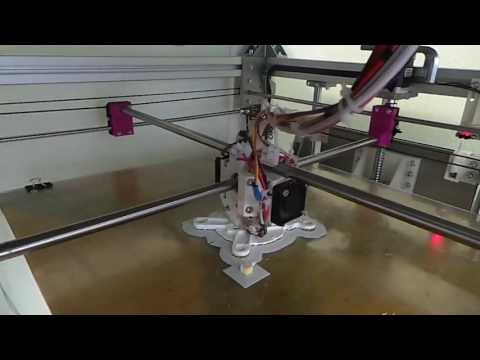

Youtube 3d printer demo

TOP 10 Best 3D Printing YouTube Channels / YouTubers (2018 Update)

3D printing news News TOP 10 Best 3D Printing YouTube Channels / YouTubers (2018 Update)

Published on January 4, 2018 by Jamie D.

The 3D printing Youtube scene is healthy and growing. Some excellent content is being made by makers, start-ups, and YouTubers. This community helps inform people, as well as showing off the amazing things they have created via 3D printing through Fused Deposition Modeling and other technologies. We’ve gone through pages of searches, narrowing down our favourite YouTube channels, to make this list of our favourites. These include categories for makers, 3D printing businesses, and informative channels, for whichever you are interested in.

Makers:

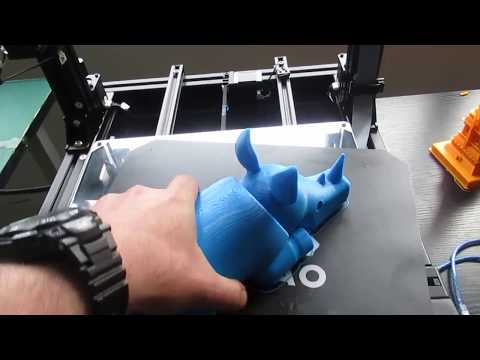

RCLifeOn

His insane 3D-printed flamethrower was posted in our Top 5 videos of the week on Sunday, so we had to include RCLifeOn in our list of best YouTubers. The channel showcases high-quality, well-edited content around creating and testing new 3D-printed items, like the fishing rod shown below. This is a great example of how 3D-printing can be applied to so many different areas, such as RC planes and cars, t-shirts, and many more.

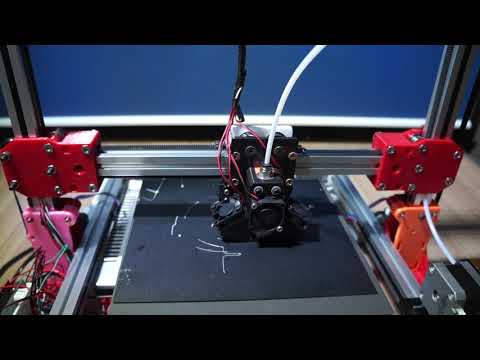

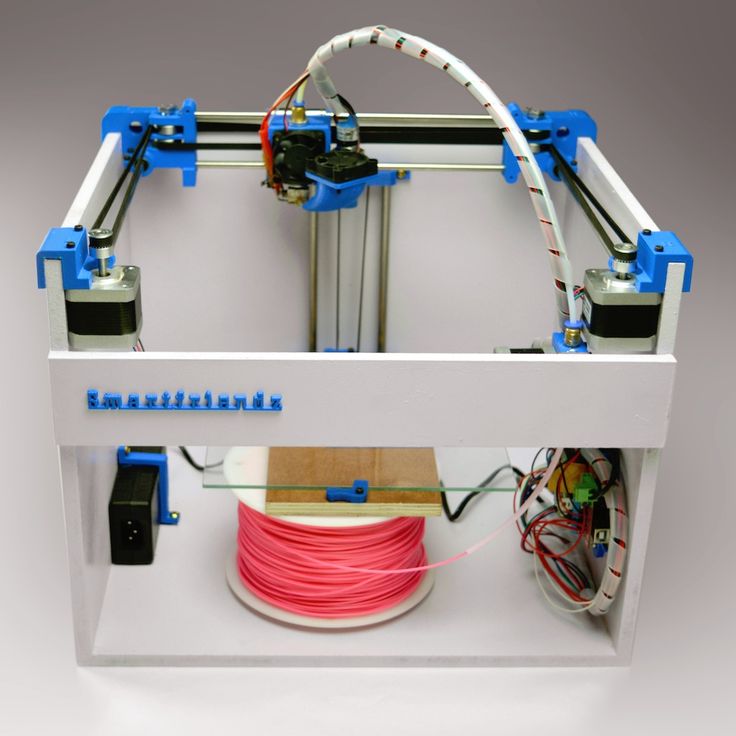

Ivan Miranda

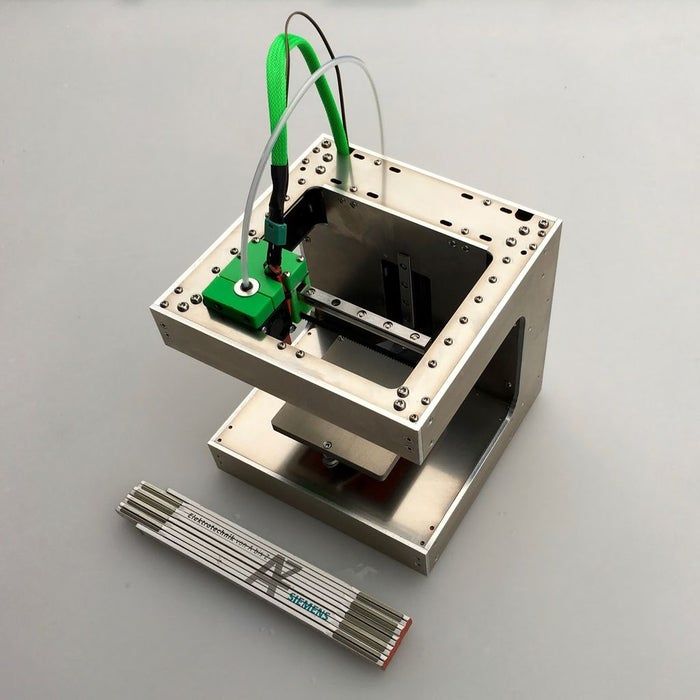

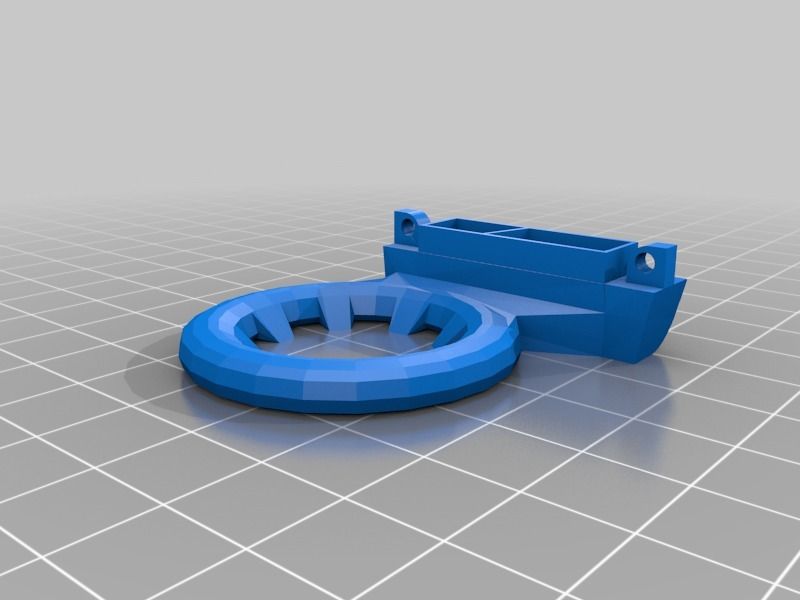

Ivan Miranda’s channel mixes “how to make” guides such as this rotary stamp below, with informative, high-quality content. These helpful tips and tricks videos help educate viewers, such as in his “how to troubleshoot a printer” video. This channel really takes DIY to the next level, too. Ivan has showcased a 3D printed violin, and tested the sound quality on video!

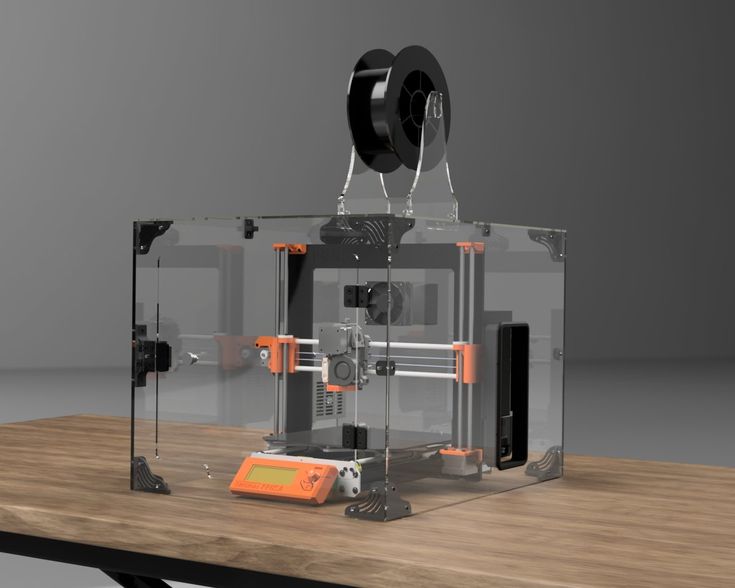

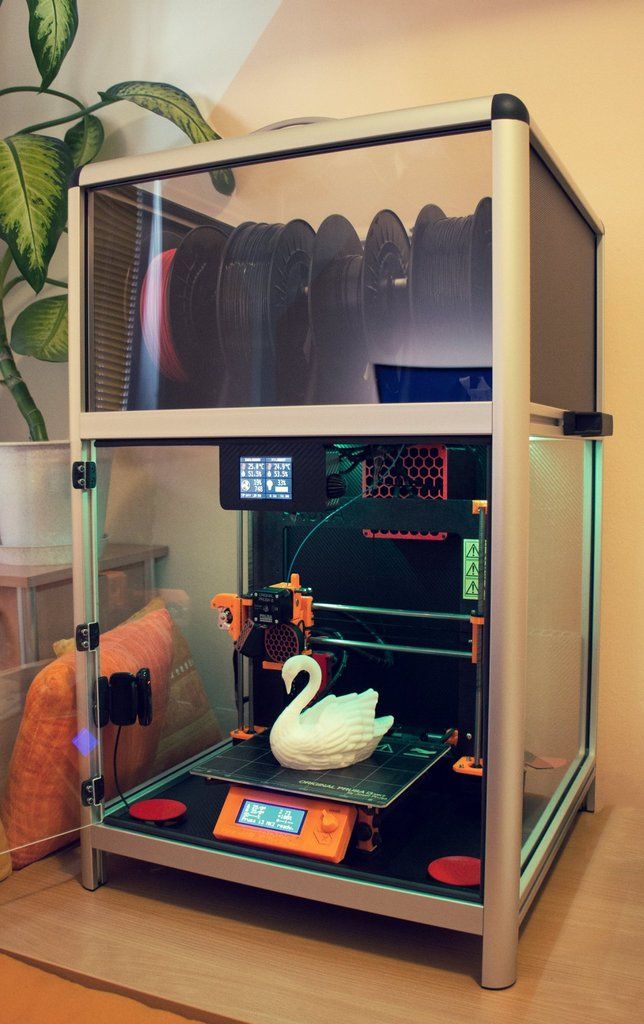

Josef Prusa

Josef Prusa presents a very informative tips and tricks-based channel, helping viewers make the most from their 3D-printers. Recently however, the channel has changed to showcase the new Prusa 3D printer and materials. The content is in-depth, detailed, and will help anybody learn more about 3D printing.

The content is in-depth, detailed, and will help anybody learn more about 3D printing.

Maker’s Muse

Maker’s Muse is a popular channel (185K+ subscribers) that covers multiple areas within 3D printing. These videos range from rating videos, to “how to” videos such as to save resin, in addition to general news updates in all things 3D-printing. For anyone wanting to learn about more of the printers available (several reviews on the channel), to just wanting some 3D printing-related entertainment, this is a great place for it.

Make Anything

This channel contains some of the most detailed guides to create 3D models such as a chess set or a fossil, that we’ve ever seen. These very impressive videos are well-made, super interesting (the VR used to create the mammoth fossil below was amazing), and generally well worth watching!

Thomas Sandladerer

Containing a huge variety of 3D-printing content, Thomas Sandladerer’s channel is a very interesting channel for everything related to the subject. These range from hairy lions, to how not to ruin your filament, and many other interesting videos. He even, after reaching 100,000 subscribers, 3D-printed himself his own YouTube play button before the real one arrived!

3D Printing Nerd

An aptly named channel, 3D Printing Nerd makes a huge amount of content, often several videos in a single week on the subject. These videos range from Q and A’s, to niche builds like the Rick and Morty portal gun below, to comparisons of different printers. As big Rick and Morty fans, we thoroughly enjoyed the research on this channel.

Information channels:

TED Talks

TED Talks are well-known as very informative in many areas. There are also a number of talks on 3D printing. If you are interesting in gaining more knowledge in the area, this is a great channel to check out.

SolidWorks Tutorial

3D printing is not all glitz and glamour. Much time may need to be spent before the actual printing process. This channel includes hundreds of guides to recreating items digitally, providing great knowledge to people interested in 3D printing these things.

Start-ups and Companies:

Faraday Motion

A German start-up, Faraday Motion have created an amazing 3D-printed skateboard that we featured on our TOP 5 videos of the week on Sunday. Their YouTube channel posts updates on the companies progress, and other social content from meetups.

Their YouTube channel posts updates on the companies progress, and other social content from meetups.

3D Systems

3D Systems are a huge name in the 3D printing world. As a result, they have a large amount of very informative content about their printers, and general 3D printing-related content. Their videos help inform owners of their printers about various uses, tips, and capabilities of their printers.

Did we miss your favourite channel? Let us know in a comment below or on our Facebook and Twitter pages! Don’t forget to sign up for our free weekly Newsletter, with all the latest news in 3D printing delivered straight to your inbox!

Video - Stratasys

VideoDecoding Fashion; Stratasys J850™ TechStyle™ 3D Printer Helps Hong Kong Polytechnic University Enable Personalized Apparel Design

Decoding Fashion; Stratasys J850™ TechStyle™ 3D Printer Helps Hong Kong Polytechnic University Enable Personalized Apparel Design

Read more

VideoStratasys FabriX Innovation Kit Automotive

Stratasys FabriX Innovation Kit transforms the J850 Prime 3D printer into an end-to-end hybrid system that extends the printers 3D printing capabilities to include 3D printing on flexible, flat substrates, such as fabric, carbon fiber, flexible polymers, mylar, netting, canvas and beyond.

Read more

VideoRapid prototyping capabilities became a major competitive advantage.

Watch how SEONG YUN TECH has increased sales and manufacturing capabilities by replacing traditional machining and molding processes with a J55 Prime full-color 3D printer, speeding up their prototyping process for a major competitive advantage in the cosmetics market.

Read more

VideoPurple Platypus and Onulis Team Up with Stratasys h450 3D Printer

Purple Platypus had the privilege of working with Onulis to create 46 production 3D printed parts for the WRAP machine, using their Stratasys h450 3D Printer.

Read more

VideoMakers for Heroes - Ron Halevi Prosthetic Upgrade 3D printing helps upgrade prosthesis for combat veteran

3D printing helps upgrade prosthesis for combat veteran. Now a competitive paralympic kayaker, amputee gets an enhancement ideal for his active lifestyle

Read more

VideoSierra Space implemented Stratasys 3D printed tooling to build a reusable commercial spacecraft 'Dream Chaser'

Testimonial of Stratasys FDM Technology from the Sierra Space Team. Witness how they applied and implemented 3D printed tooling to achieve commercial spaceflight.

Witness how they applied and implemented 3D printed tooling to achieve commercial spaceflight.

Read more

VideoFinishing methods for stereolithography

SL technology is renowned for building parts with extremely smooth surface finishes and intricate detail. This is perfect for customers who want industry leading part quality without the finishing or part preparation time needed to apply any customized finishing.

Read more

VideoMcLaren Formula One Racing Team uses Stratasys Neo Stereolithography 3D printers

Find out from McLaren Formula One Racing Team how to use Stratasys Neo Stereolithography 3D printers to innovate. We uncover some of the typical applications that help the team develop the car and look at why the Neo is perfectly suited for product development, wind tunnel test models and the world of motorsport. Download the e-book now to learn more about the capabilities of Stratasys Stereolithography.

We uncover some of the typical applications that help the team develop the car and look at why the Neo is perfectly suited for product development, wind tunnel test models and the world of motorsport. Download the e-book now to learn more about the capabilities of Stratasys Stereolithography.

Read more

VideoOne3D and the Neo800

Learn how One3D from the Czech Republic utilizes the Stratasys Neo800 3D printer to innovate in manufacturing.

Read more

VideoIncreasingly high demand for SAF™ technology parts at Prototal Damvig

A compelling insight into SAF technology on the h450. Prototal Damvig COO Jesper Damvig invested in SAF on the h450 printer in 2021 to capitalize on the technologies many strengths including part quality and repeatability, as well as the sustainability of PA11. He tells of a market for 3D parts that is fast developing and how AM technology is steadily moving from prototyping to playing a full-blown manufacturing role.

Prototal Damvig COO Jesper Damvig invested in SAF on the h450 printer in 2021 to capitalize on the technologies many strengths including part quality and repeatability, as well as the sustainability of PA11. He tells of a market for 3D parts that is fast developing and how AM technology is steadily moving from prototyping to playing a full-blown manufacturing role.

Read more

10 of 229 result(s) shown Show more

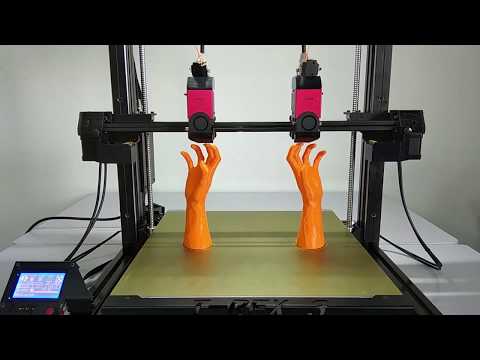

Examples of positive and negative applications of the 3D printer

Every year 3D printing becomes more and more popular. The 3D printer, as a tool for turning a digital model into a physical object, is gaining popularity, outperforming other production methods in many ways due to its affordability.

But do not forget that a 3D printer is just a tool. A lot depends on how this tool will be used.

Available 3D printing technologies

All 3D technologies can be conditionally divided into 4 types.

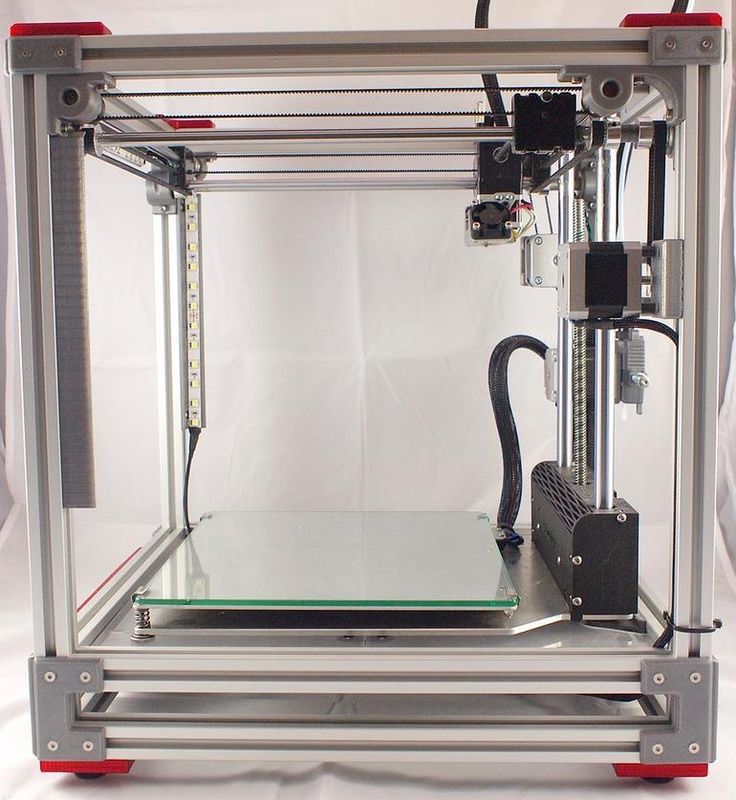

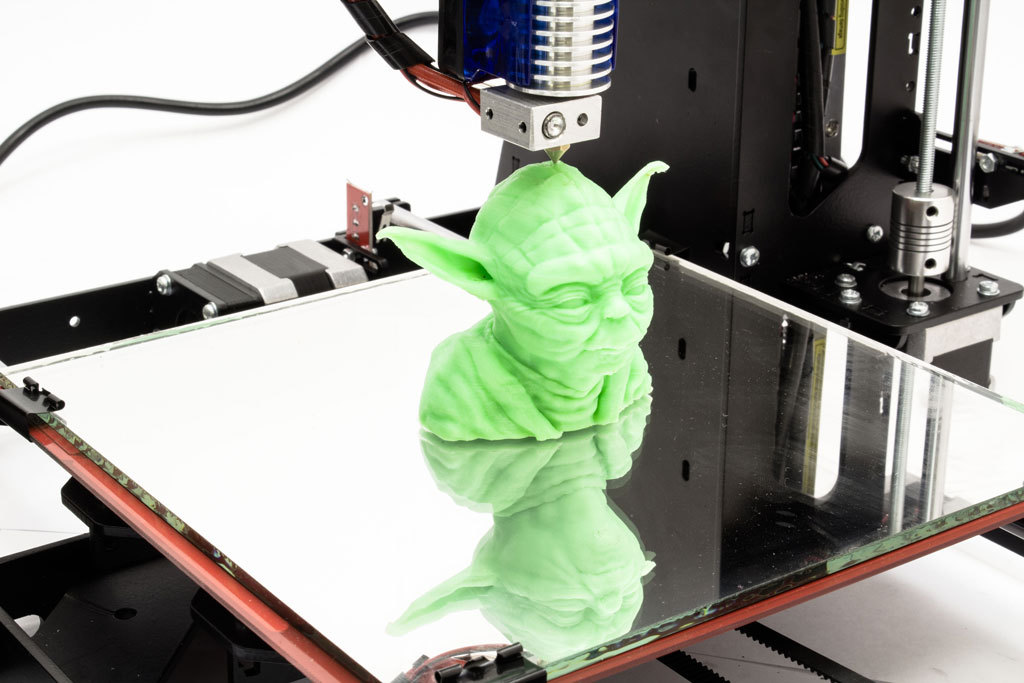

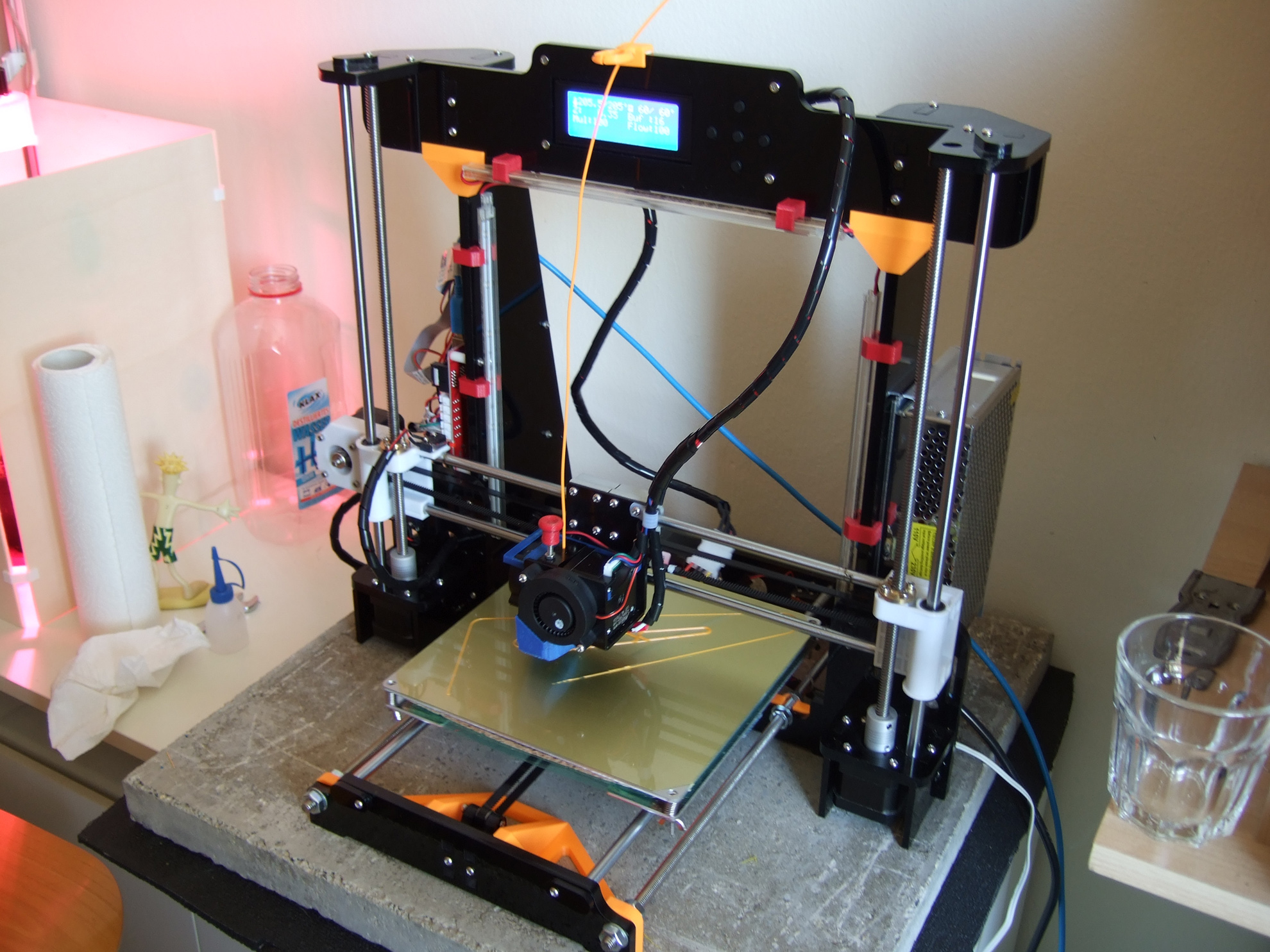

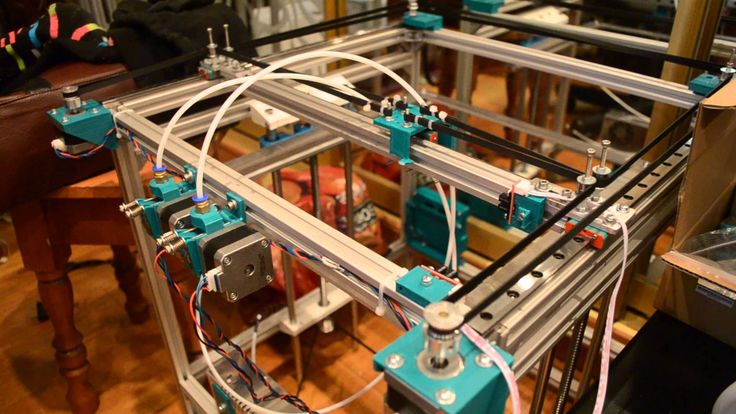

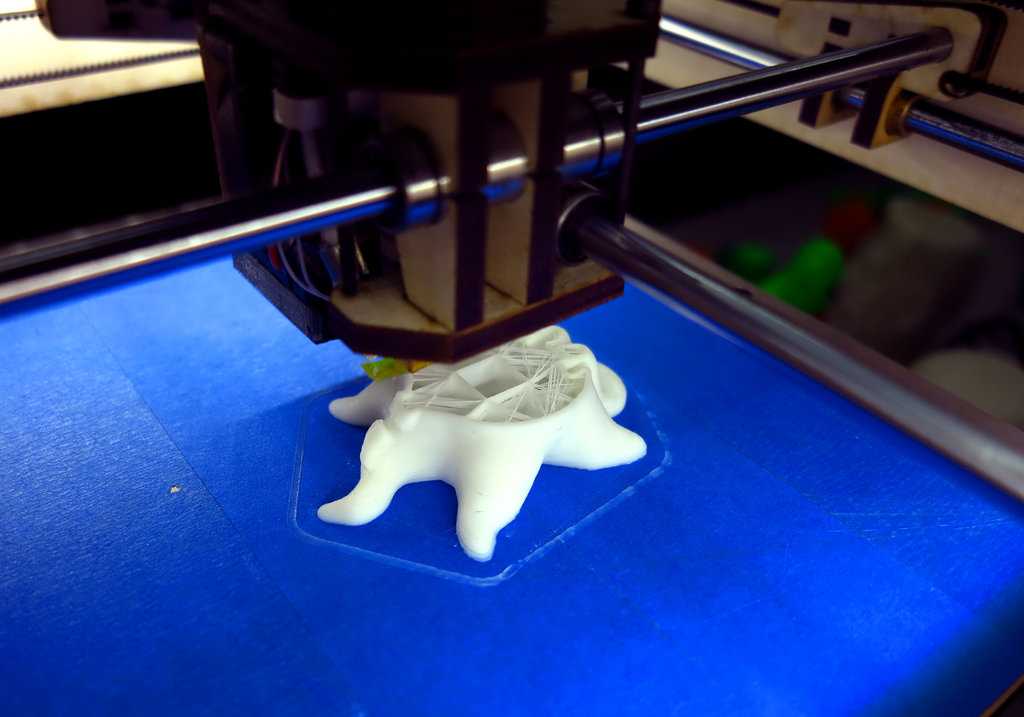

Layer by layer welding with molten material.

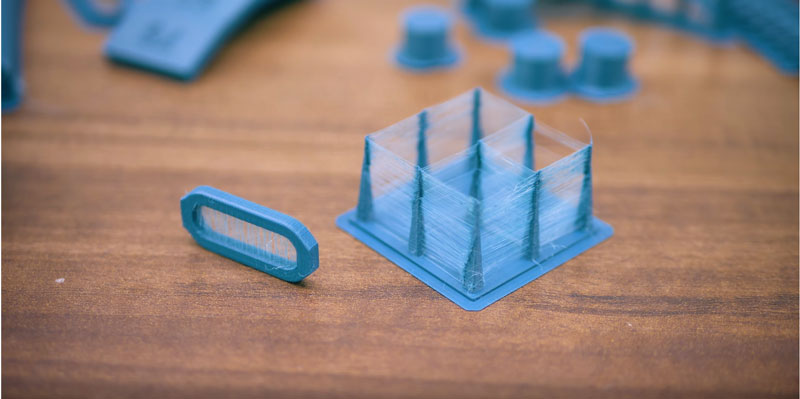

The principle of operation is similar to the familiar glue gun. The print media is melted to a semi-liquid state in the print head and applied with a nozzle to the print surface where it solidifies. This is how the finished 3D model “grows” layer by layer on the printing table. Not only thermoplastics can be used as consumables, but, for example, chocolate, icing, concrete, etc.

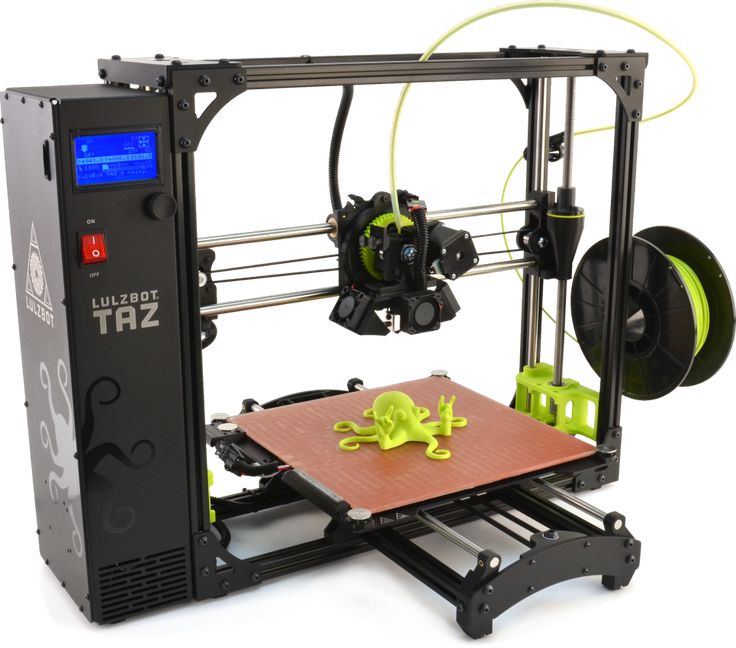

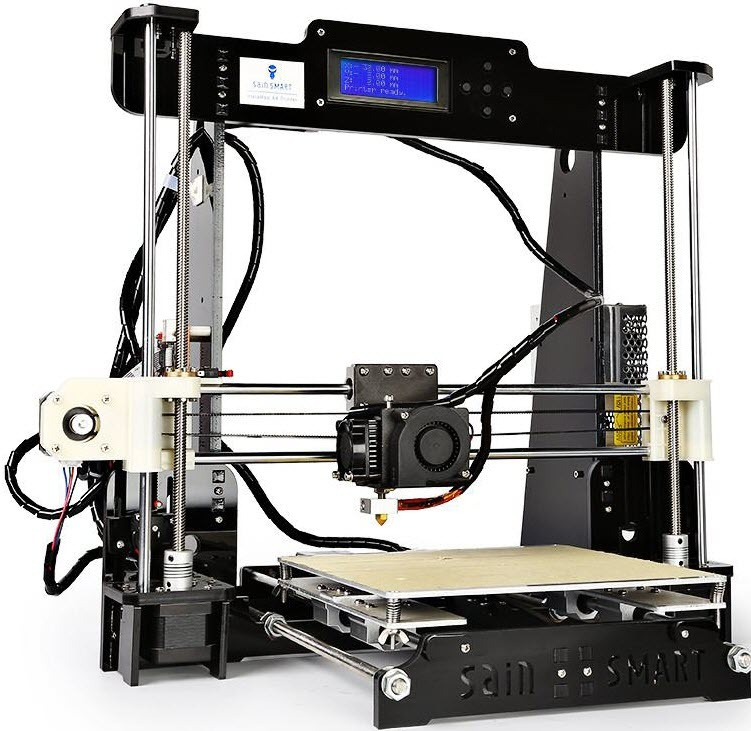

This is the most common type of printer. Inexpensive FDM printers are often used as home assistants. This is facilitated by an inexpensive price and a variety of consumables.

Selective curing of resin (photopolymer printers).

The material used is a photopolymer resin that hardens under the influence of UV radiation. As a source of UV radiation, a thin laser beam, a DLP projector or an LCD screen with a UV matrix, or any other design can be used. For example, some industrial 3D printers apply a photopolymer using thin nozzles and immediately illuminate it with a UV lamp.

As a source of UV radiation, a thin laser beam, a DLP projector or an LCD screen with a UV matrix, or any other design can be used. For example, some industrial 3D printers apply a photopolymer using thin nozzles and immediately illuminate it with a UV lamp.

Previously, these printers were quite expensive. Today, with advances in technology, photopolymer 3D printing has become affordable and photoresin printers have become popular as home hobby printers.

Selective bonding of powdered material.

On the print head of the printer there are several nozzles through which a binder is supplied, which is selectively applied to the powdered material. Various materials can be used as a material: for example, gypsum or metal powders. But gypsum is most often used.

Since dye can be added to the "glue" during printing, such printers are usually used for the production of color demonstration models or souvenirs.

Laser sintering of powdered materials.

The youngest technology, but with great potential for use in large-scale production. With the help of a laser or a heated print head, selective sintering of the metal powder occurs in an environment filled with an inert gas.

These are already serious industrial printers that are used for the production of functional metal assemblies and parts. Currently, such 3D printers are actively used in the aerospace industry.

Unethical use

3D piracy

Where there is duplication of objects, there are always disputes about copyright and piracy.

The production of any product is a long and painstaking work, and often more than one person. Before you get a finished decorative product, for example, a figurine, you need to think through everything to the smallest detail. Usually, before modeling, the artist draws a lot of sketches, the details of clothing and accessories are thought out. Only after that the 3D modeler gets to work and begins painstakingly recreating the 3D model.

Functional models are often redesigned by engineers after the prototype has been made. There can be a very long way between the initial idea and a stable working mechanism. And it’s very disappointing when such work is simply copied and posted in the public domain.

LEGO

It was one of the first mass manifestations of "3D piracy". At that time, 3D printing was only gaining popularity, and many users, having printed a dozen figurines, were looking for a useful application for a 3D printer. Given the low plastic consumption, the printed LEGO blocks were very inexpensive.

3D printed LEGO bricks

Despite the far from ideal surface, many were satisfied with such a copy. Some have argued that the accuracy of a home FDM printer is not enough for the bricks to fit well with the original LEGO, but for most users everything fit perfectly.

At the moment, LEGO is actively removing models that copy the original sizes of the famous bricks and men from the network. On popular sites, only custom elements of LEGO-men and LECO are left that are not the original size.

On popular sites, only custom elements of LEGO-men and LECO are left that are not the original size.

Custom heads for LEGO men

Games Workshop

Games Workshop, which produce the most expensive table soldiers in the world, sued Thomas Valenti (USA) back in 2012. Thomas has modeled, printed and made publicly available several miniatures based on the Warhammer universe. The court sided with Games Workshop and the models had to be removed.

3D Printed Chaplain

Chaplain 3D model from Warhammer 40k

Games Workshop went one step further by banning fans from creating art and other work based on the original settings and characters. As a boycott, users of the Warhammer 40,000 section on Reddit are proposing to abandon the company's products as much as possible - print game figures on 3D printers, use paints from other companies, or switch to other universes.

Hollywood

The production of modern films is not a cheap pleasure, and film companies try to recoup their costs not only by showing them in cinemas, but, for example, by producing souvenirs.

DreamWorks has an entire consumer goods division that helps recoup the cost of a movie if it fails at the box office. Film companies recognize that fan-made productions often surpass the official "souvenir" in accuracy and detail.

DC Universe Batman fan model

Many film companies are closely following the development of 3D printed merchandise, but do not yet know how to respond. For example, Paramount Pictures, Marvel Studios and Warner Bros. They themselves began to upload models for 3D printing to the network, before the release of new films.

Weapon Seal

Seal of weapons

24-year-old law student Cody Wilson was the first to make a gun on a 3D printer. Cody designed and 3D printed a combat pistol on his own. After 8 years, the idea of making firearms using 3D printing has not only not died out, but flared up with a bright fire.

After 8 years, the idea of making firearms using 3D printing has not only not died out, but flared up with a bright fire.

It started in Texas in 2012. It was there that the company Defense Distributed was registered, the ideology of which was the development of models of firearms that anyone could make on a home 3D printer.

Guns

Liberator

The first “swallow” was the Liberator - a compact plastic pistol printed on a 3D printer from ABS plastic. The only thing that could not be made on a 3D printer was the striker, which was successfully replaced by an ordinary nail. The first printed pistol was made on a Stratasys Dimension SST 3D printer.

Liberator - the name is borrowed from a cheap pistol that was developed in 1942 in the USA.

The Liberator fired a fairly weak .380 ACP round and could only last a dozen rounds at most.

Failed Liberator

Zig Zag

In the spring of 2014, a video appeared on the Internet with a man shooting from a plastic revolver with a huge drum. The video greatly stirred up all of Japan.

The video greatly stirred up all of Japan.

Zig Zag

Unknown was Yoshitomo Imura (Yoshitomo Imura) - 28-year-old employee of the Shonan Institute of Technology. Despite Imuru's claim that he fired blanks on the tape, he was arrested and sentenced to 2 years in prison.

The Zig Zag design was a reimagining of revolvers popular in the 19th century, which used a rotating .38 caliber barrel block mounted on a pistol grip.

Washbear

In 2015, mechanical engineering student James Patrick posted a video online showing a 3D printed PM522 Washbear in operation.

PM522 Washbear

The PM522 visually resembled a children's pistol from a science fiction movie, but at the same time the pistol had a strong and rigid frame. Washbear is also safer than its predecessors. At rest, the firing mechanism was not in line with the primer, so the PM522 was protected from accidental firing, for example, when dropped. The only metal part was the nail that replaced the striker.

The only metal part was the nail that replaced the striker.

Rifle

Grizzly

Canadian with the nickname CanadianGunNut, ThreeD Ukulele or simply Matthew, inspired by the Liberator project, designed and posted his project - Grizzly. Grizzly is an ABS+ plastic rifle. It took the Canadian 3 days to design the rifle and another 27 hours to manufacture it using a Stratasys Dimension 1200es industrial 3D printer.

Grizzly 9 Rifle0063

The first version of the Grizzly had a smooth and straight .22 barrel. But this turned out to be not a very good decision, and the barrel cracked after the first shot. Subsequently, Matthew replaced the barrel with a tapered barrel with rifling inside.

Plastic “cutting” could not affect the ballistics of the bullet in any way, but added strength to the barrel.

Shotgun

Liberator 12k

The Liberator 12k is a 12-round shotgun made by a well-known, in narrow circles, enthusiast in the world of 3D printing - Jeff Rodriguez.

Liberator 12k

Rodriguez managed to create a simple and at the same time reliable design, "mixing" a pistol and a pump-action shotgun in the design of the Liberator 12k. A huge plus for manufacturing and reliability was the absence of small parts in the shotgun mechanism.

Since the plastic was not strong enough, Rodriguez reinforced the design of the Liberator 12k with metal pins and added metal tubes inside the barrel and drum. The metal parts were purchased from a regular hardware store, so anyone could easily make a Liberator 12k with their home 3D printer.

Semi-automatic weapons

Shuty-MP1

The first sign was the Shuty-MP1, a semi-automatic pistol made by an amateur gunsmith with the nickname Derwood, in April 2017.

Shuty-MP1

Shuty AP-9

The Shuty AP-9 still uses a pistol barrel, but the trigger and return spring are taken from the civilian version of the M16. This improved the reliability of the rifle.

This improved the reliability of the rifle.

Ethical use

Despite the negative examples of application, 3D printing is actively used in many areas, helping to save time and create products that cannot be produced by other methods.

Medicine

Implants

Metal-printing 3D printers are actively used in medicine for the manufacture of titanium implants. For example, a patient needs to have a hip joint implant made. According to the results of CT, the necessary area of bone tissue replacement is agreed with the doctors and a prosthesis model is created that is ideal for this patient. After all approvals, the finished model is sent for printing.

3D model of implant

The main areas of 3D printing of implants in medicine are maxillofacial surgery, traumatology, orthopedics, oncology and veterinary medicine. A big advantage over classical methods of manufacturing implants is the ability to create a cellular or porous structure. This allows for better integration of the prosthesis into the bone tissue.

This allows for better integration of the prosthesis into the bone tissue.

Samples of printed implants and pins

Dentures

The manufacture of even a relatively simple traction prosthesis is a rather laborious and lengthy process. 3D printing has reduced costs and accelerated the production of prostheses. In addition, it became possible to customize the prosthesis.

Customized child prostheses

Some enthusiasts are modeling and posting models and detailed instructions for assembling traction prosthetic hands and fingers in the public domain so that any user can print and make a prosthesis at home.

Simple Traction Hand Model

Production

Building custom drones

Aerialtronics is a small Dutch company that specializes in building unique, customized drones. Aerialtronics manufactures and develops unique drones, the characteristics of which can vary depending on the needs of the customer.

Initially, a basic concept model was designed, which consists of a platform and a set of elements that can be changed at the request of the customer. Changes can affect almost any part of the drone. The customer can choose the number of motors and their power, payload, flight time, supported software and much more.

Aerialtronics base model

But any, even minor changes in the characteristics and design of the drone required the manufacture of new elements and design changes. Classical manufacturing methods turned out to be quite laborious and long. To save time and money, a Stratasys uPrint SE Plus 3D printer was purchased.

Drone Assembly

Thanks to 3D printing, it was possible not only to speed up production, but also to devote more time to improving individual components, because the finished model is ready the next morning. Rapid manufacturing allows you to print a part, test it, make the necessary changes to the 3D model and make a new sample. Aerialtronics engineers manage to manufacture and test 8-10 variants of a part in a few days in order to achieve maximum quality.

Aerialtronics engineers manage to manufacture and test 8-10 variants of a part in a few days in order to achieve maximum quality.

Prototyping

Gas turbine prototyping.

Prototyping by traditional methods is often time consuming and expensive. Because of this, the price of an error in calculations and 3D modeling can be very expensive.

For example, the production of turbine engine parts is usually based on careful preparatory calculations, but even this does not always prevent errors in the production of a test prototype. After all, even the most modern software methods cannot replace physical tests. But due to the high cost (over $20,000), it becomes impossible to produce multiple prototypes for testing.

Turbine Technologies (Wisconsin, USA) and its subsidiary Kutrieb Research have found a way out - 3D printing. Thanks to the 3D Systems ProJet 3D printer, it was possible to reduce the cost of prototyping by about 10 times to $2,000.

3D model and printed part of turbine

A turbine model is printed on a wax 3D printer, tested and then cast from metal. In addition to the cost, it was possible to significantly speed up production. After all, the production of traditional stencils with filling in molds took up to 5 weeks, and the 3D printed model is ready by the morning.

Totals

Despite the unethical side of 3D printing, there are still more positive use cases. 3D printers have become indispensable assistants in various industries - from home hobbies to serious industries. With the help of 3D printers, unique products are made that could not be obtained using other machines.

Popularization of 3D printers is a matter of time. But do not forget that 3D printing is just a tool, just like a drill or a hammer. It depends only on the user how it will be used.

Selective Laser Sintering (SLS) 3D Printing Manual

Selective Laser Sintering (SLS) 3D printing is a technology trusted by engineers and manufacturers across industries to create durable and functional models.

In this detailed guide, we'll explain selective laser sintering technology, the different systems and materials on the market, the workflow and different applications of SLS printers, and when to choose 3D printing with this technology over others. additive and traditional manufacturing methods.

White paper

Looking for a 3D printer to create durable, functional models? Download our white paper to learn how selective laser sintering (SLS) technology works and why it is popular in 3D printing for functional prototypes and end-use products.

Download white paper

Selective laser sintering (SLS) is an additive manufacturing technology that uses a powerful laser to sinter fine polymer powder particles into a solid structure based on a 3D model.

SLS 3D printing has been popular with engineers and manufacturers for decades. With its low model cost, high productivity, and common materials, this technology is well suited for a wide range of applications, from rapid prototyping to low-volume production, limited trial runs, or custom-made products.

Recent advances in technology, materials and software have opened up the possibility of SLS printing to a wider range of companies. Previously, such tools were used only in a few high-tech industries.

Introducing the high-performance Fuse 1 3D printer with SLS technology, finally available.

Webinar

Watch our product demo to learn about Fuse 1 and SLS 3D printing from Formlabs.

Watch webinar

Schematic representation of the selective laser sintering process. The SLS method uses a powerful laser to sinter small particles of polymer powder into a solid structure based on a 3D model.

-

Seal: A thin layer of powder is applied to the top of the platform inside the working chamber. The printer preheats the powder to just below the melting point of the feedstock. This allows the laser to more easily raise the temperature of certain areas of the powder bed and monitor the solidification of the model.

The laser scans the cross section of the 3D model, heating the powder to the material's melting temperature or just below. Particles are mechanically joined together to form a single solid object. The unsprayed powder supports the model during printing and eliminates the need for special support structures. The platform is then lowered into the working chamber one layer, typically 50-200 µm thick, and the process is repeated for each layer until the models are complete.

The laser scans the cross section of the 3D model, heating the powder to the material's melting temperature or just below. Particles are mechanically joined together to form a single solid object. The unsprayed powder supports the model during printing and eliminates the need for special support structures. The platform is then lowered into the working chamber one layer, typically 50-200 µm thick, and the process is repeated for each layer until the models are complete. -

Cooling down: After printing and before post-processing, the build chamber should cool down a little in the printer body and then outside the body to ensure optimal mechanical properties of the models and avoid their deformation.

-

Postprocessing: finished models must be removed from the working chamber, separated from each other and cleaned of excess powder. The powder can be recycled and printed models can be blasted or tumbled.

To learn more about the workflow, see the SLS 3D Printing Workflow section below.

SLS models have a slightly grainy surface, but the layer lines are almost invisible. To achieve a smooth surface, SLS models are recommended to be blasted or tumbled. This sample was printed on a Fuse 1 industrial 3D printer with SLS technology for workshops from Formlabs.

The green powder supports the model during printing and eliminates the need for special support structures. This makes SLS ideal for complex geometries, including internal features, undercuts, thin walls, and negative draft features.

Models created using SLS 3D printing have excellent mechanical properties: their strength is comparable to that of injection molded models.

Compare Selective Laser Sintering (SLS) 3D printing with other common plastic modeling technologies: Fused Deposition Modeling (FDM) and Stereolithography (SLA).

Selective Laser Sintering (SLS) is one of the first additive manufacturing technologies developed in the mid-1980s by Dr. Carl Deckard and Dr. Joe Beeman at the University of Texas at Austin. Since then, the method has been adapted to work with a variety of materials, including plastics, metals, glass, ceramics, and various powdered composite materials. Today, all of these technologies are classified as wafer synthesis, additive manufacturing processes that selectively sinter regions of a powder layer under the influence of thermal energy.

Since then, the method has been adapted to work with a variety of materials, including plastics, metals, glass, ceramics, and various powdered composite materials. Today, all of these technologies are classified as wafer synthesis, additive manufacturing processes that selectively sinter regions of a powder layer under the influence of thermal energy.

The two most common substrate synthesis systems currently available are a plastic based method commonly referred to as Selective Laser Sintering (SLS) and a metal based method known as Direct Metal Laser Sintering (DMLS) or Selective Laser Melting (SLM). ). Until recently, both systems were very expensive and complex, which limited their use to the production of small batches of expensive models or custom-made products, such as aerospace components or medical devices.

Innovation in this area will make plastic-based SLS as affordable as other 3D printing technologies such as stereolithography (SLA) and Fused Deposition Modeling (FDM) and become widely available in affordable, compact systems.

All selective laser sintering 3D printers use the process described in the previous section. Basically, such printers differ in the type of laser, the volume of printing and the complexity of the system. Different solutions are used for temperature control, powder dosing and layering in different devices.

Selective laser sintering technology requires high precision and strict control during the printing process. The temperature of the powder and (incomplete) models must be controlled within 2°C during the three stages of production: preheating, sintering and storage before extraction, in order to minimize warping, stress and thermal deformation.

For decades, selective laser sintering has been one of the most popular professional 3D printing technologies, but due to its complexity, strict requirements and high price, only service bureaus and large enterprises could use it.

Conventional industrial SLS 3D printing systems have one or more powerful lasers. An inert atmosphere (nitrogen or other gases) is needed to prevent the powder from oxidizing and breaking down during the printing process, which requires specialized air handling equipment.

An inert atmosphere (nitrogen or other gases) is needed to prevent the powder from oxidizing and breaking down during the printing process, which requires specialized air handling equipment.

These installations also require special heating, ventilation and air conditioning (HVAC) systems and industrial power supplies. In addition, even the smallest industrial installations occupy an area of at least 10 square meters. m.

Due to the high initial cost of approximately $100,000 (and much more for complete solutions), traditional industrial systems with SLS technology were out of reach for many enterprises.

As with other 3D printing technologies such as Fused Deposition Modeling (FDM) and Stereolithography (SLA), more affordable, compact systems with SLS technology have recently begun to appear on the market. However, these solutions had significant drawbacks. These include low quality models and complex manual workflows due to a lack of post-processing solutions. This severely limited their use in industrial production.

This severely limited their use in industrial production.

The Formlabs Fuse 1 printer is in a new category with these deficiencies fixed . It is the first industrial SLS 3D printer for the workshop, delivering high quality, compact size, streamlined workflow, and cost far less than traditional industrial systems of the same type.

The Fuse 1 printer does not require any special infrastructure and will easily fit into your workplace.

The Fuse 1 uses a single laser and has a smaller working chamber that requires less heat. The powder is exposed to elevated temperatures for a shorter period of time, so there is no need for inert gases and specialized ventilation equipment. Thanks to its lower power consumption, it can run on a standard AC power supply without requiring special infrastructure.

The Fuse 1 features patent pending Surface Armor technology. This creates a semi-baked shell that heats evenly around the models as they are printed. This results in excellent surface quality, stable mechanical properties, high reliability and a high material renewal rate.

In addition to providing a compact, self-sustaining ecosystem and complete powder handling capability, Fuse 1 is complemented by the Fuse Sift Station, a stand-alone stand-alone device for model retrieval, recovery, storage and powder mixing.

Overall, the Fuse 1 industrial 3D printer with SLS for workshops has slightly less print volume than traditional entry-level SLS systems, but is smaller, easier to work with and less expensive.

| Fuse 1 Industrial Printer with SLS Technology for Workshops | Conventional Industrial 3D Printers with SLS Technology | 4 Cost | 0467 | from 18,500 US dollars | 100 000 - 500,000 US dollars and more than | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Press volume | to 165 x 165 x 300 mm | 904LAYA Benefits | Availability High quality models High performance Simplified workflow Compact dimensions Low maintenance | High print volume High quality models High performance Many material options | ||||||||

| Disadvantages | Less print volume Limited material options | Expensive equipment Big sizes Infrastructure Requirements Large amount of maintenance Special Operator Required |

The most common selective laser sintering (SLS) material is nylon. It is a high performance engineering thermoplastic for both functional prototyping and end-use fabrication. Nylon is ideal for the production of complex knots and strong models with high environmental resistance.

It is a high performance engineering thermoplastic for both functional prototyping and end-use fabrication. Nylon is ideal for the production of complex knots and strong models with high environmental resistance.

3D printed SLS nylon for strength, rigidity and durability. The final models are impact-resistant and highly wear-resistant. Nylon is resistant to UV, light, heat, moisture, solvents, temperature and water. Nylon models printed on a 3D printer are also biocompatible and do not cause allergic reactions. This means that they can be worn and used safely in many situations.

Nylon is ideal for a range of functional applications, from consumer product design to healthcare applications.

Nylon is a synthetic thermoplastic polymer from the polyamide family. It is available in several versions, each designed to print different products. Nylon 12 Powder has a wide range of applications and is a general purpose, general purpose SLS 3D printing powder. Nylon 12 GF Powder is a composite material with a high fiber content, increased stiffness and heat resistance for difficult industrial conditions. Nylon 11 Powder helps fill a gap in prototyping and end-use applications where increased ductility, impact resistance and the ability to withstand wear without brittle fracture are required.

Nylon 11 Powder helps fill a gap in prototyping and end-use applications where increased ductility, impact resistance and the ability to withstand wear without brittle fracture are required.

- Impact Prototypes, Clamps and Fixtures

- Thin-walled pipes and bodies

- Rivets, fasteners and latches

- Orthopedic products and prostheses*

- High Performance Prototyping

- Small batch production

- One-piece clamping and holding fixtures and tooling

- Conventional SLS Models

- Heavy-duty clamping and fastening fixtures and spare parts

- Continuous models

- Threads and sockets

- High temperature models

* Material properties may vary depending on model design and manufacturing method. It is the manufacturer's responsibility to confirm the suitability of printed models for their intended use.

| 40% | ||||||

| Extension when rupture, Z (%) | 6% | 3% | ||||

|---|---|---|---|---|---|---|

| Drum for iso -90 | 71 J/m | |||||

Bending temperature under load at 1. 8 MPa (°C) 8 MPa (°C) | 87 °C | 113 °C | 46 °C | 170°C | 171°C | 182°C |

Nylon 12 Powder and Nylon 11 Powder are one-component powders, but some SLS 3D printers can also use two-component powders, such as coated powders or powder blends.

Nylon 12 GF Powder is a composite material with a high fiberglass content, while other nylon composites with aluminide, carbon or glass are designed to increase the strength, stiffness or flexibility of models. In such two-component powders, only the component with the lower glass transition point is sintered, which binds both components.

SLS 3D printing accelerates innovation and helps businesses in a wide range of industries such as engineering, manufacturing and healthcare.

Manage the entire product development process, from iteration of first concept design to production of ready-to-use products:

- Rapid Prototyping

- Product mockups for user feedback

- Functional Prototyping

- Functional testing of products under severe conditions (e.

g. piping, brackets)

g. piping, brackets)

Manage your supply chain and respond quickly to changing needs:

- End-Use Manufacturing

- Small batch production

- Mass production of new customized consumer products

- Spare parts manufacturing, supply chain sustainability

- Durable, durable clamping and fastening devices (such as clamps and clamps) and accessories

- Custom manufacture of automotive, motorcycle and marine parts, and restock military items on demand

Self-manufacturing of ready-to-use medical devices, taking into account the individual characteristics of patients:

- Medical device prototyping

- Prostheses and orthotics (e.g. prosthetic limbs and orthoses)

- Surgical models and instruments

- End-Use Products (Nylon 12 is biocompatible and can be sterilized*)

* Material properties may vary depending on model design and production method. It is the manufacturer's responsibility to confirm the suitability of printed models for their intended use.

Use any CAD software or 3D scan data to design the model and export it to a 3D printable format (STL or OBJ) file. All printers with SLS technology use software that allows you to adjust settings, position models, estimate print times, and layer your digital model. Once set up, the model preparation software sends commands to the printer via a wireless or cable connection.

The Fuse 1 uses PreForm print preparation software (free to download). It allows you to easily duplicate and place multiple models on a 3D grid to maximize your print volume. PreForm automatically suggests the optimal orientation and position of models with the ability to make manual changes.

The workflow for preparing the printer varies from system to system. Most traditional SLS systems require extensive training, tools, and physical actions to prepare and maintain them.

Fuse 1 redefines the SLS workflow, making it simple and efficient, as well as providing trouble-free printing and complete powder handling thanks to modular components.

The Fuse 1 can be easily loaded with powder using a special cartridge.

The Fuse 1 uses a detachable build chamber so you can start a new print while the previous build chamber is still cooling.

Once all pre-checks have been completed, the machine is ready to print. Depending on the size and complexity of the 3D models, as well as their density, printing using SLS technology can take from several hours to several days.

When printing is complete, the build chamber in the housing should cool down a bit before proceeding with the next step. To start the next print, you can remove the build chamber and insert a new one. Before post-processing, the working chamber must cool down to ensure optimal mechanical properties of the models and avoid their deformation. This can take up to half of the total print time.

Fuse 1 is equipped with a touch screen that allows you to see in real time how each new layer is formed during the printing process. This camera image can also be transferred to a computer using PreForm to monitor the print without leaving the workplace.

Compared to other 3D printing processes, post-processing of SLS-printed models requires a minimum of time and labor. With no supporting structures, it is easy to scale and provides consistent results across batches of models.

After printing is completed, remove the finished models from the build chamber, separate them and clean them of excess powder. As a rule, this is done manually at the cleaning station using compressed air or a jet apparatus.

The excess powder left after the creation of the model is filtered to remove large particles from it. After that, it can be recycled. Under the influence of high temperature, the properties of green powder deteriorate slightly, so for subsequent printing it must be mixed with new material. Due to the possibility of reusing materials, SLS technology produces a minimum amount of waste.

SLS technology typically uses separate devices for powder recovery, storage and mixing. The Fuse 1 workflow uses a single Fuse Sift to retrieve patterns and greens, store, dispense, and mix material streams.

Fuse Sift completes the Fuse 1 SLS print workflow. This system is used for safe and efficient model retrieval and powder recycling.

Fuse Sift automatically doses and mixes used and new powder, reducing waste and controlling powder delivery.

After the powder has been sieved, the 3D models printed using selective laser sintering technology are ready for use. However, there are a few more post-processing steps you can perform on these models.

By default, the surface of 3D models created using SLS technology remains grainy. To achieve a smooth surface, Formlabs recommends blasting or tumbling models made using this method. Models can be spray painted, lacquered, electroplated or otherwise to achieve the desired color, surface quality and properties such as water resistance (special coating) and electrical conductivity (electrolytic coating). Models created with SLS Formlabs are dark in color and therefore not well suited for staining.

Immersion printed SLS model from Partial Hand Solutions.

SLS models can be electroplated for a metal-like surface.

Selective laser sintering is preferred by engineers and manufacturers for its wide design options, high productivity, low model cost and proven end use materials.

Most additive manufacturing processes such as stereolithography (SLA) and Fused Deposition Modeling (FDM) require specialized support structures to fabricate overhang structures.

Selective laser sintering does not require support structures because the unsintered powder surrounds the model during printing. SLS printing makes it easy to create overhangs, intricate geometries, interconnecting parts, internal channels and other intricate details.

Intricately patterned arm splint for weight reduction.

Engineers typically design models in terms of the capabilities of the final manufacturing process, also known as design-for-technology (DFM). When additive manufacturing is only used for prototyping, it comes down to creating models and designs that can be replicated in the manufacturing process using traditional tools.

Selective laser sintering is emerging as a viable rapid production method and its application area continues to expand, so it can open up new possibilities in design and construction. 3D printers with SLS technology can create complex geometries that are impossible or incredibly expensive to manufacture using traditional processes. SLS technology also allows design professionals to combine complex assemblies into a single model that would normally require multiple models to be created. This helps avoid the problem of loose connections and saves assembly time.

Selective laser sintering can unleash the potential of generative design, as it allows the creation of lightweight models that use complex lattice structures that cannot be fabricated by traditional methods.

Selective laser sintering is the fastest additive manufacturing technology for making functional, durable prototypes and end-use products. Lasers used for powder sintering have much faster scanning speeds and are more accurate than the layering methods used in other processes such as Industrial Fused Deposition Modeling (FDM).

To maximize the available print volume in each printer, multiple models can be placed side by side. Operators can use the software to optimize print volume and maximize productivity by leaving only minimal clearance between models.

SLS technology allows operators to fill the build chamber with as many models as possible, as it allows them to be printed without supporting structures, saving time in post-processing.

SLS 3D printing requires the right materials for functionality and versatility. Nylon and its composites are proven, high quality thermoplastic materials. Laser-sintered nylon models have close to 100% density and mechanical properties that are comparable to products made using traditional manufacturing methods such as injection molding.

Screwdriver printed in Nylon 12 Powder. After a simple post-processing, nylon models have a smooth, professional quality surface.

SLS Printable Nylon is an excellent replacement for conventional injection molded plastics. The latches and other mechanical connections produced from it are superior to products created using any other additive manufacturing technology. It is ideal for making functional plastic parts that will work and not break down over time like products created through other additive manufacturing methods.

The latches and other mechanical connections produced from it are superior to products created using any other additive manufacturing technology. It is ideal for making functional plastic parts that will work and not break down over time like products created through other additive manufacturing methods.

When calculating the cost of one model, it is usually necessary to take into account the cost of ownership of equipment, material costs and labor costs:

-

Equipment cost of ownership: The more models a printer can produce over its lifetime, the lower the cost per model. Therefore, higher performance results in a lower cost of ownership per model. With high laser scanning speeds, the ability to produce multiple models at once to maximize the working volume, and a simple post-processing process, SLS 3D printing guarantees the highest productivity of any additive manufacturing method.

-

Material: Most 3D printing technologies use proprietary materials, while nylon is a common thermoplastic that is produced in large quantities for industrial applications.

This makes it one of the most inexpensive raw materials for additive manufacturing. SLS 3D printing requires no support structures and allows you to print with recycled powder with minimal waste.

This makes it one of the most inexpensive raw materials for additive manufacturing. SLS 3D printing requires no support structures and allows you to print with recycled powder with minimal waste. -

Labor: Labor is a disadvantage of many 3D printing solutions. Work processes in most technologies are quite laborious and difficult to automate, which can significantly affect the cost of one model. Easy post-processing with SLS printing reduces manual labor and allows for easy scalability.

A 3D printer with SLS technology is a significant investment initially, but it often pays off even faster than buying smaller devices. SLS for workshop technology significantly reduces initial acquisition costs and also reduces model costs in most applications.

If 3D printing is rarely used in your business, it is recommended to use the services of third-party service bureaus. But in this case, the cash costs will be higher and you will have to wait longer for the order to be completed. One of the main advantages of 3D printing is its speed compared to traditional production methods. But this advantage loses its value when it takes up to several weeks for a third-party company to deliver a model.

One of the main advantages of 3D printing is its speed compared to traditional production methods. But this advantage loses its value when it takes up to several weeks for a third-party company to deliver a model.

REEKON Tools