3D metal printer price in india

3D Printer Price In India

3D Printers are rapidly sold in India and the world sees India as a big market to grow their businesses. 3D printers can be bought in India through direct importing printers, importing DIY kits for FDM printers, official distributors in India and through local manufacturers. The 3D printer price in India varies based on the chosen approach. Read on to know more about the 3D printer price in India as per the different technologies

Contents

- 1 FDM/FFF 3D Printer Price in India

- 2 SLA/DLP 3D Printer Price in India

- 3 SLS 3D Printer Price in India

- 4 MultiJet Fusion 3D Printer Price in India

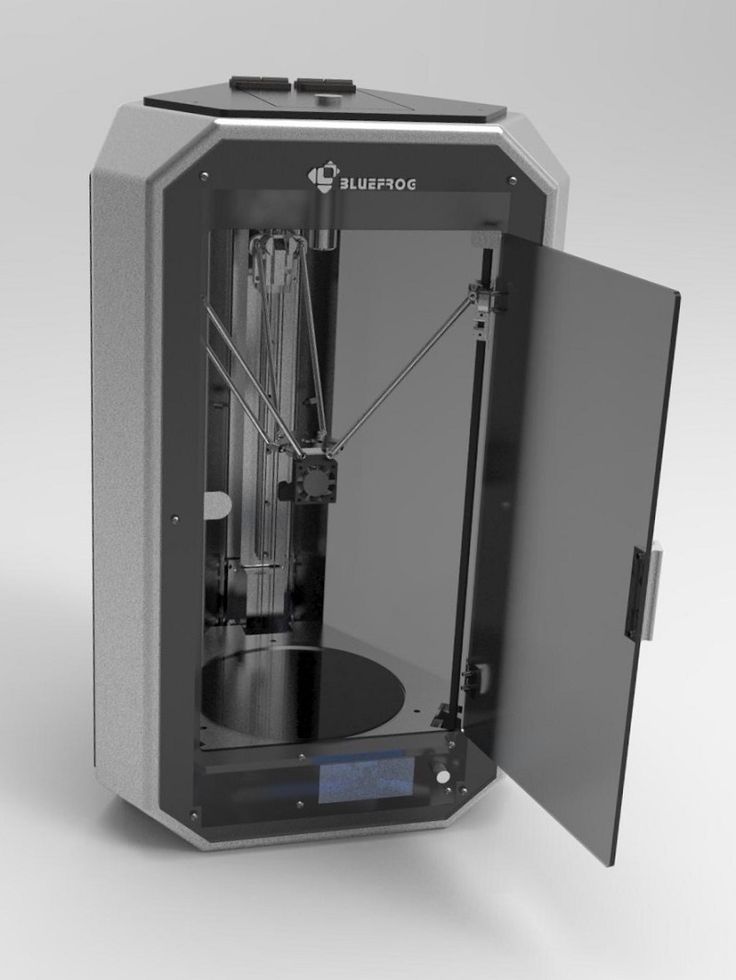

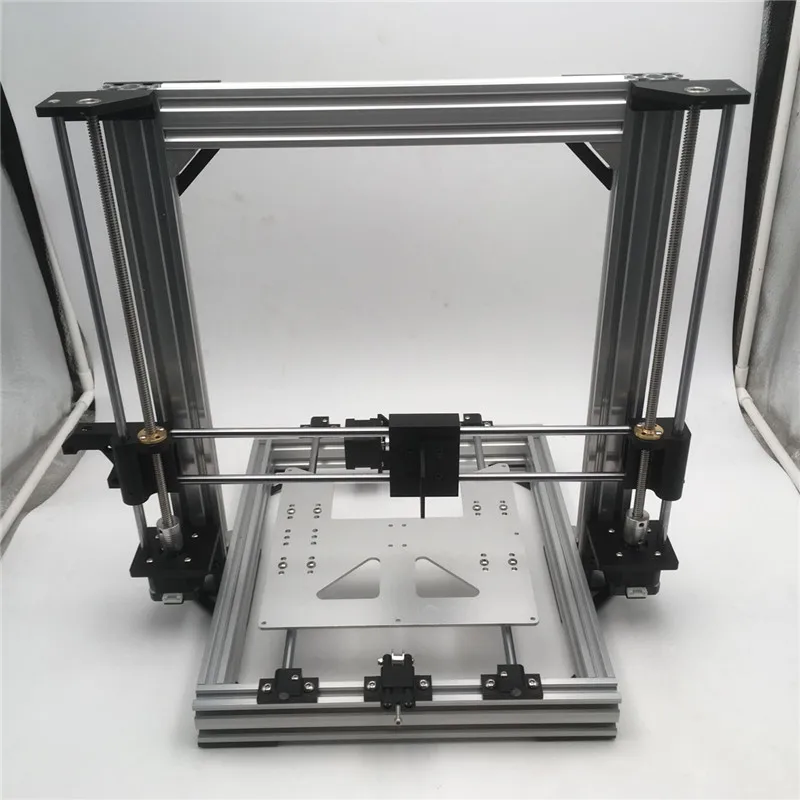

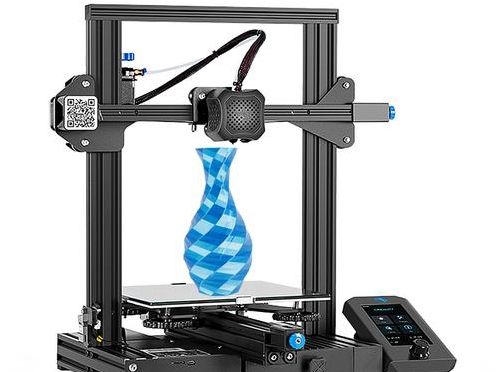

Fused Deposition Modelling (FDM) or Fused Filament Fabrication (FFF) 3D printers are the cheapest and most commonly used 3D printers all over the globe. They are generally regarded as the entry level printers and are widely used by enthusiasts, designers, SME’s, primary and secondary schools and even colleges or training institutes for technology teaching purpose.

The common materials used are PLA (for general purpose) and ABS (for industrial prototyping). Other materials like Polycarbonate, Pet-G, Nylon, speciality filaments like Glow in the dark, wood-filled, metal-filled are also used.

Globally, there is a flood of competitive products and this has led to a substantial fall in the price of FDM printers and this has given even individuals the power to own a 3D printer.

The “Make in India” campaign has encouraged many Indian engineers to locally manufacture 3D printers and over the years some really great local companies have developed reliable FDM 3D printers. As a result of this, FDM 3D Printers are now readily available in India through various manufacturers and distributors.

Enthusiasts in India can now buy a 3D printer directly from the global or local manufacturers or from their local distributor.

The 3D printer price in India varies from Rs.19,000 ($300 approx) to Rs.2.5 crore ($400,000 approx), depending on the brand, size, features and capability of the 3D printer. While a simple DIY printer (RepRap model) can cost Rs.19,000 ($300 approx), a branded dual extrusion 3D printer with a big build volume can cost close to Rs.4,50,000 ($7000 approx). The high-end printers also have added features like Wi-Fi connectivity, built-in camera to monitor the print via remote access, filament runout sensor, etc.

Also Read: An Overview of 3D Printing in India

Special printers like Markforged Mark Two 3D Printer costs around Rs.12,00,000 ($19,000 approx) in India because of its capability to print carbon fibre, kevlar as well as high-temp fibreglass. Also the Markforged X3 which is a low-cost industrial-grade 3D printer prints high-strength parts costs around Rs.32,00,000 ($50000 approx) in India. FDM 3D Printers from Stratasys are even costlier than the above mentioned brands.

In India, the most commonly bought foreign brands are Ultimaker, Flashforge, Zortrax, XYZPrinting, Stratasys (for purely industrial usage), etc. whereas the Indian brands like Divide By Zero Technologies, Garuda3D, Aha3D, etc. are also wooing the Indian consumers with their products.

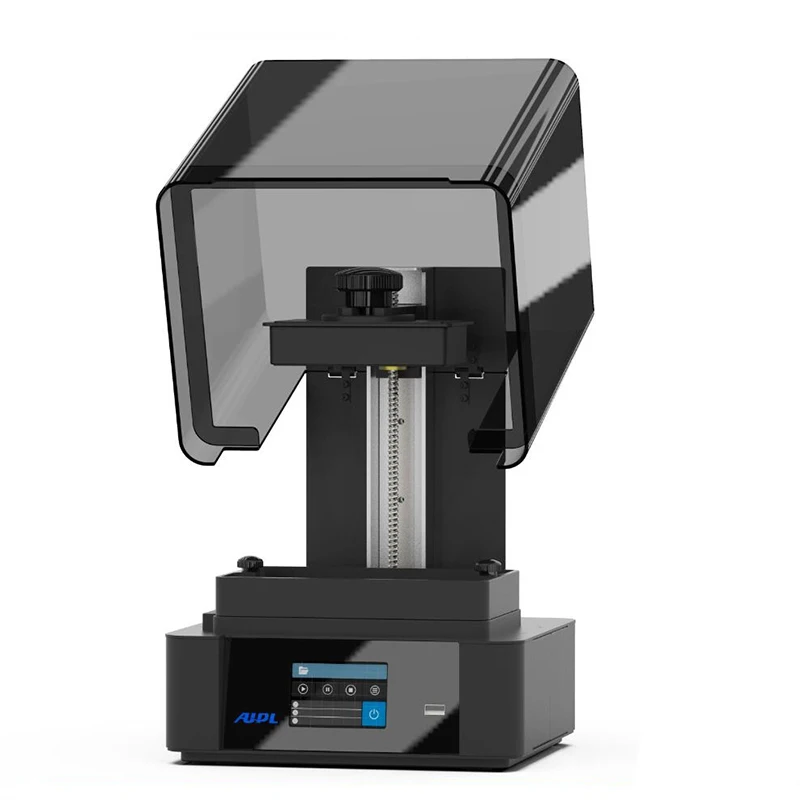

SLA/DLP 3D Printer Price in IndiaAbove: NXE400 range of Stereolithography 3D Printers/Image Credit: Nexa3DStereolithography (SLA) is the world’s first patented 3D printing technology. It is one of the most rapidly growing 3D printing technologies in the world. The industrial 3D printers require huge investment but the desktop printers are far cheaper are provide closely resembling industrial accuracy and perfection.

India is largely not into the manufacturing of Industrial SLA/DLP 3D Printers but desktop versions are developed by a lot of local manufacturers. These are mostly DLP 3D printers and provide good resolutions for printing. SLA is quite similar to Digital Light Processing (DLP). Chinese 3D printers are also flooding the Indian market but they are largely not recommended by experts.

SLA is quite similar to Digital Light Processing (DLP). Chinese 3D printers are also flooding the Indian market but they are largely not recommended by experts.

The DLP 3D printer price in India starts from Rs.50,000 ($850 approx) to upwards of Rs.6,00,000 ($9500 approx) for Desktop DLP 3D printers. These are mostly from Indian manufacturers and from foreign brands like Wanhao, XYZPrinting and Formlabs. The industrial SLA 3D printer price in India most often cost around Rs.1.5 – 2.0 crores ($235,000 – $315,000 approx).

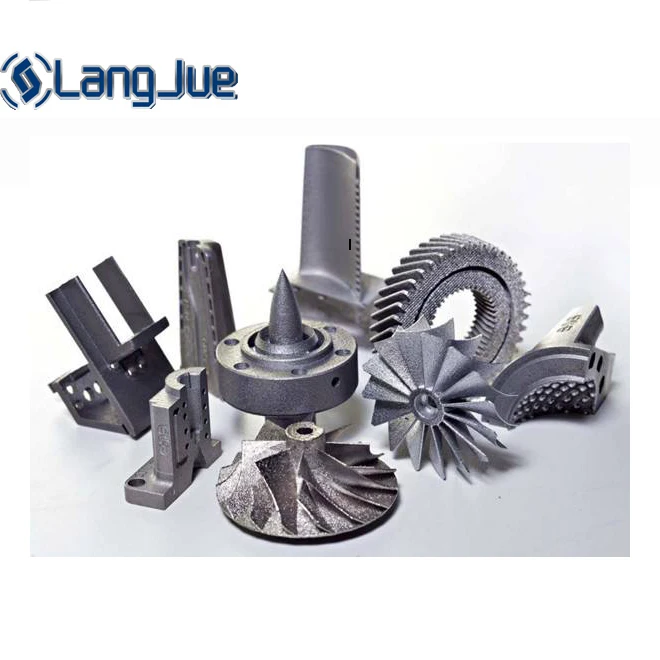

SLS 3D Printer Price in IndiaSelective Laser Sintering (SLS) is a powder bed fusion 3D printing technology wherein the material is in a fine powdered form. This powdered material maybe plastic or metal depending on the type of printer used. This material melted at a particle level with a powerful CO2 laser to fuse with the adjacent particles and trace out a layer. The object is built layer by layer to form the final object.

The material used in SLS 3D printers is usually Nylon. In case of metal printers, the commonly used materials are stainless steel & maraging steel, aluminium alloys, copper alloys, titanium, precious metals like gold, silver, platinum, etc.

Above: 3D Systems Prox SLS 6100 3D Printer / Image Credit: 3D SystemsSLS 3D printers are far costlier than FDM or SLA printers. Unlike FDM and SLA 3D printers are not meant for home use. As it uses powder material it requires an industrial setup to ensure the powder is contained and is not contaminated. Additonally, the requirement of extra industrial grade equipment’s for post-processing makes it a largely industrial technology. This makes it costly and even the desktop versions like those form Formlabs and Sinterit are out of reach of hobbyists.

The 3D printer price in India for one of the cheapest desktop SLS 3D printer is around Rs.4,50,000 [$7500 approx] (exclusive of import duty, taxes and shipping).

Broadly the industrial SLS printers are divided into plastic and metal 3D printers and companies like 3D Systems & EOS are the leading players. These printers are immensely costly and purely for industrial use.

These printers are immensely costly and purely for industrial use.

MultiJet Fusion 3D Printer Price in India

HP Inc. also has wide presence in India. It’s award-winning Multi Jet Fusion 3D Printer is quite popular in India. The Multi Jet Fusion technology is quite similar to Binder Jetting technology. This 3D printer by HP is priced at around Rs.2.5 Crore ($400,000 approx) for the Indian buyers.

3D printer price in India varies greatly depending on the type and brand of 3D printer. The market is mostly dominated by foreign manufacturers but Indian manufacturers are also growing and building remarkable 3D printers. The printer prices will obviously fall further once the local manufacturers develop the manufacturing technology.

About Manufactur3D: Manufactur3D is an online magazine on 3D Printing. Visit our Indian Scenario page for more updates on 3D Printing News from India. To stay up-to-date about the latest happenings in the 3D printing world, like us on Facebook or follow us on LinkedIn.

Indian researchers develop metal 3D printer from scratch to slash technology costs

0Shares

Engineers from the Indian Institute of Technology (IIT), Jodhpur, have developed their own low-cost metal 3D printing system based on Directed Energy Deposition (DED) technology.

The machine is special in that it was largely indigenously developed, meaning all of the components except the laser and KUKA robotic arm were designed and manufactured by the IIT team in India. The main aim of the project was to slash the cost of metal 3D printing technology in the country, while garnering more users and driving adoption.

Dr. Ravi K. R., an Associate Professor at IIT Jodhpur, explains, “Our study results show that if all the parts needed to make a metal printing machine could be manufactured indigenously, the cost of a metal 3D printing machine could be reduced by two to three times.”

Suitable for use in aerospace, defense, and other engineering sectors, the homegrown 3D printer is designed primarily for laser cladding and maintenance and repair applications, adding material to existing metal components.

The cost of metal 3D printing in India

Additive manufacturing has seen incredible growth around the world since its debut in the 1980s, but emerging markets like India have been slow to hop on the bandwagon due to prohibitive costs. As well as the 3D printers themselves being too pricey, importing metal powders from abroad contributes to ongoing operational costs that are simply too high for many manufacturing SMEs to stomach.

“Despite the fact that metal 3D printing technology started a few years after the launch of Polymer 3D printing, it is yet to experience the tremendous growth that the polymer 3D industry has achieved, especially in India,” adds Ravi. “The high price of the product and the more expensive proprietary metal powders imported from abroad are some of the reasons for the limited growth of metal 3D printers.”

The IIT team asserts that affordable metal 3D printing technologies, particularly ones developed in India, will play a key role in helping the nation keep up with the rest of the world.

An indigenous DED 3D printer

The robotic arm-based IIT 3D printer operates on DED technology, a form of 3D printing that leverages a focused energy source to melt and fuse materials as they’re deposited out of a nozzle. This energy source can be an electron beam or a plasma arc, but this particular model utilizes the commonly-used laser beam.

Capable of 3D printing metal powders produced in India, the system reportedly features the country’s first variable spot size laser optics that can preserve laser beam homogeneity.

Additionally, the team has even developed a dedicated tool path planning software and coaxial nozzle for the 3D printer. They have also integrated in-situ monitoring processes that track the temperature of the melt pool and thickness of the printed clad at all times, enabling high-performance industrial applications to be realized.

Ravi said, “Such an initiative further strengthens the policy decisions of the Government of India under the ‘Atmanirbhar Bharat’ initiative. ”

”

The commercial metal 3D printing space is as active as ever with the latest system launches. Just this month, 3D printer manufacturer Velo3D announced the launch of its largest 3D printer to date, the Sapphire XC 1MZ. The laser powder bed fusion system features a huge build volume of 600mm (dia.) x 1000mm, which is nine times larger than the original Sapphire and twice as large as the Sapphire XC.

Elsewhere, Cranfield University spin-out WAAM3D recently launched an all-new large-format 3D printer operating on the firm’s Wire Arc Additive Manufacturing (WAAM) technology. Named RoboWAAM, the metal printer sports a huge build volume of 2 x 2 x 2m and is packed full of new sensing hardware to serve customers in aerospace, defense, energy, and more.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the IIT Jodhpur researchers with their self-developed DED metal 3D printer. Photo via IIT Jodhpur.

Tags Indian Institute of Technology Jodhpur Ravi K. R.

Kubi Sertoglu

Kubi Sertoglu holds a degree in Mechanical Engineering, combining an affinity for writing with a technical background to deliver the latest news and reviews in additive manufacturing.

Metal 3D Printing - The Essential Guide

There is no hotter trend in 3D printing today than metal. We will talk about metal printing at home, how it is done on an industrial scale, about technologies, applications, printers, processes, prices and materials.

Metal 3D printing has grown in popularity over the past few years. And this is quite natural: each material offers a unique combination of practical and aesthetic qualities, can be suitable for a wide range of products, prototypes, miniatures, decorations, functional details and even kitchen utensils.

The reason metal 3D printing has become so popular is because the printed objects can be mass-produced. In fact, some of the printed parts are just as good (if not better) than those made with traditional methods.

In traditional production, working with plastic and metal can be quite wasteful - there is a lot of waste, a lot of excess material is used. When an aircraft manufacturer makes metal parts, up to 90% of the material is simply cut off. 3D printed metal parts require less energy and waste is reduced to a minimum. It is also important that the final 3D printed product is up to 60% lighter than a traditional part. Billions of dollars could be saved in the aviation industry alone—mainly through weight savings and fuel savings.

So, what do we need to know about metal 3D printing?

Metal 3D printing at home

If you want to make objects at home that will look like metal, your best bet is to look at metalized PLA filaments (Photo: colorFabb)

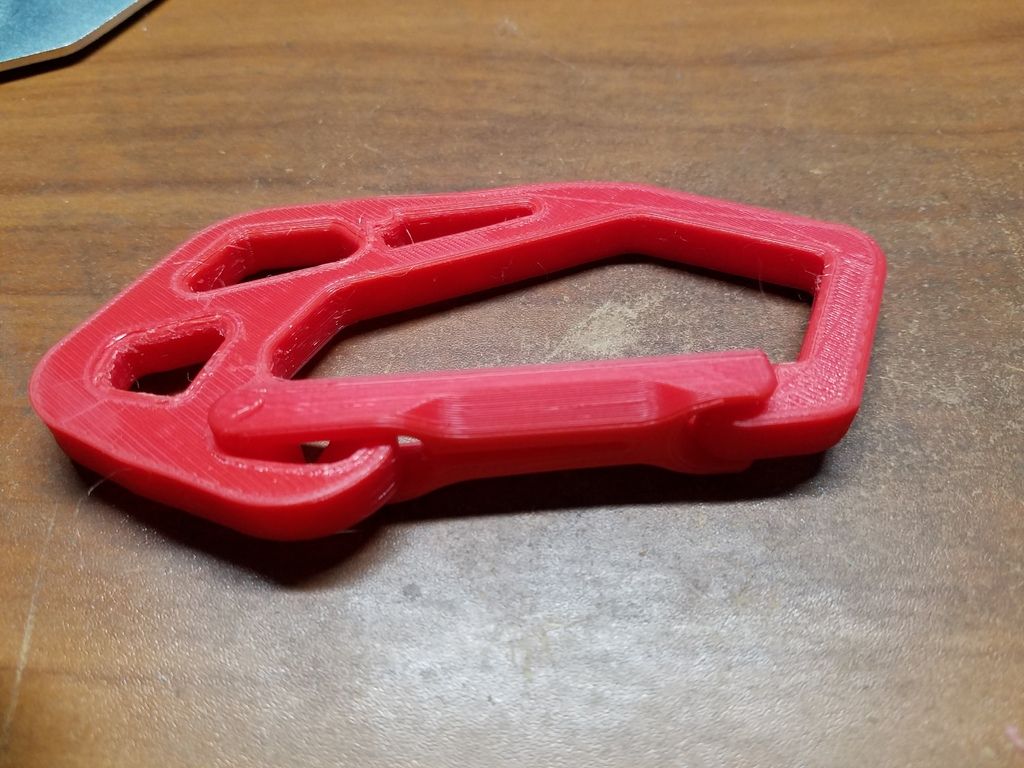

Where to start if you want to print metal objects at home ? Given the extreme heat required for true metal 3D printing, a conventional FDM 3D printer will not be able to do this.

It is unlikely that in this decade it will be possible to print with liquid metal at home. Until 2020, you probably will not have a printer specialized for this purpose at home. But in a few years, as nanotechnology advances, we may see significant developments in new applications. This can be 3D printed with conductive silver, which will emit in much the same way as it does in 2D home printers. It will even be possible to mix different materials like plastic and metal in one object.

Materials for metal 3D printing at home

Even though you can't print actual metal objects at home, you can turn to plastic filament that has metal powders added to it. ColorFabb, ProtoPasta and TreeD Filaments all offer interesting metal-PLA composite filaments. These filaments, containing a significant percentage of metal powders, remain pliable enough to be printed at low temperatures (200 to 300 Celsius) on virtually any 3D printer. At the same time, they contain enough metal to make the final object look, feel, and even weigh like metal. Iron-based filaments even rust under certain conditions.

Iron-based filaments even rust under certain conditions.

But you can go further. Typically, up to 50 percent metal powder is added to 3D printing filament. Dutch company Formfutura says they have achieved 85 percent metal powder with 15 percent PLA. These filaments are called MetalFil Ancient Bronze and Metalfil Classic Copper. They can be printed even at "moderate" temperatures from 190 to 200 degrees Celsius.

Metallic 3D Printing Filament Spools, in this case from SteelFill and CopperFill colorFabb (Steel and Bronze), Ancient Bronze (Ancient Bronze) from Formfutura

Here are the key points about metal printing at home

- Gets a unique metal surface and look

- Ideal for jewelry, figurines, housewares, replicas

- Durability

- Objects are not flexible (structure dependent)

- Objects do not dissolve

- Not considered food safe

- Typical print temperature: 195 - 220°C

- Extremely low shrinkage on cooling

- No table heating required

- Printing complexity is high, requires fine tuning of nozzle temperature, feed rate, post-processing

Preparing Your Home Printer for Metal 3D Printing

Since getting metal 3D prints is more difficult than usual, you may need to upgrade your 3D printer nozzle, especially if you are an entry-level printer. The metal filament wears it out quickly. There are hard-wearing hot-ends (like the E3D V6) that are themselves made of metal. They can withstand high temperatures and fit most printers. Be prepared for the fact that the nozzles will have to be changed frequently, because the metal filament is very abrasive.

The metal filament wears it out quickly. There are hard-wearing hot-ends (like the E3D V6) that are themselves made of metal. They can withstand high temperatures and fit most printers. Be prepared for the fact that the nozzles will have to be changed frequently, because the metal filament is very abrasive.

You will also need to take care of the final finishing of the surface (cleaning, grinding, oiling, waxing or priming) so that the printed metal object shines as it should.

How much does metal filament for 3D printing cost?

And what about metal filament for 3D printing? - you ask. Here are a few examples:

- ColorFabb's 750 gram Bronzefill spool is $56.36

- ColorFabb 750g Copperfill Coil $56.36

- Protopasta's Polishable Stainless Steel PLA Composite is $56 for 56 grams of

- Protopasta's Rustable Magnetic Iron PLA Composite is $34.99 for 500 grams of

Industrial metal 3D printing

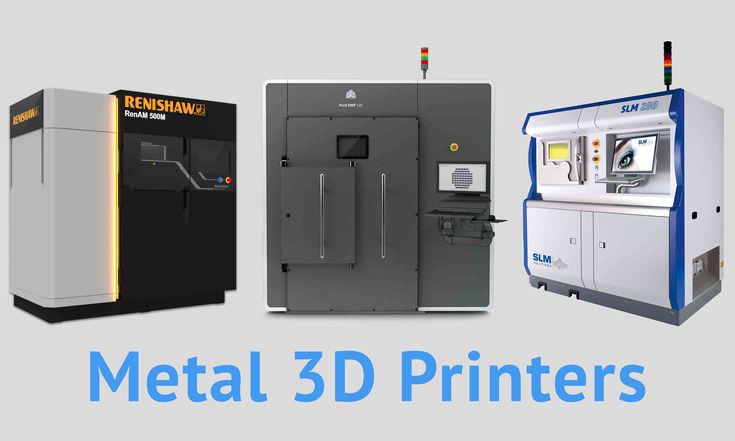

But what if you want a better result or even full metal 3D printing? Should a real "metal" 3D printer be purchased for business needs? We wouldn't recommend it - unless you're going to be doing it every day. A professional metal 3D printer is expensive: EOS or Stratasys devices will cost you 100-500 thousand dollars. In addition, the costs will be even greater, since you will have to hire an operator, a worker to maintain the machine, as well as to finalize the printouts (polishing, for example). Just a note: In 2016, an affordable metal 3D printer didn't exist.

A professional metal 3D printer is expensive: EOS or Stratasys devices will cost you 100-500 thousand dollars. In addition, the costs will be even greater, since you will have to hire an operator, a worker to maintain the machine, as well as to finalize the printouts (polishing, for example). Just a note: In 2016, an affordable metal 3D printer didn't exist.

Lowering Metal 3D Printing Costs

If you are not going to start a metal 3D printing business, but still need a professionally 3D printed metal part, it is best to contact the appropriate company that provides such services. 3D printing services like Shapeways, Sculpteo and iMaterialise offer direct metal printing.

They currently work with the following metal materials in 3D printing:

- aluminum

- steel

- brass

- copper

- bronze

- sterling silver

- gold

- platinum

- titanium

If you are a jeweler, you can also order wax models for casting in precious metals.

If we talk about wax models, then in most cases they (with subsequent melting) are used when printing with metals (including gold and silver). Not all orders are carried out directly by these firms. They usually turn to other metal 3D printing companies to complete the order. However, the number of such services around the world is growing rapidly. In addition, metal 3D printing techniques are becoming more and more common in companies that offer such services.

The reason big companies love 3D printing so much is that it can be used to build fully automated lines that produce "topologically optimized" parts. This means that it is possible to fine-tune the raw materials and make the components thicker only if they must withstand heavy loads. In general, the mass of parts is significantly reduced, while their structural integrity is preserved. And this is not the only advantage of this technology. In some cases, the product turns out to be significantly cheaper and affordable for almost everyone.

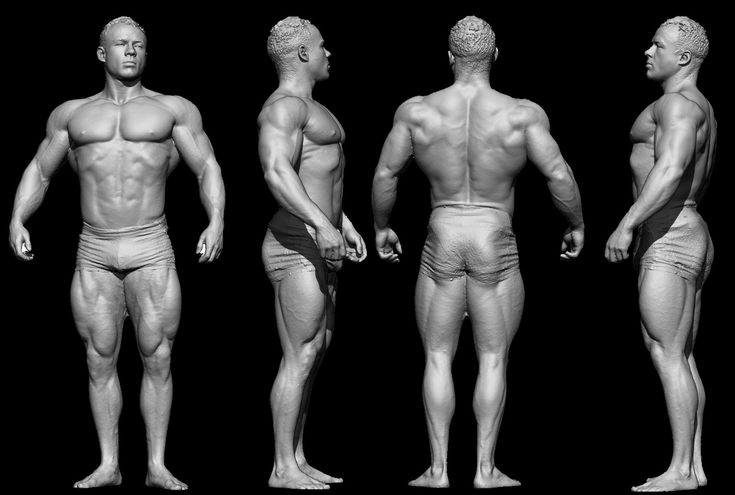

Please note that metal 3D printing requires special CAD programs for modeling. It is worth paying attention to the recommendations of Shapeways - 3D printing metal guidelines. To delve further into the topic, check out Statasys’ information on related 3D printers and the nuances of metal 3D printing.

Here are some examples of Benchy test model prices for metal 3D printing:

- Metal plastic: $22.44 (former alumide, PLA with aluminium)

- Stainless steel: $83.75 (plated, polished)

- Bronze: $299.91 (solid, polished)

- Silver: $713.47 (solid, mirror polished)

- Gold: $87.75 (gold plated, polished)

- Gold: $12,540 (solid, 18K gold)

- Platinum: $27,314 (solid, polished)

As you might expect, solid metal 3D printing prices are quite high.

Metal 3D printing. Applications

GE LEAP aircraft engine parts 3D printed at Avio Aero (Photo: GE)

There are several industries already using 3D printers to make everyday objects - you may not even know that these objects are printed.

- The most common case is surgical and dental implants, which are considered the best option for patients today. Reason: they can be tailored to individual needs.

- Another industry is jewelry. Here, most manufacturers have abandoned resin 3D printing and wax casting, switching directly to metal 3D printing.

- In addition, the aerospace industry is becoming more and more dependent on 3D printed metal objects. The Italian company Ge-AvioAero was the first to do all-metal 3D printing. It manufactures components for LEAP aircraft engines.

- Another industry targeting metal 3D printing is the automotive industry. BMW, Audi, FCA are seriously considering this technology, not only for prototyping (3D printing has been used for this for quite some time), but also for making real parts.

Before metal 3D printing really takes off, however, there are some hurdles to overcome. And first of all, this is a high price, which cannot be made lower than during molding. Another problem is the low production speed.

Metal 3D printing.

Technologies

Most metal 3D printing processes start with an “atomized” powder

You can talk a lot about “metal” 3D printers, but their main problems remain the same as any other 3D – printers: software and hardware limitations, material optimization and multimateriality. We won't talk too much about the software, we'll just say that most of the major specialized software companies, such as Autodesk, SolidWorks and solidThinking, try to emphasize as much as possible the fact that as a result of the 3D metal printing process, you can get any shape you want.

In general, printed metal parts can be as strong as parts made by traditional processes. Parts made using DMLS technology have mechanical properties equivalent to casting. In addition, the porosity of objects made on a good "metal" 3D printer can reach 99.5%. In fact, manufacturer Stratasys claims that 3D printed metal parts perform above industry standards when tested for density.

Parts made using DMLS technology have mechanical properties equivalent to casting. In addition, the porosity of objects made on a good "metal" 3D printer can reach 99.5%. In fact, manufacturer Stratasys claims that 3D printed metal parts perform above industry standards when tested for density.

3D printed metal can have different resolutions. At the highest resolution, layer thickness is 0.0008 - 0.0012" and X/Y resolution is 0.012 - 0.016". The minimum hole diameter is 0.035 - 0.045". formed layer)

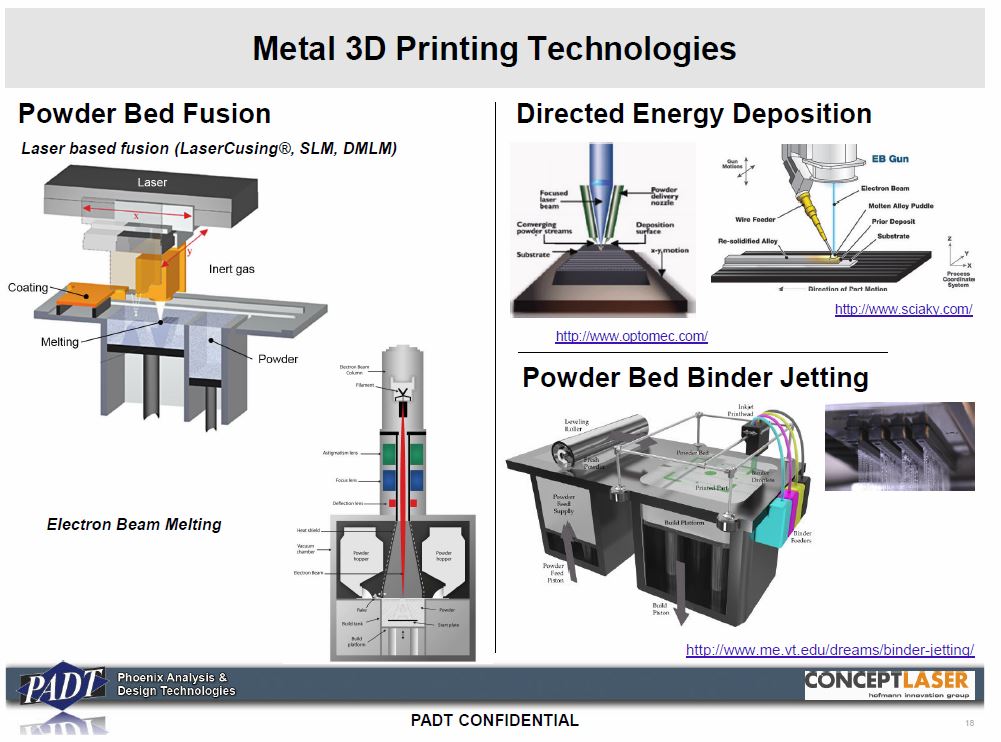

The metal 3D printing process used by most relevant large companies today is called Powder Bed Fusion. This name indicates that some source of energy (a laser or other energy beam) melts an "atomized" powder (i.e., a metal powder that is carefully ground into spherical particles), resulting in layers of a printed object.

There are eight major manufacturers of metal 3D printers in the world that already use this technology; while we are talking here, there are more and more such companies. Most of them are in Germany. Their technologies are called SLM (Selective Laser Melting - selective laser fusion) or DMLS (Direct Metal Laser Sintering - direct metal laser sintering).

Most of them are in Germany. Their technologies are called SLM (Selective Laser Melting - selective laser fusion) or DMLS (Direct Metal Laser Sintering - direct metal laser sintering).

Metal 3D-printing process No. 2:

Binder Jetting (spraying the binder)

under 3DP technology EXONE Metal objects are printed due : ExOne)

Another professional approach that also uses a powder base is called Binder Jetting. In this case, the layers are formed by gluing metal particles together and then sintering (or fusing) them in a high-temperature furnace, just like it is done with ceramics.

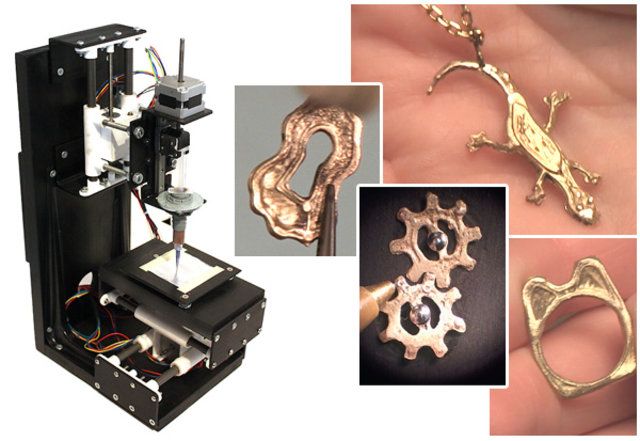

Another option, which is similar to working with ceramics, is mixing metal powder into metal paste. A pneumatically extruded 3D printer (similar to a syringe bioprinter or an inexpensive food printer) forms 3D objects. When the required shape is reached, the object is sent to the furnace, i.e. in the mountains

This approach is used in the Mini Metal Maker, apparently the only inexpensive "metal" 3D printer.

Metal 3D printing process #3: 9Metal Deposition This is not entirely true. Of course, on some desktop device, simply fusing metal threads onto the base will not work. However, very large steel companies can do it. And they do. There are two options for working with "metal surfacing".

One is called DED (Directed Energy Deposition) or Laser Cladding. Here, a laser beam is used to melt the metal powder, which is slowly released and solidifies as a layer, and the powder is fed using a robotic arm.

Normally the whole process takes place in a closed chamber, but the MX3D project used conventional 3D printing techniques to build a full-size bridge. Another option for metal fusion is called EBAM (Electron Beam Additive Manufacturing - additive electron beam technology), which is essentially soldering, in which a very powerful electron beam is used to melt 3 mm titanium wire, and the molten metal forms very large finished structures. As for this technology, its details are known so far only to the military.

Metallic 3D printing. Metals

3D Printing Metal #1: Titanium

Pure titanium (Ti64 or TiAl4V) is one of the most commonly used metals for 3D printing and is definitely one of the most versatile, strong and lightweight. Titanium is used both in the melting process in a preformed layer and in the process of spraying a binder and is used mainly in the medical industry (for the manufacture of personal prostheses), as well as in the aerospace industry, automotive and machine tools (for the manufacture of parts and prototypes). But there is one problem. Titanium is very reactive and explodes easily in powder form. Therefore, it is necessary that titanium 3D printing takes place in a vacuum or in an argon environment.

3D printing metal #2: Stainless steel

Stainless steel is one of the cheapest 3D printing metals. At the same time, it is very durable and can be used in a wide range of manufacturing and even artistic and design applications. The type of steel alloy used also contains cobalt and nickel, is very difficult to break, and has a very high elasticity. Stainless steel is used almost exclusively in industry.

The type of steel alloy used also contains cobalt and nickel, is very difficult to break, and has a very high elasticity. Stainless steel is used almost exclusively in industry.

3D Printing Metal #3: Inconel

Inconel is a superalloy manufactured by Special Metals Corporation and is a registered trademark. The alloy consists mainly of nickel and chromium and is very heat resistant. Therefore, it is used in the oil, chemical and aerospace (for black boxes) industries.

3D Printing Metal #4: Aluminum

Due to its lightness and versatility, aluminum is very popular in 3D printing. Aluminum alloys are commonly used.

3D Printing Metal #5: Cobalt Chrome

gap). It is most commonly used in the manufacture of turbines, dental and orthopedic implants, where 3D printing has become the dominant technology.

3D printing metal #5. Copper and bronze

With some exceptions, copper and bronze are used in wax melting processes, rarely in layer melting. The fact is that these metals are not very suitable for industry, they are more often used in the manufacture of works of art and crafts. ColorFabb offers both metals as the basis for a special metal filament.

The fact is that these metals are not very suitable for industry, they are more often used in the manufacture of works of art and crafts. ColorFabb offers both metals as the basis for a special metal filament.

3D printing metal #6. Iron

Iron, incl. magnetic, also mainly used as an additive to PLA-based filaments, which are produced, for example, by ProtoPasta and TreeD.

3D printing metal #7. Gold, Silver, and Other Precious Metals

Most preformed layer companies can 3D print precious metals such as gold, silver, and platinum. Here, along with the preservation of the aesthetic properties of materials, it is important to achieve optimization of work with expensive starting powder. Precious metal 3D printing is required for jewelry, medical applications and electronics.

Metallic 3D printing. Printers

Do not hesitate - the purchase of a metal 3D printer will not pass without a trace on your budget. It will cost at least 100-250 thousand dollars. Here is a list of a variety of "metal" printers, some of which can be found in firms providing 3D printing services.

It will cost at least 100-250 thousand dollars. Here is a list of a variety of "metal" printers, some of which can be found in firms providing 3D printing services.

Metal 3D Printer #1:

Sciaky EBAM 300 - Metal Filament Printing

If you need to print really large metal structures, Sciaky's EBAM technology is your best bet. By order, the device can be built in almost any size. This technique is used mainly in the aerospace industry and the military.

Sciaky's largest production printer is the EBAM 300. It prints objects in a volume of 5791 x 1219 x 1219 mm.

The company claims the EBAM 300 is also one of the fastest industrial 3D printers on the market. A three-meter-sized titanium part for an aircraft is printed on it in 48 hours, while the material consumption is about 7 kg per hour. In general, forged parts that usually take 6-12 months to complete can be made in 2 days with this 3D printer.

The metal layers are first cut and then ultrasonically welded. The largest Fabrisonic 7200 printer operates in a volume of 2 x 2 x 1.5 m. The metal powder 3D printer is the Concept Laser XLine 1000. It has a modeling volume of 630 x 400 x 500 mm and is the size of a house.

Its German company, one of the main suppliers of 3D printers for aerospace giants like Airbus, recently introduced a new machine, the Xline 2000.

This machine uses two lasers and has a working volume of 800 x 400 x 500 mm. Uses LaserCUSING laser technology (a variant of selective laser fusion) from Concept Laser, which allows you to print alloys of steel, aluminum, nickel, titanium, precious metals and even some pure substances (titanium and stainless steel).

Metallic 3D printing. Services

There are more than 100 companies worldwide offering metal 3D printing services. We list the most popular services for consumer needs.

Metal 3D Printing Service #1: Shapeways

The world's most popular 3D printing service, Shapeways offers two types of services. As a consumer, you can choose from a wide range of professionally designed objects, customize them, and then have them printed to your specifications. Like other 3D printing services, Shapeways offers a platform for designers to sell and print their work. Shapeways is also a good place for rapid prototyping: customers benefit from industrial-grade printers (EOS, 3D Systems) and personal technical support.

As a consumer, you can choose from a wide range of professionally designed objects, customize them, and then have them printed to your specifications. Like other 3D printing services, Shapeways offers a platform for designers to sell and print their work. Shapeways is also a good place for rapid prototyping: customers benefit from industrial-grade printers (EOS, 3D Systems) and personal technical support.

3D printing metals: aluminium, brass, bronze, gold, platinum, precious metal plating, silver, steel. There are also wax molds for jewelry purposes.

Metal 3D Printing Service #2: Sculpteo

Like Shapeways and i.materialise, Sculpteo is an online 3D printing service that allows anyone to upload 3D models and send them to fabrication in a wide range of materials . Like its competitors, Sculpteo provides a platform for hobbyists and professionals to showcase and sell their designs. The stable of Sculpteo printers includes highly professional machines from 3D Systems, EOS, Stratasys and ZCorp. Extensive technical documentation will help identify design flaws and select the right material for the project.

Extensive technical documentation will help identify design flaws and select the right material for the project.

Metals for 3D printing: alumide (plastic with aluminum particles), brass, silver.

Metal 3D Printing Service #3: iMaterialise

Materialise is a company that works with industrial customers to prototyp 3D printed products. For casual users and designers, Materialize offers an online 3D printing service called i.materialise. As with Shapeways, this service allows anyone to upload their 3D designs and print them out. Once an object has been uploaded and successfully printed, a designer can list it for sale either in the gallery of the i.materalise online store or by embedding some code into their site.

3D printing metals: alumide (plastic with aluminum powder), brass, bronze, copper, gold, silver, steel, titanium.

Metal 3D Printing Service #4: 3D Hubs

Through 3D Hubs, you can search for individuals and companies that offer 3D printing services in your area, upload STL files (which are immediately evaluated for defects ) and contact service providers directly to get the job done. The online 3D printing service also allows you to sort offers by materials, customer rating, distance and many other parameters. Whatever object you wish to print, chances are there is someone nearby who can do it. A significant number of materials can be printed in industrial quality, such materials have an HD mark in the search field.

The online 3D printing service also allows you to sort offers by materials, customer rating, distance and many other parameters. Whatever object you wish to print, chances are there is someone nearby who can do it. A significant number of materials can be printed in industrial quality, such materials have an HD mark in the search field.

3D printing metals: aluminium, bronze, cobalt-chromium, stainless steel, titanium.

Metal 3D printing | DMLS Printer | Additive manufacturing equipment

Equipment Additive Manufacturing Equipment

What is metal additive manufacturing?

Eplus 3D Additive Metal Manufacturing

Metal 3D printing equipment and supplies

Eplus3D metal printers, from entry-level models to multi-laser machines, can be used for industrial grade additive manufacturing.