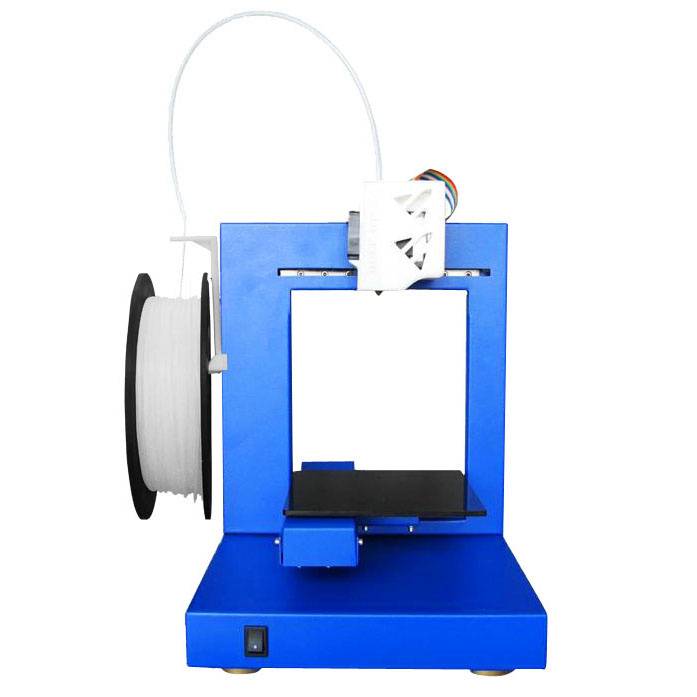

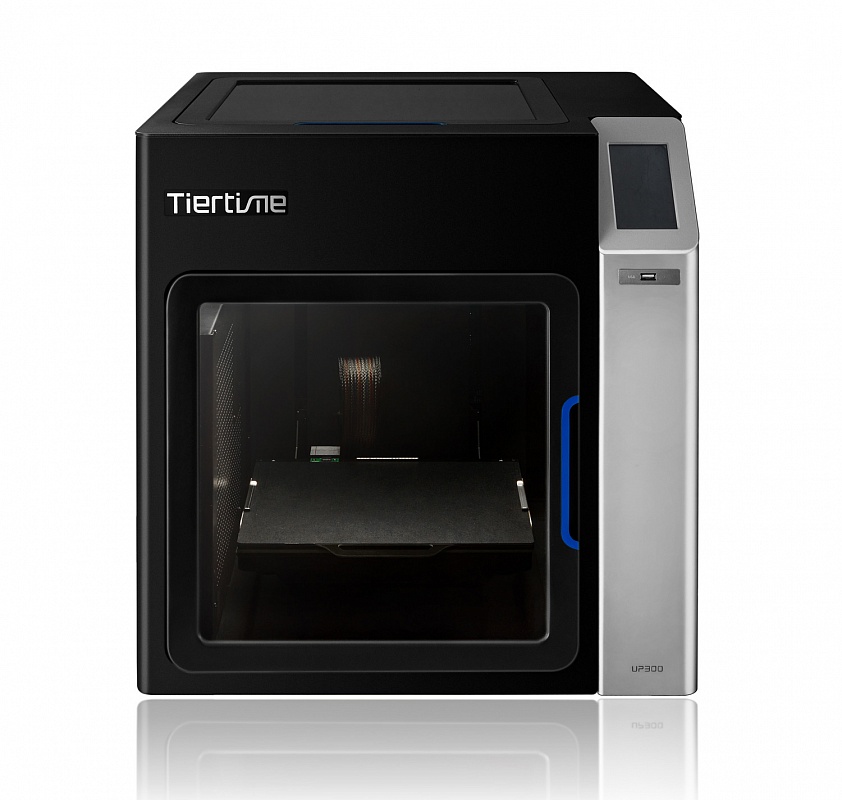

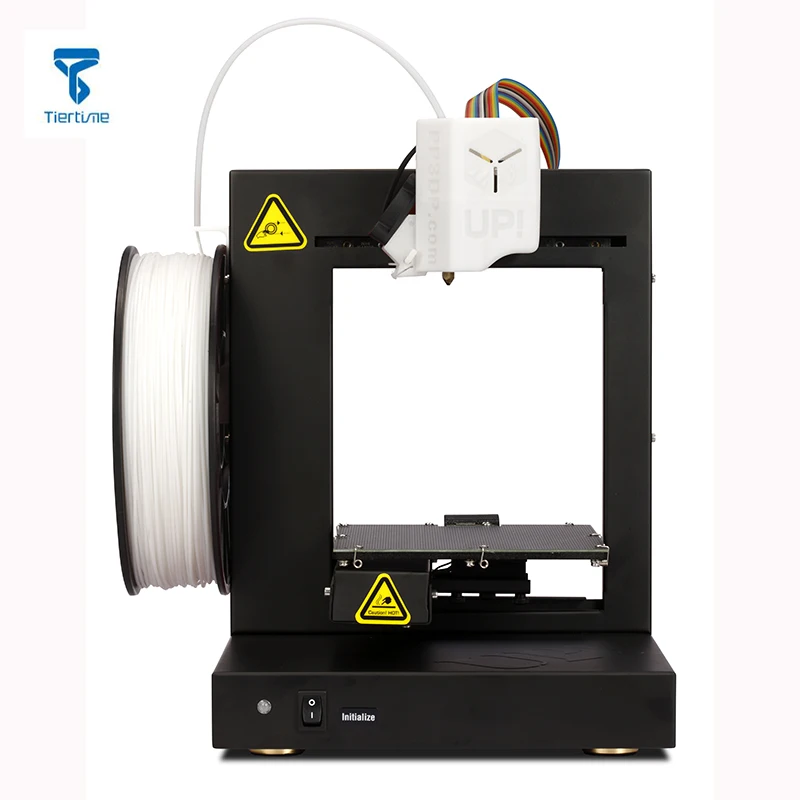

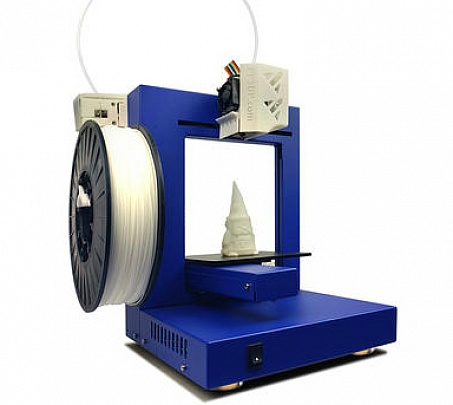

Tiertime UP Plus 2 3D Printer

Properties

| Build Volume | 140 x 140 x 135 mm (5.5 x 5.5 x 5.3 in.) |

| Layer Resolution Low | 400 micron (0.016 in.) |

| Layer Resolution High | 150 micron (0.006 in.) |

Documents

- UP Plus 2 3D Printer Manual.pdf

| Brand | Tiertime |

| Machine type | 3D Printer |

| Technology | FDM (Fused Deposition Modeling) |

| Materials | PLA, ABS, Color-Blending PLA |

| Website | http://www. |

| Average Price | $849.00 |

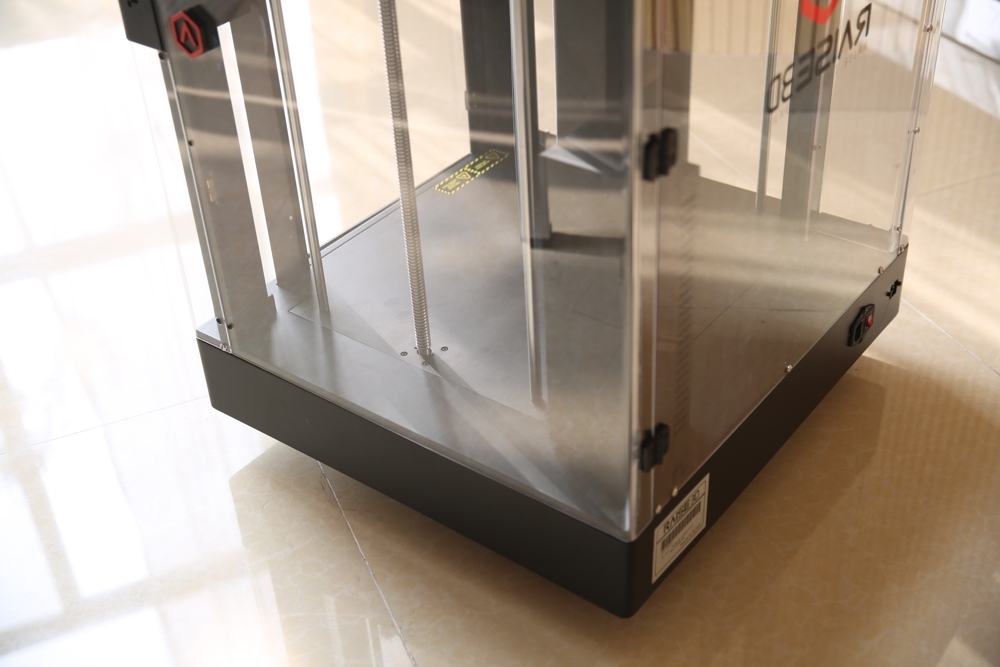

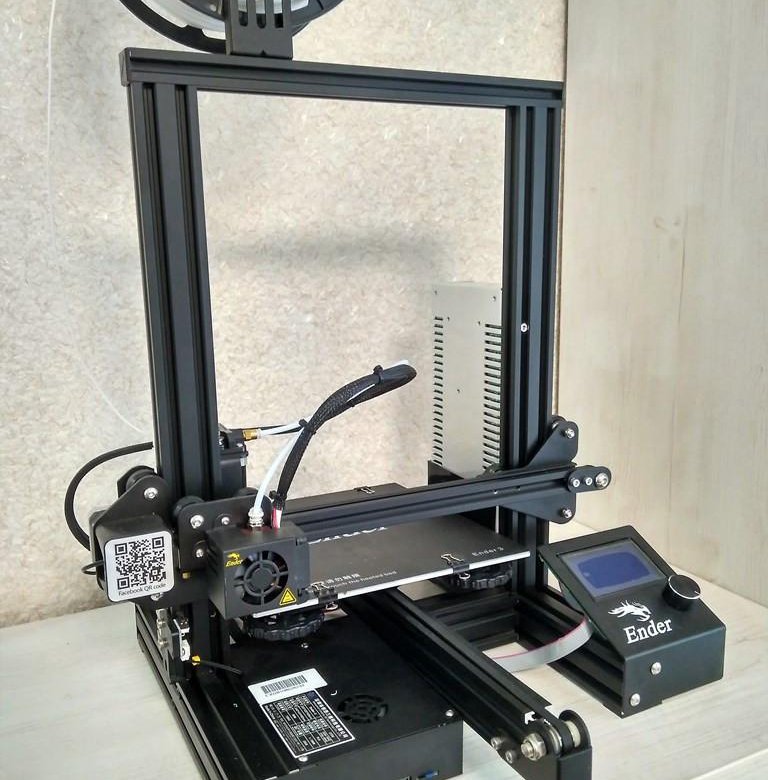

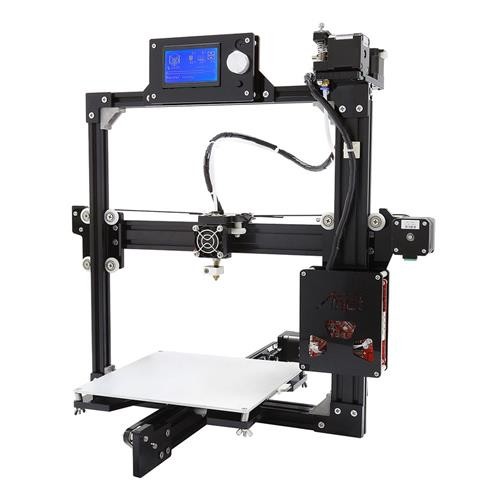

A classic prosumer 3D printer in the UP series, it is one of the most popular 3D printers in the world. Awarded by MakeMagazine for two consecutive years as the easiest 3D printer to use. Compared to the consumer level UP Mini, it can make bigger objects with more details. Its open chassis makes it convenient to use and its small foot print fit perfectly on desktop. UP Plus 2 is fitted with high precision linear bearings, so its printing quality and reliability is comparable to industrial printers. UP Plus 2 supports automatic platform leveling and nozzle height detection, so calibration becomes so easy that anyone can finish in a matter of minutes.

Features:

- Out Of The BOX 3D Printing: Without prior knowledge of 3D printer you can start your first print within 30 minutes.

- High Quality Prints At Low Price: UP Plus 2 produces better print quality than most more expensive rivals. It supports UP PLA and UP ABS filaments which guarantee great prints at low cost.

- Highly Reliable: UP Plus 2 uses high quality precision parts. It has very low failure rate that save you time and money.

- Quiet Operation: UP Plus 2 produces very little noise, you will feel comfortable working with it in the same room, on the same desk.

- Powerful But Easy To Use Software: UP software is simple to use, feature rich, fast and free. It is easy enough for rookies and versatile enough for gurus.

- Smart Support Technology: Industrial leading support generation algorithm that produces easily removable support structures and improve print quality.

This advanced technology allows difficult and complex designs to be printed at ease.

This advanced technology allows difficult and complex designs to be printed at ease.

Specifications:

- Melted Extrusion Manufacturing(MEM)Printing technology

- Single extruder, modularize for easy installation

- Layer Thickness of 0.15/0.20 /0.25 /0.30 /0.35 /0.40 mm

- Automatic Leveling and automatic detection of nozzle height

- Print Surface Heated, with perforated board or UP Flex

- Average Operational Noise 55 dB

- UP Studio Software

- Metal body, open form

Tiertime Up Plus 2 3D Printer

Tiertime

- $79900

Default Title - $799.00 USDQuantity

- Info

- Why buy from us?

- Shipping

- Price Guarantee

One of the best-selling desktop 3D printers on the market.

With Smart Supporting Technology the print success rate of Plus could be over 90%

The UP! Plus 2 3D desktop printer has an open frame, all-metal white chassis and fabricates objects using 1.75 mm ABS (acrylonitrile butadiene styrene) or PLA (polylactic acid) thermoplastic filament (sold separately), with a vertical resolution from 150 to 400 microns (0.15 to 0.40 mm). The Tiertime Up Plus 2 3D Printer can build objects to maximum dimensions of 5.3 x 5.5 x 5.5 inches/135 x 140 x 140 mm (H x W x D). The included printer management software runs on a Windows or Mac OS X computer, reads Standard Tessellation Language (STL) files generated by computer-aided design (CAD) software (sold separately), and commands the printer through the provided USB cable. An included platform-level calibration device can be used with the software to help ensure a level build surface. The software can also read the included nozzle-height detection device to calibrate the nozzle's vertical position for accurate operation.

The extruder has a heat and wind shield that helps prevent injury, and redirects air to help cool the material for a fine finish. A metal build platform heats to 105 degrees C to help provide thermal stability. A perforated cell board fastens to the platform by spring clips for a secure fabrication base. Solid metal guide rails and precision slide bearings help ensure precise movement. The belt-driven stepper motors meet the National Electrical Manufacturers Association (NEMA) standard ICS 16-2001.

Features

- Auto Nozzle Height Detection

- Auto Platform Leveling

- Easy Platform removal

- All Metal Construction

| Printing material | ABS or PLA |

| Vertical (Z-axis) resolution | 150, 200, 250, 300, 350, 400 microns (0.15, 0.20, 0.25, 0.30, 0.35, 0.40 mm) |

| Build speed | 10-100 cm3/h |

| Build volume | 5. 3 x 5.5 x 5.5 inches/135 x 140 x 140 mm (H x W x D) 3 x 5.5 x 5.5 inches/135 x 140 x 140 mm (H x W x D) |

| Printer weight | 5 kg (11 lb) |

| Printer size | 350 x 245 x 260 mm (H x W x D) |

| Power requirements | 100-240V AC, 50-60Hz, 200W |

| Input format | STL |

| Operating systems supported | Windows XP/Vista/7, Mac OS X |

Price match guarantee:

We work very hard to ensure that we offer the absolute best prices online for all of our printers including Tevo 3D printer kits. If you find another online store that offers a lower price than us on Tevo 3D printers for sale, please let us know and we will refund your original payment for the difference. Read More

30 day price assurance guarantee:

We want you to feel confident that you are getting the absolute best price for the product. If you find that our own website has a lower price for the same item you have ordered within 30 days of your purchase date, we will refund the difference! Read More

Full manufacturer direct warranty:

We are an authorized dealer for all our products and comes with the full manufacturer warranty.

Tax free (except California and Nevada):

The price you see is the price you pay but because we operate in California and Nevada we must charge tax in California and Nevada.

Safe & secure online ordering:

We are certified Level 1 PCI DSS compliant. What this means is that we meet all the requirements defined by the Payment Card Industry Security Standards Council. For additional information on PCI Compliance, visit the PCI Compliance Guide website. We also accept payment via Pay Pal, a leader in secure online payment processing.

Best customer service:

We strive to offer the best customer service we can. If you have any questions please let us know by phone or email.

Exclusive deals:

We appreciate each and every customer that comes to our store. We know you have a lot of choices when it comes to your 3D printing purchase. That's why we'd like to show our appreciation by periodically sending out exclusive coupons and deals to our past customers!

Order Confirmation:

As soon as you place your order you will receive an order confirmation e-mail. This means that we have received your order in our system and pre-authorized your credit card for the purchase. As soon as we receive your order we automatically reach out to our suppliers to confirm that it is in stock and available for immediate shipment. If your item is on backorder or unavailable we will void the pre-authorization and reach out to you via e-mail. If your item(s) are available for immediate shipment (within 5 business days) we will process the charges and submit the order for shipment.

This means that we have received your order in our system and pre-authorized your credit card for the purchase. As soon as we receive your order we automatically reach out to our suppliers to confirm that it is in stock and available for immediate shipment. If your item is on backorder or unavailable we will void the pre-authorization and reach out to you via e-mail. If your item(s) are available for immediate shipment (within 5 business days) we will process the charges and submit the order for shipment.

Order Shipment:

If your order is in stock and we process the charges to your credit card, it will ship within five business days from the date of your order. We will send you tracking information within 24 hours of your order leaving the warehouse to the e-mail address you provide when checking out. If you do not receive tracking information from us within six business days of your order feel free to follow up with us at [email protected]

Domestic Shipping:

We do not ship to P. O. Box.

O. Box.

International Shipping:

Please contact us for international shipping rates

We work very hard to ensure that we offer the absolute best prices online for all of our printers including Tevo 3D printer kits. If you find another online store that offers a lower price than us on Tevo 3D printers for sale, please let us know. We want you to feel confident when you buy a Tevo 3D printer or any of our other printers that you are getting the absolute best price for the product.

To request your partial refund simply e-mail us a link to the same product on our website, or on our competitors’ website and we will process the credit accordingly.

Our 100% Price Guarantee has some limitations:

- You must purchase the item from our website before requesting your Price Match Guarantee

- Promotions such as rebates and buy one, get one free offers are not eligible

- The item must be in stock on the competitors website

- The competitor must be an online store, they may not have a retail location

- The item must ship from the same country.

- The website cannot be a discounter or auction website (ie; eBay, overstock, etc..)

- The competitor must be an Authorized Retailer for the product in question

- The Price Match Guarantee includes the item price and the shipping charges, it excludes sales tax or any customs and duties

Info▼

One of the best-selling desktop 3D printers on the market.

With Smart Supporting Technology the print success rate of Plus could be over 90%

The UP! Plus 2 3D desktop printer has an open frame, all-metal white chassis and fabricates objects using 1.75 mm ABS (acrylonitrile butadiene styrene) or PLA (polylactic acid) thermoplastic filament (sold separately), with a vertical resolution from 150 to 400 microns (0.15 to 0.40 mm). The Tiertime Up Plus 2 3D Printer can build objects to maximum dimensions of 5.3 x 5.5 x 5.5 inches/135 x 140 x 140 mm (H x W x D). The included printer management software runs on a Windows or Mac OS X computer, reads Standard Tessellation Language (STL) files generated by computer-aided design (CAD) software (sold separately), and commands the printer through the provided USB cable. An included platform-level calibration device can be used with the software to help ensure a level build surface. The software can also read the included nozzle-height detection device to calibrate the nozzle's vertical position for accurate operation.

An included platform-level calibration device can be used with the software to help ensure a level build surface. The software can also read the included nozzle-height detection device to calibrate the nozzle's vertical position for accurate operation.

The extruder has a heat and wind shield that helps prevent injury, and redirects air to help cool the material for a fine finish. A metal build platform heats to 105 degrees C to help provide thermal stability. A perforated cell board fastens to the platform by spring clips for a secure fabrication base. Solid metal guide rails and precision slide bearings help ensure precise movement. The belt-driven stepper motors meet the National Electrical Manufacturers Association (NEMA) standard ICS 16-2001.

Features

- Auto Nozzle Height Detection

- Auto Platform Leveling

- Easy Platform removal

- All Metal Construction

| Printing material | ABS or PLA |

| Vertical (Z-axis) resolution | 150, 200, 250, 300, 350, 400 microns (0. 15, 0.20, 0.25, 0.30, 0.35, 0.40 mm) 15, 0.20, 0.25, 0.30, 0.35, 0.40 mm) |

| Build speed | 10-100 cm3/h |

| Build volume | 5.3 x 5.5 x 5.5 inches/135 x 140 x 140 mm (H x W x D) |

| Printer weight | 5 kg (11 lb) |

| Printer size | 350 x 245 x 260 mm (H x W x D) |

| Power requirements | 100-240V AC, 50-60Hz, 200W |

| Input format | STL |

| Operating systems supported | Windows XP/Vista/7, Mac OS X |

Why buy from us?▼

Price match guarantee:

We work very hard to ensure that we offer the absolute best prices online for all of our printers including Tevo 3D printer kits. If you find another online store that offers a lower price than us on Tevo 3D printers for sale, please let us know and we will refund your original payment for the difference. Read More

Read More

30 day price assurance guarantee:

We want you to feel confident that you are getting the absolute best price for the product. If you find that our own website has a lower price for the same item you have ordered within 30 days of your purchase date, we will refund the difference! Read More

Full manufacturer direct warranty:

We are an authorized dealer for all our products and comes with the full manufacturer warranty.

Tax free (except California and Nevada):

The price you see is the price you pay but because we operate in California and Nevada we must charge tax in California and Nevada.

Safe & secure online ordering:

We are certified Level 1 PCI DSS compliant. What this means is that we meet all the requirements defined by the Payment Card Industry Security Standards Council. For additional information on PCI Compliance, visit the PCI Compliance Guide website. We also accept payment via Pay Pal, a leader in secure online payment processing.

We also accept payment via Pay Pal, a leader in secure online payment processing.

Best customer service:

We strive to offer the best customer service we can. If you have any questions please let us know by phone or email.

Exclusive deals:

We appreciate each and every customer that comes to our store. We know you have a lot of choices when it comes to your 3D printing purchase. That's why we'd like to show our appreciation by periodically sending out exclusive coupons and deals to our past customers!

Shipping▼

Order Confirmation:

As soon as you place your order you will receive an order confirmation e-mail. This means that we have received your order in our system and pre-authorized your credit card for the purchase. As soon as we receive your order we automatically reach out to our suppliers to confirm that it is in stock and available for immediate shipment. If your item is on backorder or unavailable we will void the pre-authorization and reach out to you via e-mail. If your item(s) are available for immediate shipment (within 5 business days) we will process the charges and submit the order for shipment.

If your item is on backorder or unavailable we will void the pre-authorization and reach out to you via e-mail. If your item(s) are available for immediate shipment (within 5 business days) we will process the charges and submit the order for shipment.

Order Shipment:

If your order is in stock and we process the charges to your credit card, it will ship within five business days from the date of your order. We will send you tracking information within 24 hours of your order leaving the warehouse to the e-mail address you provide when checking out. If you do not receive tracking information from us within six business days of your order feel free to follow up with us at [email protected]

Domestic Shipping:

We do not ship to P.O. Box.

International Shipping:

Please contact us for international shipping rates

Price Guarantee▼

We work very hard to ensure that we offer the absolute best prices online for all of our printers including Tevo 3D printer kits. If you find another online store that offers a lower price than us on Tevo 3D printers for sale, please let us know. We want you to feel confident when you buy a Tevo 3D printer or any of our other printers that you are getting the absolute best price for the product.

If you find another online store that offers a lower price than us on Tevo 3D printers for sale, please let us know. We want you to feel confident when you buy a Tevo 3D printer or any of our other printers that you are getting the absolute best price for the product.

To request your partial refund simply e-mail us a link to the same product on our website, or on our competitors’ website and we will process the credit accordingly.

Our 100% Price Guarantee has some limitations:

- You must purchase the item from our website before requesting your Price Match Guarantee

- Promotions such as rebates and buy one, get one free offers are not eligible

- The item must be in stock on the competitors website

- The competitor must be an online store, they may not have a retail location

- The item must ship from the same country.

- The website cannot be a discounter or auction website (ie; eBay, overstock, etc..)

- The competitor must be an Authorized Retailer for the product in question

- The Price Match Guarantee includes the item price and the shipping charges, it excludes sales tax or any customs and duties

UP Plus 2 3D printer from Beijing TierTime Technology Co.

Ltd - reviews of the owners of the 3D printer, description, characteristics, photos, printed models on the 3D printer UP Plus 2

Ltd - reviews of the owners of the 3D printer, description, characteristics, photos, printed models on the 3D printer UP Plus 2 UP Plus 2 is a 3D printer that combines ease of use with high printing precision. The device has small dimensions - 245x260x350 mm and a weight of 5 kg. The printer is equipped with an automatic platform calibration system, which allows you to adjust the tilt and height. UP Plus 2 can print 3D models up to 140x140x135mm with a minimum layer thickness of 0.15mm. For construction, the printer uses FDM (Fusion Fused Modeling) technology, which allows you to create parts from ABS or PLA plastic with different physical characteristics. Software UP! The software is supplied free of charge and with its help you will be able to start working with the printer right away.

About UP Plus 2

UP! The Plus 2 is one of the first families of 3D printers originally aimed at home use. The ancestor of the family, Up Plus served as inspiration for 3D Systems Cube, and at the same time went into licensed production under the American trademark Afinia, as h579.

The ancestor of the family, Up Plus served as inspiration for 3D Systems Cube, and at the same time went into licensed production under the American trademark Afinia, as h579.

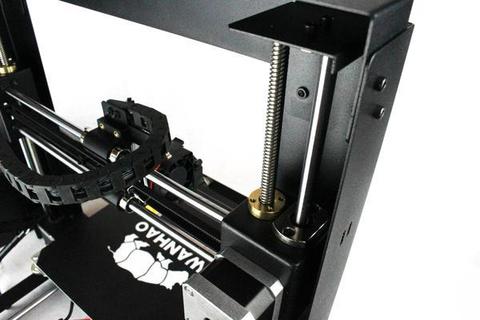

Improvements

Afinia H-Series - American clone of Chinese Up! Plus. Yes, it happens

In fact, UP! Plus 2 came to replace the original Up! Plus, which has been discontinued. Same story with Afinia h579- the h580, a clone of the Up! version, has already gone into production. Plus 2. Like the original, the new printer has an all-metal body of an extremely simple design: an L-shaped frame, a print head that moves along the X axis, and a work platform that moves along the Y and Z axes. Innovations come down mainly to fine-tuning : Platform now descends softly at the end of a print, instead of accelerating at 9.8m/s² and clanging on landing. Desktop clamps are now included. Calibration of the initial nozzle height no longer needs to be done manually - touch sensors are supplied with the device, and the corresponding function is included in the software. The extruder mounting bracket has been replaced with a more durable one. Head movement algorithms have been improved for increased smoothness. An additional connector on the printhead allows you to install an additional fan or backlight.

The extruder mounting bracket has been replaced with a more durable one. Head movement algorithms have been improved for increased smoothness. An additional connector on the printhead allows you to install an additional fan or backlight.

Design

The print area is quite small, only 140x140x135mm, but you should also consider the compact dimensions of the device itself - only 245x260x350mm. This small printer has a place in the tightest of spaces, and it weighs only five kilograms, which means it is easy to move and transport. Printing is carried out by a single extruder, so you should not count on printing supports from water-soluble PVA. Polylactide (PLA) and ABS plastics are offered as materials. It should be noted that the guide tube is very short, so with some skill you can change the material to a thread of a different color on the fly or by pausing the print. The extruder, again, is as simple as can be: a nozzle, a heating element, a filament feeder with a pinion roller, and a small fan, although upgrades are possible.

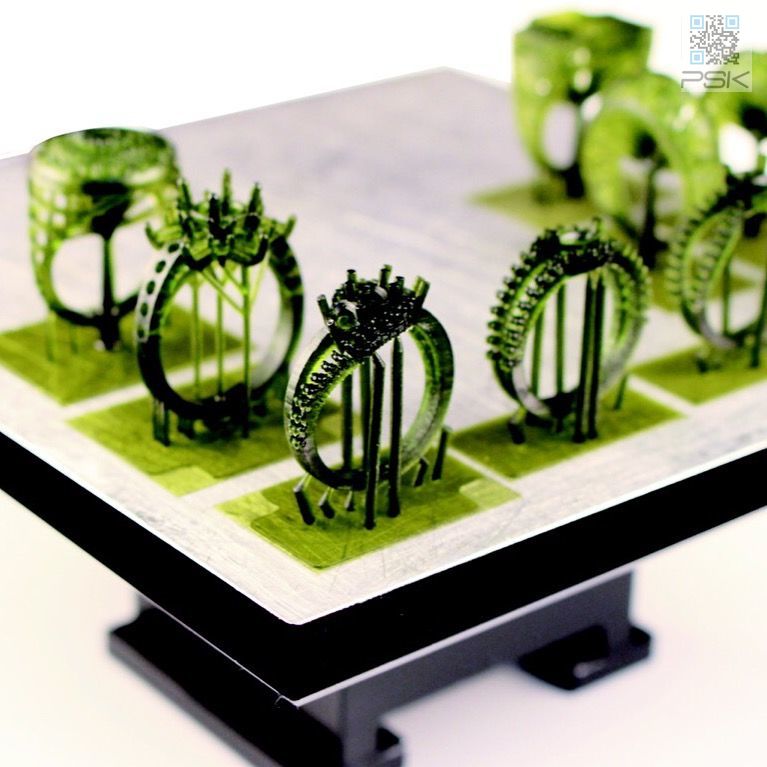

Model on a perforated desktop. Clogged holes visible

Experience has shown that open bed printers are not suitable for printing with ABS, however some of the difficulties may not be apparent due to the small size of the printed models. In addition, the developers have equipped the printer with a heated working platform, which allows to level out deformations and cracks resulting from rapid shrinkage to a certain extent. Another rather rare solution was the use of a perforated table for better plastic adhesion.

Attached sensors are used for calibration

The device is equipped with “automatic bench calibration”, although the meaning of this concept is somewhat distorted in practice. In fact, the printer measures the tilt of the platform by touching the magnetic sensor at nine points and takes into account the received data when printing. First of all, a substrate is printed, the top layer of which is aligned in a horizontal plane, and the model itself is printed on it. This means increased material consumption and the need to remove the substrate from the finished model. In addition, the holes in the platform, although they serve as a fairly reliable fastening, they tend to clog when the substrate is separated. However, "real calibration" of the platform is possible, but only manually with the help of adjustment screws.

This means increased material consumption and the need to remove the substrate from the finished model. In addition, the holes in the platform, although they serve as a fairly reliable fastening, they tend to clog when the substrate is separated. However, "real calibration" of the platform is possible, but only manually with the help of adjustment screws.

Software

Software Up! – simple and tasteful

The proprietary printer software is simply called Up! The program is as simple as the printer itself and is compatible with both Windows and Mac OS. Among the available functions there is the possibility of automatic or manual positioning of the model on the platform, automatic generation of supporting structures and scaling of models, calibration for the height and inclination of the platform. Digital models are imported in regular STL format via USB connection. There are also certain disadvantages. Experienced 3D craftsmen will be disappointed by the same simplicity of the program with the accompanying lack of fine tuning. It would not hurt to provide the possibility of manually turning on the heating of the table, which could facilitate the removal of plastic from the table.

It would not hurt to provide the possibility of manually turning on the heating of the table, which could facilitate the removal of plastic from the table.

Printing

Surprisingly, this simple device often exceeds its claims for print accuracy. So, with the official minimum layer thickness of 150 microns, Up! Plus 2 have been seen in the production of models with layers of the order of 100 microns, especially in the production of hollow models. The print speed is quite low, up to 30mm/sec, but this only benefits the quality.

Although not ideal for printing with ABS, the printer's design makes it easy to create your own solutions, such as this protective plexiglass case:

Plastic cover for ABS printing

The cover is designed as a removable structure, which allows it to be installed to maintain a higher background temperature when working with ABS or, conversely, removed when working with PLA that requires rapid cooling.

Printed with standard 1. 75mm filament. Coils can be ordered from the manufacturer, or you can buy them yourself, but you should be careful - the quality of plastic is of great importance when printing, and not only quality.

75mm filament. Coils can be ordered from the manufacturer, or you can buy them yourself, but you should be careful - the quality of plastic is of great importance when printing, and not only quality.

Packaging is also important: if purchased reels are not vacuum-packed, the plastic may become damp and dusty. Do not be too lazy to dry the thread and install the filter. The filter is easy to make with your own hands - you only need a piece of foam rubber and, possibly, a frame that would keep the foam rubber from falling into the pulling mechanism.

Pros and cons

When properly used Up! The Plus 2 is capable of producing very high quality models

Print quality reviews are mixed, with some complaining about the backlash of the platform sitting on the spring-loaded calibration screws, although if the springs are strong enough there will be no movement under the weight of small models or due to inertia. must. There are complaints about the breakage of the thread by the pulling mechanism or its insufficient power. Finally, there are cases of significant deformation of the perforated table when heated, but this is treated with additional clamps at the edges. Perforations often get clogged, but this is also easy to treat: if we are talking about ABS, the platform can simply be dipped in a bath of acetone for a couple of minutes, and the plastic will dissolve. In the case of working with PLA, you can try the organic solvent Limonen (acetone will have no effect), but, most likely, you will have to arm yourself with a needle. In the end, the table can be replaced with another one - without holes and from a more heat-resistant material, as long as it is of the correct area. Variations in thickness should not cause problems thanks to the same auto-calibration.

Finally, there are cases of significant deformation of the perforated table when heated, but this is treated with additional clamps at the edges. Perforations often get clogged, but this is also easy to treat: if we are talking about ABS, the platform can simply be dipped in a bath of acetone for a couple of minutes, and the plastic will dissolve. In the case of working with PLA, you can try the organic solvent Limonen (acetone will have no effect), but, most likely, you will have to arm yourself with a needle. In the end, the table can be replaced with another one - without holes and from a more heat-resistant material, as long as it is of the correct area. Variations in thickness should not cause problems thanks to the same auto-calibration.

The construction of supports can be done in automatic mode

Among the advantages: bulletproof metal case of sufficiently high assembly rigidity, modest dimensions and weight of the device, relatively low price, maximum ease of operation - for a beginner, automatic calibration, automatic construction of supports, the ability to print ABS plastic and relatively high print quality for an amateur printer, subject to proper operation.

The device comes with a set of tools, three Teflon-coated work tables, a massive power supply and a spool of plastic thread. The software is not supplied, but is available for free download on the manufacturer's website - apparently due to the constant updating of the program.

12 months manufacturer's warranty.

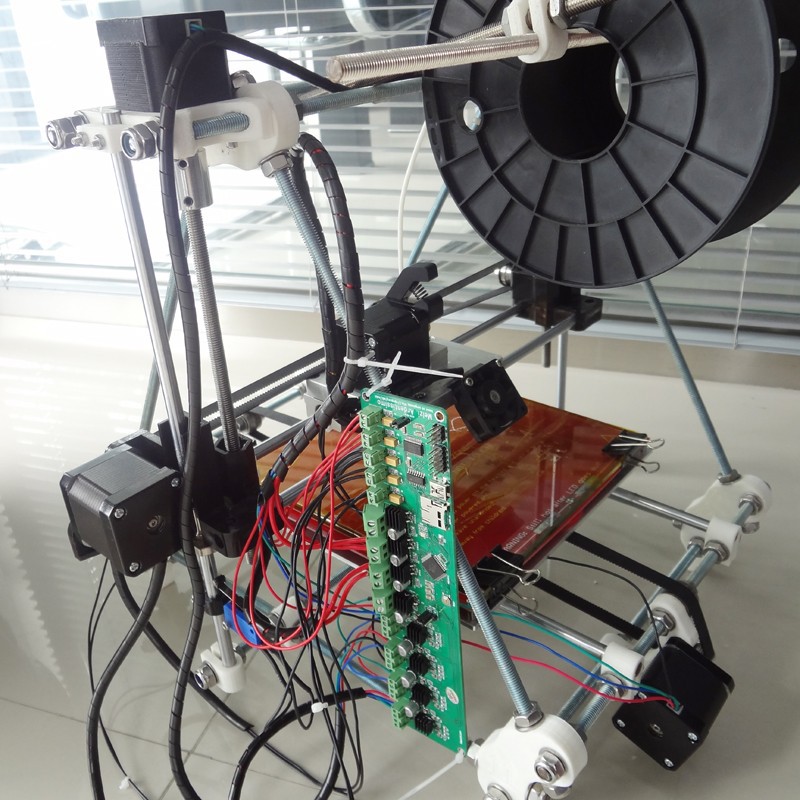

3D printer UP! Plus - the first semi-home / workshop

Writing about a completely new class of devices is never easy. No, no, 3D printers are by no means a new age invention. In one form or another, they have been around for a long time. Another thing is that for the most part these are such ingenious and very complex devices the size of at least a nightstand or chest of drawers. 3D printer UP! Plus, unlike them, is much more compact. It uses the fusing method for printing. And most importantly, it is relatively inexpensive and is available for free sale in Russia. Interesting? Well, let's get to know him better.

⇡ # Printer device

In profile, the printer looks like an inverted letter G. In a thick base in the form of a parallelepiped, an electronic filling is hidden, which is responsible for the printing process itself. A U-shaped frame is attached to the base, inside which the platform moves. It actually forms a three-dimensional model. The platform can move up and down and back and forth. And above it hangs the printing block, moving left and right. Thus, we get limited freedom in three axes, which is what is required for 3D printing.

In a thick base in the form of a parallelepiped, an electronic filling is hidden, which is responsible for the printing process itself. A U-shaped frame is attached to the base, inside which the platform moves. It actually forms a three-dimensional model. The platform can move up and down and back and forth. And above it hangs the printing block, moving left and right. Thus, we get limited freedom in three axes, which is what is required for 3D printing.

The main frame of the device is made of thick black painted metal. For aesthetes, there are other color options, more fun. Due to the metal parts, with not the largest dimensions of 245 mm (width) x 260 mm (depth) x 350 mm (height), the printer weighs a good 5 kg. Basically, not so much. Taking into account the fact that almost all the “attachments” (collapsible printing unit, platform, hanger for the reel with plastic, and so on) can be easily removed, transporting the device is quite simple. If you are interested, then on the manufacturer's website you can look with one eye at the inside of the printer.

A reel of plastic thread is suspended from the left side, which melts in the print head and is fed through a small nozzle to the print platform, where it immediately solidifies and hardens again. The actual 3D printing method used in UP! Plus, it should be clear by now.

Above the spool is a device that draws the filament evenly out of the spool during operation. It connects with a thin wire to the connector located at the base of the printer. There is also a power socket, a power button and a mini-USB port through which the printer "communicates" with the computer. Bundled with UP! Plus comes with a thick and long USB ↔ mini-USB cable.

The printer also comes with a small spatula for removing the finished model from the platform, wire cutters for cutting the plastic thread and a set of engravers. Of the consumables, the kit included a 700-gram reel with ABS plastic and special paint. The latter was not useful due to the fact that it needs to be applied only when printing on a metal platform. In our case, a plastic overlay was attached to the metal base, which greatly facilitates the process of “tearing off” the finished model.

In our case, a plastic overlay was attached to the metal base, which greatly facilitates the process of “tearing off” the finished model.

The power supply is initially striking in its size and weight. However, it produces 220 watts of power, which are primarily used to melt plastic.

By the way, if you look closely, some of the plastic parts seem a bit rough. This is not surprising, because they are printed on the printer itself.

⇡#Working with the printer

It all starts with assembling the printer. And here we must abandon the popular habit of not reading instructions with the hope that "Maybe we'll figure it out anyway - tea, you're not stupid." Not that this process was very complicated or confusing, but on the go it is unlikely that you will be able to quickly figure out what and where to screw. The same goes for the printing process - at least once you need to read all the instructions. A detailed user manual is also available in Russian. After the first connection of the device to the network and PC, you will have to manually install the driver and the necessary software. The proprietary program is available for Windows and Mac OS X.

The proprietary program is available for Windows and Mac OS X.

Before each print, it is necessary to initialize (using a button on the body or programmatically) and calibrate the printer - make sure that the distance between the extruder and the platform is within the allowable limits (0.2-0.3 mm). A rough fit is done manually, and then a more accurate calibration can be done in a semi-automatic mode. In addition, vertical calibration is possible. Also, for each new reel with plastic, its type and weight must be indicated.

UP! Plus is able to work with ABS or PLA plastic. Both are non-toxic and thermoplastic plastics. A characteristic feature of the first is impact resistance, and the second is biodegradability. Both plastics can be of different colors. PLA can also be transparent or translucent. By default, printing is done using only one type of plastic, and the finished model after the process is completed can be lightly sanded and coated, for example, with acrylic paints.

The melting temperature of PLA is about 170-180 degrees Celsius, and ABS is around 270. So it takes some time for the print head to warm up. It is claimed that there are no unpleasant odors when working with plastic. In fact, during operation, a very light, slightly sweet aroma still hovers in the air. But if you did not follow the instructions and the plastic stuck to the print head, then you will quickly pay with the characteristic stink of burnt plastic. However, with regular use, you still have to manually clean the print unit.

Proprietary software supports import of 3D models in STL (standard saving format for 3D modeling programs) or UP (compressed STL) format. The main requirement: the original model must be a completely closed surface (preferably without cracks, depressions, holes and bumps). In which case, you can enable auto-correction in the print settings. In preparation, you can adjust the size and location of the part on the platform. You can print multiple parts at the same time. The main thing is that the gaps between them are sufficient. The finished "assembly" can be saved already in the UP format - all dimensions and position of the part (s) will be remembered. Working with the program is quite simple and convenient, no special skills are required.

The main thing is that the gaps between them are sufficient. The finished "assembly" can be saved already in the UP format - all dimensions and position of the part (s) will be remembered. Working with the program is quite simple and convenient, no special skills are required.

The thickness of the filament coming out of the extruder is slightly less than 0.2 mm, and the print resolution is the same 0.2 mm (maximum 0.4 mm can be set). The print options set the resolution, substrate thickness, infill type, and various options for printing cavities and sloped surfaces. The main feature is the automatic creation of supports for printing cavities, recesses and holes. The substrate and props are a rare "grid" made of plastic. After printing, they are easily separated from the model by hand or with a chisel.

Four types of filling can be selected for the internal cavities of the model. Full (Solid), as the name implies, allows you to get a completely monolithic object with maximum strength, but also heavier. The remaining three involve the creation of external walls 1.5 mm thick with internal filling in the form of a grid of various frequencies. Immediately before printing, you can select its quality (the higher, the better, but also longer in time), set the platform heating time after printing for easier separation of the model.

The remaining three involve the creation of external walls 1.5 mm thick with internal filling in the form of a grid of various frequencies. Immediately before printing, you can select its quality (the higher, the better, but also longer in time), set the platform heating time after printing for easier separation of the model.

When all preparatory operations are done, you can send the model to print. It will take some time for the layer information to be uploaded to the printer's internal memory. After that, the program will tell you how much time is left before the completion of the work and how much plastic will be spent. From now on, the printer will print automatically - you can even disconnect it from the PC. It makes no sense to describe this process in words - watch the video.

During UP! Plus is no more noisy than a conventional inkjet printer. Unless, after initialization, the small cooler is constantly spinning and the printer's sound alerts are very loud. The working space measures 140 mm (width) x 140 mm (depth) x 135 mm (height). In practice, of course, it is necessary to indent from the edges at least a dozen millimeters. The printing time depends on the complexity, volume and type of filling of the original model. In the video, the letter model was printed in 11 minutes, with a semi-empty fill selected. And the photo below shows a voluminous half-filled model of the logo of our portal, which took a little more than 20 minutes to print.

Model length 115 mm (including backing)

The quality of the printed objects is slightly lower than that of the usual plastic items made by industrial methods such as injection molding or pressing, but still leaves a pleasant impression. Anyway, the mug printed on UP! Plus, you won't be ashamed to use it. If anything, you can rely on creativity, uniqueness and hand-made production of the product. Large objects cannot be printed, but you can make them in parts, and then glue them together. ( Colleagues first of all offered to print out what is known of which actor. But it is known that because of the dimensions it did not fit into the working space of the printer. In addition, there were some fears of prosecution by the owner of the original - copyrights, lost profits and other troubles. )

Anyway, the mug printed on UP! Plus, you won't be ashamed to use it. If anything, you can rely on creativity, uniqueness and hand-made production of the product. Large objects cannot be printed, but you can make them in parts, and then glue them together. ( Colleagues first of all offered to print out what is known of which actor. But it is known that because of the dimensions it did not fit into the working space of the printer. In addition, there were some fears of prosecution by the owner of the original - copyrights, lost profits and other troubles. )

The structure of the substrate in the form of a large grid is clearly visible

⇡#Conclusion

Has the time come for 3D printers accessible to all? Alas, not yet. First, the price is UP! Plus is low in comparison with other models. In Russia, you can buy it for $3690 (with a New Year's discount - $3,320). It costs a little less from the manufacturer - $ 2,690-2,890. Add customs and other overhead costs to this - as a result, you still won’t be able to save a lot.