Zprint 3d printer

Zcorp 3D Printer Review 2022

3.9

See Price

Although manufacturer ZCorporation no longer exists, the company’s range of printers stays a reference in the annals of 3D printing history for bringing full-color printing to the forefront of 3D possibilities.

Among the shining lights of this revolutionary series of printers is the ZCorp Z450 and today we’ll focus on this very model to determine how well it stacks up to trials and tribulations of time. Let’s jump in and find out what this 3D printer has to offer.

| Printing Area | 203 mm x 254 mm x 203 |

| Layer Resolution | 90 – 100 microns |

| Supported Filament | ZP130 Powder and ZB59 Binder |

| Printing Technology | 3DP/ZPrinting/ColorJet Printing |

| Resolution | 300 x 450 dpi |

Table of ContentsShow

Design & Features

Visually, the ZCorp Z450 isn’t the most appealing and is very much a product of tech production of the early 2010s with a rather uninspiring grey scheme covering the entire unit only interrupted by a questionably stylish orange near the control panel.

Rather than relying on Fused Deposition Modelling, the Zcorp Z450 is based on a patented additive manufacturing technology known as 3DP, ZPrinting, or ColorJet Printing depending on who you ask.

The basic tenet of the process involves a print head – very similar to that found in traditional inkjet printers – selectively laying down a liquid binding material on a thin layer of powder causing it to solidify into a specific shape and design. The main upside of the technology is a near limitless use of color because the inkjet selectively colors the binder from a range of 180,000 individual shades before applying it to the powder.

When the shape has been etched into the powder, the print bed lowers down ushering in a fresh layer of powder spread thanks to a roller for the process to repeat itself. Add up all these layers, dust off any extra powder, and you get a full-color 3D model. The results can include graded color fades, intricate patterns, and near lifelike color renditions.

The innards of the printer are divided into two chambers one for building and one for fine-powder removal. Nearing the end of the build process the first chamber runs a cursory powder removal cycle that removes the bulk of the excess powder. When the model is dry, it is moved to the second chamber where a stronger, deeper removal process cleans off any remaining powder.

The build area of the Z450 totals in at 203 mm x 254 mm x 203 for an entirely respectable surface area that is in line with similarly sized printers, but doesn’t set any records. A happy middle ground if you will. It can print up to 23 mm per hour with a layer resolution range of 90 to 100 microns and a print resolution of 300 x 450 dpi.

In what is undoubtedly the most significant negative of the Z450, the printer is only compatible with ZP130 Powder and ZB59 Binder materials. In itself, this isn’t an issue as there are many printers on the market with proprietary material limitations. The problem here is that buying the powder and binder is a bit like finding a needle in a haystack. Vendors are out there, but they charge a pretty penny for the materials.

Vendors are out there, but they charge a pretty penny for the materials.

An LCD controlled by a wheel knob sits on the front of the printer providing an array of functions ranging from de-powdering, status details, and platform raising controls. Connectivity is assured via Ethernet.

The printer runs alongside the ZPrint software that acts as both a slicer and interface to communicate with the printer. It can read STL, VRML, PLY, 3DS, ZPR file types and is compatible up to Windows 7 or older. The software isn’t innately shoddy but does show its age with an absence of functions and tinkering options we’ve come to expect from modern slicing software.

Assembly & Unpacking

Due to its 193 kg total weight and 122 cm x 79 cm x 140 cm dimensions, the Z450 falls into the crate shipped printer category, and this is precisely how the model was delivered when it was still being manufactured and how we took custody of it second hand.

The printer comes fully assembled other than fitting a new printhead and replacing the binder/powder cartridges. Both operations are straightforward and reminiscent of a standard inkjet printer in their simplicity.

Both operations are straightforward and reminiscent of a standard inkjet printer in their simplicity.

Printing

The Z450 produces high-quality prints with an eye-watering range of colors that put standard FDM 3D printers to shame. The printing process is also extremely streamlined due to the arrangement of the chambers and their various dry, vacuum, and print functions. The printer is also very waste conscious and automatically reuses excess powder. The added vacuum nozzle also works admirably for manual powder clearing.

Where this printer truly shines is in the speed of the printing process. In what is near enough twice the rate of traditional 3D printers, the Z450 is the fast prototypers dream with the ability to produce conceptual parts very quickly.

The models look and feel amazing, but there is a certain frangibility to them that is absent in PLA or ABS models for example. There’s a distinct sense that beyond being a visual representation of an idea or model, the prints from the Z450 won’t fare well being handled for practical uses or mechanical purposes, even as a functional proof of concept.

Support

In light of 3D Systems taking over Z Corporation and manufacturing of the Z450 long since abandoned, official support is unavailable. Any warranties for new units have long since expired with the chances of obtaining one is confined to merchants and auction sites flogging the printer second hand. These vendors may offer other warranties so check before committing to a purchase.

It is, however, possible to successfully hew through successive Google search pages to find advice and tips for using the Z450. Among these are niche communities of users who vow by the Z450 for all their printing needs. The difficulty lies in tracking them down.

The user manual is also a great source of information for troubleshooting problems and maintenance guidelines.

Verdict

In our eyes, the Zcorp Z450 is geared towards fast prototyping for design concepts, architectural models, form-and-fit prototypes, and demonstration pieces. Within these spheres, the Z450 performs admirably, but the questionable reliability of the end product with a propensity for being unduly brittles means practical uses are out of the picture.

Equally, a hobbyist who wants reliable models for either ornamental purposes will find use in the Z450 but venture even slightly into application based printing, and this model falls short.

The real allure of the Zcorp 3D printer is that it is possible to pick one up for a fraction of the retail price (approximately around $40,000 at its peak price). We are talking less than a $1000, if not less.

A hobbyist who wants a printer with powder/binder-based technology to add to their workshop should strongly consider the Z450 for its reliability and low cost.

ZPrinter 150 3D Printer - Buy 3D Printer

Zcorp 3D printers utilizing the jetting technology are among the fastest professional printers on the market. Speed is what makes Zcorp printers truly unique. These are professional-grade, “no messing around” 3D printers.

Zcorp has a whole line of 3D printers from the pint-sized Zprinter 150 to the industrial workhorse Zprinter 850. They all use the same technology and are relatively inexpensive for a non-hobbiest 3D printer.

Zprinter 150

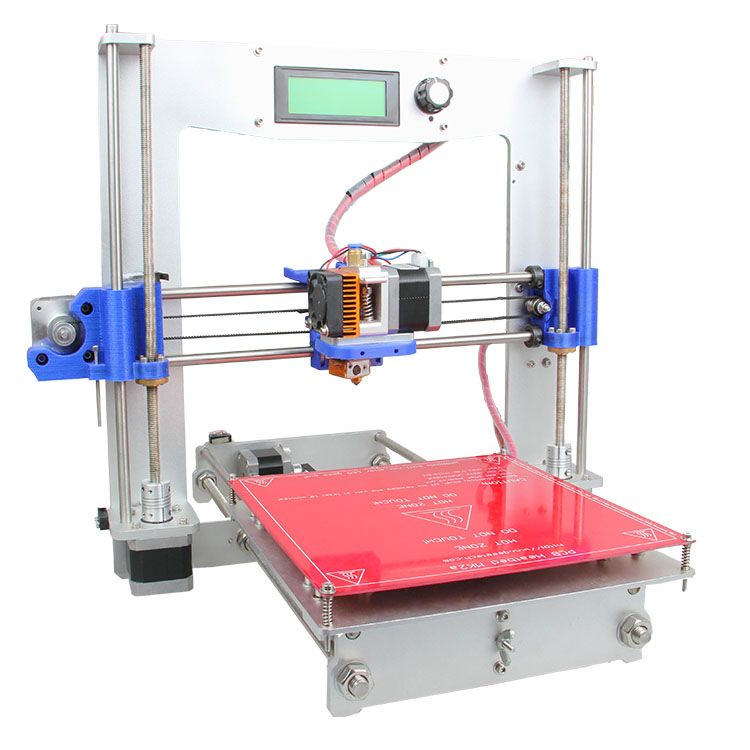

How do Zcorp 3D printers work?

The printers utilize 3D inkjet printing, or jetting. It works by mimicking 2D inkjet printing – tiny specks of fine material are deposited onto a build platform through a printing head that resembles the one 2D printers use.

There are two sub-types of 3D inkjet printing: one which deposits a binder on a powder bed, and one which deposits powdered build material on a platform. Zcorp 3D printers utilize the latter process, letting you create models with high resolution and a smooth surface at high speeds.

However, jetting also has some disadvantages. One of them is a high cost of support material. As well, jetting printer materials are typically sub-par compared to conventional materials. Zcorp solves the latter problem with a high performance composite as its main material on its line of Zprinters.

The following video demonstrates Zcorp 850’s printing process:

ZPrinter 150 Tech Specs:

| Technology | Jetting |

| Frame size (Width x Depth x Height) | ~ 29" x 31" x 55" |

| Weight | ~ 365lbs |

| Build materials | High Performance Composite |

| Vertical Build Speed | Up to 0.8" / hour |

| Accuracy | 0.1mm |

| Build volume (X,Y,Z) | 9.3" x 7.3 " x 5" |

| Price | Starting at $14,900 at EMS USA store, call 704-527-8171 to purchase materials. |

Contacting Zcorp:

ZCorp as a separate business entity was purchased by 3D Systems in early 2012. You can see the line-up of Zcorp printers at www.zcorp.com.

The 3D Systems Corporate Headquarters:

333 Three D Systems Circle

Rock Hill, SC 29730 USA

Tel: +1 803 326 3900

Twitter: @ZPrinting

Just getting started? Check out the following 3D printing:

User’s Guide to Rapid Prototyping

Looking for some training and other resources? Anvil Prototype offers seminars and other information on the ZPrinter series.

ZPrinter 150 Pros:

Zcorp 3D printer is very, very good. It’s fast, it’s accurate, and it’s cost isn’t exorbitant for a business model. The high composite material makes the ZCorp printers shine. The zp150 material can be sanded, drilled, tapped, painted and electroplated.

ZPrinters are professional models, which means that they don’t require tweaking and tuning. They will work when you plug them in. The Zprinter 150 is a very straightforward to use. Backed by a large company like 3D Systems, you can expect reliability and dependable support.

Zprinter 150 Cons:

The higher model ZPrinters, like the 850, can print in a range of colours, but unfortunately the Zprinter 150 can only print in monochrome white. It has only one printer head, so if colorful pieces are your thing, you may have to splurge on a beefier ZPrinter model.

The choice of material, while allowing for construction of robust parts, is still limited. The speed is dependent on the volume of prototypes – the larger the volume, the faster the process. For this reason you might want to stick to other printers if you wish to print small models.

For this reason you might want to stick to other printers if you wish to print small models.

Due to the nature of the support material process, the extraction of the finished part can be a bit of a hassle.

The bottom line:

The only real problem with the ZPrinter 150 is its limited material choice. Everything else – its speed, accuracy, surface finish, cost – is all on par with what you would expect from a professional grade 3D printer.

Sprint 3D is the No. 1 aggregator of 3D technologies in Russia.

Sprint 3D: 3D printing of any complexity

In 1983, Chuck Hull invented the world's first 3D printing process and called it "steleolithography". At that time it was a very expensive technology, the equipment was bulky, and its functionality was very limited. But as time went on, and today 3D printing of has become not only much more affordable, but also opened up completely new application possibilities. The opportunities that we have in the company Sprint 3D is already actively used. Welcome!

Welcome!

Our technologies and capabilities

We use the latest

Additative technologies , which allow the use of the most modern technological solutions:

- CJP - color jet printing;

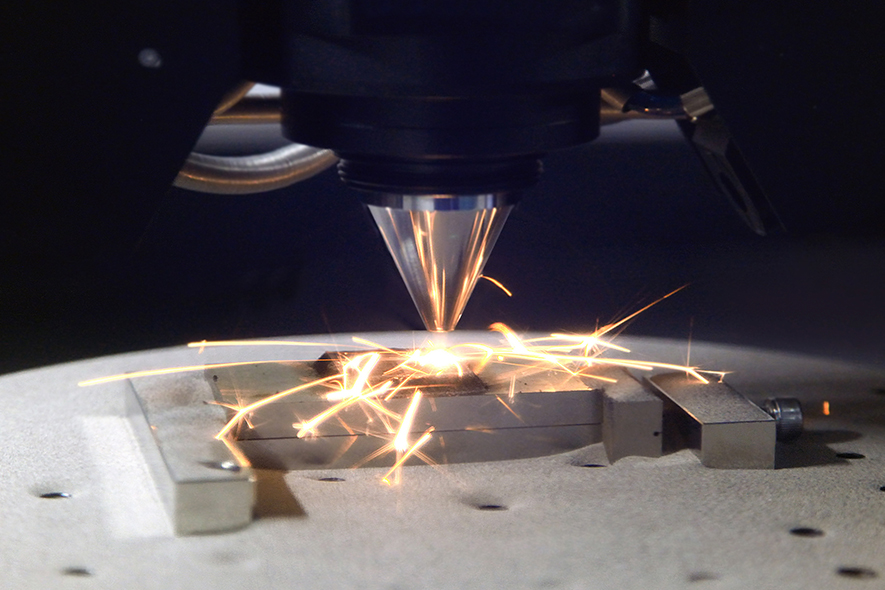

- SLM - selective laser melting;

- SLS - selective laser sintering;

- SHS - selective thermal sintering;

- DLP digital LED projection;

- MJM - multi-jet simulation technology;

- SLA - stereolithography;

- DMLS - direct metal laser sintering;

- FDM Fusion deposition modeling;

- SGC mask stereolithography;

- EBM - electron beam melting.

These terms may not mean anything to you. Do not worry, further we will more clearly describe what and how we do using the listed technologies.

For example:

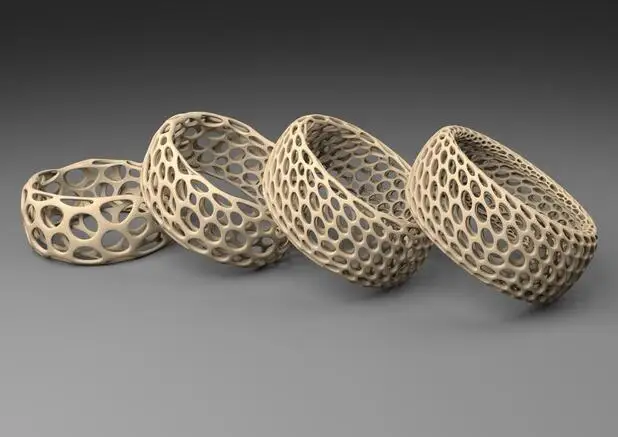

1. Figures of any complexity and original decorations : full-length sculptures, overall figures , park sculptures. Including full-height structures of any complexity - figures of people, animals, vehicles, real buildings, monuments and much more. And even whole complex compositions.

2. Business solutions : production of cases , goblets, corporate gifts, overall products, copies of architectural monuments. This also includes services prototyping , prototyping, reverse engineering and even the manufacture of dental structures based on photopolymers.

3. Artistic metal milling , which allows you to create products and parts with a highly complex configuration that is impossible or very difficult to create manually. At the same time, accuracy, quality and high speed of production are guaranteed.

4. Art molding with plastics and metals . We can produce high-strength products of any complexity and shape. We use it when creating souvenirs, parts for tools and equipment, accessories, medals, badges, etc. We can use different types of plastic, aluminium, bronze, brass and even silver and gold to create truly unique pieces.

Art molding with plastics and metals . We can produce high-strength products of any complexity and shape. We use it when creating souvenirs, parts for tools and equipment, accessories, medals, badges, etc. We can use different types of plastic, aluminium, bronze, brass and even silver and gold to create truly unique pieces.

5. Production of 3D figures: figures of people, animals, movie and cartoon characters, cartoon dolls and much more. We can make figurines according to the photos you provide. In production, a durable gypsum polymer is mainly used, which allows you to recreate in detail the shape, structure of the human body, his facial expressions, clothes and much more.

6. Non-contact 3D scanning. It allows you to convert absolutely any physical form into digital. You get a file that contains all the detailed information about dimensions, surface polygons, and so on. In the future, this file can be used for analysis, processing, production of a similar part in miniature or original size.

And this is not the whole list of Sprint 3D services. For you we are ready to fulfill 3D modeling and 3D scanning of any complexity for further application in 3D printing or for solving other problems. Using modern additive technologies , 3D modeling and printing, we create the most complex geometric shapes that cannot be realized manually. For example, parts for industrial units, equipment and machinery. Including components of space satellites.

Our important advantage is the full cycle production. That is, we do not transfer any parts of the work to third-party companies. First of all, it is cheaper for the client. And secondly, in this way we can guarantee the standardized quality of each of our products and provide a guarantee. Plus, the production time is reduced significantly.

We use not only the latest additive technologies, but also the best materials for 3D printing: polyamide, ABS plastic, PLA plastic, SBS plastic, metal, PMMA plastic, photopolymers, wax, FLEX plastic, colored plaster, aluminum and titanium. Materials are selected individually depending on what product needs to be made and what the client's wishes for a specific order. We can discuss all the details individually.

Materials are selected individually depending on what product needs to be made and what the client's wishes for a specific order. We can discuss all the details individually.

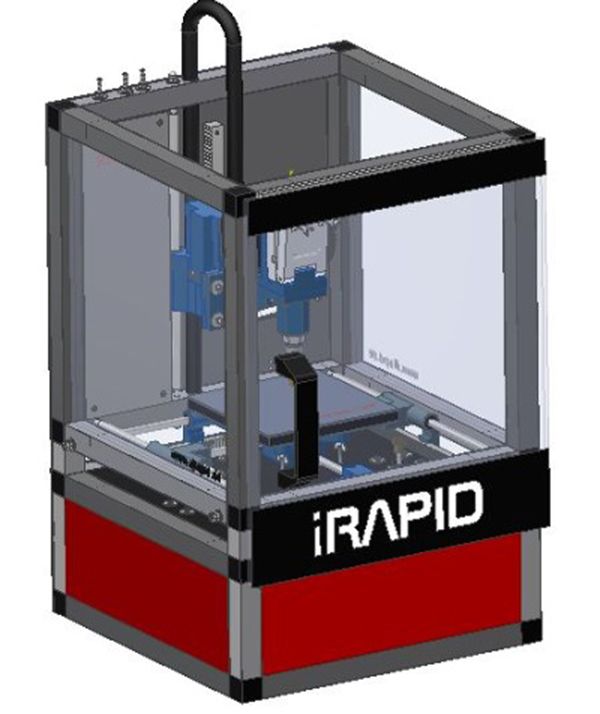

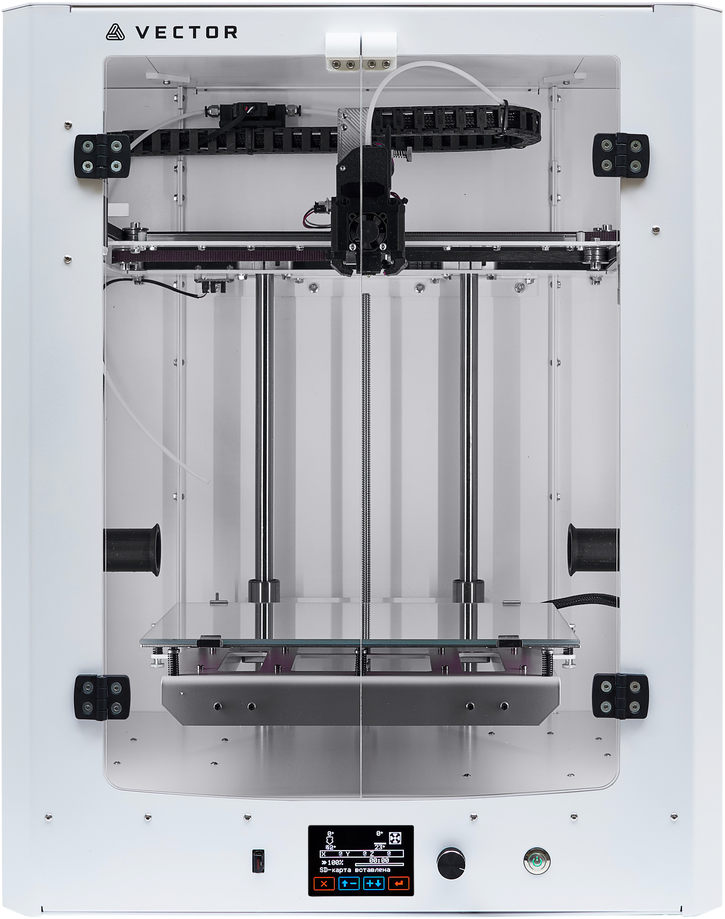

In-house solutions for the world of 3D printers

If most other companies working in the field of 3D printing and additive technologies use ready-made solutions, then we are going in a different, more advanced way. Sprint 3D creates and uses its own developments, which have received the best from the world of 3D technology and a number of our own innovations.

In our company you can order unique 3D printers SATELLITE 3D . This is a professional equipment with a large working surface - 500 x 500 x 800 mm, which is ideal for industrial purposes. At the same time, the device has a simple user-friendly interface, has two extruders, supports Smart sPrint smart printing technology and a modern Core XY positioning system.

Printer user benefits:

- automatic calibration in less than 60 seconds, allowing you to get to work very quickly;

- built-in computer that allows you to monitor the entire printing process, make the necessary settings and change them almost "on the go";

- possibility to print several parts at the same time;

- Wi-Fi remote control.

The rugged, closed aluminum housing allows the 3D printer to be used even in difficult production environments without any special restrictions. It also gives the structure better static and protects against vibrations during operation.

You can order a printer with delivery to your city, and we will provide any advice on its use and maintenance. We provide a guarantee to every client.

Why customers choose

Sprint 3D Today, not only private customers and small firms, but also real giants of industry, economy and production work with our company. Among our clients are Tinkoff Bank, Schwarzkopf, Rostelecom, EMERCOM of Russia, Knauf and others.

Among our clients are Tinkoff Bank, Schwarzkopf, Rostelecom, EMERCOM of Russia, Knauf and others.

Impeccable quality, meeting deadlines and fair prices are only a small part of the benefits that customers receive

Sprint3D . We offer much more to each of you:

- a huge range of services using additive technologies ;

- quality assurance for all types of products, regardless of volume and complexity;

- free advice on any production and 3D printing issues ;

- confidentiality of any information you provide;

- possibility to order test samples to demonstrate the quality and the expected result of production;

- flexible system of discounts and loyalty programs for regular or wholesale customers;

- professional technical support and maintenance of equipment purchased from us;

- equipment is always in stock in Moscow and St. Petersburg;

- flexible payment methods in any way convenient for you.

Ordering 3D modeling, printing and other services in our company, you will always be sure of the result. We work on a turnkey basis and provide quality control at all stages of production. Add to this the fact that we have 28 units of production equipment for 3D modeling and printing, which allows you to complete even the largest orders quickly, on time and without sacrificing quality.

And finally, a few words about us

We are young, ambitious, always keeping abreast of the latest trends in 3D printing and 3D modeling. Where other companies use outdated technology, we apply the latest technology solutions. And most importantly, we create our own, allowing you to always be one step ahead of your competitors. In addition, we constantly monitor market prices so that Sprint 3D offers are not only better than their counterparts, but also in line with current price trends.

If you have any questions or suggestions for cooperation, you want to discuss the production or purchase of equipment for use in your production, please contact our managers.

Phones for communication:

- 8 (495) 740-51-70

- (926) 190-51-70

We work on weekdays from 10:00 to 20 to 20 to 20 :00. You can also write to us at Email: [email protected], ask any questions through the form on the site or write to us on social networks. All information is available in the "Contacts" section. We will pre-calculate the cost and name the production time, if necessary, we will discuss the details of an urgent order, delivery of products across the territory of Russia and the CIS countries. We cooperate only with trusted transport companies, we guarantee the integrity and safety of all orders, regardless of complexity.

Follow the updates on the site, read our news, study examples of completed orders and order solutions for yourself and your business. Simply select the services you are interested in in the catalog and see what products we have already created for our customers. We can print everything on a 3D printer - from small souvenirs to complex monolithic structures of large volume. We are looking forward to your interesting orders and are ready to offer you a lot of interesting things!

We are looking forward to your interesting orders and are ready to offer you a lot of interesting things!

3D figures, 3D scanning, 3D modeling, 3D printing, 3D milling, molding, figures and decorations

Satellite 3D printer for sale

3D wax printing technology - uses

Modern industry is complex imagine without the basic methods of production - casting and 3D printing. In most cases, one technology can replace the other, but they work most effectively in tandem. 3D wax printing is used to create lost wax master models. The resulting blanks are used to produce molds for metal casting. The technique is suitable for the manufacture of jewelry and prototype parts for multifunctional equipment.

Wax 3D Printing Technologies

Before additive manufacturing, master models were made by hand, which was expensive and time consuming. Cast wafers are now made using MJP technology compatible with VisiJet resources.

The essence of multilayer modeling is as follows. The raw material is heated to the melting temperature and fed into the print head. Through small nozzles, the material is applied in layers to the working surface and hardens, after which the platform is lowered to the thickness of the layer. The head moves horizontally along the set trajectory. For protruding elements, special supports are installed, which are easily removed after the printout is completed. After removing the supports with a special solution, the sample is dried.

The raw material is heated to the melting temperature and fed into the print head. Through small nozzles, the material is applied in layers to the working surface and hardens, after which the platform is lowered to the thickness of the layer. The head moves horizontally along the set trajectory. For protruding elements, special supports are installed, which are easily removed after the printout is completed. After removing the supports with a special solution, the sample is dried.

Wax printing is also carried out using FDM technology. However, this method has a number of features and does not provide the required accuracy of the resulting master models.

What wax printing is used for

The discovery of 3D printing was a milestone for the classic casting process. Additive methods have diversified the possibilities of production and rationalized the technological cycle.

WAX is an environmentally friendly, harmless, soluble resource. The composition melts well and does not require complex post-processing, so it is ideal for printing stencils that faithfully reproduce the original sample.

Wax is used to print molds for technological equipment, functional prototyping, and molds for casting. The method is applied to release:

• jewelry;

• watch components;

• medical instruments and prostheses;

• Spare parts for the aerospace industry;

• Souvenir products.

Equipment

Wax printing is not possible on every 3D printer. Most requested modifications:

• The Projet MJP 2500W is a budget machine capable of producing several small batches per day or creating one large design. The compact device is designed for the production of high quality wax blanks. The device is often used in medicine, automotive and jewelry. Exclusive 3D Sprint software helps improve productivity and regulates the entire production cycle. The touch screen allows you to monitor the status of the print job and the amount of raw material remaining in the printer.

• The ProJet MJP 2500IC is an industrial casting solution used to create high quality, low cost wax products. HD mode optimizes image quality, prints with minimal support wax that can be easily removed with a hand brush. The device guarantees a low cost of finished products, therefore it is suitable for laboratory and research tasks. An intuitive interface plus an integrated touchpad allow you to quickly prepare for work, determine the amount of material, calculate the print time.

HD mode optimizes image quality, prints with minimal support wax that can be easily removed with a hand brush. The device guarantees a low cost of finished products, therefore it is suitable for laboratory and research tasks. An intuitive interface plus an integrated touchpad allow you to quickly prepare for work, determine the amount of material, calculate the print time.

• The ProJet 3600W MAX is a new product from 3D Systems designed for micro-detailed stencils. A reliable printing module guarantees the absolute repeatability of produced parts and their exact correspondence to the CAD model. The enlarged working chamber allows you to get larger objects or create several stencils in one series.

The high performance of 3D wax printers can significantly reduce prototyping time and reduce production costs. Printed models have smooth and even surfaces, high precision and filigree detailing. Waxes make it possible to create objects with complex geometry that cannot be reproduced by classical methods.

The advantages of wax 3D printers include:

• super speed printing;

• high level of detail;

• Availability of one-time construction of elements with different designs on the same desktop;

• impeccable layout accuracy;

• Possibility of round-the-clock operation;

• Comfortable to use.

Materials for 3D printing with wax

The WAX used to create waxes is similar to natural raw materials only in melting point and minimum ash content. 3D Systems proprietary materials are used for printing:

1. VisiJet M2-CAST is a compound designed to produce reliable, durable items. High-contrast dark purple color makes it possible to visualize the smallest elements.

2. VisiJet M3-CAST is a material that guarantees repeatability, wear resistance and strength of printed products. The resource allows the equipment to work with high performance.

3. VisiJet M2 SUW is a dissolvable, durable white support material for precision casting of jewelry or functional items.