3D printed bump fire stock file

Free STL file Bumpfire Stock AR-15/M4・3D print design to download・Cults

Glock 17 Frame

Free

1911 frame

Free

AR-10 Lower receiver

Free

AR-15 Lower bundle

Free

Renforced AR-10 Lower receiver

Free

Beretta M9 92FS

Free

AR 15 / M4 10 round magazine

Free

AK-47 10 rounds 7.62 Magazine

Free

Best 3D printer files of the Art category

Pumpkin dragon skull mask

€2.69

ZOMBIE - NO SUPPORT - PRINT IN PLACE

€1

Flora from Animal Crossing

Free

Trapinch - Pokemon 328

Free

Han Solo Bust

Free

Rage Meme Bulbasaur

€4. 19

Given X

€1 -50% €0.50

Energy Knight

€3.75

Best sellers of the category Art

Flexi Print-in-Place Gingerbread Man Ornament

€1.38

Adorable Articulated Axolotl, Print-In-Place Body, Snap-Fit Head, Cute Flexi

€3.30

Cute Flexi Print-in-Place Skeleton

€2.80

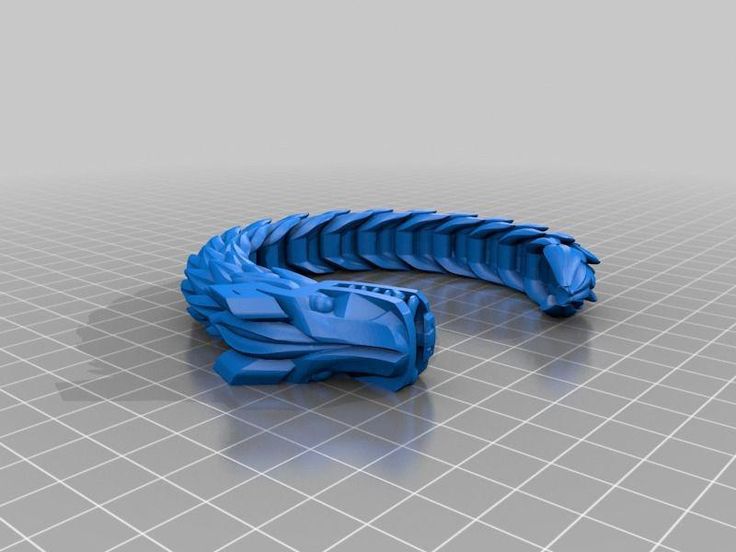

Crystal Dragon, Articulating Flexi Wiggle Pet, Print in Place, Fantasy

€3.80

FLEXI PRINT-IN-PLACE STANDING YETI

€2.80

Flexi Print-in-Place Phoenix

€3. 75

75

Elf on a shelf in Carbonite

€8.54 -50% €4.27

Flexi Print-in-Place Astronaut

€2.80

Flexi Print-in-Place Imperial Dragon

€3.75

Bearded Dragon Articulated Toy, Print-In-Place Body, Snap-Fit Head, Cute Flexi

€3.30

Stitch Love (Easy print no support)

€1.50

Cute Flexi Print-in-Place Fox

€2.37

Cute Flexi Print-in-Place T-Rex Dinosaur

€2.80

Rose Dragon, Valentine's Day, Articulating Flexi Wiggle Pet, Print in Place, Fantasy

€3. 85

85

Flexi Print-in-Place Skeleton Hand

€1.89

Cute Flexi Print-in-Place Frog

€1.85

Would you like to support Cults?

You like Cults and you want to help us continue the adventure independently? Please note that we are a small team of 3 people, therefore it is very simple to support us to maintain the activity and create future developments. Here are 4 solutions accessible to all:

ADVERTISING: Disable your AdBlock banner blocker and click on our banner ads.

AFFILIATION: Make your purchases online by clicking on our affiliate links here Amazon.

DONATE: If you want, you can make a donation via PayPal.

WORD OF MOUTH: Invite your friends to come, discover the platform and the magnificent 3D files shared by the community!

What Is and Can You 3D Print a Bump Fire Stock in the US? » 3D Printing Media Network

Stay up to date with everything that is happening in the wonderful world of AM via our LinkedIn community.

Before the horrific Las Vegas shooting, I suspect most people had never heard of a bump stock or bump fire stock, which can replace the standard stock that comes with semi-automatic assault weapons.

They are made so that there is a gap between the stock and the body of the weapon. When the weapon is fired, the operator holds the trigger finger in a stationary position. Upon firing, the recoil causes the body of the weapon and trigger to move backward, compressing the gap between the stock and the weapon. The recoiling weapon then bumps off of the stock and moves forward, gliding the trigger to the finger. When the trigger hits the finger, it fires again, repeating the process, which simulates automatic fire, achieving a rate-of-fire of 400 to 800 rounds per minute. A bump fire stock can retail in the low hundreds of dollars.

A bump fire stock can retail in the low hundreds of dollars.

Soon after the shooting, Congress started talking about enacting a law to ban the sale of bump fire stocks and the NRA may even support regulating such devices. On the assumption that anything can be 3D printed, would such a law prevent people from making their own bump fire stock?

Bluy Prints Available OnlineA Google search of “3D printed bump fire stock” revealed exactly what I expected: a YouTube video of the test firing of a 3D printed bump fire stock posted by SilkyDionysus4 in April of this year.

On October 10, 2017, gun rights advocate, The Jack News, published an article called “Here’s How to 3D Print Your Own Bump Stock Before Congress Bans Them.” The article links to a collection of FOSSCAD digital blueprints for a variety of AR-15 parts, including a bump-fire stock.

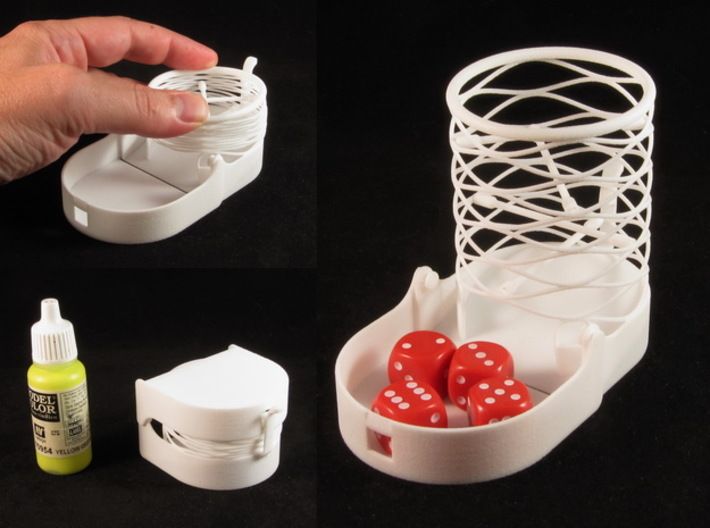

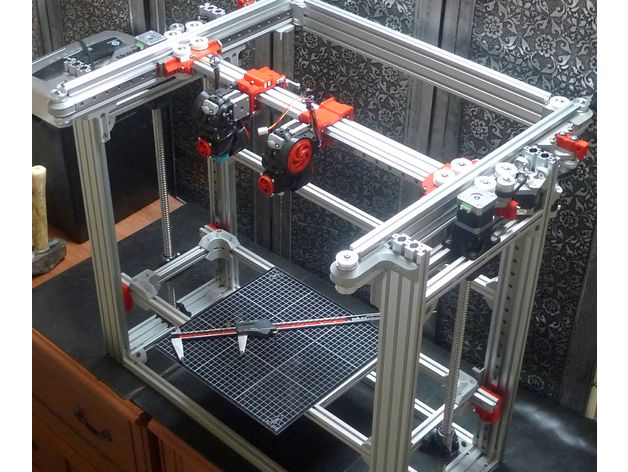

These digital blueprints supposedly can be used to 3D print a bump fire stock. According to the article, this device can be printed in a 3D printer with at least an 8” x 8” build chamber. A smaller chamber could be used if the device is built in pieces.

A smaller chamber could be used if the device is built in pieces.

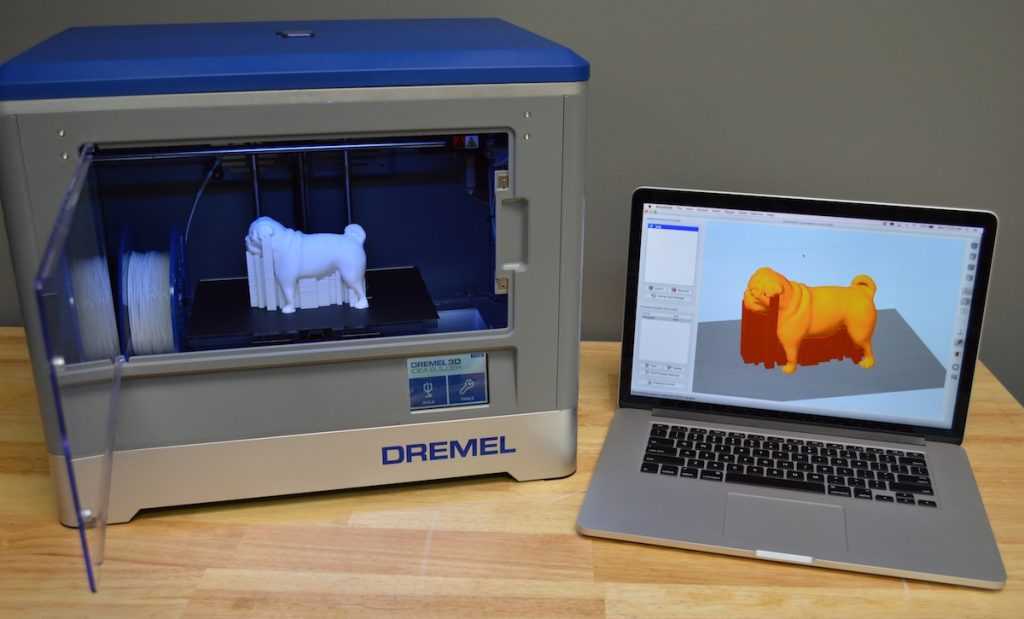

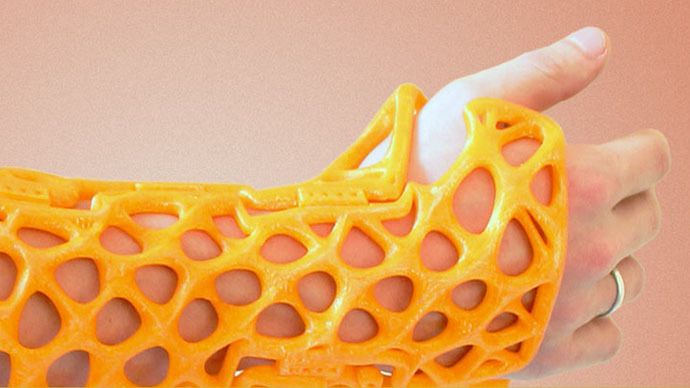

Although the type of 3D printer is not specified, the bump fire stock in the video appears to have been printed on a material extrusion machine. This is the most basic and least expensive type of 3D printer, starting at a few hundred dollars. A bump fire stock can be 3D printed in cheap plastic and have no moving parts.

A Google search also yielded a link to digital blueprints for a bump fire stock posted by Disruptive Solutions in October 2013. Online forums show that some people in the gun community are shifting into high gear to create and mass-distribute digital blueprints for bump fire stocks before any government ban takes effect. I believe the idea is that if the blueprints are distributed widely, the cat cannot be put back into the bag.

Bump fire stock digital blueprints will soon be available on the Dark Web, if they are not already there. The Dark Web is at least 20 times larger than the World Wide Web. There is no bag big enough to hold all of the cats that could roam there.

There is no bag big enough to hold all of the cats that could roam there.

Although the idea of trying to control the digital dissemination of bump fire stock design files suggests a lack of understanding of the power of the Internet, anyone who wants to 3D print a bump fire stock doesn’t really need the Internet at all.

In addition to bump fire stocks and their digital blueprints becoming available on the Black Market, if they are banned, you can design and make your own digital blueprints.

Bump fire stocks are simple devices that almost duplicate the original gun stock. Anyone with even a little design talent could design a bump fire stock from scratch (or tweak the digital blueprint for a legal, aftermarket gun stock), using any one of a number of 3D design programs, and could even customize the design. Then all you need is an inexpensive 3D printer ($500 to $1000) and some plastic filament.

Although I have read comments suggesting that the high cost of 3D printers will dissuade people from 3D printing their own bump fire stocks, this is silly. Anyone who spends hundreds or thousands of dollars on weapons can and will spend hundreds of dollars, if not more, for a machine that provides allows them to make things “away from control.”

Anyone who spends hundreds or thousands of dollars on weapons can and will spend hundreds of dollars, if not more, for a machine that provides allows them to make things “away from control.”

Away from control means the ability to make things without anyone knowing about it or being able to control it. I also discuss in my book, 3D Printing Will Rock the World, that the cost of 3D printers can easily be shared in what I call “friends networks.” Why wouldn’t a bunch of like-minded people pool their resources to be able to make things away from control, or simply to make things so they don’t have to buy them? And by pooling resources, they could buy a better 3D printer than any one of them could afford alone.

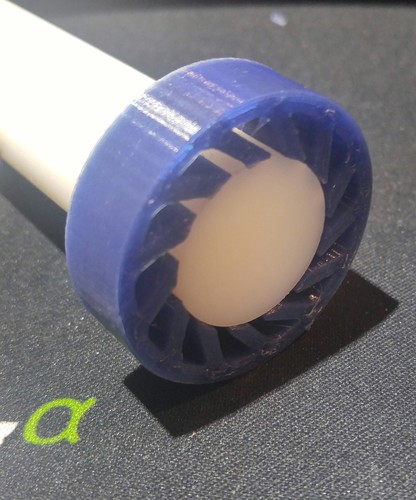

3D ScanningThere is also another way to create a digital blueprint without the Internet: 3D scanning. Anyone of a hundred inexpensive 3D scanners can be used to scan either a friend’s bump fire stock or the weapon’s original, legal gun stock. The scan is then tweaked in a 3D design program to make it a bump fire stock, which can then be 3D printed.

So this brings me back to the original question: Would banning the sale of bump-fire stocks prevent people from making their own? The answer is, probably not.

If my underlying message is not obvious, here it is: the law enforcement community needs to educate itself on 3D printing and its potential illegal uses, and plan accordingly.

About the author

John Hornick, the author of the award-winning book, “3D Printing Will Rock the World,” offers educational programs to the law enforcement community on the dark side of 3D printing, and on how 3D printing can be used to aid law enforcement. Contact him at [email protected].

Related Articles

3D printing - who is responsible for a defective item printed on a 3D printer?

For 3D printing, a CAD file (computer-aided design file) must be installed in the printer - a technical drawing that is read by the printer and contains a design of the object to be printed.

3D printing could be a revolutionary technology because it is decentralized and cheap, and in the near future everyone will be able to order 3D printing by sending a CAD file over the Internet to a 3D printing service provider. At the same time, this technology can also cause a number of problems in connection with the verification of the finished product, the possibility of counterfeiting, and risks associated with cybersecurity. From a legal point of view, the main problems are related to the protection of intellectual property rights, as well as the assessment of liability.

Since the whole process is decentralized, this means that one person can design a CAD file, another person can print it, and a third person can use the product. All of this makes it very difficult and confusing to meet security and compliance requirements from a legal standpoint.

Intellectual property rights protection

To properly address the legal issues associated with 3D printing, we must distinguish between (a) the protection of the CAD file (the result of the creative process) and (b) the protection of the finished printed product (the distribution process) . A CAD file consists of data compiled using CAD software (such as AutoCAD). They are usually in .DWG format, which can be imported into a PDF file.

A CAD file consists of data compiled using CAD software (such as AutoCAD). They are usually in .DWG format, which can be imported into a PDF file.

The data cannot be protected by the Copyright Act, only by trade secret protection. In Europe, software protection is provided by copyright. Copyright owner, i.e. the creator can always protect his rights in a way that suits him. The issue of extending copyright protection in relation to a CAD file is questionable if it is not related to artistic creation. Still, the CAD file can be protected by the database sui generis if it can be shown that the collection of the applied data set required significant effort.

During the distribution process, if the physical object is already printed and ready for distribution, the legal approach is different from the analysis applied to the CAD. In this case, copyright protection is no longer valid, and industrial property rights such as patents and design protection provide the most effective protection. Why is this happening? The actual creator of the printed object cannot be the person who orders the machine to print. The creator is the person who created the design/project contained in the CAD file. In the event that a designer/creator wants to extend protection to all creativity and dissemination, this can only be done through a patent or design protection.

Why is this happening? The actual creator of the printed object cannot be the person who orders the machine to print. The creator is the person who created the design/project contained in the CAD file. In the event that a designer/creator wants to extend protection to all creativity and dissemination, this can only be done through a patent or design protection.

Once all the requirements for patent protection have been met (technical development, innovativeness, level of invention and industrial applicability), the entire process can be patented in the name of its creator, i.e. in this case, the inventor. It is important to note that it is not possible to patent software as such in Europe. The possibility of patenting the functional characteristics of the software is determined by the presence of a technical innovation - the technical level must be different from the current technical level.

The second option for protecting printed objects is design protection, which prevents others from copying a product with the same shape and configuration. For more effective protection, it is important to register the rights to the design.

For more effective protection, it is important to register the rights to the design.

This means that the legal rules associated with 3D printing existed long before the possibility of 3D printing, and they apply to and protect the entire manufacturing process. All legal aspects related to intellectual and industrial property in Europe are suitable for the regulation of such technology. However, the most serious problem is that in each case the solutions are different. For this reason, it is always necessary to analyze each case individually in order to be sure of the rights of the creator/owner/inventor/designer.

Considering all the variables associated with 3D printing rights, it is recommended to take all possible preventive measures so that any individual case can be predicted. In this regard, it is important when licensing rights to have clear, binding terms and a license agreement that will help regulate the resolution of disputes arising in connection with 3D printing. In this way, for example, liability can be waived from the creator of the CAD file.

In this way, for example, liability can be waived from the creator of the CAD file.

Consumer protection

In the case of privately owned 3D printers, there may be a defect liability and/or product warranty issue as between the creator of the CAD file and the end user, there is no manufacturer that could act as an intermediary. This can have serious implications for consumer protection.

Who is responsible for a defective finished product? In a situation where the object was printed at home, the fault may lie with: a) the creator of the CAD file; b) a 3D printer seller; or c) a print material seller. If one of them is a legal entity, the consumer protection authority can help the consumer and hold accountable those responsible for the marriage of the product. If the seller of the defective product is an individual, it will be much more difficult for the consumer to prove that the defect arose at a particular stage.

The second problem that concerns consumers of 3D printing technology is that when they use the goods and services offered by companies, the conditions for their use are always set in advance and cannot be changed.

Intellectual Protection Facts

| Intellectual property | Protection | Owner | |

| Database | |||

Various file formats for 3D printing・Cults

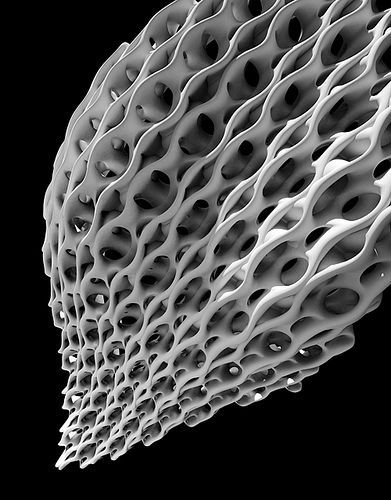

With the development of digital technology, 3D printing has become much more affordable today. Individuals and professionals can have their own equipment and make various print models. All that is required is a good understanding of the basic concepts, especially in relation to the respective file formats. Indeed, depending on the field and for historical or practical reasons, certain file formats are preferred for 3D printing. Here are the most common 3D printing formats and their main characteristics.

STL is short for "Stereolithography", one of the oldest file formats for 3D printing. Developed in the late 1980s, this type of format is still widely used today. It describes the surface geometry of a 3D object without displaying color, texture, or other attributes. The STL format has the ".STL" extension. These files are generated by computer-aided design (CAD) software. Programs such as FreeCAD, Blender, MeshLab, MeshMixer, SketchUp, SculptGL, and 3DSlash can be used to edit and repair STL files.

It describes the surface geometry of a 3D object without displaying color, texture, or other attributes. The STL format has the ".STL" extension. These files are generated by computer-aided design (CAD) software. Programs such as FreeCAD, Blender, MeshLab, MeshMixer, SketchUp, SculptGL, and 3DSlash can be used to edit and repair STL files.

The STL file simplifies a 3D surface into a "tessellation", a series of small triangles that increase in number when it is necessary to represent and recreate curved surfaces as best as possible. When a large number of triangles need to be used, the size of the 3D model STL file increases rapidly.

The OBJ file format is also very popular in the 3D printing industry. Its extension is ".OBJ". It has the advantage that it also encodes color and texture information, which is stored in a separate file with a ".MTL" extension. OBJ files allow the use of non-triangular faces, with one face adjoining another. They can be opened with programs such as Autodesk Maya 2013, Blender and MeshLab .

Developed in the 1990s, 3DS is a file format that stores only the most basic information about geometry, appearance, scenes, and animation. It allows you to save properties such as color, material, texture, transmissivity, etc. With the ".3DS" extension, this 3D printing file format also has the advantage that it can be read by most programs on the market, such as 3dsMax, ABViewer, Blender, MeshLab, messiahStudio, Rain Swift 3D, SketchUp, TurboCAD etc.

An SLDPRT file or its .SLDPRT extension is a 3D printing image format used by the SolidWorks CAD software. It contains a 3D object or "part" that can be combined with other parts into a single ".SLDASM" assembly file. SLDPRT files are usually opened with the SolidWorks program. However, they can be viewed using SolidWorks eDrawings Viewer, Autodesk Fusion 360, Adobe Acrobat 3D, Acrobat Pro 9 or later .

The SCAD format (.SCAD extension) is generated by OpenSCAD, a freeware modeling program used for various 2D and 3D projects. The SCAD file can be used to design 3D objects, specifying the object's geometry and positioning information. It can only be opened with OpenSCAD .

The SCAD file can be used to design 3D objects, specifying the object's geometry and positioning information. It can only be opened with OpenSCAD .

The .BLEND format is an extension used for 3D animation and projects designed with Blender's 3D modeling tool. This file type can contain multiple scenes as well as all project elements such as objects, textures, 3D meshes and real-time interaction data, sounds, lighting data, animation keyframes, display layouts, and interface settings. Please note that only Blender can work with this 3D file format.

The 3MF file (.3MF extension) is used by various design programs to save 3D models for printing. This format includes model, material, and property data compressed using ZIP compression. 3MF files also store a print ticket, a thumbnail image, and one or more digital signatures. They can be opened with programs such as Microsoft 3D Builder, Microsoft Paint 3D, Dassault Systemes SolidWorks, Dassault Systemes CATIA, McNeel Rhino, PTC Creo and Ultimaker Cura .

The .GCODE file contains commands that define how the 3D printer should print. It stores instructions such as print speed, set temperature, and where to move print items. This 3D file format is created with cutting software such as Simplify3D and Slic3r. Reading can be done with Simplify3D, as well as Blaze3D, GCode Viewer and NC Viewer .

A .SKP file is a 3D model format created by SketchUp. This takes into account wireframes, textures, shadows, and edge effects. This file type is also used to store components that will be inserted into the document. Of course it can be opened with SketchUp, but also with programs like IMSI TurboCAD Pro or Deluxe, Okino Computer Graphics PolyTrans, ACCA Edificius and Trimble 3D Warehouse .

FBX is a 3D printing file format popular in the film and video game industry. Developed by Kaydara and acquired by AutoDesk, it supports geometry and appearance properties such as color and texture, as well as skeletal animation and morphs. AutoDesk will use the ".FBX" FBX file as an interchange format for its software portfolio such as AutoCAD, Fusion 360, Maya, 3DS Max, etc.

AutoDesk will use the ".FBX" FBX file as an interchange format for its software portfolio such as AutoCAD, Fusion 360, Maya, 3DS Max, etc.

Other file types are not exclusive to 3D but are regularly used in the field.

A .RAR file is an archive containing one or more compressed files. The compression ratio of this format is greater than that of the classic ZIP compression. It is used to compress files to reduce their size for easier transportation and storage. You can extract files from RAR archive using various unpacking programs such as RARLAB WinRAR, Corel WinZip or B1 Free Archiver .

.DWG files are databases of 2D or 3D models created in AutoCAD. They consist of information about the vector image and metadata that describes the contents of the file. There are many utilities available to open this file format, including: Autodesk Auto CAD, Autodesk Inventor, Autodesk Design, Autodesk DWG, AutoDWG DWGSee, CADSoftTools ABViewer, Canvas X, Adobe Illustrator, Bricsys Bricscad, etc.

Used in 3D editing programs such as Adobe Photoshop and Autodesk Maya, the .MTL format is used to store material settings. This file is stored along with another in .OBJ format and is used to describe how textures should be applied and the 3D coordinates they should be applied to.

This page has been translated using machine translation. Suggest the best translation

Previous

ShareNext

Similar publications

Since their invention, 3D printers have proven that printing many objects is much more efficient than conventional manufacturing techniques. However, calibration is required for optimal performance when printing 3D parts. Many 3D printer owners find this procedure tedious and time-consuming. However, it is much easier than it seems if you know the right tips on how to do it. Cults3D presents the various steps you need to follow in order to successfully calibrate your printer.

Read more The plate is one of the most important parts of a 3D printer.