World's first 3d printed metal gun

World's first 3D-printed metal gun blows through 50 rounds

News

The 45 caliber, semi-automatic pistol was fired at a target more than 30 yards away; several rounds hit the bulls-eye

By Lucas Mearian

Senior Reporter, Computerworld |

A 3D printing services company has built a fully functioning, semi-automatic pistol and shown that it works just as a traditionally manufactured gun.

Built by Solid Concepts, the pistol is a replica of the storied .45-caliber, M1911 semi-automatic that served as the U.S. military's standard-issue sidearm for more than 70 years. Solid Concept demonstrated the gun by firing 50 rounds with it.

The accuracy? At more than 30 yards, the gun was able to strike a target bull's-eye several times, Solid Concepts said.

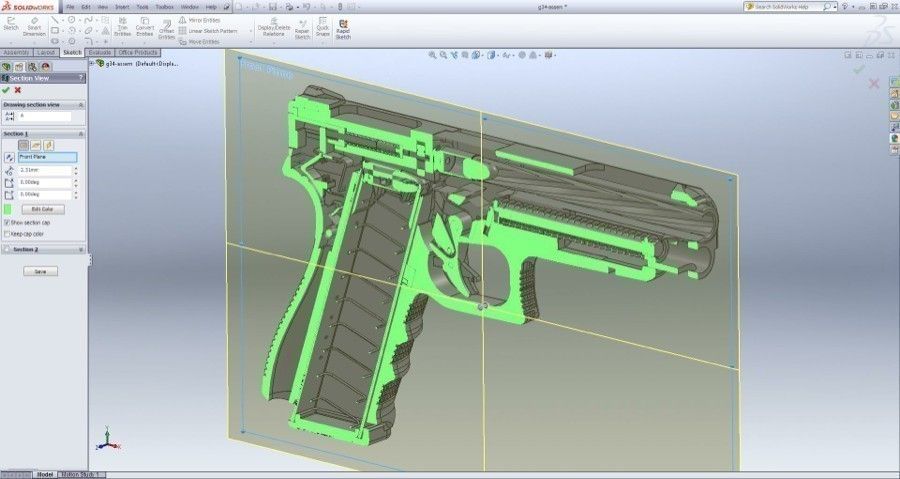

Solid Concepts' 3D printed .45 caliber M1911 pistol (Image: Solid Concepts).Previously, the only 3D printed gun was The Liberator, a single-shot plastic weapon made by Defense Distributed. That weapon didn't prove to be reliable after multiple rounds were fired through it.

Solid Concepts' intentions should not be misconstrued, according to Pete Basiliere, research director for Imaging and Print Services at Gartner. Unlike Defense Distributed's founder, 25-year-old founder Cody Wilson, Solid Concepts is not trying to promote the right to bear arms under the Second Amendment.

By 3D printing a gun, the Solid Concepts is proving its engineering prowess and equipment quality, not a method for the masses to make their own guns, Basiliere said.

"If their [3D printer] is what I think it is, it's probably a device that costs in excess of $500,000," Basiliere said.

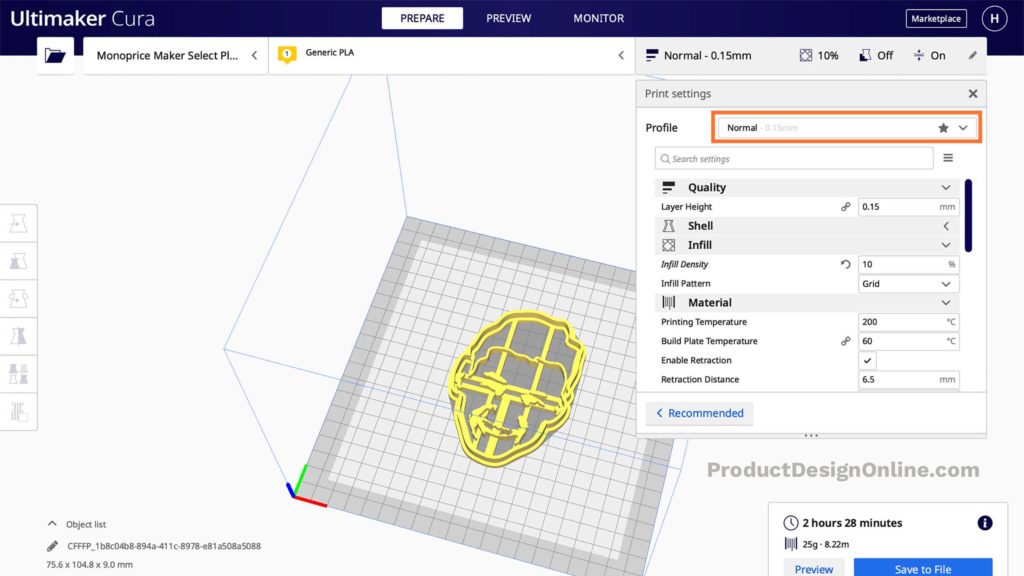

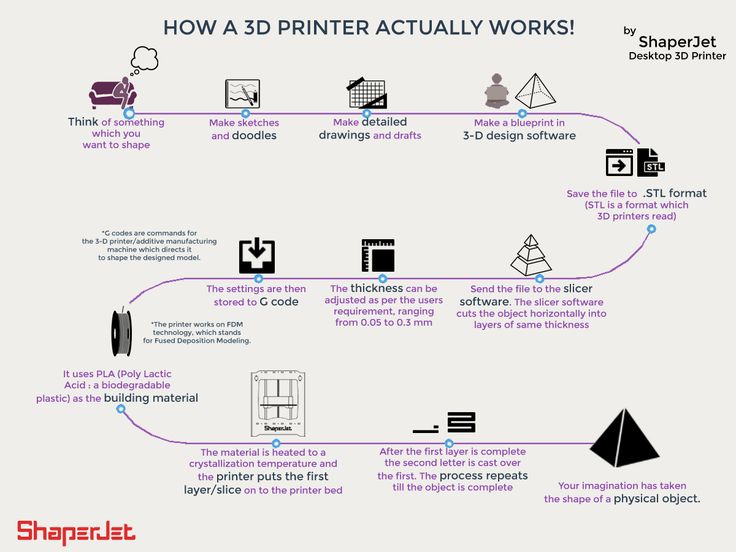

Solid Concept's pistol was made with industrial-grade 3D printers using the Selective Laser Sintering (SLS) and Direct Metal Laser Sintering techniques (DMLS). Both DMLS and SLS use lasers to melt metals, even titanium, at temperatures exceeding 3,000 degrees Fahrenheit. The 3D printers work by laying down a fine layer of powder and then using a laser to fuse granules together, building an object layer by layer from the ground up.

The difference between the two techniques is that DMLS tends to be used with alloys.

3D printers that use metal sintering techniques function differently from desktop 3D printers or other prototyping machines that use stereolithography, which melts plastic filaments and pushes them through a small extruder to build objects layer by layer.

"The industrial printer we used costs more than my college tuition (and I went to a private university)," Kent Firestone, Solid Concepts' vice president of additive manufacturing, said in a statement. "The engineers who run our machines are top of the line; they are experts who know what they're doing and understand 3D Printing better than anyone in this business. Thanks to them, Solid Concepts is debunking the idea that 3D Printing isn't a viable solution or isn't ready for mainstream manufacturing."

"The engineers who run our machines are top of the line; they are experts who know what they're doing and understand 3D Printing better than anyone in this business. Thanks to them, Solid Concepts is debunking the idea that 3D Printing isn't a viable solution or isn't ready for mainstream manufacturing."

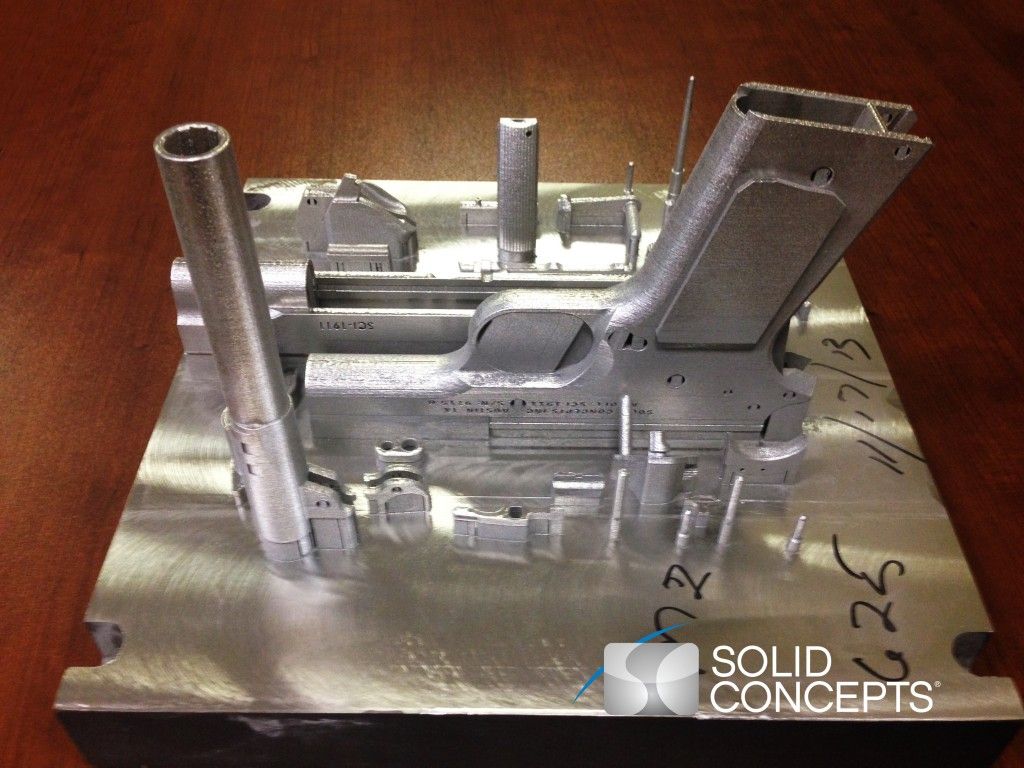

Solid Concepts' gun is composed of more than 30 3D-printed components. The slide, frame and many of the internal components are made of stainless steel. The main spring, the hammer and part of the upper grip's handle was made with a nickel-chromium-based alloy called Inconel 625.

Solid Concepts' pistol is composed of more than 30 3D printed parts (Image: Solid Concepts)"Laser sintering is one of the most accurate manufacturing processes available, and more than accurate enough to build the 3D Metal Printed interchangeable and interfacing parts within our 1911 series gun," Solid Concepts stated. "The gun proves laser sintering can meet tight tolerances."

According to the company, 3D metal printing means fewer porosity issues than are seen with the traditional method of casting metal parts.

Solid Concept said its gun's barrel experiences chamber pressure above 20,000 psi every time the gun is fired. By comparison, a factory-made M1911 pistol is rated for 17,000 psi chamber pressure.

"We're proving this is possible, the technology is at a place now where we can manufacture a gun with 3D Printing," Firestone said. "As far as we know, we're the only 3D printing service provider with a Federal Firearms License (FFL). Now, if a qualifying customer needs a unique gun part in five days, we can deliver."

The 3D printing service provider space has done a robust business throughout the history of the technology, according to Gartner's Basiliere. Customers send 3D computer-aided drawings to the service providers, and they manufacture the part and ship it -- often the very next day.

By printing a gun as historic as the M1911, Solid Concepts is demonstrating the value of distributed parts production. "This could be an example of how the military and also the private sector could enable remotely print spare parts," Basiliere said. "It's a form of long-tail manufacturing where items out of inventory are made on demand sometimes off site."

"It's a form of long-tail manufacturing where items out of inventory are made on demand sometimes off site."

As its name suggests, the Colt M1911 pistol became the military's sidearm in 1911, after legendary gun designer John Browning developed it more than a decade earlier. Since that time, many manufacturers have copied the design.

Brian Evans, an assistant professor of spatial media at the Metropolitan State University of Denver, said even on an industrial level, it doesn't make sense to 3D print guns.

3D printing (also known as additive manufacturing) does make sense in cases like Invisalign braces, where each mass produced object (a retainer in this case) is individualized to the customer, said Evans, who works with 3D printers to create art. But for guns, "it's just too expensive."

"I don't see a huge market for the mass-customization of designer firearms," Evans said. "It's a great example of the capabilities of the technology but I think that's where it goes. "

"

Solid Concepts demonstrates its ability to 3D print an M1911 .45 caliber pistol.

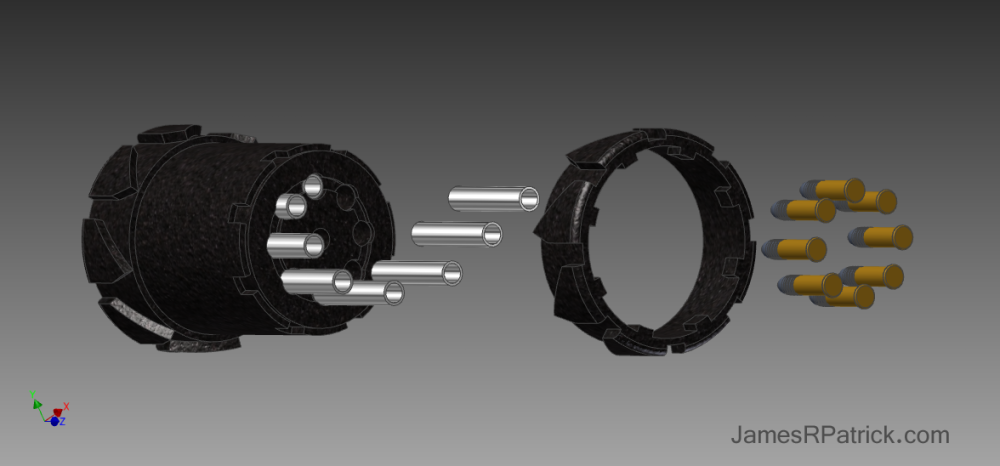

Perhaps the most remarkable achievement with the 3D printed M1911 was its barrel. As with the barrels of most modern guns, the M1911 contains rifling -- helical grooves that put a corkscrew spin on a bullet as it is fired. The spinning movement of the bullet increases its accuracy and distance as it "drills" through the air.

Solid Concepts' M1911's rifling, which requires a high degree of precision, was built directly into the barrel using 3D printing. The rifling was in no way machined, as guns are traditionally made.

"We did not machine this gun," the company stated. "It's born this way."

Lucas Mearian covers consumer data storage, consumerization of IT, mobile device management, renewable energy, telematics/car tech and entertainment tech for Computerworld. Follow Lucas on Twitter at @lucasmearian or subscribe to Lucas's RSS feed . His e-mail address is [email protected].

Follow Lucas on Twitter at @lucasmearian or subscribe to Lucas's RSS feed . His e-mail address is [email protected].

See more by Lucas Mearian on Computerworld.com.

Related:

- Emerging Technology

Senior Reporter Lucas Mearian covers Windows, Future of Work issues, mobile, AI in the enterprise, and healthcare IT.

Copyright © 2013 IDG Communications, Inc.

Bing’s AI chatbot came to work for me. I had to fire it.

Worlds first 3D-printed metal gun successfully fired by Solid Concepts

Ross Bryant | 47 comments

News: an American company has built and successfully fired the world's first metal 3D-printed gun.

American additive manufacturing firm Solid Concepts successfully fired 50 rounds using the handgun, which looks a lot closer to traditional firearms than the plastic Liberator 3D-printed gun that was first fired in May this year.

The design was based on a classic design from 1911 and manufactured using laser-sintered powdered metals. The firm says the gun "functions beautifully and has already handled 50 rounds of successful firing."

It's made from over 30 components printed in stainless steel and an alloy called Inconel 625, and has a selective laser sintered (SLS) carbon-fibre and nylon hand grip.

"We're proving this is possible," said Kent Firestone, vice president of additive manufacturing at Solid Concepts. "The technology is at a place now where we can manufacture a gun with 3D Metal Printing."

Firestone said the point of the project was to prove to quality and suitability of 3D-printed parts for real-world applications, and even its superiority over traditional techniques: the printed parts are less porous than cast parts and could be made more made complex than machined parts.

"The whole concept of using a laser sintering process to 3D-print a metal gun revolves around proving the reliability, accuracy and usability of metal 3D printing as functional prototypes and end use products," said Firestone. "It's a common misconception that 3D Printing isn't accurate or strong enough, and we're working to change people's perspective."

Image courtesy of Solid Concepts Inc.The firm chose to build the 1911 45ACP firearm because the design is in the public domain and says it is licensed to produce firearms parts.

"We're doing this legally," said Firestone. "In fact, as far as we know, we're the only 3D Printing Service Provider with a Federal Firearms License (FFL). Now, if a qualifying customer needs a unique gun part in five days, we can deliver."

Here's some more information from Solid Concepts:

Solid Concepts, a world leader in 3D Printing services, manufactures the world's first 3D Printed Metal Gun.

Solid Concepts, one of the world leaders in 3D Printing services, has manufactured the world's first 3D Printed Metal Gun using a laser sintering process and powdered metals. The gun, a 1911 classic design, functions beautifully and has already handled 50 rounds of successful firing. It is composed of 33 17-4 Stainless Steel and Inconel 625 components, and decked with a Selective Laser Sintered (SLS) carbon-fiber filled nylon hand grip. The successful production and functionality of the 1911 3D Printed metal gun proves the viability of 3D Printing for commercial applications.

The gun, a 1911 classic design, functions beautifully and has already handled 50 rounds of successful firing. It is composed of 33 17-4 Stainless Steel and Inconel 625 components, and decked with a Selective Laser Sintered (SLS) carbon-fiber filled nylon hand grip. The successful production and functionality of the 1911 3D Printed metal gun proves the viability of 3D Printing for commercial applications.

The metal laser sintering process Solid Concepts used to manufacture the 30+ gun components is one of the most accurate additive manufacturing processes available, and more than accurate enough to build the interchangeable and interfacing parts within the 1911 series gun. The gun proves the tight tolerances laser sintering can meet. Plus, 3D Printed Metal has less porosity issues than an investment cast part and better complexities than a machined part. The 3D Printed gun barrel sees chamber pressures above 20,000 psi every time it is fired. Solid Concepts chose to build the 1911 because the design is public domain.

The 3D Printed metal gun proves that 3D Printing isn't just making trinkets and Yoda heads. The gun manufactured by Solid Concepts debunks the idea that 3D Printing isn't a viable solution or isn't ready for mainstream manufacturing. With the right materials and a company that knows how to best program and maintain their machines, 3D printing is accurate, powerful and here to stay.

Subscribe to our newsletters

Your email addressDezeen Debate

Our most popular newsletter, formerly known as Dezeen Weekly. Sent every Thursday and featuring a selection of the best reader comments and most talked-about stories. Plus occasional updates on Dezeen’s services and breaking news.

Dezeen AgendaSent every Tuesday and containing a selection of the most important news highlights. Plus occasional updates on Dezeen’s services and breaking news.

Dezeen DailyA daily newsletter containing the latest stories from Dezeen.

Sent on the last Friday of every month, Dezeen in Depth features original feature articles, interviews and opinion pieces that delve deeper into the major stories shaping architecture and design.

Dezeen JobsDaily updates on the latest design and architecture vacancies advertised on Dezeen Jobs. Plus occasional news.

Dezeen AwardsNews about our Dezeen Awards programme, including entry deadlines and announcements. Plus occasional updates.

Dezeen Events GuideNews from Dezeen Events Guide, a listings guide covering the leading design-related events taking place around the world. Plus occasional updates.

We will only use your email address to send you the newsletters you have requested. We will never give your details to anyone else without your consent. You can unsubscribe at any time by clicking on the unsubscribe link at the bottom of every email, or by emailing us at [email protected].

For more details, please see our privacy notice.

Thank you!

You will shortly receive a welcome email so please check your inbox.

You can unsubscribe at any time by clicking the link at the bottom of every newsletter.

World's first 3D printed metal gun

Archive

Solid Concepts, based in Austin, Texas, has unveiled the world's first 3D printed metal gun. Using selective laser sintering technology and powdered metal, they printed a replica of the classic M1911 military pistol, which was in service with the US Army for 19 years.11-1985 years. The pistol successfully passed field tests and after 50 shots no breakdowns or malfunctions were found. The material for the pistol was 17-4 stainless steel and Inconel 625 alloy, and the grip pad was printed from nylon, also by selective laser sintering.

We have proven that this is possible and that 3D printing technology has reached the point where metal can be printed into a full-fledged weapon.And we do it legally. To the best of our knowledge, we are the only 3D printing service company licensed to manufacture weapons. Now, if someone urgently needs a unique part for some exotic weapon and he has a license, we can provide this part to em

says Kent Firestone, Vice President of 3D Printing at Solid Concepts. The selective laser sintering technology was chosen by the company to print the gun because of its high resolution and the strength of the printed products. The fact that the gun works proves once again that this 3D printing technology is able to meet the high demands of durability and precision. Metal products printed in this way are known to have fewer porosity problems than cast parts. In addition, 3D printing allows you to print much more complex parts than traditional machining methods. With each shot, the pressure in the barrel of the printed pistol jumps to 1,400 kilograms per square centimeter.

Solid Concepts says their successful experiment shows that 3D printers are good for more than just plastic cartoon characters. According to them, this gun spins a common myth that 3D printing is not accurate enough, and printed parts are not strong enough for real use. It should be noted that, despite the enthusiasm of Solid Concepts representatives, this is far from the first example demonstrating the reliability and high accuracy of parts printed using selective laser sintering technology. So, in one of the videos we published, we talked about the American aircraft manufacturer, GE Aviation, which is switching to 3D printing for the production of aircraft engines, and in this article we wrote about the successful tests by NASA of a 3D printed rocket engine injector. Model M1911 was chosen because the patents for it had already expired. I must say, the gun itself looks impressive, and is certainly a step up from the plastic guns that have flooded the internet. Article prepared for 3dtoday.ru

According to them, this gun spins a common myth that 3D printing is not accurate enough, and printed parts are not strong enough for real use. It should be noted that, despite the enthusiasm of Solid Concepts representatives, this is far from the first example demonstrating the reliability and high accuracy of parts printed using selective laser sintering technology. So, in one of the videos we published, we talked about the American aircraft manufacturer, GE Aviation, which is switching to 3D printing for the production of aircraft engines, and in this article we wrote about the successful tests by NASA of a 3D printed rocket engine injector. Model M1911 was chosen because the patents for it had already expired. I must say, the gun itself looks impressive, and is certainly a step up from the plastic guns that have flooded the internet. Article prepared for 3dtoday.ru

Subscribe to author

Subscribe

Don't want

First metal gun printed on 3D printer

First metal gun printed on 3D printer | RBC StyleTV channel

Pro

Investments

Events

RBC+

New economy

Trends

Real estate

Sport

Style

National projects

City

Crypto

Debating club

Research

Credit ratings

Franchises

Newspaper

Special projects St. Petersburg

Petersburg

Conferences St. Petersburg

Special projects

Checking counterparties

RBC Library

Podcasts

ESG index

Policy

Economy

Business

Technology and media

Finance

RBC CompanyRBC Life

Impression 3D printed first metal gun

Impression 3D printed first metal gun

Advertising on RBC www.