3D printing materials market size

3D Printing Materials Market Share

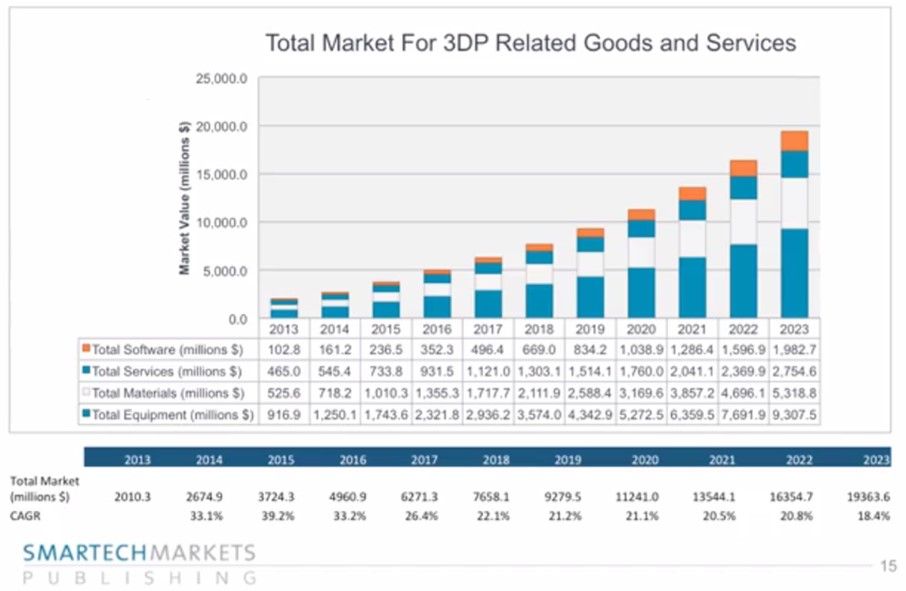

The global 3D printing materials market size was USD 1.53 billion in 2018 and is projected to reach USD 3.78 billion by 2026, exhibiting a CAGR of 12.1% during the forecast period.

We are in process of revamping 3D Printing Material Market with respect to COVID-19 Impact.

Request Sample

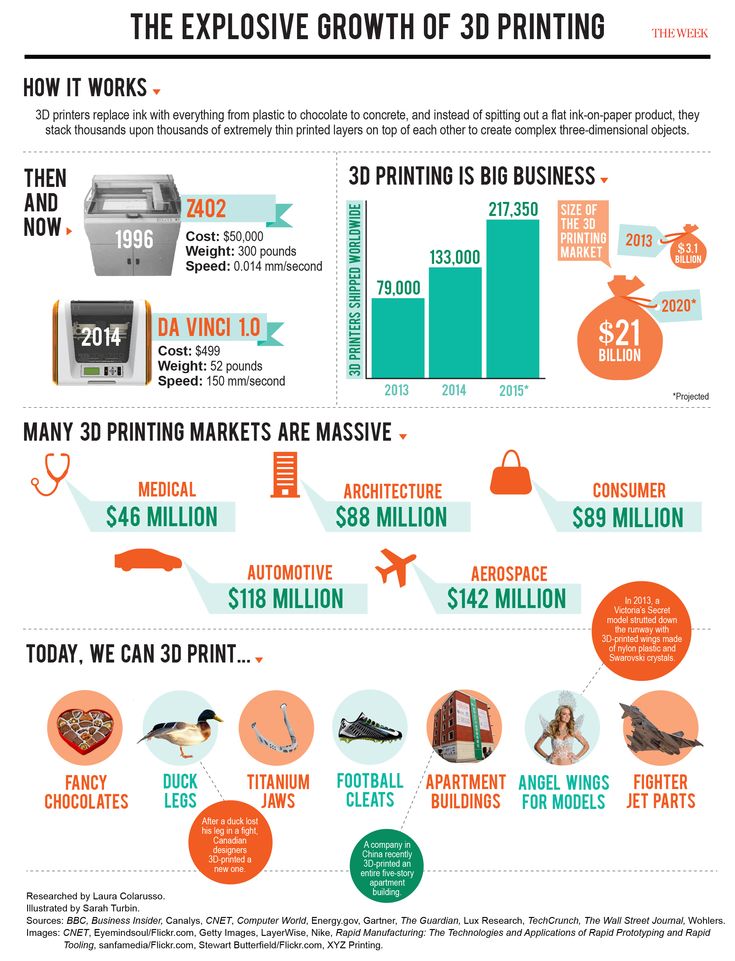

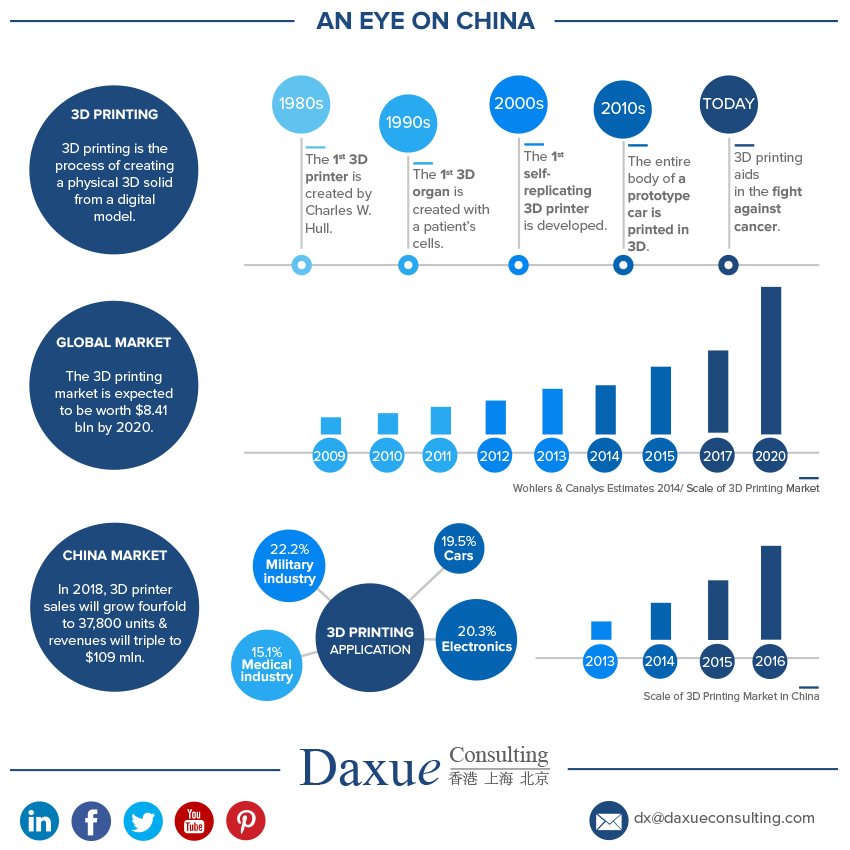

3D printing is a process of producing three-dimensional objects from a digital file. 3D printing, also called additive manufacturing involves putting down consecutive layers of material until the desired object is obtained. 3D printing is a comparatively quicker manufacturing process than conventional manufacturing processes such as injection molding, and subtractive production. The demand for 3D printing in materials is driven by the impelling demand for 3D printing in materials from various end-users such as aerospace, automotive, military, and healthcare.

MARKET TRENDS

Request a Free sample to learn more about this report.

Adoption of 3D Printing Technology by Various Industries is projected to drive the market growth

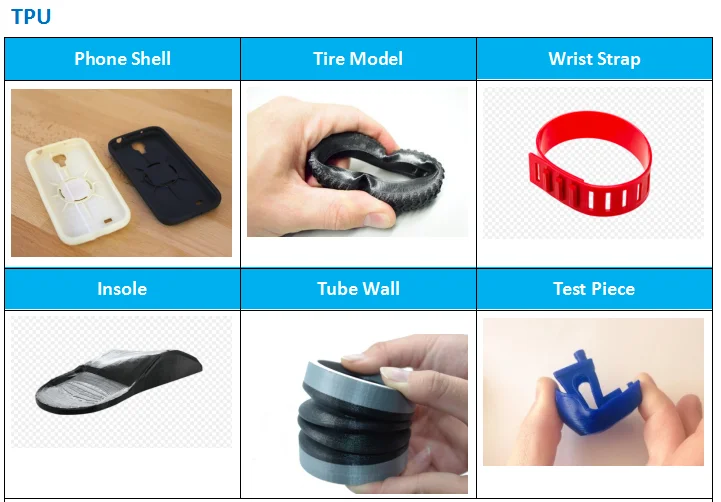

3D printing offers properties including, reduced waste, complexity in designs, cost-effectiveness, and improved design modification. This has attracted manufacturers from various sectors to implement the technology for the manufacturing of parts. Sectors such as food, footwear, music, jewelry, and medical are using 3D printing in materials to develop new products with efficient designs at a lower cost. Reduced weight, improvement in strength, reduced inventory, and mass customization are the major factors responsible for increased demand for 3D printing technology, which, in turn, will increase the demand.

MARKET DRIVERS

Rising Demand for 3D Printing from End-Users to Drive Market Growth

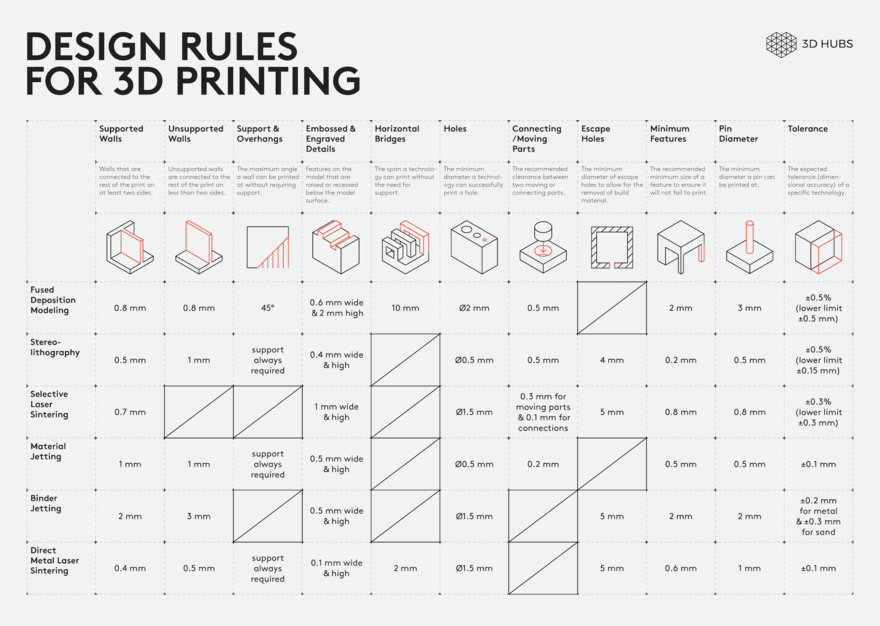

The 3D printing materials market drivers include the increasing demand from various end-users. The market is expected to advance due to the rising use of 3D printed parts in aerospace, automotive, and military applications. 3D printing technology has turned out to be a highly useful technology for manufacturing parts with intricate designs. 3D printing enables designers to create complex parts at low cost and with production feasibility. Parts made from titanium in the aerospace industry are usually 3D printed as it offers high dimensional accuracy and great mechanical properties. The above factors are expected to boost the market growth.

3D printing technology has turned out to be a highly useful technology for manufacturing parts with intricate designs. 3D printing enables designers to create complex parts at low cost and with production feasibility. Parts made from titanium in the aerospace industry are usually 3D printed as it offers high dimensional accuracy and great mechanical properties. The above factors are expected to boost the market growth.

MARKET RESTRAINT

High Production Cost of 3D Printing Materials is Expected to Obstruct the Market

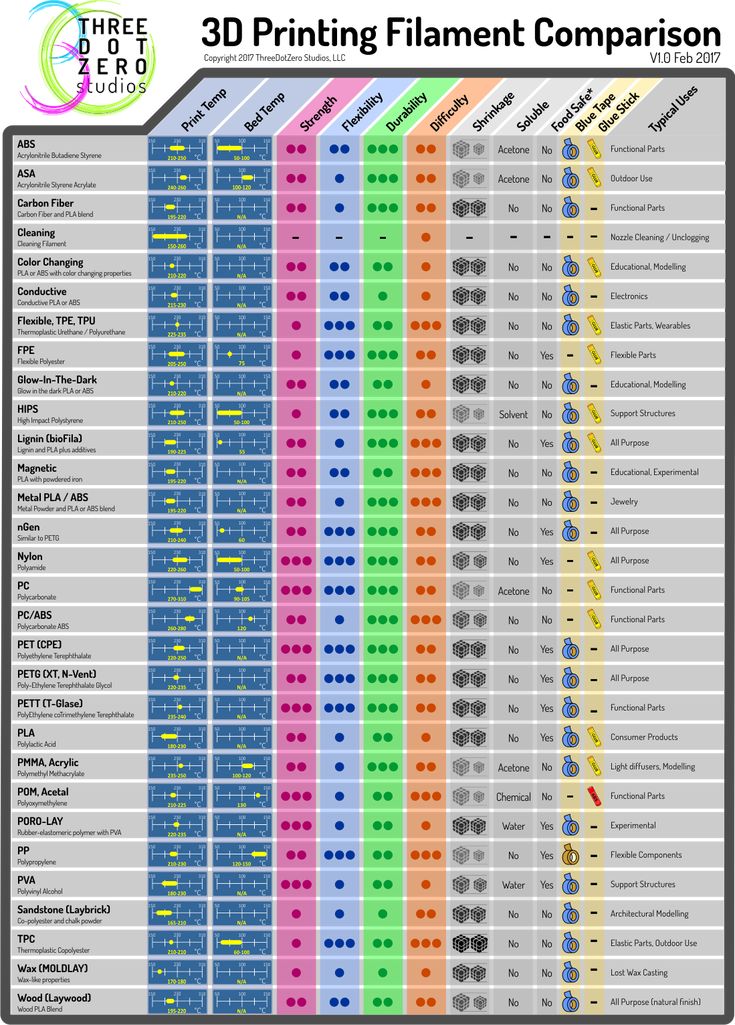

For 3D printing, materials are used in non-standard forms such as powder, filament, and liquid. The processing of the materials from standard form to the one suitable for 3D printing adds up to the cost of materials. Prices of materials compatible with 3D printers are up to 10-15 times higher compared to the materials used in traditional manufacturing processes, which is one of the major factors restraining the growth of the market.

SEGMENTATION

By Type Analysis

To know how our report can help streamline your business, Speak to Analyst

Plastics Segment to Hold Dominant Share in the Global Market

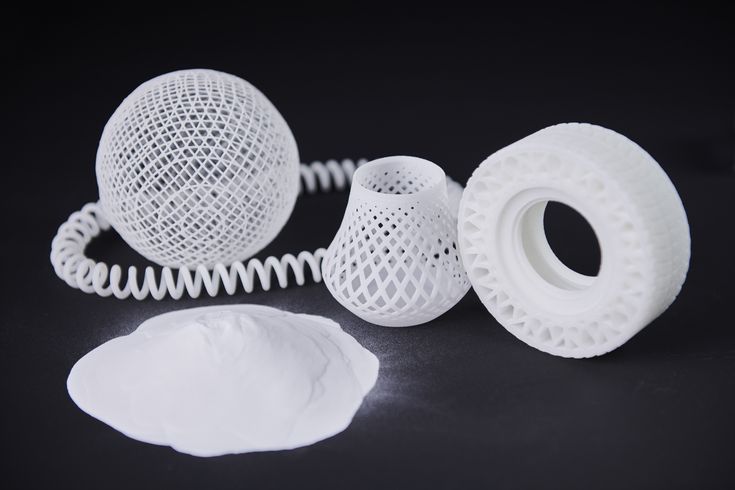

Based on type, the market of 3D printing materials is segmented into plastics, metals, ceramics, and others. Plastics dominated the 3D printing materials market. Increasing demand for 3D printing technology combined with the rising demand for high-performance materials from industries including automotive, aerospace, and military will propel the growth of the plastics segment in the market. Additionally, easy prototyping and producing complicated designs at low cost, less weight, and no material loss will boost the demand for plastics in the global market.

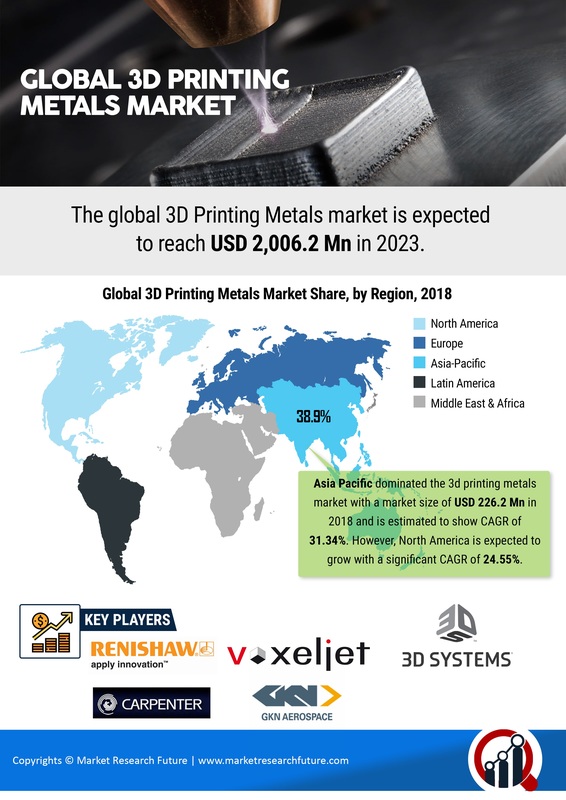

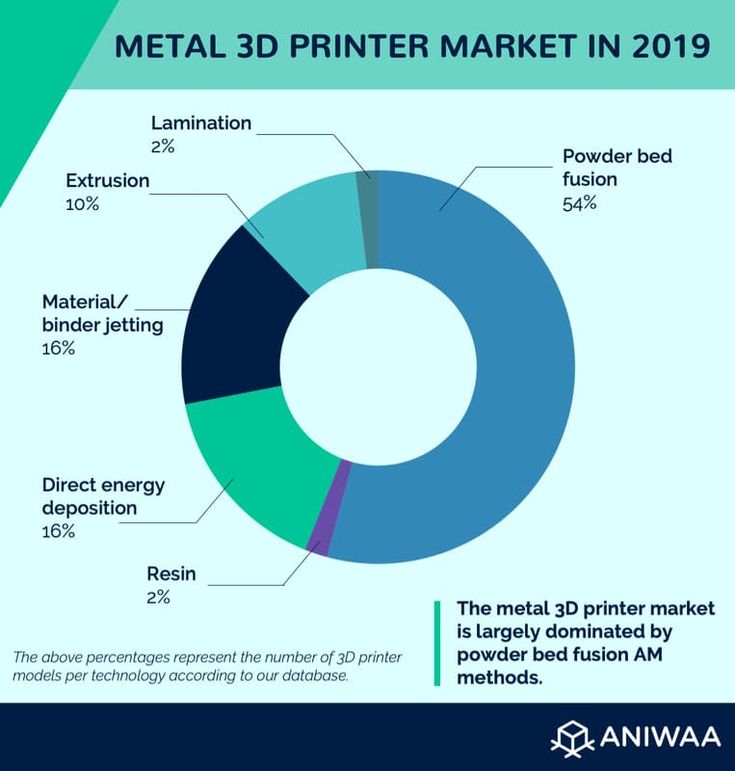

The metals segment is projected to register the fastest growth during the forecast period. Metal is one of the preferred materials in the healthcare industry for producing implants and prosthetics. The faster production process coupled with no loss of materials will increase the demand for metals for 3D printing. Furthermore, incorporation of 3D printed metal parts in automotive, aerospace, and industrial machinery are factors fueling the demand for metals in the market.

The faster production process coupled with no loss of materials will increase the demand for metals for 3D printing. Furthermore, incorporation of 3D printed metal parts in automotive, aerospace, and industrial machinery are factors fueling the demand for metals in the market.

By End-Users Analysis

Aerospace & Defense to be the Major End-Users

Based on end-users, the market for 3D printing materials is segmented into automotive, aerospace & defense, industrial, medical and others. Amongst the end-users, aerospace & defense holds the major share of the market. Aircraft components such as jigs, wings, and engine parts are made from metal by 3D printing. The ability of 3D printing technology to manufacture cost-effective and lightweight parts with high dimensional accuracy has enabled its easy incorporation in the aerospace & defense industry, thereby growing the market.

The automotive segment is estimated to register substantial growth during the forecast period. The increased demand for 3D printed plastics and metals in the automotive industry is due to its properties such as lightweight, and dimensional accuracy. This rising demand for these materials from automotive applications along with the growing automotive industry is anticipated to drive the market.

The increased demand for 3D printed plastics and metals in the automotive industry is due to its properties such as lightweight, and dimensional accuracy. This rising demand for these materials from automotive applications along with the growing automotive industry is anticipated to drive the market.

REGIONAL ANALYSIS

North America 3D Printing Materials Market Size, 2018 (USD Billion)

To get more information on the regional analysis of this market, Request a Free sample

The 3D printing materials market size in North America stood at USD 0.58 billion in 2018. The market in the region is characterized by the demand from end-users such as aerospace, military, and medical, which are progressively using 3D printing technology. High demand for metals from automotive and aerospace & defense industry is the major reason responsible for the growing 3D printing in material market share in this region. Europe accounted for a significant share of the market in 2018. The increasing adoption of 3D printing technology in the healthcare sector to produce implants and prosthetics at a very low cost will drive the growth in this region.

The increasing adoption of 3D printing technology in the healthcare sector to produce implants and prosthetics at a very low cost will drive the growth in this region.

Asia Pacific is expected to grow at a comparatively faster rate during the forecast period due to the rising demand from countries such as China, Japan, and South Korea. The growth in the end-use industries including healthcare, and consumer products, will enable the growth of the market in this region. In the Rest of the World, the market is anticipated to witness growth due to the increasing integration of 3D printing technology for applications in automotive, military, healthcare, and academics.

KEY INDUSTRY PLAYERS

Diverse Portfolio for Various Application, to Propel Stratasys Ltd. to a Leading Position

The competitive landscape of 3D printing in materials depicts a fairly fragmented market. The dominance of a company is dependent on the diversified product portfolio, and new product launches of 3D printing materials for a variety of applications. Furthermore, constant developments by the key players to improve the physical properties and reduce the cost of the 3D printing materials is expected to increase the presence of the company in the market. The rise in demand for 3d printing in materials industry such as automotive, aerospace, medical, and consumer products has encouraged companies to implement various growth strategies such as expansion, joint venture, and acquisition.

Furthermore, constant developments by the key players to improve the physical properties and reduce the cost of the 3D printing materials is expected to increase the presence of the company in the market. The rise in demand for 3d printing in materials industry such as automotive, aerospace, medical, and consumer products has encouraged companies to implement various growth strategies such as expansion, joint venture, and acquisition.

LIST OF KEY COMPANIES PROFILED:

- Stratasys Ltd.

- 3D Systems, Inc.

- Materialise NV

- Markforged, Inc.

- EOS GmbH

- Höganäs AB

- Arkema

- Royal DSM N.V.

- ExOne

- GE Additive

- Evonik Industries AG

- Höganäs AB

- BASF SE

- Covestro AG

- Solvay

- American Elements

- Other Key Players

KEY INDUSTRY DEVELOPMENTS:

- September 2019 – 3D Systems launched new materials for 3D printing namely PRO-BLK 10, and HI-TEMP 300-AMB.

The new products will diversify the company’s product portfolio and expand the range of applications for customers.

The new products will diversify the company’s product portfolio and expand the range of applications for customers. - November 2018 – Royal DSM N.V. launched “Arnitel ID2060 HT”, a high-performance thermoplastic copolyester for 3D printing by using fused filament fabrication. The filament offers a balance of properties such as chemical resistance, flexibility, and high-temperature resistance.

REPORT COVERAGE

The 3D printing materials market report provides a detailed analysis of the market and focuses on key aspects such as leading companies, product types, and leading applications of the product. Besides this, the report offers insights into the market trends and highlights key 3D printing in materials industry developments. In addition to the aforementioned factors, the report encompasses several factors that have contributed to the growth of the market over recent years.

An Infographic Representation of 3D Printing Material Market

View Full Infographic

To get information on various segments, share your queries with us

Report Scope & Segmentation

ATRIBUTTE | DETAILS |

Study Period | 2015-2026 |

Base Year | 2018 |

Forecast Period | 2019-2026 |

Historical Period | 2015-2017 |

Unit | Value (USD billion) |

Segmentation | By Type

|

By End-Users

| |

By Geography

|

3D Printing Materials Market size worth $ 8.1 Billion, Globally, by 2028 at 24.1% CAGR: Verified Market Research®

The rising demand from healthcare, automotive, and other industries, mass customization, and government initiatives to support the adoption of 3D printing are the major factors supporting the growth of the 3D Printing Materials Market.

JERSEY CITY, N.J., May 26, 2022 /PRNewswire/ -- Verified Market Research recently published a report, "3D Printing Materials Market" By Material (Plastic, Ceramic), By Application (Manufacturing, Prototyping), By End-User (Industrial, Medical), and By Geography. According to Verified Market Research, 3D Printing Materials Market size was valued at USD 1. 4 Billion in 2020 and is projected to reach USD 8.1 Billion by 2028, growing at a CAGR of 24.1% from 2021 to 2028.

4 Billion in 2020 and is projected to reach USD 8.1 Billion by 2028, growing at a CAGR of 24.1% from 2021 to 2028.

Download PDF Brochure: https://www.verifiedmarketresearch.com/download-sample/?rid=30293

Browse in-depth TOC on "3D Printing Materials Market"

202 - Pages

126 – Tables

37 – Figures

Global 3D Printing Materials Market Overview

The Global 3D Printing Materials Market is driven by increasing defrayal by the producing sector around the globe for analysis and development. The increasing demand for 3D printing at the side of increasing demand for superior materials across varied industries together with automotive and part and defense is anticipated to fuel the market growth. Besides, 3D printing reduces the chance of errors and is extremely desirable for production that is expected to propel market growth. However, factors like the high price of 3D printing materials and also the product made are less sturdy than those made through typical molding and casting techniques are key factors clogging the market growth. The COVID-19 pandemic has negatively affected the 3D printing materials demand across varied end-use industries like defense, automotive, construction, and different industries.

The COVID-19 pandemic has negatively affected the 3D printing materials demand across varied end-use industries like defense, automotive, construction, and different industries.

These industries are severely tormented by COVID-19. The disruption within the provide chain has resulted in delays or non-arrival of raw materials, noncontinuous monetary flows, and growing absence among assembly line staff have compelled craft and automobile makers to work at zero or partial capacities, leading to reduced 3D printing materials demand. Education is one of the fastest-growing industries in the 3D Printing Materials Market. Though the usage of 3D printing within the education sector is at a developing stage, several establishments are setting out for 3D printing.

Key Developments

- In May 2021, Covestro AG launched a new 3D Printing Material (Arnite AM2001 GF (G) rPET), a glass-fiber filled recycled polyethylene terephthalate (rPET) for 3D pellet printing, which is derived from post-consumer PET waste.

- In June 2021, Covestro AG and Nexeo Plastics have announced the development of a new PC/ABS filament (Addigy FPB 2684 3D) for 3D printing. The company offers this product through Nexeo Plastics' distribution platform.

Key Players

The major players in the market are 3D Systems Corporation, Royal DSM N.V., Arkema S.A., Stratasys, Ltd., Exone Company, Eos GmbH Electro Optical Systems, General Electric, Evonik Industries AG, Materialise Nv, and Sandvik AB.

Verified Market Research has segmented the Global 3D Printing Materials Market On the basis of Material, Application, End-User, and Geography.

- 3D Printing Materials Market, By Material

- Plastic

- Ceramic

- Metal

- Others

- 3D Printing Materials Market, By Application

- Manufacturing

- Prototyping

- Others

- 3D Printing Materials Market, By End-User

- Automotive

- Consumer Electronics

- Industrial

- Medical

- Others

- 3D Printing Materials Market, by Geography

- North America

- U.

S

S - Canada

- Mexico

- Europe

- Germany

- France

- U.K

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- Rest of Asia Pacific

- ROW

- Middle East & Africa

- Latin America

Browse Related Reports:

Metal 3D Printing Market By Form (Powder, Filament), By Type (Titanium, Steel, Nickel, Aluminum), By End-user (Medical And Dental, Automotive, Aerospace And Defense), By Geography, Forecast, 2021-2028

3D Printing Market By Offering (Printer, Material, Software, Service), By Process (Binder Jetting, Direct Energy Deposition, Material Extrusion), By Technology (Direct Metal Laser Sintering, Fused Deposition Modelling), By Vertical (Automotive, Aerospace and Defense, Healthcare, Industrial, Printed Electronics), By Geography, Forecast, 2021-2028

Industrial 3D Printing Market By Process (Directed Energy Deposition, Vat Polymerization, Material Jetting), By Materials (Plastics, Thermoplastics, Photopolymers), By Software (Design Software, Inspection Software, Printing Software), By Services (Manufacturing and Consulting), By Industry (Automotive, Aerospace & Defense, Food & Culinary), By Geography, Forecast, 2021-2028

3D Printing Services Market By Product (3D Printed Metal, 3D Printed Plastic, 3D Printed Ceramic), By Application (Electronics, Architecture and Designing, Aerospace and Defense, Medical and Healthcare, Automobile, Education), By Geography, Forecast, 2021-2028

Top 10 3D Printing Material Companies – Manufacturing made simpler

Visualize 3D Printing Materials Market using Verified Market Intelligence:-:

Verified Market Intelligence is our BI Enabled Platform for narrative storytelling of this market. VMI offers in-depth forecasted trends and accurate Insights on over 20,000+ emerging & niche markets, helping you make critical revenue impacting decisions for a brilliant future.

VMI offers in-depth forecasted trends and accurate Insights on over 20,000+ emerging & niche markets, helping you make critical revenue impacting decisions for a brilliant future.

VMI provides a holistic overview and global competitive landscape with respect to Region, Country, and Segment, and Key players of your market. Present your Market Report & findings with an inbuilt presentation feature saving over 70% of your time and resources for Investor, Sales & Marketing, R&D, and Product Development pitches. VMI enables data delivery In Excel and Interactive PDF formats with over 15+ Key Market Indicators for your market.

About Us

Verified Market Research is a leading Global Research and Consulting firm servicing over 5000+ customers. Verified Market Research provides advanced analytical research solutions while offering information enriched research studies. We offer insight into strategic and growth analyses, Data necessary to achieve corporate goals and critical revenue decisions.

Our 250 Analysts and SME's offer a high level of expertise in data collection and governance use industrial techniques to collect and analyze data on more than 15,000 high impact and niche markets. Our analysts are trained to combine modern data collection techniques, superior research methodology, expertise and years of collective experience to produce informative and accurate research.

We study 14+ categories from Semiconductor & Electronics, Chemicals, Advanced Materials, Aerospace & Defense, Energy & Power, Healthcare, Pharmaceuticals, Automotive & Transportation, Information & Communication Technology, Software & Services, Information Security, Mining, Minerals & Metals, Building & construction, Agriculture industry and Medical Devices from over 100 countries.

Contact Us

Mr. Edwyne Fernandes

Verified Market Research®

US: +1 (650)-781-4080

UK: +44 (753)-715-0008

APAC: +61 (488)-85-9400

US Toll Free: +1 (800)-782-1768

Email: [email protected]

Web: https://www. verifiedmarketresearch.com/

verifiedmarketresearch.com/

Follow Us: LinkedIn | Twitter

SOURCE Verified Market Research

Overview of the 3D printing market in 2020

Analytics and business

Experts recommend

Author: Andrey Kombarov

Author: Andrey Kombarov

Additive Manufacturing Trends | Application of 3D printing | A look at additive technologies | Business Strategies for 3D Printing | Overview of the 3D printing industry over the past 6 years | Key Findings

The future of additive manufacturing starts with understanding the goals and expectations of 3D printing users around the world. This was the reason for the launch of an ambitious research project by the French company Sculpteo - the annual State of 3D Printing report. Today it is one of the most authoritative and comprehensive sources of information about the real situation and prospects of the industry.

This year, 1,600 respondents from 71 countries took part in the Sculpteo survey. According to the report, a growing number of companies are realizing the possibilities of additive manufacturing, increasing investments and demonstrating undeniable confidence in the future of professional use of 3D printing.

According to the report, a growing number of companies are realizing the possibilities of additive manufacturing, increasing investments and demonstrating undeniable confidence in the future of professional use of 3D printing.

This material offers a complete overview of the world of additive manufacturing and will help you develop the right business strategy.

In the blog , the State of the 3D Printing Market 2020 is published in abbreviated form. You can download the full version for free in our virtual library:

Additive Manufacturing Trends

Materials

- New and available materials.

- Improving the quality and stability of budget additive technologies.

- Improving post-processing technologies to obtain parts with the highest quality surface.

- 3D printing from multiple materials at once.

Environmental sustainability

- Biodegradable materials and materials of biological origin.

- Manufactured on demand and on site to reduce transport and environmental costs.

- Application of 3D printing to meet the challenges of renewable energy and energy efficiency.

Technology Development

- Improved usability of software and printers

- Mass Production: Printing and 3D Scanning Speed

- Generative design

Availability

- Reducing the cost of 3D printers and materials (metals, photopolymers).

- Low post-processing costs.

- Sharing projects and tools.

iQB Technologies experts recommend articles:

3D printing as a full-fledged manufacturing technology in the context of the COVID-19 pandemic

2020 results and forecasts: the 3D printing market will grow by 25% annually

Application of 3D printing

The possibilities of 3D printing are growing every day, and with them the scope of its application is expanding. Gradually, companies begin to feel more confident in relation to 3D technologies. 68% of respondents are looking to use additive manufacturing to solve more problems, and 44% of are going to introduce new 3D printing technologies. Most professionals outsource SLS and Jet Fusion printing, as well as metal 3D printing, so they do not need to maintain their own equipment, and this will encourage them to test new technologies.

Gradually, companies begin to feel more confident in relation to 3D technologies. 68% of respondents are looking to use additive manufacturing to solve more problems, and 44% of are going to introduce new 3D printing technologies. Most professionals outsource SLS and Jet Fusion printing, as well as metal 3D printing, so they do not need to maintain their own equipment, and this will encourage them to test new technologies.

So what are the most popular 3D printing and post-processing technologies? Let's find out!

We emphasize once again that production volumes using 3D printing continue to grow. We are seeing this growth in research and development and education, which is in line with the increased demand for new materials and technologies in the market.

Click image to enlarge

The use of photopolymers is increasing through both internal and external services, while for metal 3D printing, most users outsource.

Design, testing and prototyping remain the main tasks solved with the help of 3D printing.

Stability and quality control remain a major concern for users seeking to scale up the use of 3D printing.

Most users use SLS, Jet Fusion and metal 3D printing technologies through outsourcing without purchasing equipment.

3D printing users are interested in exploring new applications, technologies and materials.

Typically, 3D printing is used in conjunction with traditional manufacturing methods such as laser cutting, CNC machining, and injection molding.

A look at additive technologies

What do respondents think about 3D printing technologies? In this section, we will look at the main benefits of 3D printing for users and their companies. How exactly does it optimize production processes?

66% of respondents use 3D printing to create parts with complex geometries. Survey participants cite the reduction in iterations, lead times and costs as the most important benefits of this technology.

In this section, we will also look at the future of the additive industry and the factors driving its growth and business adoption. What needs to be done to accelerate the adoption of 3D technologies? Now we'll find out.

As technology and materials become more accessible, the cost savings of 3D printing become clear to more and more users. Many also cite time savings due to reduced iterations and lead times as a benefit.

Set-up costs and lack of knowledge are seen as the main limiting factors for the adoption of 3D printing.

The role of 3D printing in business and manufacturing continues to grow.

New materials and reliable technologies are in demand for more than 55% industries.

Business Strategies for 3D Printing

Additive manufacturing is a huge competitive advantage. With some significant benefits of 3D printing, such as reduced lead times and speed of innovation, the vast majority of respondents view 3D printing as a significant improvement for their business.

As for money, investment in additive technologies is growing every year. Most of these users will increase their investments in 2020! It can also be seen that the vast majority of those surveyed have been using 3D printing for several years and plan to invest more in this technology in the near future. The business world believes in the promise of additive manufacturing.

Let's watch how 3D printing becomes a real asset for companies, helping them develop their business strategy!

63% of see a significant or dramatic impact on sales. Reduced lead times and speed of innovation are the most important success metrics for 3D printing.

Nearly 60% of consider 3D printing one of their strengths compared to the competition.

65% of companies plan to increase their investment in 3D printing in 2020.

The integration of 3D printing into manufacturing processes continues to increase: 74% of actively use 3D printing in their companies.

Overview of the 3D printing industry over the past 6 years

The Sculpteo report offers a look at the analysis of the state of the 3D printing industry for each year since 2015. How has the use of 3D printing evolved over the period 2015-2020? Let's look at the answers of the latest polls.

Large-scale production using 3D printing continues to spread, becoming as commonplace as prototyping and testing.

Accelerating development and offering customized products and limited editions remains a major challenge for companies using 3D printing.

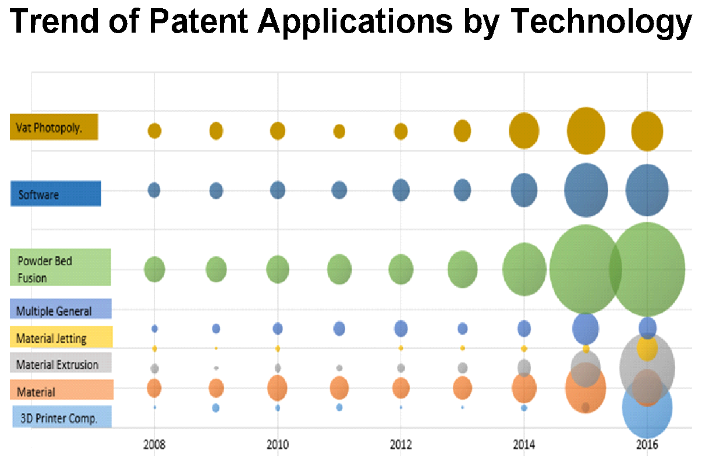

The market share of photopolymers continues to increase, showing significant growth over the past two years.

Key Findings

1. Lack of stability is the Achilles' heel of 3D printing

In order for additive technologies to become an integral part of any production, it is necessary to develop equipment and materials that ensure high stability.

- 51% claims to use 3D printing mostly for quality control purposes.

- 62% of believe the 3D printing industry needs more robust technology to grow.

2. 3D printing is gaining ground in certain industries

Many industries are beginning to increase their use of 3D printing as its role in their manufacturing processes becomes more significant. Users are constantly deepening their knowledge and experience in the application of additive technologies.

- 80% of have been using 3D printing in their companies for over 2 years.

- 33% expect up to 50% increase in investment this year, which is a more conservative estimate than in previous years.

3. 3D printing may not be profitable

For wider use of additive technologies, the cost of manufactured parts must be reduced - this will attract more industries and sectors.

- More than 50% of outsource SLS, Jet Fusion, SLM/DMLS and Binder Jetting to offset equipment and service costs.

- 59% indicate that the cost of organizing production is a limiting factor for the adoption of 3D printing.

4. Changing Perceptions: From Prototyping to Full Manufacturing Technology

Despite the increasing use of 3D printing in manufacturing, its benefits are so far only apparent for prototyping and small-scale production. Businesses need to be shown the real benefits of 3D printing for industrial production.

- 60% report a significant reduction in part cost when using 3D printing.

- 52% of use 3D printing for manufacturing, while 68% of use 3D printing for prototyping.

This article is an abridged version of the Sculpteo report. The full version is available at link .

© 2020 Sculpteo. The material was translated by iQB Technologies exclusively for the 3D experts' blog blog.iqb.ru.

Download material

Article published on 08/20/2020, updated on 06/11/2021

Ceramic 3D printing market overview in the world and Russia

in the world and in Russia.

The purpose of research is to analyze the market of additive technologies with ceramic materials.

This work is a desk study . As sources of information, data were used from foreign surveys, the Federal Customs Service of the Russian Federation, materials from industry and regional press, annual and quarterly reports of companies, websites of enterprises, scientific and technical literature, the Infomine database.

Study timeline : 2017-2021, forecast - until 2025

Research geography : world, Russia.

Scope of study : the report consists of 4 chapters, contains 45 pages, including 12 tables, 15 figures and 1 appendix.

P The first chapter of the report is devoted to a brief overview of the state of additive technologies in the world. At the same time, attention is paid to 3D printing with ceramic materials - an assessment of the dynamics of this market, the main market participants and some development trends are given.

At the same time, attention is paid to 3D printing with ceramic materials - an assessment of the dynamics of this market, the main market participants and some development trends are given.

Chapter 2 of covers the basic technologies for additive manufacturing with ceramic materials. A potential range of ceramic materials for 3D printing and quality requirements for ceramic powders are also presented.

In the third chapter of shows the world's major companies in the market of additive manufacturing ceramics. The characteristics of manufactured 3D printers that work with the use of ceramic materials are given.

V the fourth chapter gives an overview of the Russian market for 3D printing with ceramic materials.

A separate chapter describes Russian companies producing 3D printers and implementing projects to create equipment for additive technologies using ceramic materials.

In addition, data on Russian imports in 2017-2021 are given. equipment for additive technologies using ceramic materials with distribution by supply lines. The chapter is supplemented with information about Russian importers, foreign suppliers of 3D printers, and characteristics of the equipment supplied.

equipment for additive technologies using ceramic materials with distribution by supply lines. The chapter is supplemented with information about Russian importers, foreign suppliers of 3D printers, and characteristics of the equipment supplied.

Imports of the Russian Federation in 2017-2021 were also identified and analyzed. ceramic materials for additive technologies with distribution by supply lines. The chapter is supplemented with information about Russian importers, foreign suppliers of ceramic materials for additive technologies.

Description of the main Russian importers of ceramic materials and 3D printers for them.

A brief description of the situation with the development of 3D printing with ceramics in Russia and individual projects of enterprises in this direction is given.

An assessment of the prospects for the development of additive technologies with ceramics in Russia has been made.

Appendix contains contact information of the main enterprises operating in the market of additive technologies in Russia.

Target audience of the research:

- additive technologies market participants;

- potential investors.

The proposed study claims to be a reference guide for specialists working in the market of additive technologies and making management decisions.

Abstract

Introduction

1. World market of AT. The share and prospects of 3D printing with ceramic materials

2. The main technologies for 3D printing with ceramic materials, the raw materials used and the requirements for its quality

3. The world's main manufacturers of 3D printers for printing with ceramic materials products

3DCERAM SINTO

Lithoz GmbH

Admatec

Other companies

Production of 3D printers for printing with ceramic materials, announced projects.

Learn more

S. and Canada)

S. and Canada)