3D polyjet printing

PolyJet 3D Printing | Get Elastomeric 3D-Printed Prototypes

Back

-

Materials

Materials by Service

Injection MoldingCNC Machining3D PrintingSheet Metal

Materials by Type

PlasticsMetalsElastomers

Related Links

Customer Supplied ResinsColors

Injection Molding Material Alternatives Guide

Struggling with thermoplastic material shortages? We created a detailed guide to resin substitutes for ABS, PC, PP, and other commonly molded thermoplastics.

Download

-

Resources

Design Tips Guides and Trend Reports Success Stories Design Aids Webinars and Trade Shows

Blog Videos FAQs Educators and Students Glossary

Industries Medical Aerospace Automotive Consumer Electronics Industrial Equipment

-

About Us

Who We Are Why Protolabs? Research and Development Cool Idea Award Partnerships Sustainability and Social Impact

Careers Investors Locations Press Procurement

Contact Us

Proto Labs, Inc.

5540 Pioneer Creek Dr.

Maple Plain, MN 55359

United StatesP: 877.479.3680

F: 763.479.2679

E: [email protected]Best-in-Class Online Quoting

After uploading your part design, you'll receive an online quote that includes manufacturing analysis to help improve part manufacturability. Within your quote, you can also adjust quantity and material and see price changes in real-time.

Learn More

Get a QuoteSign In

Get 3D-printed elastomeric parts within days. Request an online quote today.

UPLOAD A PART

Jump to Section→ Capabilities

→ Materials

→ PolyJet 3D Printers

→ About PolyJet 3D Printing

PolyJet is an industrial 3D printing process that builds multi-material prototypes with flexible features and complex parts with intricate geometries in as fast as 1 day. A range of hardnesses (durometers) are available, which work well for components with elastomeric features like gaskets, seals, and housings.

Common applications for PolyJet 3D printing:

- prototyping designs for overmolding or silicone rubber parts

- combining two colors or durometers into a single part

- simulating elastomers or flexible parts

If you have any issues getting your guide, click here to download.

3D Printing Surface Finish Guide

Get this quick reference guide to explore your surface finish options across our six 3D printing technologies.

United States of AmericaAfghanistanÅland IslandsAlbaniaAlgeriaAmerican SamoaAndorraAngolaAnguillaAntarcticaAntigua and BarbudaArgentinaArmeniaArubaAustraliaAustriaAzerbaijanBahamasBahrainBangladeshBarbadosBelarusBelgiumBelizeBeninBermudaBhutanBolivia, Plurinational State ofBonaire, Sint Eustatius and SabaBosnia and HerzegovinaBotswanaBouvet IslandBrazilBritish Indian Ocean TerritoryBrunei DarussalamBulgariaBurkina FasoBurundiCambodiaCameroonCanadaCape VerdeCayman IslandsCentral African RepublicChadChileChinaChristmas IslandCocos (Keeling) IslandsColombiaComorosCongoCongo, the Democratic Republic of theCook IslandsCosta RicaCôte d'IvoireCroatiaCubaCuraçaoCyprusCzech RepublicDenmarkDjiboutiDominicaDominican RepublicEcuadorEgyptEl SalvadorEquatorial GuineaEritreaEstoniaEthiopiaFalkland Islands (Malvinas)Faroe IslandsFijiFinlandFranceFrench GuianaFrench PolynesiaFrench Southern TerritoriesGabonGambiaGeorgiaGermanyGhanaGibraltarGreeceGreenlandGrenadaGuadeloupeGuamGuatemalaGuernseyGuineaGuinea-BissauGuyanaHaitiHeard Island and McDonald IslandsHoly See (Vatican City State)HondurasHong KongHungaryIcelandIndiaIndonesiaIran, Islamic Republic ofIraqIrelandIsle of ManIsraelItalyJamaicaJapanJerseyJordanKazakhstanKenyaKiribatiKorea, Democratic People's Republic ofKorea, Republic ofKuwaitKyrgyzstanLao People's Democratic RepublicLatviaLebanonLesothoLiberiaLibyaLiechtensteinLithuaniaLuxembourgMacaoMacedonia, the Former Yugoslav Republic ofMadagascarMalawiMalaysiaMaldivesMaliMaltaMarshall IslandsMartiniqueMauritaniaMauritiusMayotteMexicoMicronesia, Federated States ofMoldova, Republic ofMonacoMongoliaMontenegroMontserratMoroccoMozambiqueMyanmarNamibiaNauruNepalNetherlandsNew CaledoniaNew ZealandNicaraguaNigerNigeriaNiueNorfolk IslandNorthern Mariana IslandsNorwayOmanPakistanPalauPalestine, State ofPanamaPapua New GuineaParaguayPeruPhilippinesPitcairnPolandPortugalPuerto RicoQatarRéunionRomaniaRussian FederationRwandaSaint BarthélemySaint Helena, Ascension and Tristan da CunhaSaint Kitts and NevisSaint LuciaSaint Martin (French part)Saint Pierre and MiquelonSaint Vincent and the GrenadinesSamoaSan MarinoSao Tome and PrincipeSaudi ArabiaSenegalSerbiaSeychellesSierra LeoneSingaporeSint Maarten (Dutch part)SlovakiaSloveniaSolomon IslandsSomaliaSouth AfricaSouth Georgia and the South Sandwich IslandsSouth SudanSpainSri LankaSudanSuriNameSvalbard and Jan MayenSwazilandSwedenSwitzerlandSyrian Arab RepublicTaiwan, Province of ChinaTajikistanTanzania, United Republic ofThailandTimor-LesteTogoTokelauTongaTrinidad and TobagoTunisiaTurkeyTurkmenistanTurks and Caicos IslandsTuvaluUgandaUkraineUnited Arab EmiratesUnited KingdomUnited States Minor Outlying IslandsUruguayUzbekistanVanuatuVenezuela, Bolivarian Republic ofViet NamVirgin Islands, BritishVirgin Islands, U. S.Wallis and FutunaWestern SaharaYemenZambiaZimbabwe

S.Wallis and FutunaWestern SaharaYemenZambiaZimbabwe

I agree to receive email messages containing service updates and Design Tips from Protolabs and its affiliates

PolyJet Design Guidelines and Capabilities

Our basic guidelines for PolyJet include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and reduce overall production time.

| US | Metric | |

| Maximum Part Size | 19.3 in. x 15.4 in. x 7.9 in. | 490mm x 390mm x 200mm |

| Layer Thickness | 0.00118 in. | 30 microns |

| Minimum Feature Size | 0.012 in. | 0.3mm |

| Minimum Freestanding Wall, Hole, or Channel Size | 0.030 in. | 0.76mm |

Tolerances for PolyJet: For well-designed parts, tolerances of ±0. 005 (0.1mm) for the first inch plus 0.1% of nominal length can typically be achieved. Note that tolerances may change depending on part geometry.

005 (0.1mm) for the first inch plus 0.1% of nominal length can typically be achieved. Note that tolerances may change depending on part geometry.

PolyJet Material Options

PolyJet provides the ability to choose a desired hardness or combine material properties into a single build, which makes it ideal for prototyping overmolding parts. Shore A hardnesses of 30A, 40A, 50A, 60A, 70A, 85A, 95A, and rigid are available in these colors:

- Digital Clear/Translucent

- Digital Black

- Digital White

Compare PolyJet Material Properties

- US

- Metric

| Material | Tensile Tear Strength | Tensile Strength | Elongation |

|---|---|---|---|

| 30A | 85 psi | 399 psi | 245% |

| 40A | 100 psi | 508 psi | 200% |

| 50A | 114 psi | 508 psi | 190% |

| 60A | 121 psi | 580 psi | 160% |

| 70A | 185 psi | 725 psi | 130% |

| 85A | 341 psi | 1,088 psi | 80% |

| 95A | 398 psi | 1,740 psi | 60% |

| Rigid | n/a | 8,702 psi | 17. 5% 5% |

| Material | Tensile Tear Strength | Tensile Strength | Elongation |

|---|---|---|---|

| 30A | 0.59 MPa | 2.75 MPa | 245% |

| 40A | 0.69 MPa | 3.5 MPa | 200% |

| 50A | 0.79 MPa | 3.5 MPa | 190% |

| 60A | 0.83 Mpa | 4.0 Mpa | 160% |

| 70A | 1.28 Mpa | 5.0 Mpa | 130% |

| 85A | 2.35 Mpa | 7.5 Mpa | 80% |

| 95A | 2.74 Mpa | 12.0 Mpa | 60% |

| Rigid | n/a | 60.0 Mpa | 17.5% |

These figures are approximate and dependent on a number of factors, including but not limited to, machine and process parameters. The information provided is therefore not binding and not deemed to be certified. When performance is critical, also consider independent lab testing of additive materials or final parts.

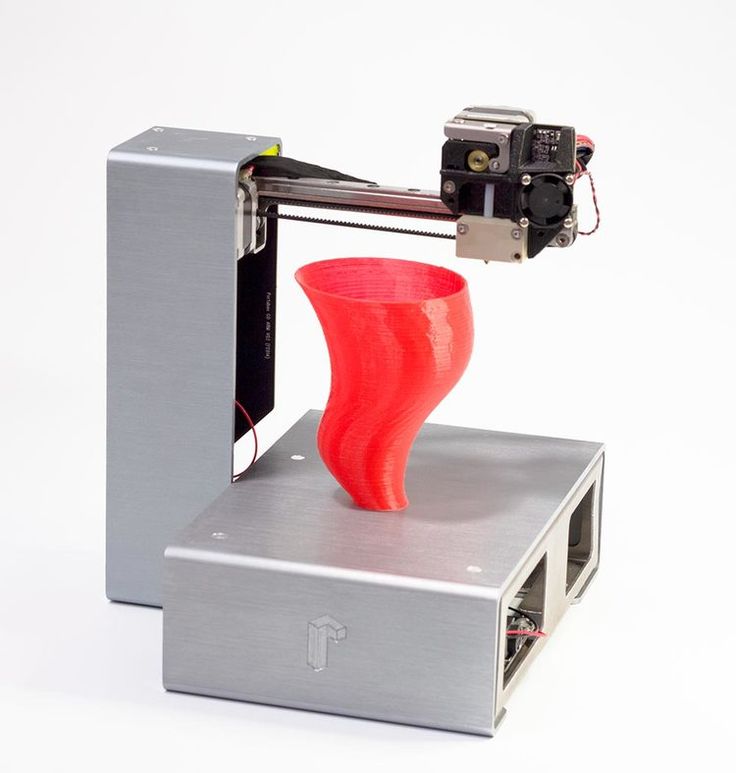

Our PolyJet 3D Printers

We use multiple additive machines that offer large build sizes, accurate parts, and quick production times. Our PolyJet equipment consists of:

- Objet260 Connex3

- Objet350 Connex3

How Does PolyJet 3D Printing Work?

The PolyJet process begins by spraying small droplets of liquid photopolymers in layers that are instantly UV cured. Voxels (three-dimensional pixels) are strategically placed during the build, which allow for the combination of both flexible and rigid photopolymers know as digital materials. Each voxel has a vertical thickness equal to the layer thickness of 30 microns. The fine layers of digital materials accumulate on the build platform to create accurate 3D-printed parts.

Each PolyJet part is completely coated in support material during the build, which ultimately is removed by hand using a pressurized water stream and a chemical solution bath. No post-curing is required after the manufacturing process.

Resources

Design Tip

Exploring Manufacturing Options for Elastomeric Components

What are your material options when designing elastomeric parts for 3D printing and injection molding?

Read Design Tip

Guide

What is 3D Printing?

Gain an understanding of additive manufacturing and how it can be leveraged to improve product development through rapid prototyping and production.

Read Guide

Design Tip

Prototyping with PolyJet 3D Printing

Use PolyJet to combine elastomeric and rigid properties together for prototyping two-material components.

Read Design Tip

Blog

Post-Printing Automation Accelerates PolyJet Process

Post-printing automation accelerates PolyJet's 3D printing process and improves efficiencies.

Read Blog

Get an instant quote on your 3D printing design.

UPLOAD A PART

PolyJet High Resolution 3D Printing Technology

PolyJet 3D Printing Technology

PolyJet technology is renowned for its outstanding realism and breathtaking aesthetics. The technology works similarly to traditional inkjet printing, but instead of jetting ink onto paper, a print head jets liquid photopolymers onto a build tray where each droplet cures in a flash of UV light.

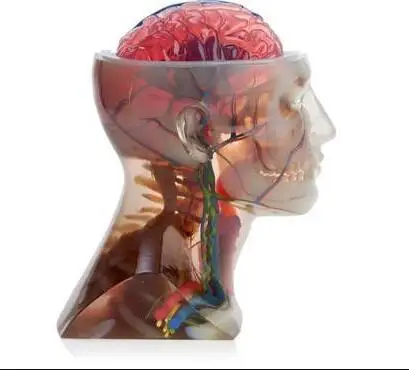

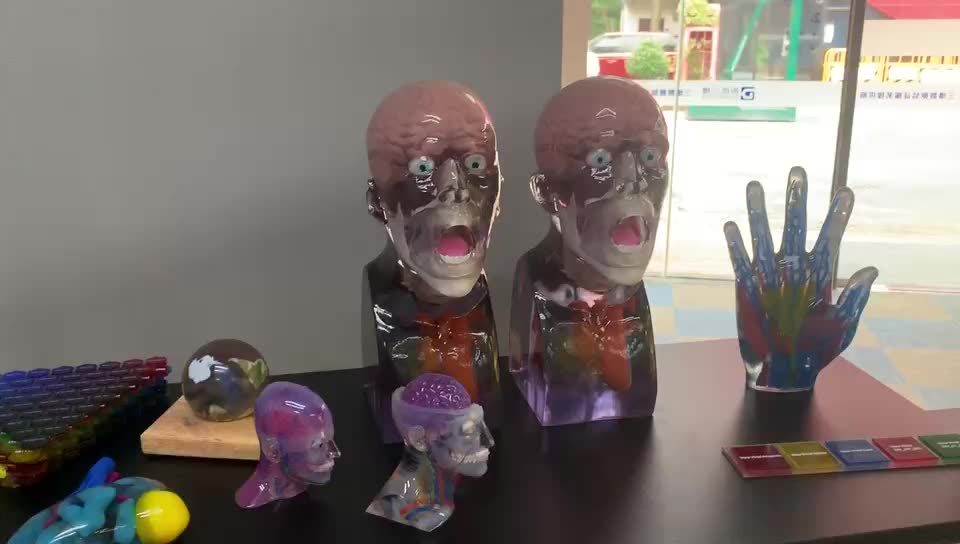

Every PolyJet 3D Printer offers sharp precision, smooth surfaces and ultra-fine details. And, by combining a variety of photopolymers in specific concentrations and microstructures the most sophisticated PolyJet systems can simulate everything from plastics and rubber to human tissue — and produce a full gamut of colors. You can now create prototypes, models, textures, and patterns that are incredibly detailed and with 1000s of material options to choose from you can incorporate diverse material properties and aesthetics.

Synonyms and similar technologies: multijet printing, photopolymer jetting

Multiple materials in a single print

High resolution down to 16-microns

Full-colour with overlays and textures

Over-mold without tooling

How Polyjet Works

Polyjet 3D printing technology works by jetting layers of curable liquid photopolymer onto a build tray.

- Pre-Processing: Preparation software determines the arrangement of photopolymers to be cured and support material from a native 3D CAD file automatically.

- Production: Polyjet printers instantly cure the droplets of liquid photopolymer using UV. Thin layers accrue onto the build tray to create the 3D part(s). Where support is needed, the printer will jet removable support material.

- Support Removal: Material is easily removable by hand, with water or in a solution bath.

No post-curing is required as the 3D printed part is ready to handle straight off the build tray.

No post-curing is required as the 3D printed part is ready to handle straight off the build tray.

Advantages

Printed parts with Polyjet technology are smooth, polished and accurately detailed.

- Polished, smooth and detailed prototypes that simulate end use parts.

- Detailed and precise parts such as realistic teeth and gums, implant models, and even maxillofacial models

- Create complex shapes, intricate detail, and delicate features.

- Integrate a wide variety of materials and colors into individual models for unmatched efficiency.

Materials

PolyJet Technical Specifications

Maximum Accuracy | Maximum Accuracy0.1-0.3 mm |

Layer Resolution | Layer Resolution16 microns, or 0.016mm/0.0006"X/Y resolution of 0.0017 |

Minimum Wall Thickness | Minimum Wall Thickness1mm |

Maximum Part Dimensions (Single Build) | Maximum Part Dimensions (Single Build)490 x 390 x 200 mm (19. 3 x 15.35 x 7.9 in.) 3 x 15.35 x 7.9 in.) |

Shore Hardness Ranges | Shore Hardness Ranges27A - 95A |

Finishes | Finishesmatte or glossy, additional finishes available as a service |

Desktop Design Series

Print small, precise models in a single material, right on your desktop.

Design Series

Gain efficiency and design freedom with more material options and hands-free support removal.

Objet Eden260VS

Objet260 Connex3

Production Series

Bring agility and aesthetics to every stage of product development with the widest range of colors and material properties for prototypes and tooling.

3D Floor Printer | Parking lot paint sprayer

Powered by HKHR Tech

After Sales Support

We have the best English speaking support team to offer 24/7 technical support to our customers worldwide.

Clients and partners

We have clients and partners all over the world. Partners in North America, EU, Russia, Middle East …

A more economical and environmentally friendly way to decorate floors

Unlike printing on PVC sticky film and costly installation labor, and hiring expensive hand-painted art to apply graffiti directly to the ground. TFP can do full color direct printing on cement roads, brick roads, asphalt roads, metal panels and other materials. TFP uses eco-friendly UV ink, which can restore colors and details of images with high quality.

Direct digital industrial printing on horizontal floor surfaces.

The Floor Printer (“TFP”) is a unique full color digital printing system specially designed for digital coloring of any floor surface graphics. TFP uses UV technology to print on floors of multiple materials, including wood floor, cement, ceramic tile, paved road, brick, lime, epoxy, etc. With the tracking system, TFP can print on curved and uneven brick surfaces.

Add any content here

Printing on an uneven surface

To ensure print quality, the floor standing printer has two high-precision sensors that can automatically detect the distance between the print head and the ground. Even on uneven floors, the print head automatically shrinks (up to 120mm) to maintain the optimum distance from the floor for the best print quality.

Add any content here

Application on various substrates

Floor standing printer uses LED UV printing technology, which can print on various materials. Such as: wood floor, ceramic tile, paving slab, plastic, cement, plastic, ceramic and so on. You just need to put it on the ground, adjust the settings, and TFP will automatically print the desired image.

Add any content here

Image Stitching

To overcome the limitation of mechanical dimensions and print large format images, we have developed an image stitching program. Combined with laser positioning, you can endlessly stitch images in a horizontal plane and expand your imagination. Because TFP can print endlessly in the vertical plane, so with image stitching technology, you don't have to worry about the image print format.

Combined with laser positioning, you can endlessly stitch images in a horizontal plane and expand your imagination. Because TFP can print endlessly in the vertical plane, so with image stitching technology, you don't have to worry about the image print format.

Latest News

We will share our latest achievements and knowledge about the floor printer here.

Our blog

Material blasting allows you to create three-dimensional objects

You are here

Home

14.00

Normal

0

false

false

false

EN

X-NONE

X-NONE

various combinations of materials drop by drop.

14.00

Normal

0

FALSE

FALSE

FALSE

RU

X-None

X-None

Timothy V. Simpson, Paul Mortar, Professor of Engineering Pear

14 ) that are blended together to create the third material (purple). Photo Credit: Nick Meisel, PA.

Photo Credit: Nick Meisel, PA.

Of the seven major Additive Manufacturing (AM) processes available, material inkjet is the technology closest to what we use to print text and images on paper. This is because the printheads that are used to inkjet material are very similar to the printheads used for inkjet printing, except that instead of supplying ink, they deposit droplets of material that create a layer upon layer of a 3D object.

The origins of material inkjet technology date back to the mid-1990s when Solidscape (originally called Sanders Prototype Inc.) commercialized "Drop-on-Demand" technology for wax 3D printing. The company continues to specialize in material blasting systems for making very precise wax models for jewelry and investment casting. It was acquired in 2011 by Stratasys and then sold in 2018 to Prodways.

3D Systems introduced its ThermoJet material inkjet platform about two years after Solidscapes was introduced, and has continued to push the technology into what it calls MultiJet Printing (MJP). Meanwhile, the Israeli company Objet was the first to introduce photopolymer blasting in the late 1990s. The company continues to develop and market its PolyJet material blasting systems by merging with Stratasys in 2012.

Meanwhile, the Israeli company Objet was the first to introduce photopolymer blasting in the late 1990s. The company continues to develop and market its PolyJet material blasting systems by merging with Stratasys in 2012.

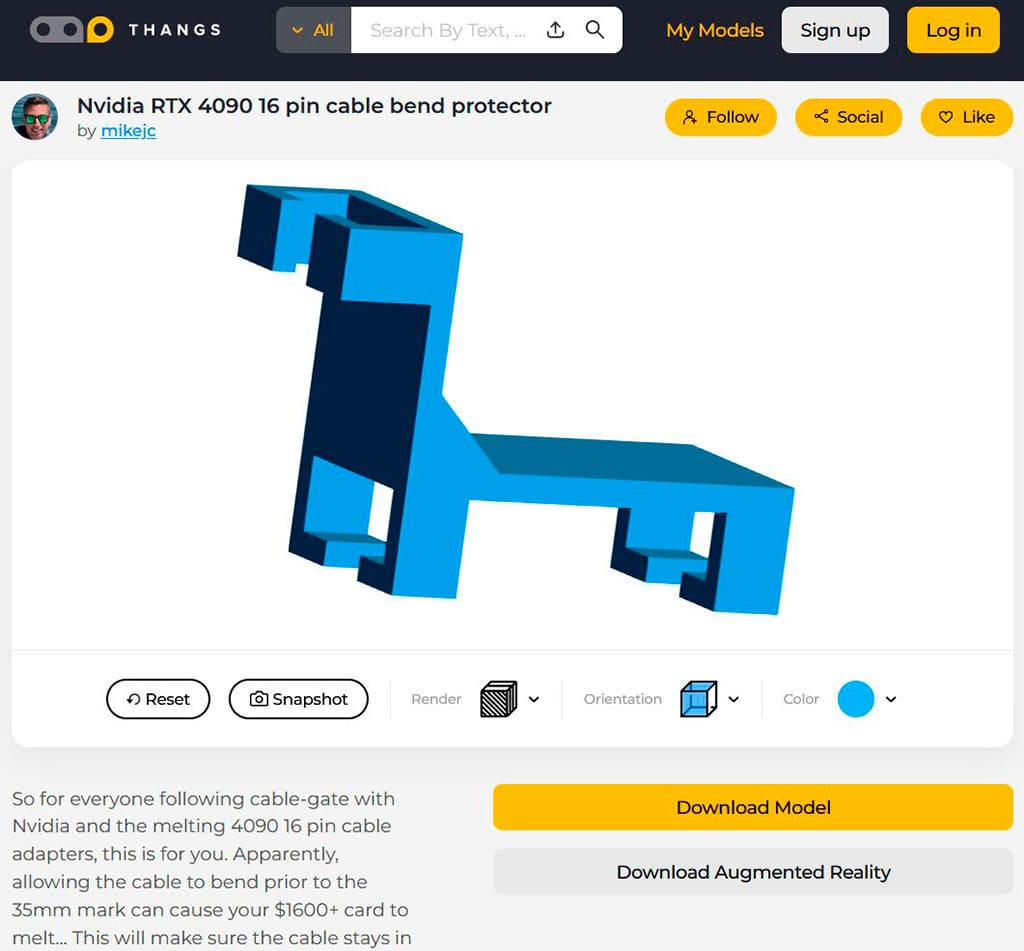

Material blasting offers some distinct advantages over other AM technologies, but also has its drawbacks. First, the jet of material is fast. The material is blown one line at a time compared to extruding from a nozzle or curing/melting with a laser. The material that is sprayed is photosensitive and cures with ultraviolet (UV) light almost immediately after application. Because the layers are very thin (typically 16 to 32 microns), the material is fully cured during the printing process. No additional curing or thermal post-treatment is required compared to parts made using many bath photopolymerization processes. Unfortunately, material inkjet systems are still expensive given the complexity and proprietary printhead technology. Material blasting also requires supports for overhanging structures. However, due to the low layer thickness, the dimensional accuracy of the inkjet material is very good, even when printing large parts, and the inkjet-produced parts have excellent surface finish. The mechanical properties of blasted materials are uniform, but the product tends to be very brittle. This limits its use as functional components and end-use parts, but material blasting is great for prototypes, visual aids, and tools. In fact, one area where media inkjet excels is multi-material printing, because modern systems offer multiple printheads on a single machine. This allows users to print materials at the same time and mix them in different compositions (see image). As a result, material blasting can be used to combine hard and soft or opaque and transparent materials in one part. It is the creation of "digital material" that can be manipulated at the voxel level. For those of you familiar with Minecraft, this is a good analogy - instead of creating virtual structures block by block, inkjet material modeling allows you to create 3D objects by dropping different combinations of materials.

However, due to the low layer thickness, the dimensional accuracy of the inkjet material is very good, even when printing large parts, and the inkjet-produced parts have excellent surface finish. The mechanical properties of blasted materials are uniform, but the product tends to be very brittle. This limits its use as functional components and end-use parts, but material blasting is great for prototypes, visual aids, and tools. In fact, one area where media inkjet excels is multi-material printing, because modern systems offer multiple printheads on a single machine. This allows users to print materials at the same time and mix them in different compositions (see image). As a result, material blasting can be used to combine hard and soft or opaque and transparent materials in one part. It is the creation of "digital material" that can be manipulated at the voxel level. For those of you familiar with Minecraft, this is a good analogy - instead of creating virtual structures block by block, inkjet material modeling allows you to create 3D objects by dropping different combinations of materials.

As you might guess, inkjet material printing also allows you to print 3D objects in color, just like we can print 2D images (and text) in color. Full color detail is another reason why material blasting is great for prototyping, and finds a real niche for creating medical models and visual aids for training physicians and surgeons. MRI and CT data for a patient can be easily converted into a 3D point cloud and printed in color - with different textures and material properties - to help clinicians plan complex surgeries and medical procedures. This not only reduces the time in the operating room, but also helps to save the lives of patients in many difficult cases.

Finally, like many other AM processes, material blasting is gaining new interest due to recent advances. For example, Xjet recently introduced Nanoparticle Jetting technology, which paves the way for 3D printing of ceramic materials. Meanwhile, researchers at the University of Nottingham are releasing metallic inks along with insulating polymer materials for functional electronic 3D printing.