3D pancake printer video

PageNotFound

The page you are looking for cannot be found.

We apologize for any inconvenience. Please check the link again or use the site navigation or search function above to locate the item for which you were looking.

The 16' Glowing Inflatable Jack O' Lantern

$349.95

( 59 )

The 12' Haunted Halloween Archway

$349.95

( 3 )

The Thousand Points of Light Tree

$499.95

( 104 )

The Two Story Inflatable Black Cat

$349. 95

( 55 )

The Life Size Animated Grinch

$249.95

( 67 )

The World's Best Prelit Concolor Fir (4.5' Full)

$379.95

( 8 )

The Cordless Prelit Autumn Celebration Trim (Wreath)

$79.95

( 15 )

The Brightness Zooming Natural Light Lamp

$149.95

( 1618 )

The Choreographed Illuminated Galloping Reindeer

$399. 95

95

( 9 )

The Cordless Color Changing Ghosts

$79.95

( 17 )

The Best Smartphone Photo Printer

$179.95

( 131 )

The Peanuts "It's The Great Pumpkin" Illuminated Halloween Tree

$139.95

( 40 )

The Best Automatic Cordless Tire Inflator

$99.95

( 36 )

The Countertop Ice Maker

$239. 95

95

( 80 )

The Peanuts Trick Or Treating Trio

$199.95

( 6 )

The 15' Inflatable Illuminated Bumble

$399.95

( 3 )

The 5' Animated Dancing Skeleton

$149.95

( 51 )

The Adjustable Height Fold And Store Puzzle Table

$279.95

( 1 )

The Video Projecting 10' Frosty The Snowman

$369. 95

95

( 55 )

The Rechargeable Heated Massaging Stadium Seat

$99.95

( 110 )

The 30" Cordless Prelit Red And White Stairway Swag

$69.95

( 19 )

The Cordless Prelit Christmas Plaid Holiday Trim

$99.95

The Twinkling Lawn Sculpture (Stallion)

$249.95

( 64 )

The Rotating End Table

$249.95

( 44 )

The Mobility Roadster

$3,995. 00

00

The Only Cordless Vacuuming Yard Mulcher

$299.95

( 1 )

The Italian Countertop Pizza Oven

$149.95

( 28 )

The Cordless Prelit Silver And Champagne Holiday Trim

$99.95

The Outdoor 5' Twinkling Nutcracker

$199.95

The Best Multi Handset Cordless Telephone

$179.95

( 392 )

The Jabbering Jack O' Lantern

$69.95

( 38 )

The Air Combat Battling Helicopters

$129. 95

95

( 37 )

The Best Gentleman's Foil Shaver

$349.95

( 189 )

The 5' Animated Holiday Locomotive

$249.95

( 63 )

The Rotating LP Storage Tower

$249.95

( 82 )

The Leaf Collecting Lawn Sweeper

$149.95

( 265 )

The 5' Animated Juggling Snowman

$149.95

( 188 )

The Best Long Reach Hedge Trimmer

$199. 95

95

( 124 )

The Twinkling Pumpkin Wagon

$199.95

( 13 )

The Giant Classic Christmas Lights

$199.95

( 3 )

The Illuminated Peanuts Ice Skating Trio

$279.95

( 23 )

The Prelit Candy Corn Halloween Trim (Wreath)

$89.95

The Fireproof/Waterproof Document Box

$99.95

( 77 )

The How The Grinch Stole Christmas Animated Max The Dog

$129. 95

95

( 17 )

The World's Lightest Carry On

$169.95

( 121 )

The Truck Driver's Comfort Cushion

$99.95

( 202 )

The Complete Health Monitor Smart Watch

$99.95

( 17 )

The 36" Ultrabright Candled Wreath

$169.95

( 7 )

The Six Minute Laser Hair Regrowth Therapy Cap For Balding Scalps

$3,000. 00

00

The Animated Fiber Optic Angel

$199.95

( 1 )

The 360 Swivel Upholstered Armchair

$329.95

The Easy Read Full Disclosure Clock

$99.95

( 615 )

The Non-Slip Furniture Protecting Pet Covers

$99.95

( 86 )

The Best Ideal Temperature Dry Eye Relief Mask

$129.95

( 565 )

The Full Page Illuminated Desktop Magnifier

$99. 95

95

( 117 )

The Choreographed Light Show Tree

$279.95

( 68 )

The Heated Shiatsu Full Body Massage Mat

$249.95

( 13 )

The Illuminated Grinch Sleigh

$129.95

( 6 )

The Space Saving Rotating CD/DVD Tower

$299.95

( 35 )

The Hammacher Schlemmer Three Passenger Electric Ride On Train

$299. 95

95

( 22 )

The Best Portable DVD Player

$179.95

( 77 )

The Clinically Proven Stabilized Walking Shoes

$149.95

( 7 )

The 15' Inflatable Lightshow Christmas Tree

$379.95

( 2 )

The Disney Christmas Carousel Tree

$199.95

( 136 )

The Most Powerful Handheld Car Vacuum

$199. 95

95

( 125 )

The Commercial Grade Patio Heater

$199.95 $299.95

( 2 )

The CD Playing Multiformat Tabletop Radio

$199.95

( 13 )

The Ultrasonic Plaque Remover

$39.95

( 30 )

The 5' Pumpkin Juggling Skeleton

$169.95

TheSleeper Lift Chair With Massage And Heat

$2,500.00

( 3 )

The Life Size Animated Frosty

$249. 95

95

The 60" Ultrabright Estate Wreath

$349.95

( 4 )

The Freshly Cut Christmas Trees

$109.95

( 10 )

The World's Best Prelit LED Noble Fir (7.5' Full)

$1,200.00

The 12' Head Turning Grinch

$399.95

The Best Digital Camera Binoculars

$199.95

( 98 )

The Fireproof/Water-Resistant Safekeeping Backpack

$129.95

The Pelvic Floor Electrotherapy Muscle Strengthener

$149. 95

95

( 3 )

The Any Music Format Stereo

$279.95

( 256 )

The Lighted Rudolph And Bumble Decor

$99.95 $249.95

( 5 )

The Cordless Prelit Silver And Champagne Stairway Swag

$69.95

( 21 )

The New York Times Jigsaw Puzzle Of Your Birth Date (1,000 Pieces)

$79.95

( 128 )

The Wegner Inspired Stacking Deck Chairs

$699. 95

95

( 178 )

The 12' Spellcasting Witch Coven

$349.95

The 24" Portable TV/DVD Player

$299.95

The Gentleman's Walk On Air Indoor/Outdoor Slippers

$99.95

( 559 )

The Washable Cashmere Sweatshirt

$159.95

( 312 )

The Best Children's Interactive Teaching Globe

$129.95

( 100 )

The Cordless Prelit Red And White Holiday Trim

$99. 95

95

( 1 )

The Illuminated Halloween Gnomes

$169.95

( 1 )

The Best Arthritis Gloves

$34.95

( 287 )

The Italian Electric Tomato Press

$399.95

( 36 )

The Cordless Reading Lamp

$249.95

( 375 )

The Compression Knee Massager

$199.95

( 177 )

The 4' Twinkling Christmas Bubble Light

$199. 95

95

( 19 )

AMERICA'S LONGEST RUNNING CATALOG

Save

$15 on Your Next Order & more exclusive offers when you sign up for text alertsText Hello to 20446

By signing up via text, you agree to receive recurring automated promotional and personalized marketing text messages (e.g. cart reminders) from Hammacher Schlemmer at the cell number used when signing up. Consent is not a condition of any purchase. Reply HELP for help and STOP to cancel. Msg frequency varies. Msg & data rates may apply. View Terms & Privacy.

*Offer valid on orders over $99

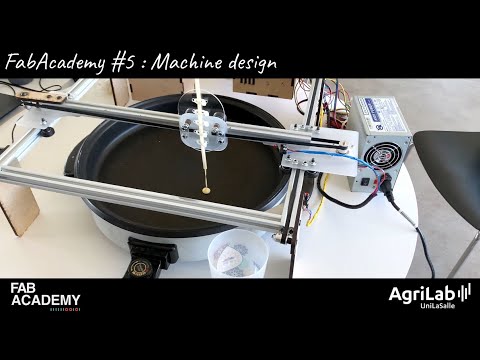

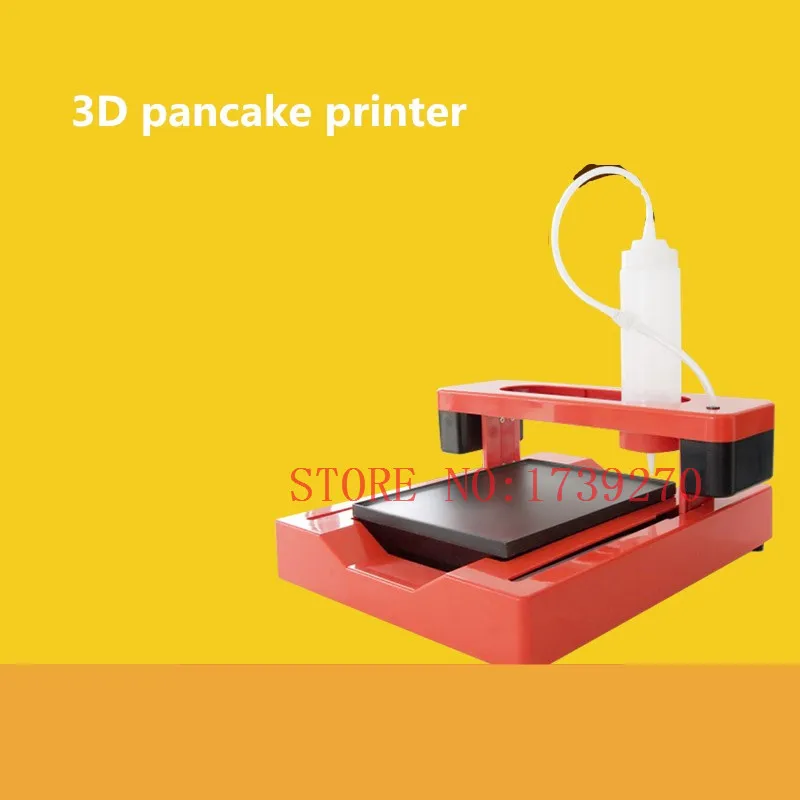

3D printing just became more delicious

By: Lucy Vernasco

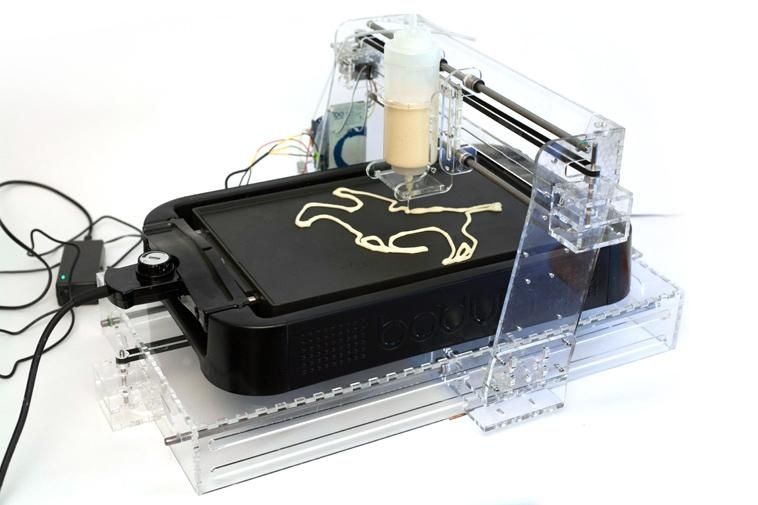

3D printing is more delicious than ever. With more than 1,000 Kickstarter backers, PancakeBot is the world’s first 3D pancake printer.

With more than 1,000 Kickstarter backers, PancakeBot is the world’s first 3D pancake printer.

“It’s a project I did for my kids to get them inspired. It’s a family project,” Miguel Valenzuela said about his invention. Valenzuela is a civil engineer, inventor and father living in Norway.

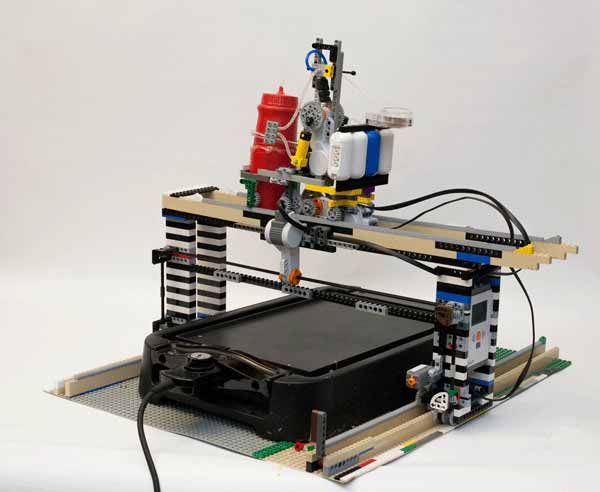

PancakeBot was first prototyped as a LEGO model before Valenzuela made it into the current machine.

Launched in 2013, PancakeBot won’t hit stores until mid 2015, but Kickstarter backers can get their own for half the anticipated retail price by pledging $149 dollars.

“I’ve always wanted to dabble with 3D printing, especially since it was coming online with Makerbot,” Valenzuela said. “I learned how to program with LEGO code, pretty much spent six months making a pancake machine out of LEGOs. We posted the video on YouTube and then it went viral. It was all made out of LEGOs except for the ketchup bottle”

[youtube http://www.youtube.com/watch?v=f3Q8nbtRNT0&w=560&h=315]

The idea originated with a question from Valenzuela’s daughter as he was reading an article in Make Magazine about prototyping with LEGO, Valenzuela said.

“My daughter Lily asked, ‘What are you doing, dad?’ and I said I was reading about a guy who made a pancake stamping machine out of LEGOs. Her eyes opened up really big, and she turned to Maya, her sister, and yelled, ‘Papa’s going to build a pancake machine out of LEGOs!’”

Valenzeula began bringing his PancakeBot LEGO prototype to Maker Faires including one at The White House. After partnering with StoreBound, he began a Kickstarter campaign in order to reach a wider audience and bring the project to stores later this year. PancakeBot, which comes with pre-loaded designs and an SD card for custom designs, lets users create pancakes in any pattern they can dream of.

And, yes, then you pour syrup on it and eat it. Valenzeula reveals more secrets about his Bot.

How long does the process take?

It depends on the size of the pancake, of course. For a simple one it can trace something out in 45 seconds to a couple of minutes, the outline of it, and then it needs to come back to fill. You can do the fill by hand, or you can do the fill with PancakeBot. You’re looking at three to four minutes for a decent sized pancake with a custom design and logo on it.

You can do the fill by hand, or you can do the fill with PancakeBot. You’re looking at three to four minutes for a decent sized pancake with a custom design and logo on it.

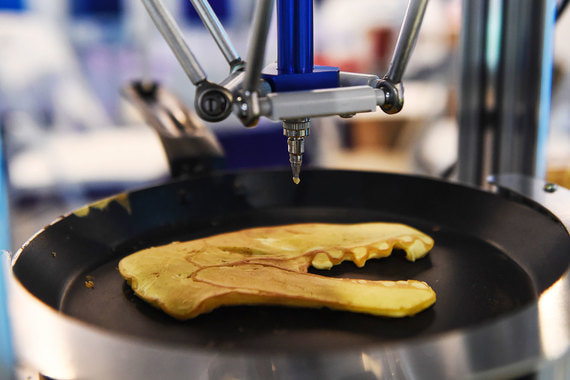

How does PancakeBot work?

The way it works is that you import the image for the background into the software. Then you have a window where you trace over the background. You trace lines. There are no curves, just lines. If you want to draw a circle, you draw a bunch of small lines. Once you draw your dark lines, you go back and you click a [15 second delay] into it. That allows the brown stuff to cook and get browner. Then you come back and do the fill. The fill fills it in with a lighter batter. Then you give it a flip and you have your image revealed to you. Every time you flip the pancake you don’t know exactly what you’re going to get, because you don’t know how long it’s cooked. The cool thing is the reveal. Like ‘ooh look at that, it came out perfect.’

PancakeBot printing a butterfly pancakeYou can print layers, but it’s very limited in the amount of layers it’ll print. The main thing is that pancake batter is in this liquid form, so it’s not like taking an apple and making it into liquid form and squirting it out. So there’s a natal progression of going from pancake batter to pancake. That’s what’s really cool about this. For stuff that has the same viscosity as pancake batter and you can cook it, the sky’s the limit on that. We use 3D printing technology and it uses the idea of food and cooking. It’s the only printer out there that actually cooks food while it’s being made. We went from LEGO to this.

The main thing is that pancake batter is in this liquid form, so it’s not like taking an apple and making it into liquid form and squirting it out. So there’s a natal progression of going from pancake batter to pancake. That’s what’s really cool about this. For stuff that has the same viscosity as pancake batter and you can cook it, the sky’s the limit on that. We use 3D printing technology and it uses the idea of food and cooking. It’s the only printer out there that actually cooks food while it’s being made. We went from LEGO to this.

How do you hope people use Pancake Bot?

Number one, I hope people will make pancakes out of it. I don’t want it to end there. I want people to look at what we’ve created here as a tool for learning, a tool for exploration and a tool for inspiring kids to look at technology in a different way. Now what we’re doing is we’re putting a computer system and machine into the kitchen and you can tell it what to do. You’re the artist now. We’re looking into allowing the user to hack it. They can upload their own programs to it, and draw out custom shapes. It would be nice to see it at places like Disney Land, resorts, hotels.

We’re looking into allowing the user to hack it. They can upload their own programs to it, and draw out custom shapes. It would be nice to see it at places like Disney Land, resorts, hotels.

Do you ever get tired of pancakes?

The kids still love pancakes. They never get sick of them. I love pancakes too, so I think that shows a little bit. What the challenge is is challenging ourselves to come up with different designs and pushing ourselves to see what we can come up with and things like that.

Have your kids been inspired from you invention?

Totally! Now my kids are inventing stuff and making things. They’re playing with robotics and [are] interested in programming. The kids look at things differently now. They say, “Dad, can you build a robot for this?” They’re seeing now that technology can be used on a daily basis.

This project would not have been possible without the Maker community, because this is one of the reasons we decided to do it, is to inspire kids to get involved with technology. The Maker community has been very awesome in helping us out.

The Maker community has been very awesome in helping us out.

Photo at top: A butterfly pancake created by PancakeBot.

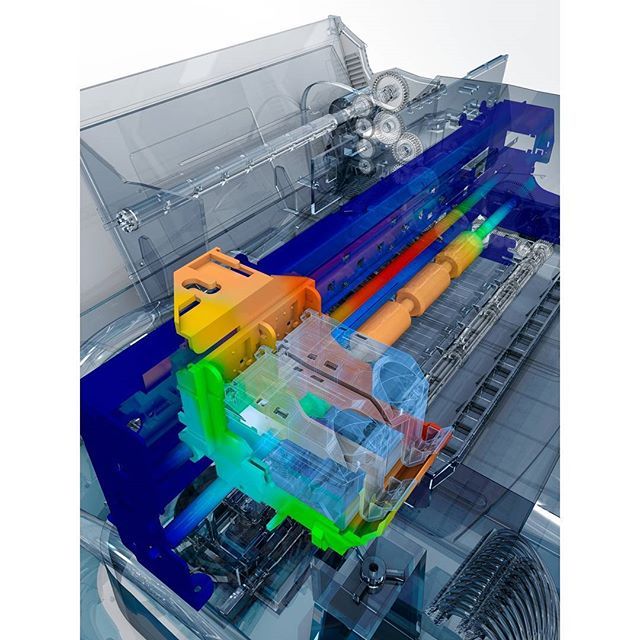

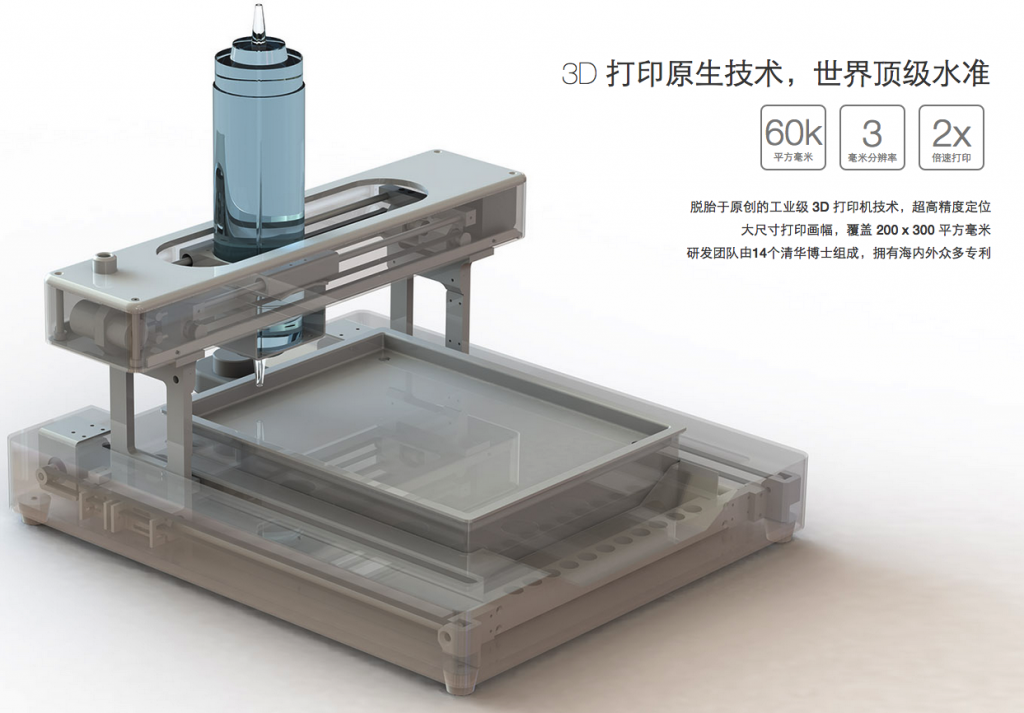

how it works, a review of culinary (confectionery) models and examples of work for cakes and chocolate printing . Interest in 3D food printing is understandable - every year manufacturers release new models that open up more and more prospects for owners of 3D printers. In the article we will talk about the device of a 3D food printer and what can be done with it. We'll also talk about 3D printing with sugar and chocolate, edible prints on drinks, and even 3D pancakes. Get ready to be amazed - the scale of food printing on 3D printers will amaze even the most sophisticated user.

How it works and types of devices

The principle of operation of a 3D food printer is similar to a conventional inkjet printer. The only difference is that instead of simple ink cartridges in a food 3D printer, food coloring cartridges are used. The memory of the device allows you to store many recipes. To print the desired dish, you just need to select the saved recipe and press the button. After the dish is sent to print, the printer will begin to lay out the ingredients in layers on the work surface or directly on the plate. The printed dish can be sent to cool in the refrigerator or baked in the oven.

To print the desired dish, you just need to select the saved recipe and press the button. After the dish is sent to print, the printer will begin to lay out the ingredients in layers on the work surface or directly on the plate. The printed dish can be sent to cool in the refrigerator or baked in the oven.

Views

Despite the fact that 3D food printing technology is the youngest in the field of 3D modeling, it is dynamically developing and improving in several directions at once. Food 3D printers have significant differences and are divided into several types:

- Food extrusion type 3D printer - this type of device extrudes the edible mass layer by layer onto the work surface until the dish is completely formed. The operation of the printer is controlled by a computer, on which the three-dimensional model of the object and the recipe are located. The printer itself, like its inkjet counterparts, is very simple - it consists of a table and a print head. The head moves along three coordinate axes, and an extruder is placed inside it to heat the mixture.

The extruder is the main element of extrusion type printers. The printing ingredients are filled into a special syringe, which is placed in the print head. A significant disadvantage of this type of device is that the more complex the model in terms of composition and color scheme, the more often you will have to stop printing and replace the syringe. Extrusion-type printers include Chokola 3D - the device allows you to work with chocolate and pasty ingredients.

The extruder is the main element of extrusion type printers. The printing ingredients are filled into a special syringe, which is placed in the print head. A significant disadvantage of this type of device is that the more complex the model in terms of composition and color scheme, the more often you will have to stop printing and replace the syringe. Extrusion-type printers include Chokola 3D - the device allows you to work with chocolate and pasty ingredients.

Please note! The smaller the diameter of the nozzle through which the raw material is extruded, the neater, more accurate and more realistic the printed dish will be.

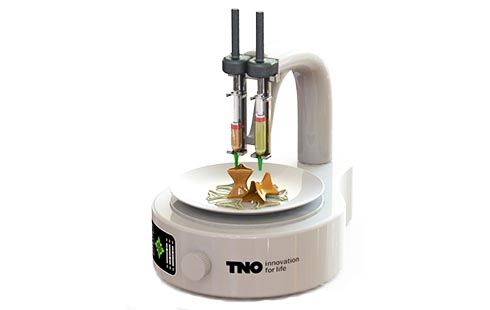

- 3D food carousel printer - despite the fact that the main working element of this type of printer is an extruder, such devices are called carousels because of the feed mechanism. The carousel 3D printer rotates over the working surface of the container with raw materials, selecting the desired ingredient and squeezing out the dosage of the product indicated in the recipe.

Outwardly, the printer really resembles a kind of carousel - containers with products rotate at a slow pace over the table. An almost unlimited number of recipes can be stored in the base of a carousel-type food 3D printer, and special skills are not needed to use it. All that is required from the user is to simply press a button and start printing. The carousel printer independently dispenses raw materials, alternately squeezing out the food mixture from the desired container. Depending on the model of the device, the containers can be from 4 to 16 pieces. Author's product from Martha Stewarts Crafts - the Cricut Cake carousel printer will help you create an original cookie or decoration for a festive cake. The owner of the printer just needs to press the start button - everything else will be done by Cricut Cake. Included with the device is a large cookbook with ideas for creating real edible works of art.

Outwardly, the printer really resembles a kind of carousel - containers with products rotate at a slow pace over the table. An almost unlimited number of recipes can be stored in the base of a carousel-type food 3D printer, and special skills are not needed to use it. All that is required from the user is to simply press a button and start printing. The carousel printer independently dispenses raw materials, alternately squeezing out the food mixture from the desired container. Depending on the model of the device, the containers can be from 4 to 16 pieces. Author's product from Martha Stewarts Crafts - the Cricut Cake carousel printer will help you create an original cookie or decoration for a festive cake. The owner of the printer just needs to press the start button - everything else will be done by Cricut Cake. Included with the device is a large cookbook with ideas for creating real edible works of art.

What can be done with a 3D food printer?

A wide range of 3D-compatible ingredients make it possible to create virtually any 3D model - the scale is limited only by the user's imagination. With the help of a food 3D printer, you can create figures of any complexity that will give even a simple cake a designer look.

With the help of a food 3D printer, you can create figures of any complexity that will give even a simple cake a designer look.

Three-dimensional models of the bride and groom or any hero of the occasion; mask-cast of chocolate; planes, cars and cartoon characters on cakes for children; voluminous bouquets; edible figurines; original inscriptions and company logos - all this can be printed on a food 3D printer.

That is why such devices are gaining more and more popularity in hand made confectioneries - exclusive products attract customers and emphasize the professionalism of the creator.

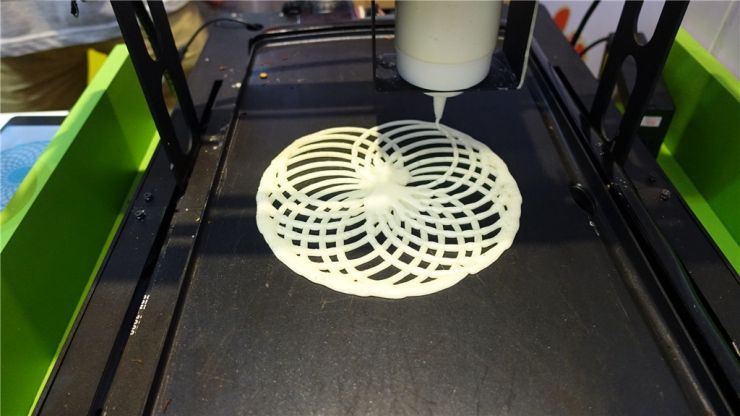

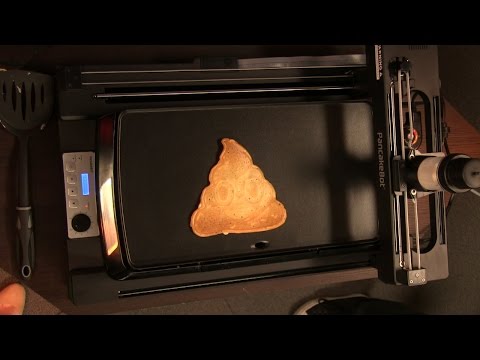

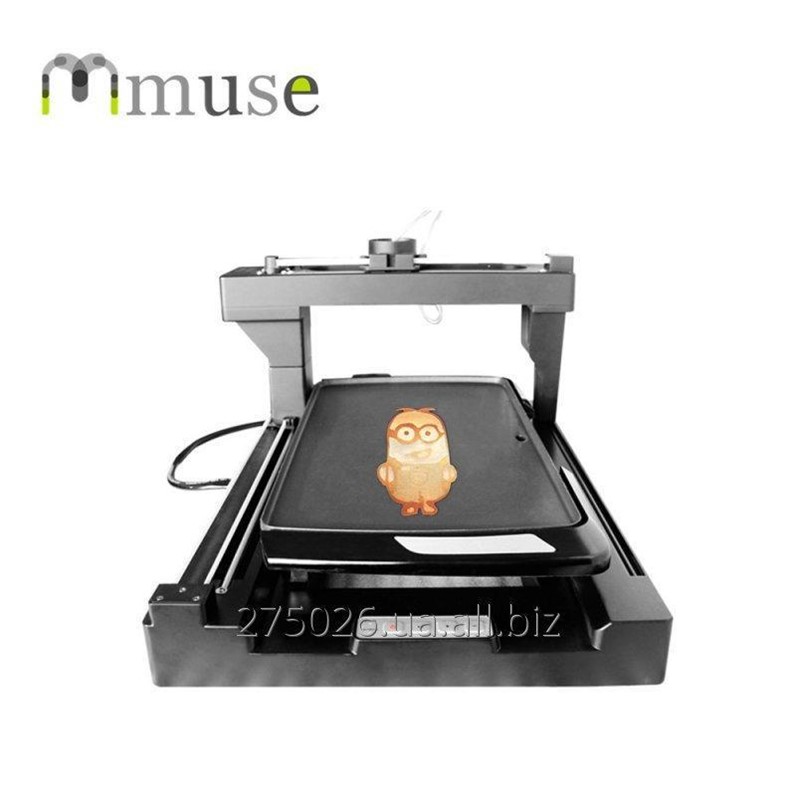

Printing pancakes

If you are not impressed by unusual cake decorations and original edible models, and you think that 3D food printing is just pampering, then especially for you and other connoisseurs of a rational approach, manufacturers have released 3D printers that bake pancakes. The device is a dream of housewives and pancake lovers, it costs more than a pancake maker or an ordinary frying pan, but can even the most modern pancake maker bake pancakes in the shape of a dinosaur, your favorite character or even your own head for breakfast?

As an example, consider the PancakeBot model, which not only bakes pancakes and pancakes, but also knows how to create shadows and halftones. Thanks to these unique features, 3D images printed on the PancakeBot are as realistic and voluminous as possible. During the printing process, the printer immediately fries the products.

Thanks to these unique features, 3D images printed on the PancakeBot are as realistic and voluminous as possible. During the printing process, the printer immediately fries the products.

The PancakeBot uses a heated non-stick surface as its working base and computer controlled heat and extruder action. The model is equipped with one print head, connects to a computer via an SD card or USB cable. The productivity of the printer is 100mm/s.

Like any device, PancakeBot and other 3D food printers have their advantages and disadvantages.

The main drawback of the design of printers that print pancakes, users consider the inadmissibility of even the slightest lumps in the dough. The fact is that even the smallest lump can clog the nozzles of the device and stall the printing process. The problem is solved simply - just monitor the viscosity of the dough.

The advantages of PancakeBot are highly appreciated by artists and creative personalities - the user can draw absolutely everything that his talent and imagination allow him to draw.

Indisputable plus - simple ingredients. PancakeBot does not require expensive raw materials - the printer works with a simple pancake dough, the taste of which depends only on the user.

Please note! The manufacturer's website notes that any image can be downloaded to the PancakeBot's SD card, be it pictures downloaded from the Internet or your own photos.

Another benefit of PancakeBot is its availability. The device is relatively inexpensive.

PancakeBot will suit both private mini-confectioneries and catering chains, as well as simple pancake lovers — unusual pancakes and pancakes will delight children, decorate any holiday and surprise customers.

Sugar printing

Back in 2013, architects Kyle and Liz von Hasseln founded The Sugar Lab and, to the delight of sweet lovers, found a new application for 3D inkjet printing. Using the ChefJet confectionery food 3D printer as an example, we will talk about the production of three-dimensional models from sugar.

ChefJet applies a thin layer of granulated candy to the work surface and then selectively glues it with water, which is fed through the nozzle of the print head. The ChefJet head follows the contours of a digital model, moving in two dimensions. The printer then applies a new layer of ingredients, repeating the process to form the next layer of the shape.

Food additives and dyes make it possible to create models of various flavors and colors.

The ChefJet is a little too big for a typical kitchen, but the size of the working area inspires respect and allows you to decorate the average birthday cake.

Even the most inexpensive version of ChefJet has a significant plus - the printer can print mint, vanilla, chocolate, cherry and apple candies and icing. The disadvantage of the basic configuration is the inability to print multi-color sweets.

More advanced version of ChefJet allows you to print different colors of candy and mix flavors. Only one comparative disadvantage overshadows the professional model - the dimensions of the device have increased somewhat.

Only one comparative disadvantage overshadows the professional model - the dimensions of the device have increased somewhat.

Perhaps the main advantage of ChefJet is the ability of the printer to work not only on powdered sugar, but also on caramel and even on chocolate chips.

The use of additive manufacturing allows ChefJet to create highly geometrically accurate sugar models.

Please note! ChefJet can even print hollow sugar products with free-flowing fillings in any flavor. For example, it is quite possible to print an edible rattle - ChefJet accurately prints edges, avoiding sharp corners and unsafe chips.

ChefJet 3D Food Printer is designed for professional chefs and pastry chefs who will operate printers in bakeries, pastry shops and restaurants. Especially for users, the manufacturer plans to complete the devices with software and a digital cookbook. As an example, the manufacturer cites the possibility of printing figurines for wedding cakes.

Perhaps the high cost of ChefJet is the main disadvantage of this printer. However, there is always an opportunity to save money - on the market you can find used devices in good condition at a lower price.

Chocolate printing

Choc Creator 2.0 Plus is the best example of a chocolate printing 3D food printer. In our opinion, this is one of the most stable working models, affordable and creating real miracles from chocolate.

Choc Creator 2.0 Plus is the perfect assistant for chocolatiers, professional confectioners and just lovers of real Belgian chocolate.

Choc Creator 2.0 Plus was developed taking into account all the disadvantages of the previous version - the creators improved the convenience and technology of work, but did not forget about the design of the device - the new Choc Creator conquers with its compact dimensions, high performance, intuitive interface and unlimited possibilities for working with chocolate .

A few words about the design - the printer is equipped with a 5-inch touch screen. The start and settings buttons are conveniently located on the screen.

The start and settings buttons are conveniently located on the screen.

Choc Creator 2.0 Plus will fit both in a professional pastry chef's kitchen and in an apartment - the printer can easily be placed on a bar counter, window sill and any other flat surface.

Another indisputable plus for visuals is the opportunity to observe the process of printing chocolate figures.

Choc Creator 2.0 Plus is a master of chocolate, from miniature cake decorating figures to large chocolate models.

The manufacturer's concern for its customers deserves special attention, which is felt from the moment you open the box with the printer. First, Choc Creator 2.0 Plus is in assembled condition. Secondly, a small transparent suitcase, complete with the necessary accessories, emphasizes the premium model. Inside the case are:

- stainless steel syringe;

- two nozzles of different diameters;

- special needle for cleaning clogged nozzles;

- magnets for easy paper fixing;

- 5 loading heads;

- Stylish USB flash drive in gold casing;

- height calibration disc;

- hex.

The manufacturer has not forgotten about the brush for cleaning the syringe, the stylus for the touchscreen and other useful little things that express concern for the buyer. It would seem that Choc Creator 2.0 Plus is one solid plus, but there is also a relatively small drawback - the printer only works on high-quality raw materials without additives.

The creators of the printer strongly recommend using only Belgian chocolate with a cocoa content of at least 54.5%.

Choc Creator 2.0 Plus will suit both professional chocolatiers and confectioners, as well as simple connoisseurs of quality chocolate.

3D printing on drinks

Just a few years ago, only a few baristas could draw a simple pattern on coffee. The process took time, and the result did not always meet the client's expectations. Serious competition for the creative workers of coffee houses and their flowers on the foam was 3D printers. These devices can print anything on any drink, including milkshakes and beer.

CafeMaker is a 3D inkjet printer that can print images on various types of drinks, and can do it with three food colors at the same time. CafeMaker's print speed is 10 seconds/cup, allowing you to design your drinks in seconds.

Important! The CafeMaker doesn't just print on drinks, it can also print on small cream cakes.

An indisputable plus of CafeMaker is its own CupShow application, in which you can select pictures for printing from those saved in the device's memory, as well as create inscriptions, logos, or even print personal photos.

CafeMaker can print in one color or in a set of cyan, red and yellow.

The process of refilling the CafeMaker is similar to working with a conventional inkjet printer - dye is slowly poured into the cartridge, and then the finished cartridges are placed inside the device.

A small drawback of the device lies in its requirements for a cup or glass - containers should not be transparent, their height should not exceed 18 cm, and their diameter should not exceed 11 cm.

restaurant - any client will be happy to receive a cup of coffee, a glass of beer or a cupcake with an original image.

Printing with paste ingredients

Printing with sugar and chocolate is no longer just a fantasy. Now you will not surprise anyone with three-dimensional models from familiar products, so 3D printer manufacturers decided to take a step towards lovers of everything unusual and create devices that print almost any product from various ingredients.

The Foodini 3D printer will give a confident rebuff to multicookers and other kitchen gadgets - the device can independently print dumplings, prepares the finest Italian pasta, cookies, donuts covered with icing, and even hamburgers.

Up to five different textures can be loaded into the Foodini printer at the same time. Thanks to the nozzles of different diameters, which are supplied with the printer, a wide variety of dishes are suitable for printing.

Unlike its counterparts, Foodini has firmly taken its place in the restaurant business. Of course, not all establishments can afford an expensive unit. For example, the Foodini printer is used in one of the most popular restaurants in Barcelona, La Enoteca. One of the institution's most unusual dishes is seafood puree, which is almost impossible to decorate by hand so gracefully.

Of course, not all establishments can afford an expensive unit. For example, the Foodini printer is used in one of the most popular restaurants in Barcelona, La Enoteca. One of the institution's most unusual dishes is seafood puree, which is almost impossible to decorate by hand so gracefully.

The print speed of the Foodini printer is 100 mm/s, which is another advantage of the device.

Perhaps the only relative disadvantage of Foodini is its high price, but it is compensated by the increased interest of customers in the dishes produced and, as a result, an increase in the institution's profit. The Foodini printer is ideal for restaurants and other catering establishments that want to emphasize the creative approach of the management and the chef, as well as the high class of the company.

What raw materials are used for printing?

The following ingredients can be used as raw materials for 3D edible printing:

- plain chocolate and chocolate chips;

- food mastic;

- sugar;

- curd mass;

- fish, meat and liver pates;

- cheese;

- vegetable and fruit pastes;

- flour;

- food colors and flavors.

This list can be continued by unusual ingredients - the instructions for each food 3D printer include a detailed list of products that can be used in the operation of the device.

The market for food 3D printers is growing steadily, offering the consumer an ever wider range of devices with a convenient and intuitive interface. Most printers are designed to print chocolate and sugar figurines, but there are also more professional devices that are much more expensive, but their purchase opens up a wide horizon of opportunities for its owner. Do not neglect the details - we are sure that customers appreciate the individual approach and creativity, and therefore a 3D food printer will be useful both in a coffee shop or home confectionery, as well as in a large-scale production or restaurant.

- February 27, 2020

- 13185

Get expert advice

ZAV PRO V3 assembly. What Alex Korvin didn't talk about

Sorry for the slightly clickbait title, but this long text will focus on exactly those details that the authors did not mention in Alex Korvin's review and other videos and texts. I missed some information when assembling, I hope that this article will be useful to someone who will assemble the printer or plans to buy it and will become a useful addition to well-known videos (I wrote more about some of the reasons for buying and choosing ZAV earlier).

I missed some information when assembling, I hope that this article will be useful to someone who will assemble the printer or plans to buy it and will become a useful addition to well-known videos (I wrote more about some of the reasons for buying and choosing ZAV earlier).

I must say right away that I did not regret my choice and am ready to recommend the printer for purchase, despite a few minor problems, which are discussed below.

So, inspired by this video (by the way, many thanks to Alex, apart from a few details, the video helped me a lot, and the printer is still in a slightly different version), I decided to buy a set.

I immediately decided to order an additional aluminum portal and an integrated belt tensioner. From mounting on a direct extruder, I, on reflection, have so far refused. Unfortunately, at that time, HIWIN rails, linear bearings and a trapezoid motor were not available on the site. About the lack of a belt I was informed by letter. Placed an order and began to choose the rest of the details. One of the difficult decisions was the choice of screws, because the printer must also be beautiful!

Placed an order and began to choose the rest of the details. One of the difficult decisions was the choice of screws, because the printer must also be beautiful!

As a result, I ordered with the lowest hats. I must say that one minus they found out during assembly - the size of the Allen key is very small, it can sometimes turn. And I also didn’t take into account that I don’t have such bits and I can’t use an electric screwdriver. But after all, I have a printer - I quickly modeled the adapter, sawed off part of the hex wrench with a dremel and you're done!

Everything worked, however, not for long, perhaps the matter is in the soft metal of the key, and I already wrote about the small size of the hexagonal holes. So in the end, most of the screws were tightened by hand (not bare, of course). But it's not bad, you can stretch the pleasure. I ordered square nuts and screws from two stores at once, because it would be a shame if the case arrives, and the hardware is still on the way (by the way, if someone needs it, write, the second set is available).

The package arrived from Novosibirsk in a week (thanks to SDEK). Packed well, lined with something like fine-grained foam. Judging by the inscription - a heater, but this does not play a role, it is functionally suitable.

But, in our age of CNC, these pieces are cut off a little crooked, by hand. Perhaps manufacturers should make a foam cutter or something similar, the presentation will become much better.

Inside - body parts, table, upgrade parts I ordered and a bag of small things. Its content, as I think, is standard, in the photo (there is also an aluminum tensioner with a mount to the radiator, which I paid separately):

By the way, when ordering, I asked not to send me a steel portal X and a standard head mount, and to give me a discount, but they put them on me (although they did give me a discount).

The quality of the printed parts is excellent, and the tuning portal is almost not felt in the hand. I haven't weighed each, but the difference is very noticeable.

I haven't weighed each, but the difference is very noticeable.

When I took out the table base, I thought I was seeing double. My heart skipped a beat - “Is it really because of a mistake or a failure that the holes were drilled twice? Or is it for different case models?

This was one of two cases when I decided to write to Alexey Zakatny, he dispelled my doubts and confirmed my guess: “That's right, under the old models of plywood cases. They had 200 mm bearings, then it became 194 mm.” Of course, I joined the VKontakte group, read everything that was possible there. But I realized that you can wait for answers there for a long time (and sometimes not wait). Perhaps everything is in the telegram chat (I don’t have one). Alexei answered quickly and to the point, but did not want to pull him. I hope the ZAV team will forgive me for the unsolicited advice: in my opinion, it would be good to make a FAQ from repeated questions and answers and put them in a prominent place. Well, make / remove the assembly manual, it is only for plywood versions so far.

Well, make / remove the assembly manual, it is only for plywood versions so far.

The first parts to come were SKF shafts from Technobering. More precisely, one shaft. I don’t know who to thank - the St. Petersburg packers or DPD delivery ... They brought it in the morning, my wife did not pay attention to a small hole in the end. I had to order another one in St. Petersburg, and SKF was already absent, I was offered TECHNIX. In work, apparently, it will not hurt, but it looks a little yellower than the pair.

Almost immediately there is another message - HIWIN guides from XieWei. Arrived very quickly, well packaged, but how is it in work? Even before the purchase, I looked for reviews, found a discussion where they wrote that it might be a fake, but very accurate. On one short rail, the carriage went very well, along the long one on X it was normal, but the second short rail sometimes jammed, slowed down, it was even possible to hold it in the hand on weight:

I made up my mind and removed one block, to see if there are not enough balls there? Putting on blocks is more difficult than taking them off, I didn’t touch the others.

I sent the video to the store, they offered to increase the protection period so that I could check it on the printer (now, having looked at the work, it is clear that my fears were unfounded). In the ZAV store, the price of the kit is about the same, but as I wrote, then they were not available.

I bought Mobilux EP2 for lubrication (apparently, it will last a lifetime), put on a syringe from a pharmacy a “nozzle” bought for printing with clay - a glue dispenser tip. The grease did not want to go into the complete needle. At the same time, Hephaestos smeared.

By the way, there were many questions with the list of components. Firstly, on the site there are lists for older versions, I found in the VKontakte group that is relevant to me, and then not immediately. I really wish the sellers of the printer to post this list on the site.

And some parts were hard to find by description. Here is a piece from the correspondence “Tell me, what is the length of the motor-trapeze shaft for assembling ZAV PRO V3. The list of parts indicates the size of 320mm, according to the link from it with a shaft of 300mm, on the website in the accessories section there is a shaft 324. I could not find it on Ali 320 "-" The motor is a trapezoid, the length is ideally 325 mm, but if the nut is moved under the table as low as possible, then and 300 mm is enough. I was lucky, I found 324 mm from HANPOSE, the issue was resolved.

The list of parts indicates the size of 320mm, according to the link from it with a shaft of 300mm, on the website in the accessories section there is a shaft 324. I could not find it on Ali 320 "-" The motor is a trapezoid, the length is ideally 325 mm, but if the nut is moved under the table as low as possible, then and 300 mm is enough. I was lucky, I found 324 mm from HANPOSE, the issue was resolved.

Okay, let's move on to assembly. First you need to clean the parts from the film. Or from shavings? I did this - I cleaned it first in a film so as not to scratch the case, and then again after removing the coating. It is on the one hand, external.

And there was only one scratch, and quite deep. But, fortunately, it was the underside of the lid, so it doesn't spoil the view.

A small life hack - the adhesive side of the removed film perfectly collects chips from parts:

Assembling is generally easy, clear and pleasant, but some parts have a slight bend that goes away after joining:

And in this case I had to use a mallet, very delicately, but I had to knock. I think this is due to the fact that here two prefabricated parts are located close:

I think this is due to the fact that here two prefabricated parts are located close:

I liked that the “high-voltage” compartment of the basement is separated from the “electronic” one:

These are the parts that I put together incorrectly at first. I thought that, by analogy with others, the same parts should be connected in pairs. No, this is the only place where a large one must be connected to a small one. It's good that I didn't glue it right away:

This hole in the inner part, I think, was made for the encoder. But I did not install it:

Some difficulties arose with square nuts, which were installed in grooves with a slight misalignment. Therefore, some of the screws (a little, 6 out of 100 pieces) had to be tightened with pliers - the hexagon simply turned in the socket. Sometimes it helped to unscrew and screw again several times until the thread entered the nut.

Very carefully join the tongue and groove in these places. A very thin jumper tends to bend:

A very thin jumper tends to bend:

To level it, I had to carefully grab the edge (I used pliers) and knock it out with a mallet. After assembly, everything is smooth, especially since this part is hidden behind the front panel (it has no holes in this place).

These parts can simply be torn off the block and cleaned with a file (well, or not cleaned, they are not visible):

By the way, here, in the photo above, everything is also unscrewed by hand and cleaned. But I didn’t like the scuffed look and I tinted it with a permanent marker:

On the advice from the parts list, I immediately replaced the nut with POM:

I found out by experience that the stiffer the springs for the table, the more accurate the print will be. And the washers do not allow the springs to bend:

After assembling the case, I realized that I had not thought about some of the fasteners. For example, plastic for installing the power supply. I did not want to press it against the composite, if not for electrical safety, but at least for ventilation. I cut off pieces from the silicone tube and made inserts:

I did not want to press it against the composite, if not for electrical safety, but at least for ventilation. I cut off pieces from the silicone tube and made inserts:

The same procedure was repeated to install the board (otherwise its height will not match the holes for the flash drive). But with the installation of the board, another surprise happened. In addition to it, I ordered a WiFi module. It turned out that without it, the board rises, but not with it, it rests against the wall (I hope the manufacturers will fix this).

I found this out after assembly, of course, I didn’t want to disassemble it, and it was possible to crawl with a dremel only in one plane. I had to cut through two parallels with a breadboard knife, slowly and painfully. Well, pick out the core of the composite (not very soft), adapting a screwdriver as a chisel and knocking it out with a hammer.

I made a backlight - after the repair, almost a meter of tape remained in the apartment. I decided to place it on the top panel in front, as well as on the front - on the left and right. At first I thought to put it on the top and on the sides, then bright LEDs would be reflected in the mirror (I cut a couple of these from a wonderful master on the Savelovsky market). By the way, a spare / replacement mirror is conveniently stored under the printer.

I decided to place it on the top panel in front, as well as on the front - on the left and right. At first I thought to put it on the top and on the sides, then bright LEDs would be reflected in the mirror (I cut a couple of these from a wonderful master on the Savelovsky market). By the way, a spare / replacement mirror is conveniently stored under the printer.

When I turned on the light for the first time (it can be adjusted from the screen), the view was completely finished, although there was still a lot to do:

One of the most incomprehensible nodes was the head. I did not immediately understand how to collect everything in one module. Perhaps the photos will come in handy for someone, specially made from different sides:

Version 1.5 of the blower is used here (I learned about the new product, as usual, immediately after I printed version 1.4 on the old Hephaestos).

Of course, there were some mistakes. Having read from someone that the motors are not connected to the Lerge contacts like the others, and looking at the diagrams, I saw that my cables are not suitable. We need to change contacts. Moreover, they are badly removed from the XH 2.54, I found DuPont (it is easier to bend the plastic petals there), redid everything ... But only the Z-axis motor worked. It didn’t immediately dawn on me that I didn’t change the pins only on this motor.

Having read from someone that the motors are not connected to the Lerge contacts like the others, and looking at the diagrams, I saw that my cables are not suitable. We need to change contacts. Moreover, they are badly removed from the XH 2.54, I found DuPont (it is easier to bend the plastic petals there), redid everything ... But only the Z-axis motor worked. It didn’t immediately dawn on me that I didn’t change the pins only on this motor.

I have not used snakeskin braids before and did not take into account that it unravels at the edges. I would have known earlier, I put a heat shrink, but I’m already too lazy on the assembled and stretched wires (secured with a screed).

But the most feil happened when the wires were lengthened (inserted). In principle, I don’t like soldering, and when I found out that for several hours I soldered wires of a shorter length than necessary ... I don’t know how I could intend to do so. I was able to recover and continue the assembly only a week later.

Almost everything is quite convenient during installation, except for attaching the belt. More precisely, its ends - you can’t see anything from above, and sticking your head into the printer and looking from below is inconvenient (maybe a mirror would help, but then this thought didn’t arise).

I got it out like this - I inserted it upside down, and then tightened it. By the way, loosening the tension helps to temporarily remove the belt without unhooking it from the carriage (you also need to remove the pulley from one motor). What for? I, like probably many, having collected everything, forgot to install the top frame-cover. Of course, for those who use a detachable head with connectors, this is not a problem, but not so far for me.

I connected the limit switches as in the diagrams and symbols on the limit switches (and not along the extreme pins, as in many videos), then changed the open to closed settings for a long time until it worked. I really liked the settings management in Lerdge. After editing codes and flashing, like in Marlin, it's just a resort. I installed cork dampers on XY - so the pulleys on the motors are a little higher. The decision is controversial, but we'll see.

I really liked the settings management in Lerdge. After editing codes and flashing, like in Marlin, it's just a resort. I installed cork dampers on XY - so the pulleys on the motors are a little higher. The decision is controversial, but we'll see.

The extruder has so far been supplied with an ordinary all-metal extruder:

Here is the complete cellar. The power supply is not Minwell, but not bad, 24v. I bought it almost two years ago for the Zatsit project that impressed me, but, alas, it froze.

And, finally, the first print:

After that, a series of tests, setting the flow, temperature, speed. The main problem is the lack of ventilation. It was not possible to manage at a speed of 60 mm / s (the outer perimeters are smaller).

But, unexpectedly, I decided to swap two coolers. They are almost identical in characteristics (flow, for example), but one of them is EB40202S2-999 with a slightly higher starting voltage, another MF40202V2-A99-A Vapo with a lower one. The airflow got better, but I lost the ability to adjust the air flow. I'll replace it then.

The airflow got better, but I lost the ability to adjust the air flow. I'll replace it then.

One of the tests - astronaut, layer 0.1/0.4, 60mm/s, PLA. There is still a slight overheating and possibly overflow:

And it is the same but with a layer of 0.2:

When printing PETG, the overhangs came out even:

“plug”, and the effect always appeared with an increase in the retract (after the middle of the model). Reduced it right up to 2mm (as in direct) and everything went. Perhaps the Capricorn tube played a role, preventing the bar from bending. But I can’t cope with the quality of the corners, I thought it was overextrusion, but no, its reduction did not affect:

Nevertheless, I really like the quality of the mechanics, almost no echo or wobble is visible (printing with a layer of 0.2 in a spiral mode with standard settings of 2 walls):

only the fans can be heard. Well, not really. Maybe the matter is in SUNON (you have to look at small ones or bring your hand to understand that they work), it has become noticeably quieter, in comparison with Gephestos 2, but not silently (yes, no stealthchop).