3D printer engine parts

3D printed engine: What is possible?

Posted By Lucie Gaget on Aug 18, 2020 |

3D printing is offering a lot of possibilities for many industries, and aeronautics and aerospatial are some of them. These industries are actually making the most of this technology, both for prototyping and production. New opportunities are constantly offered to these industries with the development of new advanced technologies and materials. Many mechanical items can be created thanks to additive manufacturing, such as engine parts for an aircraft, a rocket, or a car! In this blogpost, we will discuss 3D printed engines. First, we will see how 3D printing is helping to create mechanical parts, and how it is now possible to produce a 3D printed engine, thanks to the variety of 3D printing materials available on the market. Let’s see what could be improved thanks to this technology and get ready for space exploration!

Additive manufacturing used in aerospace, aeronautics & automotive

Why could 3D printing an engine be a great advantage?

This advanced manufacturing process can really be a great asset for engine component production. Using 3D printers for prototyping and for production has many advantages and could help you to improve your product development, optimizing volumes and performance, creating parts with intricate geometries, and great aerodynamic properties.

- Prototyping with 3D printing

Additive manufacturing is known to be a good prototyping method. It is allowing the manufacturers to make many iterations at a lower cost and quite quickly. Moreover, as you have to work on CAD software to create your parts, you only have to make modifications on your 3D file if you need to change something. It will allow you to work way faster than with other processes. Optimize your prototyping process by using materials such as high-performance plastics.

- Production with 3D printing

Additive manufacturing is well used for prototyping, but it is now more and more used for production, even to create mechanical parts! This manufacturing process is totally able to create viable parts for mechanical projects.

Indeed, the 3D printing technology is evolving really fast and many resistant engineering materials are now entering the market. When it comes to aerospace, aeronautics, or even automobile, it is important to have heat resistant parts, especially if you want to produce engine components. In aerospace, additive manufacturing is often used to create lightweight components. It depends on the 3D printing material that is used, but 3D printed structures can be way lighter if the design is well optimized, and if the right material is used.

3D printing becoming a trusted technology

3D printed motor projects are mostly developed in the aerospace industry for the moment, but this trend is quickly spreading to the automotive world. Materials such as metals are widely used in these demanding and technical sectors. Metal 3D printing technologies such as DMLS/SLM are perfect for these projects. But the additive manufacturing industry is now developing and putting on the market new high-performance polymers, already used in these sectors using traditional manufacturing techniques such as CNC machining or injection molding. This way, PA6 FR, PA6 MF, TPU, and Polypropylene are now 3D printable for these sectors.

This way, PA6 FR, PA6 MF, TPU, and Polypropylene are now 3D printable for these sectors.

NASA and the ESA are really interested in this fabrication process, they see all the benefits of this technology and how they could use it for prototyping and for the production of mechanical parts. Indeed, this technology is allowing us to work on designs, and to create complex geometries really easily. That is why this technology is beginning to be interesting for some projects, for example, to manufacture motor parts. A lot of recent NASA tests are including 3D printing technology. We will talk about the RS25 later in this blogpost!

SpaceX is also working a lot with this advanced manufacturing process. This aerospace manufacturer used 3D printing to make spaceflight hardware and actually launched a 3D printed rocket engine to space.

Using 3D modeling software to create mechanical parts to improve your process

In order to prototype or even produce with 3D printing, you will need to use a 3D modeling software for mechanical engineering projects. Indeed, some software on the market dedicated to mechanical engineering that will help you to design technical parts for your rocket engine projects. For example, Autodesk edited different 3D modeling software that could perfectly be used for mechanical engineering, such as Fusion 360 or Inventor. But you can also use software such as CATIA that is a professional software that could help you with complex geometries. We also made selections of software according to the industry you are working in: car design app, and aircraft design software. These programs might offer some interesting features for your projects. More than design and 3D modeling, these software can offer you some great possibilities in terms of simulation, visualization, and rendering, improving your processes and making it easier to develop complex devices.

Indeed, some software on the market dedicated to mechanical engineering that will help you to design technical parts for your rocket engine projects. For example, Autodesk edited different 3D modeling software that could perfectly be used for mechanical engineering, such as Fusion 360 or Inventor. But you can also use software such as CATIA that is a professional software that could help you with complex geometries. We also made selections of software according to the industry you are working in: car design app, and aircraft design software. These programs might offer some interesting features for your projects. More than design and 3D modeling, these software can offer you some great possibilities in terms of simulation, visualization, and rendering, improving your processes and making it easier to develop complex devices.

Manufacturing engines using additive manufacturing

Here are a few examples of engines featuring the use of 3D printing. These could inspire you for your next project. If you have any questions about the services offered by Sculpteo please contact us!

If you have any questions about the services offered by Sculpteo please contact us!

3D printed rocket engine goes into space from New Zealand

This motor has been 3D printed in only 24 hours. This rocket engine has been developed by a US company called RocketLab. Details about the materials and the manufacturing process are not available, but we know that additive manufacturing allowed them to create important engine components really quickly. This process is allowing them to get lighter parts, thanks to an optimized design. Here is how the 3D printed engine made by RocketLab looks:

https://www.3dnatives.com/en/rocket-lab-3d-printed-engine260520174/

Australian engine rocket has successfully been fire tested

Here is another 3D printed engine created by engineers in Australia’s Monash University. 3D printing allowed to create a rocket with a different shape, to improve the propulsion of the rocket. The goal of this experiment was to work on a new design to make the rocket even more efficient, and 3D printing is the best method to improve this aspect really easily.

This manufacturing process definitely allows to work faster: this project went from idea to testing in only four months. In the end, this engine and its aerospace design succeeded the hotfire tests!

Credit: COURTESY OF MONASH UNIVERSITY

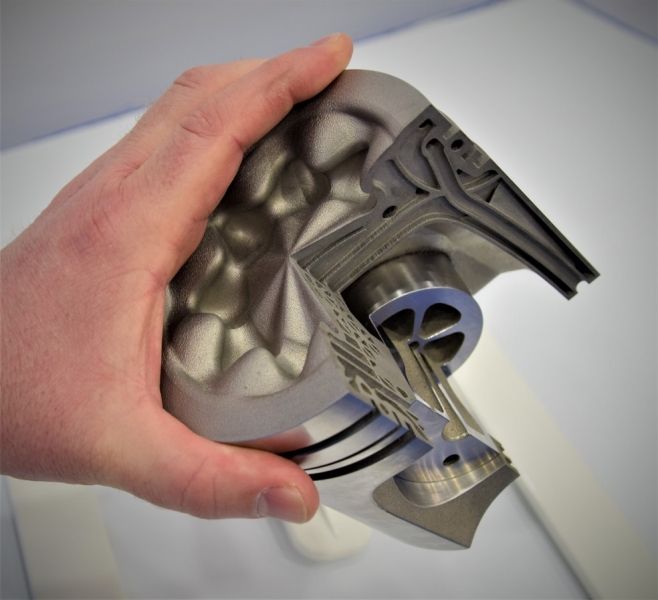

3D printed internal combustion engine

Each year, the Shell Eco-marathon invites students from all over the world to compete and develop innovative and energy-efficient vehicles. If 3D printing has been used by some participants, a team from the University of Canterbury in New Zealand created the world’s first 3D printed titanium internal combustion engine (ICE) for their car in this year’s Eco-marathon Asia!

Most of the time, while 3D printing is used in the manufacturing process of engines, only a few components are actually 3D printed. In this precise project, the whole engine has been 3D printed using titanium and runs on sustainable, carbon-neutral ethanol. This project is showing how it is possible to develop innovative solutions, with technologies such as 3D printing.

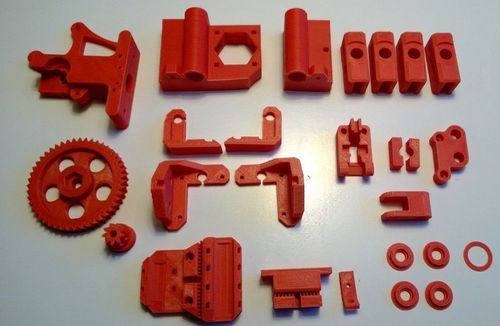

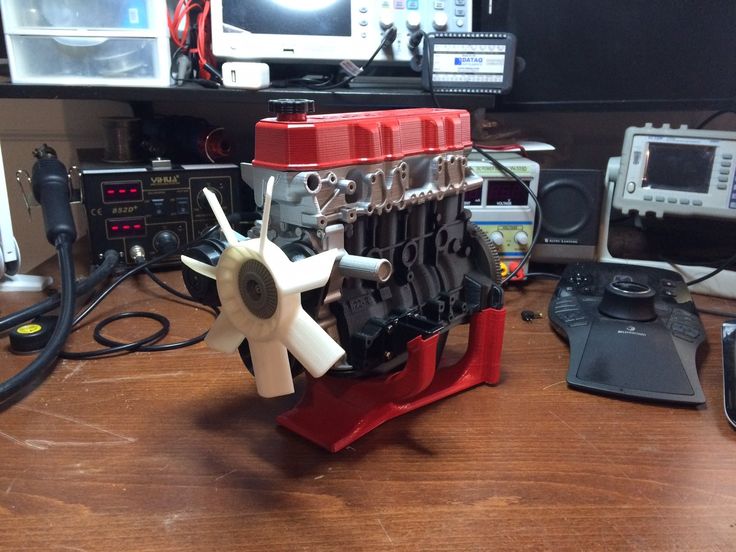

3D printed Toyota 4 22RE engine

Chinese company Winbo Smart Tech 3D printed a four-cylinder Toyota engine in only three days using FDM 3D printers. This engine is composed of 130 entirely 3D printed parts, to show the potential of 3D printing machines: all kinds of parts are 3D printable and can easily be assembled.

Engineers working for NASA are prototyping a rocket engine

Additive manufacturing is an amazing tool to make prototypes. Prototyping with metal 3D printing is now possible, but using this technology to print with two different materials is still difficult. But for NASA engineers, difficult doesn’t mean impossible. They actually created a rocket engine prototype using two different metals: copper alloy and Inconel. They used a process called brazing, in order to join 2 different types of metal, creating a brand new component. This advanced process is offering promising possibilities for future 3D printed metal parts.

SuperDraco, an engine made thanks to additive manufacturing

SpaceX is known to use 3D printing a lot. They actually built a rocket engine using 3D printing, it is called SuperDraco. This process has been used on different levels. First, for testing, 3D printing has been used instead of the traditional casting method. 3D printing has also been an advantage for the manufacturing process, and it really reduced the lead-time. The 3D printed parts were even more resistant than traditional ones.

They actually built a rocket engine using 3D printing, it is called SuperDraco. This process has been used on different levels. First, for testing, 3D printing has been used instead of the traditional casting method. 3D printing has also been an advantage for the manufacturing process, and it really reduced the lead-time. The 3D printed parts were even more resistant than traditional ones.

3D printing: A way to reduce costs for NASA

Creating motor parts using 3D printing is actually helping NASA to reduce engine costs. Indeed, it is allowing them to get more affordable parts. 3D printing complex shapes in just one part allows to avoid welds. Indeed, optimizing the design helps to reduce the number of welds, and it can obviously reduce costs and production time. That is why this manufacturing process will be more and more used in the future to build rocket engines for NASA tests.

3D printing is really seen as a serious technology. It has even been part of the recent RS25 tests. The RS25 engine is the most powerful rocket engine ever created. This Space Launch System has a 3D printed component called pogo accumulator, a shock absorber placed inside of the rocket engine.

The RS25 engine is the most powerful rocket engine ever created. This Space Launch System has a 3D printed component called pogo accumulator, a shock absorber placed inside of the rocket engine.

https://www.nasa.gov/press-release/nasa-prepares-to-fly-first-rs-25-flight-engine-test-set-for-march

The future of 3D printing for engines

New 3D printers and new 3D printing materials are now appearing on the market, allowing to manufacture impressive projects. For example, metal 3D printing is becoming more and more accurate, which is a real game-changer for many industries. Printer manufacturers are also developing large-scale 3D printers. Instead of components, it will be possible to print larger parts more easily. Last but not least, more and more impressive 3D printing materials are developed each year, which makes the future of 3D printing really promising! Projects developed with 3D printing are always getting more ambitious, pushing the boundaries of manufacturing. This is proof that this additive process is making it possible to improve product development and the product itself very easily.

This is proof that this additive process is making it possible to improve product development and the product itself very easily.

You need to 3D print a project, for prototyping or production? Upload your 3D file on our online 3D printing service right now.

How To 3D Print Replacement Car Parts [2022 Guide]

If you're looking to create your own car parts, you can do so with ease. Here is a guide on how to 3D print replacement car parts very cheap.

By Justin Evans

As 3D printing technology grows more popular, hobbyists and automotive industry leaders alike are starting to 3D print car parts as an alternative to expensive repairs and manufacturing.

This may seem unbelievable to people outside of the 3D printing space, but it is true. 3D printers can create all kinds of car parts, and they work just as well as traditionally manufactured parts.

There are plenty of reasons why people do this. They may want to personalize their car, make their car lighter, or just replace a part quickly without needing to pay an excessive amount for it.

For people who want to get into it, it is a lot easier than it looks.

Table of ContentsShow

What Kind of Parts Can You Make With 3D Printers?

There are several types of parts that you can use 3D printing to manufacture:

- Cosmetic customization (rear-view mirrors, cup holders, custom frames)

- Small parts (lids, valves, specialized parts)

- Larger parts (grills, dashboards)

While you can make powerful parts with 3D printing (like with carbon fiber), it is not recommended for making internal car parts. These parts must deal with excessive heat or pressure and require a specialized manufacturing process.

So long as you keep the part, your intended material, and what that part is used for in mind, the sky is the limit as far as what you can create.

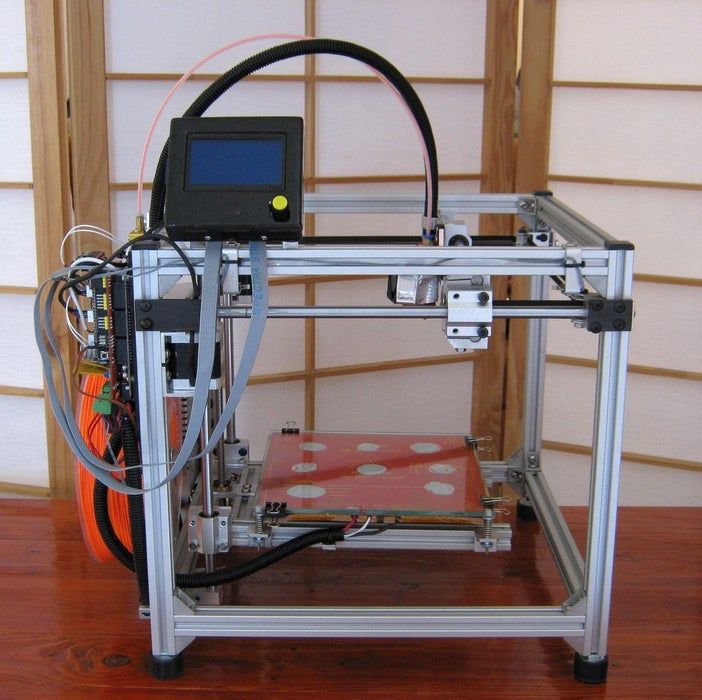

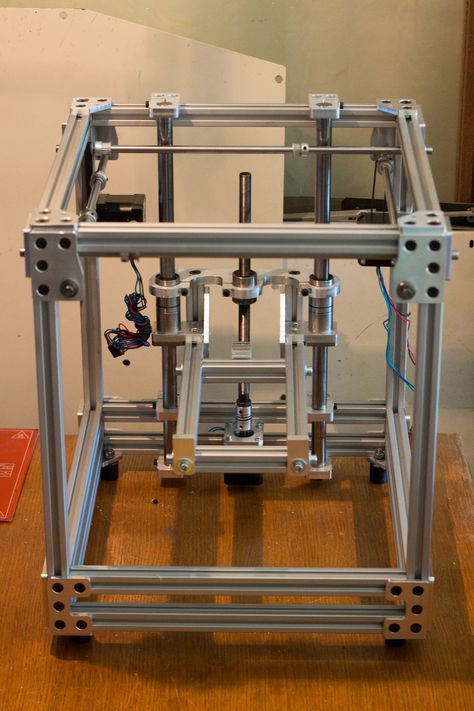

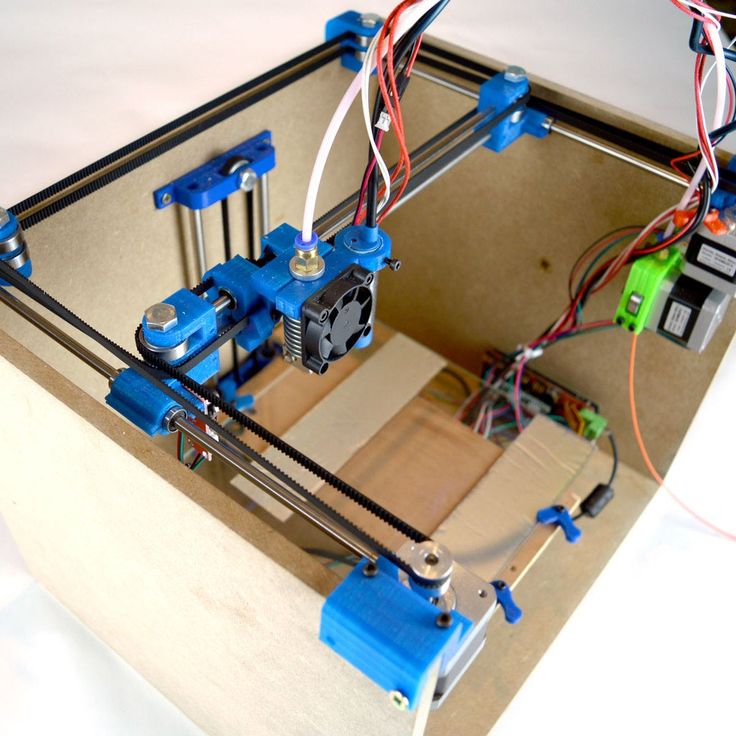

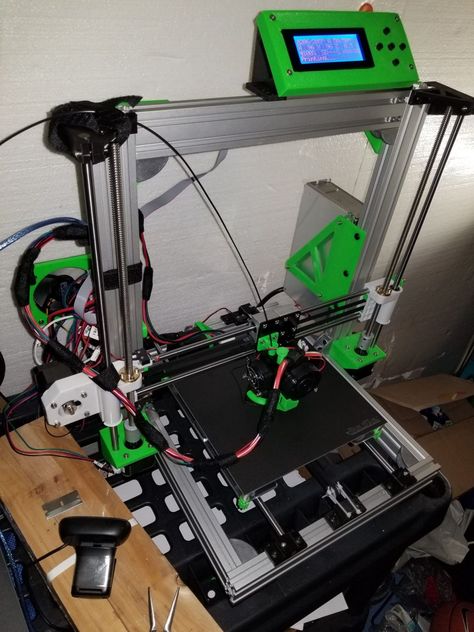

What Kinds of 3D Printers Are Best for 3D Printing Car Parts?

When 3D printing car parts, the ideal printer can vary depending on what you are trying to print.

For most things, an inexpensive basic printer is fine. Plenty of car parts are small and simple and should not need a heavy-duty machine to do the lifting.

If you plan on printing more complex parts or want intricate engravings on your customized parts, you may want to use a higher-end model that can handle that.

What Materials Should You Use?

There are plenty of materials you can use to 3D print your car parts, but the rule of thumb is they should be durable, lightweight, and flexible.

A few standout materials are:

- TPU (shock-absorbent, flexible, and durable)

- Polypropylene (great for airflow and fluid systems)

- Nylon PA11 (great if you are worried about sustainability)

- Polyamide 6 (heat resistant)

What material you use depends entirely on what part you want to make, so always do your due diligence and research what materials work best for each part before you start printing.

How Do You Go About 3D Printing Car Parts?

3D printing car parts seems complex, but when you get down to it, it is a simple process that only requires a few steps.

Make or Find a Scale Model

This is the most important step of the entire process. A high-quality 3D printed car part relies on using the proper material and creating it from a good model.

You can set up your scale model in one of two ways. You can make the model yourself using a 3D modeler or find a model online. If you are not confident in your 3D modeling skills, it may be best to find an online model rather than make it yourself.

Many websites offer 3D models for parts that you can download and use with your 3D printer. Make sure the model is from a reputable source for the best results.

Pick Your Material

After picking out your model, the next step is to pick what material you want to use. This will depend entirely on what part you are making and your specific needs.

Remember, materials are not a one-size-fits-all solution. Make sure the material you choose matches your part’s use (heat resistance or flexibility, for example). If you make a part with the wrong material and install it, it can break or damage your car.

Make sure the material you choose matches your part’s use (heat resistance or flexibility, for example). If you make a part with the wrong material and install it, it can break or damage your car.

Also, keep in mind that just because you can theoretically make engine parts with 3D printing does not mean that you should.

Print the Part

After you have your model and material, it is time to make your part. Make sure the parameters are set the way you want them and double-check everything before printing. Follow the instructions based on your specific printer.

Finishing Touches

Once your part is printed, it is time to add any finishing touches. This is when you paint any small details, like numbers on a knob, or coat the part in another material for a better finish.

You should also use this time to check over the part and make sure everything is up to standard. If there are any defects or issues with the part, you will need to start over.

Install the Part

After printing the part, it is time to install it. This is simple for a part like a cup holder or knob — just pop it in and see if it fits.

This is simple for a part like a cup holder or knob — just pop it in and see if it fits.

If you 3D printed a part like a grill or a dashboard, try going on a test drive first and see how it holds up under a stress test. If it looks like it is not holding up well, it’s time to go back to the drawing board.

What if You Don’t Want to Do It Yourself?

Sometimes 3D printing car parts is not feasible for everyone. A person may want to 3D print a part, but they do not have access to a printer or are not confident in their 3D modeling skills.

In this case, you may want to consider hiring a business that specializes in 3D printing car parts. Be sure to check the business’ rates, selection, and reviews before committing.

Conclusion

3D printing car parts is an easy way to customize and repair your car without breaking the bank. With the right model, materials, and plenty of patience, 3D printing your own parts is a reliable way to take care of your car and make it your own.

There are no limits to what can be done with 3D printing, whether you do it yourself or hire someone else to make the parts for you.

3D Printed Engine Parts Could Make Cargo Ships Greener

You Are Here

Home

New cleaner fuels and the goal of higher productivity could make 3D printing of engine parts for large cargo ships attractive.

Large marine cargo ship engines are an important area of concern in the marine industry's environmental efforts. This also applies to the individual parts of the engine, which must be constantly optimized to meet future requirements for lower and more environmentally friendly fuel consumption.

The most important component in this context is the injector, which injects the fuel into the engine, where it is mixed with oxygen for optimal combustion. As part of a joint project between DTU and MAN Energy Solutions, a young researcher carried out extensive research to find out whether it could be profitable to manufacture an injection nozzle using 3D printing.

"At MAN Energy Solutions, we have known for a long time that metal 3D printing can provide us with some possibilities for designing critical parts of our marine engines that were not previously possible. This made collaborating with DTU to explore the potential an obvious choice," says Peter Hagen , Mechanical Engineer at MAN Energy Solutions.

Postdoc Thomas Dahmen from DTU's mechanical engineering department conducted a study that he started by analyzing the quality rollout function for 3D printing. 3D-QFD is an analysis model used to provide an overview of the value that 3D printing can add to an overall product.

"Using this model and combining it with technical knowledge of both 3D printing techniques and fuel injection, I created a modular set of how injectors can be 3D printed to increase engine performance and product life" , says Thomas Dahmen

The injector improvement was based on the fact that better fuel flow can be achieved with a slightly different - more curved - design. Thus, the new design of the injector improves the combustion of fuel in the engine. Early testing also shows that the injector can potentially help reduce engine NOx emissions, but further research will be needed to prove such an effect.

Thus, the new design of the injector improves the combustion of fuel in the engine. Early testing also shows that the injector can potentially help reduce engine NOx emissions, but further research will be needed to prove such an effect.

The new 3D printed injector showed such promising results in the DTU laboratory that it was subsequently tested on a full-scale MAN Energy Solutions test engine at the Copenhagen Research Center.

"Testing went well and we are looking forward to the next long-term testing. Thomas's thorough research has given us a fantastic basis for moving forward in the field of 3D printing of metal components for marine engines. I am sure that we will soon see them in real engines " said Peter Hagen.

Peter Hagen emphasizes that the cooperation with DTU for further optimization of marine engines will continue in the future. In his comprehensive analysis, Thomas Dahmen not only looked at nozzle design, but also compared the advantages and disadvantages of two different 3D printing technologies - laser powder deposition and binder jetting - in combination with different types of nozzle materials.

"This part of the analysis showed the suitability of Binder Jetting for creating complex flow-related nozzle features and special high-temperature materials that cannot be realized with other manufacturing processes," says Thomas Dahmen.

Source

Other materials:

- INFINITE FLEX INTRODUCES PURE COPPER POWDER FOR SLM 3D PRINTING

- BASF WILL DEVELOP COMPACT SLS 3D PRINTING WITH SINTERIT

- Technopark "SuperFood Technology" will become a major business accelerator for young startups

- GOAL - DOUBLE IN FIVE YEARS

- Participation of 3D Systems in the development of spacecraft

Attention!

We accept news, articles or press releases

with links and images. [email protected]

Printing an engine on a 3D printer (5 best models for 3D printing)

3DPrintStory 3D printing process How to 3D Print an Engine (Top 5 Models for 3D Printing)

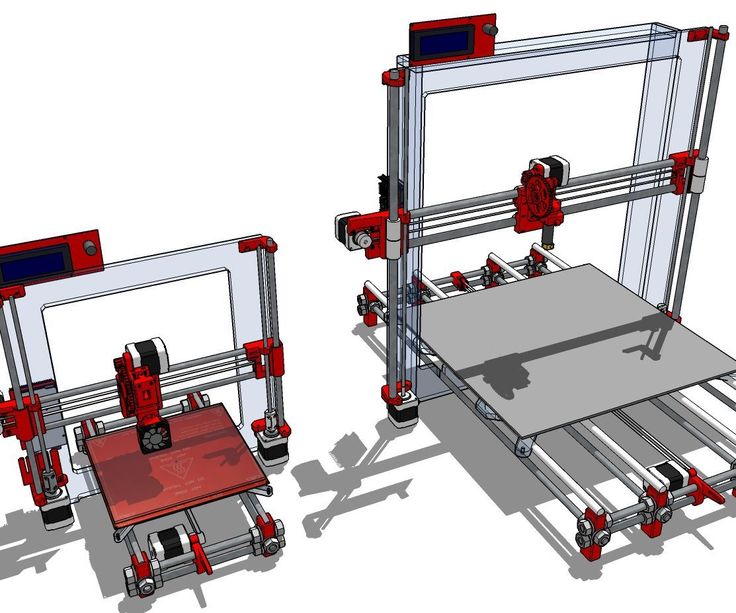

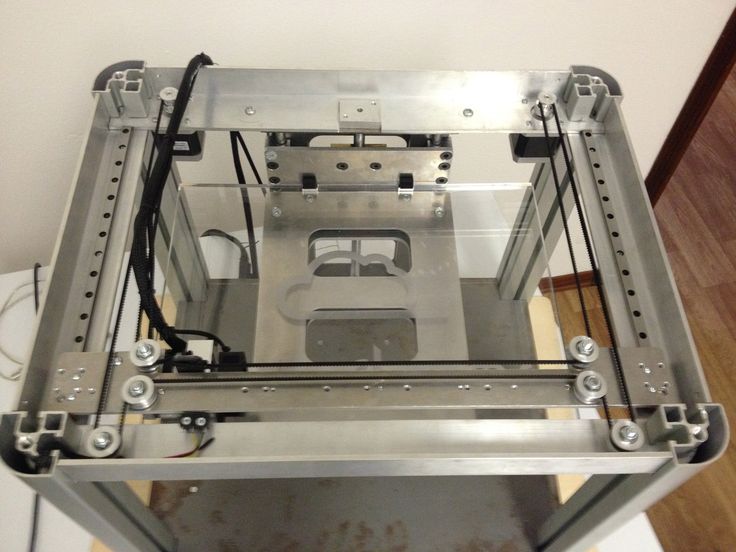

3D printing at home has come a long way. To date, there are a huge number of 3D printers in various price ranges, there are plenty to choose from. And as there are more and more happy owners of 3D printers, the community is growing, there is a huge number of 3D models that people share. But the static figures downloaded from Thingiverse are gradually getting bored and I want new challenges and experiments. Well, you've come to the right place. How about printing a running electric motor?

To date, there are a huge number of 3D printers in various price ranges, there are plenty to choose from. And as there are more and more happy owners of 3D printers, the community is growing, there is a huge number of 3D models that people share. But the static figures downloaded from Thingiverse are gradually getting bored and I want new challenges and experiments. Well, you've come to the right place. How about printing a running electric motor?

If you are interested, then welcome to the rest of the article, as here we have collected for you the best options for engine designs that you can print on your 3D printer.

Brushless motor

Designed and manufactured by Christophe Laimar, this motor has impressive power. The 3D printed motor uses a 3D printed rotor and stator and delivers 600W of power with an efficiency of 80%. The complexity of 3D printing rightly allows it to be used as a demonstration of technical prowess as well as knowledge of 3D printing.

Where to find : You can download the part files from the developer's website for a fairly small $10 license fee. Also included is an approved list of 3D printing hardware and engine components.

How to make : Christoph provides very detailed information on how to print and assemble this impressive brushless motor project. You can find the full instructions for 3D printing and assembling this model on Instructables.

You can see how this engine works in the video below.

Simple DC Motor

This motor is amazing in its simplicity: it was designed for training purposes by user Thingiverse for MakerEd Challenge 2.0.

Where to find : Thingiverse has all the parts you need to 3D print this DC motor. In addition, there are detailed instructions for assembling the model, as well as materials with examples of its use.

How to make : Follow instructions on Thingiverse where the author recommends printing at a high resolution of 0.1mm. In addition, it provides a complete list of required parts for a complete build so that even before starting this project, you can be fully prepared and armed with everything you need.

A short video showing the operation of this 3D printed motor is shown below.

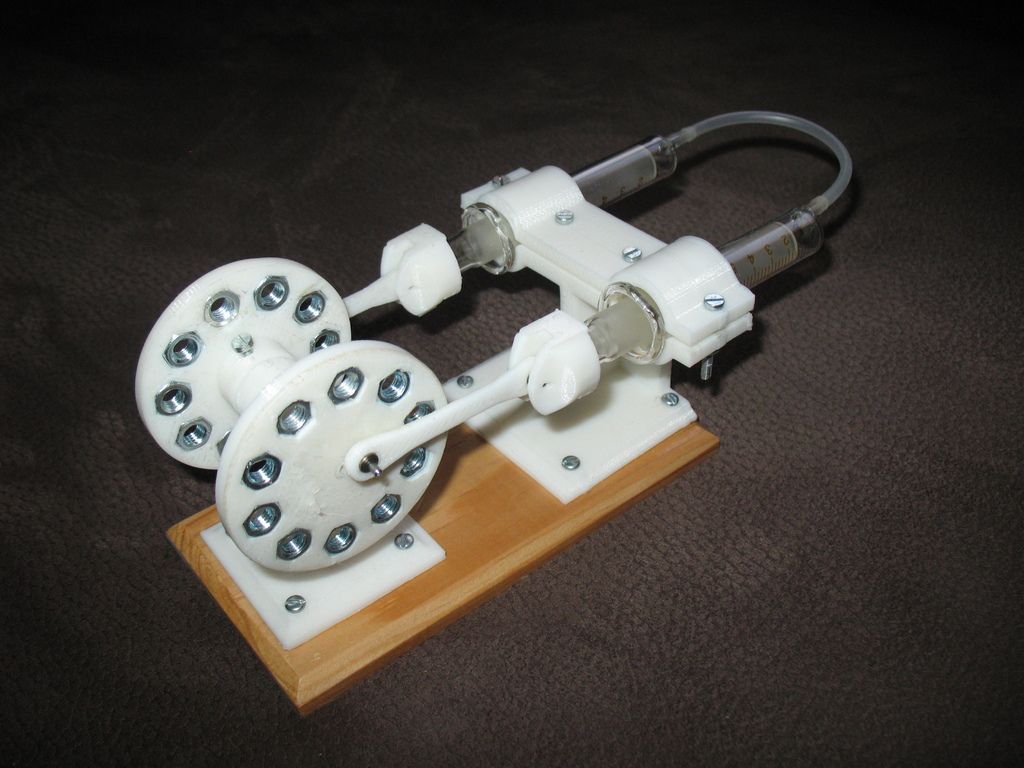

Mendocino small solar motor

As stated by the creator, "The Mendocino engine is a solar-powered electric motor with magnetic levitation." Watching a video of his work will definitely make you wonder how interesting this design really is. The assembled model is practically a work of art, with a stylish floating design.

Where to find : This unusual engine model can be found on Thingiverse.

How to make : The author used a 0. 5 mm nozzle with a layer height of 0.2 mm for the stator components. Detailed instructions are also provided on the Thingiverse page.

5 mm nozzle with a layer height of 0.2 mm for the stator components. Detailed instructions are also provided on the Thingiverse page.

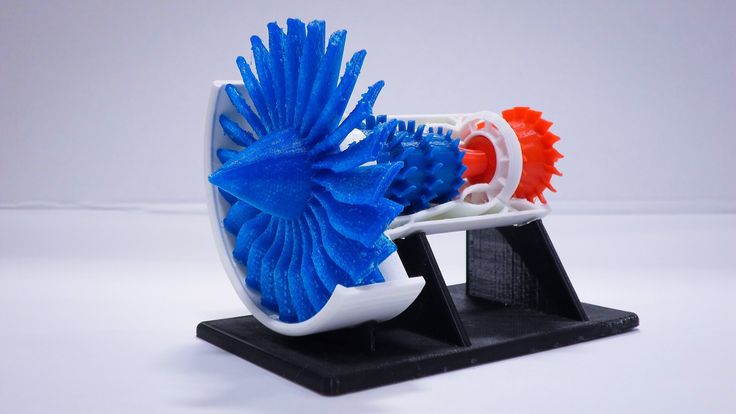

Tesla Turbine

The model was originally designed and manufactured by the Portuguese manufacturer and engineer Integza. This 3D printed engine is based on a Tesla turbine. It is propelled by the use of high-pressure air, acting in a vortex through thin, 3D printed plates. The original design used a few 3D printed components, but the current second iteration is almost entirely 3D printed.0005

Where to find : The author has posted 3D printing files and instructions on her Thingiverse page.

How to make : unfortunately the author does not offer any technical documentation. But the author has a video where he reveals some background of this project, and also describes the build process.

Spring Motor

Designed and printed by Greg Zumwalt, this powerful 3D printed spring motor demonstrates the unique properties of PLA plastic. And it's especially impressive that Greg has created many other models based on the lessons learned in this project.

Where to find : Greg Zumwalt has posted all his part files on MyMiniFactory.

How to make : Greg has posted instructions on MyMiniFactory that explains in detail how to print and assemble each of the parts. The most important tip is to print with 100% coverage. In addition, he recommends using light machine oil for lubrication.

Here are just a few options to make your 3D printed projects even more colorful and impressive. As you can see, 3D printing is about more than just static miniatures. Implement at least a couple of the above projects, and your knowledge in the field of 3D printing (and not only) will expand significantly.