1 cubic meter 3d printer

Largest 3D printers in 2023 for XXL prints

Large-scale 3D printers are able to print massive objects thanks to their gigantic build volumes. This guide covers some of the largest 3D printers in the world that are commercially available.

Last update June 16, 2022

We removed discontinued products and updated the BLB Industries The BOX lineup, which has been replaced by The Industry MAGNUM. We also added MASSIVit's latest solution, the Massivit 10000.

Table of contents

Handpicked related content

Large scale 3D printers (XXL): 2023 selection

BIG-Meter V4

F1000

BigRep ONE v4

400 Series WORKBENCH XTREME

T3500

MAGNUM

Massivit 10000

MAMA

3D printing furniture

3D printing large prototypes

3D printing production series

Customized large scale 3D printers

What are the best large scale 3D printers?

Large-scale 3D printers have been in the spotlight for quite some time. When we say large scale, we mean it– these machines can 3D print objects of over 1 square meter. They can be used to 3D print pieces of furniture, large prototypes, or several series of smaller objects in one go.

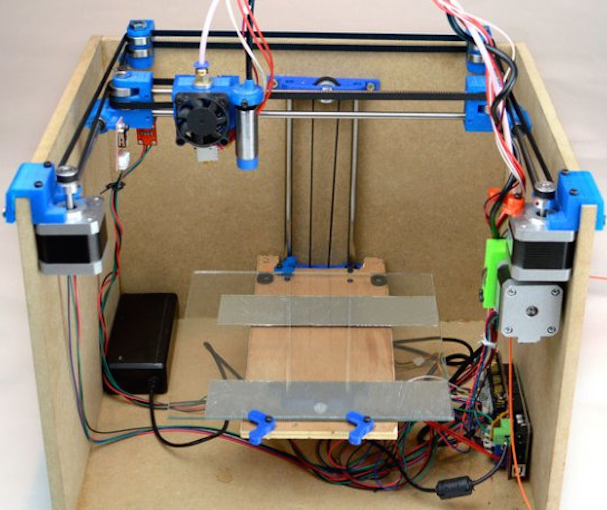

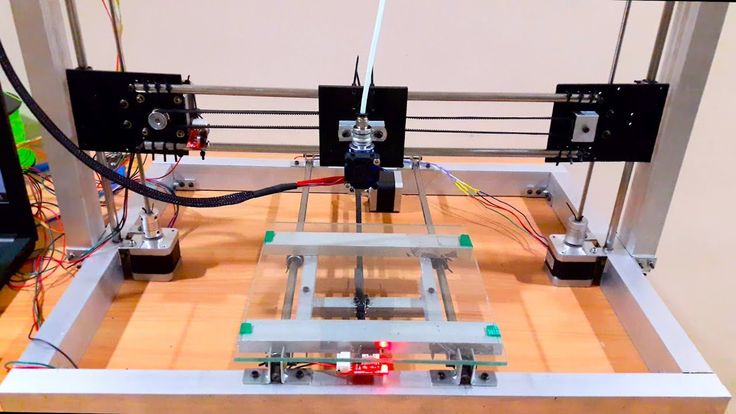

The professional 3D printers featured in our article are basically super-sized versions of ordinary desktop 3D printers. They almost all use extrusion 3D printing technology (FFF) and work the same way as regular desktop printers.

Our “largest 3D printers” selection does not include construction 3D printers, which fit into a different category.

Handpicked related content

If these large scale 3D printers (XXL) are too big, check out our other selections:

- Large format 3D printers (XL)

- Large volume 3D printers (L) for desktops/benchtops

- Large resin 3D printers (L)

Large scale 3D printers (XXL): 2023 selection

| Brand | Product | Build size | Country | Price Approximate starting prices based on supplier-provided information and public data. | |

|---|---|---|---|---|---|

| Modix This brand is a certified partner from our network. | BIG-Meter V4 | 1010 × 1010 × 1010 mm39.76 × 39.76 × 39.76 in | Israel | $ 13,50013 723 €11,975 £2,012,256 ¥ | Buy |

| CreatBot | F1000 | 1000 × 1000 × 1000 mm39.37 × 39.37 × 39.37 in | China | $ 29,99930 494 €26,610 £4,471,531 ¥ | Quote |

| BigRep | BigRep ONE v4 | 1005 × 1005 × 1005 mm39.57 × 39.57 × 39.57 in | Germany | $ 30,00030 000 €26,611 £4,471,680 ¥ | Quote |

| 3D Platform | 400 Series WORKBENCH XTREME | 1000 × 1500 × 700 mm39.37 × 59.06 × 27.56 in | United States | $ 49,99950 823 €44,351 £7,452,651 ¥ | Quote |

| Tractus3D | T3500 | ⌀ 1000 x 2100 mm | Netherlands | $ 59,00049 900 €52,335 £8,794,304 ¥ | Quote |

| The Industry | MAGNUM | 1500 × 1200 × 1200 mm59. 06 × 47.24 × 47.24 in 06 × 47.24 × 47.24 in | Sweden | $ 135,000129 990 €119,750 £20,122,560 ¥ | Quote |

| MASSIVit 3D | Massivit 10000 | 1420 × 1110 × 1500 mm55.91 × 43.7 × 59.06 in | Israel | upon request | Quote |

| Modix This brand is a certified partner from our network. | MAMA | 2000 × 5000 × 1000 mm78.74 × 196.85 × 39.37 in | Israel | upon request | Quote |

Expand to see more specs

The products in the table are ranked by price (low to high).

| Brand | Product | Build size | Build volume | Country | Price Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …). | |

|---|---|---|---|---|---|---|

| Modix This brand is a certified partner from our network. | BIG-Meter V4 | 1010 × 1010 × 1010 mm39.76 × 39.76 × 39.76 in | 1030.3 L | Israel | $ 13,50013 723 €11,975 £2,012,256 ¥ | Buy on Modix |

| CreatBot | F1000 | 1000 × 1000 × 1000 mm39.37 × 39.37 × 39.37 in | 1000 L | China | $ 29,99930 494 €26,610 £4,471,531 ¥ | Get a quote |

| BigRep | BigRep ONE v4 | 1005 × 1005 × 1005 mm39.57 × 39.57 × 39.57 in | 1015.08 L | Germany | $ 30,00030 000 €26,611 £4,471,680 ¥ | Get a quote |

| 3D Platform | 400 Series WORKBENCH XTREME | 1000 × 1500 × 700 mm39.37 × 59.06 × 27.56 in | 1050 L | United States | $ 49,99950 823 €44,351 £7,452,651 ¥ | Get a quote |

| Tractus3D | T3500 | ⌀ 1000 x 2100 mm | 1649.34 L | Netherlands | $ 59,00049 900 €52,335 £8,794,304 ¥ | Get a quote |

| The Industry | MAGNUM | 1500 × 1200 × 1200 mm59. 06 × 47.24 × 47.24 in 06 × 47.24 × 47.24 in | 2160 L | Sweden | $ 135,000129 990 €119,750 £20,122,560 ¥ | Get a quote |

| MASSIVit 3D | Massivit 10000 | 1420 × 1110 × 1500 mm55.91 × 43.7 × 59.06 in | 2364.3 L | Israel | upon request | Get a quote |

| Modix This brand is a certified partner from our network. | MAMA | 2000 × 5000 × 1000 mm78.74 × 196.85 × 39.37 in | – | Israel | upon request | Get a quote |

Overview of the best large scale professional 3D printers

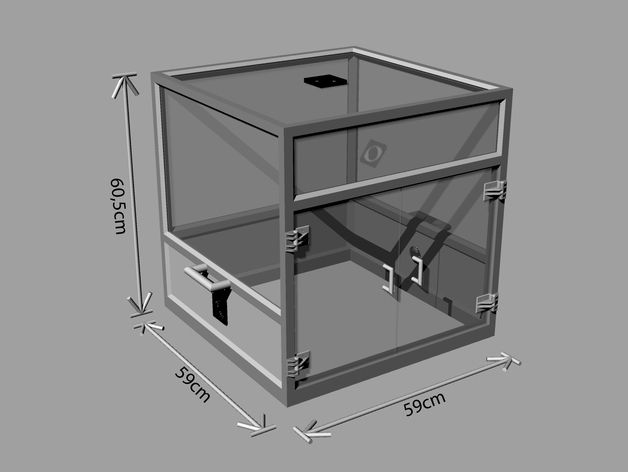

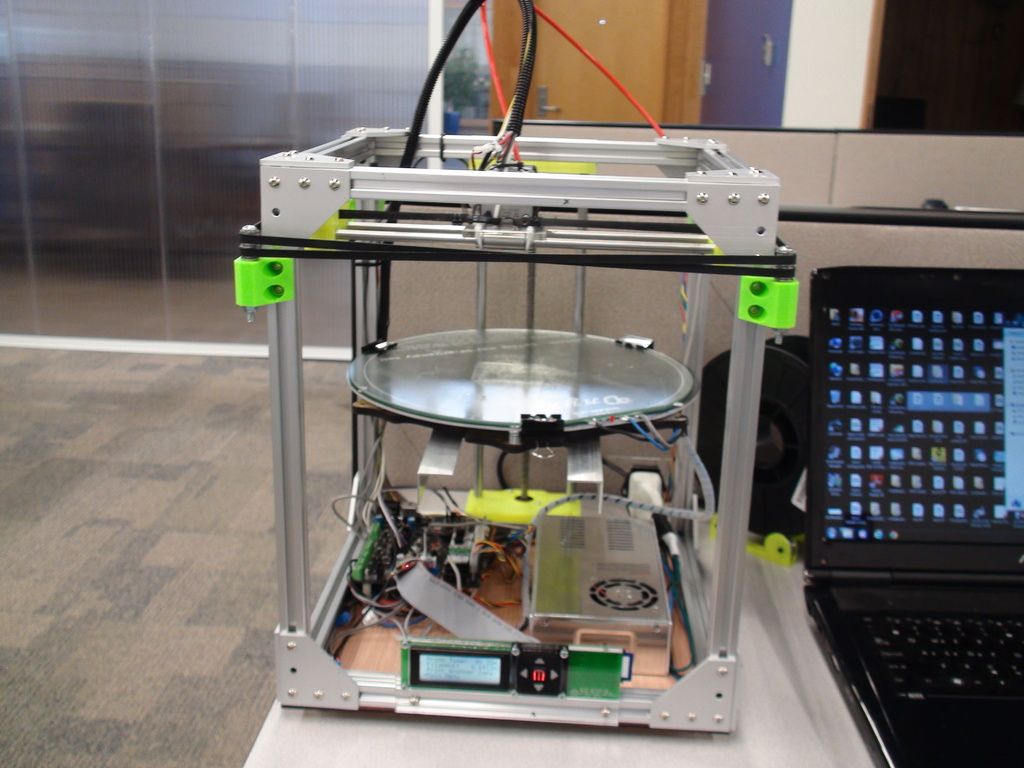

The Modix BIG-Meter offers over one cubic meter of build volume. As all Modix printers do, the BIG-Meter is delivered as a self-assembly kit, which contributes to the printer’s relatively low price point.

This large scale 3D printer comes with a dual extruder (E3D Aero and E3D Volcano print heads), full automatic bed leveling (bed tile and bed mapping), a Wi-Fi controller, and a range of industrial-grade components. The print bed heats up to 120°C.

The print bed heats up to 120°C.

Buy on Modix Get a quote Add to comparison

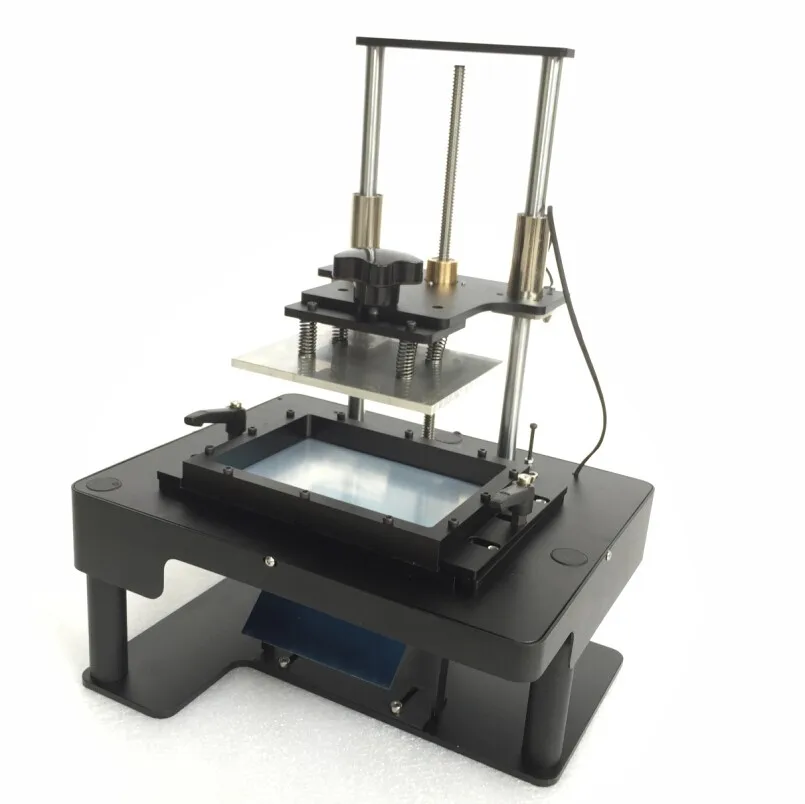

The F1000 from CreatBot offers a full cubic meter of fully enclosed and heated (60°C) build volume. There’s also a filament chamber that can hold two spools of up to 5kg each and heat up to 45°C or 65°C.

Its dual nozzles are able to heat up to 420°C, while the print bed heats up to 100°C. Compatible materials range from standard PLA and ABS to PETG and carbon fiber-filled and flexible materials.

Contact manufacturer Get a quote Add to comparison

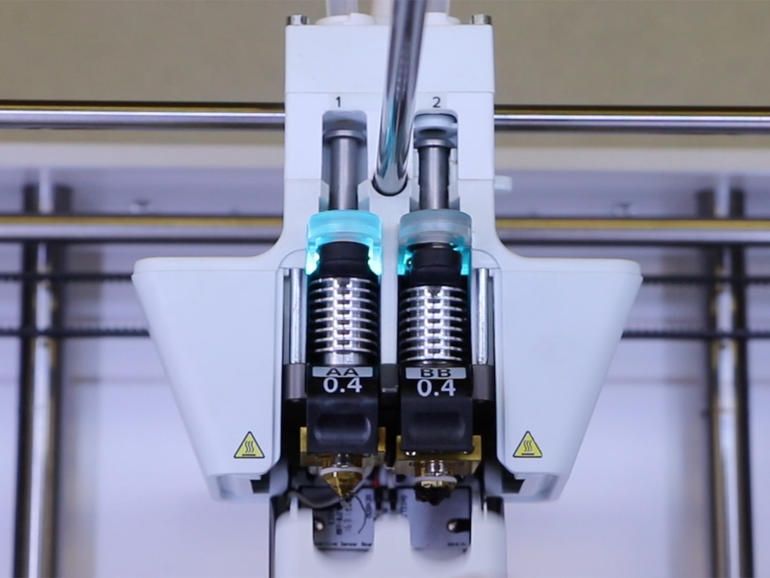

The BigRep ONE, currently in its third generation of upgrades and updates, is one of the only large-sized 3D printers to provide independent dual extrusion (IDEX). IDEX can cut production times in half thanks to duplication or mirror modes.

The printer’s large touchscreen grants access to the webcam and allows users to resume prints even after a power outage. The filament holder is able to hold multiple spools of up to 8kg.

Contact manufacturer Get a quote Add to comparison

This large format 3D printer with dual extrusion is customizable. Various extruders are available, and it’s possible to add an enclosure. The enclosure can be heated and/or include an air filter as well.

Various extruders are available, and it’s possible to add an enclosure. The enclosure can be heated and/or include an air filter as well.

It’s possible to choose from two different control systems; with Wi-Fi or with Ethernet connectivity. The automatic leveling probe touches over 400 points on the print bed to ensure optimal calibration.

Contact manufacturer Get a quote Add to comparison

The T3500, a huge delta 3D printer, offers a massive build size that can 3D print to an exact scale of 1:1 up to 2.1 meters high.

The large-scale Tractus3D T3500 can 3D print exotic materials with its hot-end extruder capable of reaching up to 300°C. This 3D printer features a heated bed and can be equipped with an optional dual extruder.

Contact manufacturer Get a quote Add to comparison

The Industry MAGNUM is a very large format 3D printer by The Industry (previously called BLB Industries), a manufacturer based in Sweden. This XXL 3D printer offers a build volume of 2. 16m³ and comes with a set of nozzles ranging from 2 to 8mm in diameter. The MAGNUM is based on the company’s previous model, the BLB Industries THE BOX.

16m³ and comes with a set of nozzles ranging from 2 to 8mm in diameter. The MAGNUM is based on the company’s previous model, the BLB Industries THE BOX.

Contact manufacturer Get a quote Add to comparison

The Massivit 10000 is an industrial large format 3D printer produced by MASSIVit 3D. MASSIVit 3D is a 3D printer manufacturer based in Israel. This 3D printer offers a build volume of 1420 x 1110 x 1500 mm.

Contact manufacturer Get a quote Add to comparison

Modix has nicknamed their printer “Personal Car Factory”, a quick way to indicate how big the MAMA (Modular Additive Manufacturing Assembler) system really is. It’s equipped with a high-speed pellet extruder, and is also capable of 3D printing with spools of filament.

This huge FFF 3D printer isn’t available yet.

Contact manufacturer Get a quote Add to comparison

Applications for large scale 3D printing

3D printing furniture

The largest 3D printers can be used to 3D print furniture in one go. This includes tables, chairs, and even bathtubs. 3D printing furniture can also generate unique, complex pieces that would be difficult to create otherwise.

This includes tables, chairs, and even bathtubs. 3D printing furniture can also generate unique, complex pieces that would be difficult to create otherwise.

Hence, customized furniture is becoming more and more accessible thanks to extra-large 3D printers.

The BigRep One is in action. Source: QMES3D printing large prototypes

The professional large-scale 3D printers featured in our article can also be used to 3D print large prototypes. This enables businesses to test out their products before actually launching production. Industrial designers and engineers are able to perform more revisions in significantly less time.

They can test their future products extensively while at the same time reducing the production-to-market time.

3D printing production series

Large-scale 3D printers don’t have to exclusively 3D print large objects and prototypes. Their huge build platform also enables 3D printing big series of smaller objects.

Customized large scale 3D printers

There are several manufacturers that mainly offer tailored solutions rather than standardized 3D printer models. Tobeca, for instance, is a French team that builds 3D printers from scratch and is based entirely on their customers’ needs and requirements.

US-based Erectorbot also provides on-demand builds, although they do have a lineup of standard models. Then there’s Colossus, a company in Belgium that constructs 3D printers within shipping container-like structures. CNC Barcenas, a Spanish manufacturer, also offers tailored, large-scale 3D printers with a range of options to choose from.

Welcome to 3D Platform

3D Printing Case Studies

Alstom and Amtrak

Alstom and Amtrak

Prototyping the train cockpit

Read More. ..

..

Highland Community College

Highland Community College

Aiding higher education, inspiring elementary students, and connecting with local organizations.

more...

Idaho Virtualization Lab: Giant Spider

Idaho Virtualization Lab: Giant Spider

IVL uses large 3D printed parts to create stunning exhibits.

more...

Idaho Virtualization Lab: Prehistoric Fish

Idaho Virtualization Lab: Prehistoric Fish

Idaho Virtualization Lab (IVL) 3D prints a giant Prehistoric Fish

more...

PBC Linear Factory Model

PBC Linear Factory Model

Using 3D printed models to diagram the new manufacturing facility

Read more...

Ridoret Group

Ridoret Group

Window prototypes and manufacturing

Read More...

Sunnyslope High School

Sunnyslope High School

Components for robotics competition

Read More. ..

..

C7 Cabon

C7 Cabon

Prototypes and consumer-ready car parts

Read More...

PBC Linear

PBC Linear

Ramp fixtures for shop floor

Read More...

Rapid 3D: Not So Miniature

Rapid 3D: Not So Miniature

Radio-controlled truck body

Read More...

3D Printing Tech

3D Printing Tech

Giant Coke bottle promotion

Read More...

Fox Sports Robot

Fox Sports Robot

Larger-than-life FOX Sports Robot

Read More...

Thermoform

Thermoform

Large thermoforming dies

Read More...

Progress Rail

Progress Rail

Casting and machining tool mock-ups

Read More...

Thingergy

Thingergy

Specialty item techniques

Read More...

Warwick Drone

Warwick Drone

Seven-foot drone

Read More. ..

..

Titanic Design

Titanic Design

Full sized models

Read More...

Innovative 3D

Innovative 3D

Metal parts with complex shapes

Read More...

Gonzaga University

Gonzaga University

Ankle Foot Orthosis

Read More...

XFAB Printing Lab

XFAB Printing Lab

Marine Corps capitalizes on 3D Printing technology.

more...

Large build volume

3D Platform is committed to making your biggest ideas a reality. We design products that push the limits of innovation, and that’s why we are a leader in the manufacturing of large format, industrial-strength 3D printers. A widening variety of industries in manufacturing, entertainment, and academia have continued to take full advantage of these large format printers to create prototypes, mass-produce products, and build the future.

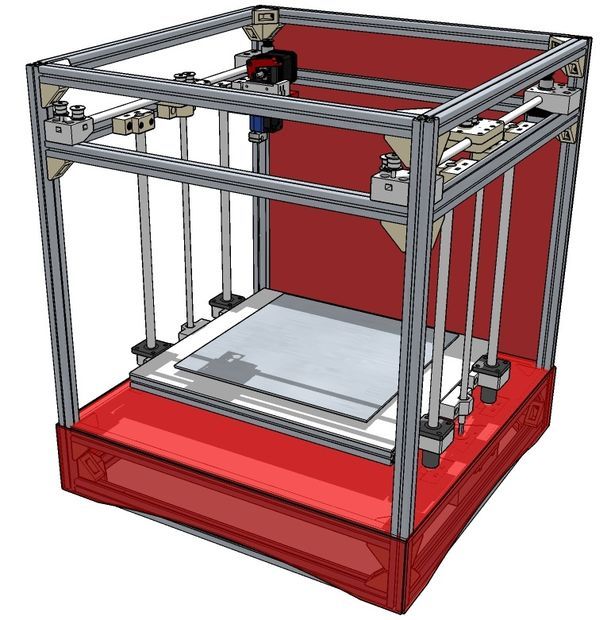

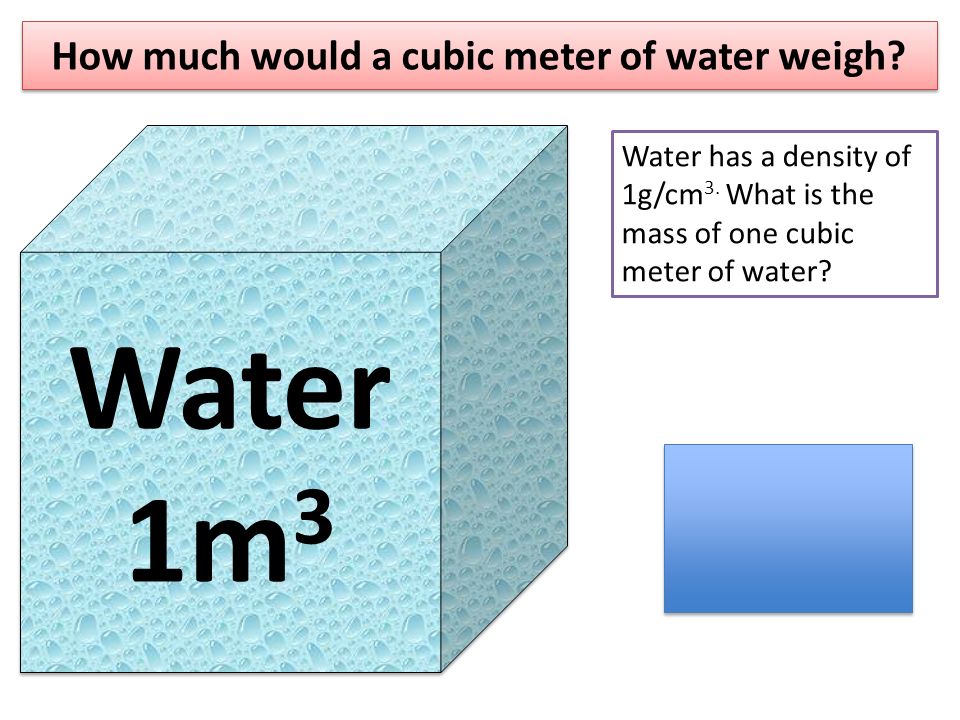

What is large? Our large build area is up to 1 meter x 1. 5 meter x 0.7 meter. This offers over 200-percent more creative space than a typical desktop 3D printer, and means our customers don’t have to scale down or print multiple parts that require assembly. In addition, a large build area can incorporate rapid design iterations to vastly reduce market entry time.

5 meter x 0.7 meter. This offers over 200-percent more creative space than a typical desktop 3D printer, and means our customers don’t have to scale down or print multiple parts that require assembly. In addition, a large build area can incorporate rapid design iterations to vastly reduce market entry time.

Traditional desktop 3D printers are fine for prototyping parts, but can be costly in terms of volume production and time-to-market. In contrast, industrial manufacturers can customize our large format 3D printers, providing the ability to produce near-net shape parts. The result is decreased costs and reduced time-to-market.

Large format 3D printing made easy

Don’t let the words industrial strength or large format scare you! Printing with 3DP can be as easy as easy as 1 - 2 - 3D! Learn the different steps on how to successfully create a 3D print by watching our video 1-2-3D Printing.

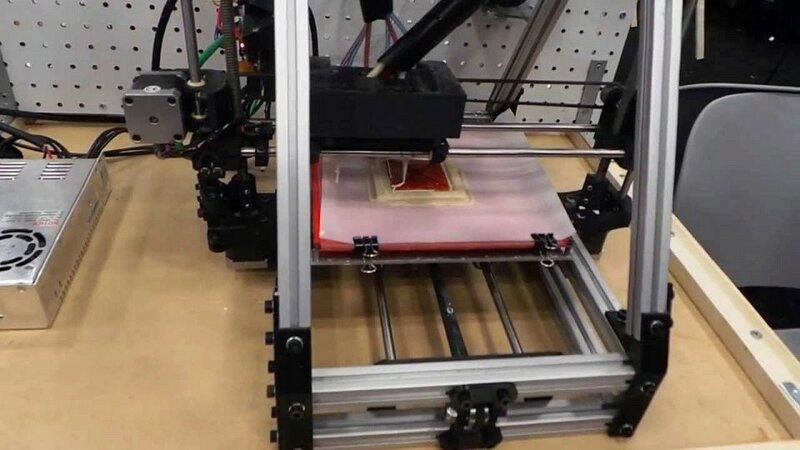

Create your 3D model. Start with a 3D model that was either created in 3D modeling software or download from the internet. Next, save the model as an OBJ or an STL file. The 3D printer processing software best understands these file types.

Next, save the model as an OBJ or an STL file. The 3D printer processing software best understands these file types.

Process the model in 3D printing software. Import the file and set a few standard model modifiers such as the number of top and bottom layers, perimeters, and infill. Next, increase the strength in the infill box by setting the interior fill percentage to 20 percent. If supports are needed, they can be added by clicking the “generate support material” button. Click “Ok” to accept the process settings and observe the model with its new layer slices. Finally, save the file in g-code format, which gives the printer step-by-step instructions.

Send file to printer. Heat the bed and remember to home the axes prior to each print. Next, select the g-code file. Once the target temperature for the extruder is reached, then the print will begin. Watch the first few layers to make sure the print adheres to the build area and that the filament is flowing smoothly.

Unmatched speed with 3DP extruders

Push your additive manufacturing to new heights with 16-times the speed of competitors’ extruders. Current market extruders are limited in terms of their thermal capacity, therefore making them insufficient in their abilities to melt and dispense filament rapidly. They typically have an average throughput of 36 grams per hour. In contrast, our HFE 900 high flow extruders can provide a throughput of 1,350 grams per hour, resulting in a substantial decrease in 3D print time.

Our flexible line of extruders allows you to change nozzles depending upon your application and purpose. Use a small diameter nozzle for fine layer resolutions or go bigger with large diameter nozzles for fast printing and strong parts. Modular designs can accommodate filament sizes from 1. 75 mm to 6 mm and nozzles sizes from 0.2 mm to 5 mm. In addition, quick-swap dual extruder heads deliver high quality 3D prints while being independently controlled for speed and extruded material amounts.

75 mm to 6 mm and nozzles sizes from 0.2 mm to 5 mm. In addition, quick-swap dual extruder heads deliver high quality 3D prints while being independently controlled for speed and extruded material amounts.

Reliability with the open market advantage

Technology used for commercial-grade products won’t work for production applications. Therefore, companies need to answer the demands of reliability and performance by utilizing industry-proven mechanical and electrical components. For this reason, 3DP offers motion system technology that improves cycle time and final part quality.

3DP is harnessing the energy of a global network of material scientists by using open market solutions. Within these open markets, skilled experts blend various polymers to achieve specific end goals for certain projects. Additionally, open software markets can spark innovation by providing real-time 3D printed models that can be easily accessed and shared. Open source and reliability are why top industry leaders look to 3D Platform to stay competitive in demanding markets.

Go big with the power of innovation

Think BIG, Print BIG, Save BIG! 3D Platform is using innovation to create large format 3D printers that are sized to meet any need. Take a look at the future of 3D printing!

WorkCenter 500 Series – This extra-large format 3D printer not only boasts a bigger build area, but it’s also affordable. The extra-large build volume of 1,400 mm x 2,800 mm x 700 mm provides affordability, but without sacrificing quality or throughput. The WorkCenter 500 is currently the only machine in the large format category to provide the option of pellet or filament extruder(s) – or both!

WorkCell – Our large format 3D printer with heated enclosure is currently in the design process! With a print volume of more than 1 cubic meter, the WorkCell’s heated enclosure will enable users to go beyond polymers that are typically printed in an open ambient environment, including commodity plastics, engineered plastics, and high-performance plastics.

Blog Posts from 3D Platform

3D Printer Configurator

Request a Sample

high performance low cost industrial 3D printer

The CreatBot F1000 is an industrial size 3D printer with auto-elevating dual extruders, 1000x1000x1000mm build volume and other great features at a lower price than other brands.

Large scale FDM 3D printers tend to be expensive, especially those capable of printing high quality models using professional grade materials. The high price tag of these massive industrial machines has kept many small businesses and manufacturers from using 3D printing technology to create prototypes or even make functional parts.

The new CreatBot F1000 aims to make large-scale 3D printing more accessible. How? Combining serious print volume and an impressive array of professional features with a secret ingredient – affordability.

CreatBot F1000: large build volume and smart features

CreatBot F1000 offers a full cubic meter of build volume (1000 x 1000 x 1000 mm) as well as:0018

Accuracy and reliability make the CreatBot F1000 a terrific option for both industrial and professional users who need to print large prototypes or functional parts in one go.

One cubic meter for 3D assembly is quite a lot. Such a space could allow 3D printing of small production runs or huge prototypes, or even mass production of standard quality products! Here is one of the happy customers of the F1000 3D printer:

Besides the outstanding build volume, there are a few other big features that make this new big 3D printer a big deal (pun intended). The CreatBot F1000 features new dual auto-elevating extruders, a heated enclosed chamber, an auto-leveling system, and a built-in monitoring system that allows you to control your printing process with an easy-to-use app.

This massive workhorse also features a fast build plate heat that, together with a heated chamber, produces incredible results from professional quality materials. Needless to say, the CreatBot F1000 sets a new standard in additive manufacturing and expands the material capabilities of large-scale FDM 3D printers, which in turn saves our customers significant time and money.![]()

The CreatBot F1000 has more than enough capacity for all real-world applications

The CreatBot F1000 is designed to make 3D printing large-scale objects and prototypes as easy as possible. This industrial 3D printer is the answer to growing market demand across a range of industries.

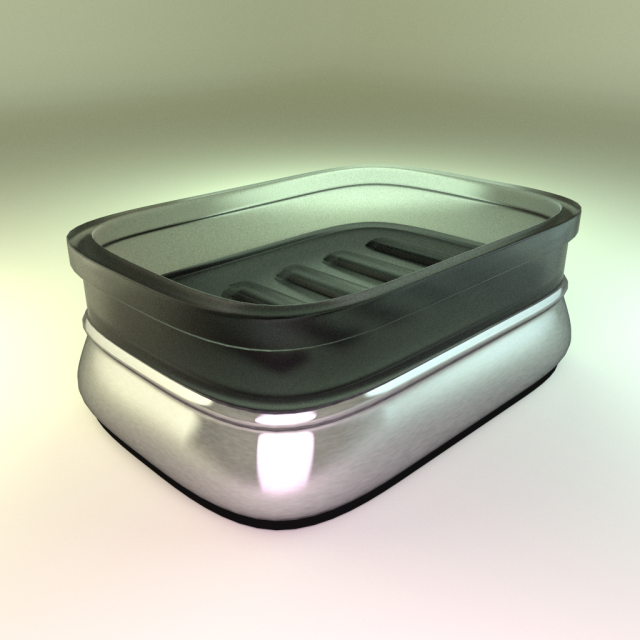

The F1000 has recently been printed with a large theme park snake head (pictured). The result was a high-resolution object, one meter high and weighing 35 kg. Can you imagine how this huge 3D printer prints such a heavy model 24/7? A nozzle with a diameter of 1.5 mm was used, it took more than 200 hours to print.

There are many other examples of real work CreatBot F1000 in professional conditions. For example, one global supplier of advanced automotive systems and equipment used the CreatBot F1000 to design and develop molds for Audi, Volkswagen, Nissan, and GM car seats.

This video shows how these forms are printed. The bowl and lid must withstand pressure up to 100 MPa, so 50% nylon carbon fiber materials were used for production. The final accuracy of the model was +0.1 mm and passed the rigorous tests often required in the automotive industry.

The bowl and lid must withstand pressure up to 100 MPa, so 50% nylon carbon fiber materials were used for production. The final accuracy of the model was +0.1 mm and passed the rigorous tests often required in the automotive industry.

The mold cover took 120 hours to 3D print and weighed 9 kg. The size of the part was 820 × 748 × 160 mm.

The mold bowl took 200 hours and weighed 16 kg. The size of this part was 820 × 748 × 200 mm.

After test runs, the performance of the CreatBot F1000 proved to be on par with or even better than some well-known brands of industrial 3D printers from Germany or the USA, with the difference, however, that this printer is more than three times cheaper than competitors. Someone now regrets buying expensive large-scale 3D printers instead of the impressively inexpensive and equally capable CreatBot F1000!

Without a doubt, the CreatBot F1000 is the best choice for an industrial large scale 3D printer that can handle engineering grade materials.

Specifications CreatBot F1000

| Displacement | 1000 × 1000 × 1000 mm |

| Extruders | Automatic rising double extruder |

| Minimum layer thickness | 0.05 mm |

| Maximum print speed | 120 mm/s |

| Maximum nozzle temperature | 420°C |

| Maximum platform temperature | 100 °C |

| Maximum temperature of assembly chamber | 60°C |

| Filament storage temperature | 45/65°C |

| XY positioning accuracy | 11 µm |

| Z positioning accuracy | 2. |

| Dimensions | 1740 × 1300 × 1920 mm |

| Weight | 550 kg |

ROBOZE INTRODUCES ARGO 1000 3D PRINTER WITH 1 CUBIC METER HEATED CHAMBER

THE NEW PRINTER WAS DESIGNED TO PRODUCE LARGE POLYMER AND COMPOSITE PARTS FOR INDUSTRIAL APPLICATIONS.

The Italian manufacturer of industrial 3D printers has unveiled the new ARGO 1000 system, which it calls "the world's largest heated chamber 3D printer". The system is expected to be commercially available in 2022.

ARGO 1000 is the third 3D printing system in the Roboze production series and complements the smaller format platforms ARGO 500 and ARGO 350. , Carbon PEEK and ULTEM AM9085F, which the company believes will reduce the current pressure on global supply chains by quickly replacing metal parts and critical components for extreme applications.

"After years of specializing in superpolymers and high temperature composites and paving the way for the future of industrial 3D printing, we are excited to introduce our flagship production series solution, the ARGO 1000," said Alessio Lorusso, founder and CEO of Roboze. As we announced a new North American headquarters earlier this year, we have grown our global customer base and invested in R&D to meet customer demand for a much larger heated chamber superpolymer 3D printer."

Main features of ARGO 1000:

heated and controlled working chamber 1000 x 1000 x 1000 mm;

process control at CNC machining and injection molding level, resulting in 99.96% accuracy and repeatability of parts produced on multiple machines;

Significant reduction in production time due to comprehensive monitoring capabilities, remote diagnostics and predictive maintenance;

continuous remote updates for continuous performance improvement;

Certification of each manufactured part using the comprehensive Print Log System, which tracks all parameters, temperatures and factors involved in the process to create a digital model of the manufactured part;

over 10 media options including PEEK, Carbon PEEK, Carbon PA and ULTEM AM9085F;

dual extruder capable of printing dissolvable and tear-off supports;

supply up to 8 kg of material with automatic change if the material runs out during the printing process;

remote control of the machine and interaction with production ERP systems.

Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …).

Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …).

5 µm

5 µm