Zcorp 3d printer for sale

Zcorp 3D Printer Review 2022

3.9

See Price

Although manufacturer ZCorporation no longer exists, the company’s range of printers stays a reference in the annals of 3D printing history for bringing full-color printing to the forefront of 3D possibilities.

Among the shining lights of this revolutionary series of printers is the ZCorp Z450 and today we’ll focus on this very model to determine how well it stacks up to trials and tribulations of time. Let’s jump in and find out what this 3D printer has to offer.

| Printing Area | 203 mm x 254 mm x 203 |

| Layer Resolution | 90 – 100 microns |

| Supported Filament | ZP130 Powder and ZB59 Binder |

| Printing Technology | 3DP/ZPrinting/ColorJet Printing |

| Resolution | 300 x 450 dpi |

Table of ContentsShow

Design & Features

Visually, the ZCorp Z450 isn’t the most appealing and is very much a product of tech production of the early 2010s with a rather uninspiring grey scheme covering the entire unit only interrupted by a questionably stylish orange near the control panel.

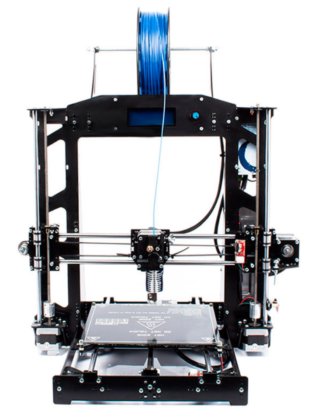

Rather than relying on Fused Deposition Modelling, the Zcorp Z450 is based on a patented additive manufacturing technology known as 3DP, ZPrinting, or ColorJet Printing depending on who you ask.

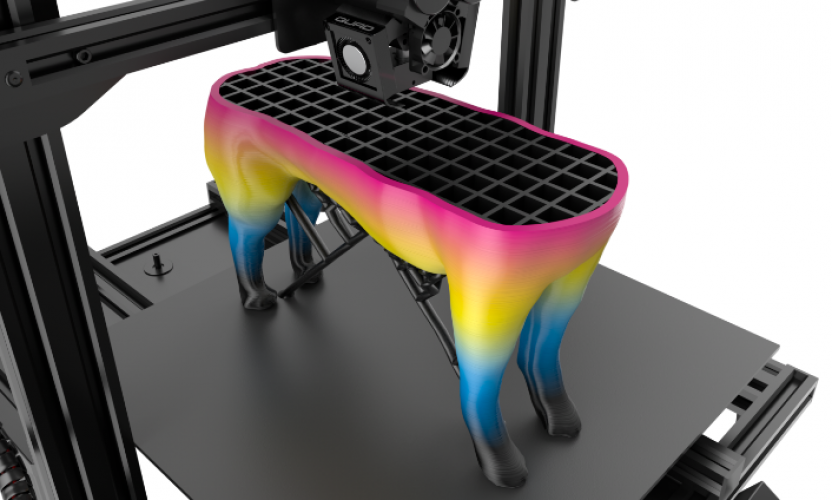

The basic tenet of the process involves a print head – very similar to that found in traditional inkjet printers – selectively laying down a liquid binding material on a thin layer of powder causing it to solidify into a specific shape and design. The main upside of the technology is a near limitless use of color because the inkjet selectively colors the binder from a range of 180,000 individual shades before applying it to the powder.

When the shape has been etched into the powder, the print bed lowers down ushering in a fresh layer of powder spread thanks to a roller for the process to repeat itself. Add up all these layers, dust off any extra powder, and you get a full-color 3D model. The results can include graded color fades, intricate patterns, and near lifelike color renditions.

The innards of the printer are divided into two chambers one for building and one for fine-powder removal. Nearing the end of the build process the first chamber runs a cursory powder removal cycle that removes the bulk of the excess powder. When the model is dry, it is moved to the second chamber where a stronger, deeper removal process cleans off any remaining powder.

The build area of the Z450 totals in at 203 mm x 254 mm x 203 for an entirely respectable surface area that is in line with similarly sized printers, but doesn’t set any records. A happy middle ground if you will. It can print up to 23 mm per hour with a layer resolution range of 90 to 100 microns and a print resolution of 300 x 450 dpi.

In what is undoubtedly the most significant negative of the Z450, the printer is only compatible with ZP130 Powder and ZB59 Binder materials. In itself, this isn’t an issue as there are many printers on the market with proprietary material limitations. The problem here is that buying the powder and binder is a bit like finding a needle in a haystack. Vendors are out there, but they charge a pretty penny for the materials.

Vendors are out there, but they charge a pretty penny for the materials.

An LCD controlled by a wheel knob sits on the front of the printer providing an array of functions ranging from de-powdering, status details, and platform raising controls. Connectivity is assured via Ethernet.

The printer runs alongside the ZPrint software that acts as both a slicer and interface to communicate with the printer. It can read STL, VRML, PLY, 3DS, ZPR file types and is compatible up to Windows 7 or older. The software isn’t innately shoddy but does show its age with an absence of functions and tinkering options we’ve come to expect from modern slicing software.

Assembly & Unpacking

Due to its 193 kg total weight and 122 cm x 79 cm x 140 cm dimensions, the Z450 falls into the crate shipped printer category, and this is precisely how the model was delivered when it was still being manufactured and how we took custody of it second hand.

The printer comes fully assembled other than fitting a new printhead and replacing the binder/powder cartridges. Both operations are straightforward and reminiscent of a standard inkjet printer in their simplicity.

Both operations are straightforward and reminiscent of a standard inkjet printer in their simplicity.

Printing

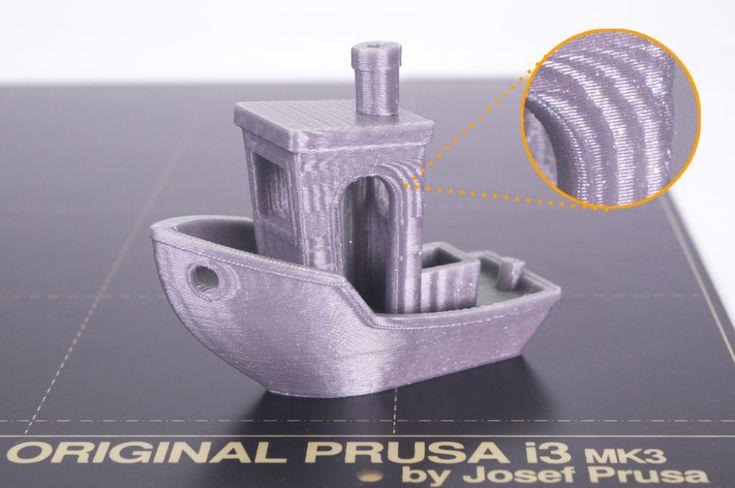

The Z450 produces high-quality prints with an eye-watering range of colors that put standard FDM 3D printers to shame. The printing process is also extremely streamlined due to the arrangement of the chambers and their various dry, vacuum, and print functions. The printer is also very waste conscious and automatically reuses excess powder. The added vacuum nozzle also works admirably for manual powder clearing.

Where this printer truly shines is in the speed of the printing process. In what is near enough twice the rate of traditional 3D printers, the Z450 is the fast prototypers dream with the ability to produce conceptual parts very quickly.

The models look and feel amazing, but there is a certain frangibility to them that is absent in PLA or ABS models for example. There’s a distinct sense that beyond being a visual representation of an idea or model, the prints from the Z450 won’t fare well being handled for practical uses or mechanical purposes, even as a functional proof of concept.

Support

In light of 3D Systems taking over Z Corporation and manufacturing of the Z450 long since abandoned, official support is unavailable. Any warranties for new units have long since expired with the chances of obtaining one is confined to merchants and auction sites flogging the printer second hand. These vendors may offer other warranties so check before committing to a purchase.

It is, however, possible to successfully hew through successive Google search pages to find advice and tips for using the Z450. Among these are niche communities of users who vow by the Z450 for all their printing needs. The difficulty lies in tracking them down.

The user manual is also a great source of information for troubleshooting problems and maintenance guidelines.

Verdict

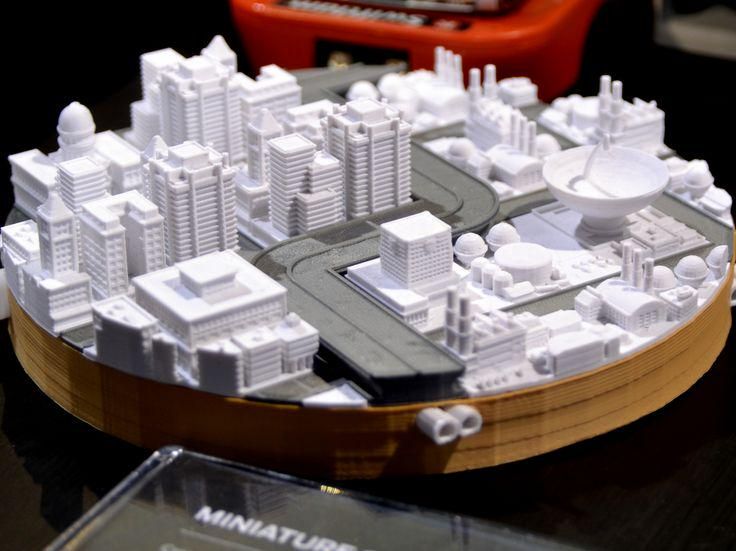

In our eyes, the Zcorp Z450 is geared towards fast prototyping for design concepts, architectural models, form-and-fit prototypes, and demonstration pieces. Within these spheres, the Z450 performs admirably, but the questionable reliability of the end product with a propensity for being unduly brittles means practical uses are out of the picture.

Equally, a hobbyist who wants reliable models for either ornamental purposes will find use in the Z450 but venture even slightly into application based printing, and this model falls short.

The real allure of the Zcorp 3D printer is that it is possible to pick one up for a fraction of the retail price (approximately around $40,000 at its peak price). We are talking less than a $1000, if not less.

A hobbyist who wants a printer with powder/binder-based technology to add to their workshop should strongly consider the Z450 for its reliability and low cost.

Used 3D Systems - Z Corp 3D Printers for sale

Düsseldorf, Germany

Düsseldorf, Germany

Düsseldorf, Germany

Düsseldorf, Germany

Düsseldorf, Germany

Düsseldorf, Germany

Düsseldorf, Germany

Düsseldorf, Germany

Düsseldorf, Germany

Düsseldorf, Germany

Düsseldorf, Germany

Düsseldorf, Germany

Düsseldorf, Germany

Germany

Z Corporation Introduces First Automated Monochrome 3D Printer

Z Corporation announces the launch of the world's first automated monochrome 3D printer, the ZPrinter 350.

Z Corporation's most affordable 3D printing device today makes advanced fast modeling technology even more accessible to a wide range of engineers and architects. Like all Z Corporation 3D printers, the ZPrinter 350 converts electronic data about a 3D object into a physical model in the same way that a conventional printer turns a text file into a paper document.

Unlike other 3D printers, only the ZPrinter 350 provides the following top quality 3D printing functionality:

- automatic media loading;

- quick release binder cartridges;

- complex processing of unused structural materials;

- self-diagnosis during operation;

- control from both a computer and a printer;

- vertical build speed 20 mm/h;

- working chamber size 203×254×203mm;

- resolution 300×450 dpi;

- consumables safe for indoor use; active dedusting, no liquid waste.

Available today, the ZPrinter 350 is the ideal choice for organizations looking for the best way to quickly create monochrome models in an office environment.

« ZPrinter 350 will bring cutting-edge 3D printing technology to a much larger number of design departments at a very affordable price, says CEO Z Corporation John Kawola. "Our 3D printing technology is designed to improve the quality of the products we develop, grow companies faster, and ultimately increase profits."

The new device brings all the benefits of Z Corporation's 3D printers :

- The has the lowest operating cost of its kind, five times lower than other technologies.

- Fastest print speed - Create models 5 to 10 times faster than other systems.

- Revolutionary Ease of Use - Automated most operations.

- High productivity - Easily print multiple designs at the same time; ensured efficiency required by design departments and educational institutions.

- High resolution - models with complex shapes and intricate details are possible.

- Safe, Indoor - No bulky props to dissolve with toxic chemicals or cut off.

Metal 3D Printing - A Fundamental Guide

There is no hotter trend in 3D printing today than metal. We will talk about metal printing at home, how it is done on an industrial scale, about technologies, applications, printers, processes, prices and materials.

Metal 3D printing has grown in popularity over the past few years. And this is quite natural: each material offers a unique combination of practical and aesthetic qualities, can be suitable for a wide range of products, prototypes, miniatures, decorations, functional details and even kitchen utensils.

The reason metal 3D printing has become so popular is because the printed objects can be mass-produced. In fact, some of the printed parts are just as good (if not better) than those made with traditional methods.

In traditional production, working with plastic and metal can be quite wasteful - there is a lot of waste, a lot of excess material is used. When an aircraft manufacturer makes metal parts, up to 90% of the material is simply cut off. 3D printed metal parts require less energy and waste is reduced to a minimum. It is also important that the final 3D printed product is up to 60% lighter than a traditional part. Billions of dollars could be saved in the aviation industry alone—mainly through weight savings and fuel savings.

When an aircraft manufacturer makes metal parts, up to 90% of the material is simply cut off. 3D printed metal parts require less energy and waste is reduced to a minimum. It is also important that the final 3D printed product is up to 60% lighter than a traditional part. Billions of dollars could be saved in the aviation industry alone—mainly through weight savings and fuel savings.

So, what do we need to know about metal 3D printing?

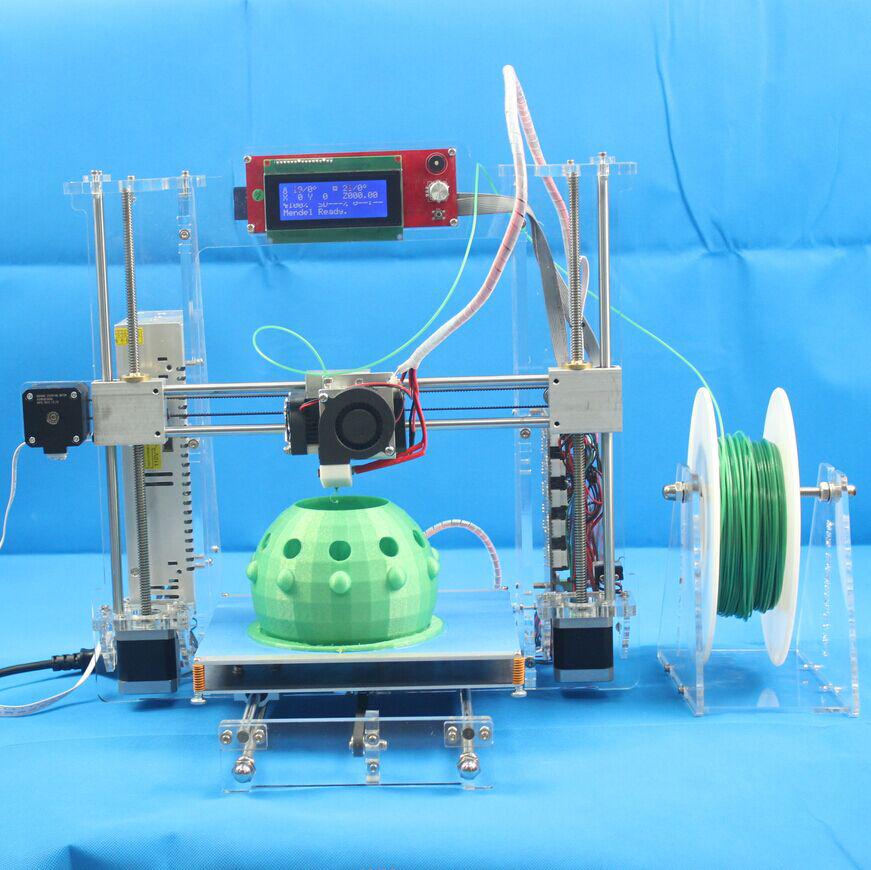

Metal 3D printing at home

where to start if you want to print metal objects at home? Given the extreme heat required for true metal 3D printing, a conventional FDM 3D printer will not be able to do this.

It is unlikely that in this decade it will be possible to print with liquid metal at home. Until 2020, you probably will not have a printer specialized for this purpose at home. But in a few years, as nanotechnology advances, we may see significant developments in new applications. This can be 3D printed with conductive silver, which will emit in much the same way as it does in 2D home printers. It will even be possible to mix different materials like plastic and metal in one object.

It will even be possible to mix different materials like plastic and metal in one object.

Materials for metal 3D printing at home

Even though you can't actually print metal objects at home, you can turn to plastic filament that has metal powders added to it. ColorFabb, ProtoPasta and TreeD Filaments all offer interesting metal-PLA composite filaments. These filaments, containing a significant percentage of metal powders, remain pliable enough to be printed at low temperatures (200 to 300 Celsius) on virtually any 3D printer. At the same time, they contain enough metal to make the final object look, feel, and even weigh like metal. Iron-based filaments even rust under certain conditions.

But you can go further. Typically, up to 50 percent metal powder is added to 3D printing filament. Dutch company Formfutura says they have achieved 85 percent metal powder with 15 percent PLA. These filaments are called MetalFil Ancient Bronze and Metalfil Classic Copper. They can be printed even at "moderate" temperatures from 190 to 200 degrees Celsius.

Metal 3D Printing Filament Spools, in this case from SteelFill and CopperFill colorFabb (Steel and Bronze), Ancient Bronze (Ancient Bronze) from Formfutura

Here are the key points about metal printing at home

- Gets a unique metal surface and look

- Ideal for jewelry, figurines, housewares, replicas

- Durability

- Objects are not flexible (structure dependent)

- Objects do not dissolve

- Not considered food safe

- Typical print temperature: 195 - 220°C

- Extremely low shrinkage on cooling

- No table heating required

- Printing complexity is high, requires fine tuning of nozzle temperature, feed rate, post-processing

Preparing your home printer for metal 3D printing

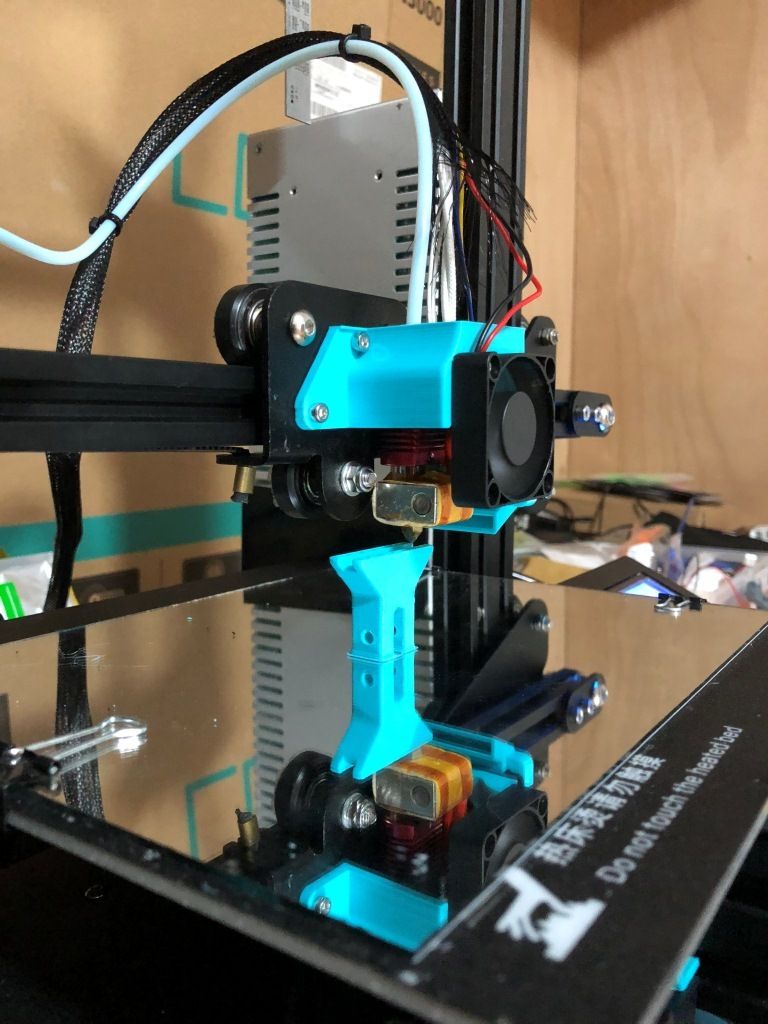

Since getting metal 3D prints is more difficult than usual, you may need to upgrade your 3D printer nozzle, especially if you are an entry-level printer. The metal filament wears it out quickly. There are hard-wearing hot-ends (like the E3D V6) that are themselves made of metal. They can withstand high temperatures and fit most printers. Be prepared for the fact that the nozzles will have to be changed frequently, because the metal filament is very abrasive.

The metal filament wears it out quickly. There are hard-wearing hot-ends (like the E3D V6) that are themselves made of metal. They can withstand high temperatures and fit most printers. Be prepared for the fact that the nozzles will have to be changed frequently, because the metal filament is very abrasive.

You will also need to take care of the final finishing of the surface (cleaning, sanding, oiling, waxing or priming) so that the printed metal object shines as it should.

How much does metal filament for 3D printing cost?

And what about metal filament for 3D printing? - you ask. Here are a few examples:

- ColorFabb's 750 gram Bronzefill spool is $56.36

- ColorFabb 750g Copperfill Coil $56.36

- Protopasta's Polishable Stainless Steel PLA Composite is $56 for 56 grams of

- Rustable Magnetic Iron PLA Composite from Protopasta is $34.99 for 500 grams of

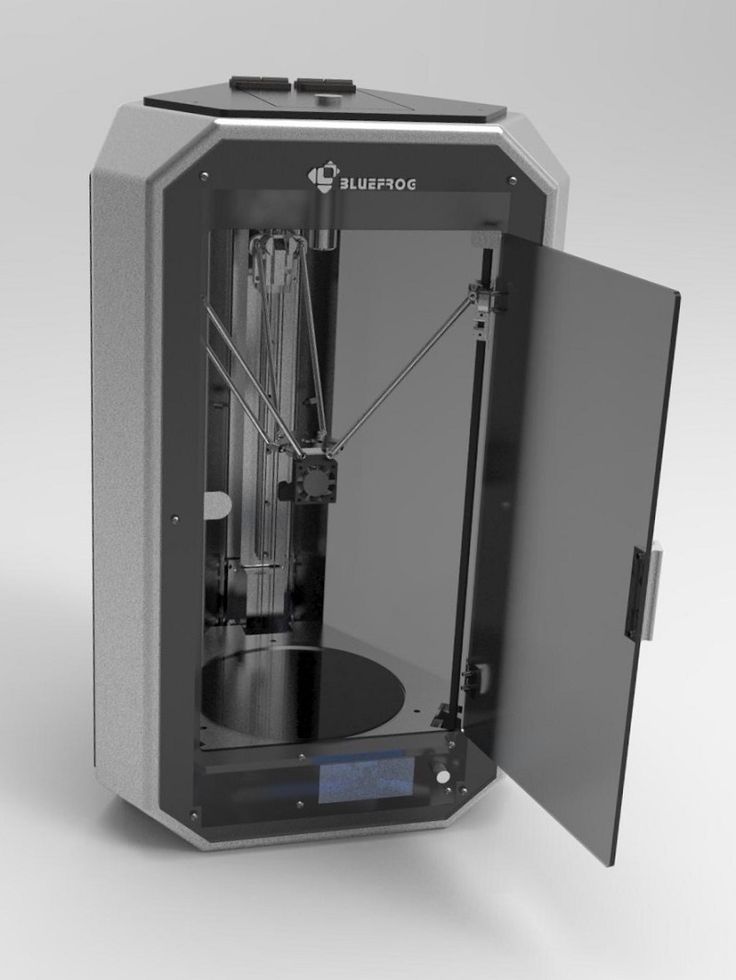

Industrial metal 3D printing

But what if you want a better result or even full metal 3D printing? Should a real "metal" 3D printer be purchased for business needs? We wouldn't recommend it - unless you're going to be doing it every day. A professional metal 3D printer is expensive: EOS or Stratasys devices will cost you 100-500 thousand dollars. In addition, the costs will be even greater, since you will have to hire an operator, a worker to maintain the machine, as well as to finalize the printouts (polishing, for example). Just a note: In 2016, an affordable metal 3D printer didn't exist.

A professional metal 3D printer is expensive: EOS or Stratasys devices will cost you 100-500 thousand dollars. In addition, the costs will be even greater, since you will have to hire an operator, a worker to maintain the machine, as well as to finalize the printouts (polishing, for example). Just a note: In 2016, an affordable metal 3D printer didn't exist.

Lowering Metal 3D Printing Costs

If you are not going to start a metal 3D printing business, but still need a professionally 3D printed metal part, it is better to contact the appropriate company that provides such services. 3D printing services like Shapeways, Sculpteo and iMaterialise offer direct metal printing.

They currently work with the following metal materials in 3D printing:

- aluminum

- steel

- brass

- copper

- bronze

- sterling silver

- gold

- platinum

- titanium

If you are a jeweler, you can also order wax models for casting in precious metals.

If we talk about wax models, then in most cases they (with subsequent melting) are used when printing with metals (including gold and silver). Not all orders are carried out directly by these firms. They usually turn to other metal 3D printing companies to complete the order. However, the number of such services around the world is growing rapidly. In addition, metal 3D printing techniques are becoming more and more common in companies that offer such services.

The reason big companies love 3D printing so much is that it can be used to build fully automated lines that produce "topologically optimized" parts. This means that it is possible to fine-tune the raw materials and make the components thicker only if they must withstand heavy loads. In general, the mass of parts is significantly reduced, while their structural integrity is preserved. And this is not the only advantage of this technology. In some cases, the product turns out to be significantly cheaper and affordable for almost everyone.

Please note that metal 3D printing requires special CAD software for modeling. It is worth paying attention to the recommendations of Shapeways - 3D printing metal guidelines. To delve further into the topic, check out Statasys’ information on related 3D printers and the nuances of metal 3D printing.

Here are some examples of Benchy test model prices for metal 3D printing:

- Metal plastic: $22.44 (ex-aluminum, PLA with aluminium)

- Stainless steel: $83.75 (plated, polished)

- Bronze: $299.91 (solid, polished)

- Silver: $713.47 (solid, mirror polished)

- Gold: $87.75 (gold plated, polished)

- Gold: $12,540 (solid, 18K gold)

- Platinum: $27,314 (solid, polished)

As you might expect, the prices for solid metal 3D printing are quite high.

Metallic 3D printing. Applications

GE LEAP aircraft engine parts 3D printed at Avio Aero (Photo: GE)

There are several industries already using 3D printers to make everyday objects - you may not even know that these objects are printed.

- The most common case is surgical and dental implants, which in this design are now considered the best option for patients. Reason: they can be tailored to individual needs.

- Another industry is jewelry. Here, most manufacturers have abandoned resin 3D printing and wax casting, switching directly to metal 3D printing.

- In addition, the aerospace industry is becoming more and more dependent on 3D printed metal objects. The Italian company Ge-AvioAero was the first to do all-metal 3D printing. It manufactures components for LEAP aircraft engines.

- Another industry targeting metal 3D printing is the automotive industry. BMW, Audi, FCA are seriously considering this technology, not only for prototyping (3D printing has been used for this for quite some time), but also for making real parts.

Before metal 3D printing really takes off, however, there are some hurdles to overcome. And first of all, this is a high price, which cannot be made lower than during molding. Another problem is the low production speed.

Metal 3D printing.

Technologies

Most metal 3D printing processes start with an “atomized” powder

You can talk a lot about “metal” 3D printers, but their main problems remain the same as any other 3D – printers: software and hardware limitations, material optimization and multimateriality. We won't talk too much about the software, we'll just say that most of the major specialized software companies, such as Autodesk, SolidWorks and solidThinking, try to emphasize as much as possible the fact that as a result of the 3D metal printing process, you can get any shape you want.

In general, printed metal parts can be as strong as parts made by traditional processes. Parts made using DMLS technology have mechanical properties equivalent to casting. In addition, the porosity of objects made on a good "metal" 3D printer can reach 99.5%. In fact, manufacturer Stratasys claims that 3D printed metal parts perform above industry standards when tested for density.

Parts made using DMLS technology have mechanical properties equivalent to casting. In addition, the porosity of objects made on a good "metal" 3D printer can reach 99.5%. In fact, manufacturer Stratasys claims that 3D printed metal parts perform above industry standards when tested for density.

3D printed metal can have different resolutions. At the highest resolution, layer thickness is 0.0008 - 0.0012" and X/Y resolution is 0.012 - 0.016". The minimum hole diameter is 0.035 - 0.045". formed layer)

The metal 3D printing process used by most relevant large companies today is called Powder Bed Fusion. This name indicates that some source of energy (a laser or other energy beam) melts an "atomized" powder (i.e., a metal powder that is carefully ground into spherical particles), resulting in layers of a printed object.

There are eight major manufacturers of metal 3D printers in the world that already use this technology; while we are talking here, there are more and more such companies. Most of them are in Germany. Their technologies are called SLM (Selective Laser Melting - selective laser fusion) or DMLS (Direct Metal Laser Sintering - direct metal laser sintering).

Most of them are in Germany. Their technologies are called SLM (Selective Laser Melting - selective laser fusion) or DMLS (Direct Metal Laser Sintering - direct metal laser sintering).

Metal 3D printing No. 2:

Binder Jetting (spraying the binder)

under 3DP technology of Exone metal objects are printed by binding the powder before its binding in the mining (photos : ExOne)

Another professional approach that also uses a powder base is called Binder Jetting. In this case, the layers are formed by gluing metal particles together and then sintering (or fusing) them in a high-temperature furnace, just like it is done with ceramics.

Another option, which is similar to working with ceramics, is mixing metal powder into metal paste. A pneumatically extruded 3D printer (similar to a syringe bioprinter or an inexpensive food printer) forms 3D objects. When the required shape is reached, the object is sent to the furnace, i. e. in the mountains

e. in the mountains

This approach is used in the Mini Metal Maker, apparently the only inexpensive "metal" 3D printer.

Metal 3D printing process #3:

Metal Deposition

It may seem that the only 3D printing process that is left out of working with metals is layer-by-layer deposition. This is not entirely true. Of course, on some desktop device, simply fusing metal threads onto the base will not work. However, very large steel companies can do it. And they do. There are two options for working with "metal surfacing".

One is called DED (Directed Energy Deposition) or Laser Cladding. Here, a laser beam is used to melt the metal powder, which is slowly released and solidifies as a layer, and the powder is fed using a robotic arm.

Normally the whole process takes place in a closed chamber, but the MX3D project used conventional 3D printing techniques to build a full-size bridge. Another option for metal fusion is called EBAM (Electron Beam Additive Manufacturing - additive electron beam technology), which is essentially soldering, in which a very powerful electron beam is used to melt 3 mm titanium wire, and the molten metal forms very large finished structures. As for this technology, its details are known so far only to the military.

Another option for metal fusion is called EBAM (Electron Beam Additive Manufacturing - additive electron beam technology), which is essentially soldering, in which a very powerful electron beam is used to melt 3 mm titanium wire, and the molten metal forms very large finished structures. As for this technology, its details are known so far only to the military.

Metal 3D printing. Metals

3D Printing Metal #1: Titanium

Pure titanium (Ti64 or TiAl4V) is one of the most commonly used metals for 3D printing and is definitely one of the most versatile, strong and lightweight. Titanium is used both in the melting process in a preformed layer and in the process of spraying a binder and is used mainly in the medical industry (for the manufacture of personal prostheses), as well as in the aerospace industry, automotive and machine tools (for the manufacture of parts and prototypes). But there is one problem. Titanium is very reactive and explodes easily in powder form. Therefore, it is necessary that titanium 3D printing takes place in a vacuum or in an argon environment.

Therefore, it is necessary that titanium 3D printing takes place in a vacuum or in an argon environment.

3D printing metal #2: Stainless steel

Stainless steel is one of the cheapest 3D printing metals. At the same time, it is very durable and can be used in a wide range of manufacturing and even artistic and design applications. The type of steel alloy used also contains cobalt and nickel, is very difficult to break, and has a very high elasticity. Stainless steel is used almost exclusively in industry.

3D Printing Metal #3: Inconel

Inconel is a superalloy manufactured by Special Metals Corporation, its registered trademark. The alloy consists mainly of nickel and chromium and is very heat resistant. Therefore, it is used in the oil, chemical and aerospace (for black boxes) industries.

3D Printing Metal #4: Aluminum

Due to its lightness and versatility, aluminum is very popular in 3D printing. Aluminum alloys are commonly used.

Aluminum alloys are commonly used.

3D Printing Metal #5: Cobalt Chrome

gap). It is most commonly used in the manufacture of turbines, dental and orthopedic implants, where 3D printing has become the dominant technology.

3D printing metal #5. Copper and bronze

With some exceptions, copper and bronze are used in wax melting processes, rarely in layer melting. The fact is that these metals are not very suitable for industry, they are more often used in the manufacture of works of art and crafts. ColorFabb offers both metals as the basis for a special metal filament.

3D printing metal #6. Iron

Iron, incl. magnetic, also mainly used as an additive to PLA-based filaments, which are produced, for example, by ProtoPasta and TreeD.

3D printing metal #7. Gold, Silver, and Other Precious Metals

Most preformed melt process companies can 3D print precious metals such as gold, silver, and platinum. Here, along with the preservation of the aesthetic properties of materials, it is important to achieve optimization of work with expensive starting powder. Precious metal 3D printing is required for jewelry, medical applications and electronics.

Here, along with the preservation of the aesthetic properties of materials, it is important to achieve optimization of work with expensive starting powder. Precious metal 3D printing is required for jewelry, medical applications and electronics.

Metal 3D printing. Printers

Do not hesitate - the purchase of a metal 3D printer will not pass without a trace on your budget. It will cost at least 100-250 thousand dollars. Here is a list of a variety of "metal" printers, some of which can be found in firms providing 3D printing services.

Metal 3D Printer #1:

Sciaky EBAM 300 - Metal Filament Printing

If you need to print really large metal structures, Sciaky's EBAM technology is your best bet. By order, the device can be built in almost any size. This technique is used mainly in the aerospace industry and the military.

Sciaky's largest production printer is the EBAM 300. It prints objects in a volume of 5791 x 1219 x 1219 mm.

It prints objects in a volume of 5791 x 1219 x 1219 mm.

The company claims the EBAM 300 is also one of the fastest industrial 3D printers on the market. A three-meter-sized titanium part for an aircraft is printed on it in 48 hours, while the material consumption is about 7 kg per hour. In general, forged parts that usually take 6-12 months to complete can be made in 2 days with this 3D printer.

The metal layers are first cut and then ultrasonically welded. The largest Fabrisonic 7200 printer operates in a volume of 2 x 2 x 1.5 m. The metal powder 3D printer is the Concept Laser XLine 1000. It has a modeling volume of 630 x 400 x 500 mm and is the size of a house.

Its German company, one of the main suppliers of 3D printers for aerospace giants like Airbus, recently introduced a new machine, the Xline 2000.

This machine uses two lasers and has a working volume of 800 x 400 x 500 mm. Uses LaserCUSING laser technology (a variant of selective laser fusion) from Concept Laser, which allows you to print alloys of steel, aluminum, nickel, titanium, precious metals and even some pure substances (titanium and stainless steel).

Metallic 3D printing. Services

There are more than 100 companies worldwide offering metal 3D printing services. We list the most popular services for consumer needs.

Metal 3D Printing Service #1: Shapeways

The world's most popular 3D printing service, Shapeways offers two types of services. As a consumer, you can choose from a wide range of professionally designed objects, customize them, and then have them printed to your specifications. Like other 3D printing services, Shapeways offers a platform for designers to sell and print their work. Shapeways is also a good place for rapid prototyping: customers benefit from industrial-grade printers (EOS, 3D Systems) and personal technical support.

3D printing metals: aluminium, brass, bronze, gold, platinum, precious metal plating, silver, steel. There are also wax molds for jewelry purposes.

Metal 3D Printing Service #2: Sculpteo

Like Shapeways and i. materialise, Sculpteo is an online 3D printing service that allows anyone to upload 3D models and send them to fabrication in a wide range of materials . Like its competitors, Sculpteo provides a platform for hobbyists and professionals to showcase and sell their designs. The stable of Sculpteo printers includes highly professional machines from 3D Systems, EOS, Stratasys and ZCorp. Extensive technical documentation will help identify design flaws and select the right material for the project.

materialise, Sculpteo is an online 3D printing service that allows anyone to upload 3D models and send them to fabrication in a wide range of materials . Like its competitors, Sculpteo provides a platform for hobbyists and professionals to showcase and sell their designs. The stable of Sculpteo printers includes highly professional machines from 3D Systems, EOS, Stratasys and ZCorp. Extensive technical documentation will help identify design flaws and select the right material for the project.

Metals for 3D printing: alumide (plastic with aluminum particles), brass, silver.

Metal 3D Printing Service #3: iMaterialise

Materialise is a company that works with industrial customers to prototype 3D printed products. For casual users and designers, Materialize offers an online 3D printing service called i.materialise. As with Shapeways, this service allows anyone to upload their 3D designs and print them out. Once an object has been uploaded and successfully printed, a designer can list it for sale either in the gallery of the i.