3D house printing austin tx

The Genesis Collection – ICON

Homes at Wolf Ranch

Built by ICON and Lennar, one of the nation’s leading homebuilders, and co-designed by BIG-Bjarke Ingels Group, the innovative community of one hundred 3D-printed homes feature eight floorplans, 24 elevations, and will be powered by the sun with rooftop solar panels.

03 Bedrooms | 02 Baths | 1,574 Sq Ft

This stylish single-story home located in the incredible community of Wolf Ranch has 3 bedrooms, 2 bathrooms, and boasts more than 1,500 square feet of living space, a rear patio and an open floor plan for entertaining. The primary suite sits off the living area, and includes a beautiful walk-in closet, a double vanity, a standalone tub and shower.

Learn More

03 Bedrooms | 02 Baths | 1,781 Sq Ft

The perfect home for entertaining, Genesis 02 has an open floor plan that allows you to see your guests or family across the kitchen, living and dining spaces. This spacious 3-bedroom, 2-bathroom single-story home features a large walk-in closet in the primary suite, as well as a double vanity, a standalone tub and shower.

Learn More

03 Bedrooms | 02 Baths | 2,014 Sq Ft

A private primary bedroom retreat anchors this home and provides a sanctuary with its own patio. The focal point of the home is the open kitchen, which connects to both the living and dining spaces—a host’s dream. The 3-bedroom, 2-bath home offers ample closet space, large windows and a spacious kitchen island.

The focal point of the home is the open kitchen, which connects to both the living and dining spaces—a host’s dream. The 3-bedroom, 2-bath home offers ample closet space, large windows and a spacious kitchen island.

Learn More

03 Bedrooms | 02 Baths | 1,977 Sq Ft

Genesis 04 is a 3-bedroom, 2-bath home with nearly 2,000 square feet of living space, in addition to a 385-square-foot outdoor patio. Large sliding doors off the living room allow you to bring the outdoors in. The primary bedroom offers a large walk-in closet.

Learn More

04 Bedrooms | 02 Baths | 1,993 Sq Ft

This 4-bedroom, 2-bathroom home is perfect for those looking for larger space. It boasts more than 2,000 square feet of living space and flex spaces that could be used for a home office—or even two. The primary suite sits towards the rear of the house, offering privacy for its occupants. The gorgeous en-suite bathroom features a large walk-in closet.

It boasts more than 2,000 square feet of living space and flex spaces that could be used for a home office—or even two. The primary suite sits towards the rear of the house, offering privacy for its occupants. The gorgeous en-suite bathroom features a large walk-in closet.

Learn More

03 Bedrooms | 02 Baths | 2,010 Sq Ft

Genesis 06 has an open-concept living room attached to a spacious patio, allowing for both indoor and outdoor entertaining. Large glass sliding doors allow the space to fill with natural light or close out the outside world. The home offers 2,000+ square feet of living space with an open-concept kitchen.

Learn More

04 Bedrooms | 03 Baths | 2,031 Sq Ft

Genesis 07 is a 4-bedroom, 2. 5-bath with ample living space for homeowners. The open kitchen sits between living and dining spaces, allowing for seamless transitions and entertaining.

5-bath with ample living space for homeowners. The open kitchen sits between living and dining spaces, allowing for seamless transitions and entertaining.

Learn More

04 Bedrooms | 03 Baths | 2,112 Sq Ft

A 4-bedroom, 3-bathroom home, The Genesis 08, offers over 2,000 square feet of living space. The front door allows for side entry and greater privacy in the home. Upon entering the foyer, there is a separation between living and dwelling spaces. This home offers a large, open kitchen and dining space with an adjacent living room and access to the outdoors.

Learn More

Reservations Begin 2023Get On The List

ICON and Lake Flato build 3D-printed House Zero in Austin

Ben Dreith | Leave a comment

Construction technology outfit ICON and architecture studio Lake Flato have completed a 3D-printed, modern ranch-style home in Austin to be displayed during the SXSW festival.![]()

ICON, the company to first sell ready-to-own 3D homes in the US, worked with San Antonio and Austin-based architecture studio Lake Flato to design House Zero.

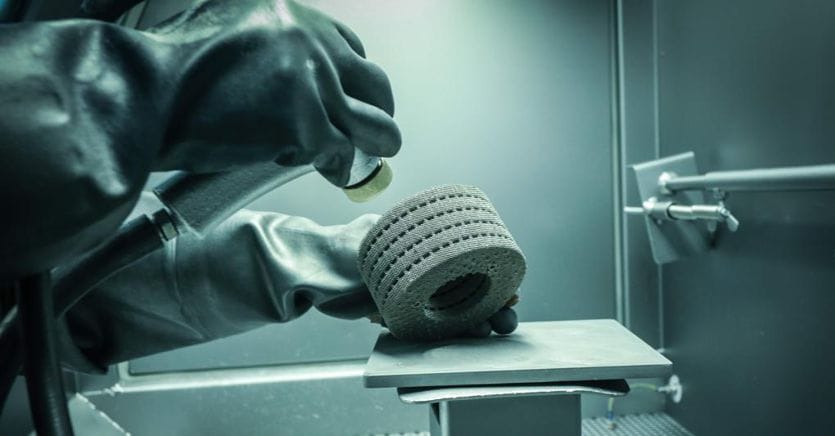

ICON worked with Lake Flato Architecture studio to 3D print House ZeroThe home is sited in a single-family residential neighbourhood in East Austin, Texas, and was built using ICON's Vulcan construction system.

The system uses 3D printing, a technology that dispenses layers of material mechanically based on a computer program, to lay the walls of the 2,000-square-foot (186-square-metre) home. The 3D-printed wall aspects took 10 days to print.

"House Zero is ground zero for the emergence of entirely new design languages and architectural vernaculars that will use robotic construction to deliver the things we need most from our housing: comfort, beauty, dignity, sustainability, attainability, and hope," said Jason Ballard, co-founder and CEO of ICON, in a release.

House Zero has walls made of ICON's proprietary material LavacreteReinforced by steel, the walls are printed with a proprietary material ICON calls Lavacrete – a cement-like substance that is air-tight while also providing increased insulation.

"We let the Lavacrete lead the way," Ashley Heeren, associate architect for Lake Flato, told Dezeen. "We could then use other materials in ways that were not only honest to their nature but also supported and complemented the concrete".

Lavacrete is a cement-like material used in ICON's 3D printing"While the organic nature of the 3D-printed concrete and curved walls are new design languages for us, House Zero was still entirely in line with the natural connections we seek in our architecture," said Heeren continued.

"The home expresses our shared passions for craft and performance in an inviting and comfortable family home constructed through a totally new way of building".

The smooth Lavacrete walls are present in most of the home's roomsAccording to ICON, the home was built using biophilic design principles, claiming that the soft curves of the 3D-printed support walls create "naturalistic circulation routes throughout the home".

In addition to being able to build houses faster, the technology could mean that homes like this could be built at lower cost.

Seven 3D-printed houses that have been built around the world

House Zero has three bedrooms with two and a half baths, along with a one bed and bath accessory dwelling unit. While the exterior walls are composed of the soft lines of the Lavacrete, many of the interior walls, ceiling, and rafters are made of wood.

"It’s regional and sensible and welcoming so, in that way, it’s what a really good mid-century ranch house wants to be," said Lewis McNeel, associate partner at Lake Flato. "And yet the new technology has freed it from rigid stylistic definitions and easy labels."

The 3D-printed walls were reinforced with steelThe living space at the front of the home is surrounded by the semi-circular Lavacrete walls punctuated by glass that provides views of the street. The flat roof is supported by rafters that run the width of the home and cantilever into awnings.

ICON does not currently have plans to sell House Zero, the company told Dezeen, but instead will use it as a place to bring "partners, architects, organisations, developers, and showcase the future of homebuilding".

The building was completed in time for the SXSW festival, which takes place in Austin from 11-20 March 2022.

ICON uses its Vulcan construction system to 3D print homesIn terms of sustainability, McNeel said that both the insulation properties and the cutting down of material used makes it a viable option.

"You can eliminate a number of separate materials and construction steps on a job site if you can print the equivalent of cladding, sheathing, thermal breaks, formwork for structure and interior finish all in one pass of the printer," he said.

3D-printed houses have been gaining in popularity worldwide and even beyond.

ICON has been active in this push, working with designers like Yves Behar to create a 3D-printed community in Latin America as well as with BIG and NASA to plan buildings for the moon.

The photography is by Casey Dunn.

Subscribe to our newsletters

Your email addressDezeen Debate

Our most popular newsletter, formerly known as Dezeen Weekly. Sent every Thursday and featuring a selection of the best reader comments and most talked-about stories. Plus occasional updates on Dezeen’s services and breaking news.

Sent every Thursday and featuring a selection of the best reader comments and most talked-about stories. Plus occasional updates on Dezeen’s services and breaking news.

Sent every Tuesday and containing a selection of the most important news highlights. Plus occasional updates on Dezeen’s services and breaking news.

Dezeen DailyA daily newsletter containing the latest stories from Dezeen.

New! Dezeen In DepthSent on the last Friday of every month, Dezeen in Depth features original feature articles, interviews and opinion pieces that delve deeper into the major stories shaping architecture and design.

Dezeen JobsDaily updates on the latest design and architecture vacancies advertised on Dezeen Jobs. Plus occasional news.

Dezeen AwardsNews about our Dezeen Awards programme, including entry deadlines and announcements. Plus occasional updates.

Dezeen Events GuideNews from Dezeen Events Guide, a listings guide covering the leading design-related events taking place around the world. Plus occasional updates.

Plus occasional updates.

We will only use your email address to send you the newsletters you have requested. We will never give your details to anyone else without your consent. You can unsubscribe at any time by clicking on the unsubscribe link at the bottom of every email, or by emailing us at [email protected].

For more details, please see our privacy notice.

Thank you!

You will shortly receive a welcome email so please check your inbox.

You can unsubscribe at any time by clicking the link at the bottom of every newsletter.

More images

Startup Icon raised $207 million to build houses using 3D printing - Services on vc.ru

Image credit: ICON, Lake/FLATO Architects

292 hits

Startup Icon from Austin, Texas is developing innovative building technologies . In particular, the company creates houses using 3D printing. In addition to private residences for sale, project prints housing for the homeless and low-income people, together with NASA, is developing building systems for creating future infrastructure on the Moon and Mars, and also creating barracks for the military department in Texas.

Earlier this week, the company announced that it had raised $.207 million in its Series B funding round. US VC firm Norwest Venture Partners led the round, along with several major investment funds. The total amount of project financing thus increased to $266 million.

ICON was founded by at the end of 2017, and in March 2018 presented its first 3D printed house at the SXSW media festival in the USA. The area of the house was about 33 square meters. meters, it took about 48 hours to print. Concrete was chosen as the print material because, according to company co-founder and CEO Jason Ballard, is "one of the most sustainable materials on Earth."

According to TechCrunch, the company has 3D-printed more than two dozen houses and structures for the United States and Mexico in three years using the 3D printer. About half of these houses are designed to accommodate the homeless or the extremely poor.

The company entered the private housing market in early 2021, listing two 3D homes for sale in Austin.![]() Two more houses from the same series should go on sale on August 31st.

Two more houses from the same series should go on sale on August 31st.

Vulcan 9 system0041 Image credit: iconbuild.com

ICON recently introduced the Vulcan , a patented "next generation" building system, as well as the new Exploration house series. The first house in this series, House Zero , is designed and optimized specifically for 3D printing. The startup says Vulcan's technology makes it possible to build "sustainable, energy-efficient" homes faster than traditional building methods. Vulcan can print homes up to 270 square meters, Ballard said.

The CEO of ICON also claims that since the inception of the company, its revenue has been growing by 400% almost every year. Over the past year, the startup has tripled its team to 90,007 over 100 employees.

The company plans to invest in new funding to further create homes with its technology, provide housing assistance to the homeless or those affected by natural disasters, and develop building systems to create habitats on the Moon and Mars with NASA.

Hybrid homes using both 3D printing and traditional technologies - Apartment, house, cottage - September 24 - 43987592031

Austin, Texas, completed the construction of four unique houses that were built on two opposite technologies at the same time. The first floor of the spacious mansions is built of concrete using 3D printing by construction technology company ICON, while the second floor is made on the principle of a wireframe. The hybrid construction method was chosen for a reason, as it turned out to be more reliable in a region suffering from flooding. But this is not all the features and advantages of the new project.

Hybrid homes have appeared in Texas, using both 3D printing and traditional technologies.

In recent years, 3D printing has evolved from a highly specialized hobby and experimental industry to a mainstream construction technology, thanks in large part to the developments of ICON (in the US market), which develops and upgrades the Vulcan construction printer. Shortly after the concept of a 3D printed base on Mars was unveiled, in which NASA and Bjarke Ingels Group also participated in the development, ICON set about implementing a pilot project. This time, social small-sized housing, the creation of which was recently reported on the pages of Novate.ru, did not work out.

Shortly after the concept of a 3D printed base on Mars was unveiled, in which NASA and Bjarke Ingels Group also participated in the development, ICON set about implementing a pilot project. This time, social small-sized housing, the creation of which was recently reported on the pages of Novate.ru, did not work out.

The East 17th St 3D-printed Home in East Austin, Texas, USA.

East Austin, Texas, has now completed four homes designed by local firm Logan Architecture and built using 3D printing technology from innovative company ICON. Residences from 141 to 179 sq. m on East 17th Street is completely ready for occupancy and is currently on the real estate market, which, according to specialists from the construction company ICON and developers from 3-strands, is the first such proposal in the United States.

East 17th Street houses were built using two technologies at once - 3D printing and traditional (Austin, Texas).

The main feature of the new residential complex, called The East 17th St 3D-printed Home, was a hybrid construction method. To create the first floor, a Vulcan 3D printer was used, which extrudes a specially designed cement mixture from a nozzle in layers, while the top floor was made in the traditional way using frame construction technology.

To create the first floor, a Vulcan 3D printer was used, which extrudes a specially designed cement mixture from a nozzle in layers, while the top floor was made in the traditional way using frame construction technology.

Two large awnings can be used as you please.

This method of housing construction has many advantages, as the lower part of the building is made of a stronger and more durable building material, which is lavacrete, a portland cement-based mortar that saves the building from extreme weather conditions. But the natural wood, which became the basis for the assembly of the second floor, facilitates the construction and helps to create original objects, which have no analogues at the moment.

Innovative residences will be sold fully equipped with appliances and furniture (Austin, Texas). | Photo: newatlas.com.

Spacious open plan living room allows you to organize the space as you wish (Austin, Texas). | Photo: designboom.![]() com.

com.

According to the company: “3D printing technology provides safer and more durable homes that are designed to better withstand fire, flood, strong winds and other natural disasters than buildings built in the traditional way.”

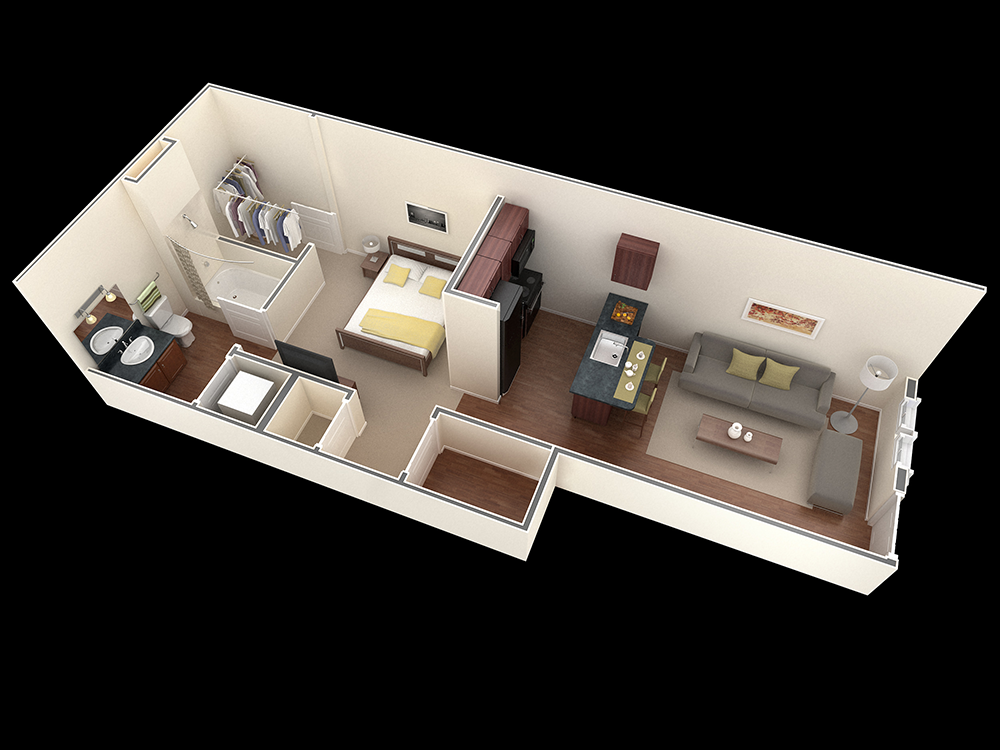

Design features: Despite the fact that the residences have different sizes, in general they have the same layout. All 4 houses have an open plan interior space, including a living room, kitchen, dining room, 4 bedrooms (some can be used as a home office), 3 or 4 bathrooms (depending on the size of the house). Each residence is distinguished by an individual interior design, with a predominance of a minimalist style.

In houses with an area of 141 sq. m residential areas are slightly reduced, but fully functional (Austin, Texas). | Photo: © ICON - 3D Tech.

Interior design was done by local designer Claire Zinnecker, who drew inspiration from the natural building materials of wood, metal and concrete. She opted for a simplistic color palette of green, white and terracotta, as well as hand-woven woven rugs, glazed Saltillo tiles from her collection for local Clay Import (for wet areas), and lighting fixtures that effectively accentuate refined materials.

She opted for a simplistic color palette of green, white and terracotta, as well as hand-woven woven rugs, glazed Saltillo tiles from her collection for local Clay Import (for wet areas), and lighting fixtures that effectively accentuate refined materials.

Fully equipped kitchen will delight new owners (Austin, TX).

The designer preferred natural wood furniture with mahogany elements and textiles, emphasizing the local flavor. Wavy walls, typical for 3D printed buildings, which do not require additional finishing, have become a kind of decoration. On the first floor, a floor of polished concrete was left, as if emphasizing the industrial style and modern possibilities of technology. But in the superstructure, characterized by minimalism and white tones, the walls were plastered, and the floor was made of laminate.

The interior of two bedrooms in the hybrid house of The East 17th St 3D-printed Home in East Austin (Texas, USA).

Each bedroom has its own bathroom (Austin, Texas).