Everything to know about 3d printing

Everything you need to know about 3D printing and its impact on your business

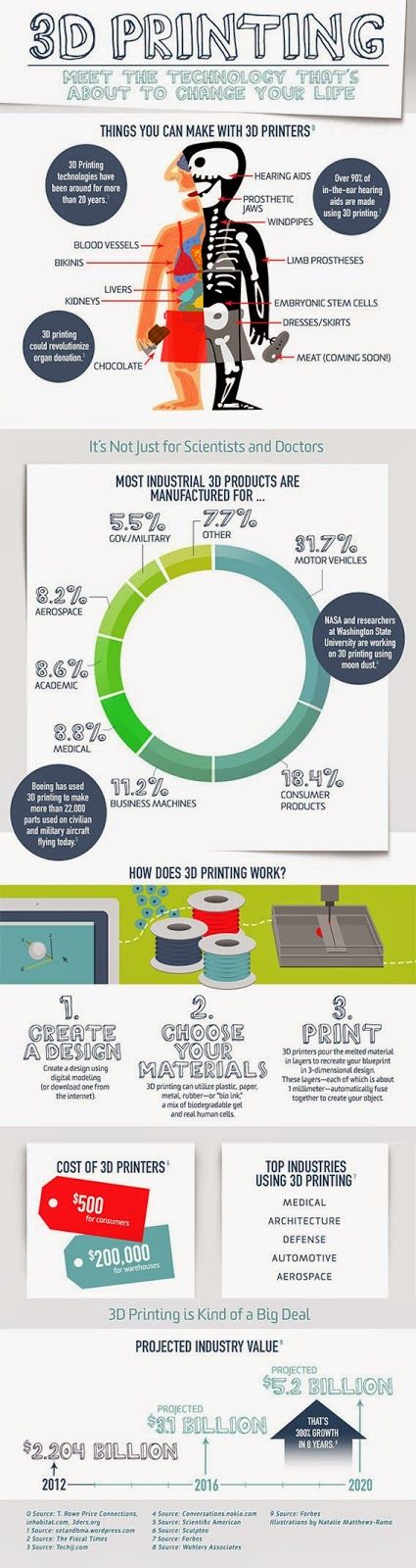

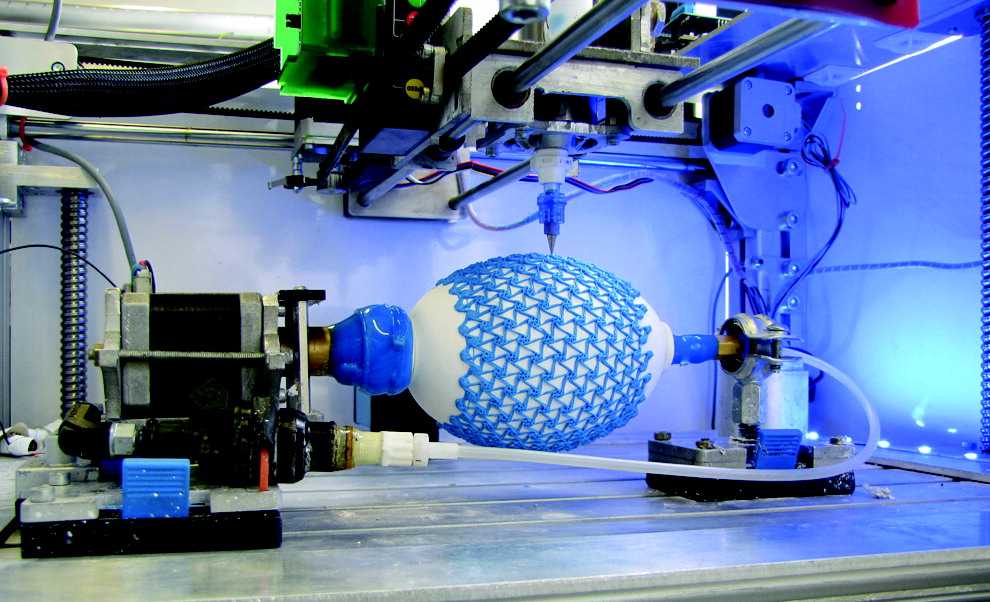

3D printing transforms spools of plastic filament or trays of resin into physical objects. 3D printing is quite literally out of this world. NASA maintains a 3D printer on the International Space Station and astronauts can build custom tools (like this maintenance wrench) without having to fly them into space.

3D printing has been adopted by students, entrepreneurs, hobbyists, and massive factories. Because 3D printing allows for the transformation of a digital design into a tangible object, a wide array of uses have been found.

Also: How Heineken is using 3D printing for on-demand brewery parts

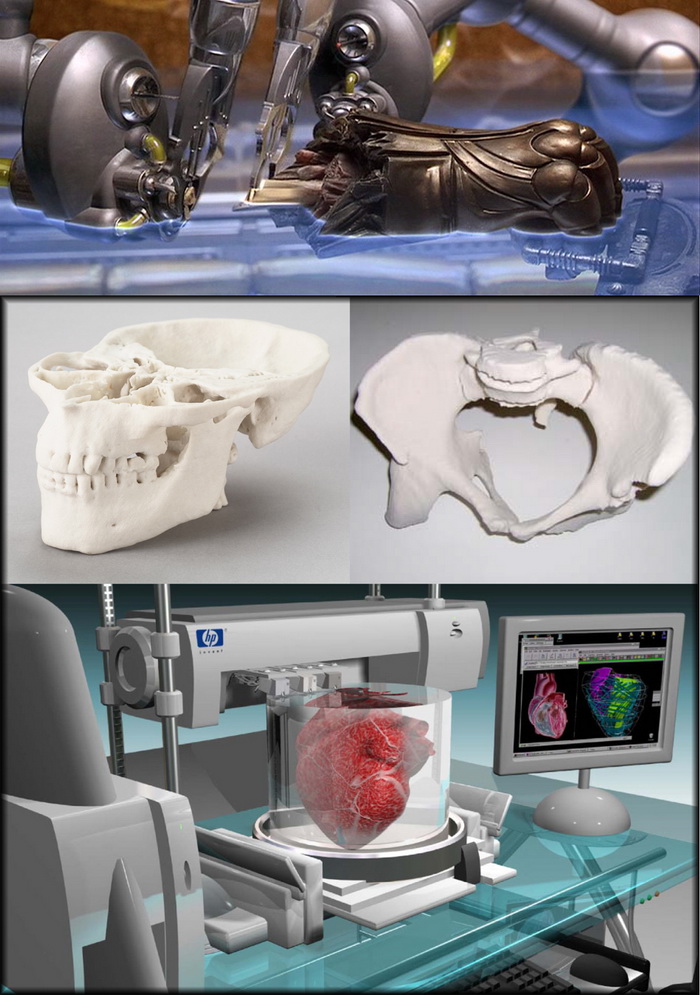

Physicians can print physical models of portions of patient anatomy to better visualize procedures and demonstrate practice. Engineers in factories can create custom jigs and fixtures that both save time and reduce injury during the manufacturing process. Communities foster makerspaces that teach STEM skills and aid in the start-up of new businesses, thereby creating new jobs and local opportunities.

Although mostly used for the creation of plastic objects, 3D printing can also generate metal objects, although this is a much more costly and far less common process than plastic 3D printing.

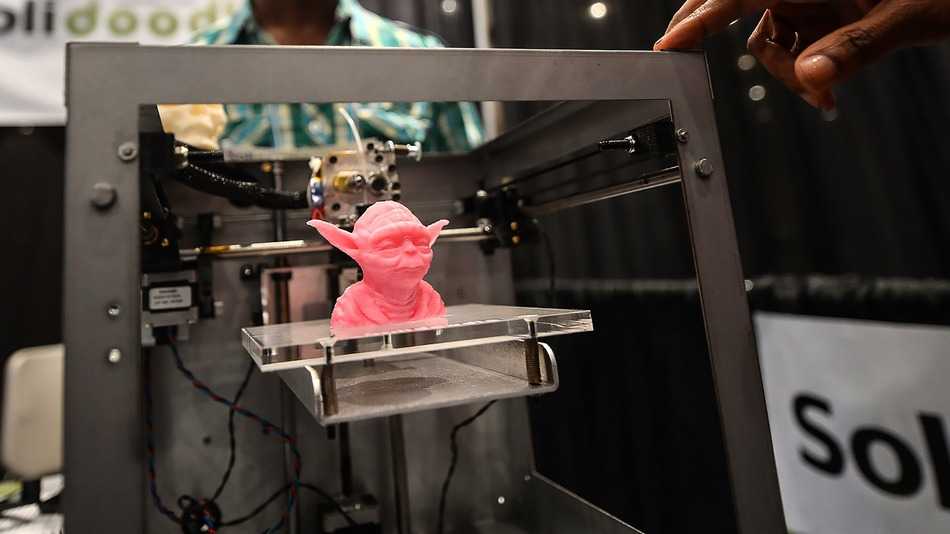

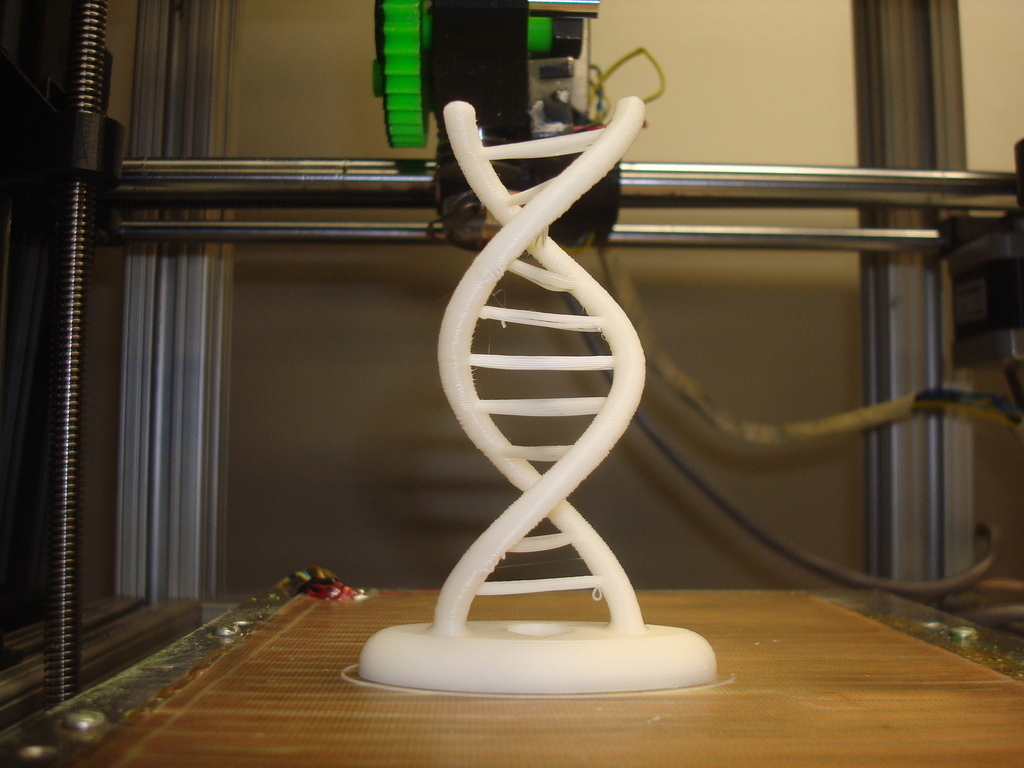

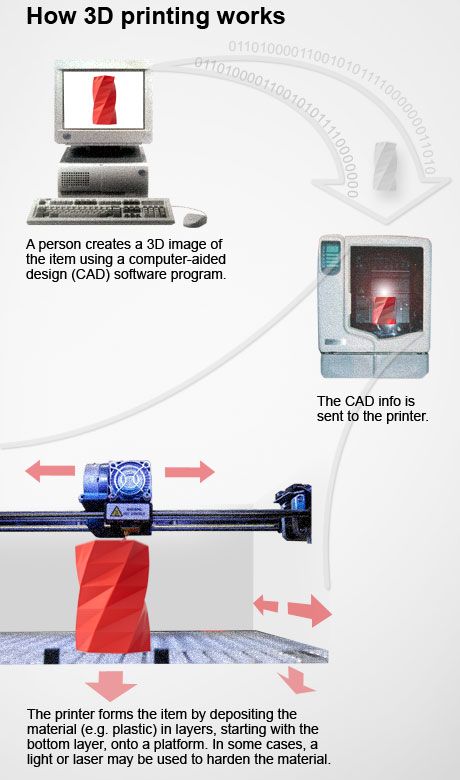

What is 3D printing? 3D printing is the process of creating a physical object from a digital model. 3D printing is an additive process. Layers of plastic are built up one after the other to create an object.

How does 3D printing impact the economy? 3D printing is a component of the maker movement, which has benefits to communities, education, entrepreneurship, and traditional enterprises. It helps foster the creation of new products and new companies, and teaches skills transferable into a wide variety of technical and professional jobs.

How expensive is 3D printing compared to traditional manufacturing processes? That depends. It's far less expensive and takes far less time to create prototypes, jigs, tools, and fixtures using 3D printing. But once the setup and tooling costs are paid for, traditional manufacturing techniques like injection molding can produce objects in volume more quickly and at lower cost.

How does 3D printing affect the supply chain? 3D printing is ideal for short-run manufacturing and small production jobs. It also allows spare parts to be "stored in the cloud," so physical inventory isn't required until there is a demand for an object. By delivering 3D objects across the globe in digital form and printing locally, the cost and time of shipping can be completely eliminated.

Can 3D printing transform the manufacturing industry? The manufacturing industry is undergoing a vast transformation of which 3D printing is one element. Other factors include a huge increase in data volume and processing, improved analytics, improved human factors, and the automation of various production processes.

3D printing is the process of creating objects (usually plastic, but sometimes metal or composite material) from a digital model. Most 3D printers add material to the object one very thin layer at a time, which is why 3D printers are classified as "additive manufacturing."

How does additive manufacturing work?

The analogy to printing is not perfect. Computer printers generally operate a row at a time. 3D printers work much more like plotters, moving a print head along both the X and Y axis to draw a pattern. In the case of a 3D printer, the pattern is usually drawn with plastic, not ink. What makes the 3D printer three-dimensional is that once a pattern is drawn, the print head moves up (or the print surface moves down), and another pattern is drawn on top of the first.

How does a 3D printer work?

There are several types of 3D printers out there, but we'll be focusing on two: fused-deposition modeling (or FDM) and stereolithography (or SLA).

FDM starts with rolls of filament as its source material. These typically come in strands either 1.75 or 2.85 millimeters thick, rolled onto a spindle. An FDM printer heats the filament, squeezes it out through an extruder nozzle, and lays down layers on a build surface. The layers are incredibly thin, and as each molten layer is laid down on top of the previous layer, it partially fuses as it cools.

Also: 3D printing and robots power largest furniture maker in the world

Over time -- sometimes a lot of time -- an object is built up from hundreds or thousands of these layers.

SLA starts with a liquid resin as its source material. A build tray is lowered into the resin (usually upside down) and light (sometimes from an LCD, sometimes from an ultraviolet laser) creates a chemical reaction in the resin that causes it to harden. As each layer is exposed to the light, the printer raises the build platform slightly out of the resin pool, exposing the next layer to light.

Innovation

- These experts are racing to protect AI from hackers. Time is running out

- How to use ChatGPT: Everything you need to know

- This 3D printing system converts waste sawdust into stunning wooden lamps and guitars

- The best affordable EVs and how the federal tax credit can save you $7,500

FDM is the most common form of material extrusion 3D printing. SLA is the most common form of light polymerization 3D printing. These two printing methods have reached a cost level low enough that consumers, hobbyists, educators, entrepreneurs, and small businesses can afford them, but they are generally limited to the production of plastics, plastic composites, and nylon-like materials.

Other forms of 3D printers are available, but at a substantial buy-in cost. These include powder bed 3D printing (which drops powder that is then fused in form), laminated object manufacturing (which glues sheets of material together and then cuts them to form), directed energy deposition (which is kind of like what would happen if a welding machine and an FDM printer gave birth), and electron beam freeform manufacturing (which shoots an electron beam in a vacuum to create molten metal based on a 3D model).

These last forms of 3D printing are generally used to fabricate metal parts, while FDM and SLA are most often used to fabricate plastic objects.

What all of these have in common is that they're creating new objects by incrementally adding and fusing a raw material.

Also: 3D printing: A cheat sheet TechRepublic

What 3D printing is not

3D printers are not Star Trek replicators. As anyone who owns a 3D printer will tell you, as soon as guests see the printer in action, their imagination stirs. Nearly immediately, they'll start calling out the types of objects they'd like to have made. Often these are not even existing items, but entirely new inventions they think can be produced overnight through the magic of 3D printing.

You can't ask one to produce a slice of pecan pie or a perfect, doll-sized replica of Captain Kirk's command chair. While there are 3D printers that actually will create chocolate creations and three-dimensional models of the Captain's chair, 3D printing does have production constraints and design limitations.

Over the next few sections of this guide, we'll dive into the strengths and weaknesses of common 3D printers and what it takes to make 3D prints.

How does 3D printing impact the economy?

In the same way that 3D printing is one element of the larger trend of digital manufacturing transformation, 3D printing is one element of a larger trend economically, the rise of the maker movement.

One exciting aspect of making is that it's all-inclusive and gender neutral. It encompasses everything from doll crafting to robot design, from scrapbooking to making furniture, from leatherworking to 3D printing. It's a word that embraces anyone who makes stuff, pure and simple.

Making is different from manufacturing, although making often leads to manufacturing. When someone designs a product, and builds a prototype, that can be considered making. Once that prototype is in active production, that's manufacturing. Now, combining desktop fabrication with crowdfunding, a very sophisticated prototype can be designed, and then the manufacturing funded by prospective customers.

The National League of Cities' Center for City Solutions and Applied Research has studied the maker movement, and believes that making empowers individuals and improves cities:

The maker movement is centered in cities. And this new, hyperlocal manufacturing environment holds potential not only for individual hobbyists but also for community-wide advances in local entrepreneurship and job creation. Cities have a great opportunity to catalyze this movement as a way to improve our local economies, diversify workforce opportunities, and support the creative economy.

They also believe that 3D printing can lower the barrier of entry for entrepreneurship, stating:

The emergence of makerspaces is effectively lowering the cost of entry for entrepreneurs. Whereas until recently an entrepreneur may have had to spend upwards of $100,000 to produce a prototype for a new product, the operating terrain has changed, and that cost can now range from as little as $2,000 to $4,000.

In short, the cost of developing prototypes has quickly become much more affordable for would-be entrepreneurs.

This cost reduction for prototypes (and by extension jigs, fixtures, and tools) applies to large organizations as well. When you can take an expense and reduce it to just 2-4% of its previous cost, innovation increases because the cost of risk decreases.

According to Paul Heiden, SVP of Product Management for 3D printer maker Ultimaker:

The future of additive manufacturing will not be in the hands of a select few engineers, but rather with any worker who may not have 3D printing experience. Software solutions enable those untrained workers to create parts and tools, closing their own personal skills gap and preparing them for a career in the factory of the future.

One interesting metric is the number of projects and the amount of money pledged through Kickstarter projects. Kickstarter is a crowdfunding platform that enables creators to fund products and projects. In fact, many 3D printer vendors have funded their efforts through Kickstarter.

In fact, many 3D printer vendors have funded their efforts through Kickstarter.

3D Printing

- The best 3D printers: From FDM to resin

- These are the most googled 3D printing questions of 2022, answered

- A 3D printed orthotic device made from castor oil

- This device recycles plastic water bottles into 3D printing filament

As of the moment of this writing, Kickstarter's always-updated stats page shows a cumulative $4.2 billion pledged for 162,912 successfully funded projects. This is directly relevant to 3D printing, because the company no longer allows photo-realistic images for funding pitches and requires an actual prototype be built -- which is often accomplished in part through 3D printing.

Another way to gauge the scope of the maker economy is to look at Etsy, which is fundamentally a marketplace for unique and creative goods. In its 2018 annual report, the company stated that it supports 2. 1 million active sellers, 87 percent of whom are women, and 97 percent who run their creative businesses from their home. According to an economic impact study conducted by ECONorthwest on behalf of Etsy, Etsy sellers...

1 million active sellers, 87 percent of whom are women, and 97 percent who run their creative businesses from their home. According to an economic impact study conducted by ECONorthwest on behalf of Etsy, Etsy sellers...

- Generated more than $1.76 billion in income.

- Contributed $5.37 billion to the U.S. economy, more than double their direct business sales.

- Created 1.52 million jobs in the independent worker economy.

- Produced $3 billion in additional economic value.

Of course, only a small percentage of Etsy sellers use 3D printing, but since many Etsy sellers are candidates for some form of desktop fabrication technology, they are a good proxy for market growth data.

Fundamentally, making in general and 3D printing in specific are transformative drivers for economic growth, helping to train students in tangible skills that produce value, helping entrepreneurs build and test prototypes and engage in initial manufacturing, all of which lead to a potent job-creation force all across the world.

Also:

- Mass production 3D printing? It's coming, and it's a big deal

- 3D Systems integrated into Nokia's Factory in a Box additive manufacturing effort

- Stratasys sheds more light on its metals additive manufacturing plans

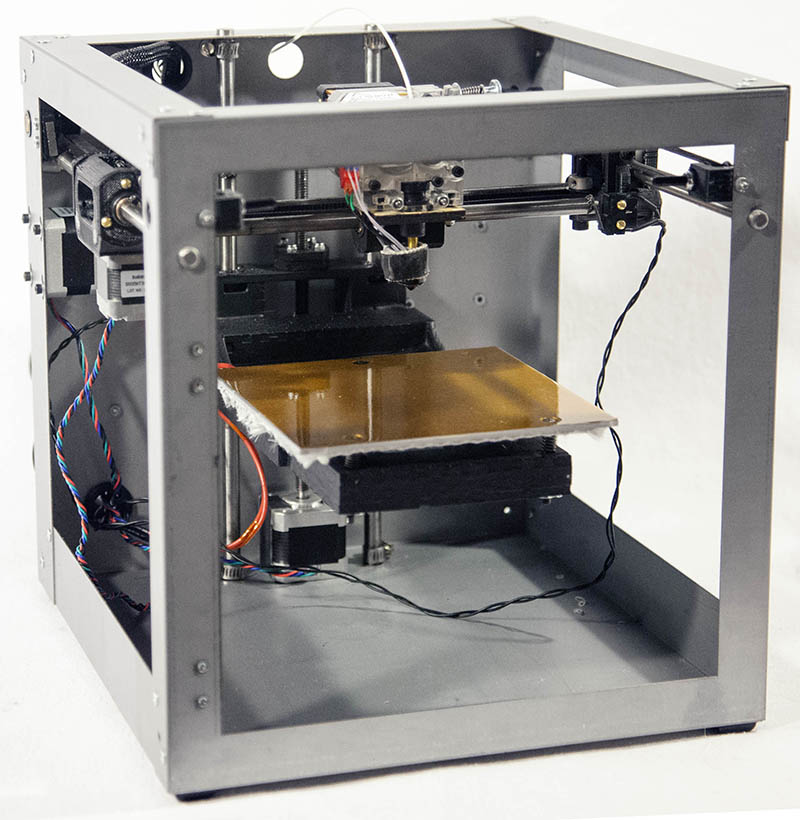

Because FDM and SLA printers have become available for both hobbyists and professionals, they are the most common types of 3D printers. Consumer versions are available for a few hundred dollars and professional machines, used for prototyping and jig-making, are priced in the $3,000-6,000 range.

These are the 3D printing technologies in which you're most likely to invest.

FDM printers

FDM was the first mainstream hobbyist 3D printing technology and still leads the market in terms of brands and product offerings, as well as number of units sold.

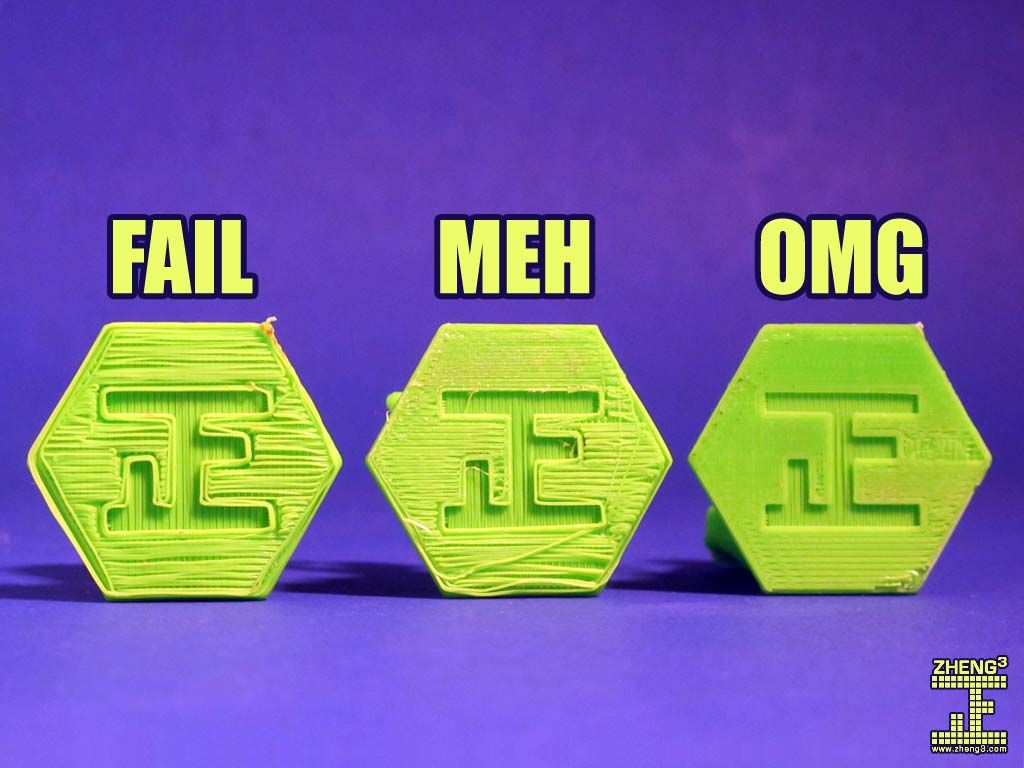

One of the key challenges with 3D printing is getting an object to successfully print. Prints fail because the deposited plastic heats or cools too quickly, because layers don't bond successfully, because the print detaches from the build plate print surface, because filament jams in the extruder, and a wide range of other production gotchas.

Prints fail because the deposited plastic heats or cools too quickly, because layers don't bond successfully, because the print detaches from the build plate print surface, because filament jams in the extruder, and a wide range of other production gotchas.

FDM printers will print in a wide range of plastics. Each plastic has differing characteristics, which can make printing easier or more difficult, and which yield differing characteristics in finished parts.

The most common filament type is PLA (polyactic acid), which is very easy to print, but can be brittle and will deform in sunlight.

Nylon is strong and flexible, but often requires a lot of fiddling to get its print settings to work.

ABS is stronger (it's what LEGOs are made from), but it cools at a rate that often causes the bottom layers to curl up, deforming the entire print. It also has a nasty odor and moderately toxic fumes.

Some vendors infuse the basic plastic (mostly PLA) with other materials, including wood, metals, and carbon fiber.

Each of these change the characteristics of the finished, printed object.

Each of these change the characteristics of the finished, printed object.

Most FDM printers have a single extruder and can print from a single filament roll at a time. More advanced (and expensive) FDM printers can print two, three, four or more filaments at a time, allowing the printer to mix colors, functional characteristics (like solid plastic with flexible hinges), and dissolvable support materials.

Prints are built up from strings of molten plastic, so overhangs can become an issue. While FDM printers can generally print circles or angles up to 45-60 degrees, they can't print over large air gaps because the molten plastic will simply settle into the gap.

To compensate for the problem of large gaps, most printers will generate supports, or temporary towers of plastic that can hold up the bridged areas. Single filament printers use the same material as the object itself, with a variety of settings that can enable the supports to be removed with moderate ease.

Dual filament printers often print with a dissolvable support material like PVA (polyvinyl alcohol) which is pretty much the same material that Elmer's Glue is made from. Once the dual filament print is completed, it's submerged in water for hours (or sometimes days) and the PVA dissolves, leaving an intact print with the open voids the designer intended for the final object.

Because FDM printers print in layers, the orientation of the object being printed can be important. Bonds between layers are often weaker than linear runs of plastic. As such, placement on the bed should take that into account for any objects that are likely to be under stress.

FDM printers come in a variety of sizes. The larger the size, the more challenging the print, because it's often difficult to balance the heat characteristics within the full build area.

FDM printers also offer a variety of nozzle sizes. The larger the nozzle, the more material extruded per minute, but the less refined the final result. The smaller the nozzle, the more detailed the print. Printing with large nozzles or small nozzles will introduce other challenges, often related to supports, bridging, and heat management.

The smaller the nozzle, the more detailed the print. Printing with large nozzles or small nozzles will introduce other challenges, often related to supports, bridging, and heat management.

Also: 3D Printer Reviews CNET

SLA printers

SLA printers have a number of characteristics that have kept them out of the mainstream:

- They use a liquid resin that is quite toxic in its uncured form. If you get it on you, it could cause painful burns or rashes.

- Finished prints need to be processed in a bath and then cured. During this processing time, they are subject to deformation. They also remain toxic.

- Because of the liquid resin and the processing bath, SLA printers are much messier to work with than FDM printers.

SLA printers often have very small build areas, resulting in generally tiny prints. The resin is often specifically formulated for a given printer, so users can be locked into a vendor's offerings, which may limit material and color choices.

Even so, SLA printers have started to grow in popularity, mostly because they are capable of producing prints with very fine detail and few layer lines. This makes them particularly suited for prototyping jewelry designs and molds, small medical and dental designs, and hobbies, like model railroading and gaming miniatures.

Design and preparation of printsThe process of going from an idea to a 3D-printed object must always pass through two software tool technologies first: 3D-modeling (or CAD) software and slicers.

3D-modeling software

Think of 3D-modeling software, also called CAD (for Computer-Aided Design), as the creation engine for 3D models. In the same way you might use Photoshop to create a graphic, Illustrator to create an illustration, or Word to create an article like this one, CAD software is used to create the design for a 3D model.

There are many CAD programs out there, each best-suited to different tasks. I alternate between TinkerCAD and Fusion 360, depending on whether I need to build a quick part or a more complex design.

TinkerCAD is a very easy-to-use program that's often taught to school kids. It allows for super-quick prototyping of simple designs. Fusion 360 is a full engineering design program with features not only for design, but motion simulation and stress testing as well. There are many other tools, like ZBrush and Meshmixer, that are often used for sculpting in virtual space.

If you can draw a rectangle in PowerPoint, you can use a CAD program to make simple designs. Resources for learning common 3D printing programs are available in many online classes, taught in colleges, and found in abundance on YouTube.

That said, since tools like Fusion 360 can be used to design and virtually test projects like car engines, they can be challenging to master. Often specific-discipline engineering skill is required to understand not only how the tool works, but the physics involved in the operation of the final object.

Slicers

CAD programs produce virtual models of 3D objects. But most 3D printing occurs layer-by-layer, in slices. The process of converting a 3D design into a series of machine movements on a two-dimensional plane (and then moving the plane) is the job of a slicer program.

But most 3D printing occurs layer-by-layer, in slices. The process of converting a 3D design into a series of machine movements on a two-dimensional plane (and then moving the plane) is the job of a slicer program.

Featured

- These experts are racing to protect AI from hackers. Time is running out

- Apple M2 Mac Mini review: Faster, cheaper, better

- The new Bing waitlist is long. Here's how to get earlier access

- The best AI chatbots: ChatGPT and other interesting alternatives to try

Most slicers produce G-code, a standard form of numerical control language understood by most computer-aided fabrication devices (not just 3D printers). While G-code is a standard (specifically, "EIA Standard RS-274-D Interchangeable Variable Block Data Format for Positioning, Contouring, and Contouring/Positioning Numerically Controlled Machines"), vendors often add extensions and modifications. This means that G-code usually needs to be generated by the slicer for specific brands and models of numerically controlled devices.

This means that G-code usually needs to be generated by the slicer for specific brands and models of numerically controlled devices.

While some slicers can be operated programmatically by just passing a 3D model file into it and getting G-code output, most slicers today allow for a fully interactive interface. This allows the operator to adjust print orientation and examine the print process layer-by-layer in order to locate potential print problems before a print is sent to the printer.

It's also at this time that different printing settings are configured, ranging from nozzle and build plate temperature, adhesion techniques, infill methods, print speeds, and even custom G-code blocks to account for special procedures, like stopping a print to embed magnets, and then allowing the print to continue.

As with 3D printers and CAD programs, there are many slicers available to choose from. Some of the most popular, like Cura and Slic3r, are open source. There are also robust commercial offerings like Simplify3D.

Additionally, some vendors (like Zortrax and MakerBot) have created their own proprietary slicers tied to their individual hardware. As you might imagine, there are some benefits in this approach for tight machine integration, but the lock-in often means that operators who own multiple brands of 3D printers can't standardize on one slicing tool if they use these machines. Some machines with custom slicers ship with incomplete software, which tends to reflect poorly on the product's design and usability.

3D printing and manufacturingFor those organizations used to traditional production processes, 3D printers can save a tremendous amount of time. One example is Volkswagen Autoeuropa. In a discussion with 3D printer maker Ultimaker's president back in 2017, I was told:

The company [Volkswagen] turned to desktop 3D printing to create custom tools and jigs that are used daily on the assembly line, replacing an old process that required outsourcing and long lead times.

Not only did 3D printing introduce a more cost-effective way to produce the tools, it gave time back to the company. The seemingly minor change saved $160,000 in just one plant in 2016, and it's projected to save $200,000 this year.

3D prints can take hours or days to print. I built a set of custom adapters that go between my shop dust collection system and the dust port for each of my tools. Printing each adapter at low resolution took about three hours. A detailed model of the Star Trek starship USS Discovery took a few days to produce as did a scale model of a Ford engine block.

I was able to create a custom adapter system perfectly tailored to my specific needs. 3D printing allowed me to make one-off objects at a material cost in pennies each. Because I was able to do my own design, I incurred no design cost.

Also: HP's new 3D printer has 3D-printed parts

How expensive is 3D printing compared to traditional manufacturing processes?

Adapters like these, built using traditional methods, would have required custom machining, and take weeks from design to delivery. Costs would have been thousands of dollars more than I paid. Because the turnaround from idea to object was so short, and because the out-of-pocket cost was so low, I was able to avail myself of a productivity-improving custom solution I might not otherwise have had.

Costs would have been thousands of dollars more than I paid. Because the turnaround from idea to object was so short, and because the out-of-pocket cost was so low, I was able to avail myself of a productivity-improving custom solution I might not otherwise have had.

This is another benefit of 3D printing: because the cost is so low, there's very little cost barrier to innovation, and as such, more innovation happens.

The thing is, comparing 3D printed objects to traditionally manufactured objects can't necessarily be quantified by cost. Traditionally manufactured objects often have a huge upfront expense necessary to build molds, fixtures, and even factories. But once those expenses have been incurred, the individual unit cost and time to delivery can be nearly instantaneous.

A tangible comparison

LEGO bricks (which are produced from ABS plastic) are made in astonishing quantities. The company reports:

- 19 billion LEGO elements are produced every year

- 2.

16 million LEGO elements are molded every hour

16 million LEGO elements are molded every hour - 36,000 are created every minute

Also: Stratasys launches F120 3D printer for $11,999; V650 Flex

I downloaded a classic 4x2 (four studs by two studs) rectangular LEGO brick model from 3D object sharing site Thingiverse. This is an exact fit-compatible version, which gives us an ideal comparison of production processes. We're comparing the exact models using the same plastic.

On my Ultimaker S5 (which is the same machine used in the Ford and Volkswagen factories), it would take 29 minutes to 3D print one brick, or about two an hour. Filling the large build plate, it's possible to print 65 bricks at once, but the process will take one day, seven hours, and 39 minutes to complete.

In the same 31 hours it takes to produce one plate of 65 bricks, LEGO produces 66.96 million. In other words, you'd need roughly one million 3D printers running full time to produce what LEGO produces in its factories.

Each brick produced by a 3D printer takes about 3g of filament (about half a meter). 3D printing costs about $0.06 per gram of filament for PLA or ABS. Not counting the cost of power, labor, maintenance, and real estate, each brick costs roughly $0.18. By contrast, LEGO sells its bricks to consumers for an average of 10.4 cents.

While it might be possible to produce LEGO bricks in volume via 3D printing, it's neither practical nor cost-effective. On the other hand, when LEGO wants to prototype and test new brick models, at about $0.18 per prototype, the hands-on design and testing process is certainly wildly cost-effective.

How does 3D printing affect the supply chain?

3D printing is also ideal for low volume or short run manufacturing. While some companies need to churn out products in the thousands or millions, other companies need to produce a relatively small number of units or produce units on-demand.

Low-volume production is needed in a variety of applications:

Production for in-house use: A small number of internal departments or users can benefit from the build.

Jigs and frameworks fit this need perfectly.

Jigs and frameworks fit this need perfectly. Test market production: A limited number of units are produced at a manageable cost to test for either suitability for sale, or functionality and performance of features. If buyers respond well, more units can be produced using traditional production means.

On-demand production: Units needed rarely, or in a back catalog can be "stored in the cloud" and produced only when needed. This allows a large warehouse of parts to be stored virtually, and yet made available to customers as needed.

Entrepreneurial ventures: Small numbers of units can be produced as proof-of-concept for crowdfunding or to provide to influencers and reviewers to create initial press and awareness of a product before full funding has been closed.

It's this low-volume, on-demand capability that 3D printing provides that can be transformative to industry overall, not just manufacturing. By being able to quickly and inexpensively create and test new objects, it's possible to innovate at a pace impossible with traditional means.

By being able to quickly and inexpensively create and test new objects, it's possible to innovate at a pace impossible with traditional means.

Additionally, 3D printing promotes the idea of "think global, make local" in the sense that designs for objects can be shared internationally, but new units can be printed out wherever they are needed.

Take, for example, a fixture used in Ford's pilot plant in Cologne, Germany. The company has a small-scale manufacturing line which tests production of new vehicles. As part of this process, engineers use 3D printers to create jigs, tools, and fixtures.

Once tested and confirmed to be effective, delivering fixtures and jigs to other plants around the world would take shipping time, cost for international express shipping, as well as possible customs or other international transit paperwork. But if engineers at the AutoAlliance plant (a joint venture between Ford and Mazda) in the Rayong province of Thailand wanted to use a jig developed in Cologne, all they would need to do is download the digital file and print it.

The result would be the transferring of a custom-made tool across the world in hours, not days, for pennies, not hundreds or thousands of dollars, and with none of the paperwork hassle normally involved in international shipping.

How can 3D printing transform the manufacturing industry?

According to Ultimaker's Heiden: "3D printing continues to evolve within the manufacturing sector, and factory workers have led the adoption of the technology. As their skills continue to develop, the impact of 3D printing will continue to grow in every aspect of the manufacturing process."

That said, 3D printing is not necessarily suited to volume manufacturing. Because prints can take hours or days, once a prototype is developed, you may want to move to a faster production process for your final sale products.

On the other hand, 3D printing is ideal for creating molds, so you can design your object in a CAD program like Autodesk's Fusion 360, print out a prototype, and refine it until it meets your needs. Filament producer Polymaker, for example, has created a special ash-free filament called PolyCast. This filament can produce investment-casting objects that can be placed inside mold shells and then burnt out, creating a mold with no ash, ready for metal casting.

Filament producer Polymaker, for example, has created a special ash-free filament called PolyCast. This filament can produce investment-casting objects that can be placed inside mold shells and then burnt out, creating a mold with no ash, ready for metal casting.

But if you look at manufacturing solely through the lens of 3D printing, you'll be missing a much larger trend, that of "Industry 4.0." McKinsey estimates that the global manufacturing sector is worth roughly $10 trillion per year. The consulting firm contends there are four vast disruptions that will drive change in industrial processes and goods manufacturing:

Data volume and compute capacity: It's not just big data, it's the tremendous flow of data, the increase in computational power, and ubiquitous connectivity. McKinsey specifically calls attention to the impact of low-power, wide-area networks common among Internet of Things.

Analytics: Between AI and big data, the opportunity to subject every process to detailed examination and optimization based on advanced business analytics will drive supply chains that can be both dynamically reactive to worldwide events and micro-changes, as well as predictive based on accumulations of analytical resources from global sources.

New user interfaces: McKinsey believes that touch-interfaces, augmented-reality systems, and other forms of human-machine interaction will drive change in the manufacturing sector. You can consider 3D printing a new user interface as well, because the opportunity to hold a design concept in your hand can transform how you understand an object at a visceral level.

Digital numerical control: McKinsey describes this as "improvements in transferring digital instructions to the physical world," which is, in effect, G-code. But it's actually more than that. It's not only the transfer of instructions, which we've had for years. It's the technologies (ranging from 3D printing to robotics) capable of acting on those instructions that are proving to be transformative.

In looking at how manufacturing is transforming, it's necessary to look beyond just basics of production to transformations in asset management, labor (human, robot, and hybrid solutions), inventory management, quality (via advanced process control, machine vision, and business intelligence), supply chain management, time-to-market, and even after sales service.

Also: Despite growth, 3D printing represents only 0.1% of global manufacturing TechRepublic

Hands-on with 3D printingIf you're curious about 3D printing, perhaps the best way to understand how it might impact your business is to buy a 3D printer. Consumer-level 3D printers can be had for under $500, and excellent professional printers like those from Ultimaker, LulzBot, and MakerBot are available from about $3,000 to $6,000.

Here at ZDNet, we have run an extensive 3D Printing Discovery Series, with a whole range of articles, reviews, and hands-on video guides. Feel free to read and watch this series. In doing so, you'll be able to quickly and easily develop an in-depth understanding of 3D printing processes and potentials.

Now, go out there and make something great!

Related stories:

- HP sees 3D printing potential in transforming APAC manufacturing

- Dell Technologies using 3D printing to transform prosthetics

- 3D printing guns at home: Does new technology change America's gun control debate?

- Photos: 26 weird and useful things to 3D print for your desk TechRepublic

- Scientists build a 3D printer that turns goo into solid objects CNET

- Best 3D Printer of 2020 CNET

What is 3D printing? How does a 3D printer work? Learn 3D printing

3D printing or additive manufacturing is a process of making three dimensional solid objects from a digital file.

The creation of a 3D printed object is achieved using additive processes. In an additive process an object is created by laying down successive layers of material until the object is created. Each of these layers can be seen as a thinly sliced cross-section of the object.

3D printing is the opposite of subtractive manufacturing which is cutting out / hollowing out a piece of metal or plastic with for instance a milling machine.

3D printing enables you to produce complex shapes using less material than traditional manufacturing methods.

Table of Contents

- How Does 3D Printing Work?

- 3D Printing Industry

- Examples of 3D Printing

- 3D Printing Technologies & Processes

- Materials

- Services

Jump to your field of interest:

- Rapid Prototyping & Manufacturing

- Automotive

- Aviation

- Construction

- Consumer Products

- Healthcare

- Food

- Education

Jump to process:

- All Technologies & Processes

- Vat Photopolymerisation

- Material Jetting

- Binder Jetting

- Material Extrusion

- Powder Bed Fusion

- Sheet Lamination

- Directed Energy Deposition

How Does 3D Printing Work?

It all starts with a 3D model. You can opt to create one from the ground up or download it from a 3D library.

You can opt to create one from the ground up or download it from a 3D library.

3D Software

There are many different software tools available. From industrial grade to open source. We’ve created an overview on our 3D software page.

We often recommend beginners to start with Tinkercad. Tinkercad is free and works in your browser, you don’t have to install it on your computer. Tinkercad offers beginner lessons and has a built-in feature to export your model as a printable file e.g .STL or .OBJ.

Now that you have a printable file, the next step is to prepare it for your 3D printer. This is called slicing.

Slicing: From printable file to 3D Printer

Slicing basically means slicing up a 3D model into hundreds or thousands of layers and is done with slicing software.

When your file is sliced, it’s ready for your 3D printer. Feeding the file to your printer can be done via USB, SD or Wi-Fi. Your sliced file is now ready to be 3D printed layer by layer.

3D Printing Industry

Adoption of 3D printing has reached critical mass as those who have yet to integrate additive manufacturing somewhere in their supply chain are now part of an ever-shrinking minority. Where 3D printing was only suitable for prototyping and one-off manufacturing in the early stages, it is now rapidly transforming into a production technology.

Most of the current demand for 3D printing is industrial in nature. Acumen Research and Consulting forecasts the global 3D printing market to reach $41 billion by 2026.

As it evolves, 3D printing technology is destined to transform almost every major industry and change the way we live, work, and play in the future.

Examples of 3D Printing

3D printing encompasses many forms of technologies and materials as 3D printing is being used in almost all industries you could think of. It’s important to see it as a cluster of diverse industries with a myriad of different applications.

A few examples:

- – consumer products (eyewear, footwear, design, furniture)

- – industrial products (manufacturing tools, prototypes, functional end-use parts)

- – dental products

- – prosthetics

- – architectural scale models & maquettes

- – reconstructing fossils

- – replicating ancient artefacts

- – reconstructing evidence in forensic pathology

- – movie props

Rapid Prototyping & Rapid Manufacturing

Companies have used 3D printers in their design process to create prototypes since the late seventies. Using 3D printers for these purposes is called rapid prototyping.

Why use 3D Printers for Rapid Prototyping?

In short: it’s fast and relatively cheap. From idea, to 3D model to holding a prototype in your hands is a matter of days instead of weeks. Iterations are easier and cheaper to make and you don’t need expensive molds or tools.

Besides rapid prototyping, 3D printing is also used for rapid manufacturing. Rapid manufacturing is a new method of manufacturing where businesses use 3D printers for short run / small batch custom manufacturing.

Automotive

Car manufacturers have been utilizing 3D printing for a long time. Automotive companies are printing spare parts, tools, jigs and fixtures but also end-use parts. 3D printing has enabled on-demand manufacturing which has lead to lower stock levels and has shortened design and production cycles.

Automotive enthusiasts all over the world are using 3D printed parts to restore old cars. One such example is when Australian engineers printed parts to bring a Delage Type-C back to life. In doing so, they had to print parts that were out of production for decades.

Aviation

Aviation loves additive manufacturing, largely due to the promise of lightweight and stronger structures offered by 3D printing. We’ve seen a whole bunch of innovations in the domain of aviation lately, with the appearance of more critical parts being printed.

Turbine Center Frame

One such large component printed this year was the turbine center frame which was printed by GE as part of the EU Clean Sky 2 initiative.

The Advanced Additive Integrated Turbine Centre Frame (TCF) is a 1 meter diameter part printed in nickel alloy 718 by GE and a consortium from Hamburg University of Technology (TUHH), TU Dresden (TUD) and Autodesk. It is one of the largest single metal parts printed for aviation.

Big turbine center frame. (Image credit: GE AAT Munich)Typically components like this are manufactured using casting, and consist of multiple parts. In the case of the 3D printed version, it was reduced from an assembly of 150 parts down to just 1 single piece. The printed version also benefits from a reduction of both cost and mass by 30%, and a reduction in lead time from 9 months to just 10 weeks.

Metal Parts Certified by EASA

Back in June 2022 it was reported that Lufthansa Technik and Premium AEROTEC had created the first load-bearing metal part that had been approved for use in aviation.

The new A-link was produced using LPBF and had demonstrated higher tensile strength compared to the traditionally-forged version.

The part was made at Premium AEROTEC’s facility in Varel, Germany, and a large number of test parts were printed and tested to ensure quality and repeatability for certification.

Printed titanium A-links (Image credit: Lufthansa Technik)Printing the part represented a cost saving for the component and set the stage for using this manufacturing method for creating structurally important metal parts in the future. It was also used to test the process and to demonstrate the certification process of load-bearing AM parts.

Hypersonic Fuel Injector

This next printed item was never destined to be fitted to an aircraft, but rather it was designed to be installed in a facility for testing flow conditions at hypersonic speeds.

When flying in the hypersonic flight regime above (Mach 5), the air passing around the vehicle becomes incredibly hot, and the pressure increases significantly. These conditions can cause the air itself to become chemically reactive, which causes issues for fuel burning vehicles.

Simulating flow conditions with CFD is computationally expensive (if not impossible), and so to replicate the flow conditions, researchers at Purdue fabricated a giant burner to recreate the hot, fast, high pressure experienced in hypersonic flight. In short, they basically built a rocket nozzle and they placed the test components in the exhaust plume to see how they performed.

The injectors that they printed feed fuel and air into the combustion chamber to create specific turbulent flow fields and a stable flame.

The injectors were printed with Hastelloy X, which is a superalloy with superior temperature resistance. The team printed multiple different injectors in rapid time, and tested them all in the burner to see which performed the best.

Now they are able to replicate the hypersonic conditions for flight on Earth at a fraction of the cost (and risk) associated with doing it miles above the Earth’s surface. This can benefit fast aircraft such as scramjet powered vehicles as well as space vehicles.

Relativity Space

We have covered US-based rocket printing company Relativity Space quite a lot on this website.

From their super large metal printer the “Stargate” to the rocket themselves, this company has been doing big things with both printing and rockets. The 4th gen Stargate 3D printer is capable of printing objects measuring 120ft long and 24ft in diameter, and 12x faster than their previous printers.

The new AI-assisted robotic printer has been able to achieve faster printing speeds thanks to its innovative multi-wire print head. This print head allows for multiple metal feedstock wires to be fed into it at the same time, resulting in higher deposition rates.

The company is scheduled to make their first LEO test flight of the printed Terran-1 rocket this month of January 2023, so we just thought we would give them an honorable mention in this article as a reminder.

You can see the Terran-1 undergoing a hot fire test in the video below.

Construction

Is it possible to print a building? – yes it is. 3D printed houses are already commercially available. Some companies print parts prefab and others do it on-site.

Most of the concrete printing stories we look at on this website are focused on large scale concrete printing systems with fairly large nozzles for a large flow rate. It’s great for laying down concrete layers in a fairly quick and repeatable manner. But for truly intricate concrete work that makes full use of the capabilities of 3D printing requires something a little more nimble, and with a finer touch.

Consumer Products

When we first started blogging about 3D printing back in 2011, 3D printing wasn’t ready to be used as a production method for large volumes. Nowadays there are numerous examples of end-use 3D printed consumer products.

Footwear

Adidas’ 4D range has a fully 3D printed midsole and is being printed in large volumes. We did an article back then, explaining how Adidas were initially releasing just 5,000 pairs of the shoes to the public, and had aimed to sell 100,000 pairs of the AM-infused designs by 2018.

With their latest iterations of the shoe, it seems that they have surpassed that goal, or are on their way to surpassing it. The shoes are available all around the world from local Adidas stores and also from various 3rd party online outlets.

Eyewear

The market of 3D printed eyewear is forecasted to reach $3.4 billion by 2028. A rapidly increasing section is that of end-use frames. 3D printing is a particularly suitable production method for eyewear frames because the measurements of an individual are easy to process in the end product.

But did you know it’s also possible to 3D print lenses? Traditional glass lenses don’t start out thin and light; they’re cut from a much larger block of material called a blank, about 80% of which goes to waste. When we consider how many people wear glasses and how often they need to get a new pair, 80% of those numbers is a lot of waste. On top of that, labs have to keep huge inventories of blanks to meet the custom vision needs of their clients. Finally, however, 3D printing technology has advanced enough to provide high-quality, custom ophthalmic lenses, doing away with the waste and inventory costs of the past. The Luxexcel VisionEngine 3D printer uses a UV-curable acrylate monomer to print two pairs of lenses per hour that require no polishing or post-processing of any kind. The focal areas can also be completely customized so that a certain area of the lens can provide better clarity at a distance while a different area of the lens provides better vision up close.

Jewelry

There are two ways of producing jewelry with a 3D printer. You can either use a direct or indirect production process. Direct refers to the creation of an object straight from the 3D design while indirect manufacturing means that the object (pattern) that is 3D printed eventually is used to create a mold for investment casting.

Healthcare

It’s not uncommon these days to see headlines about 3D printed implants. Often, those cases are experimental, which can make it seem like 3D printing is still a fringe technology in the medical and healthcare sectors, but that’s not the case anymore. Over the last decade, more than 100,000 hip replacements have been 3D printed by GE Additive.

The Delta-TT Cup designed by Dr. Guido Grappiolo and LimaCorporate is made of Trabecular Titanium, which is characterized by a regular, three-dimensional, hexagonal cell structure that imitates trabecular bone morphology. The trabecular structure increases the biocompatibility of the titanium by encouraging bone growth into the implant. Some of the first Delta-TT implants are still running strong over a decade later.

Another 3D printed healthcare component that does a good job of being undetectable is the hearing aid. It is estimated that 99% of hearing aids manufactured are made with the use of additive manufacturing, and it’s clear to see why.

Dental

In the dental industry, we see molds for clear aligners being possibly the most 3D printed objects in the world. Currently, the molds are 3D printed with both resin and powder based 3D printing processes, but also via material jetting. Crowns and dentures are already directly 3D printed, along with surgical guides.

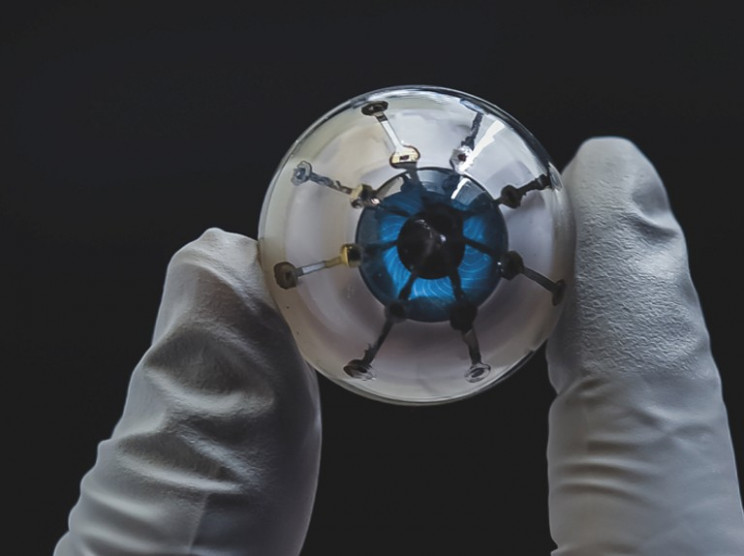

Bio-printing

As of the early two-thousands 3D printing technology has been studied by biotech firms and academia for possible use in tissue engineering applications where organs and body parts are built using inkjet techniques. Layers of living cells are deposited onto a gel medium and slowly built up to form three dimensional structures. We refer to this field of research with the term: bio-printing.

Food

Additive manufacturing invaded the food industry long time ago. Restaurants like Food Ink and Melisse use this as a unique selling point to attract customers from across the world.

Education

Educators and students have long been using 3D printers in the classroom. 3D printing enables students to materialize their ideas in a fast and affordable way.

While additive manufacturing-specific degrees are fairly new, universities have long been using 3D printers in other disciplines. There are many educational courses one can take to engage with 3D printing. Universities offer courses on things that are adjacent to 3D printing like CAD and 3D design, which can be applied to 3D printing at a certain stage.

In terms of prototyping, many university programs are turning to printers. There are specializations in additive manufacturing one can attain through architecture or industrial design degrees. Printed prototypes are also very common in the arts, animation and fashion studies as well.

Types of 3D Printing Technologies and Processes

The American Society for Testing and Materials (ASTM), developed a set of standards that classify additive manufacturing processes into 7 categories. These are:

- Vat Photopolymerisation

- Stereolithography (SLA)

- Digital Light Processing (DLP)

- Continuous Liquid Interface Production (CLIP)

- Material Jetting

- Binder Jetting

- Material Extrusion

- Fused Deposition Modeling (FDM)

- Fused Filament Fabrication (FFF)

- Powder Bed Fusion

- Multi Jet Fusion (MJF)

- Selective Laser Sintering (SLS)

- Direct Metal Laser Sintering (DMLS)

- Sheet Lamination

- Directed Energy Deposition

Vat Photopolymerisation

A 3D printer based on the Vat Photopolymerisation method has a container filled with photopolymer resin. The resin is hardened with a UV light source.

Stereolithography (SLA)

SLA was invented in 1986 by Charles Hull, who also at the time founded the company, 3D Systems. Stereolithography employs a vat of liquid curable photopolymer resin and an ultraviolet laser to build the object’s layers one at a time. For each layer, the laser beam traces a cross-section of the part pattern on the surface of the liquid resin. Exposure to the ultraviolet laser light cures and solidifies the pattern traced on the resin and fuses it to the layer below.

After the pattern has been traced, the SLA’s elevator platform descends by a distance equal to the thickness of a single layer, typically 0.05 mm to 0.15 mm (0.002″ to 0.006″). Then, a resin-filled blade sweeps across the cross section of the part, re-coating it with fresh material. On this new liquid surface, the subsequent layer pattern is traced, joining the previous layer. Depending on the object & print orientation, SLA often requires the use of support structures.

Digital Light Processing (DLP)

DLP or Digital Light Processing refers to a method of printing that makes use of light and photosensitive polymers. While it is very similar to SLA, the key difference is the light source. DLP utilizes other light sources like arc lamps. DLP is relatively quick compared to other 3D printing technologies.

Continuous Liquid Interface Production (CLIP)

One of the fastest processes using Vat Photopolymerisation is called CLIP, short for Continuous Liquid Interface Production, developed by Carbon.

Digital Light Synthesis

The heart of the CLIP process is Digital Light Synthesis technology. In this technology, light from a custom high performance LED light engine projects a sequence of UV images exposing a cross section of the 3D printed part causing the UV curable resin to partially cure in a precisely controlled way. Oxygen passes through the oxygen permeable window creating a thin liquid interface of uncured resin between the window and the printed part known as the dead zone. The dead zone is as thin as ten of microns. Inside the dead zone, oxygen prohibits light from curing the resin situated closest to the window therefore allowing the continuous flow of liquid beneath the printed part. Just above the dead zone the UV projected light upwards causes a cascade like curing of the part.

Simply printing with Carbon’s hardware alone does not allow for end use properties with real world applications. Once the light has shaped the part, a second programmable curing process achieves the desired mechanical properties by baking the 3d printed part in a thermal bath or oven. Programmed thermal curing sets the mechanical properties by triggering a secondary chemical reaction causing the material to strengthen achieving the desired final properties.

Components printed with Carbon’s technology are on par with injection molded parts. Digital Light Synthesis produces consistent and predictable mechanical properties, creating parts that are truly isotropic.

Material Jetting

In this process, material is applied in droplets through a small diameter nozzle, similar to the way a common inkjet paper printer works, but it is applied layer-by-layer to a build platform and then hardened by UV light.

Material Jetting schematics. Image source: custompartnet.comBinder Jetting

With binder jetting two materials are used: powder base material and a liquid binder. In the build chamber, powder is spread in equal layers and binder is applied through jet nozzles that “glue” the powder particles in the required shape. After the print is finished, the remaining powder is cleaned off which often can be re-used printing the next object. This technology was first developed at the Massachusetts Institute of Technology in 1993.

Binder Jetting schematicsMaterial Extrusion

Fused Deposition Modeling (FDM)

FDM schematics (Image credit: Wikipedia, made by user Zureks)FDM works using a plastic filament which is unwound from a spool and is supplied to an extrusion nozzle which can turn the flow on and off. The nozzle is heated to melt the material and can be moved in both horizontal and vertical directions by a numerically controlled mechanism. The object is produced by extruding melted material to form layers as the material hardens immediately after extrusion from the nozzle.

FDM was invented by Scott Crump in the late 80’s. After patenting this technology he started the company Stratasys in 1988. The term Fused Deposition Modeling and its abbreviation to FDM are trademarked by Stratasys Inc.

Fused Filament Fabrication (FFF)

The exactly equivalent term, Fused Filament Fabrication (FFF), was coined by the members of the RepRap project to give a phrase that would be legally unconstrained in its use.

Powder Bed Fusion

Selective Laser Sintering (SLS)

SLS uses a high power laser to fuse small particles of powder into a mass that has the desired three dimensional shape. The laser selectively fuses powder by first scanning the cross-sections (or layers) on the surface of a powder bed. After each cross-section is scanned, the powder bed is lowered by one layer thickness. Then a new layer of material is applied on top and the process is repeated until the object is completed.

Multi Jet Fusion (MJF)

Multi Jet Fusion technology was developed by Hewlett Packard and works with a sweeping arm which deposits a layer of powder and then another arm equipped with inkjets which selectively applies a binder agent over the material. The inkjets also deposit a detailing agent around the binder to ensure precise dimensionality and smooth surfaces. Finally, the layer is exposed to a burst of thermal energy that causes the agents to react.

Direct Metal Laser Sintering (DMLS)

DMLS is basically the same as SLS, but uses metal powder instead. All unused powder remains as it is and becomes a support structure for the object. Unused powder can be re-used for the next print.

Due to of increased laser power, DMLS has evolved into a laser melting process. Read more about that and other metal technologies on our metal technologies overview page.

Sheet Lamination

Sheet lamination involves material in sheets which is bound together with external force. Sheets can be metal, paper or a form of polymer. Metal sheets are welded together by ultrasonic welding in layers and then CNC milled into a proper shape. Paper sheets can be used also, but they are glued by adhesive glue and cut in shape by precise blades.

Simplified schematics of ultrasonic sheet metal process (Image credit: Wikipedia from user Mmrjf3)Directed Energy Deposition

This process is mostly used in the metal industry and in rapid manufacturing applications. The 3D printing apparatus is usually attached to a multi-axis robotic arm and consists of a nozzle that deposits metal powder or wire on a surface and an energy source (laser, electron beam or plasma arc) that melts it, forming a solid object.

Materials

Multiple materials can be used in additive manufacturing: plastics, metals, concrete, ceramics, paper and certain edibles (e.g. chocolate). Materials are often produced in wire feedstock a.k.a. filament, powder form or liquid resin. Learn more about our featured materials on our materials page.

Services

Looking to implement 3D printing in your production process? Get a quote for a custom part or order samples on our 3D print service page.

Everything you need to know about 3D printing materials

Here is a guide to help you learn about the materials used in modern industrial and home 3D printing.

When it comes to 3D printing, there is (almost) nothing impossible when it comes to materials, and researchers are constantly creating new ones.

There are certain "master" materials. The most common of these are plastics, ranging from industrial grade plastics like PEEK to very easy-to-handle plastics like PLA. Another common material is polymers, which are used in SLA printers. Composites are another category, and, as the name suggests, they are created (as if composed by a composer) by combining several materials, and the best is taken from each. The next large group of materials are metals. They are printed only by industrial machines.

In this guide, we will only consider commercially available 3D printing materials. This means that we have excluded those that cannot be bought in the store, such as biological ones.

So, it's time to start talking about what materials you can work with in 3D printing, about their applications, properties and technologies.

Which material should I choose?

Sorry, but it depends on a lot of circumstances. For example, if you need to print a food container, you will need a 3D printing material that is also food compatible, like PETG. If you want to see in advance and on a smaller scale what will then be made as a result of injection molding, then it is not necessary to immediately use expensive materials when thermoplastics such as nylon are available.

There are also additive technologies such as Binder Jetting (jet printing with a binder) or stereolithography, which greatly expanded the range of materials used in 3D printing. Many jobs that have been the domain of manual craftsmen for centuries are now automated and can be done by anyone with even the slightest understanding of 3D printing 3D modeling. Here you can point to the wide possibilities of producing full-color concepts, architectural models and visualization of art projects from paper (SDL), sandstone (Binder Jetting) and polymers (PolyJet). Thus, it can be said that 3D printing materials have led to a kind of democratization of rapid prototyping of design ideas.

Materials for 3D printing with metals have revealed forms and applications that were previously unimaginable. Nowadays, it is no longer surprising that the aerospace industry is creating complex one-piece structures that use less material than before, and are therefore lighter, resulting in lower fuel consumption for aircraft compared to traditional approaches.

PLASTIC

Most consumer goods today are made from thermoplastics, so this guide to 3D printing materials would be incomplete without them. And if we talk about widespread things, then here the plastics come out in all their glory. Designers and engineers prefer to create functional prototypes from 3D printing materials with the same or very similar properties as injection molding materials, the technology that creates the final product.

Most 3D printing thermoplastics can be handled at home in much the same way as professional solutions. The only thing is that some experts began to stare at laser sintering instead of filament fusing (FFF).

ABS

(Source: Wikipedia)

Do you remember the quality of Lego bricks? And this is ABS plastic, which is one of the most common materials for desktop 3D printing today.

It is completely inexpensive, strong and light. ABS filament comes in a variety of colors. There are some complaints about the smell that ABS emits when heated to its melting point, and if you're worried about that, there are alternatives like PLA. Because ABS is printed at temperatures between +220 and +250 °C, it is recommended to use a heated platform and in a closed working space so that the material cools in a controlled manner and does not warp. Also, 3D printing materials like ABS break down when exposed to atmospheric moisture, so you need to store them in airtight bags or containers.

Learn more about ABS: Everything you need to know about ABS filament for 3D printing

- Technologies: FDM, resin inkjet, SLA, PolyJetting

- Features: Rugged, lightweight, high resolution, quite flexible

- Applications: architectural models, concepts, assembly models, mass production

PLA

Another crowd favorite in our guide to 3D printing materials is PLA, which is made from cornstarch (although sugar cane and tapioca are also available). This is a simple material that exudes a pleasant sweetish aroma when heated, which is why many people prefer it over ABS. In addition, it can print disposable tableware and does not shrink as much when cooled compared to ABS. However, PLA is not as durable as ABS, and is afraid of heat. Therefore, ABS is better for any working structures.

(Source: thingiverse)

Don't Miss: PLA Durability, Biodegradability Experiment

PLA is sold in a variety of colors and is found in many composites that give it the appearance of, for example, wood or metal. Like ABS, PLA filament breaks down when exposed to moisture in the air, so store it in airtight bags or containers.

- Technologies: FDM, SLA, SLS

- Features: easy to print, no toxic smell when printed, food grade

- Applications: concepts, assembly models, functional models, serial production

Nylon (polyamide)

Thanks to its flexibility and strength, nylon has become a leader in a wide range of applications, from engineering to artistic. In some places it is simply called "white plastic". Nylon printouts have a rough surface that can be easily polished. Among FDM filaments, nylon has the strongest layer bonding, making it ideal for 3D printing parts that require high tensile strength and mechanical strength. Like other thermoplastics, nylon decomposes when exposed to ambient moisture and is best stored in airtight containers or bags.

- Technologies: FDM, SLS

- Characteristics: strong, smooth surface (after polishing), rather flexible, chemically resistant

- Applications: concepts, functional models, medical applications, instruments, visual arts

PEEK

PEEK is another 3D printing material designed for heavy duty parts. Plastics of this family perfectly tolerate mechanical stresses, temperature fluctuations and chemical influences. And that's not it. PEEK parts can be irradiated with X-rays and gamma rays. And with such reliability, this material is easily processed and produced. But here there is an ambush in the temperature, which in a 3D printer should reach +400 ° C, and it is better to entrust such work to professionals. In addition to high cost, security considerations can also be an argument for abandoning it. PEEK materials with their excellent properties are used in the most demanding applications - automotive, aerospace, chemical and medical industries. In particular, medical instruments and semiconductor components can be mentioned.

- Technologies: FDM, SLS

- Characteristics: biocompatible, very durable, heat resistant, wear resistant

- Applications: series production (automotive, aerospace, chemical and medical industries)

PET

Our next 3D printing material is PET, the material used to make plastic bottles, another alternative to ABS. Unlike ABS, PET does not stink when melted and is strong and flexible without the stench. More importantly, PET does not require heated print bed. The material gives a shiny surface, it is not hazardous to food, and this in some cases makes it a popular choice. Store PET materials for 3D printing in airtight bags or containers, the material is afraid of moisture.

- Technologies: FDM

- Characteristics: durable, food compatible, flexible, gives a smooth surface

- Applications: assembly models, mass production, functional models

PETG

PETG is a version of PET combined with glycol that has received a number of desirable properties in the 3D printing business, such as high transparency. What's more, PETG materials can be printed at lower temperatures and at higher flow rates (up to 100 mm/s), which speeds up production. PETG objects are not afraid of the weather, so they can often be found in gardens. Another commercial quality is food compatibility. Store PETG in airtight bags or containers, the material is afraid of moisture.

Don't Miss: All You Need to Know About 3D Printing with PETG Filament

- Technologies: FDM

- Features: Rugged, food grade, all weather, flame retardant

- Applications: concepts, assembly models, functional models, serial production

ULTEM

ULTEM is an amazing 3D printing material often found in demanding applications. On the one hand, the plastics of this family perfectly tolerate mechanical stresses, temperature fluctuations and chemical influences, but at the same time they are easy to process and obtain. The only problem is heat resistance, because the extrusion temperature in a 3D printer must reach +400 ° C, and for safety reasons, it is better not to do this work at home, but to entrust it to specialized 3D printing services. Due to its ruggedness, ULTEM is used in the most demanding applications in the automotive, aerospace, chemical and medical industries. It can be found in electrical circuits, medical instruments, and microchip sockets.

- Technologies: FDM, SLS

- Characteristics: biocompatible, very durable, heat resistant, wear resistant

- Applications: series production (automotive, aerospace, chemical and medical industries)

HIPS

HIPS has two main applications. First of all, it is often used in FDM or SLA printing as a backing material because it dissolves in a substance called limonene. With similar properties, HIPS works best in combination with ABS. But, if you decipher the name of this plastic, and HIPS is High-Impact Polystyrene, i.e. high-impact polystyrene, it becomes clear why it is also widely used for the manufacture of containers and in general where increased impact resistance is important. When printing, HIPS gives off fumes, so the room must be ventilated, especially at home. Like many other materials for 3D printing, this one is also capricious in relation to environmental conditions, so it must be stored tightly.

- Technologies: FDM, SLA

- Characteristics: soluble, soft to the touch

- Applications: assembly models, print stands, shipping containers

PVA

PVA, like HIPS, was designed as a soluble support material, but unlike all other similar materials, it dissolves in plain water. And, like most filaments, it needs to be stored in an airtight container.

- Technologies: FDM

- Characteristics: instant

- Applications: assembly models, printing supports

COMPOSITES

Composites are filaments made up of several materials and using the best qualities of each. PLA, for example, can be paired with everything from wood to metal. Other composites are targeted at specific industries or applications and are used, for example, in engineering applications.

Conductive

A relatively new addition to the filament shelf are 3D printable conductive materials that open up many interesting possibilities. Such materials can be used, for example, in touch panels or in MIDI instruments. Other uses for conductive composites are wearable electronics, computer-to-computer interfaces, Arduino boards, and more for DIY projects. Conductive filaments for 3D printing are usually based on PLA or ABS, each with its pros and cons. Conductive ABS is more durable and heat-resistant than PLA-based, but has the same odor issues as regular ABS.

- Technologies: FDM

- Features: conductive

- Applications: DIY projects

Metal-plastic filament

All "metal" filaments on the market are actually thermoplastics mixed with a small amount of metal. Such 3D printing materials allow you to create objects with the visual properties of these metals. Metal-plastic filaments are heavier than conventional thermoplastics. Popular composites for 3D printing are bronze, copper, steel, and iron. Keep in mind that these printouts require post-processing to make them look like metal. Also make sure your printer's nozzle can handle this material.

- Technologies: FDM

- Features: metal look

- Applications: fine arts

Alumide

This is a nylon variant with aluminum particles. In terms of durability and physical characteristics, it is very similar to nylon. The difference is that it is shiny, wear-resistant and has a porous surface. Objects printed with alumide can be very precise in size, durable and long lasting. Alumide, like other similar materials for 3D printing, lends itself well to various kinds of post-processing, such as polishing and coating.

- Technologies: SLS

- Features: Rugged, heat resistant, high resolution

- Applications: DIY projects, functional prototypes, mass production

Wood

Human inquisitiveness knows no bounds, so it was only a matter of time before engineers succeeded in adding wood fibers to plastic filament. Wood 3D prints can be processed like real ones, they can be sawn, sanded and painted. And while this kind of exotic 3D printing material is aesthetically pleasing, it doesn't have the same functional characteristics as the original. For example, you will not be able to make a chair out of it.

Interestingly, by changing the extrusion temperature, it is possible to change the shades of brown in the wood filament. 3D printing at a lower temperature produces a very light shade, while at a higher temperature it produces a solid dark brown. Therefore, if you decide to imitate growth rings in a printout, play with temperature. Depending on the brand of wood filament, the printing process may be accompanied by the smell of wood. Some manufacturers offer a wide selection of such material - birch, olive, bamboo, willow ...

- Technologies: FDM

- Characteristics: fragile

- Applications: concept models, fine arts

METALS

Our guide to 3D printing materials would be incomplete without metals. Metal 3D printing has gained particular popularity in the aerospace, automotive and medical industries for its ability to create complex designs that do not require additional welding or machining. The disadvantage of these materials is that they require a lot of experience in development and combination.

In addition, they cannot be printed at home because they require high temperatures and large, specialized printers.

Learn more about metal 3D printing in our comprehensive article Everything you need to know about metal 3D printing

Aluminum

wide range of applications. Basically, we are talking about different alloys based on it. Aluminum elements can have thin walls and complex geometries, they tolerate physical stresses and high temperatures well, which is extremely important for low-cost prototypes, functional models, in particular for engines in the automotive and aerospace industries.

- Technologies: direct metal deposition, binder inkjet printing

- Characteristics: light, strong, heat-resistant, not afraid of corrosion

- Applications: functional models, mass production (automotive and aerospace)

Cobalt Chrome

The next material on the list is used for very serious applications. Chrome-cobalt is sometimes referred to as chromium-cobalt-molybdenum or cobalt-chromium, and sometimes simply as a superalloy. Its main use is in medical applications and in the aerospace industry, where it can be found in turbines and jet engines. It has outstanding strength, heat and corrosion resistance and is suitable for fine work.

- Technologies: direct metal laser sintering, SLM

- Characteristics: biocompatible, durable, corrosion resistant, heat resistant, wear resistant, low electrical conductivity

- Applications: series production (medical and aerospace)

Copper and Bronze

With rare exceptions, copper and bronze are used in investment casting processes and to a lesser extent in formed bed sintering. Due to their electrical conductivity, they are often used in electrical engineering. They are also very popular as art materials and with artisans.

- Technologies: investment casting, formed layer sintering, direct metal deposition

- Characteristics: electrical conductivity, wear resistance

- Applications: series production (electrical engineering), fine arts

Inconel

Inconel is a super alloy designed for the most extreme conditions. It consists mainly of nickel and chromium and is extremely heat resistant. Also resistant to extreme pressures, Inconel is indispensable in the production of aircraft black boxes and even rocket engine parts. Even more often, these features are used in solutions for the oil and chemical industries. The material is very strong and difficult to process, so direct laser sintering is preferred to obtain products of the desired shape.

- Technologies: direct metal laser sintering

- Characteristics: heat resistant, wear resistant

- Applications: petroleum, chemical and aerospace industries

Nickel

Nickel alloys are popular for 3D printing applications. Nickel alloy elements are stronger and more durable than traditional methods such as casting. This, in turn, allows engineers to create thinner parts, leading to more fuel-efficient aircraft, for example. There are many types of alloys that combine the characteristics of nickel and other materials such as monel or inconel.

- Technologies: formed bed sintering, direct metal deposition

- Features: strong, lightweight

- Applications: series production (automotive and aerospace)

Precious metals (gold, silver, platinum)

Most formed bed sintering firms can work with precious metals such as gold, silver and platinum. Here, in addition to the aesthetic qualities of materials, it is very important not to lose a single crumb of precious powder. Therefore, such parts are more often produced where a more easily controlled investment casting technology is used. Precious metals are used as materials for 3D printing in jewelry, medical solutions and electronics. Depending on the technology used, some of these materials may be used for casting.

- Technologies: Formed-bed sintering, investment casting, bonded inkjet printing

- Features: high resolution, smooth surface

- Applications: jewelry, dentistry, functional models

Stainless steel

If you're looking for cheaper metal in this guide to 3D printing materials, it's stainless steel. It is also very durable and can be used in many industrial and even artistic applications. Stainless steel alloys containing cobalt or nickel are extremely difficult to break, but have excellent elasticity and good magnetic properties. If you need a different color - please: steel can be coated, for example, with gold. The materials in question are mainly used for industrial purposes.

- Technologies: direct metal deposition, binder inkjet printing

- Characteristics: high resolution, corrosion resistance, some flexibility, strength

- Applications: tools, function models, mass production

Titanium

Pure titanium powder is often used in 3D printing. This is one of the most versatile materials - it is both durable and lightweight. They work with it using the technology of sintering in the formed layer or inkjet printing with a binder. It is most commonly found in demanding medical solutions, such as custom-made prostheses. Other uses for this material are parts and prototypes for aerospace, automotive and tool manufacturing. In addition to the price, it has another unpleasant feature - its powder explodes easily. Therefore, they print in a vacuum or in argon.

- Technologies: formed bed sintering, binder inkjet printing, direct metal deposition

- Characteristics: biocompatibility, high resolution, heat resistance, high wear resistance

- Applications: tools, function models, mass production (automotive, aerospace and medical)

CERAMIC

(Source: SONY DSC)